Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "High Q*f value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

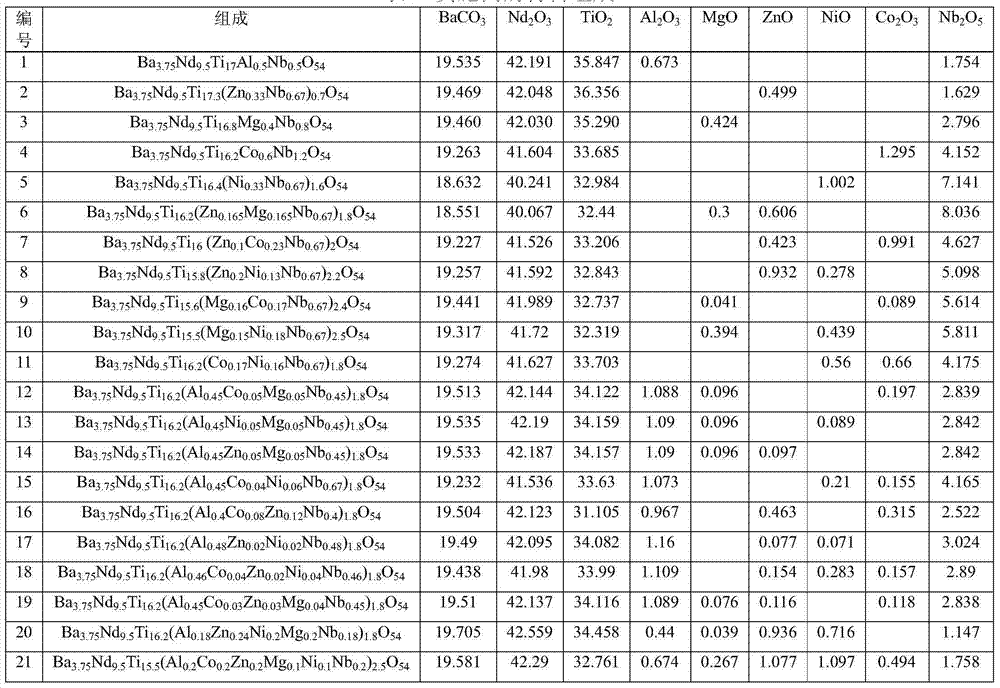

Low temperature sintered composite microwave medium ceramic in series of lithium, niobium and titanium, and prepartion method

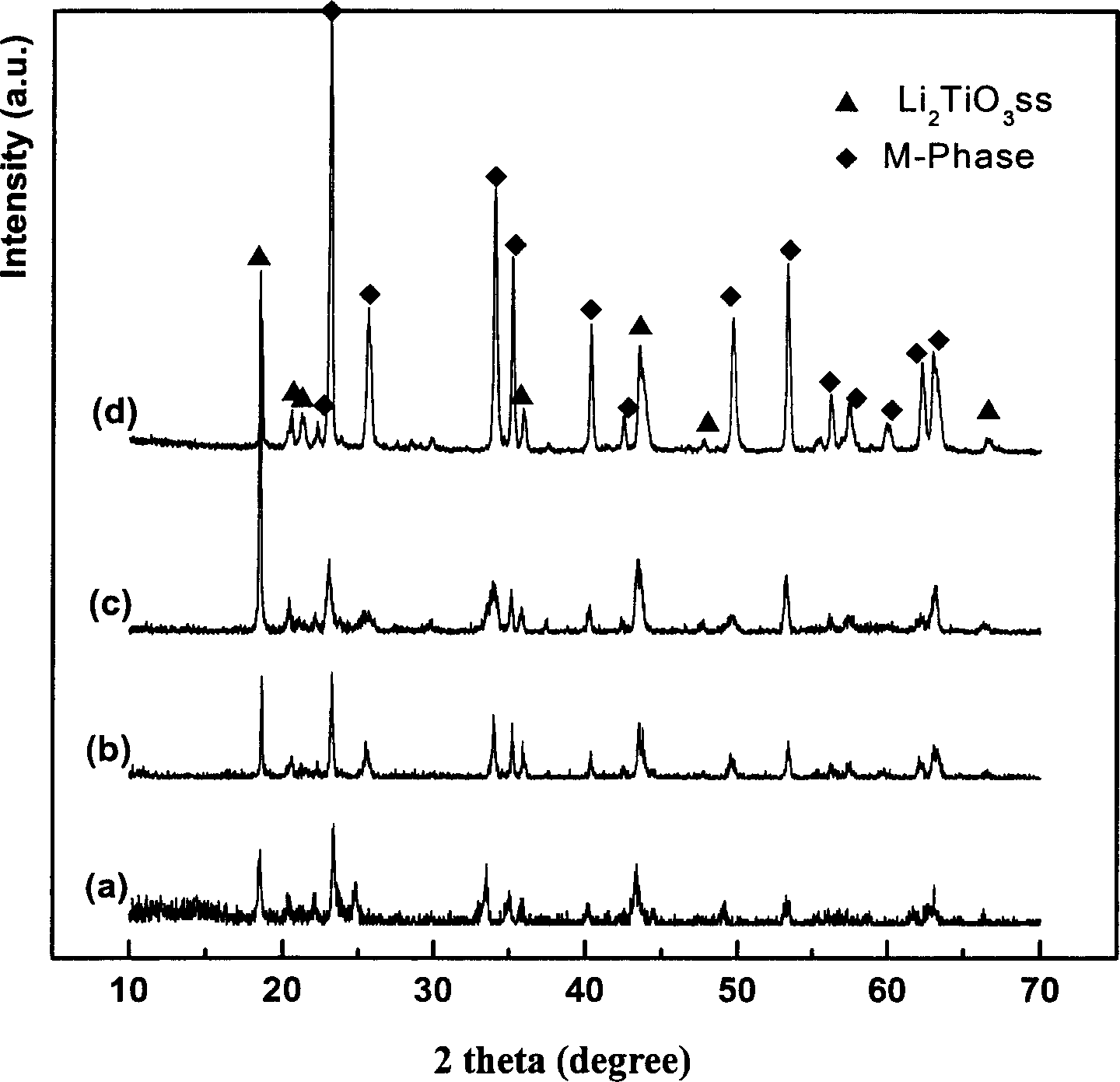

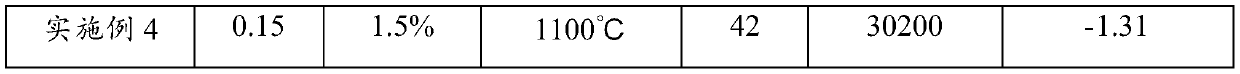

This invention relates to a method for preparing low-temperature-sintered lithium-niobium-titanate composite microwave dielectric ceramic, which is composed of Li2TiO3 solid solution and M-phase solid solution. The composite microwave dielectric ceramic is prepared from Li2CO3, Nb2O5 and TiO2 at a mol ratio of 5: x: y (x is in 1-2 and y in 4-6), and B2O3 or V2O5 0-5 wt. % by conventional solid-phase reaction. The composite microwave dielectric ceramic has a low sintering temperature (about 1100 deg.C), good dielectric property with a dielectric constant of 34-50, a high Q*f value (Q is quality factor), and a low resonance frequency temperature coefficient, and can be used in sheet dielectric resonator, filter, antenna, balun, etc. when added with a small quantity of low-melting-point oxide, the composite microwave dielectric ceramic has a lower sintering temperature of about 900 deg.C, while its good microwave dielectric property can be maintained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A-B site simultaneously substituting microwave dielectric ceramic material and preparation method thereof

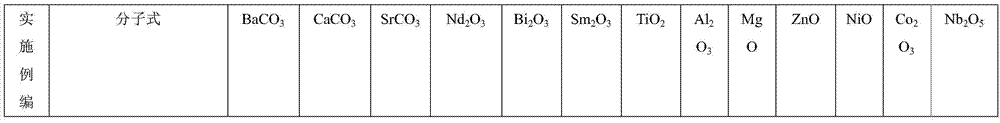

The invention provides an A-B site simultaneously substituting microwave dielectric ceramic material and a preparation method thereof. The general chemical formula of the material is (Ba1-aAa)6-3x(Nd1-bBb)8+2x(Ti1-cCc)18O54, C=MN, wherein x=3 / 4, a is greater than or equal to 0.05 and smaller than or equal to 0.2, b is greater than or equal to 0.05 and smaller than or equal to 0.15, c is greater than or equal to 0.02 and smaller than or equal to 0.08, A represents divalent Ca and Sr elements substituting A1 sites, B represents trivalent Sm and Bi elements substituting A2 sites, M represents Nb with the valence state higher than tetravalency, N represents other one or more elements with a valence state lower than tetravalency and an ionic radius similar to Ti, and M and N substitute simultaneously or individually. The preparation method includes: determining the respective mass percentage content according to the general chemical formula, conducting ball mill mixing, performing presintering under 1000-1150DEG C, and then conducting sintering at 1250-1450DEG C. The prepared material has adjustable dielectric constant and frequency-temperature coefficient and at the same time maintains a high Q*f value. The formula does not contain Pb, Cd and other volatile or heavy metals, the performance is greatly enhanced, the raw materials are in abundant supply, and the price is low, so that low cost of high performance microwave ceramics becomes possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

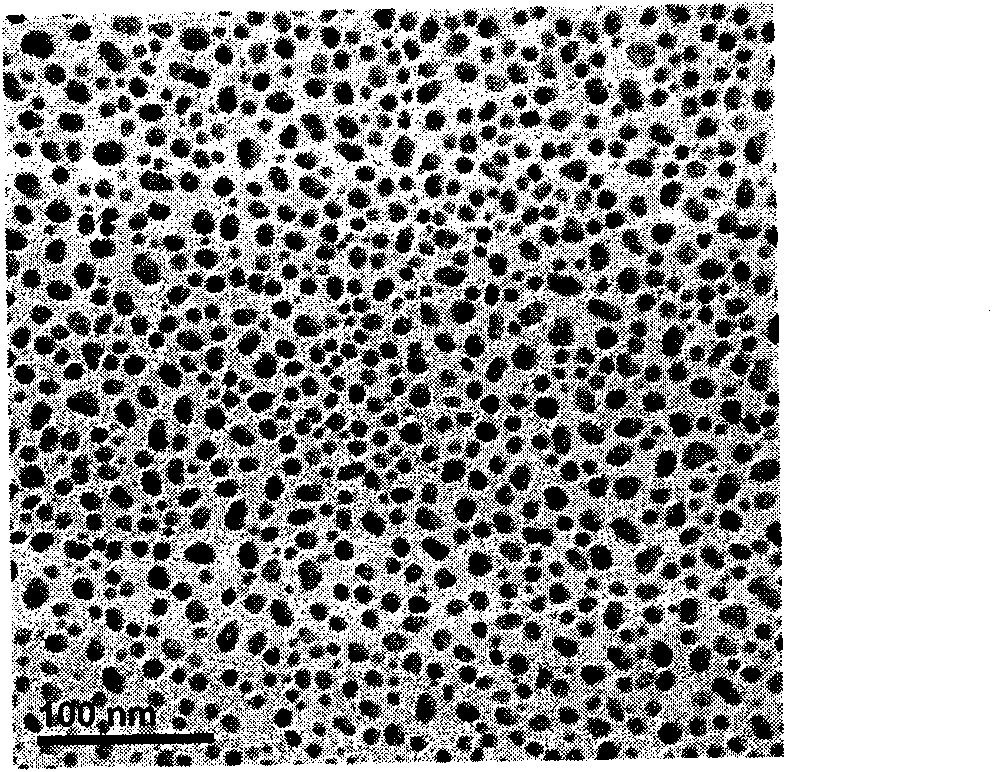

Low temperature synthesis of ultra-fine ZnO-SiO2 microwave dielectric ceramic powder by sol-gel method

The invention discloses a preparation method of sol-gel to synthesize the ultrafine microwave dielectric ceramic powder of ZnO-SiO2 in the low temperature, which comprises the steps that: the zinc salt and the tetraethyl orthosilicate are respectively dissolved in the anhydrous ethanol to form the ethanol solution of zinc salt and the ethanol solution of tetraethyl orthosilicate; the two solutions are stirred and mixed with the mole ratio of Zn to Si being 2 : 1, then proper anhydrous ethanol is added to control the density of the zinc salt in the mixed solution within a range of 0.5 to 1 mol / l; deionized water is added to promote hydrolytic polymerization; at least one of nitric acid and acrylic acid is added dropwise to adjust the pH value; proper dispersing agent is added to overcome the powder agglomeration; and the gel is obtained after even stirring, sealing and standing of the obtained solution, and then the obtained gel is dried and calcined to obtain the ultrafine microwave dielectric ceramic powder of ZnO-SiO2. The preparation method has the advantages that the ultrafine powder with an adjustable particle size of 80 to 200 nm can be calcined and synthesized under the low temperature condition of 800 to 850 DEG C; and the powder has good microwave property after sintering.

