Ultra-low temperature sintering microwave dielectric ceramic material system, and preparation method and application thereof

A technology for microwave dielectric ceramics and ceramic materials, applied in the field of low-loss tungsten-based ultra-low temperature sintered microwave dielectric ceramic materials and their preparation, can solve the problems of difficulty in meeting industrial stability requirements, unsuitable for mass production, expensive Te, and the like, and achieve excellent The effect of microwave dielectric properties, high Qf value and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

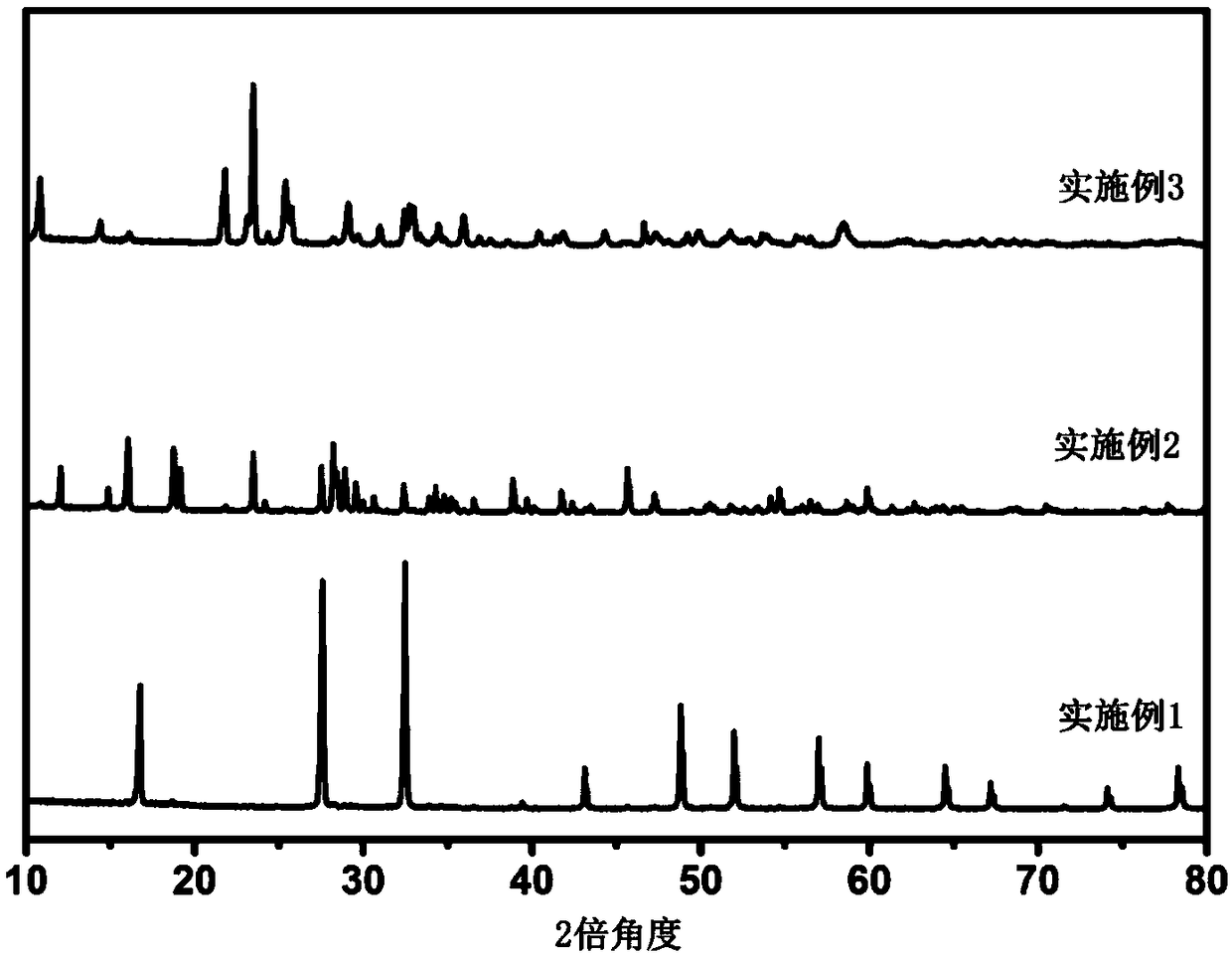

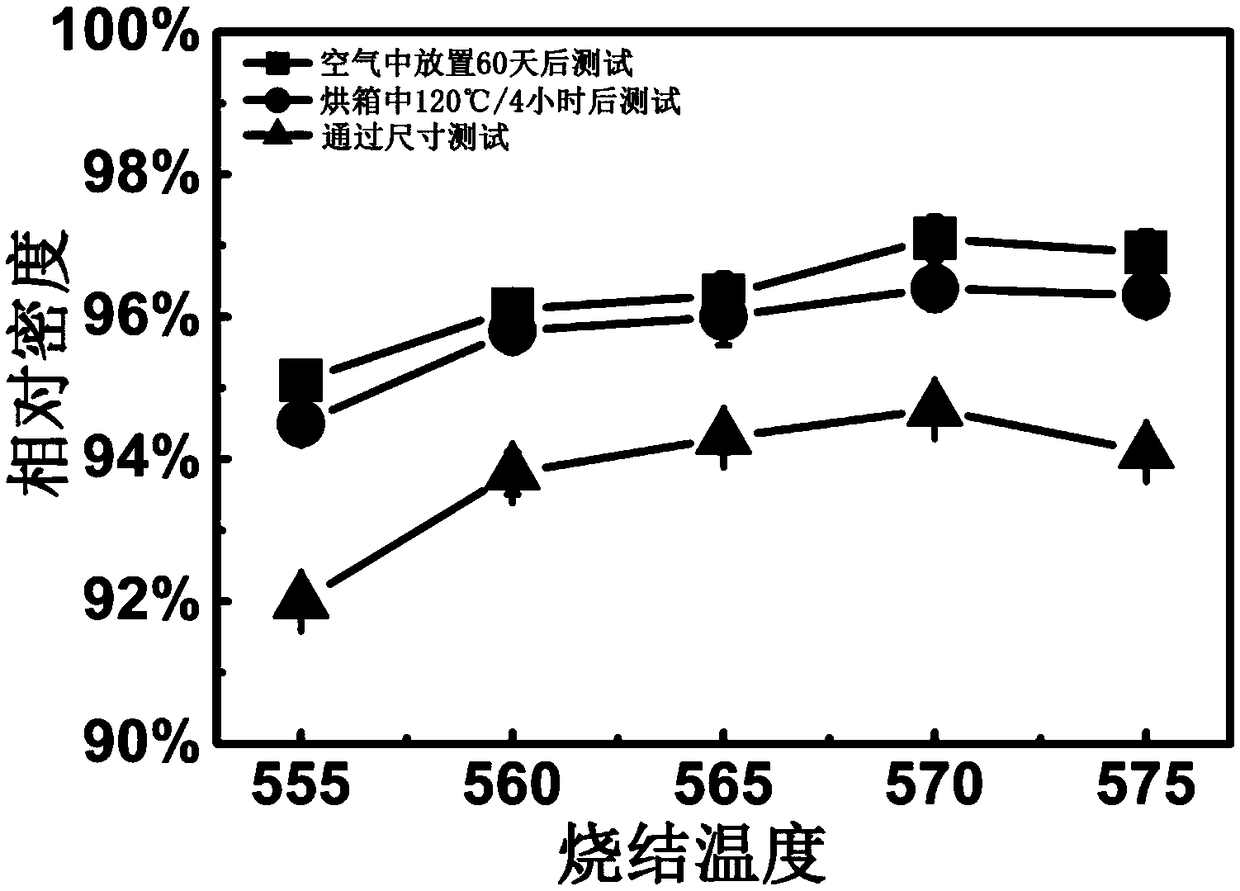

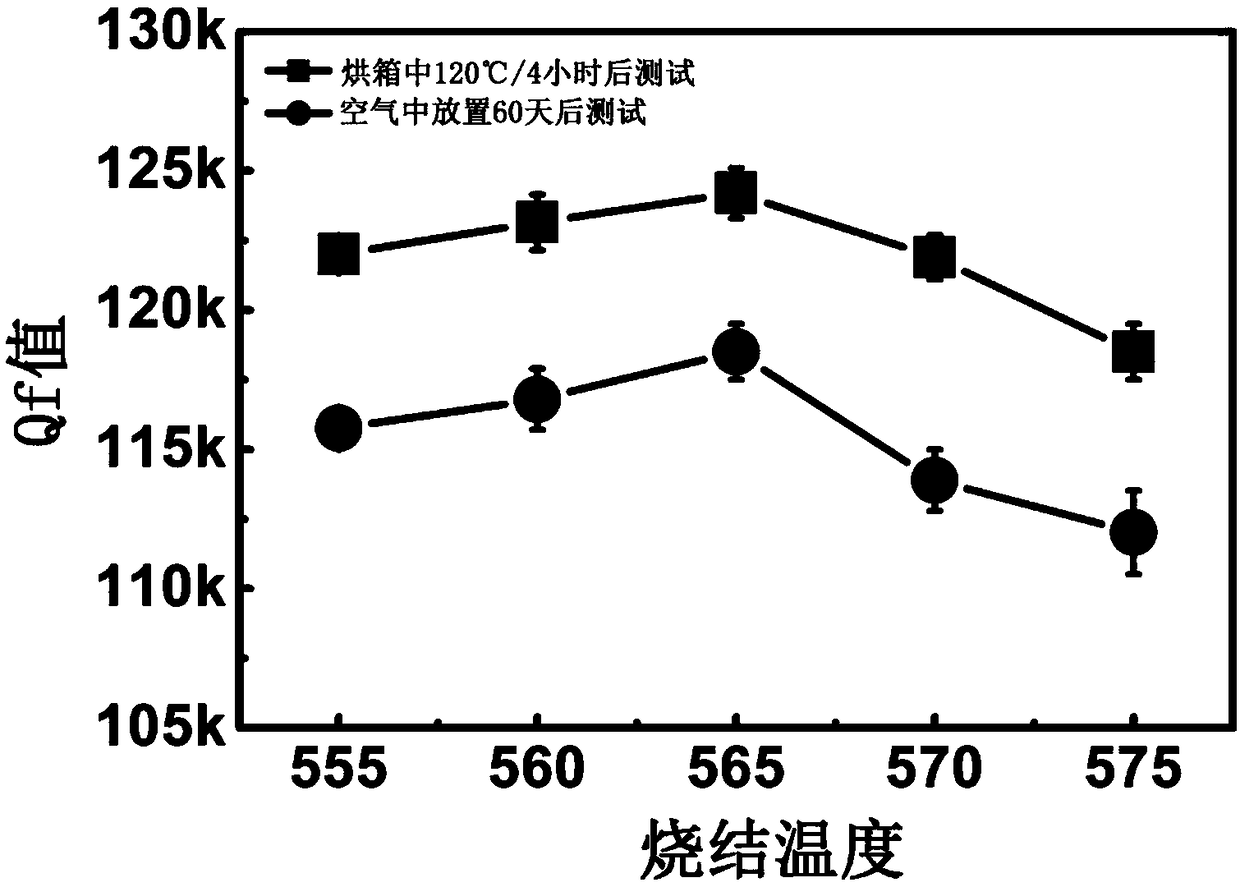

Embodiment 1

[0043] Raw material Na will be analyzed for purity 2 CO 3 and WO 3 Prepare the main powder according to the ratio of 1:1, then fully mix the main powder and ball mill for 4 hours, pre-fire at 400°C for 4 hours after drying, and then crush the pre-fired block sample for the second time Ball mill for 4 hours, add 10wt% ethanol after grinding and drying, shape (sheet or column) as required under a pressure of 100MPa, press under a pressure of 200MPa in an isostatic press, and keep warm at 120°C for 2 hours to remove the ethanol. Then it is sintered at 565°C for 6 hours to form porcelain, and then the ultra-low temperature sintered microwave dielectric ceramic material can be obtained.

