Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Ceramic chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic chemistry studies the relationship between the physical properties of fired ceramics and ceramic glazes and their chemistry. Although ceramic technicians have long understood many of these relationships, the advent of computer software to automate the conversion from batch to formula and analysis has brought this science within the reach of many more people. Physical properties of glazes in fired products (like thermal expansion, hardness, index of refraction, color and melting temperature or range) are directly (but not solely) related to the chemistry. Properties of glass melts like viscosity and surface tension are also principally products of chemistry.

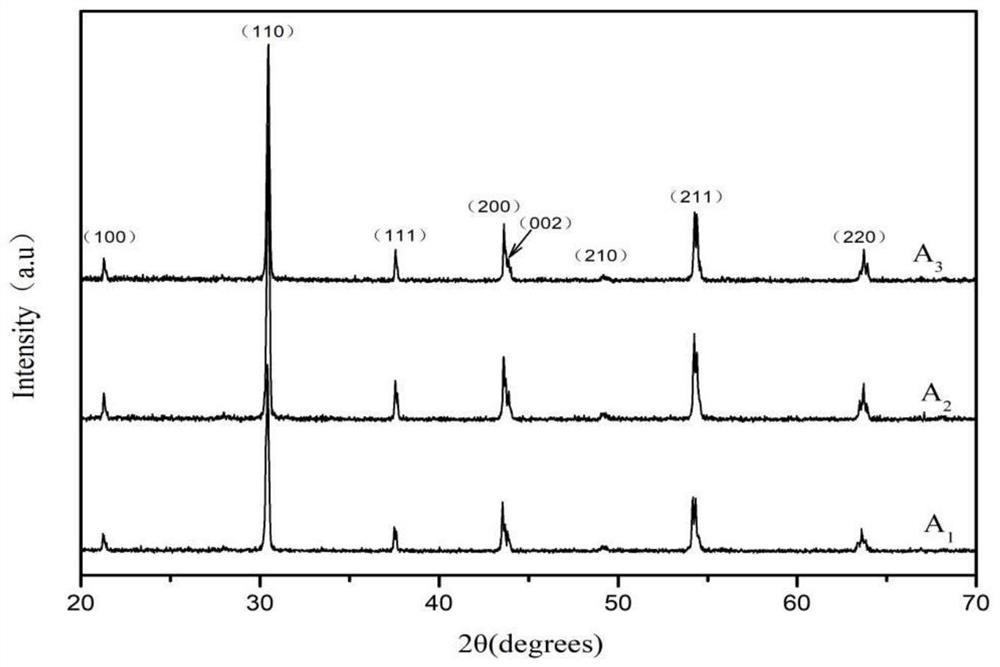

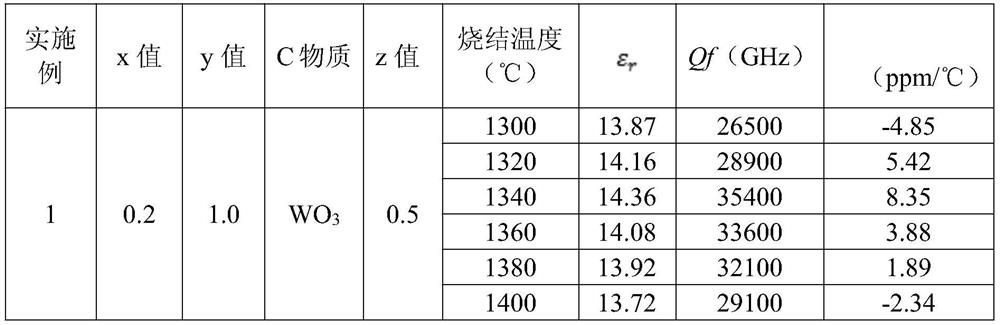

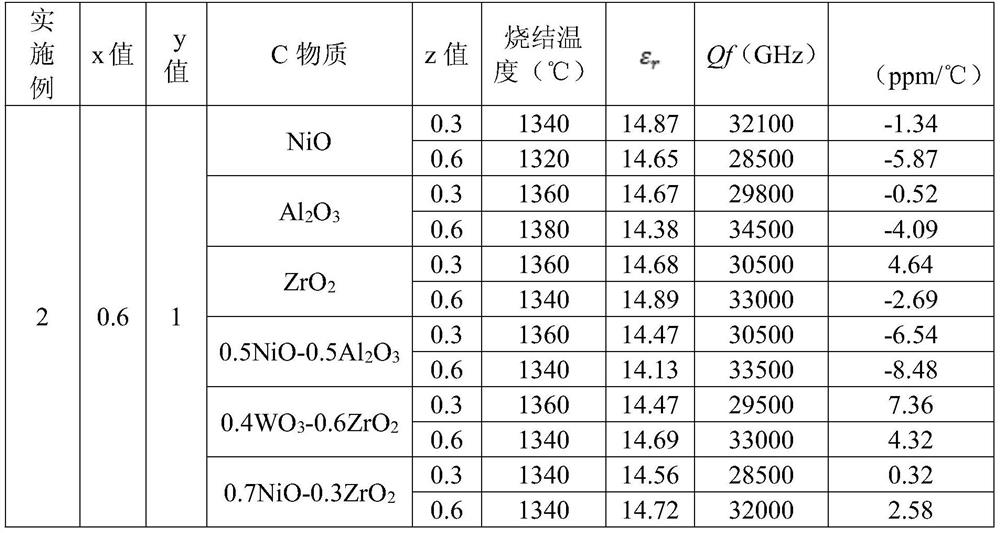

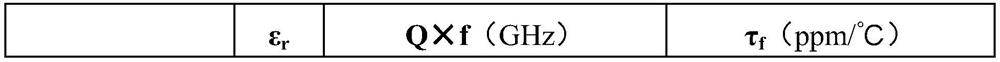

Microwave dielectric ceramic and preparation method thereof

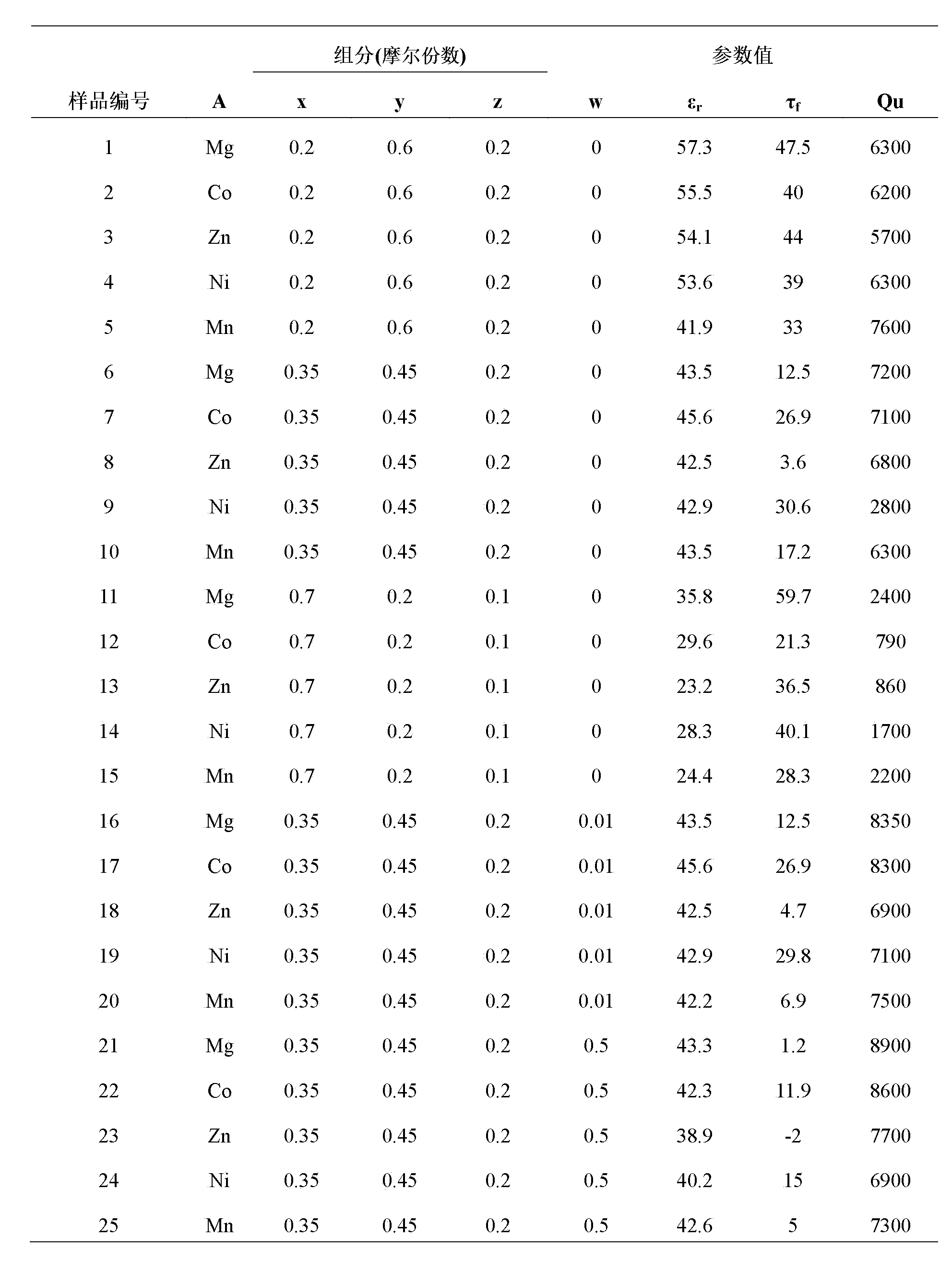

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is mainly composed of ZrO2, TiO2 and Nb2O5; the microwave dielectric property of the microwave dielectric ceramic can be improved by selectively adding MgO, CoO, ZnO, NiO and MnO2; the chemical constitution formula of the ceramic is xZrO3-YTiO2-zA(1+W) / 3Nb(2-w) / 2O3; in formula (I), A is one or more elements of Mg, Co, Zn, Ni and Mn; x, y and z are molar ratios, wherein x is between 0.2 and 0.7, y is between 0.2 and 0.6,, z is between 0.1 and 0.2, and, x plus y plus z is equal to 1; numerical range of w is l between 0 and 0.5. According to the microwave dielectric ceramic and the preparation method thereof, the ceramic has the characteristics that the dielectric constant is high, the loss is low, and the temperature coefficient is close to zero, and is liable to sinter; the preparation method has the characteristics that the price of raw materials is low, and a technology during production is simple.

Owner:HEFEI NORMAL UNIV

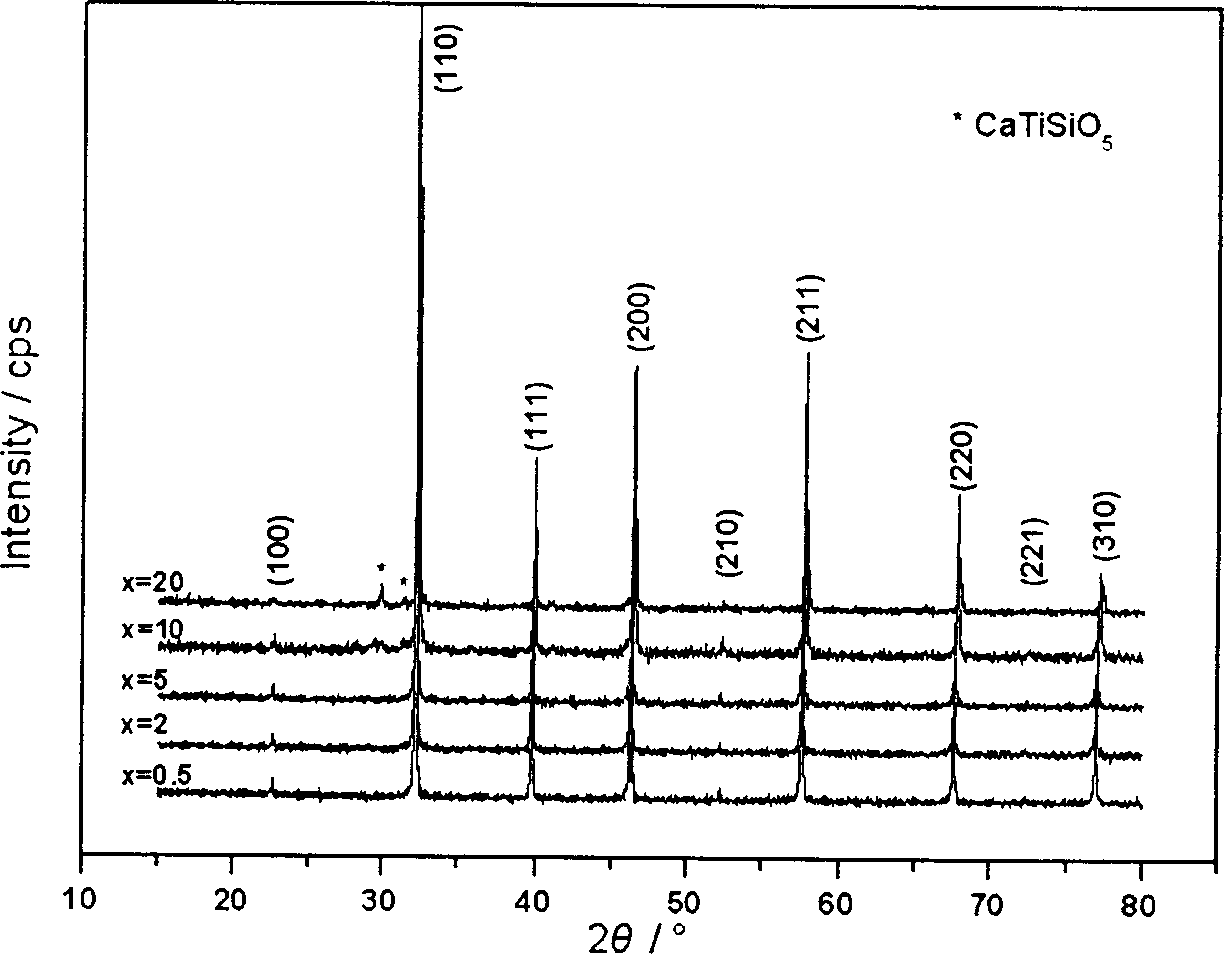

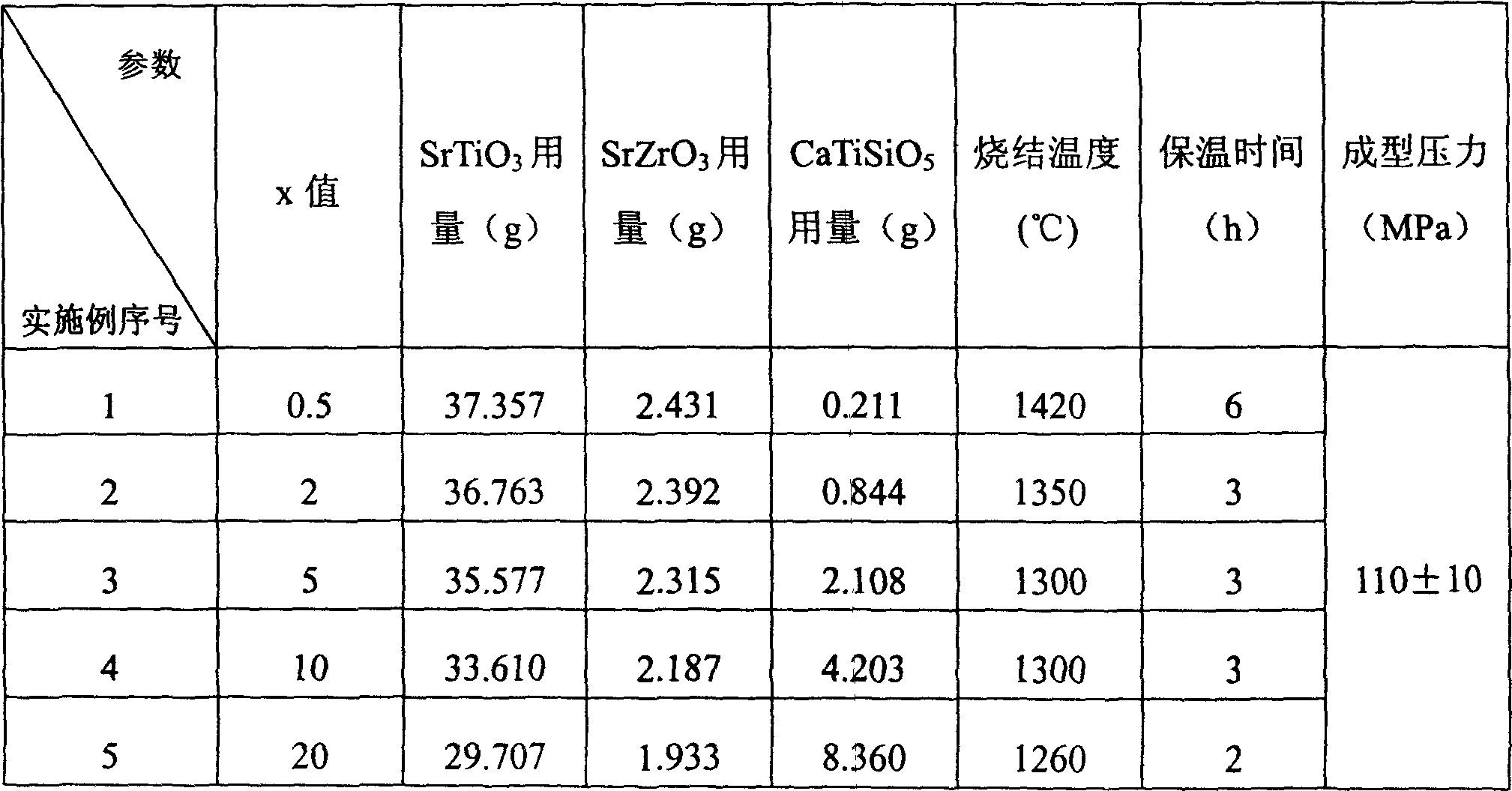

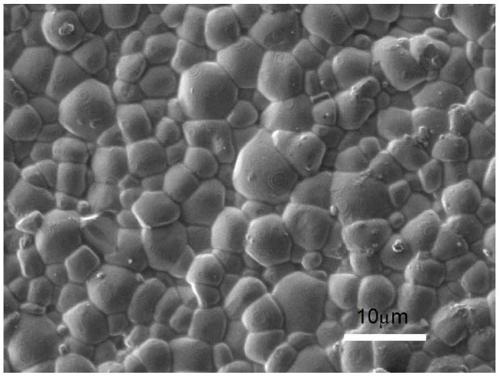

Pressure proof strontium titanate base energy storage medium ceramic and its preparation method

ActiveCN1785897AOvercome the disadvantage of high firing temperatureHigh dielectric constantStrontium titanateAir atmosphere