Owner:ZHEJIANG UNIV

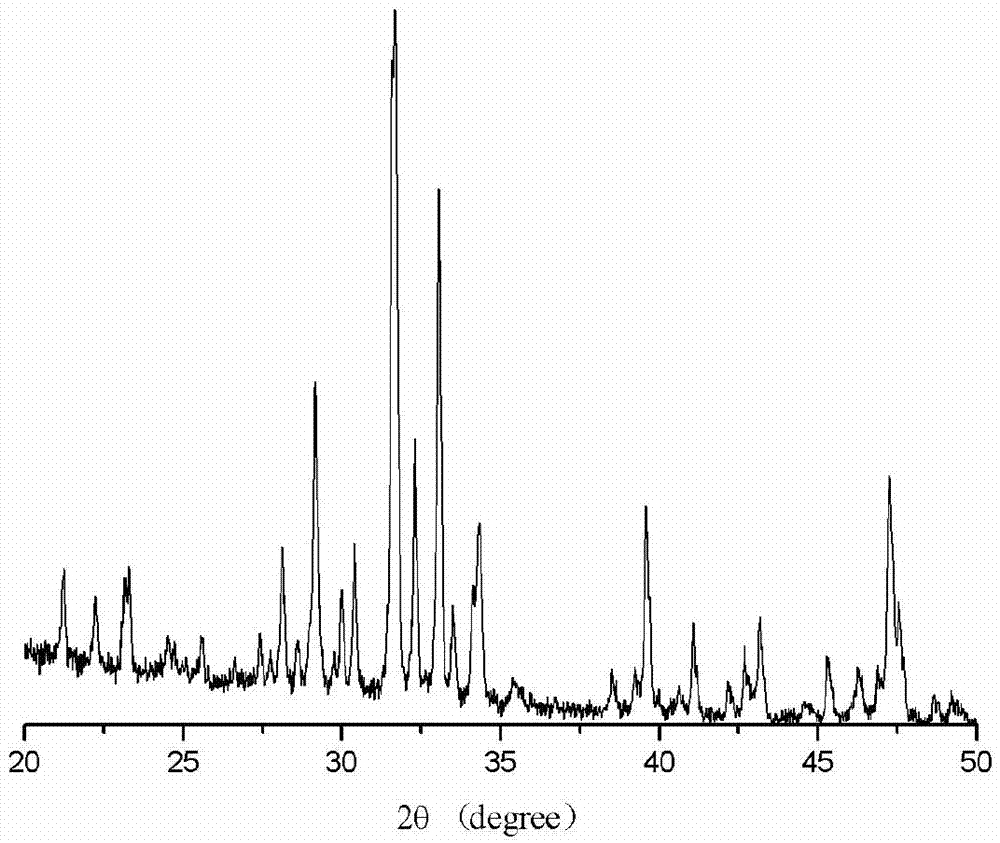

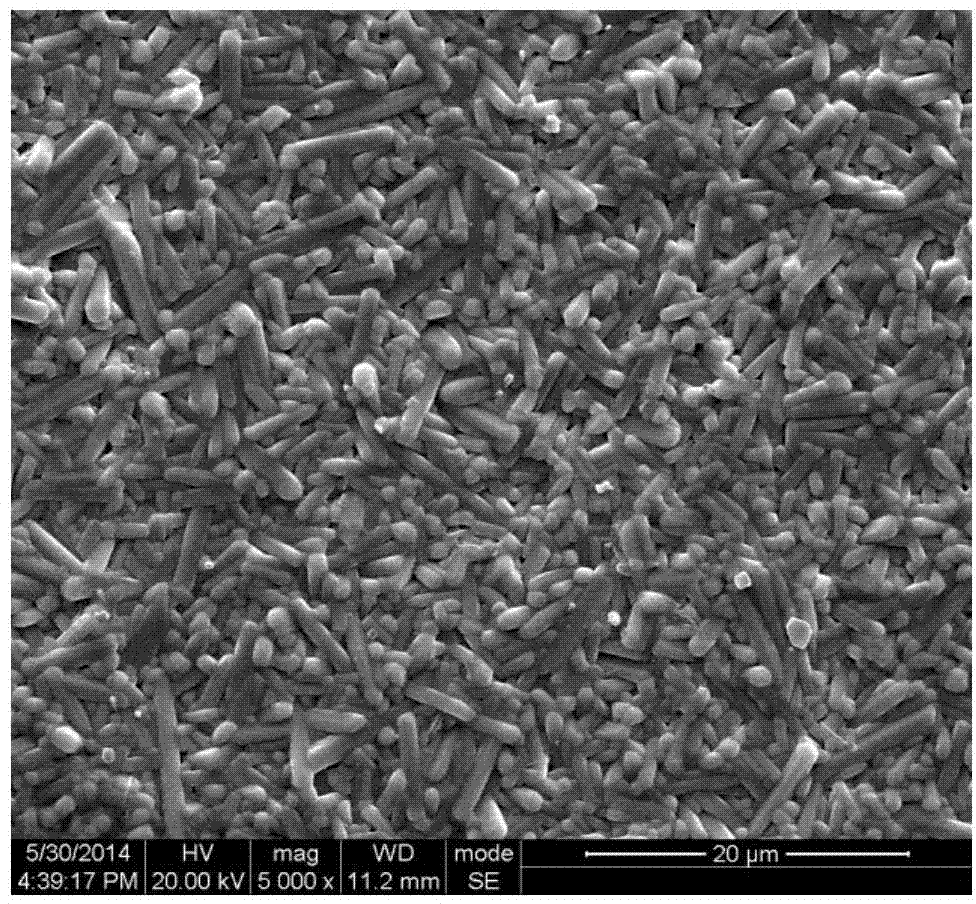

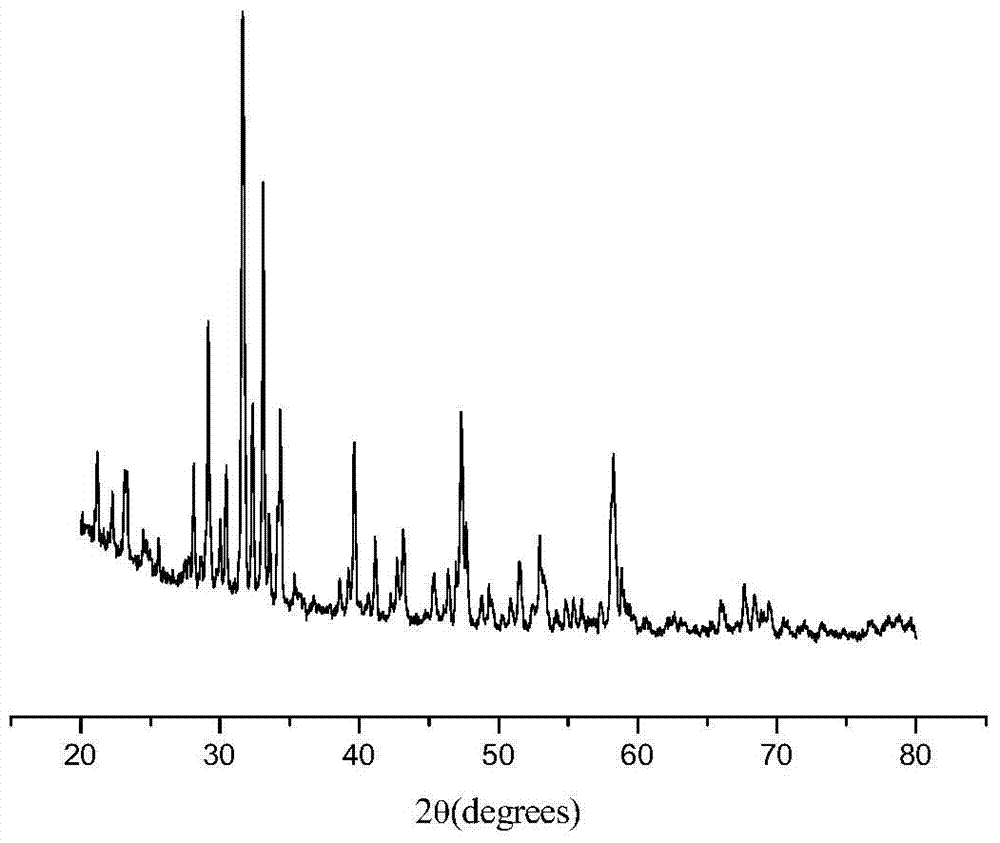

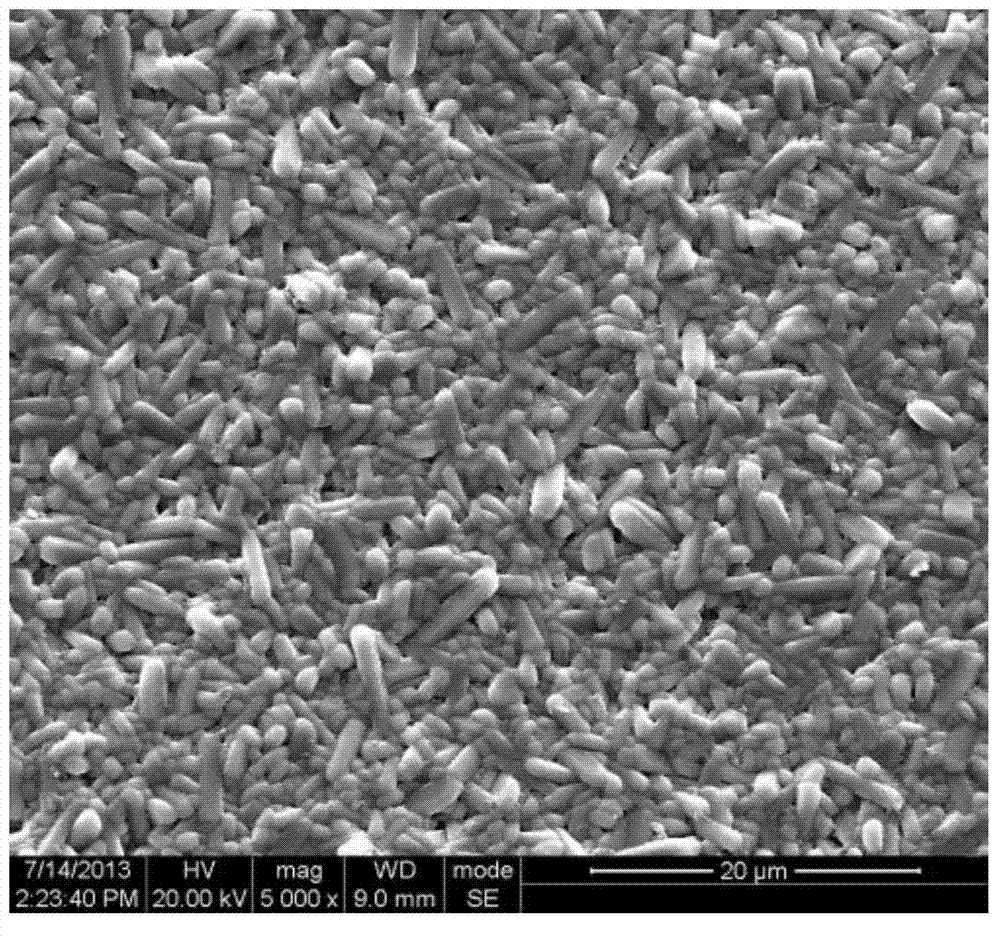

B-substituted BNT microwave dielectric ceramic material and preparation method

A B-substituted BNT microwave dielectric ceramic material and its preparation method belong to the technical field of a functional material. The general chemical formula of the microwave dielectric ceramic material is Ba3.75Nd9.5Ti18-y(M,N)yO54, wherein y is less than or equal to 2.5 and greater than or equal to 0.6; the microwave dielectric ceramic material is prepared by steps of: burdening BaO, Nd2O3, TiO2, oxides of metallic elements M and N according to mole ratio of the general chemical formula, carrying out ball-milling, presintering and sintering; an oxide of the element M is Nb2O5; and an oxide of the element N is one or more compounds selected from Al2O3, MgO, ZnO, Co2O3 and NiO. According to the invention, simultaneous substitution of high and low valence elements is carried out in the B position of Ba6-3xNd8+2xTi18O54. The microwave dielectric ceramic material prepared by a one-step synthesis process has high dielectric constant, low loss characteristic and low frequency-temperature coefficient, can meet requirements in the microwave communication industry, and is especially suitable for manufacturing of RFID tags.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

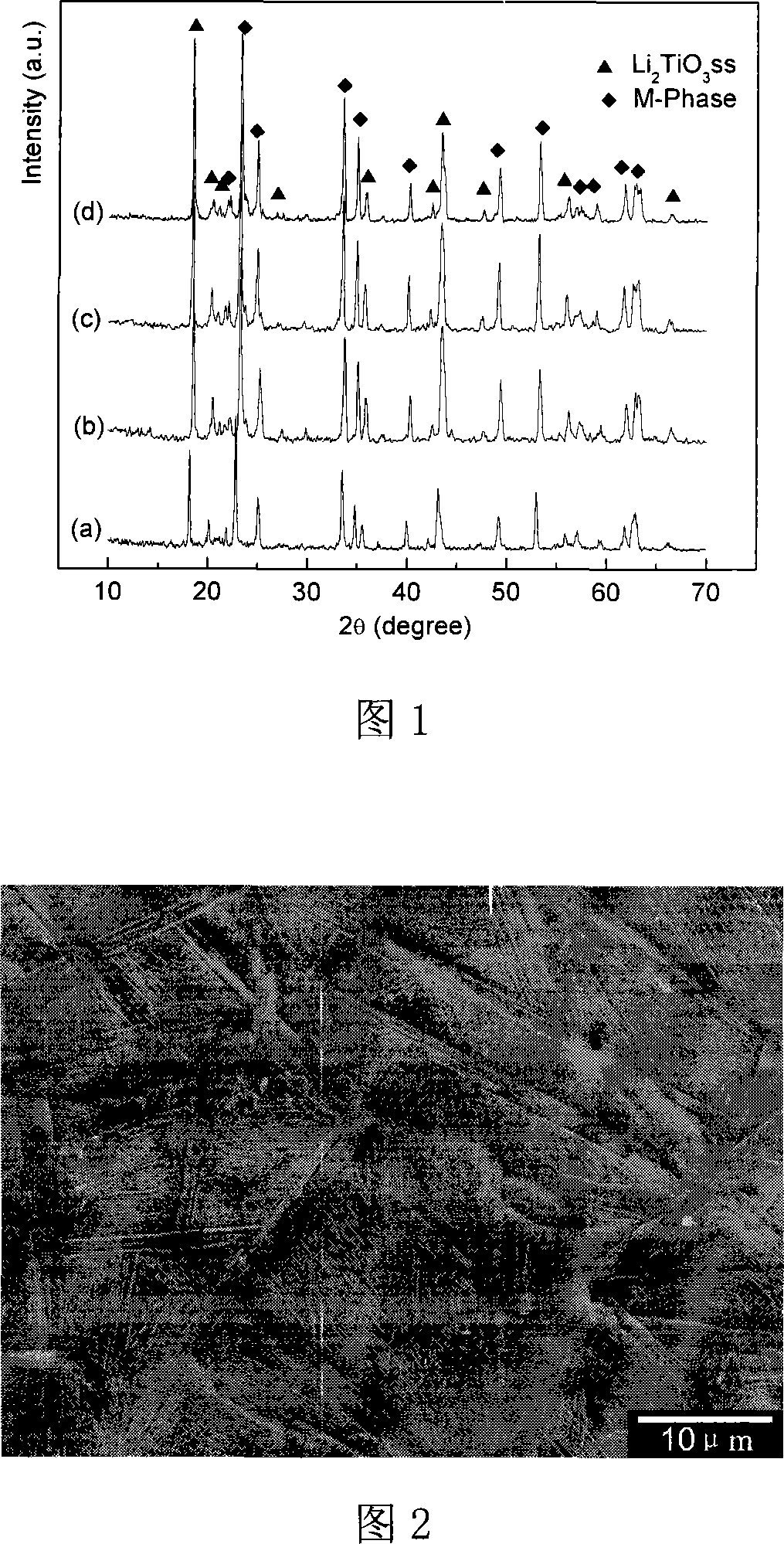

Composite microwave medium ceramic material

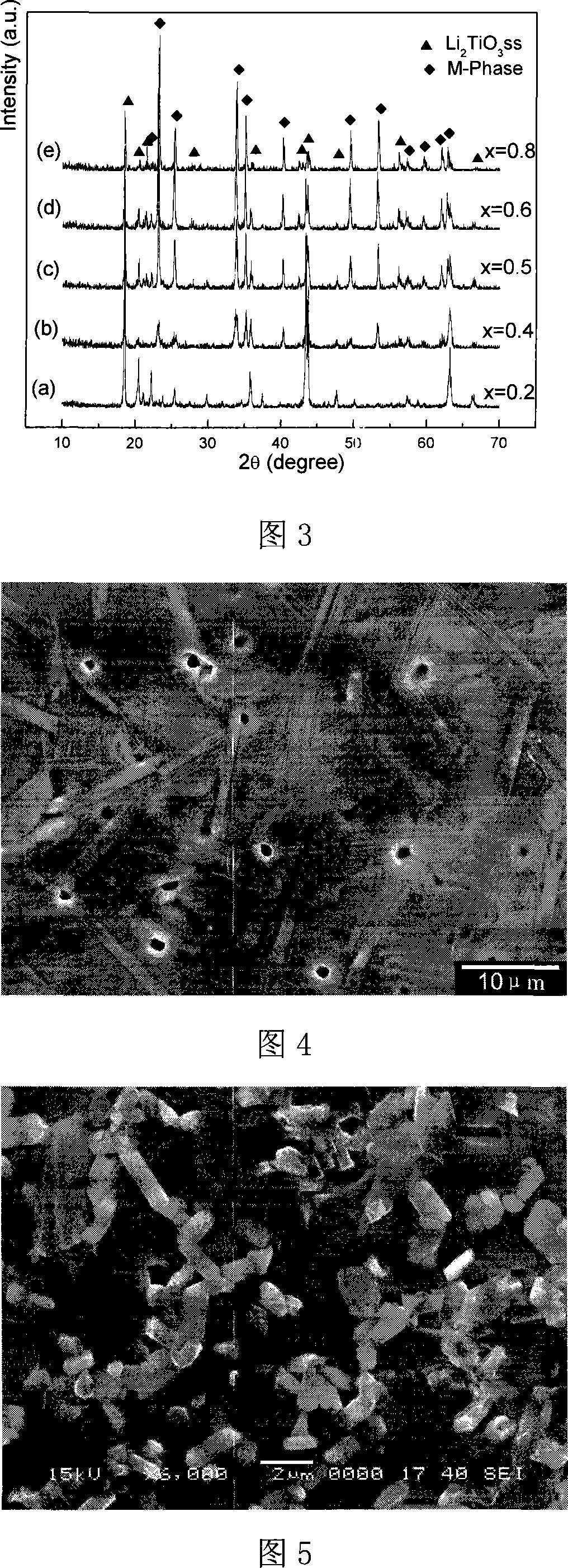

This invention relates to a composite microwave medium ceramic material-Li2O-Nb2O5-TiO2 series material. It is composed of Li2TiO3 sosoloid (Li2TiO3ss phase) and M-phase sosoloid. The compositions are: xLi1+a-bNb1-a-3bTia+4bO3+(1-x)Li2+dNb3dTi1-4dO3, wherein: 0<x<1,0.05<a<0.2, 0<b<0.18,0<d<0.2; this inventive material is obtained by traditional preparation method. This inventive product has lower sintering temperature (1100deg.C), excellent microwave medium properties, adjustable dielectric constant (epsilon r=18-70), low resonant frequency temperature coefficient.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-dielectric low-loss microwave dielectric ceramic material and preparation method thereof