[0044] The present invention uses a network analyzer (8720ES Agilent) and a thermostat (DELTA 9023, Delta Design) to test the microwave dielectric properties and temperature spectrum of the sample by using a closed-cavity resonance method. The calculation formula of TCF is as follows:

[0045]...

Embodiment 2

[0050] Raw material Na will be analyzed for purity 2 CO 3 and WO 3 Prepare the main powder according to the ratio of 1:2, then fully mix the main powder and ball mill for 4 hours, pre-fire at 400°C for 4 hours after drying, and then crush the pre-fired block sample for the second time Ball mill for 4 hours, add 10wt% ethanol after grinding and drying, shape (sheet or column) as required under a pressure of 100MPa, press under a pressure of 200MPa in an isostatic press, and keep warm at 120°C for 2 hours to remove the ethanol. Then it is sintered in air at 650°C for 6 hours to form porcelain, and the ultra-low temperature sintered microwave dielectric ceramic material can be obtained.

[0051] The present invention uses a network analyzer (8720ES Agilent) and a thermostat (DELTA 9023, Delta Design) to test the microwave dielectric properties and temperature spectrum of the sample by using a closed-cavity resonance method. The calculation formula of TCF is as follows:

[005...

Embodiment 3

[0057] Raw material Na will be analyzed for purity 2 CO 3 and WO 3 Prepare the main powder according to the ratio of 1:4, then fully mix the main powder and ball mill for 4 hours, pre-fire at 550°C for 4 hours after drying, and then crush the pre-fired block sample for the second time Ball milling for 4 hours, adding 10wt% ethanol after grinding and drying, molding (sheet or column) as required under a pressure of 100MPa, pressing under a pressure of 200MPa in an isostatic press, keeping the temperature at 120°C for 2h to remove the ethanol, and then After sintering at 740°C for 6 hours in air, the ultra-low temperature sintered microwave dielectric ceramic material can be obtained.

[0058] The present invention uses a network analyzer (8720ES Agilent) and a thermostat (DELTA 9023, Delta Design) to test the microwave dielectric properties and temperature spectrum of the sample by using a closed-cavity resonance method. The calculation formula of TCF is as follows:

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Qf | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com