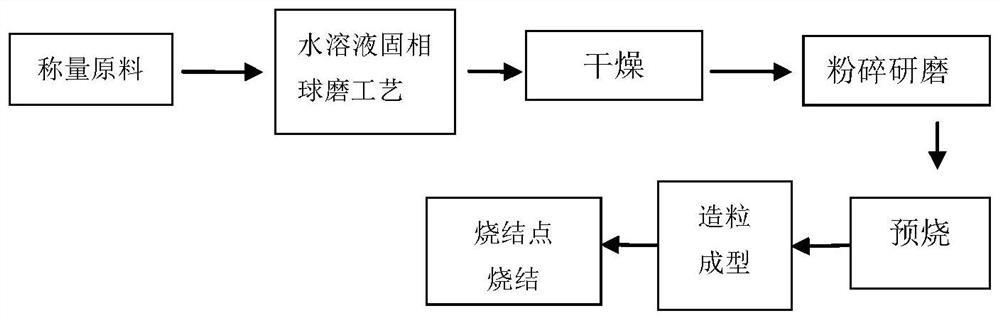

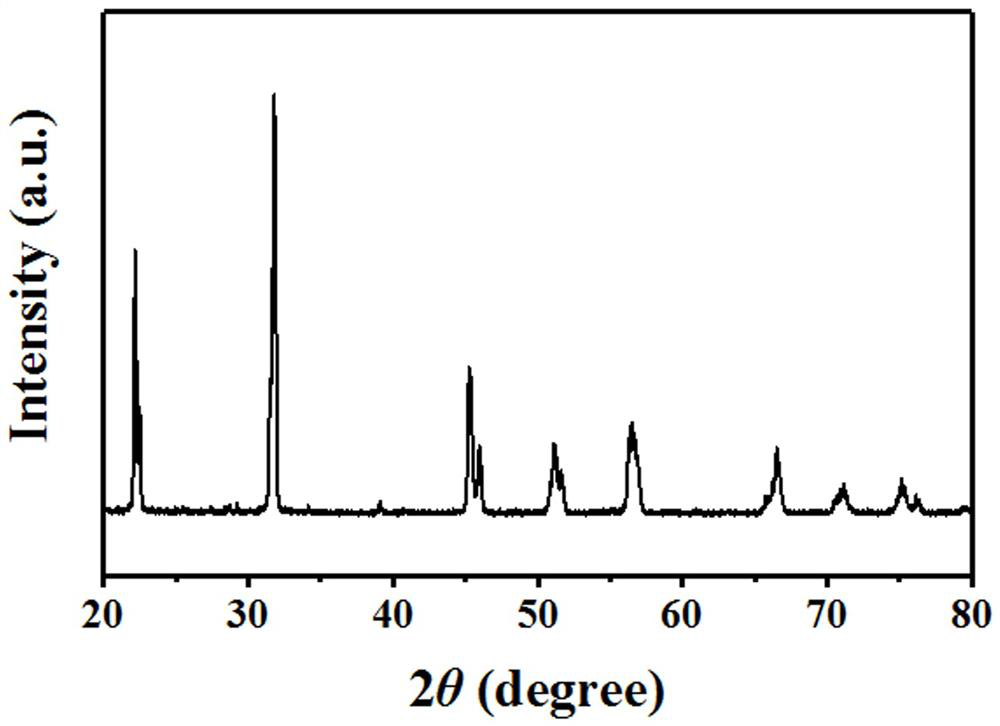

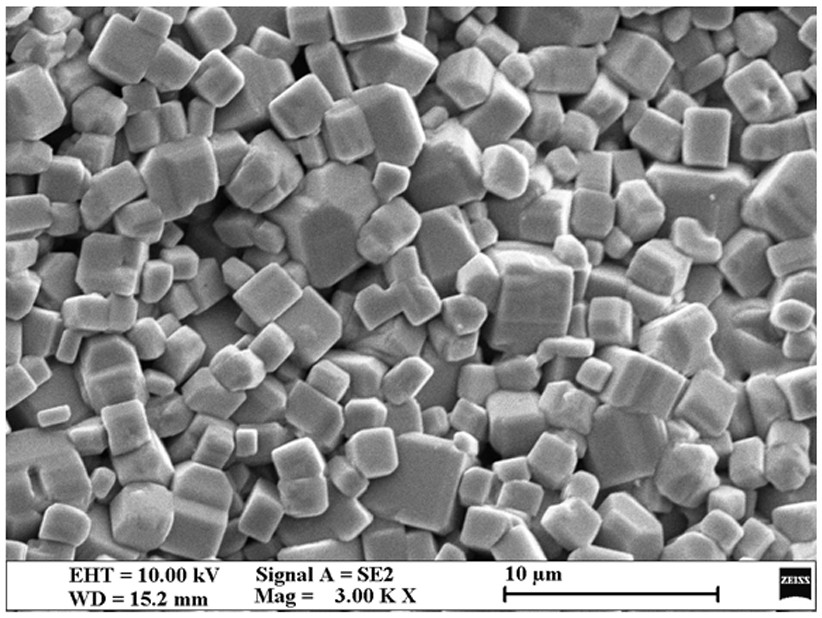

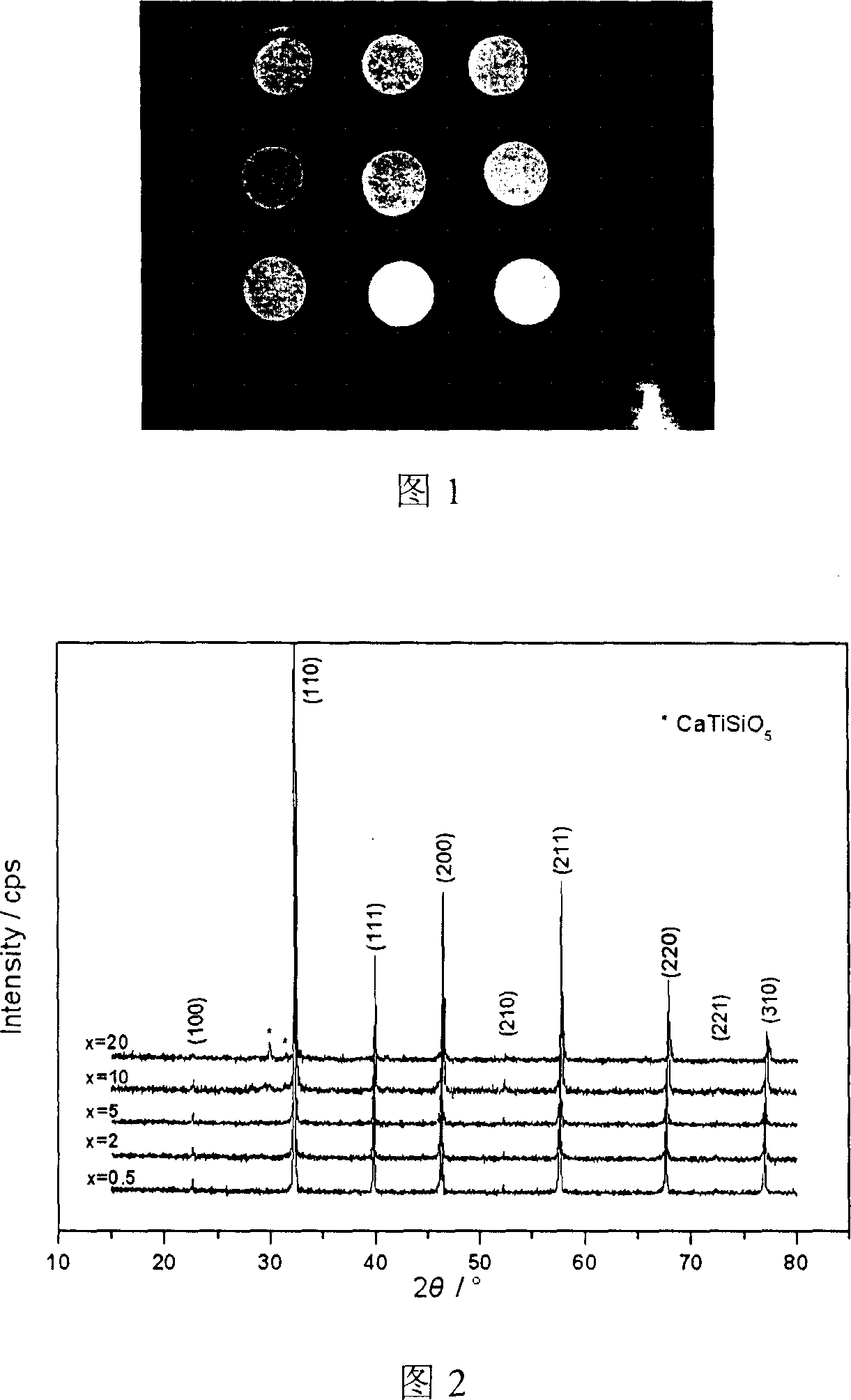

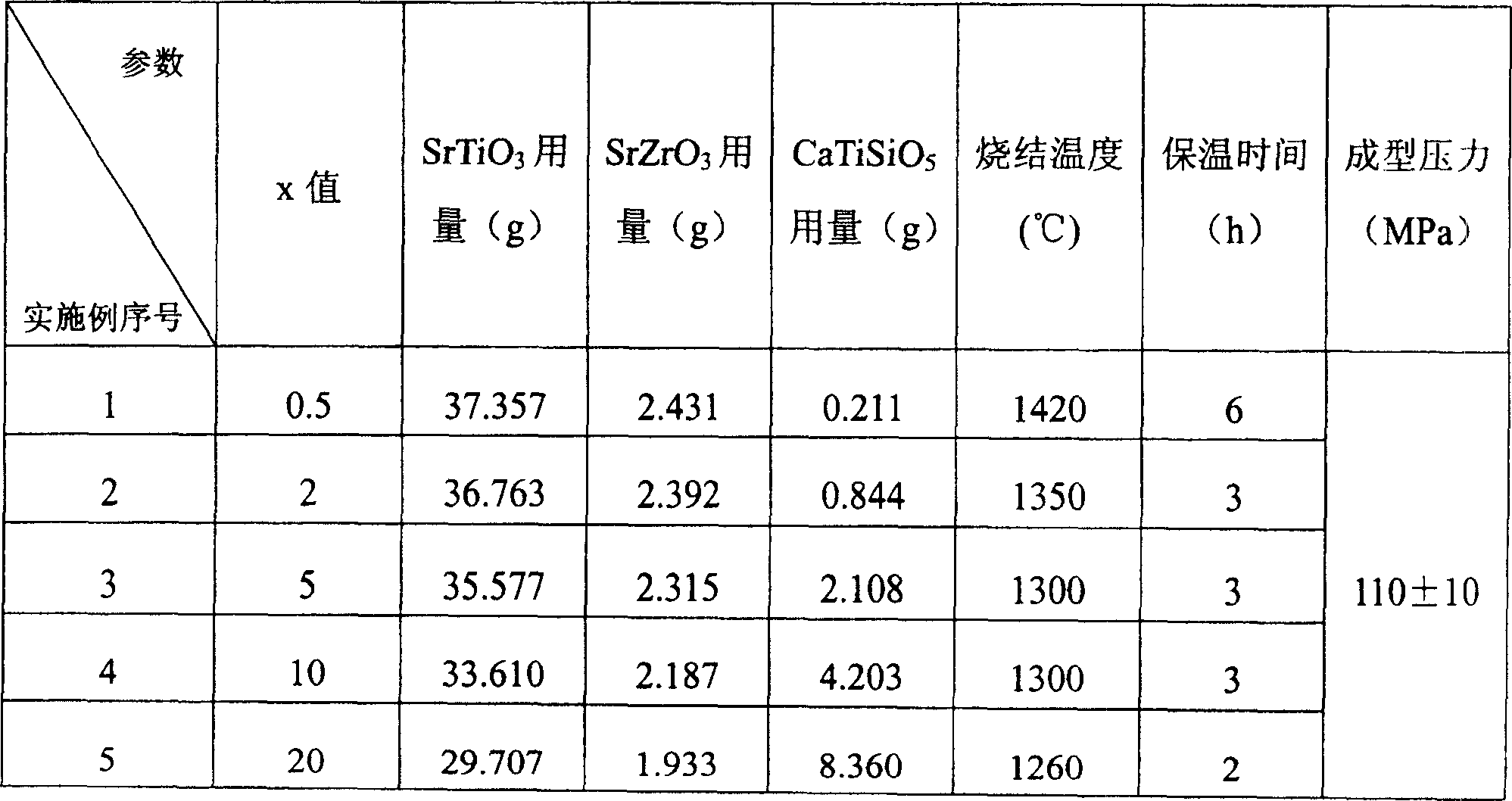

The present invention relates to a high pressure-resistant energy-storing medium ceramic and its preparation method. The chemical composition of said ceramic is Sr(Ti0.95 Zr0.05) O3+Xmol% CaTiSiO5, in which X is greater than O and less than or equal to 20. Its preparation method includes the following steps: adopting solid-phase method, using SrCO3 and TiO2 to synthesize SrTiO3; using SrCO3 and ZrO2 to synthesize SrZrO3; using CaCO3 SiO2 and TiO2 to synthesize CaTiSiO5 powder body; mixing materials according to the above-mentioned chemical composition formula; ball-grinding according to the ratio of material; ball: water=1:1:1-1.2, drying; adding polyvinyl alcohol solution as binding agent, granulating, sieving with 40 meshes, press-forming, slowly heating to 600-650deg.C to remove binding agent, sintering at 1260-1420deg.C, heat-insulating for 2-6hr, so as to obtain the invented product.