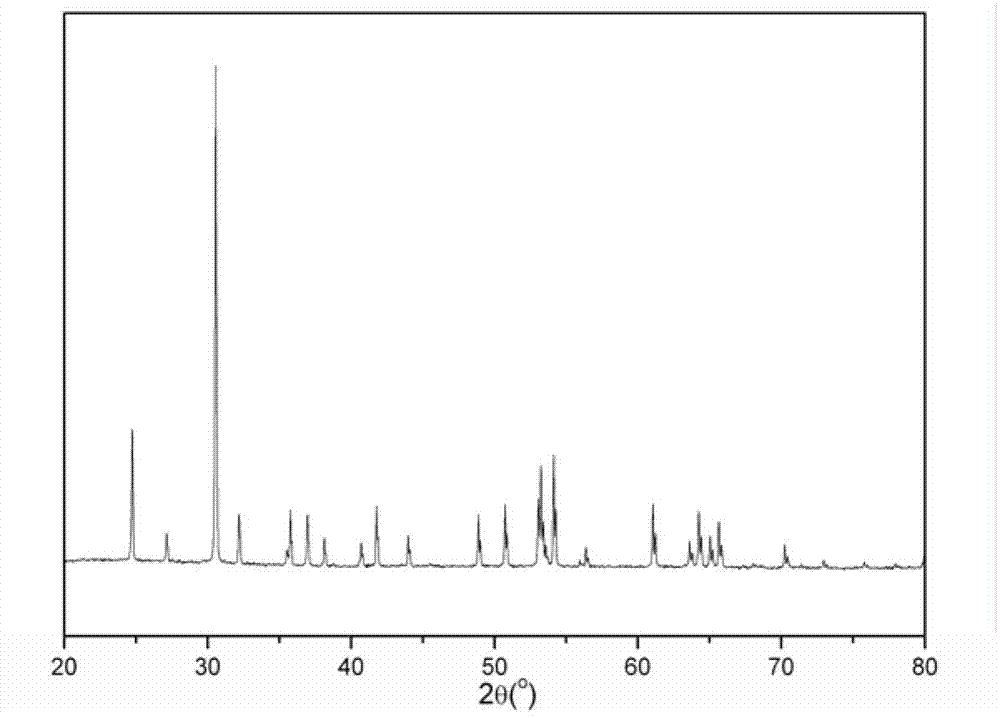

The invention provides a high-dielectric low-loss microwave dielectric ceramic material. The general chemical formula of the material is (Na0.5+yLn0.5)(Ti1-xCx)O3, Ln=La or Nd or Sm, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.04, y is larger than or equal to 0.05 or is smaller than or equal to 0.12, the composition of C is VW, V represents Nb with the valence state higher than four, W represents a single ion or compound ions with the valence state lower than or equal to four and the average ion radius approximating to Ti4+, and V and M achieve simultaneous replacement or independent replacement. The invention further provides a preparation method of the high-dielectric low-loss microwave dielectric ceramic material. The preparation method comprises the steps of burdening, ball grinding, drying and sieving, presintering, pelleting, compression molding and sintering. The prepared material has the high dielectric constant and high Q*f value, contains no Pb or Cd or other volatile toxic metals in the formula, and is stable in performance and capable of meeting application requirements of modern microwave devices, raw materials are sufficiently supplied in China, the cost is relatively low, and the high-performance microwave ceramic can be low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Microwave dielectric ceramic material and preparation method thereof

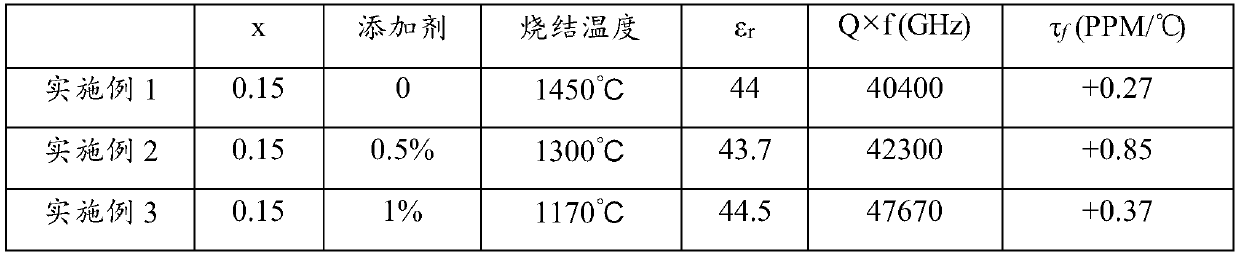

The invention provides a microwave dielectric ceramic material prepared by a composite oxide and an additive. The composite oxide is represented by the following general formula: MLa4Ti3M'O15, whereinM is Ca, Ba or Mg, and M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the invention is prepared by the compound oxide represented by a specificgeneral formula and the additive and is a medium-dielectric-constant microwave dielectric ceramic; the microwave dielectric ceramic material satisfies the dielectric constant near 45 and is continuously adjustable, has an extremely high Q*f value and good sintering stability, and also can achieve continuous adjustment of temperature drift to meet various needs. Experimental results show that therelative dielectric constant [epsilon]r of the microwave dielectric ceramic material provided by the invention is 43.2-46.8, the quality factor Q*f value is more than or equal to 46200 GHz, and the sintering is stable; at the same time, the temperature drift adjusting range is from -8 to +13 ppm / DEG C and can be continuously adjustable to meet various needs, and the microwave dielectric ceramic material has excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Zr-Ti-based microwave dielectric ceramic material and preparation method thereof

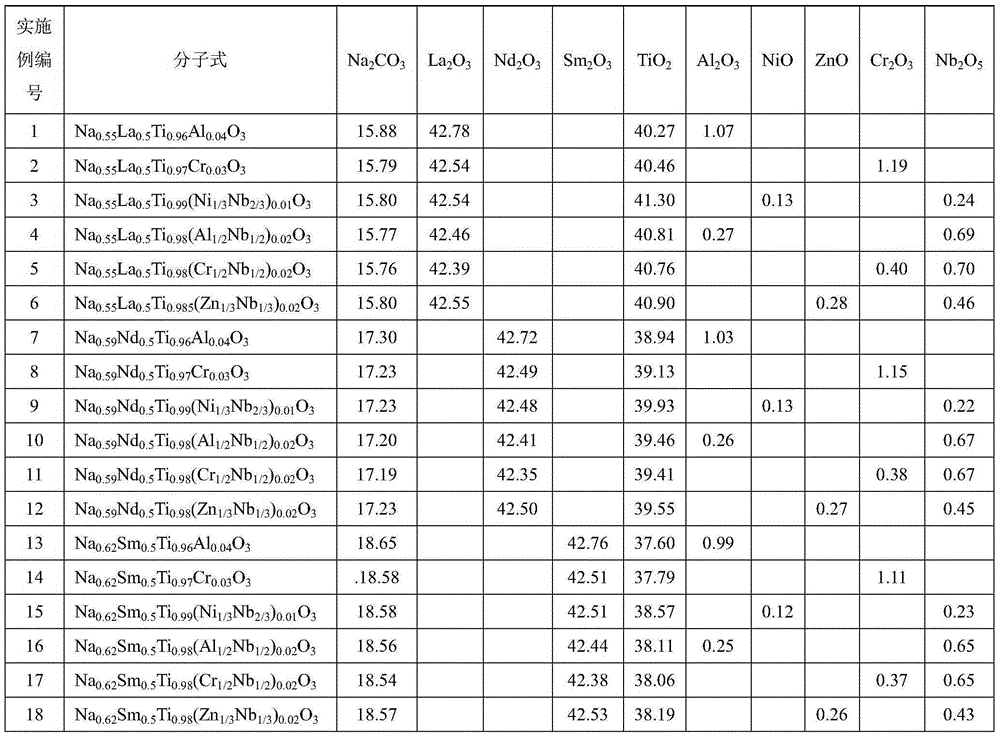

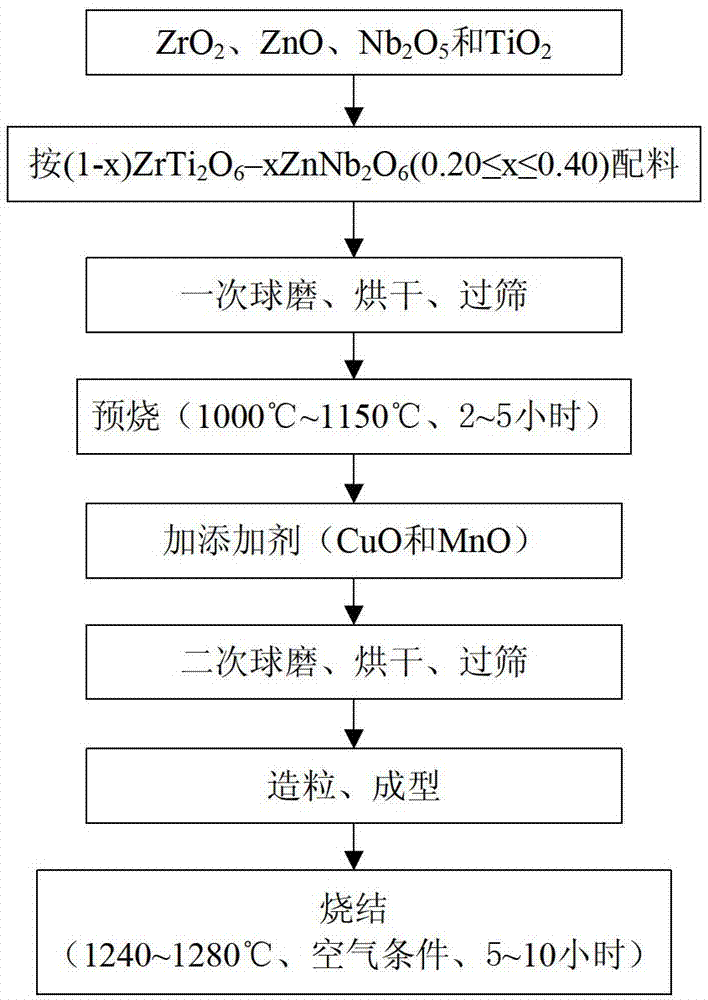

The invention discloses a Zr-Ti-based microwave dielectric ceramic material and a preparation method of the Zr-Ti-based microwave dielectric ceramic material, and belongs to the field of information functional materials and devices. The microwave dielectric ceramic material comprises a base material and an additive; the base material is represented by (1-x)ZrTi2O6-xZnNb2O6, wherein x is more thanor equal to 0.20 and is less than or equal to 0.40; the additive comprises CuO equaling to 0.50-2.50% of the weight of the base material and MnO equaling to 0.12-0.90% of the weight of the base material; the crystalline phase of the Zr-Ti-based microwave dielectric ceramic material comprises ZrTi2O6 phase and TiO2 phase; the dielectric constant epsilon r of the microwave dielectric ceramic material is between 41 and 53; the (Q*f) value of the microwave dielectric ceramic material is between 35,000GHz and 49,000GHz; and the frequency-temperature coefficient tau f of the microwave dielectric ceramic material is adjustable on the both sides of zero. The Zr-Ti-based microwave dielectric ceramic material is prepared by a normal process, is sintering in air, and has great popularization value and practical value. The Zr-Ti-based microwave dielectric ceramic material is suitable for production of microwave communication components, such as dielectric resonators, dielectric filters, dielectric substrates, dielectric antennae and the like, in the modern communication technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Niobate system low-temperature sintered microwave dielectric ceramic material and preparation method thereof

