Biomorphic silicon carbide ceramic high-temperature photo-thermal storage material

A silicon carbide ceramic, biomorphic technology, applied in heat exchange materials, ceramic products, chemical instruments and methods, etc., can solve the constraints of renewable energy and waste heat efficient utilization technology, weak adaptive regulation ability, and low energy utilization rate. and other problems, to achieve the effects of excellent quality transmission capacity, improved energy conversion efficiency, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Each parameter measuring method in the implementation of the present invention and ratio is:

[0040] 1. Use a laser thermal conductivity meter to measure the thermal conductivity of the material.

[0041] 2. Use DSC to test the latent heat value of the phase change of the material.

[0042] 3. Use DSC to test the specific heat capacity of the material.

[0043] 4. Use a spectrophotometer to test the spectral absorptivity of the material.

[0044] Below with example, the embodiment of the present invention is described further:

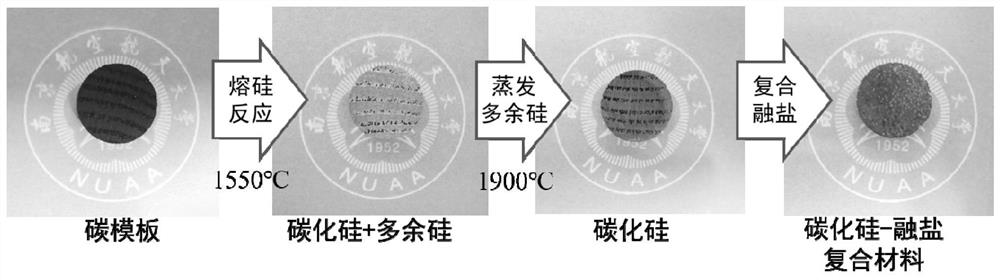

[0045] The first step: preparation of biomimetic silicon carbide ceramic skeleton.

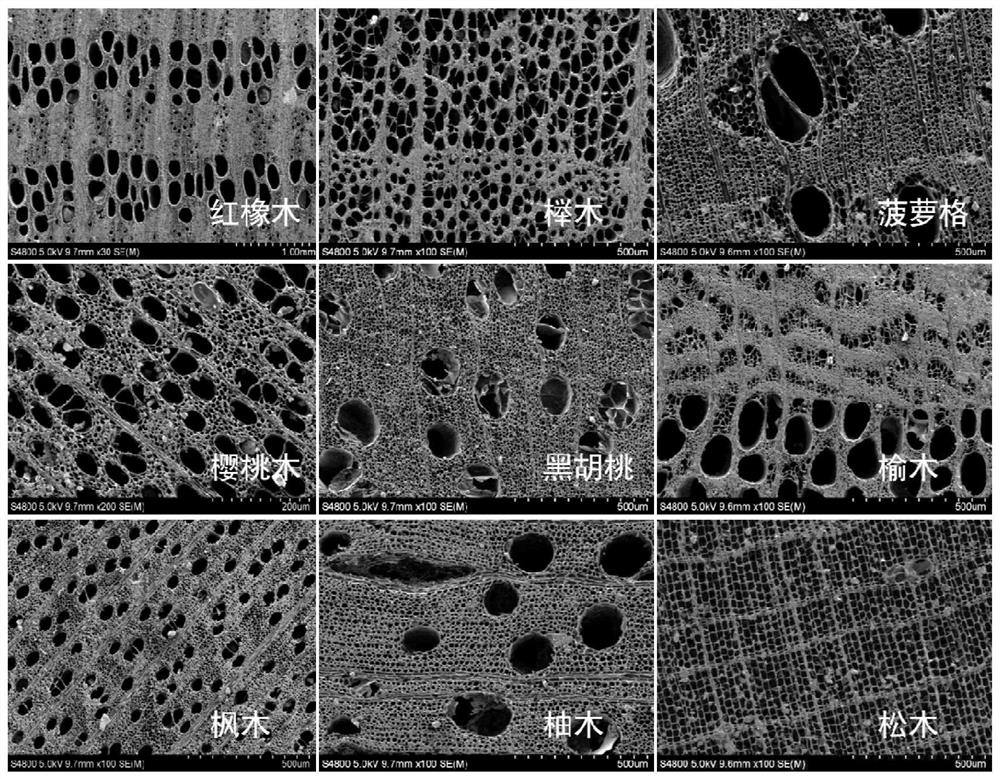

[0046] Cut the wood into a cuboid with a length of 70mm, a width of 50mm, and a thickness of 30mm. The cut wood is dried in a drying oven at 70°C for 2-3 days. Place in a tube furnace with nitrogen protection atmosphere, raise the temperature to 500°C at a heating rate of 0.5°C / min, and then raise the temperature to 900~1100°C at a heating rate of 1°C / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com