Owner:WUHAN UNIV OF TECH

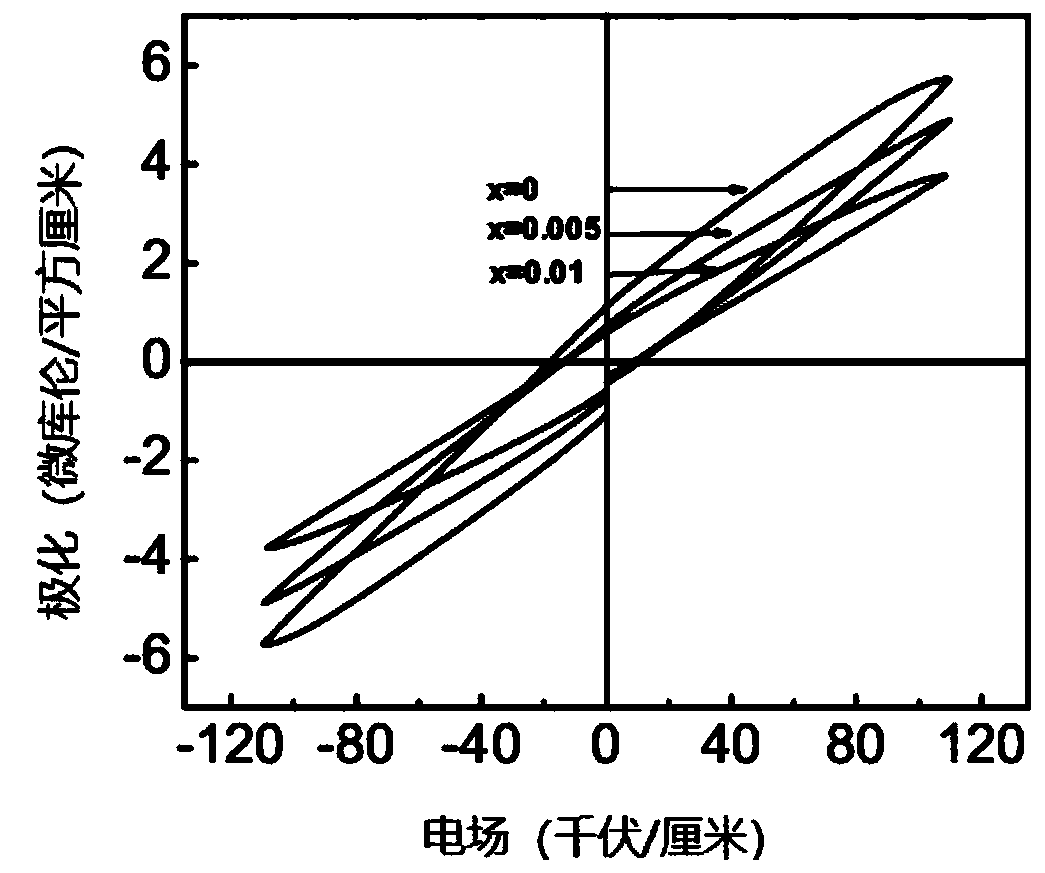

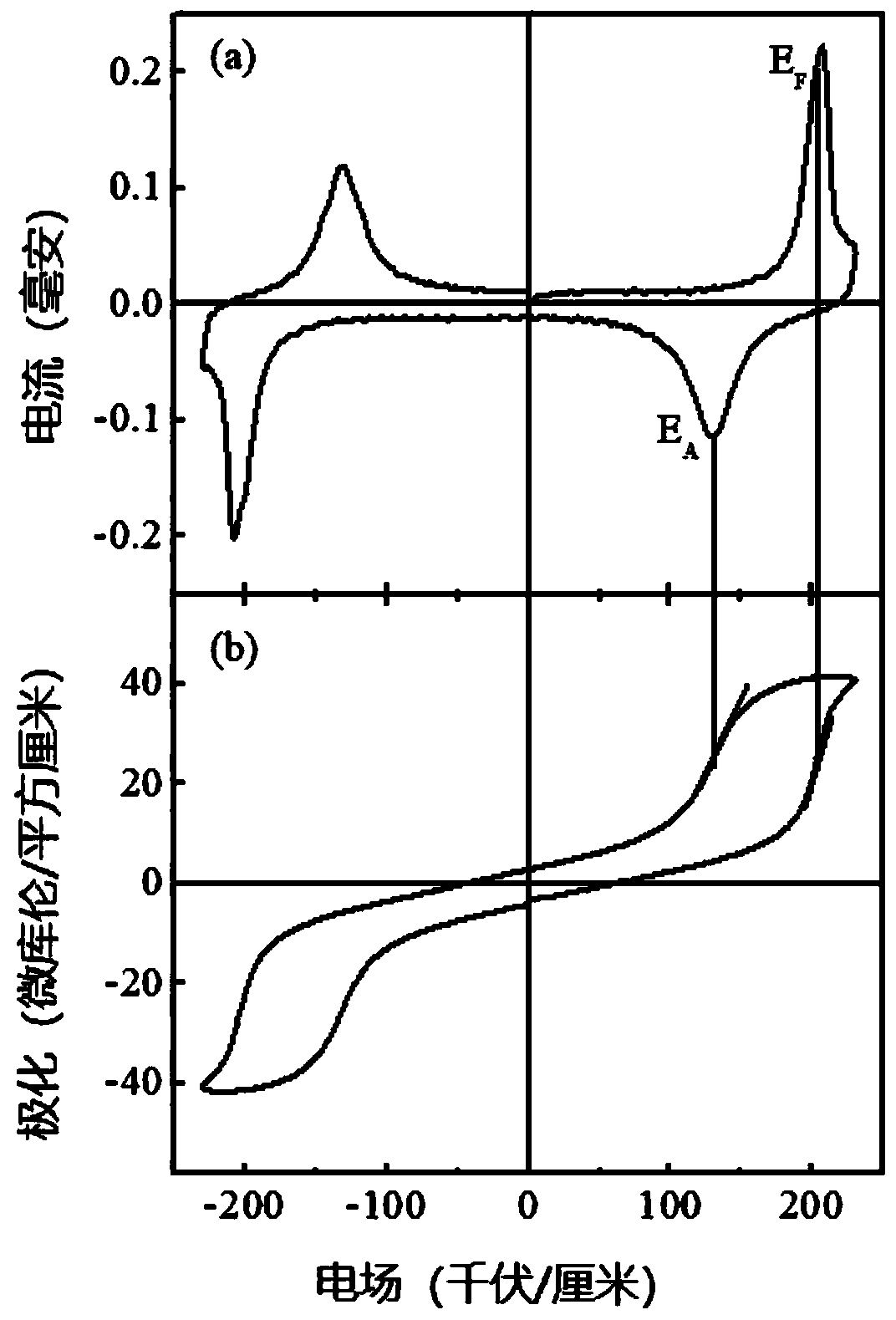

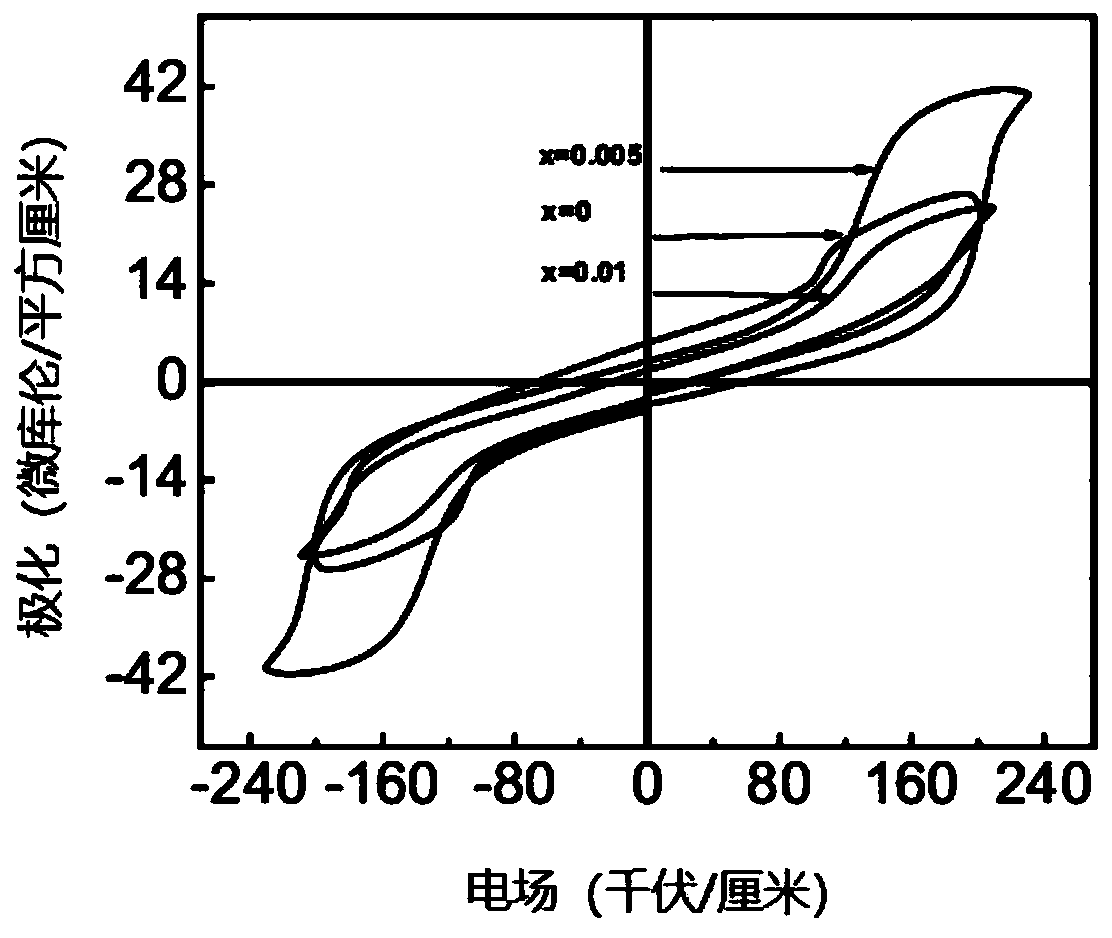

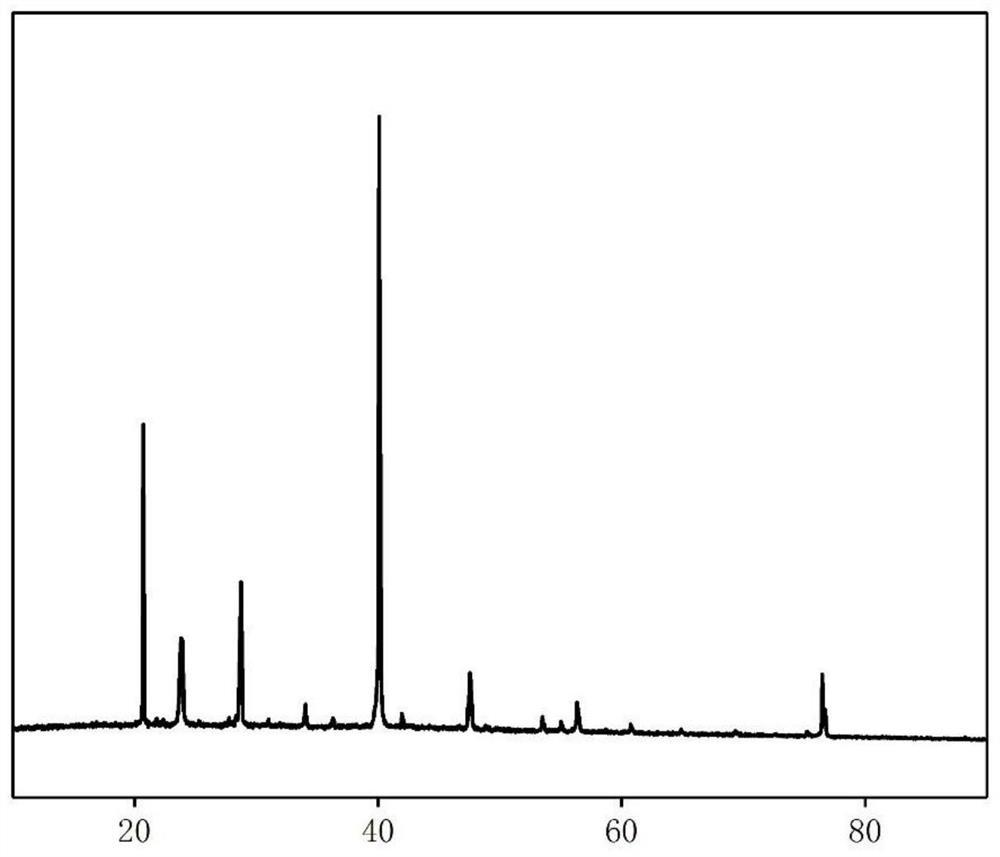

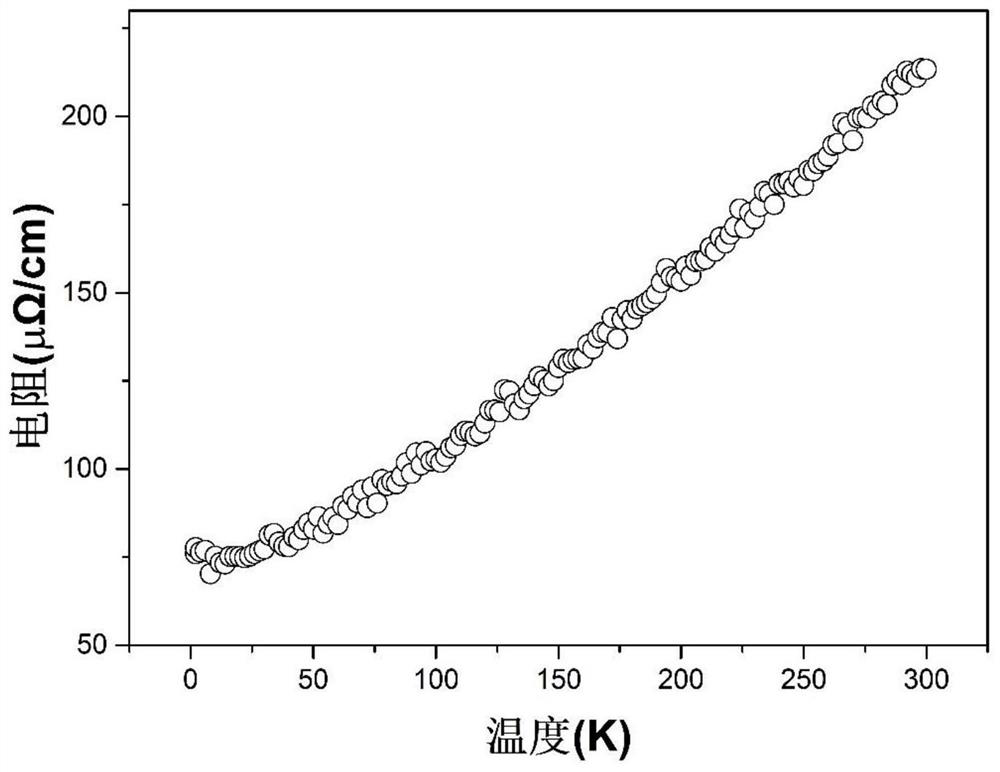

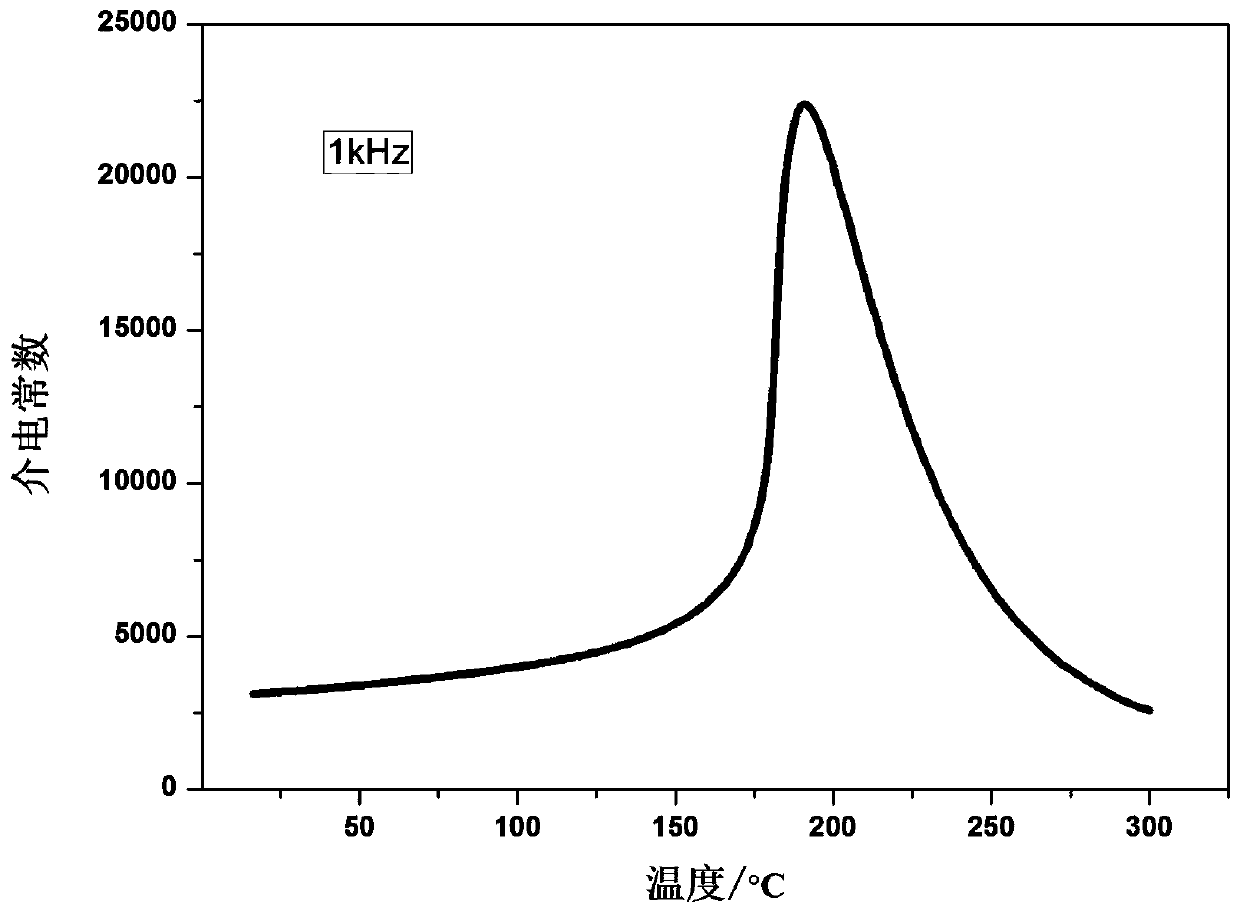

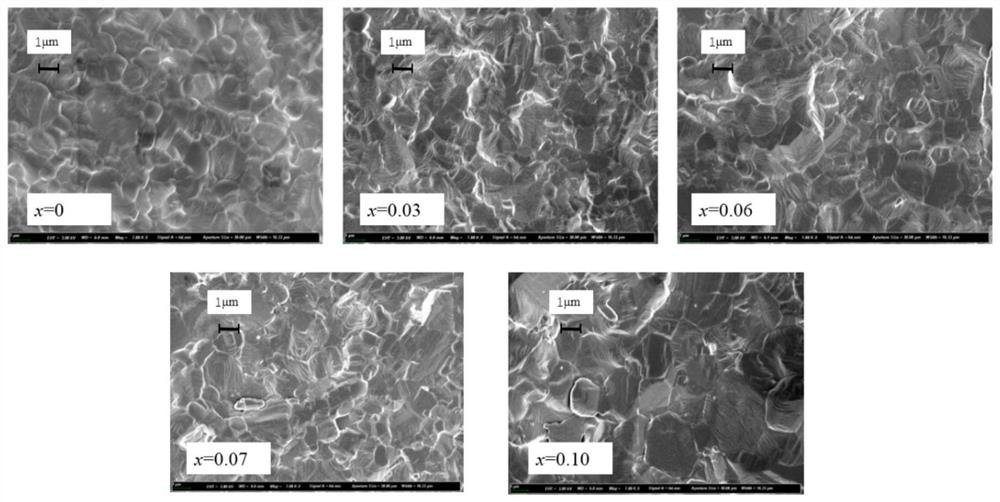

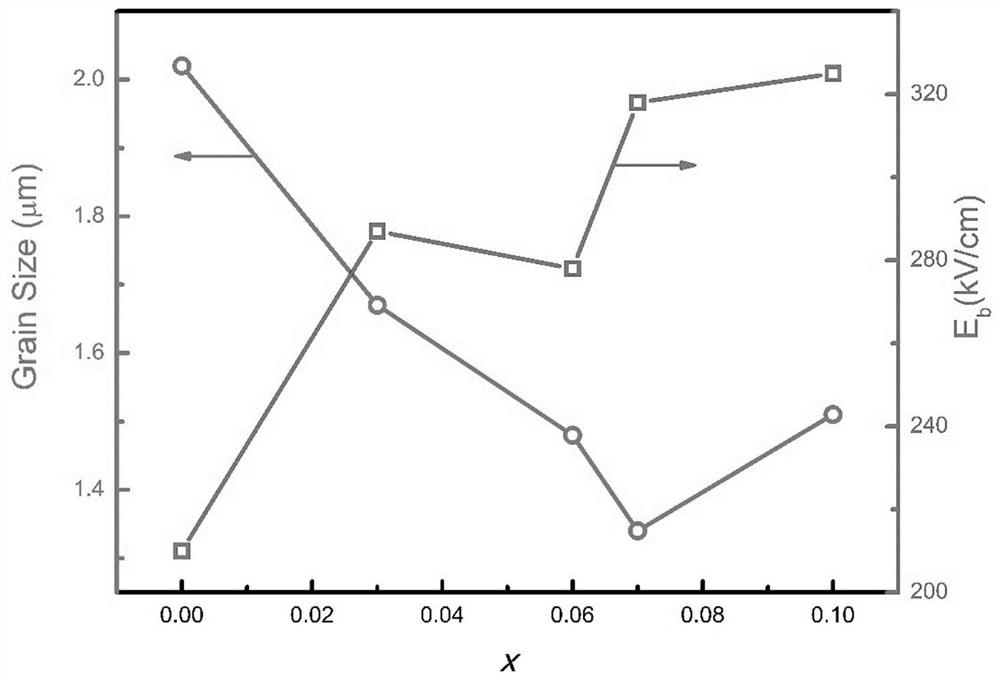

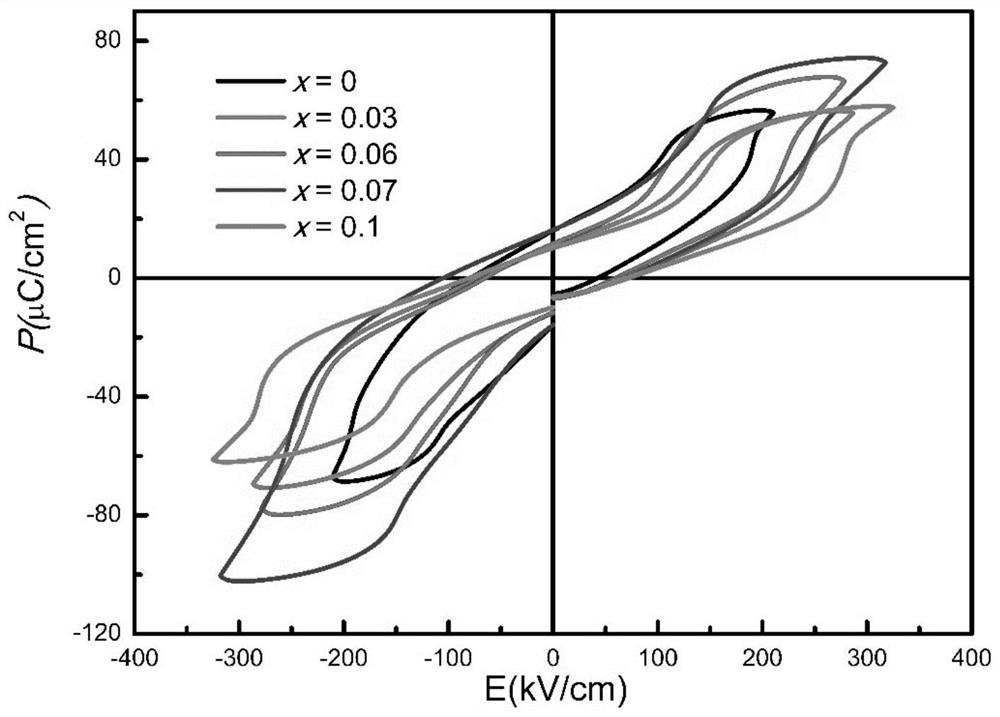

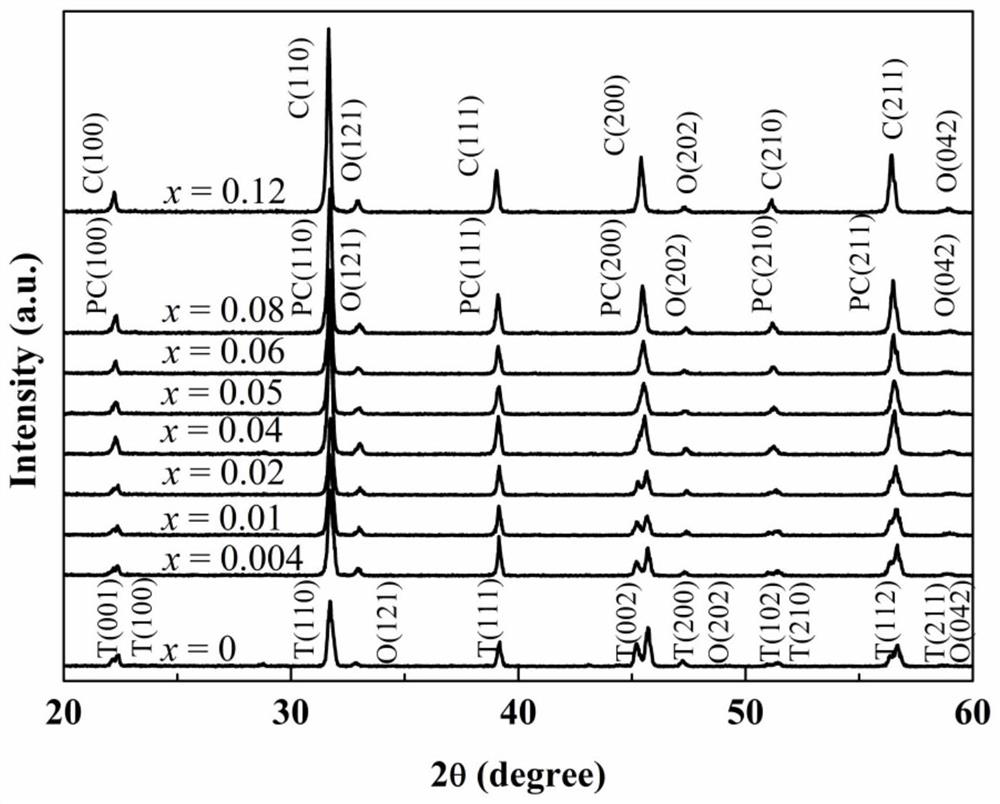

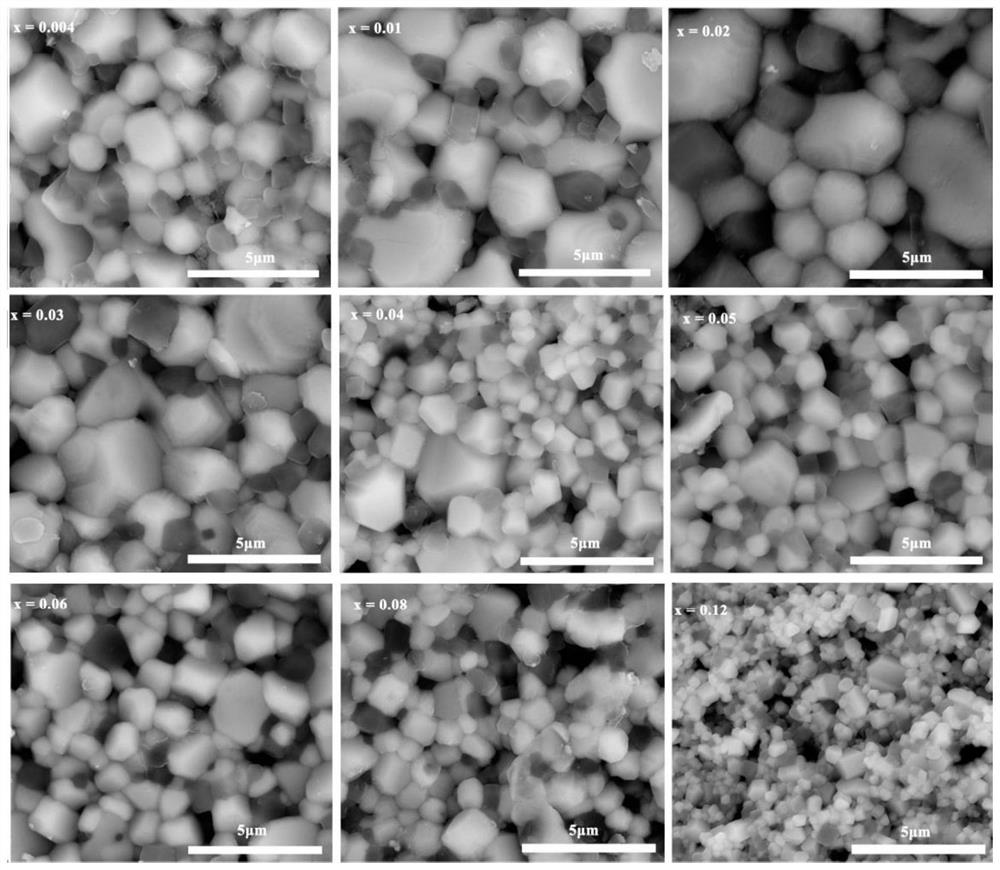

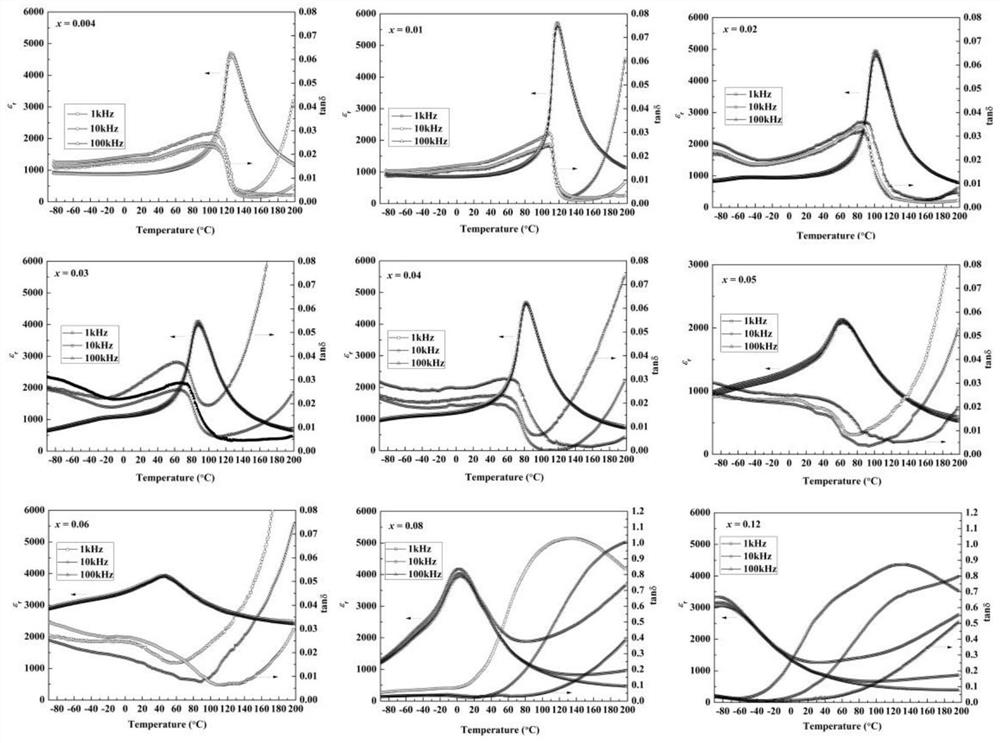

Strontium titanate base energy storage medium ceramics and preparing method

The energy storing strontium titanate base dielectric ceramic has the chemical expression of Sr(ZrxTi1-x)O3, where x is 0.01-0.10, and has doped MnO2 with purity higher than 85 %. The preparation process includes the following steps: compounding material with SrCO3, ZrO2 and TiO2 in 99 % over purity as initial material in the chemical ratio of SrTiO3 and SrZrO3, grinding in deionized water and stoving, maintaining at 1150 deg.c for 4 hr to synthesize SrTiO3 powder, maintaining at 1250 deg.c for 6 hr to synthesize SrZrO3 powder, compounding material based on Sr(ZrxTi1-x)O3, where x is 0.01-0.10, adding MnO2 powder with purity higher than 85 %, grinding in deionized water and mixing, stoving in air atmosphere, adding PVA aqua to pelletize, pressing to form, and sintering in air atmosphere inside high temperature furnace to produce the dielectric ceramic. The dielectric ceramic has high dielectric constant, low loss and high dielectric strength.