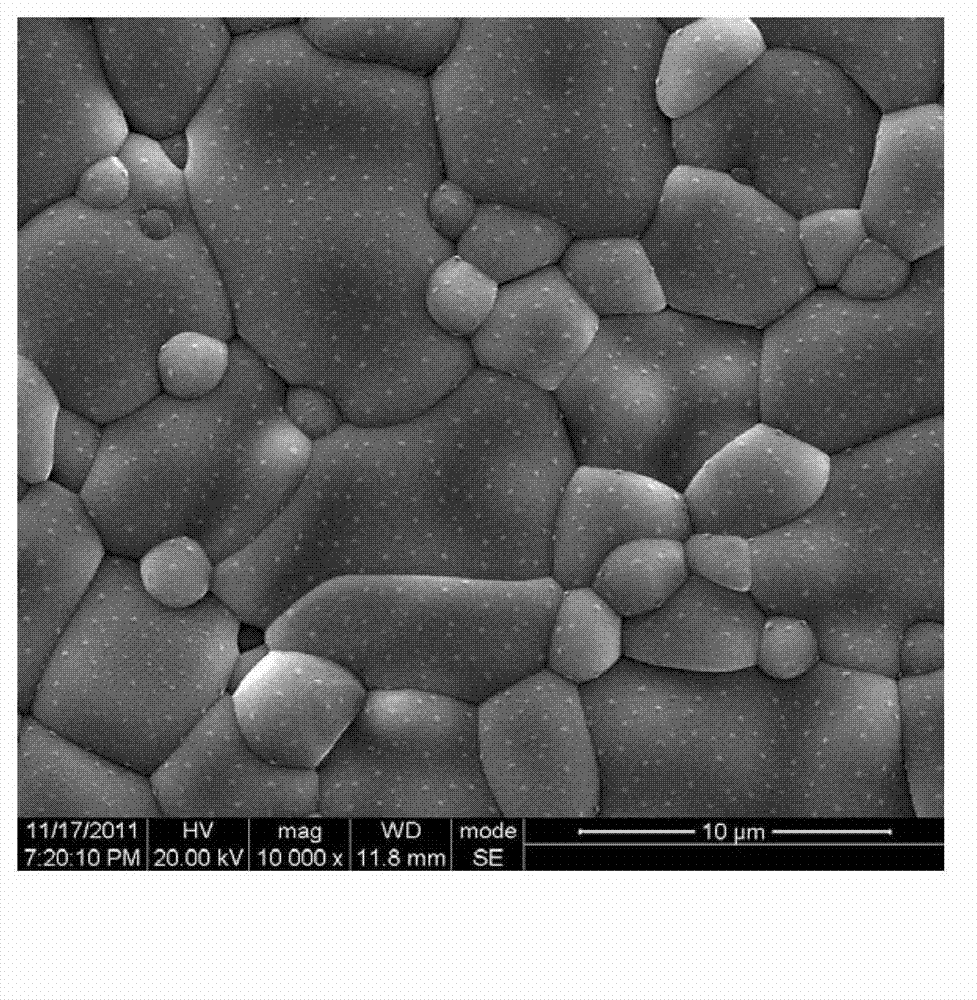

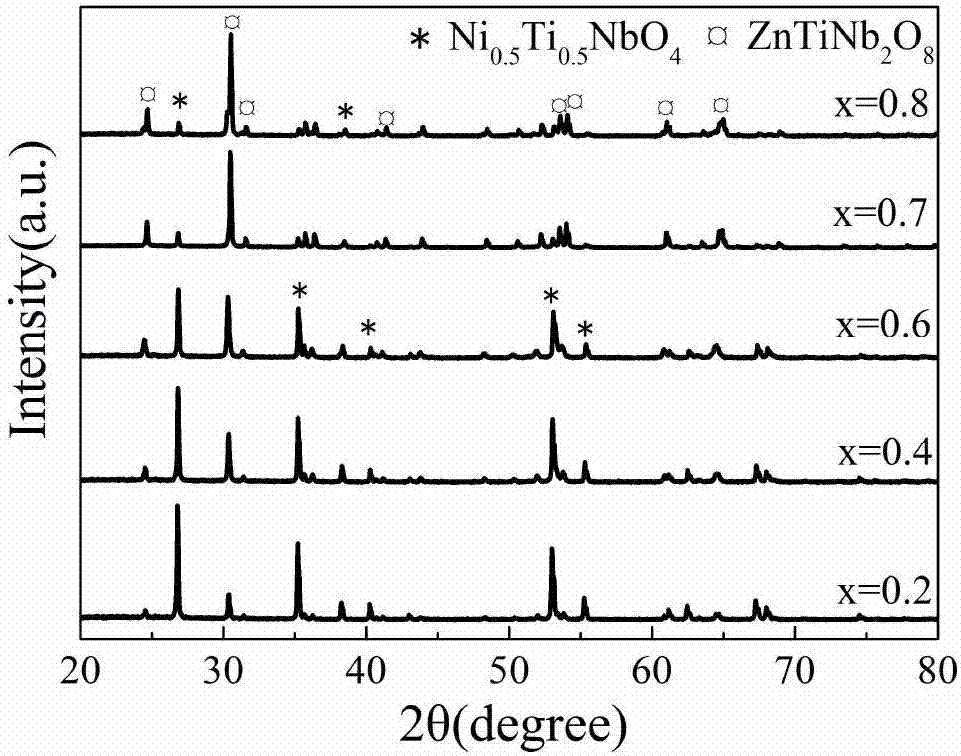

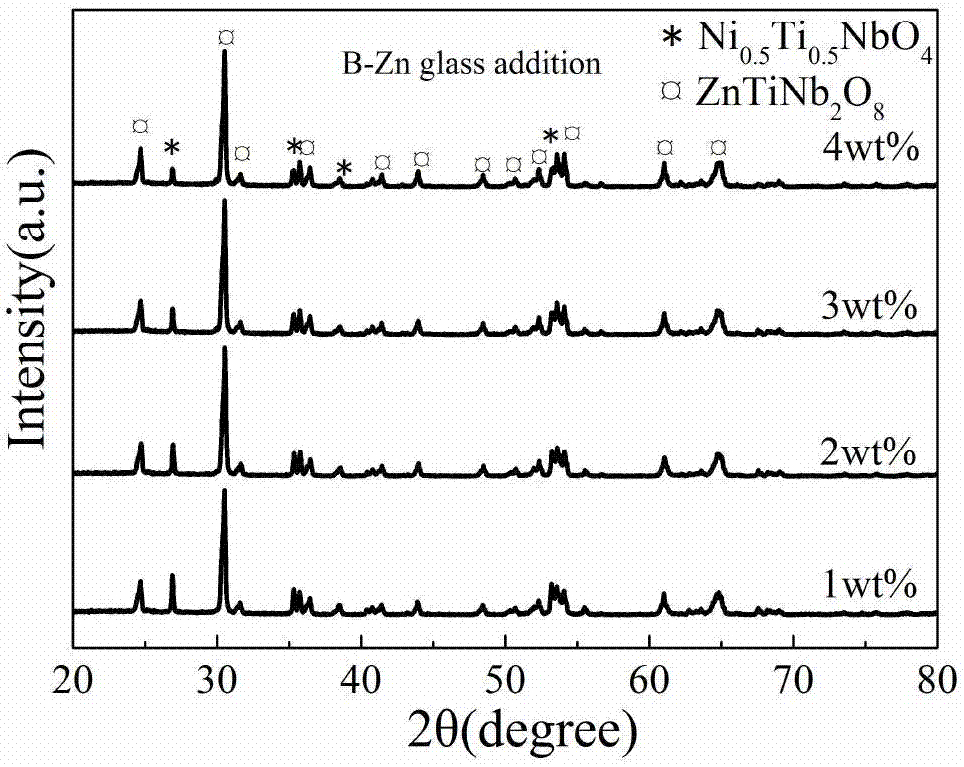

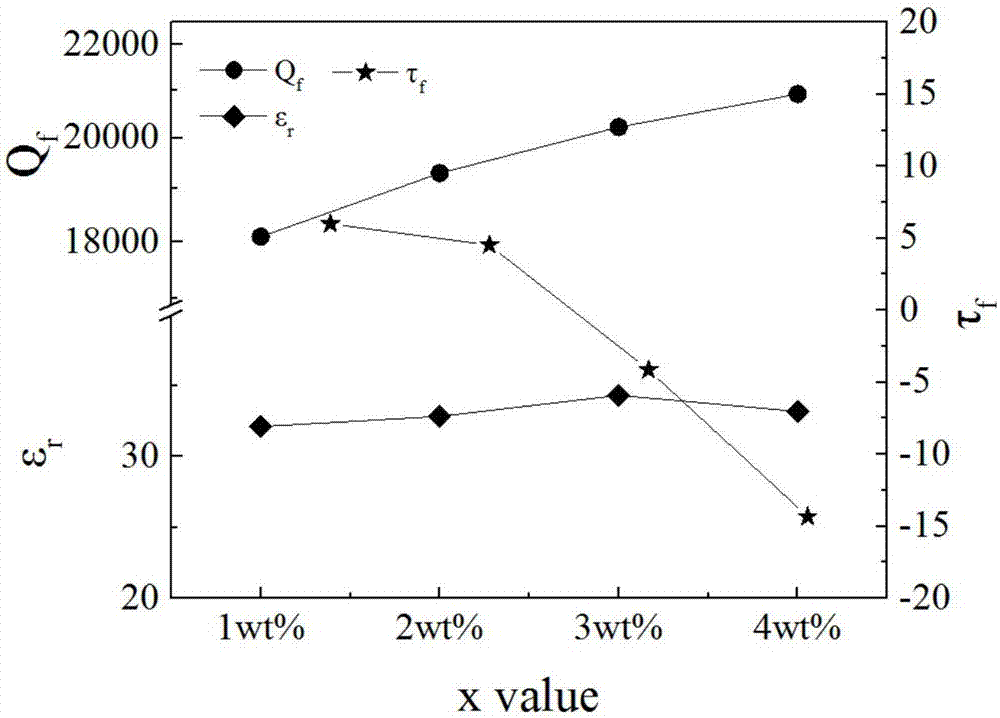

The invention discloses a niobate system low-temperature sintered microwave dielectric ceramic material and a preparation method thereof, and belongs to the field of microwave electronic ceramic materials and preparation thereof. The niobate system low-temperature sintered microwave dielectric ceramic material comprises a main crystal phase and zinc-boron glass accounting for 1-4% of the weight of the main crystal phase, and the main crystal phase is Ni1-xZnxTiNb2O8, wherein x is not less than 0.2 and not more than 0.8; and the zinc-boron glass (by standard material) comprises 50-70 mol% of ZnO and 30-50 mol% of HBO3. The ceramic material can be well sintered at 900-950 DEG C, the dielectric constant epsilon r is 32-35, the Q*f value is 13000-21000 GHz, the resonant frequency temperature coefficient tau f is -15 ~ +6 ppm / DEG C, and the ceramic material can be widely applied to LTCC laminated microwave devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Two phase compound microwave dielectric ceramic having medium dielectric constant, and preparation method thereof

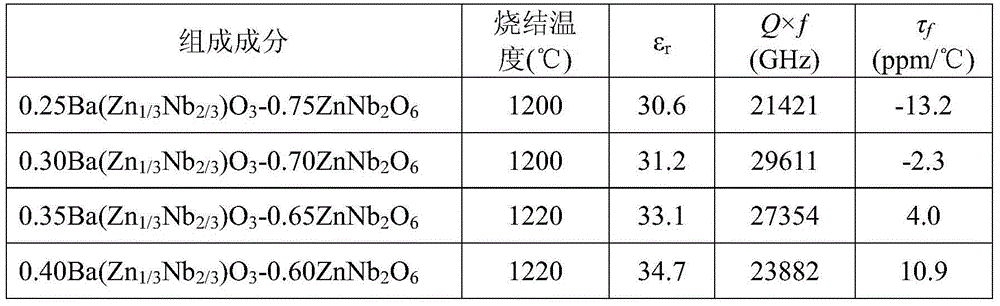

InactiveCN103553603AHigh Q×f valueThe resonant frequency temperature coefficient is close to zeroMicrowaveResonance

The invention relates to a two phase compound microwave dielectric ceramic having a medium dielectric constant, and a preparation method thereof. A molar ratio composition formula of the ceramic material is xBa(Zn1 / 3Nb2 / 3)O3+(1-x)ZnNb2O6, wherein 0.25 <= x <= 0.40 and x is a mole percent. The preparation method comprises the steps of pre-synthesizing ZnNb2O6 and Ba(Zn1 / 3Nb2 / 3)O3 by a solid phase reaction of ZnO, Nb2O5 and BaCO3; weighing according to a chemical general formula; mixing; milling for two times; drying; pressing powder into cylindrical bodies by isostatic pressing; sintering for 2 h and cooling. The invention provides a novel material having a medium dielectric constant, high Q*f value and nearly zero temperature coefficient of resonance frequency. A preparation process matching with the material is provided by the invention; the microwave dielectric ceramic with good quality is obtained; and selection scope of microwave dielectric application materials is broadened.

Owner:西安广芯电子科技有限公司

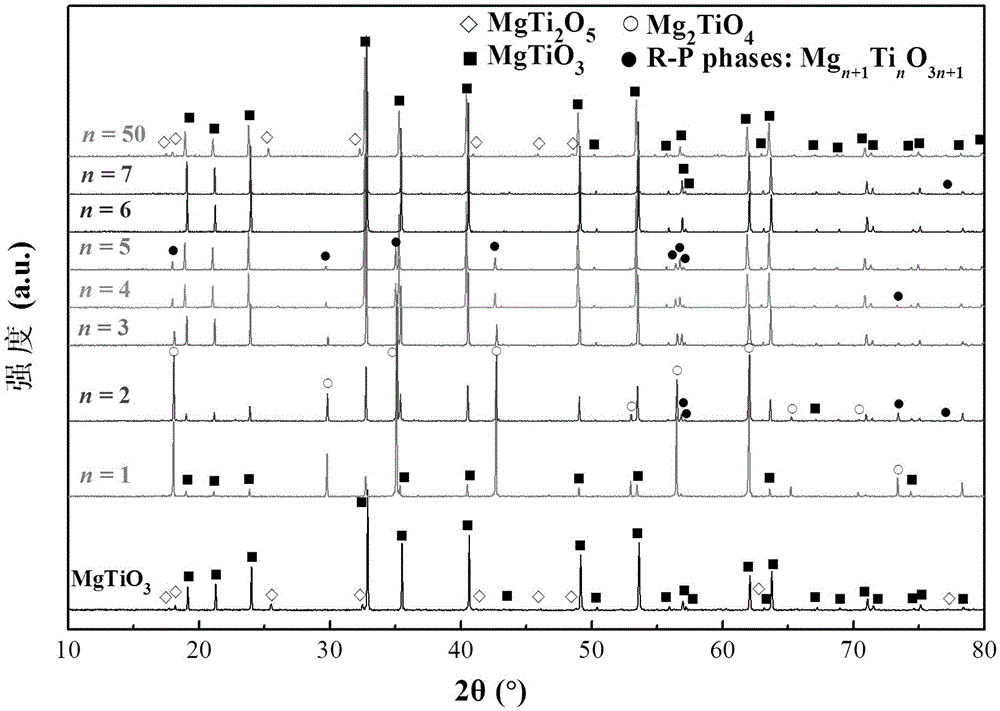

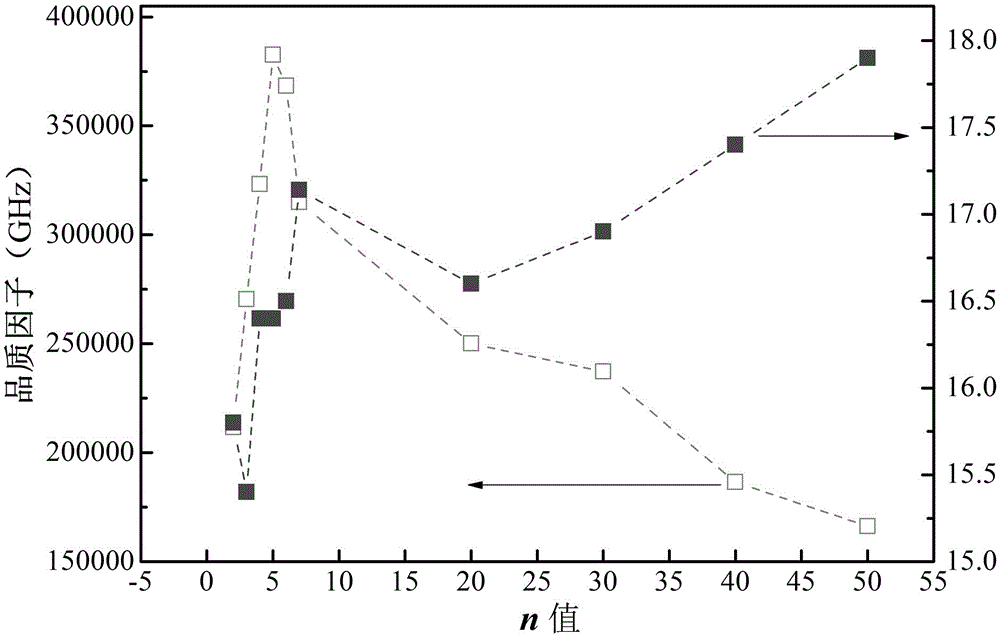

Ultralow loss limit type Mgn+1TinO3n+1 microwave ceramic and making method thereof

The invention discloses ultralow loss limit type Mgn+1TinO3n+1 microwave ceramic and a making method thereof. The chemical formula of the ceramic is: Mgn+1TinO3n+1, wherein n is equal to 2, 3, 4, 5, 6, 7, ... 50. According to the making method, Mgn+1TinO3n+1 powder is synthesized first, polyvinyl alcohol is added into the obtained powder, the mixture is mixed to be uniform and pressed into a cylindrical green body, the green body is sintered for 4 hours at the temperature of 1,340-1,380 DEG C to become ceramic, and then the ultralow loss limit type Mgn+1TinO3n+1 microwave ceramic can be obtained. Compared with MgTiO3 and Mg2TiO4 ceramic materials, the dielectric constant and temperature coefficient of resonance frequency of the Mgn+1TinO3n+1 series microwave ceramic do not change a lot, but the Q*f value is remarkably increased. The Mgn+1TinO3n+1 microwave ceramic (n=5) sintered for 4 hours at the temperature of 1,360 DEG C can obtain optimal microwave dielectric performance: Q*f is up to 382, 500 GHz (f0=7.534 GHz), epsilon r is up to 16.4, and tau f is up to -55.3 ppm / DEG C. It is predicated that the Mg6Ti5O16 ceramic material can be applied to a microwave circuit of large communication equipment in the high frequency field to serve as a main material of a dielectric substrate.

