Single tank phase change thermal storage device for solar energy

A phase change heat storage and solar energy technology, applied in the field of solar energy, can solve the problems of increased difficulty in large-scale application of solar energy, poor stability and safety, intermittent solar irradiance, etc. Improve the effect of efficient and stable utilization and heat storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

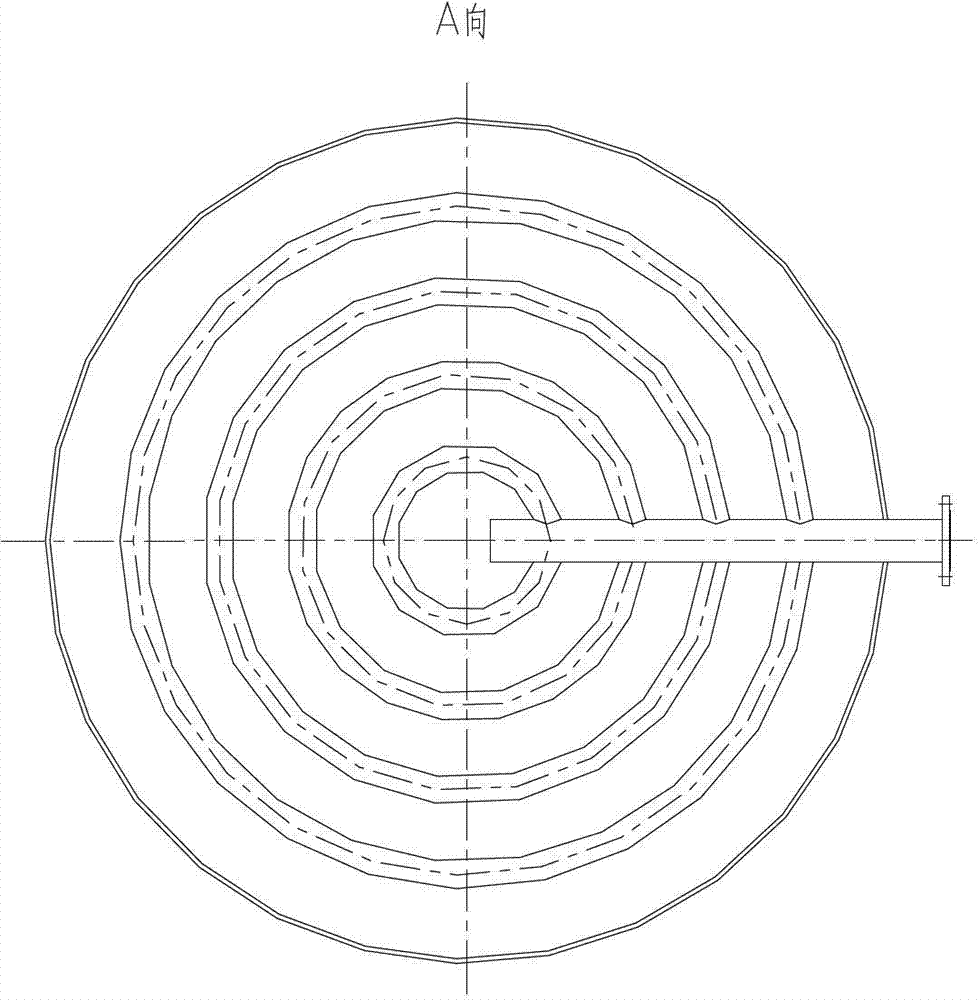

[0027] Example 1: A single-tank phase-change heat storage device for solar energy, see figure 1 , figure 2 , image 3 , there are breathing port 1, heat storage medium feed port 2, upper cover 4, heat storage medium discharge port 13, heat storage medium discharge port 14 on the tank body, and multi-ring multi-layer heat exchange is arranged in the tank body Coil, the multi-ring multi-layer heat exchange coil is arranged in parallel between the heat transfer medium outlet pipe 6 at the upper end of the heat exchange coil and the heat transfer medium inlet pipe 11 at the lower end of the heat exchange coil to form a heat transfer medium circulation pipe, The flow direction in the formed heat transfer medium flow channel is bottom-in and top-out. The tank body is surrounded by the inner wall 8, the upper cover 4 and the discharge port 14 of the heat storage medium to form a heat storage chamber, which contains a heat storage medium 10, and the heat exchange between the heat t...

Embodiment 2

[0036] Embodiment 2: In the single-tank phase-change heat storage device for solar energy, a vertical pipe is provided at the center of the coil and connected in parallel with each layer of coil. All the other structures are the same as in Example 1.

Embodiment 3

[0037] Embodiment 3: The single-tank phase-change heat storage device for solar energy also includes the inner wall 8 of the storage tank and the outer wall 5 of the storage tank to form an airtight insulation interlayer 7, which is a vacuum insulation layer, and the outer wall 5 of the storage tank There is a vacuum port 15 on the top, which is connected with the vacuum equipment, and the vacuum degree is 10 -2 Pa. All the other structures are the same as in Example 1. The difference is:

[0038] The diameter of the storage tank is 4m, and the heat exchange coils are distributed in 6 rings in the radial direction, among which the number of coils between the first ring heat exchange coil 16 and the central ring heat exchange coil is 6 rings, and the spacing is equal. The diameter is 20mm.

[0039] The heat storage medium is paraffin heat storage material.

[0040] The heat conduction medium is high-temperature steam, and the steam parameters are: pressure 4MPa, temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com