Owner:WUHAN UNIV OF TECH

High-energy-storage silver niobate-based lead-free antiferroelectric ceramic and preparation method thereof

InactiveCN111170739AHigh energy storage densityImprove energy storage efficiencyCompression moldingSilver electrode

The invention discloses high-energy-storage silver niobate-based lead-free antiferroelectric ceramic and a preparation method thereof.The chemical formula of the high-energy-storage silver niobate-based lead-free antiferroelectric ceramicis Ag<1-3x>La<x>Nb<0.9>Ta<0.1>O<3>, wherein x is the molar percentage, and the value of x can meets the electric neutrality requirement. The preparation method ofthe high-energy-storage silver niobate-based lead-free antiferroelectric ceramic comprises the following steps: (1) weighing raw materials according to a stoichiometric ratio in thechemical formula Ag<1-3x>La<x>Nb<0.9>Ta<0.1>O<3>, carrying out ball-milling mixing, drying, sieving and tabletting on the raw materials, and presintering the raw materials for 4-6 hours to obtain a rough blank; (2) grinding the rough blank, carrying out secondary ball milling, drying, sieving, granulating, and uniaxial compression molding, and carrying out isostatic cool compression molding to obtain a biscuit; (3)discharging glue from the biscuit, and sintering to obtain a ceramic chip; and (4) grinding and polishing the ceramic chipinto a ceramic sheet, brushing the ceramic sheet with a silver electrode, calcining, and cooling. The energy storage ceramic with high energy storage density and high energy storage efficiency can be obtained by doping a trace amount of La < 3 + > at ceramicA site, the energystorage density is up to 4.6 J / cm < 3 >, and the energy storage efficiency is up to 59%.

Owner:NANJING UNIV OF POSTS & TELECOMM

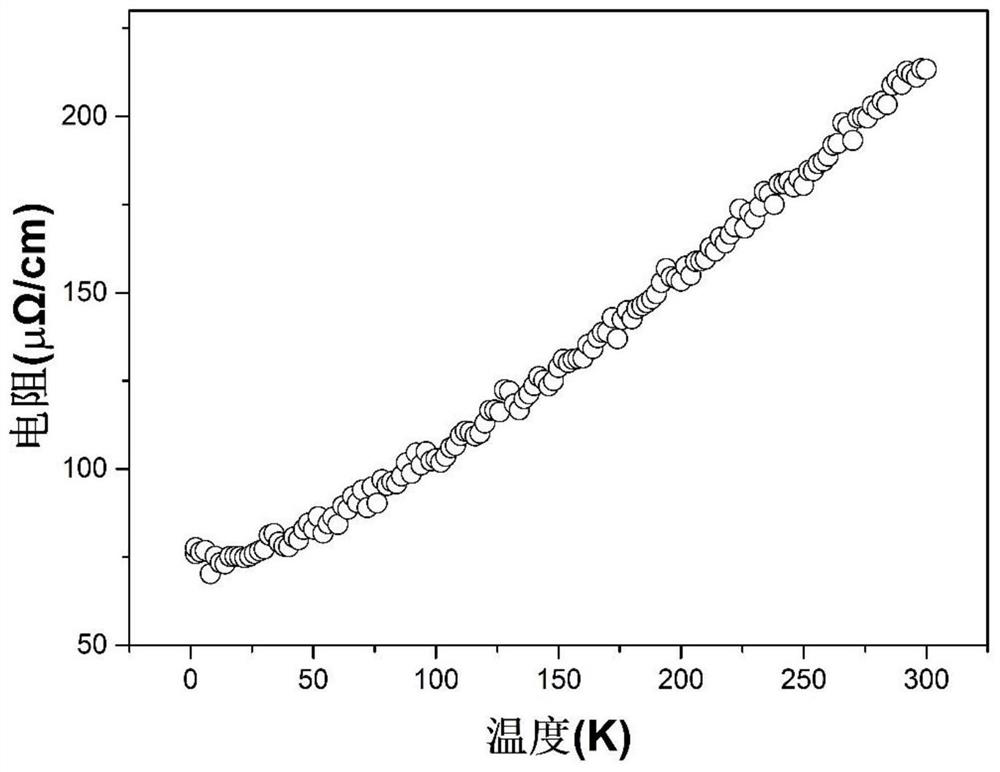

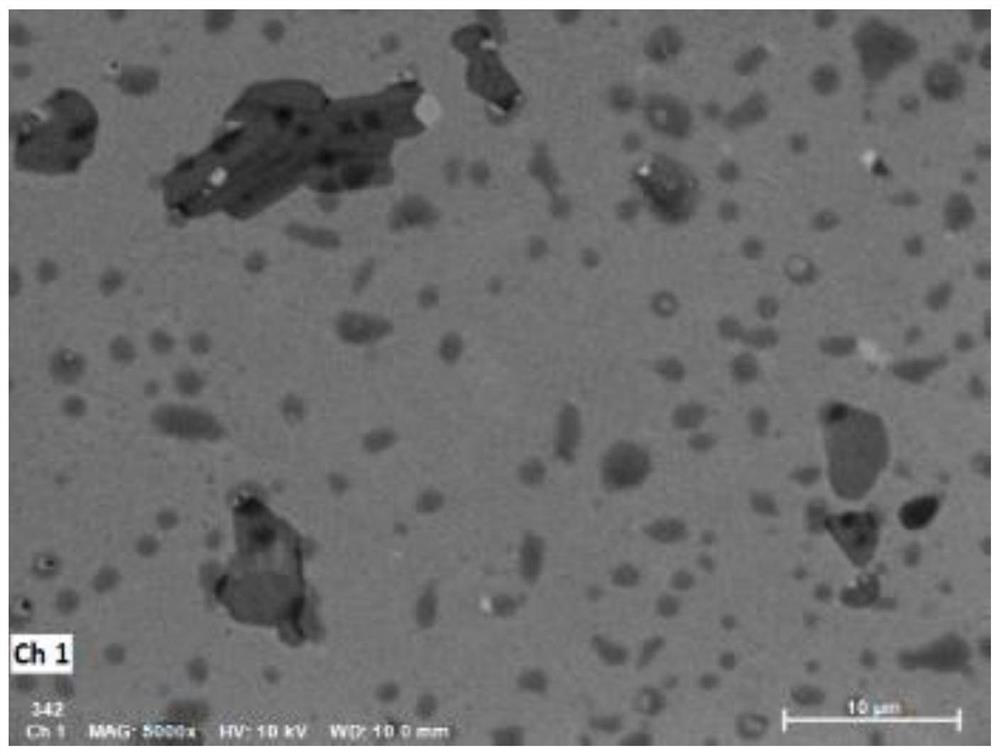

High-entropy ceramic with high hardness and high conductivity as well as preparation method and application of high-entropy ceramic

The invention relates to high-entropy ceramic with high hardness and high conductivity as well as a preparation method and application of the high-entropy ceramic. The chemical formula of the high-entropy ceramic is (AaBbCcDdEe)B12. The dodecaboride high-entropy ceramic provided by the invention has high hardness and high conductivity, enriches a boride high-entropy ceramic material system, has the advantages of low cost, simplicity, feasibility, wide application range and the like, and has great application potential in the field of electrical equipment bearing high stress and high conductivity.

Owner:DONGHUA UNIV +2

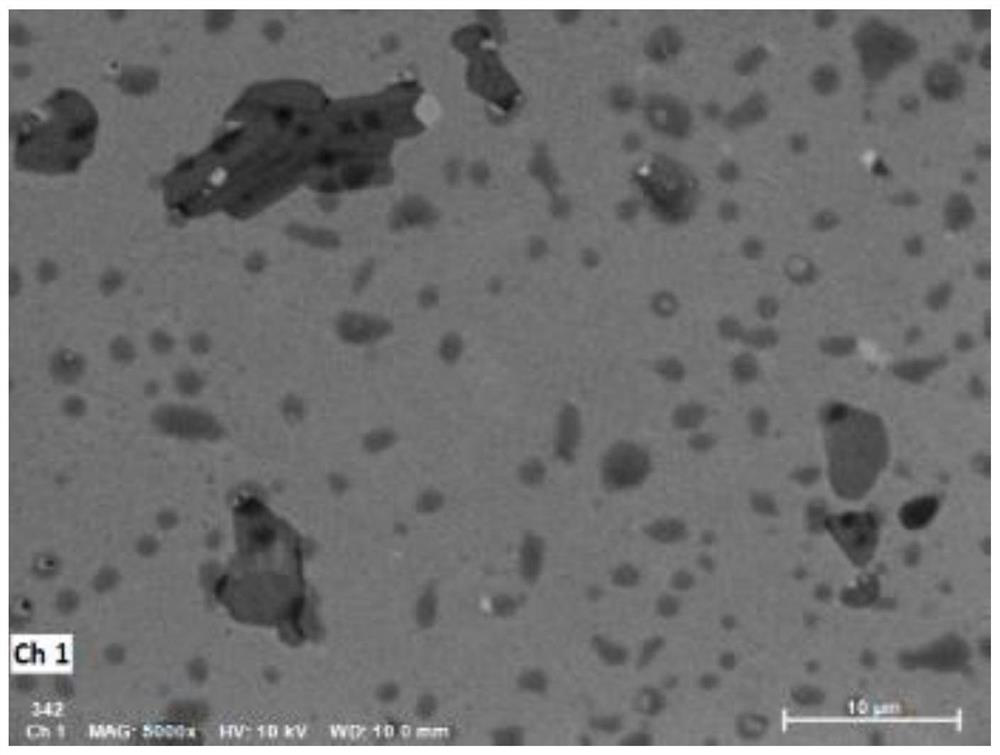

Method for preparing low-loss wolframite-structure microwave dielectric ceramic by means of reaction sintering technology

The invention discloses a method for preparing low-loss wolframite-structure microwave dielectric ceramic by means of a reaction sintering technology.The chemical composition expression of the ceramic is AZrNb2O8, wherein A represents Mg, Co, Ni and Mn.When the ceramic is prepared, the raw materials such as ZrO2, MgO, CoO, NiO, MnO and Nb2O5 are blended according to the chemical formula, the technologies of material mixing, drying, sieving, granulating, compression molding and the like are conducted, sintering is conducted at 1,250 DEG C-1,300 DEG C by means of the reaction sintering technology, and the AZrNb2O8 ceramic is obtained.According to the method for preparing the low-loss wolframite-structure microwave dielectric ceramic by means of the reaction sintering technology, the technological processes of presintering and secondary material mixing are omitted, the preparation time is greatly reduced, the preparation cost is reduced, the reaction sintering process technology is simple, the obtained ceramic is excellent in microwave dielectric property, the process is environmentally friendly, and the ceramic has a great application value in industry.

Owner:UNIV OF JINAN

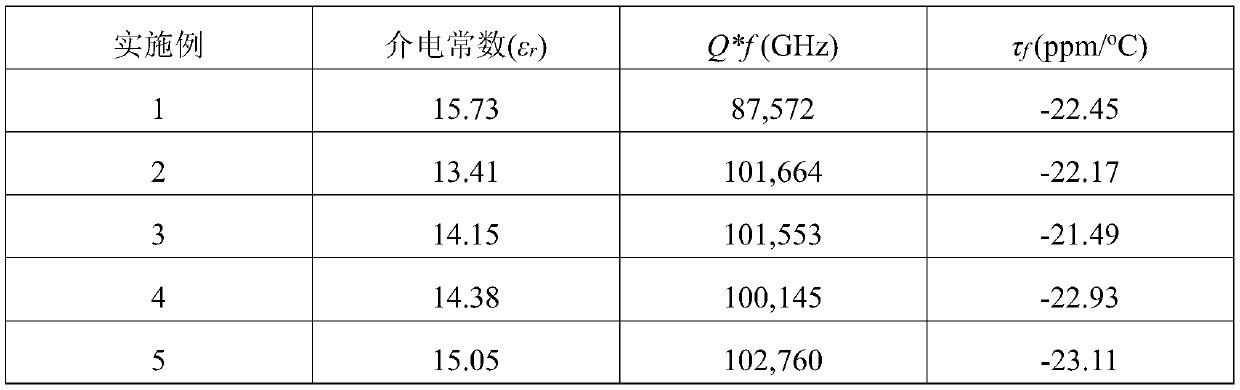

Microwave dielectric ceramic with near-zero frequency temperature coefficient and preparation method thereof

Disclosed is a microwave dielectric ceramic with near-zero frequency temperature coefficient and preparation method, wherein the ceramic has the chemical formula of Ca1-xZnxLa4Ti5O17, wherein x=0.005-0.4, the ceramic is prepared from BaCO3, ZnO, La2O3, TiO2 as raw material through wet grinding and mixing, drying into powder, calcining at 1100-1200 deg. C, wet grinding again, drying and charging polyvinyl alcohol (PVA), press forming, calcining 2-4 hours in high temperature furnace, the prepared microwave dielectric ceramics can be widely applied to the manufacture of various dielectric resonators, electric wave filters and other microwave devices.

Owner:TSINGHUA UNIV

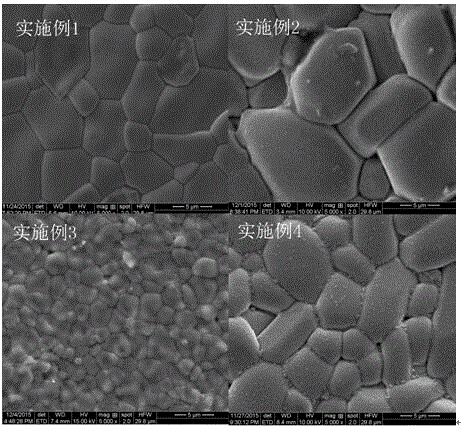

Lithium-magnesium-niobium-aluminum-tungsten microwave dielectric ceramic and preparation method thereof

InactiveCN111302795AImprove compactnessExcellent microwave dielectric propertiesPhysical chemistryCeramic chemistry

The invention belongs to the technical field of ceramic materials, and discloses a lithium-magnesium-niobium-aluminum-tungsten microwave dielectric ceramic and a preparation method thereof. The chemical expression of the ceramic is Li3Mg2Nb1-x(Al1 / 3W2 / 3)xO6, and x is larger than or equal to 0.02 and smaller than or equal to 0.08. The preparation method comprises the following steps: by adopting asolid-phase synthesis method, mixing Li2CO3, MgO, Nb2O5, Al2O3 and WO3 according to a stoichiometric ratio, carrying out ball milling, drying and sieving, presintering at 925-1000 DEG C to obtain presintered powder, performing ball milling again, drying, sieving and granulating, pressing into a green body, sintering the green body at 1075-1175 DEG C, keeping the temperature, and cooling to room temperature to obtain the required microwave dielectric ceramic. The microwave dielectric ceramic has the advantages of excellent microwave dielectric properties, low cost, simple preparation technique,no toxicity or pollution, and wide application prospects.

Owner:TIANJIN UNIV

Lanthanum aluminate green ceramic as well as preparation method and application thereof

The invention provides lanthanum aluminate green ceramic as well as a preparation method and application thereof, and relates to the technical field of ceramic. The chemical component of the lanthanum aluminate green ceramic provided by the invention is LaAl < 11-2X-YNi < X > Cr < Y > Ti < X > O < 18 >, X is equal to 1.5-5.0, and Y is equal to 0.0-2.0. The lanthanum aluminate ceramic provided by the invention is green and bright in color, and has relatively high hardness, toughness and color saturation.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

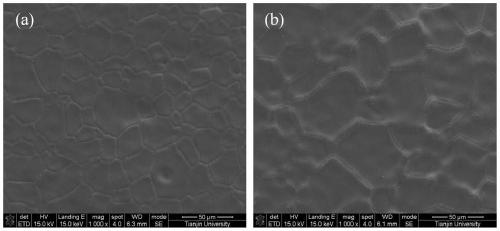

Magnesium-zircon-germanium-niobium microwave dielectric ceramic with low dielectric constant and ultra-low dielectric loss and preparation method and application

InactiveCN109336596AExcellent microwave dielectric propertiesHigh dielectric constantNiobiumCeramic chemistry