Owner:GUILIN UNIV OF ELECTRONIC TECH

High-permittivity microwave dielectric ceramic material and preparation method thereof

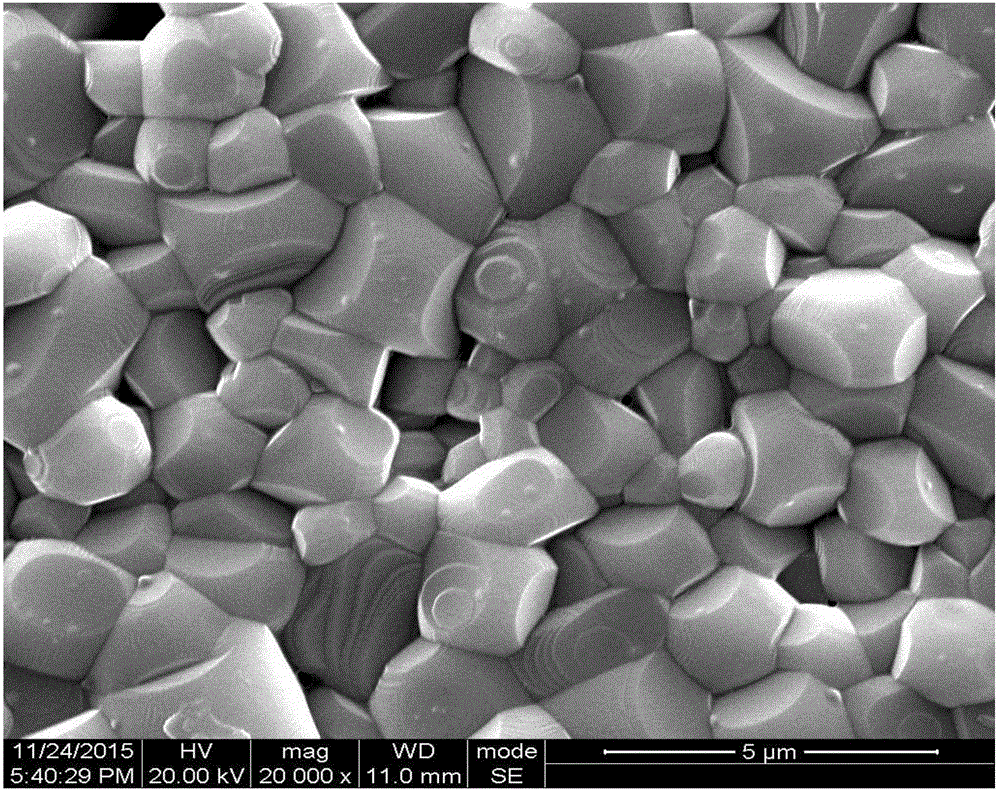

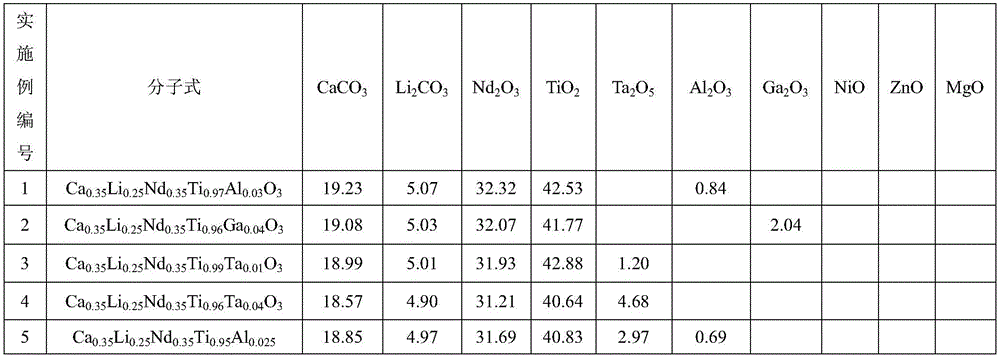

The invention provides a high-permittivity microwave dielectric ceramic material. The material has the material chemical formula (Ca0.35Li0.25Nd0.35)(Ti1-xDx)O3, wherein x is larger than or equal to 0.01 and smaller than or equal to 0.05, the composition of D is VW, V represents Ta with the valence state higher than 4, W represents one or more elements with the valence state lower than four and the average ion radius close to Ti4+, and V and W can be substituted at the same time or independently. The invention further provides a preparation method of the high-permittivity microwave dielectric ceramic material. The method includes the steps of material mixing, ball grinding, drying, screening, pre-sintering, granulating, compression molding forming and sintering. The prepared material has a high dielectric constant, a high Q*f value and an adjustable frequency and temperature coefficient. Volatile toxic metal such as Pb and Cd is not contained in the formula, performance is stable, application requirements of modern microwave devices can be met, the raw materials can be sufficiently supplied in China, the price is relatively low, and low cost of high-performance microwave ceramic is made possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

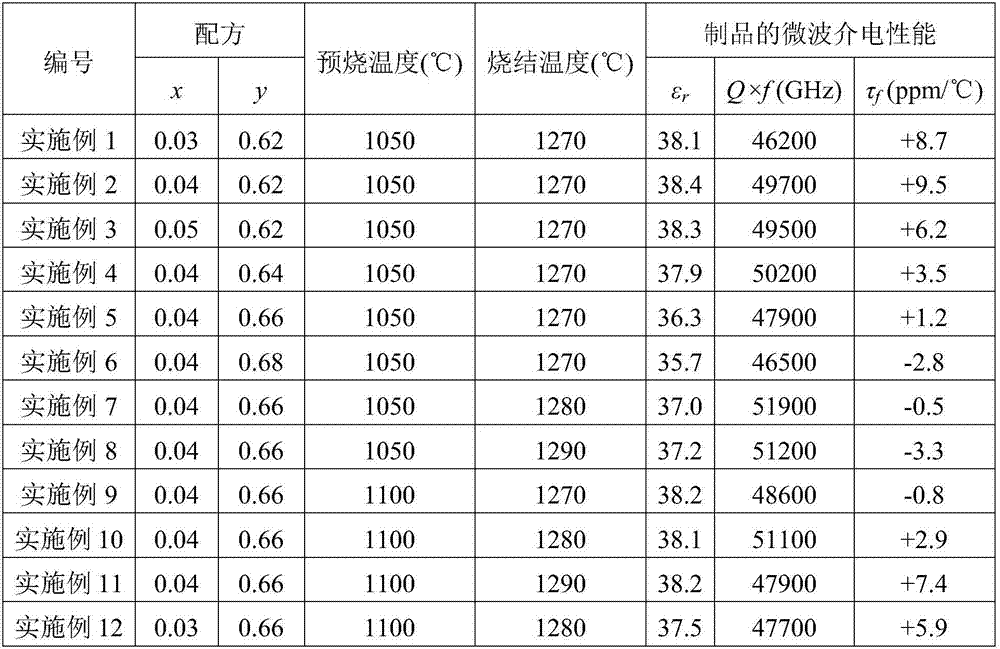

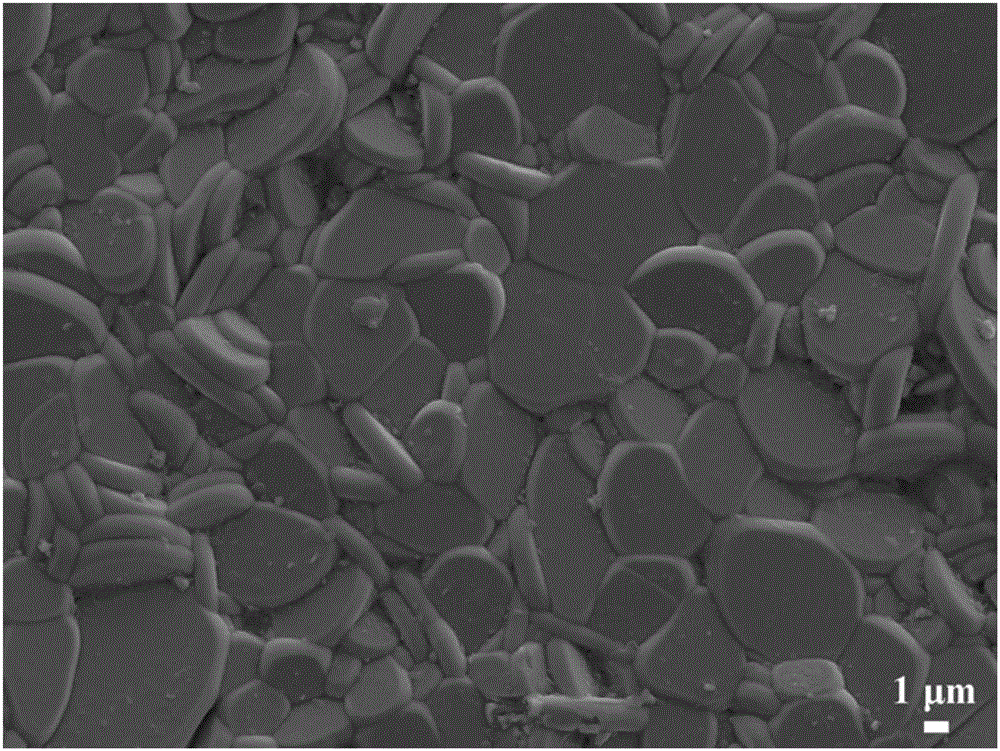

Middle-dielectric-constant microwave dielectric ceramic with adjustable temperature coefficient of resonance frequency

InactiveCN106904969AFilling the void defectChanging the Frequency Temperature CoefficientDielectricMicrowave

