High dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material and preparation method thereof

A technology of bao-ln2o3-tio2 and microwave dielectric materials, which is applied in the field of high dielectric constant BaO-Ln2O3-TiO2 series microwave dielectric materials and its preparation, can solve the problems of low Q f and large temperature coefficient, and achieve excellent microwave The effect of dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

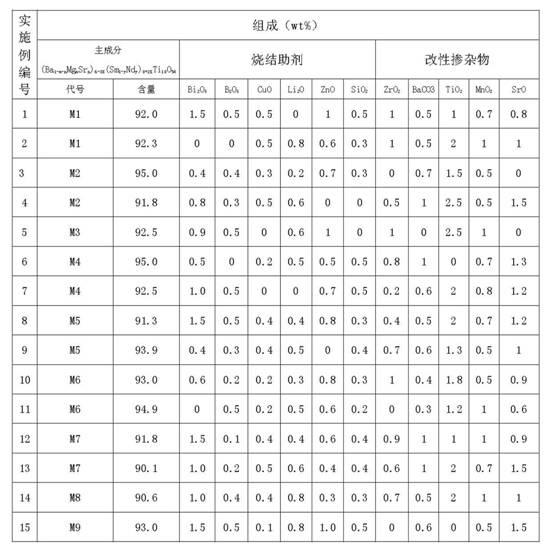

[0014] A kind of high dielectric constant BaO-Ln described in the present invention 2 o 3 -TiO 2 It is a microwave dielectric material and its preparation method. In combination with the above-mentioned content of the invention, the present invention will be further described by the following examples.

[0015] (1) To analyze pure BaCO 3 、TiO 2 、Sm 2 o 3 、Nd 2 o 3、 SrCO 3 , Mg(OH) 2 The raw materials are prepared according to the composition ratio of Table 1, and are obtained after processes such as ball milling, drying, pre-burning, pulverizing, and filtering according to the main material preparation process described in 1 in the Summary of the Invention (Ba 1-m-n Mg m Sr n ) 6-3X (Sm 1-y Nd y ) 8+2X Ti 18 o 54 .

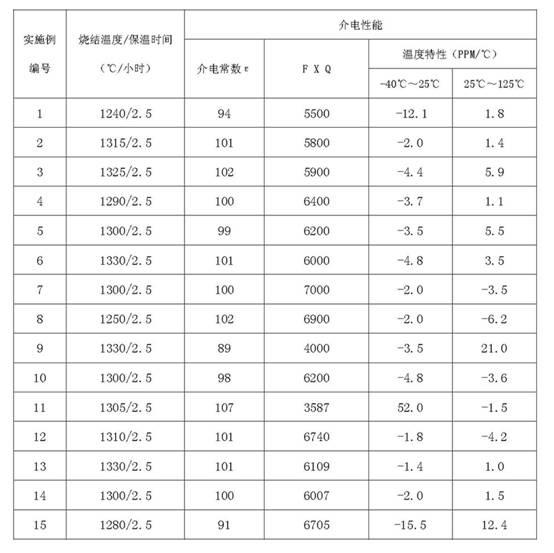

[0016] Table 1 Main material (Ba 1-m-n Mg m Sr n ) 6-3X (Sm 1-y Nd y ) 8+2X Ti 18 o 54 Example recipe of

[0017]

[0018] (2) According to the composition of Table 2, the main material is (Ba 1-m-n Mg m Sr n ) 6-3X (Sm 1-y Nd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com