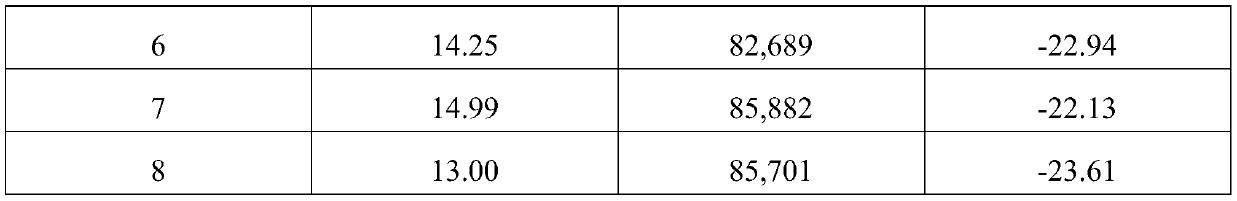

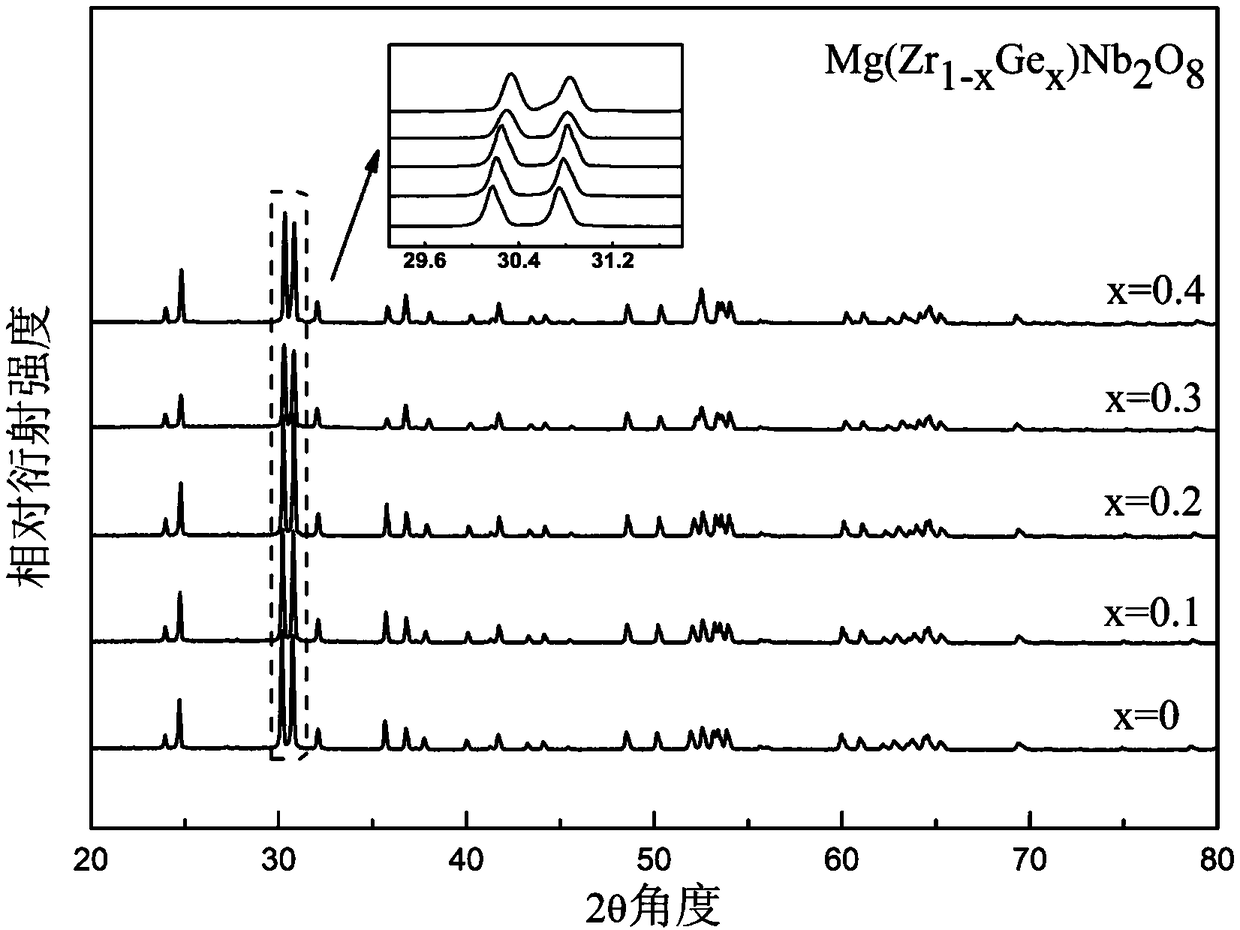

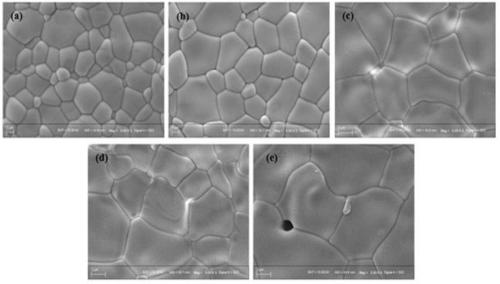

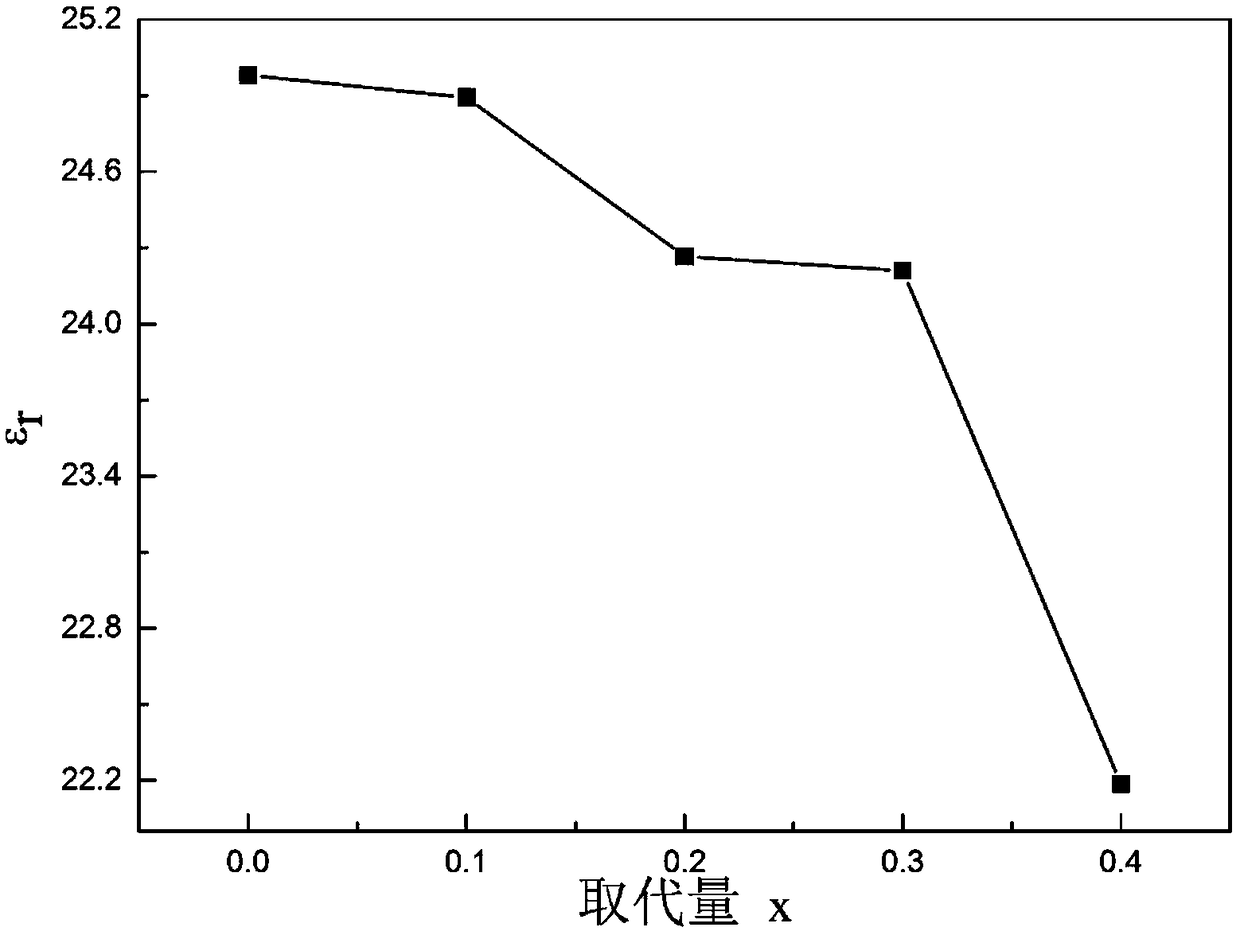

The invention discloses magnesium-zircon-germanium-niobium microwave dielectric ceramic with a low dielectric constant and an ultra-low dielectric loss and a preparation method and an application. A chemical expression of the microwave dielectric ceramic is Mg(Zr1-xGex)Nb2O8, wherein x is greater than 0 and less than or equal to 0.4. The preparation method comprises the following steps of: (1) preparing raw materials according to the chemical formula Mg(Zr1-xGex)Nb2O8 (x greater than 0 and less than or equal to 0.4), adding a certain proportion of deionized water and zirconia grinding media for ball milling on a ball mill, (2) drying the raw materials ball-milled in step (1), screening the raw materials with a 40-mesh sieve to form even grained powder, (3) calcining the powder in step (2),(4) performing secondary ball milling, drying and pelletizing on the ceramic powder prefired in step (3), screening the ceramic powder with a 60-mesh sieve, pressing the powder into a green body through a powder compressing machine, and (5) sintering the green body in step (4) at 1260-1320 DEG C for 3-6h to form the magnesium-zircon-germanium-niobium microwave dielectric ceramic. The microwave dielectric ceramic is applied in the field of communication. According to the microwave dielectric ceramic, the very excellent microwave dielectric property can be obtained only by partially replacing zircon ions with micro germanium ions.

Owner:TIANJIN UNIV

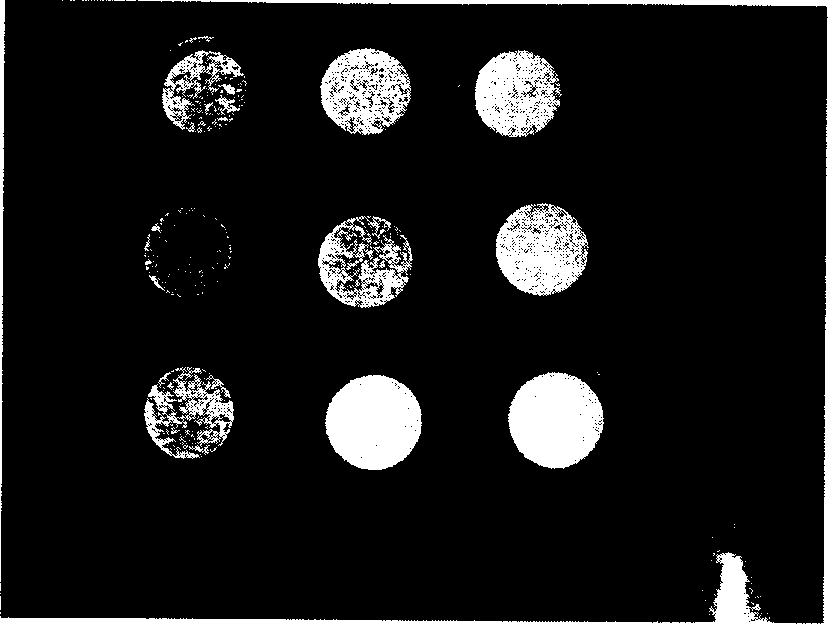

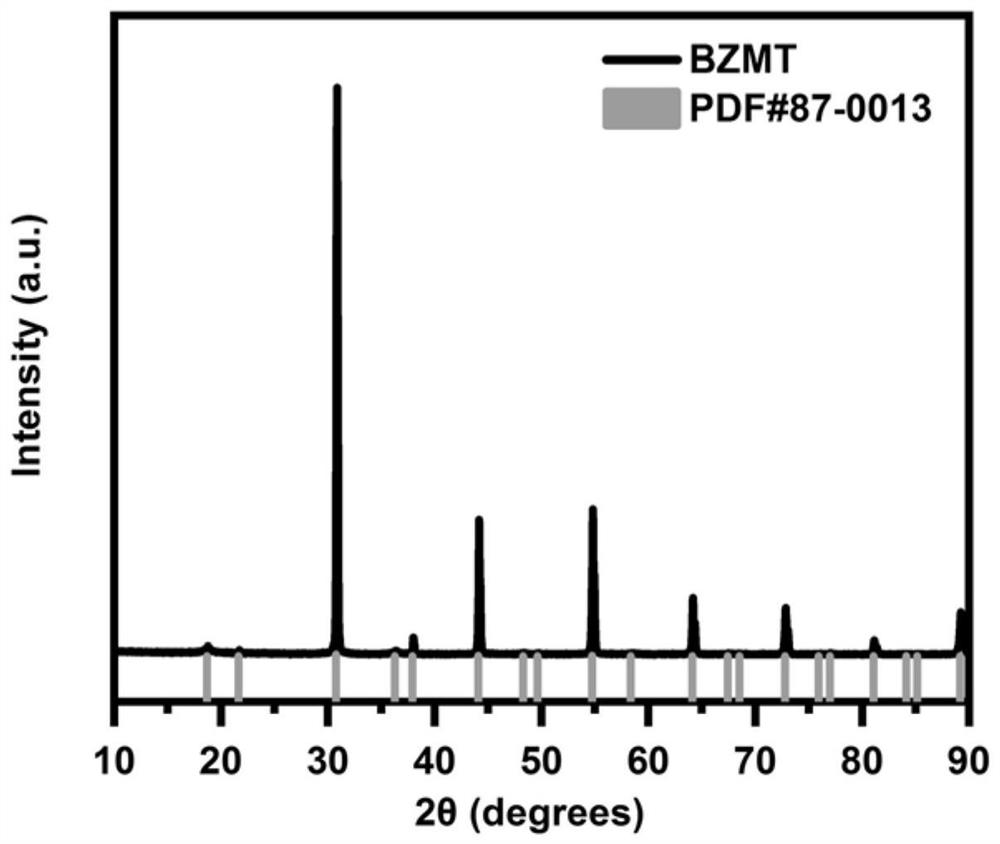

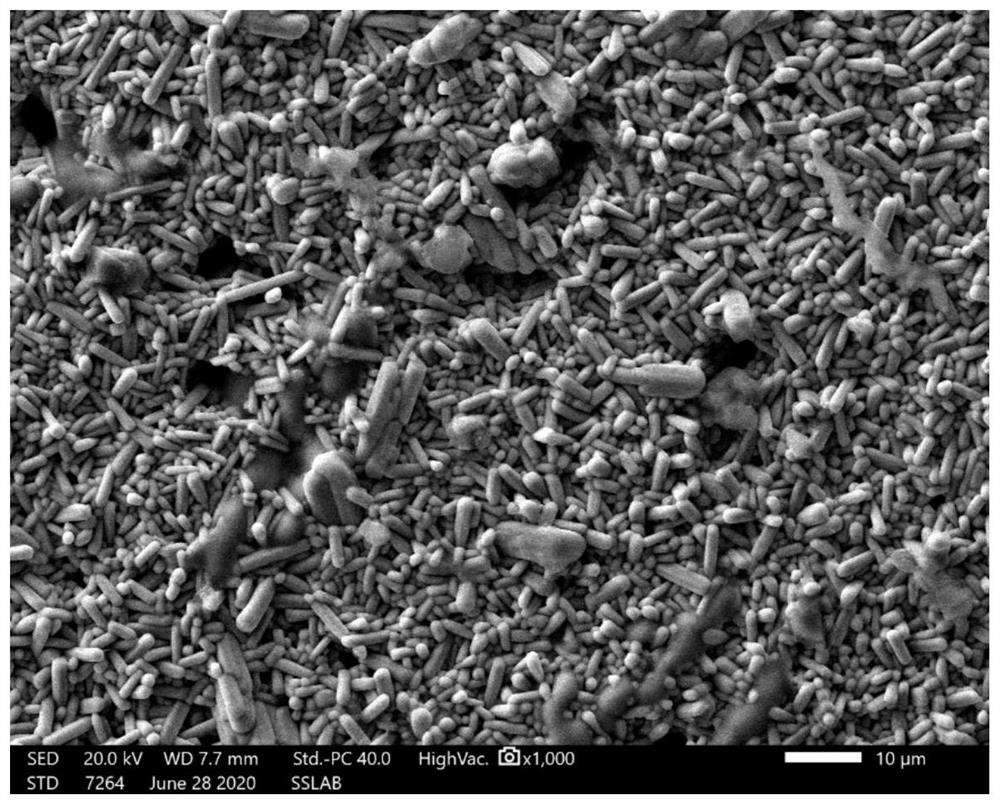

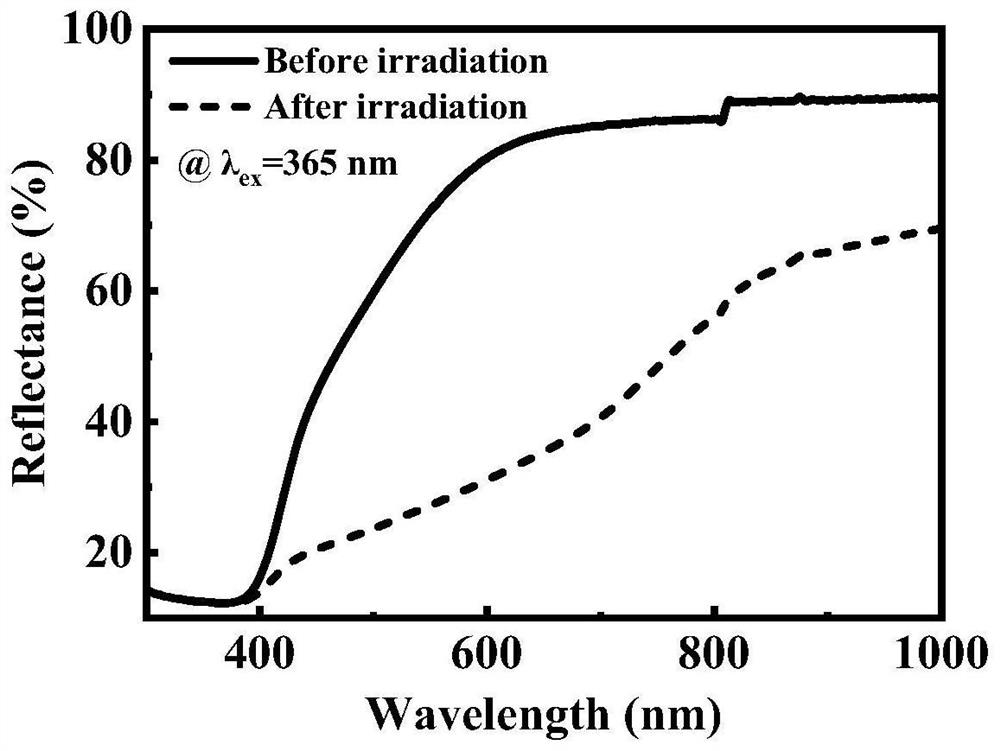

Reversible photochromic transparent ceramic as well as preparation method and application thereof

ActiveCN114149262AColor changing high contrastFast coloring/restoration response timeLight protection screensTenebresent compositionsChemical compositionCeramic chemistry

The invention relates to the technical field of ceramic materials, in particular to reversible photochromic transparent ceramic as well as a preparation method and application thereof. The chemical composition of the reversible photochromic transparent ceramic is Ba (AxMgyBz) O3, wherein A is selected from at least one of Zr, Sn, Ti and Hf; b is selected from at least one of Ta and Nb; 4x + 2y + 5z = 4, x is greater than 0 and less than 1, y is greater than 0 and less than 1, and z is greater than 0 and less than 1. The reversible photochromic transparent ceramic disclosed by the invention has the characteristic of reversible conversion from grey white to brown. The Ba (AxMgyBz) O3 photochromic ceramic changes color under the condition of irradiation of about 365 nm and can restore to the original shape under the condition of irradiation of about 450 nm or heating, and the reversible photochromic transparent ceramic is high in color change contrast.

Owner:SONGSHAN LAKE MATERIALS LAB +1

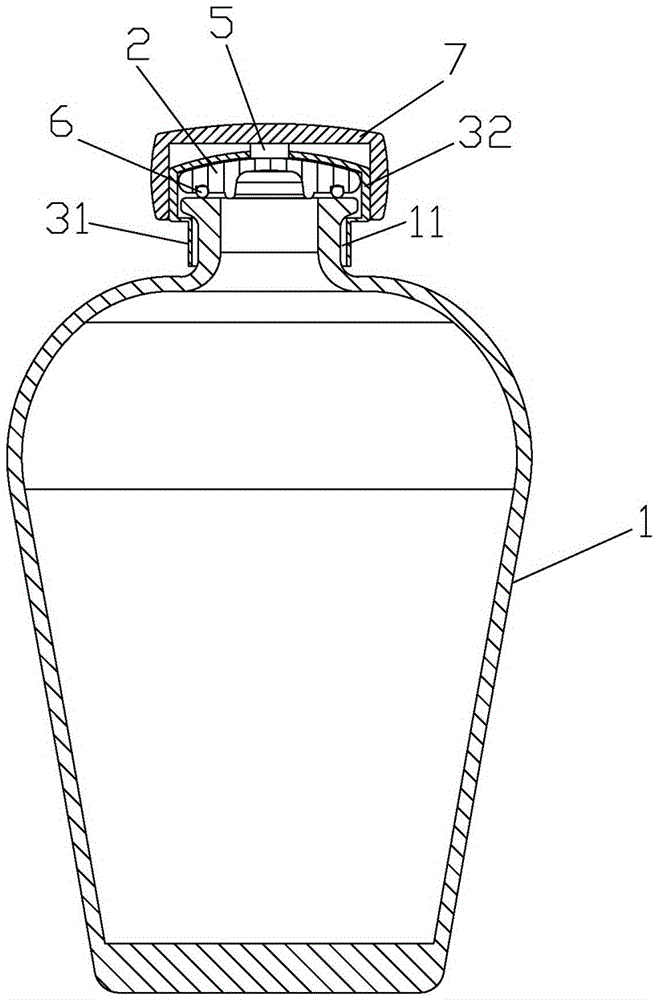

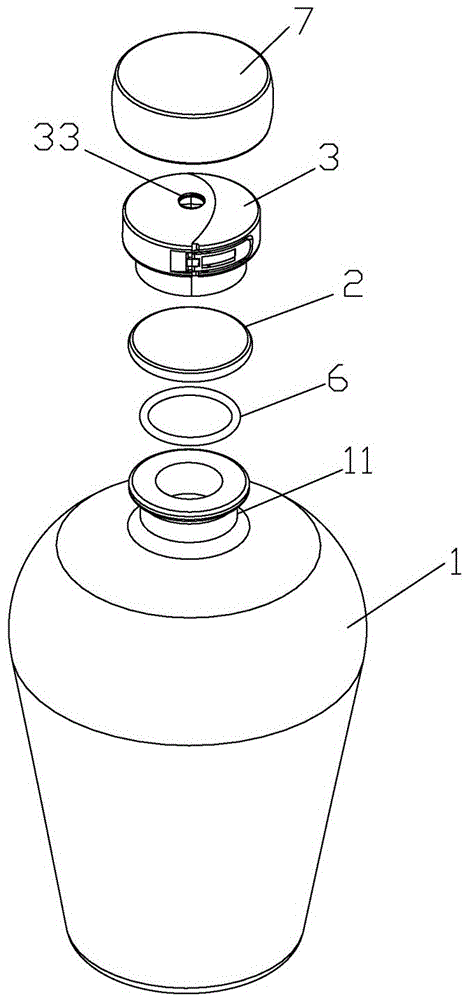

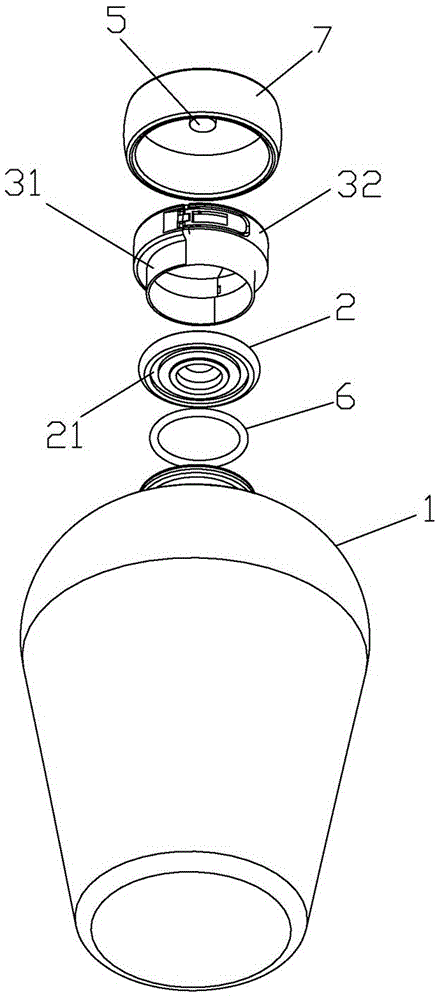

Large-opening wine jar packaging anti-theft device

ActiveCN105460378AGuaranteed tightnessImprove qualityLocking devicesHazardous substanceCeramic chemistry

The invention relates to a large-opening wine jar packaging anti-theft device. A ceramic wine jar is sealed through a ceramic jar cover, the ceramic jar cover is jacked through a closely-packaging screw or a closely-compression cover, so that the ceramic jar cover and an opening of the ceramic wine jar at kept in the good sealing effect. A sealing screw is used for extrusion sealing, as the chemical property of ceramics is stable, cannot age, cannot separate out hazardous substance when being in contact with wine, and is suitable for long-term storage; and the longer the storage time is, the better the quality of the wine is.