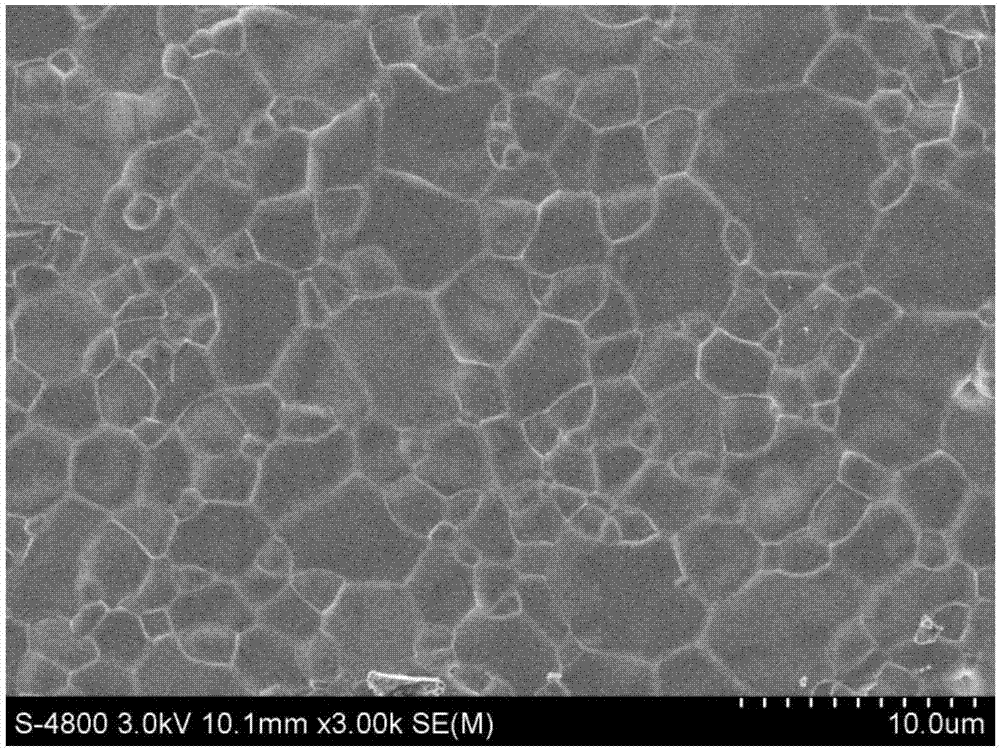

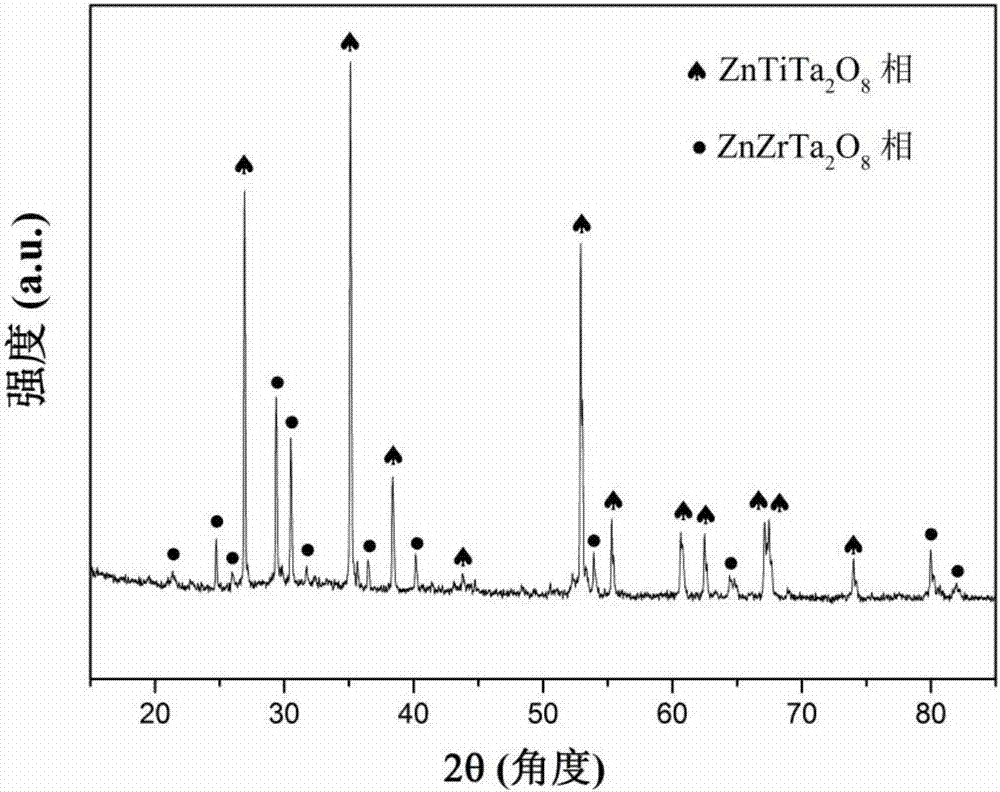

The invention discloses middle-dielectric-constant microwave dielectric ceramic with an adjustable temperature coefficient of resonance frequency. The expression is (Zn1-xMgx)(Ti1-yZry)Ta2O8, wherein x is larger than or equal to 0.03 and smaller than or equal to 0.05, and y is larger than or equal to 0.62 and smaller than or equal to 0.68. Firstly, ZnO, MgO, TiO2, ZrO2 and Ta2O5 are taken as raw materials and blended in a mole ratio; the mixture is subjected to ball milling, dried, sieved and presintered at the temperature of 1,050-1,100 DEG C, and clinker is synthesized; polyvinyl alcohol with the mass percent being 0.75%-1.25% is added to the clinker, and secondary ball milling is performed; blanks are formed after drying, sieving and pressure forming and then sintered at the temperature of 1,270-1,300 DEG C, and the required microwave dielectric ceramic is prepared. The performance of the product is improved after composite doping and modification, the dielectric constant epsilon r ranges from 35.7 to 38.4, the value of the quality factor Q*f ranges from 46,200 GHz to 51,900 GHz, the temperature coefficient tau f of resonance frequency is adjustable around zero, and the preparation process is simple, meets requirements of environment protection and facilitates large-scale industrial production.

Owner:TIANJIN UNIV

Method for preparing (Ca, Nd) TiO3 microwave dielectric ceramic by adopting sol-gel method

ActiveCN101613205AGuaranteed homogeneityNo special environmental requirementsCeramicsCopper nitrateMolecular level

The invention discloses a method for preparing (Ca, Nd) TiO3 microwave dielectric ceramic by adopting a sol-gel method. The method selects neodymium nitrate, calcium nitrate and tetrabutyl titanate as raw materials, selects boric acid, copper nitrate and lithium nitrate as a sintering additive, adopts the sol-gel method to obtain sol precursors which are mixed evenly on molecular level, leads the following crystalline phase forming to be easier and leads the temperature of crystalline phase forming to be reduced, thus obtaining the (Ca, Nd) TiO3 microwave dielectric ceramic with narrow granularity and particle size of 10 to 20nm. The powder leads the ceramic to be sintered compactly under low temperature of 1100 DEG C due to nano small size effect and sintering additive synergy, and keeps excellent microwave dielectric ceramic. The method has simple needed equipment, no particular environment requirements, stable technique under normal temperature and strong repeatability. The method can be used for preparing miniature multilayer frequency device designs of capacitors, antennas, Baran and various filters and the like and has extreme large industrial application value.

Owner:ZHEJIANG UNIV

Microwave dielectric ceramic material with low intrinsic sintering temperature and preparation method thereof

The invention discloses a microwave dielectric ceramic material with a low intrinsic sintering temperature and a preparation method thereof. Main raw materials of Li2O3 and MgO or Co2O3 and TiO2, that have a purity no less than 99%, are calcined and synthesized into a main powder, according to a molecular formula of M (Li2 / 3Ti4 / 3)O4, wherein M represents Mg or Co; then TiO2 or CaTiO3 is added into the main powder to adjust a temperature coefficient of resonance frequency of the main powder, so as to obtain a microwave dielectric material with a high dielectric constant and Q*f and a temperature coefficient of resonance frequency near zero. The microwave dielectric ceramic prepared by the invention has a low sintering temperature no more than 1100 DEG C and excellent microwave performances of high dielectric constant (epsilon r), high Q*f value and low tau f, and can be used in manufacture of microwave devices, such as resonator, microwave antenna and filter, etc.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

MAS-LT composite microwave dielectric ceramic and preparation method thereof

ActiveCN110357607AStable structureContinuously adjustable dielectric constantDielectric lossDielectric ceramics

The invention provides an MAS-LT composite microwave dielectric ceramic, which has a general formula shown in the following formula: Mg2-xBaxAl4Si5O18-Li2TiO3; wherein x = 0 ~ 0.16; the MAS-LT composite microwave dielectric ceramic contains 6-24% of Li2TiO3 by mass. Compared with the prior art, the MAS-LT composite microwave dielectric ceramic takes a composite oxide with the specific general formula as a main material, and can realize the dielectric constant between 4 and 6 and the continuous adjustment of the frequency temperature coefficient by adjusting the content of the Li2TiO3. Moreover, the MAS-LT composite microwave dielectric ceramic has a stable structure, a specific dielectric constant and a higher Q * f value, and the resonant frequency temperature coefficient is continuouslyadjustable. Experimental results show that the dielectric constant of the MAS-LT composite microwave dielectric ceramic is 4-5.8, the Q * f is more than or equal to 35,800 GHz, and the dielectric constant can reach 87,600 GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, the system has high Q * f value and low dielectric loss; at the same time, the resonantfrequency temperature coefficient is continuously adjustable between -12 ppm / DEG C to +13 ppm / DEG C, the sintering temperature is as low as 950 DEG C, and the formula can be flexibly adjusted.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

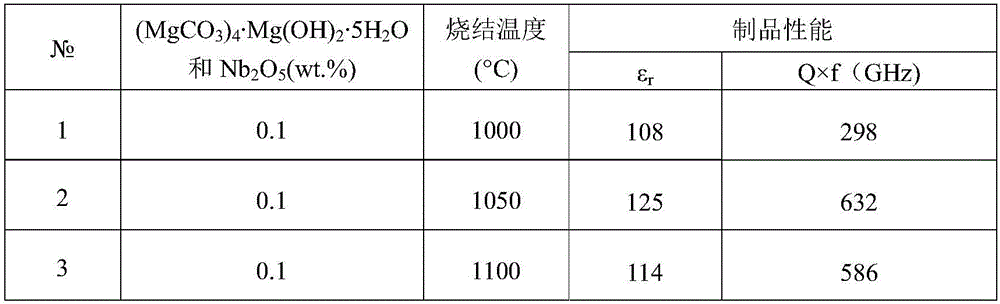

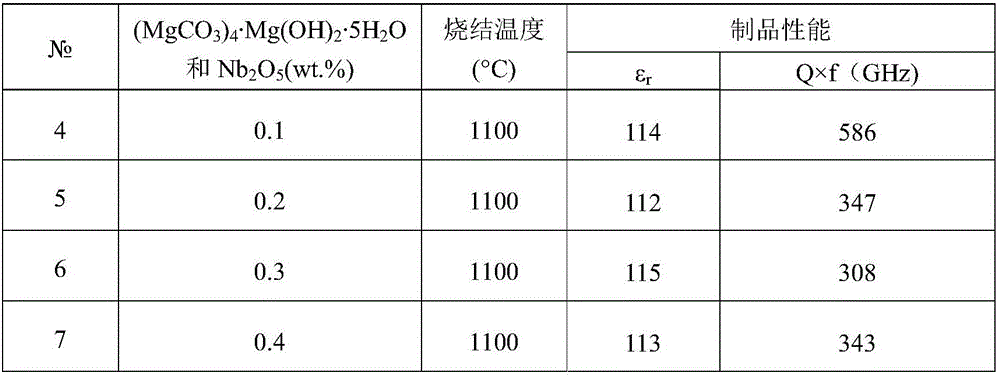

Mg-Nb doped bismuth titanate microwave dielectric ceramic and preparation method thereof

The invention discloses Mg-Nb doped bismuth titanate microwave dielectric ceramic. The chemical formula of the Mg-Nb doped bismuth titanate microwave dielectric ceramic is MgxBi[4-x]Ti[3-x]NbxO12, wherein x ranges from 0.1 to 0.4. A preparation method comprises the steps that the raw materials of Bi2O3, TiO2, (MgCO3)4.Mg(OH)2.5H2O and Nb2O5 are mixed according to the stoichiometric ratio of MgxBi[4-x]Ti[3-x]NbxO12 of which the x ranges from 0.1 to 0.4 and ball-milled for 6 h, drying is conducted at 90 DEG C, and grinding and sieving are conducted; synthesis is conducted at 800 DEG C, secondary ball milling is conducted for 12 h, drying, grinding and sieving are conducted, 7 wt% of polyvinyl alcohol water solution is additionally added for granulation, compression column homogenization is conducted, mashing, grinding and sieving are conducted, and compression molding is conducted to form a green body, the green body is subjected to heat preservation for 1 h at 650 DEG C, and organic matter eliminating is conducted; sintering is conducted at 1,000 DEG C to 1,100 DEG C, and the Mg-Nb doped bismuth titanate microwave dielectric ceramic is obtained. According to the Mg-Nb doped bismuth titanate microwave dielectric ceramic and the preparation method thereof, the Mg-Nb doped bismuth titanate microwave dielectric ceramic with a high dielectric constant is obtained at low sintering temperature, dielectric loss of bismuth titanate is reduced, the product performance is improved, the best sintering temperature is 1,050 DEG C, epsilon r equals to 125, and Q*f equals to 632 GHz.

Owner:TIANJIN UNIV

BCSLTM-SA composite microwave dielectric ceramic and preparation method thereof

The invention provides a BCSLTM-SA composite microwave dielectric ceramic and a preparation method thereof. The BCSLTM-SA composite microwave dielectric ceramic is prepared from Ba1.2Ca0.4Sm3La1.26Ti8.99Mn0.01O26 and SmAlO3, wherein the mass percent of the SmAlO3 is 5 to 15 percent. Compared with the prior art, the BCSLTM-SA composite microwave dielectric ceramic provided by the invention is formed by compounding BCSLTM and SA in specific proportion. The BCSLTM-SA composite microwave dielectric ceramic comprises two crystal phase structures of Ba1.2Ca0.4Sm3La1.26Ti8.99Mn0.01O26 and SmAlO3; thestructure is stable; specific dielectric constant and high Q*f values are realized; meanwhile, the resonant frequency temperature coefficient is continuous and adjustable.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Microwave dielectric ceramic and preparation method thereof

ActiveCN110372370AContinuously adjustable dielectric constantStable structureMicrowaveDielectric loss

The invention provides a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic has the following general formula: (1-x)Ca2Sm4Ti5O18-xSmAlO3, wherein x=0.05 to0.25. Compared with the prior art, the microwave dielectric ceramic provided by the invention uses a composite oxide represented by the above specific general formula as a main material, and throughadjustment of a content of SmAlO3, the dielectric constant is about 45, and the frequency temperature coefficient is continuously adjustable; the microwave dielectric ceramic has a stable structure, aspecific dielectric constant, a higher Q x f value, and a continuously-adjustable resonant frequency temperature coefficient; experimental results show that the microwave dielectric ceramic providedby the invention has the dielectric constant of 40 to 46.1, the Q x f value is >30000 GHz and can be as high as 49700 GHz, compared with other microwave dielectric ceramic system with the same dielectric constant, the system provided by the invention has a high Q x f value and low dielectric loss; and at the same time, the resonant frequency temperature coefficient is continuously adjustable in the range from -7.4 PPM / DEG C to +6.7 PPM / DEG C, and the microwave dielectric ceramic provided by the invention is suitable for large-scale commercial use.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