Owner:蔡灵明

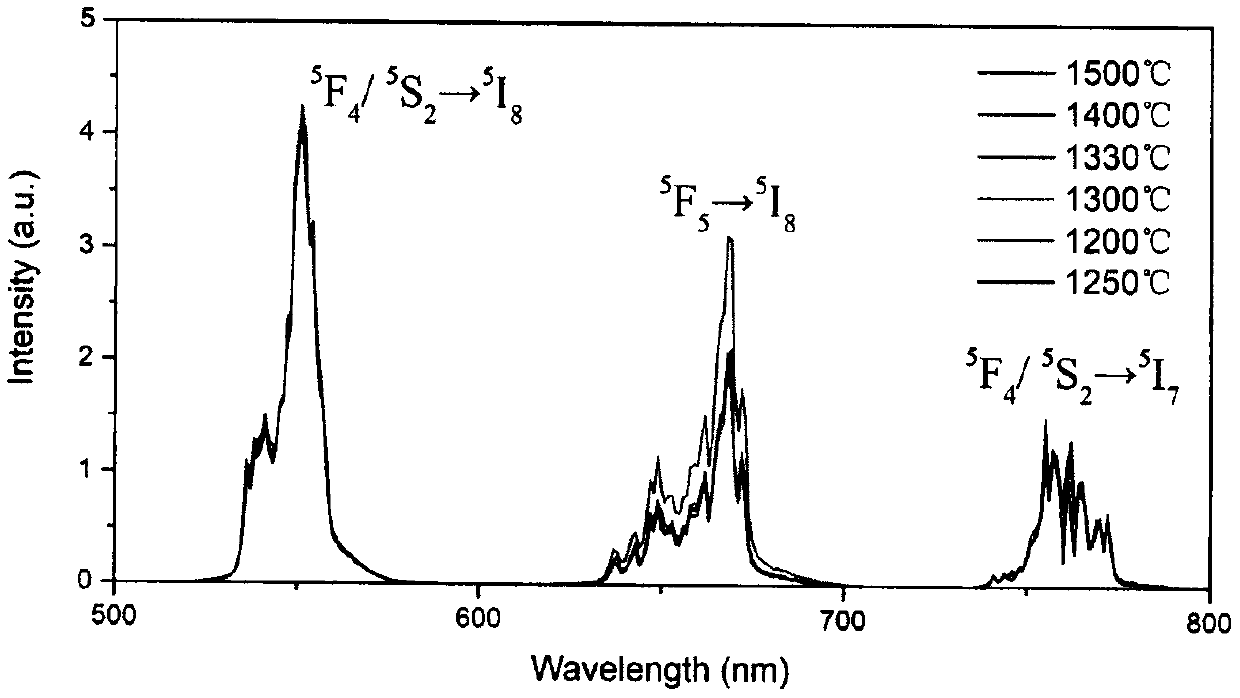

Organic dye-infrared up-conversion luminescent transparent ceramic composite material and preparation method thereof

The invention, on one aspect, provides an organic dye-infrared up-conversion luminescent transparent ceramic composite material, which is composed of an organic dye and an infrared up-conversion luminescent transparent ceramic. The composite material is an organic matter with a strong absorption effect on near-infrared light with a wavelength of 780nm-1100nm. The chemical formula of the infrared up-conversion luminescent transparent ceramic is (HoxYbyY1-x-yZr0.03)2O3, wherein x is greater than or equal to 0.0005 and less than or equal to 0.02, and y is greater than or equal to 0.005 and less than or equal to 0.2. And the composite material is uniformly coated on a surface of the infrared up-conversion luminescent transparent ceramic. According to the material, organic dye molecules with strong absorption and long excited state service life in an infrared region are used as a sensitizing layer to absorb infrared light firstly, and then excited state electrons are transferred to a <2>F5 / 2 excited state energy level of Yb<3+> ions through resonance energy transfer, so that infrared up-conversion luminescence enhancement is realized. The up-conversion luminescent transparent ceramic Ho<3+> / Yb<3+>:Y2O3 and the preparation method thereof have important application in biomedicine and infrared sensing.

Owner:北京科易达知识产权服务有限公司

Low temperature sintered microwave dielectric ceramics and its preparing method

InactiveCN100378031CExcellent microwave dielectric propertiesLow costCeramicsDielectric ceramicsCeramic chemistry

The present invention relates to low temperature sintered microwave dielectric ceramic and its preparation process, and belongs to the field of microwave dielectric ceramic technology. The material has the composition of Li2+xNb3xTi1-4xO3+yB2O3, where 0 C04B 35 / 462 C04B 35 / 622 H01B 3 / 12 1 8 2 2006 / 3 / 9 1821171 2006 / 8 / 23 100378031 2008 / 4 / 2 2008 / 4 / 2 2008 / 4 / 2 Shanghai Inst. of Ceramic Chemistry and Technology, CAS Shanghai 200050 Li Wei Zeng Qun Shi Jianlin Wu Wenjun Guo Jingkun

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

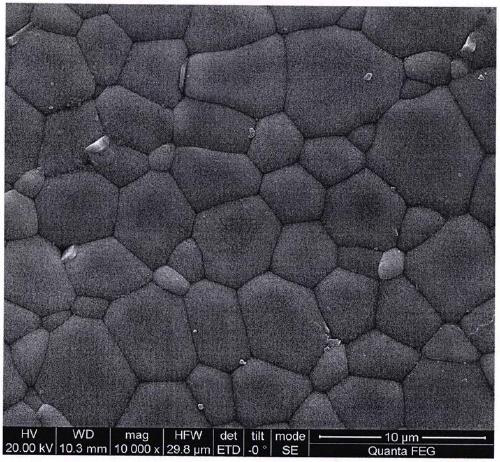

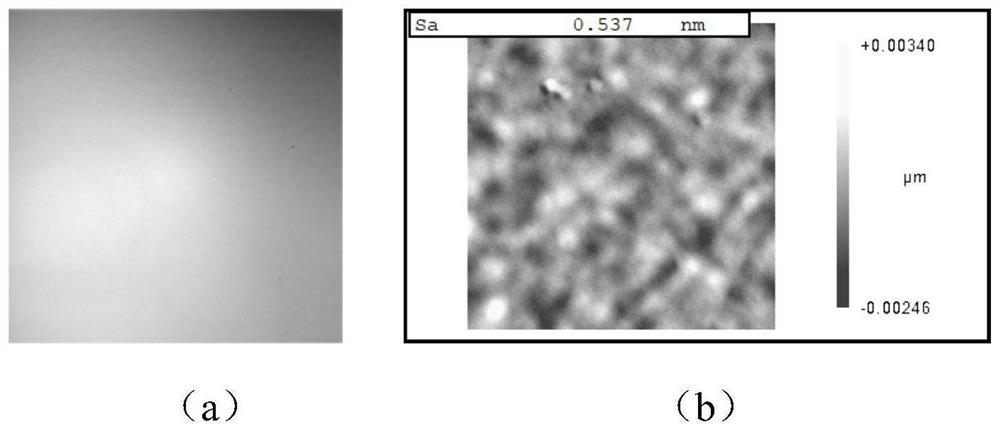

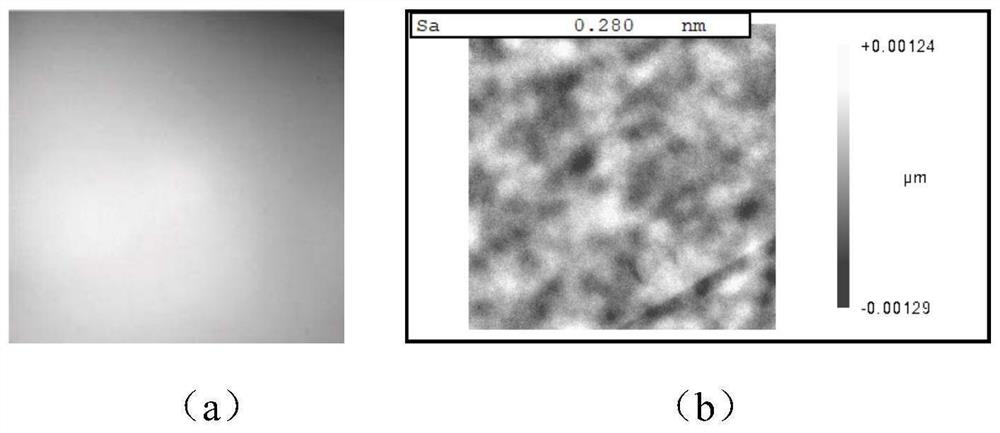

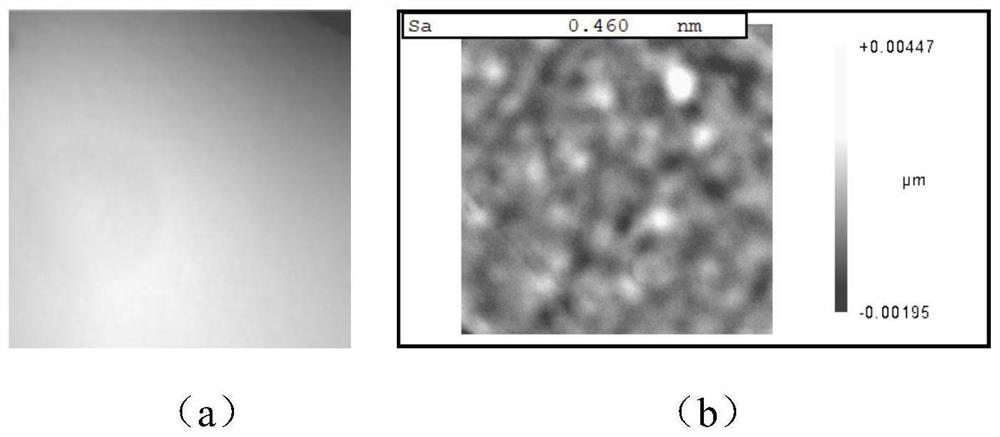

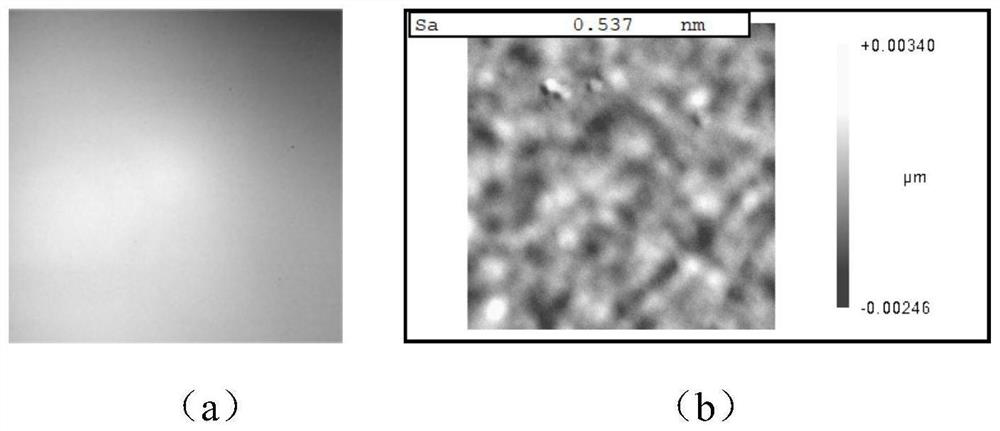

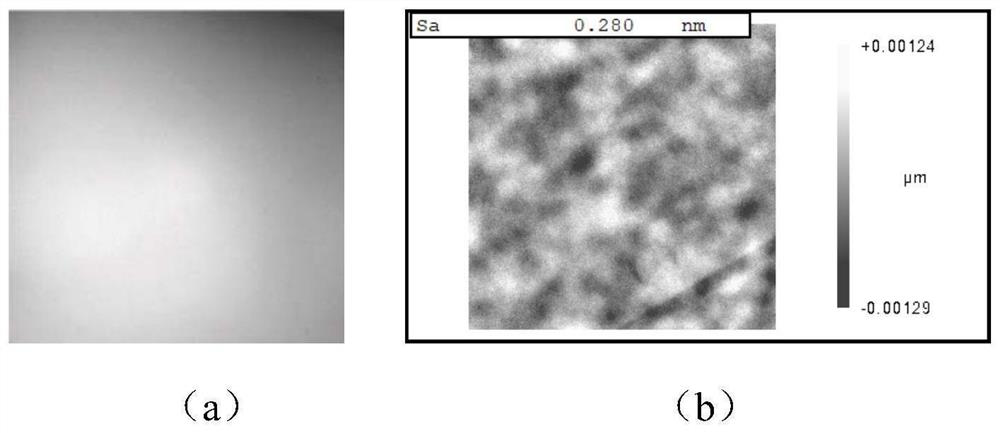

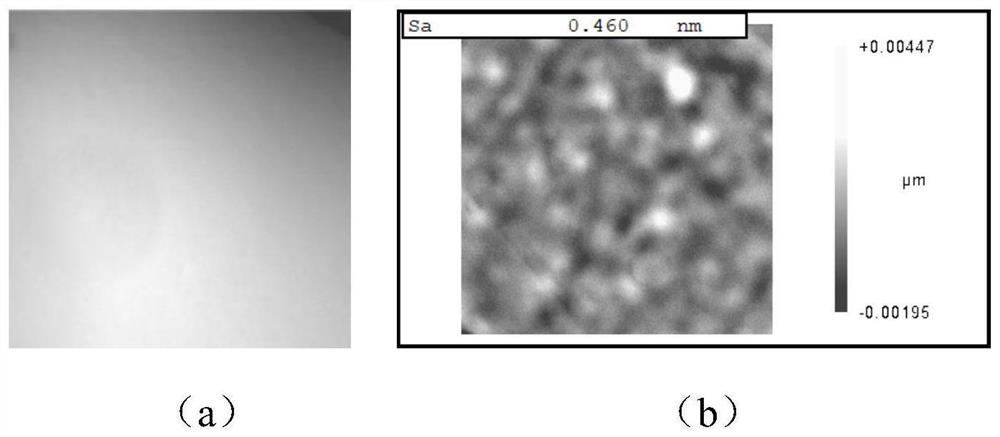

A chemical mechanical polishing fluid for polycrystalline YAG ceramics

ActiveCN113480942BModerate chemistryImprove removal efficiencyPolishing compositions with abrasivesMaterial removalCeramic chemistry

The invention discloses a polycrystalline YAG ceramic chemical mechanical polishing fluid, which belongs to the technical field of precision / ultraprecision processing. The polycrystalline YAG ceramic chemical mechanical polishing fluid has a pH of 7 and contains two parts: a solute and a solvent: the solvent is deionized water. Based on 100% of the total mass fraction of the polishing liquid, its components and mass percentages are as follows: 10-30 wt% silica sol, 1-5 wt% alumina abrasive grains, 0.1-0.5 wt% abrasive grain dispersant, appropriate pH Regulator, each substance is mixed uniformly by ultrasonic in deionized water. The ultra-smooth polishing of polycrystalline YAG ceramics can be realized by using the polishing liquid. The grain boundary height difference of the polished polycrystalline YAG crystal surface is significantly reduced, and an ultra-smooth and non-damaged polycrystalline YAG crystal surface can be obtained; In addition, the polishing liquid of the present invention has high material removal efficiency, which is significantly improved compared with the polishing liquid containing only silica sol or alumina.

Owner:DALIAN UNIV OF TECH +1

Microwave dielectric ceramic with near-zero frequency temperature coefficient and preparation method thereof

Owner:TSINGHUA UNIV

A kind of tin-doped lead lanthanum zirconate titanate thick film ceramics and its preparation and application

ActiveCN108929112BHigh energy storage densityImprove temperature stabilityLead zirconate titanateHigh energy

The invention provides a tin-doped lead lanthanum zirconate titanate thick film ceramic and its preparation and application, belonging to the technical field of energy storage ceramic materials. The tin-doped lead lanthanum zirconate titanate thick-film ceramic has a chemical composition conforming to the general chemical formula Pb 0.94 La 0.06 (Zr 0.95~x Sn x Ti 0.05 ) 0.985 O 3 , where 0.05≦x≦0.15. The preparation method includes the following steps: (1) weighing each raw material in proportion, mixing, ball milling, drying, sieving and calcining to obtain a sintered product; (2) subjecting the sintered product to high-energy ball milling, drying and sieving to obtain fine particles Powder; (3) Mixing the fine powder with dispersant and solvent, tumbling, adding binder and tumbling, then adding dispersant, binder, solvent and plasticizer, and tumbling to obtain casting slurry ; (4) Casting the casting slurry to obtain a thick film green body, sintering, that is, obtained. The tin-doped lead lanthanum titanate ceramic thick film can withstand an electric field strength of 400 kv / cm, significantly improves the energy storage density and energy storage efficiency of the ceramic thick film, and has wide application prospects.

Owner:GUANGDONG UNIV OF TECH

Modified lead niobate nickelate-lead zirconate titanate piezoelectric ceramic and preparation method thereof

InactiveCN106220169BHigh curie temperatureTurn simplePiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateElectromechanical coupling coefficient

Owner:重庆胜普昂凯科技有限公司

Stoichiometric mismatched high-energy-storage silver niobate-based ceramic and preparation method thereof

The invention discloses stoichiometric mismatched high-energy-storage silver niobate-based ceramic and a preparation method thereof, wherein the chemical formula of the ceramic is Ag[0.985] La[0.005]Nb[1-x]O[3-2.5x], x is molar percentage, and the value of x meets the electric neutrality. Under the condition of not introducing other elements, the high-energy-storage lead-free antiferroelectric ceramic with the maximum energy storage density of 7.05 J / cm<3> (the value is the maximum value in the research field) can be obtained only by reducing the niobium ion content and changing the stoichiometric ratio of the material; and the lead-free energy storage ceramic has the advantages of high energy storage density, high breakdown electric field (318 kV / cm), high polarization intensity (74 [mu]C / cm<2>) and the like, and is expected to be applied to the fields of novel dielectric energy storage devices, pulse power devices, hybrid electric vehicles and the like. Particularly, experiments prove that under the condition that other elements are not introduced, only the innovative idea of changing the stoichiometric ratio of the material is an effective new method in research of the silver niobate-based lead-free energy storage ceramic, and the idea can be applied to the field of other dielectric energy storage research.