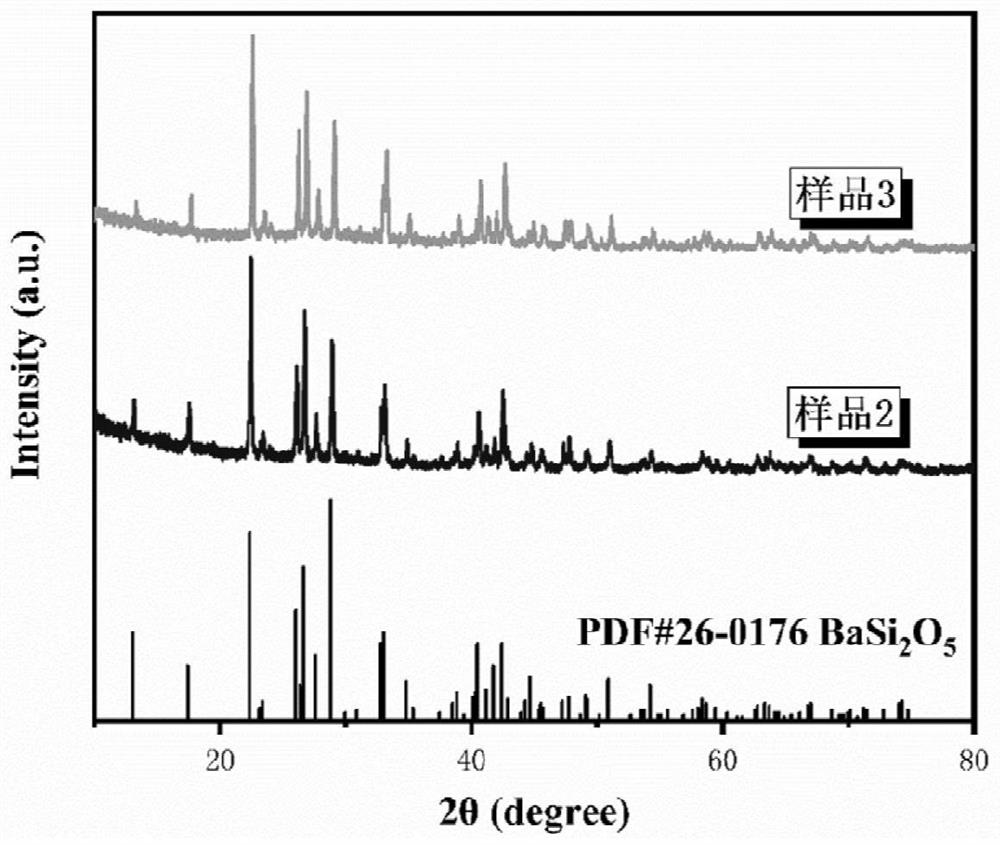

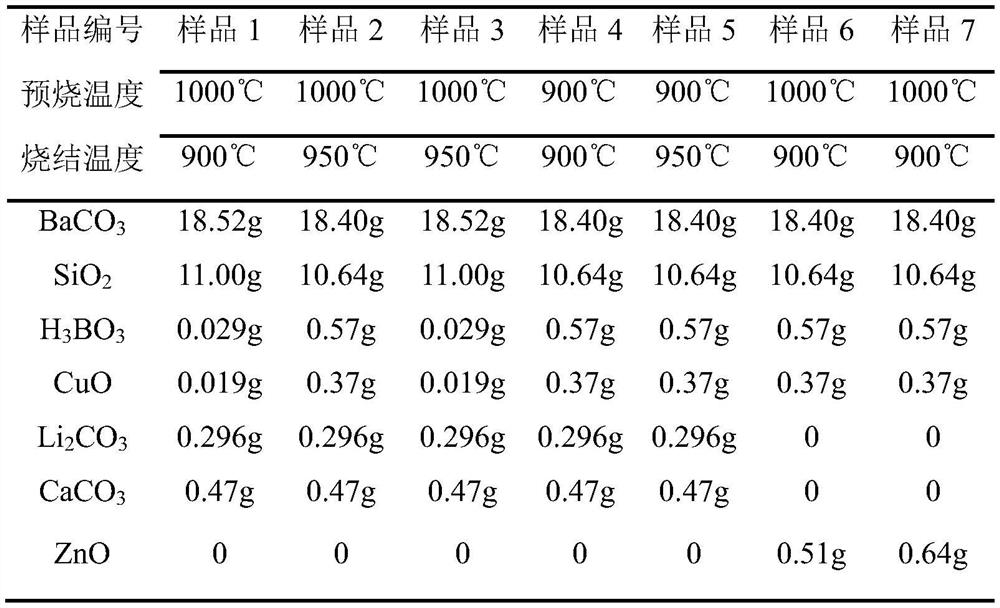

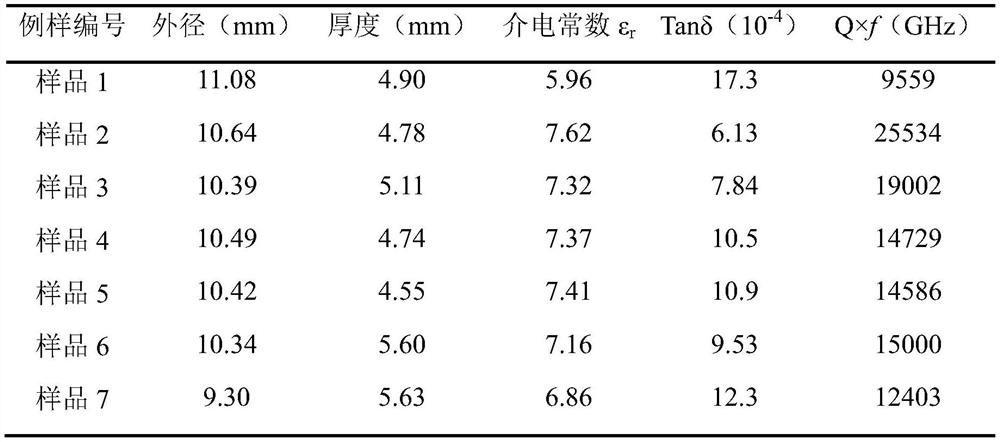

Low-dielectric low-loss Ba-Si-B-M-based LTCC material and preparation method thereof

The invention belongs to the field of electronic information ceramics and manufacturing thereof, and particularly relates to a low-dielectric low-loss Ba-Si-B-M-based LTCC (Low Temperature Co-Fired Ceramic) material and a preparation method thereof. The compact Ba-Si-B-M-based microwave ceramic material is sintered and molded at the low temperature of 850-950 DEG C by adjusting the formula of the Ba-Si-based ceramic raw materials and adopting a solid phase method by fully utilizing the characteristic that the lattice energy of Si-O bonds is high due to the fact that Si < 4 + > ions are low in polarizability and the covalent bonding property of the Si-O bonds in the complex chemical bond theory. A eutectic compound is formed in the sintering process, so that grain rearrangement is promoted, and BaSi2O5 phase ceramic is separated out along with sintering; the low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low-dielectric-constant low

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-heat-stability high-Q-value lithium-magnesium-niobium microwave dielectric ceramic

InactiveCN106830933AGood microwave dielectric propertiesSimple preparation processLithiumCompression molding

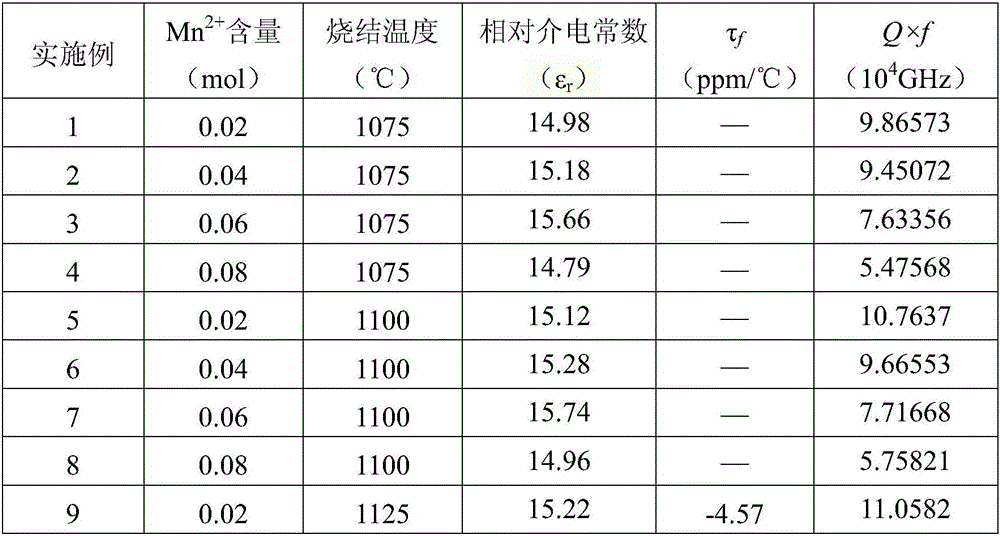

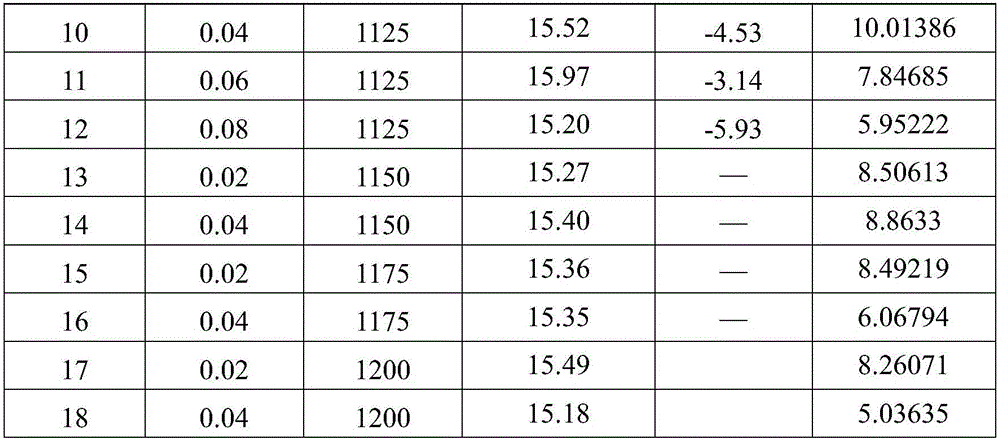

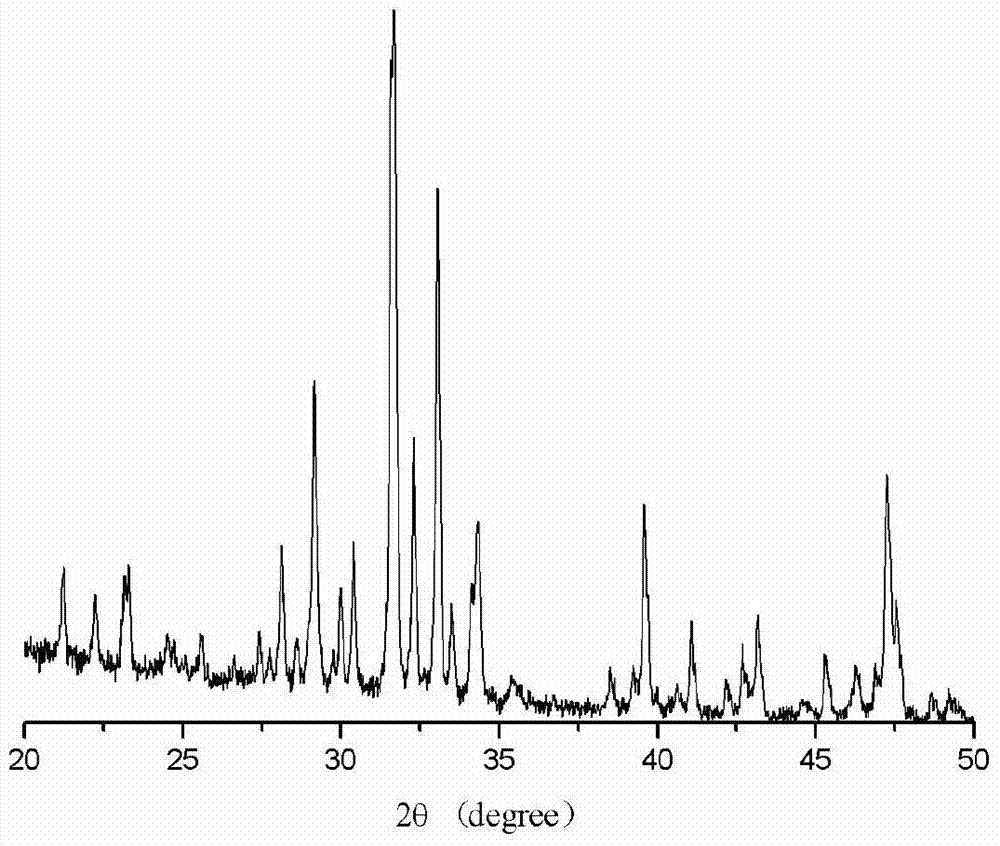

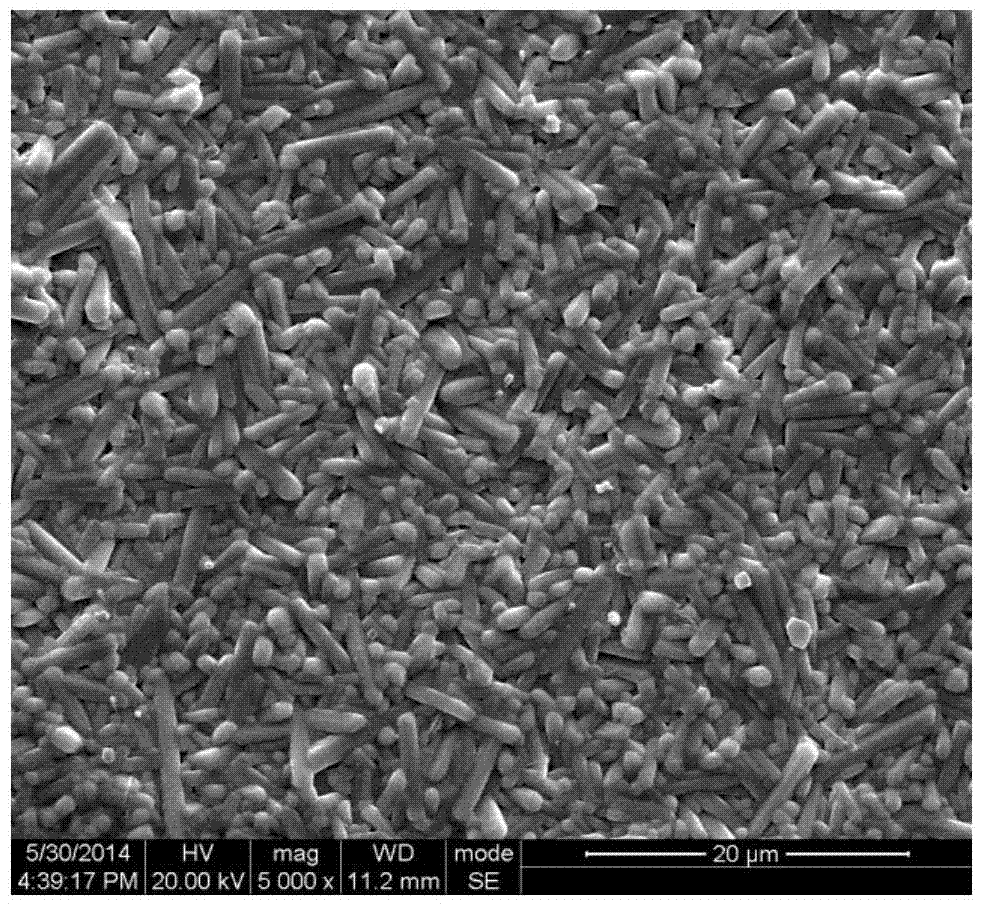

The invention discloses a high-heat-stability high-Q-value lithium-magnesium-niobium microwave dielectric ceramic. The microwave dielectric ceramic is prepared by the following steps: proportioning Li2CO3, MgO, Nb2O5 and MnCO3 as raw materials according to the stoichiometric proportion of Li3(Mg[1-x]Mnx)2NbO6 (0.02<=x<=0.08); carrying out ball milling, drying and screening, calcining at 925 DEG C, and carrying out secondary ball milling, granulation and compression molding to obtain a billet; and sintering the billet at 1075-1200 DEG C, thereby obtaining the high-heat-stability high-Q-value lithium-magnesium-niobium microwave dielectric ceramic. Different contents of Mn<2+> are adopted to replace Mg<2+> to obtain excellent microwave dielectric properties: the relative dielectric constant is 15.22, the Q*f value is 110.582 GHz, and the temperature coefficient of resonance frequency is -4.57 ppm / DEG C. The microwave dielectric ceramic has the advantages of simple preparation technique and no pollution in the process, and is a promising novel high-heat-stability high-Q-value microwave dielectric material.

Owner:TIANJIN UNIV

Nb-based composite microwave dielectric ceramic material and preparation method thereof

The invention discloses Nb-based composite microwave dielectric ceramic. The constituting expression of the Nb-based composite microwave dielectric ceramic is (1-x)(Zn0.95Ni0.05)3Nb2O(8-x)Ni0.5Ti0.5NbO4, wherein x is larger than or equal to 0.5 and smaller than or equal to 0.7. The Nb-based composite microwave dielectric ceramic is prepared through steps as follows: ZnO, NiO and Nb2O5 in a mole ratio being 2.85:0.15:1 are blended firstly and subjected to ball milling, drying, sieving, pre-sintering, secondary ball milling, drying and sieving, and pre-sintered powder of (Zn0.95Ni0.05)3Nb2O8 is obtained; NiO, TiO2 and Nb2O5 in a mole ratio being 1:1:1 are blended, and pre-sintered powder of Ni0.5Ti0.5NbO4 is prepared with the same method; the pre-sintered powder of (Zn0.95Ni0.05)3Nb2O8 and the pre-sintered powder of Ni0.5Ti0.5NbO4 are blended in a stoichiometric ratio and subjected to compression moulding, and a green body is obtained; the green body is sintered at the temperature of 1,140-1,180 DEG C, and the Nb-based composite microwave dielectric ceramic is prepared. The dielectric constant epsilon r of the ceramic is 32.8-44.1, a Q*f value of a quality factor is 37,500 GHz-57,600 GHz, temperature coefficient tau f of resonant frequency is (-25.6) ppm / DEG C-(+6.7) ppm / DEG C, and the Nb-based composite microwave dielectric ceramic has important industrial application value.