Owner:NANJING UNIV OF POSTS & TELECOMM

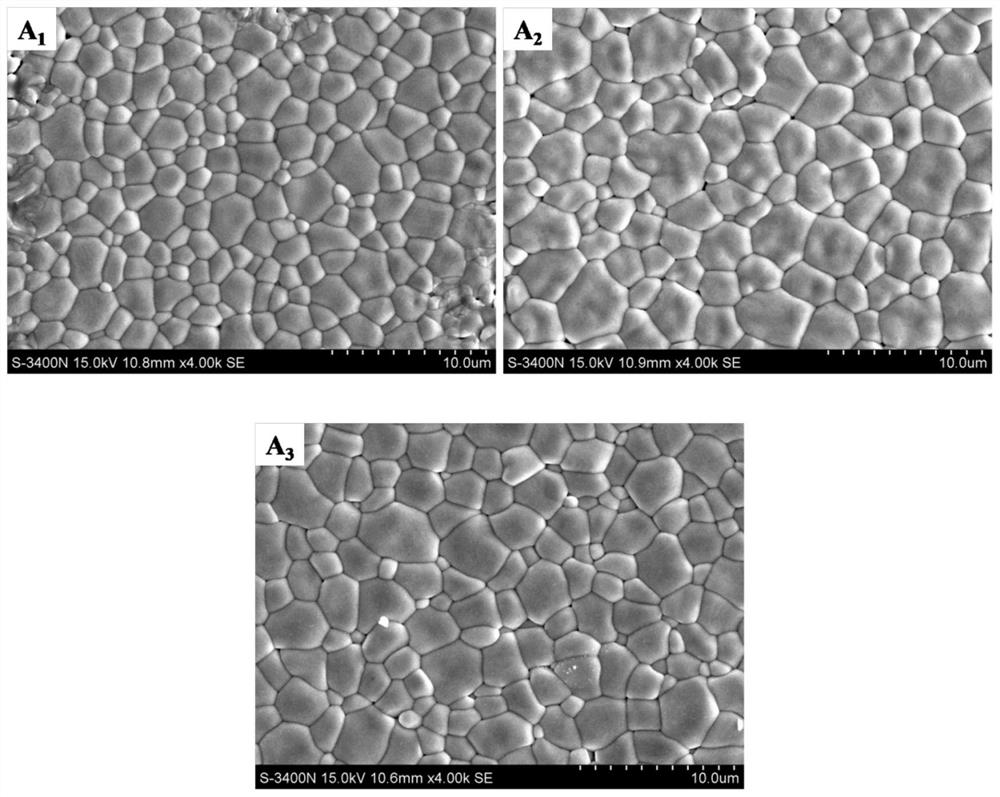

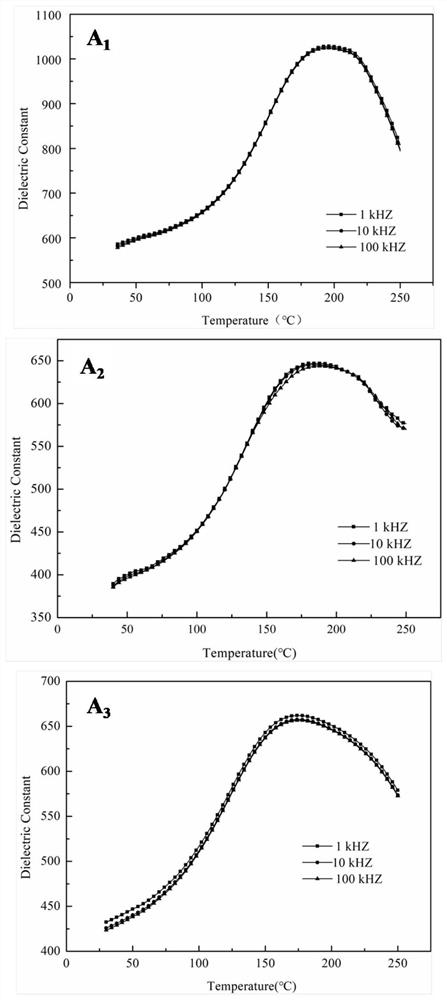

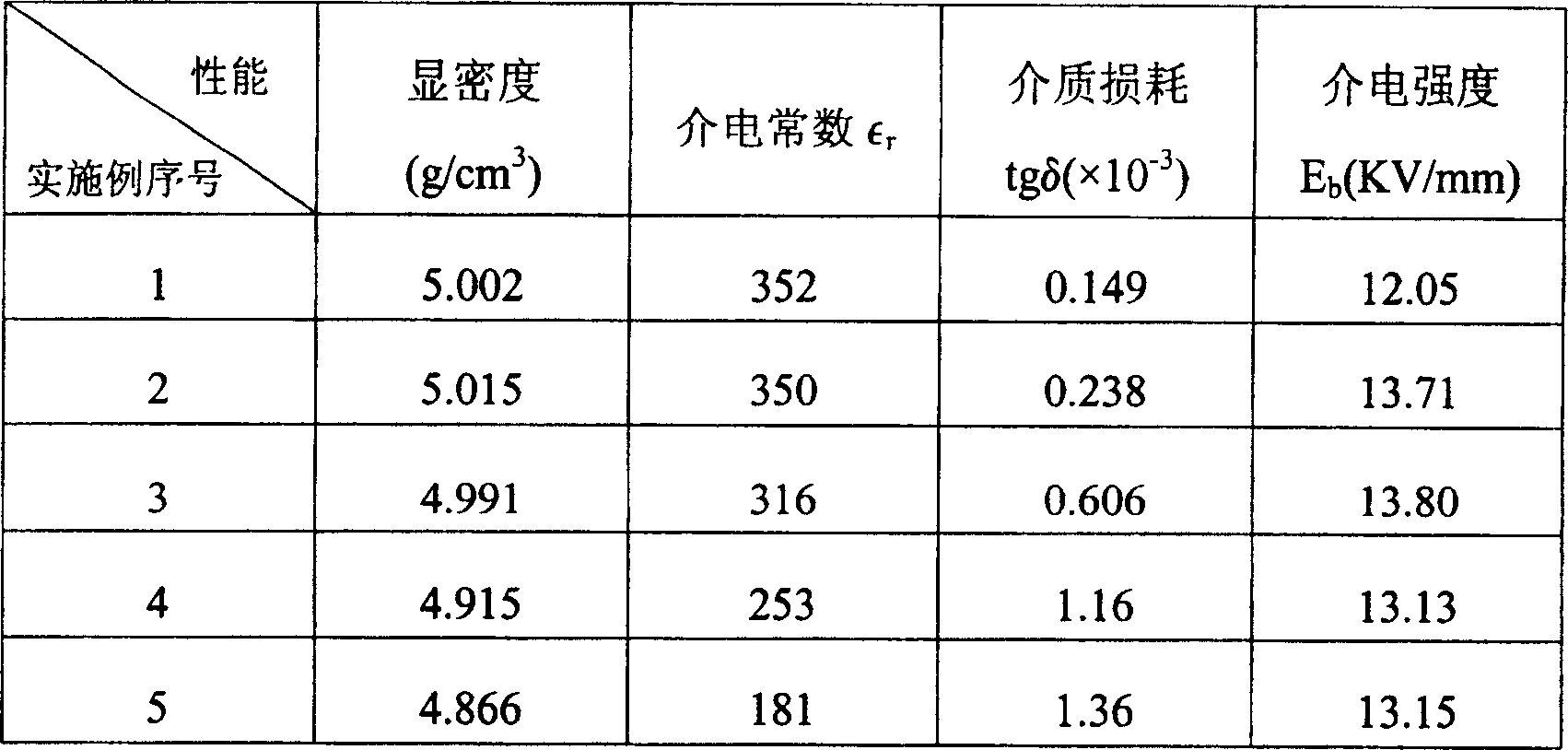

High-dielectric low-loss doped barium calcium titanate ceramic and preparation method thereof

PendingCN114853468AGood dielectric temperature stabilityLower sintering temperatureFixed capacitor dielectricBarium titanateHigh energy

The invention relates to a high-dielectric low-loss doped barium calcium titanate ceramic and a preparation method thereof, and belongs to the technical field of inorganic non-metallic materials. The lead-free, non-volatile and toxic element-free doped barium calcium titanate ceramic is prepared by adopting a traditional solid-phase reaction method, the chemical formula is Ba0. 70Ca0. 30Ti1-x (Nb0. 5Fe0. 5) xO3, x is the mole number of (Nb0. 5Fe0. 5) 4 < + > and is larger than or equal to 0.04 and smaller than or equal to 0.06, and the material is simple in preparation process, low in cost, low in sintering temperature (1230-1300 DEG C), larger than 4100 in room temperature relative dielectric constant and low in dielectric loss (tan delta lt below 1kHz); 0.037), the dielectric temperature stability is good (the change rate 1t of the relative dielectric constant along with the temperature in the range of room temperature to 200 DEG C; the preparation method is suitable for preparing a high-energy density memory and a high-capacity capacitor, and has a relatively high industrial application value.

Owner:HARBIN UNIV OF SCI & TECH

A kind of degradable low-temperature co-fired ceramics and its preparation method

ActiveCN108863324BHas hydrolytic propertiesChanges in hydrolytic propertiesRare-earth elementSilicic acid

The invention discloses a degradable low-temperature co-fired ceramic, which is a ceramic material mainly composed of borosilicate inorganic polymer molecular structure, and its composition chemical formula is xB 2 o 3 ·ySiO 2 · zAl 2 o 3 ·wMO, where MO is MgO, CaO, SrO, BaO, Na 2 O, Al 2 o 3 、K 2 At least one of O, ZnO or rare earth element oxides, x, y, z, w are mass percentages, 20wt%≤x≤65%, 15%≤y≤65%, 0%≤z≤30%, 0 %≤w≤30%. The preparation method of the ceramic is based on SiO 2 , SiO 2 ·nH 2 O, H 3 BO 3 , B 2 o 3 , NaOH, KOH, Ba(OH) 2 ·8H 2 O, Al(OH) 3 , MgO, CaO, SrO, ZnO and rare earth oxides as raw materials, through ball milling, drying, grinding, calcination, granulation, molding and sintering process steps. The degradable ceramic can not only be co-fired with electrode materials such as silver, copper and gold, but also can be co-fired with low-melting-point metal electrodes such as aluminum. Based on its unique borosilicate-rich inorganic polymeric structure as the hydrolysis trigger phase, through the control of the chemical composition of the ceramic and the design of the dispersion distribution of the hydrolysis trigger phase in the structure, the ceramic can degrade itself in humid conditions, water and salt solutions.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of composite phosphate microwave dielectric ceramic and its preparation method

The invention discloses a composite phosphate-based microwave dielectric ceramic, the chemical formula of which is Ca 4 (La 4 ‑xBi x PR 2 ) (SiO 4 ) 4 (PO 4 ) 2 o 2 (0.2≤x≤0.8)+ywt%Li 2 CO 3 (0.5≤y≤1.0)+zwt%C(0 <z≤1)。本发明还公开一种复合磷酸盐系微波介质陶瓷的制备方法,具体制备步骤如下:(1)将化学原料将化学原料将caco3. La 2 o 3 , SiO 2 、 Bi 2 o 3 、Pr 2 o 3 and NH 4 h 2 PO 4 stoichiometric Ca 4 (La 4 ‑xBi x PR 2 ) (SiO 4 ) 4 (PO 4 ) 2 o 2 (0.2≤x≤0.8) The stoichiometric composition weighs the ingredients into pre-ground ingredients; (2) puts the pre-ground ingredients into a ball mill tank for ball milling, and after ball milling, puts them in a drying oven to dry them into powder; (3) puts the powder (4) weigh the calcined powder and put it into a ball mill jar, add 0.5-1.0wt% Li 2 CO 3 , 0~1.0wt% C, zirconia balls and deionized water, ball milling and drying to obtain drying powder; add binder to the drying powder to granulate, and press into embryo body; (5) embryo body Carry out middle temperature sintering into microwave dielectric ceramics; (6) test the microwave dielectric properties of microwave dielectric ceramics.

Owner:福建溥昱电子科技有限公司

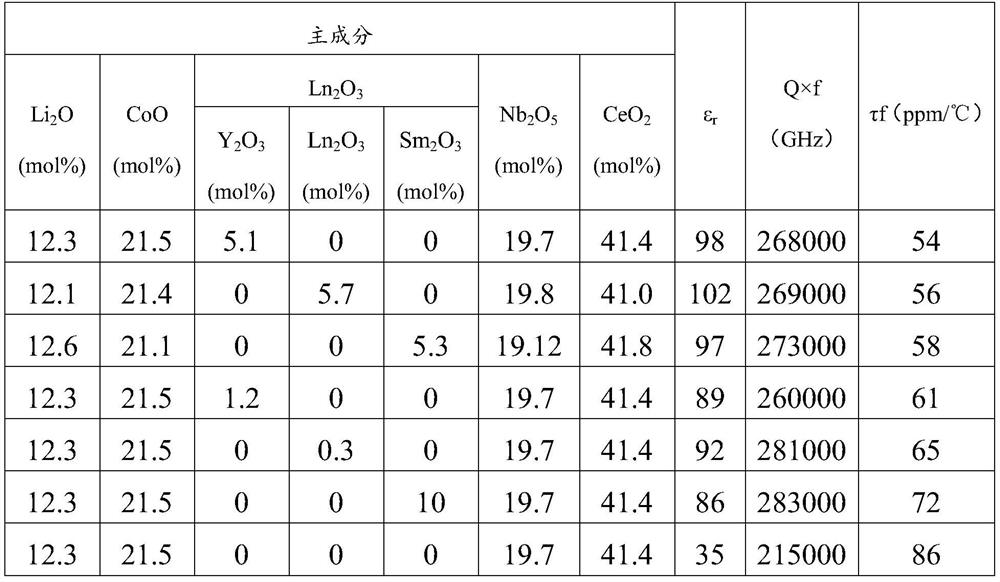

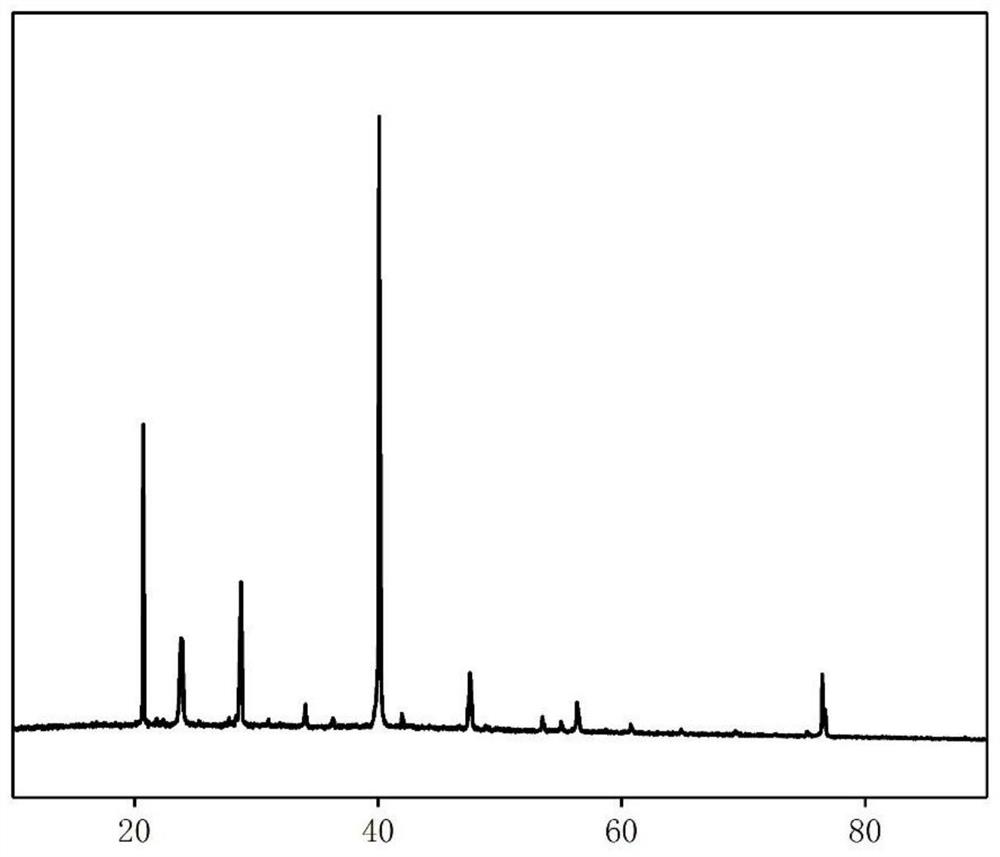

High-dielectric microwave dielectric ceramic and preparation method thereof

InactiveCN112759394AExcellent microwave dielectric propertiesLow priceRare-earth elementChemical composition

The invention discloses a high-dielectric microwave dielectric ceramic and a preparation method thereof, the chemical composition expression of the ceramic is aLi2O.bCoO.cLn2O3.dNb2O5.eCeO2 (I), and Ln is equal to Y, La or Sm. The microwave dielectric ceramic contains oxides of rare earth elements Y, La or Sm and has good microwave dielectric properties, and the microwave dielectric ceramic obtained by sintering the two oxides of the rare earth elements, Nb2O5 and CeO2 together has good microwave dielectric properties.

Owner:苏州研资工业技术有限公司

A kind of high-entropy ceramics with high hardness and high conductivity and its preparation method and application

Owner:DONGHUA UNIV +2

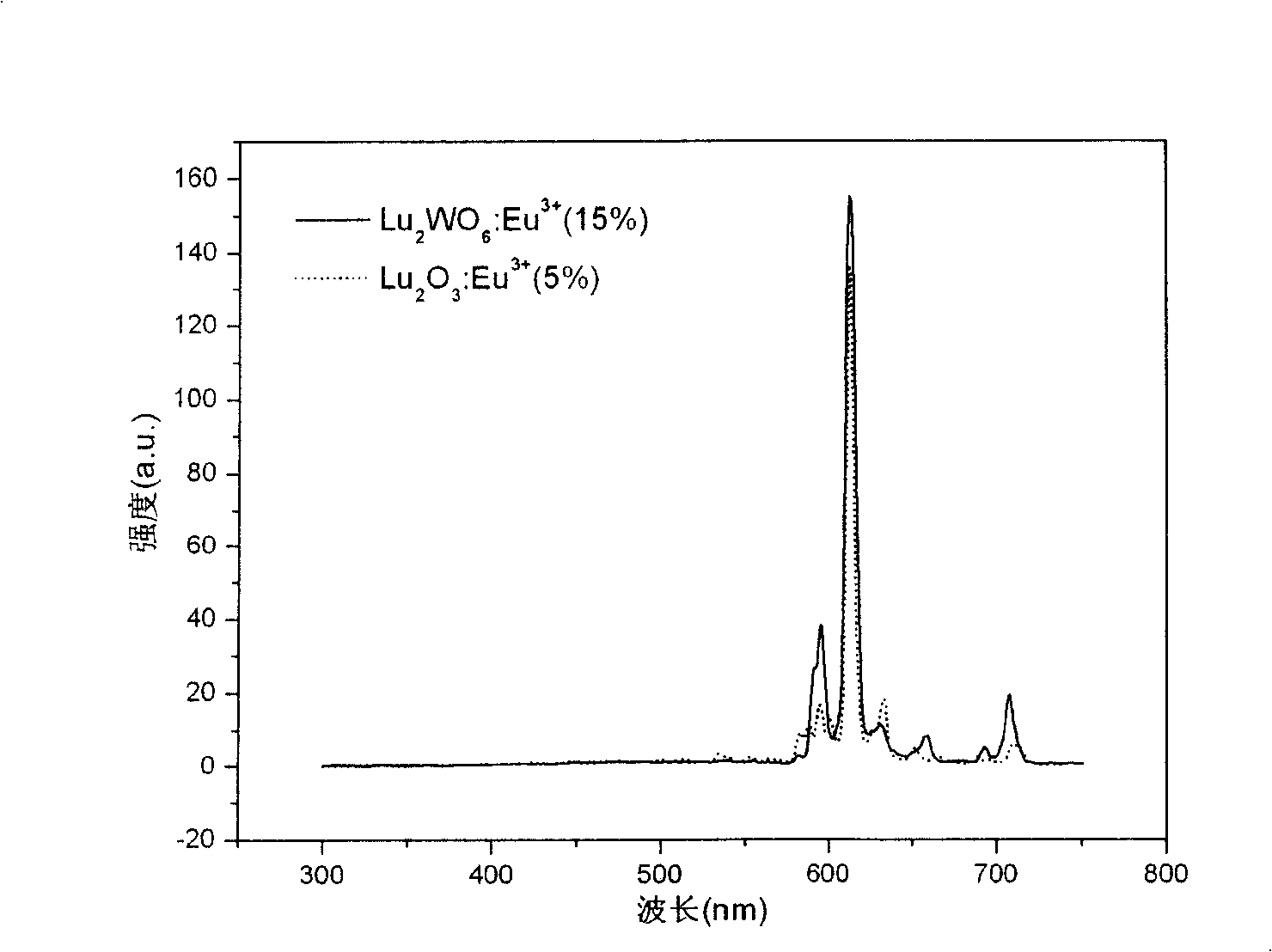

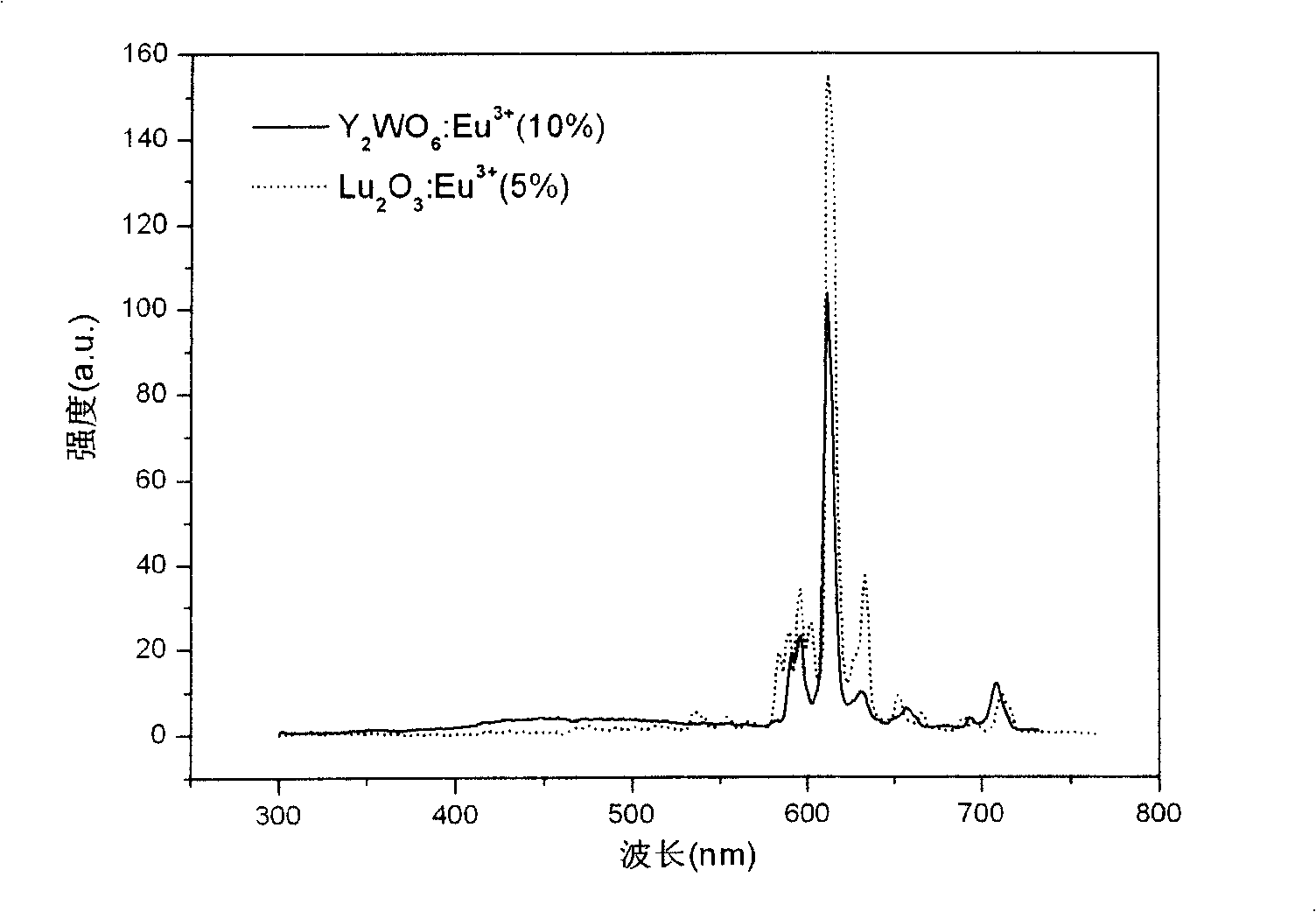

X-ray excited rare-earth ion blended tungstate flash luminous material and its preparing method

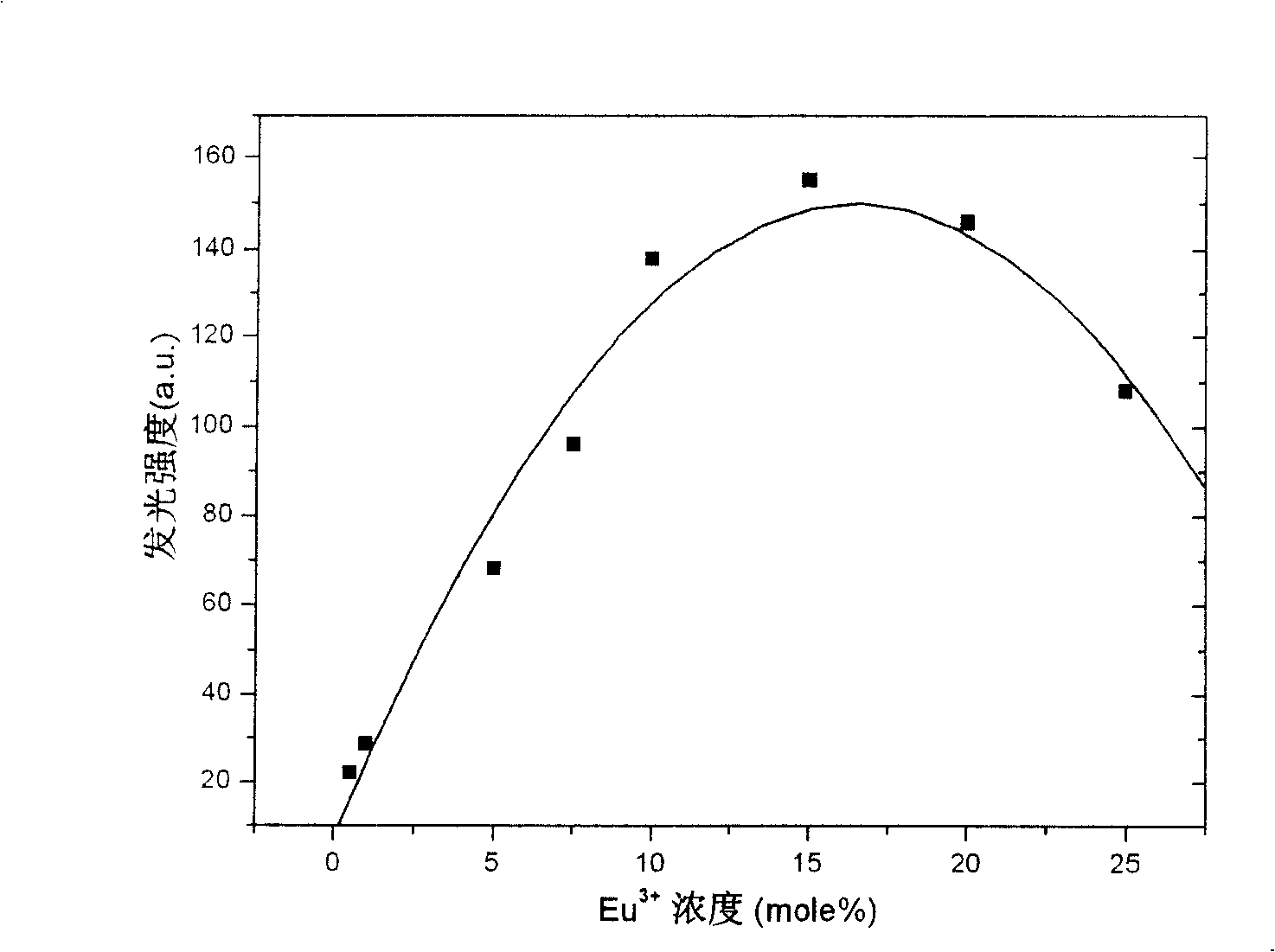

InactiveCN100412157CHigh luminous intensityPromote absorptionLuminescent compositionsHigh energyTungstate

The present invention relates to flashing luminescent material technology, and is especially flashing luminescent material with relatively high light output under the excitation of X-ray or other high energy ray and slow attenuation and its preparation process. The flashing luminescent material is trivalent RE ion activated RE tungstate in the chemical composition of RE2(1-x)Eu2xWO6, where, RE is at least one of Y, La, Gd and Lu, x is the content of activator Eu3+, and 0.05 C09K 11 / 78 2 5 2 2006 / 6 / 9 1858150 2006 / 11 / 8 100412157 2008 / 8 / 20 2008 / 8 / 20 2008 / 8 / 20 Shanghai Inst. of Ceramic Chemistry and Technology, CAS Shanghai 200050 Zhang Zhijun Zhao Jingtai Duan Chengjun Yuan Junlin Wang Xiaojun Chen Haohong Yang Xinxin pan zhen 31002 Shanghai Patent Agency of the Chinese Academy of Sciences No.319 Yueyang Road, Shanghai 200031

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Microwave dielectric ceramic and preparation method thereof

InactiveCN112759382AExcellent microwave dielectric propertiesImprove qualityRare-earth elementChemical composition

The invention discloses a microwave dielectric ceramic and a preparation method thereof, the chemical composition expression of the ceramic is aCaO.bSrO.cLn2O3.dNb2O5.eTiO2 (I), and Ln is equal to Y, Nd or Sm. The microwave dielectric ceramic contains rare earth element oxides of Y, Nd or Sm, and has good microwave dielectric properties, and the microwave dielectric ceramic obtained by sintering the two rare earth element oxides, Nb2O5 and TiO2 and performing combined action has good microwave dielectric properties.

Owner:苏州研资工业技术有限公司

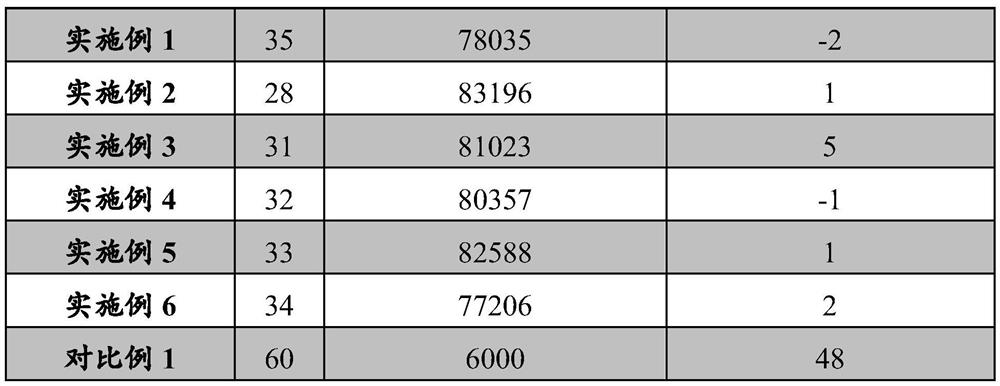

Method for promoting cold sintering of potassium-sodium niobate-based leadless piezoelectric ceramics

The invention discloses a method for promoting cold sintering of potassium-sodium niobate-based leadless piezoelectric ceramics through heat treatment of powder in a reducing atmosphere. The method comprises the following steps: firstly preparing potassium-sodium niobate powder, then carrying out heat treatment in a reducing atmosphere to improve the wettability of the powder and promote cold sintering, then adding deionized water into the potassium-sodium niobate powder, performing grinding, carrying out molding at a set temperature and uniaxial pressure, and then carrying out drying and sintering to obtain the KNN ceramic with excellent performance. The method is simple in process step and easy to operate, the wettability of the powder surface is improved, the problem that a liquid phase is not uniformly distributed on the surfaces of KNN particles in a conventional cold sintering process is solved, the surfaces of the KNN particles are wrapped with a potassium-rich phase more completely, volatilization of K and Na elements is effectively inhibited, deviation of a stoichiometric ratio of the KNN ceramic is reduced, and the performance of the potassium-sodium niobate-based ceramics is improved.

Owner:FUZHOU UNIV

Pressure proof strontium titanate base energy storage medium ceramic and its preparation method

ActiveCN1330606CHigh dielectric constantHigh breakdown strengthStrontium titanateChemical composition

Owner:WUHAN UNIV OF TECH

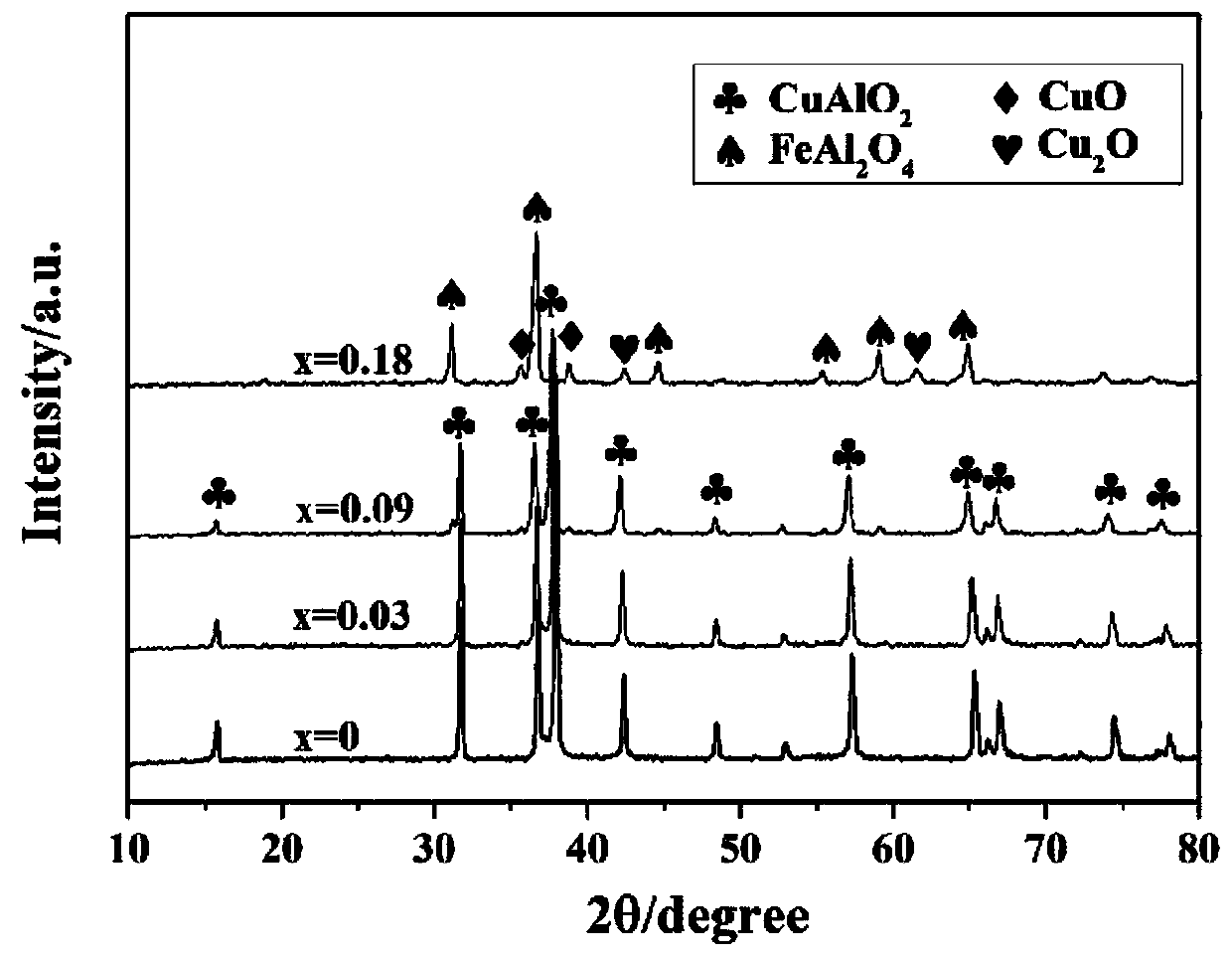

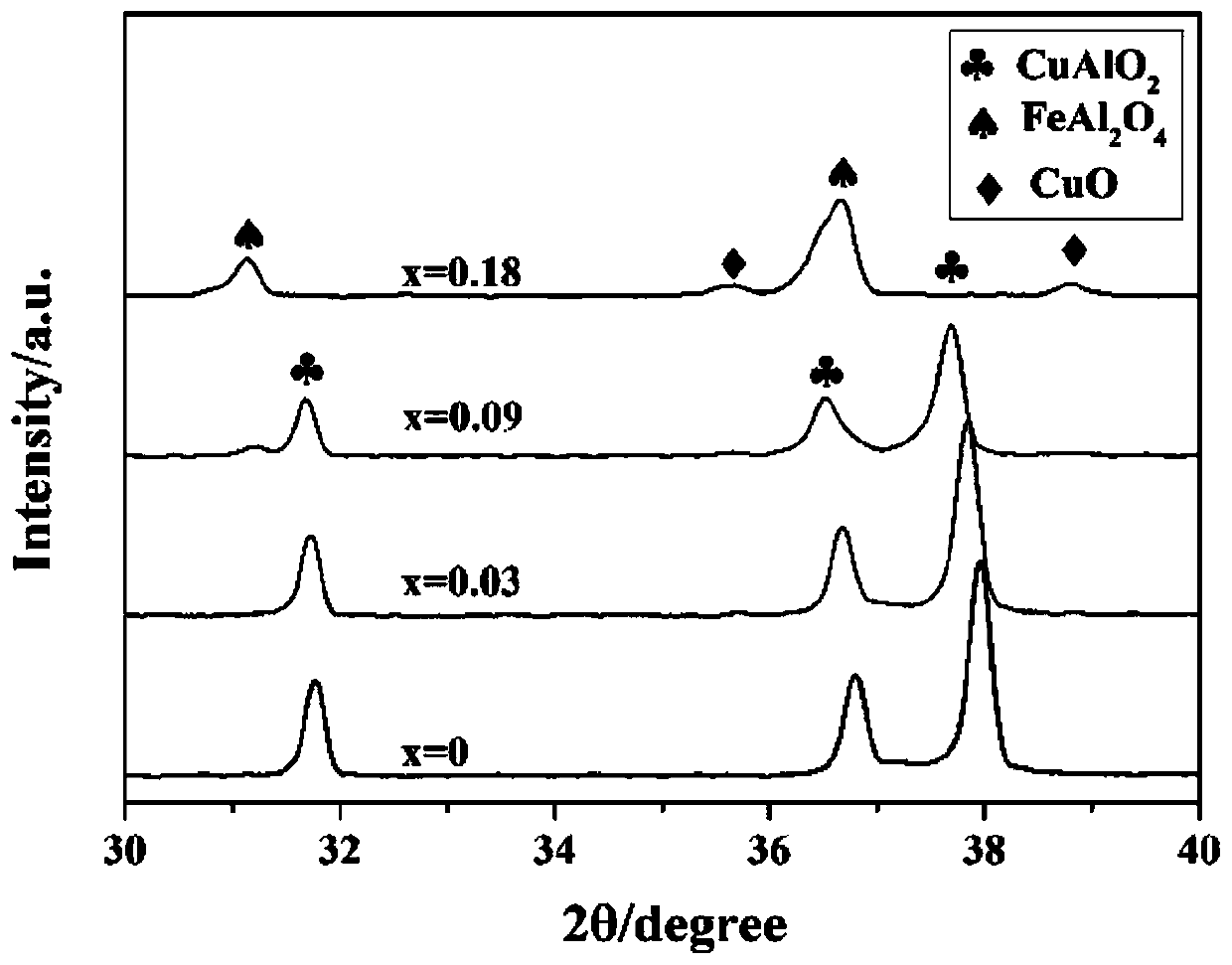

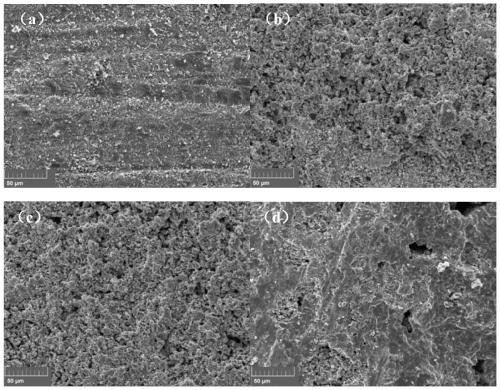

Fe-doped CuAlO2 high-temperature wave-absorbing ceramic and preparation method thereof

The invention discloses Fe-doped CuAlO2 high-temperature wave-absorbing ceramic and a preparation method thereof, and belongs to the technical field of wave-absorbing material preparation. According to the preparation method, Fe is used for doping CuAlO2 to change the conductivity and electromagnetic parameters of CuAlO2 and to generate CuAl<1-x>Fe<x>O2 powder with x smaller than or equal to 0.2,and firing is further performed to form the ceramic. By adopting a Cu source substance, an Al source substance and a Fe source substance as reactants, a ball-milling grinding process and a pre-sintering sintering glue discharging process are matched, and finally the Fe-doped CuAlO2 high-temperature wave-absorbing ceramic is prepared. The preparation method is good in process stability, wide in rawmaterial application range and low in cost, and can be popularized to macro production of the material. The Fe-doped CuAlO2 high-temperature wave-absorbing ceramic prepared by the preparation methodhas a chemical formula of CuAl<1-x>Fe<x>O2, wherein x is smaller than or equal to 0.2, and due to introduction of Fe, the CuAl<1-x>Fe<x>O2 ceramic has relatively large dielectric loss, magnetic property and high-temperature resistance, so that the finally prepared Fe-doped CuAlO2 high-temperature wave-absorbing ceramic has high temperature resistance and excellent wave-absorbing property, and canbe widely applied to high-tech industries such as space flight and aviation.

Owner:SHAANXI UNIV OF SCI & TECH

Polycrystalline YAG ceramic chemical mechanical polishing solution

ActiveCN113480942AModerate chemistryImprove removal efficiencyPolishing compositions with abrasivesMaterial removalCeramic chemistry

The invention discloses a polycrystalline YAG (yttrium aluminum garnet) ceramic chemical mechanical polishing solution, and belongs to the technical field of precision / ultra-precision machining. The pH value of the polycrystalline YAG ceramic chemical mechanical polishing solution is 7, and the polycrystalline YAG ceramic chemical mechanical polishing solution comprises a solute and a solvent, wherein the solvent is deionized water. The polishing solution comprises the following components in percentage by mass: 10-30wt% of silica sol, 1-5wt% of aluminum oxide abrasive particles, 0.1-0.5 wt% of an abrasive particle dispersing agent and a proper amount of a pH (Potential of Hydrogen) regulator according to the total mass fraction of 100%, and all the substances are uniformly mixed in deionized water through ultrasonic waves. By adopting the polishing solution, the ultra-smooth polishing of the polycrystalline YAG ceramic can be realized, the grain boundary height difference of the polished polycrystalline YAG crystal surface is obviously reduced, and the ultra-smooth and damage-free polycrystalline YAG crystal surface can be obtained; the grain boundary height difference can be effectively inhibited, and the purpose of super-smooth surface is achieved; and in addition, by adopting the polishing solution provided by the invention, the material removal efficiency is high, and compared with a polishing solution only containing silica sol or aluminum oxide, the removal efficiency is obviously improved.

Owner:DALIAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com