Owner:TIANJIN UNIV

Microwave dielectric ceramic material with ab positions substituted simultaneously and preparation method thereof

The invention provides a microwave dielectric ceramic material with AB positions replaced simultaneously and a preparation method thereof. The general chemical formula of the material is (Ba1-aAa)6-3x(Nd1-bBb)8+2x(Ti1-cCc)18O54, C=MN , where x=3 / 4, 0.05≤a≤0.2, 0.05≤b≤0.15, 0.02≤c≤0.08, A represents the divalent Ca and Sr elements that replace the A1 position, B represents the trivalent Sm and Bi that replace the A2 position Elements, M represents Nb whose valence is higher than tetravalent, N represents one or several other elements whose valence is lower than tetravalent and the ionic radius is similar to Ti, M and N are substituted at the same time or alone, and the preparation method is according to chemical The general formula determines the respective mass percentages, which are mixed by ball milling, pre-fired at 1000-1150°C, and then sintered at 1250-1450°C; the dielectric constant and frequency temperature coefficient of the prepared material can be adjusted while maintaining high The Q×f value of the formula does not contain Pb, Cd and other volatile or heavy metals, and the performance has been greatly improved. The domestic supply of raw materials is sufficient and the price is low, making it possible to reduce the cost of high-performance microwave ceramics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

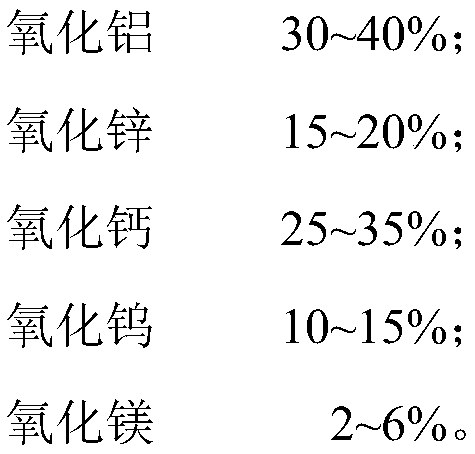

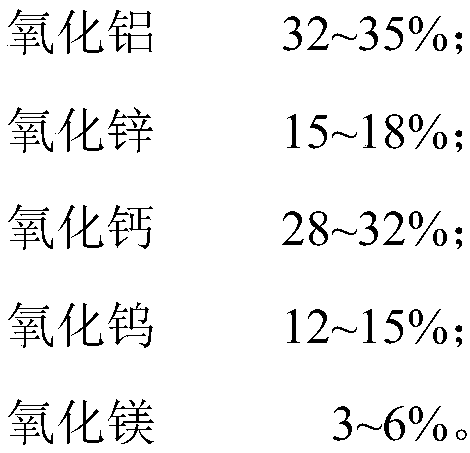

Dielectric ceramic material and preparation method thereof

The invention relates to a dielectric ceramic material and a preparation method thereof. The dielectric ceramic material is prepared fromcomprises the following ingredients in percentage by mass: 30 to 40 percent of aluminum oxide, 15 to 20 percent of zinc oxide, 25 to 35 percent of calcium oxide, 10 to 15 percent of tungsten oxide and 2 to 6 percent of magnesium oxide. The specific content of aluminum oxide, zinc oxide, calcium oxide, tungsten oxide and magnesium oxide are used for compounding and mixing; high-temperature sintering is performed, so that the sintering temperature of the dielectric ceramic material can be lowered; in addition, the dielectric ceramic material has the smaller dielectric constant (about 9.6) and higher Q*f value.

Owner:上海金赞陶瓷材料有限公司

Composite microwave dielectric ceramic material with medium dielectric constant and method for preparing composite microwave dielectric ceramic material

The invention relates to the field of material science, and aims to provide a composite microwave dielectric ceramic material with a medium dielectric constant. A chemical expression of the compositemicrowave dielectric ceramic material is (1-x)Li<2>Ti<0.75>(Mg<1 / 3>Nb<2 / 3>)<0.25>O<3+x>BaTi<4>O<9+ywt%>M. The x is larger than or equal to 0.4 and is smaller than or equal to 0.6, the y represents themass fraction of the total mass of Li<2>Ti<0.75>(Mg<1 / 3>Nb<2 / 3>)<0.25>O<3> and BaTi<4>O<9>, is larger than or equal to 0.5 and is smaller than or equal to 2, and the M represents auxiliaries and is one of LiF, MnCO<3>, CuO and GeO2 or a mixture of a plurality of the LiF, the MnCO<3>, the CuO and the GeO2. The composite microwave dielectric ceramic material has the advantages that the dielectric constant of the composite microwave dielectric ceramic material is approximately 30, and the composite microwave dielectric ceramic material has a high QXf (quality factor) value and a small temperature coefficient of resonance frequency; the requirements of microwave components such as resonators, filters and GPS (global positioning system) antennas on microwave dielectric ceramic materials with dielectric constants of approximately 30 can be met; processes for preparing the composite microwave dielectric ceramic material are simple and are good in repeatability.

Owner:ZHEJIANG UNIV

Low-dielectric high-Q lithium magnesium phosphate dielectric material and preparation method thereof

InactiveCN109851350ANo pollution in the processMeet environmental protection requirementsDielectricLithium

The invention belongs to the technical field of ceramic materials, and discloses a low-dielectric high-Q lithium magnesium phosphate dielectric material and a preparation method thereof, wherein the chemical formula of the dielectric material is LiMg(P1-xNbx)O4 (x is greater than or equal to 0.02 and less than or equal to 0.08). The preparation method comprises the following steps: preparing Li2CO3, MgO, NH4H2PO4 and Nb2O5 in proportion; performing primary ball milling and drying and sieving the raw materials; calcining the raw materials at a certain temperature to obtain pre-sintered powder;performing secondary ball milling on the pre-sintered powder, drying, sieving, granulating and sieving the powder and pressing the powder into a green body; sintering the green body at a certain temperature, preserving heat, and cooling the product to room temperature. According to the invention, a traditional solid-phase method is adopted, and P<5+> ions in the LiMgPO4 dielectric material are replaced by Nb<5+>, so that the Q*f value is obviously improved. In addition, the lithium-magnesium-phosphorus dielectric material disclosed by the invention is non-toxic and pollution-free, and meets the environmental protection requirement; and the preparation process is simple, low in cost and suitable for large-scale production. The material is used for manufacturing microwave components such asresonators and filters.

Owner:TIANJIN UNIV

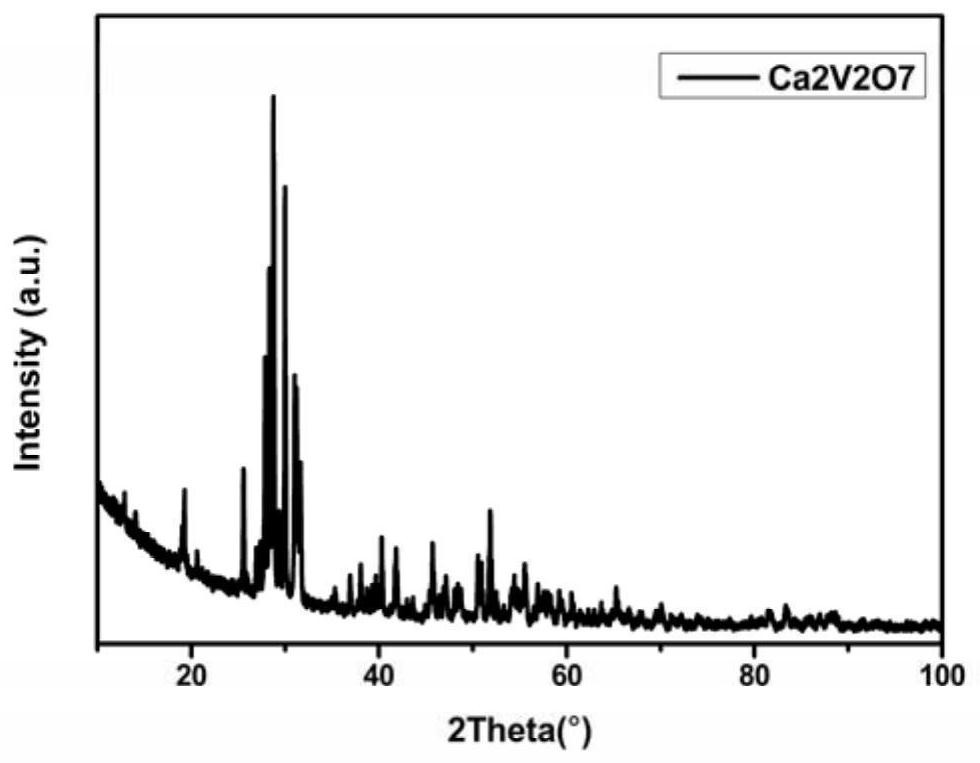

Ultralow-temperature sintered microwave dielectric material Ca2V2O7-H3BO3 and preparation method thereof

The invention belongs to the field of electronic materials and manufacturing thereof, provides an ultralow-temperature sintered microwave dielectric material Ca2V2O7-H3BO and a preparation method thereof, and aims to solve the problems that the sintering temperature is too high and the microwave performance of the prepared material is not good enough in a conventional preparation method of the microwave dielectric material Ca2V2O7. According to the preparation method, a traditional solid phase method is adopted, H3BO3 is added into a pre-synthesized Ca2V2O7 base material to serve as a sintering aid, the sintering temperature is greatly reduced, and ultralow-temperature sintering at 660 DEG C is achieved; meanwhile, the sintering aid greatly promotes densification of a sample without any chemical reaction with Ca2V2O7, so that the Q*f value of the microwave dielectric material is greatly increased while ultralow-temperature sintering is realized, the Q*f value of the material sintered at the temperature of 725-850 DEG C is 34605-43348 GHz, and the Q*f value of the material sintered at the ultralow temperature (660 DEG C) is 18749 GHz; in addition, the process is simple, industrial production is easy, ultralow-temperature sintering has the remarkable advantage of saving energy, and the method can be used for producing microwave components such as resonators and filters.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

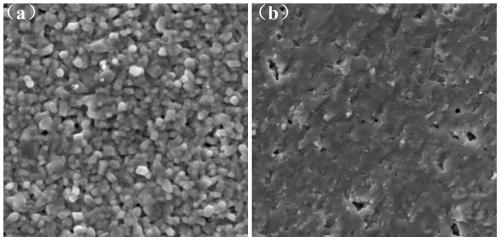

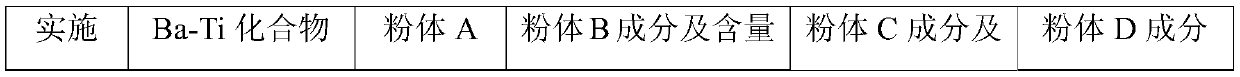

Intermediary electric constant low temperature cofiring ceramic material and preparation method

The invention discloses an intermediary electric constant low temperature cofiring ceramic material and a preparation method, wherein the ceramic material comprises 50-70 parts by weight of a Ba-Ti compound, 0-5 parts by weight of powder A, 30-45 parts by weight of powder B, 2-15 parts by weight of powder C and 0-2 parts by weight of powder D; wherein the Ba-Ti compound comprises BaCO3 and TiO2, the powder A is BaZn2Ti4O11, the power B comprises Ba(OH)2, H3BO3, ZnO and La2O3, the ingredient(s) of the powder C is / are one or a plurality of SrTiO3, TiO2 and CaTiO3, and the powder D is one or a plurality of MnO2, Co2O3 and Cr2O3. By the technical scheme of the invention, the intermediary electric constant low temperature cofiring ceramic material obtains a relatively excellent ceramic microwave characteristic, is simple in preparation process and suitable for large-scale production, has good compatibility with a microwave matrix material, and lowers the sintering temperature of materials effectively.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108821768BContinuously adjustable dielectric constantHigh Q*f valueDielectricDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the composite oxide has the general formula shown in the following formula: MLa 4 Ti 3 M'O 15 ; Wherein, M is Ca, Ba or Mg; M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and is a microwave dielectric ceramic with a medium dielectric constant; the microwave dielectric ceramic material satisfies a dielectric constant near 45 and It is continuously adjustable, and has a very high Q*f value and good sintering stability. At the same time, it can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r 43.2~46.8, quality factor Q*f value ≥46200GHz, and sintering is stable; at the same time, the temperature drift adjustment range is ‑8~+13ppm / ℃, and can be continuously adjusted to meet various needs. It has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

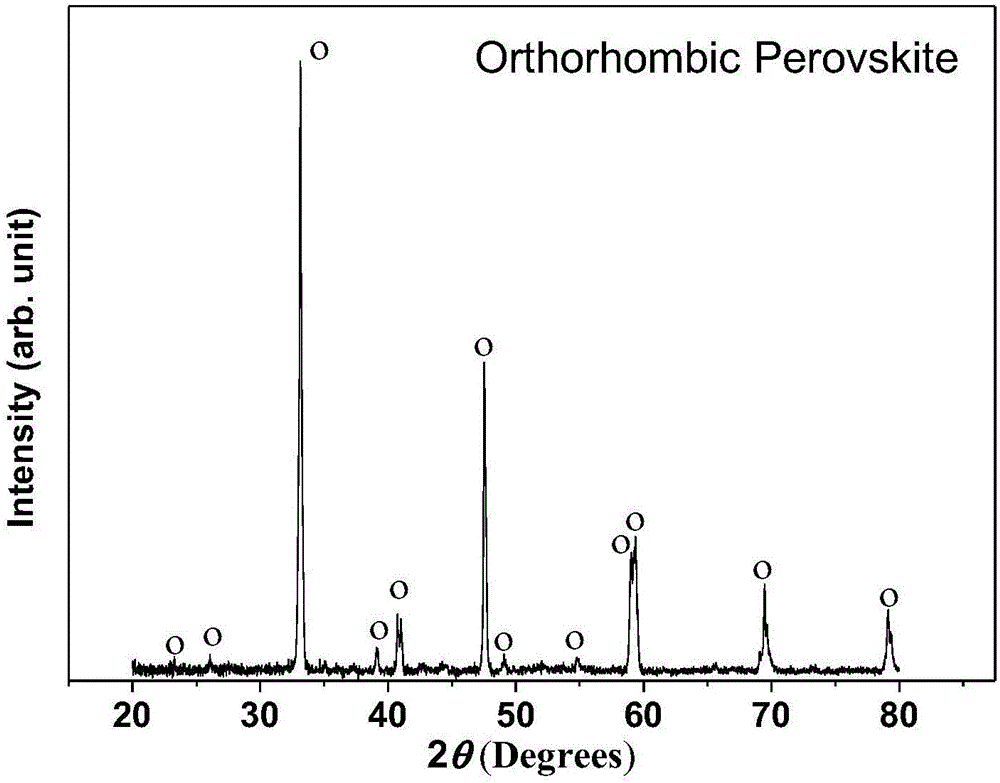

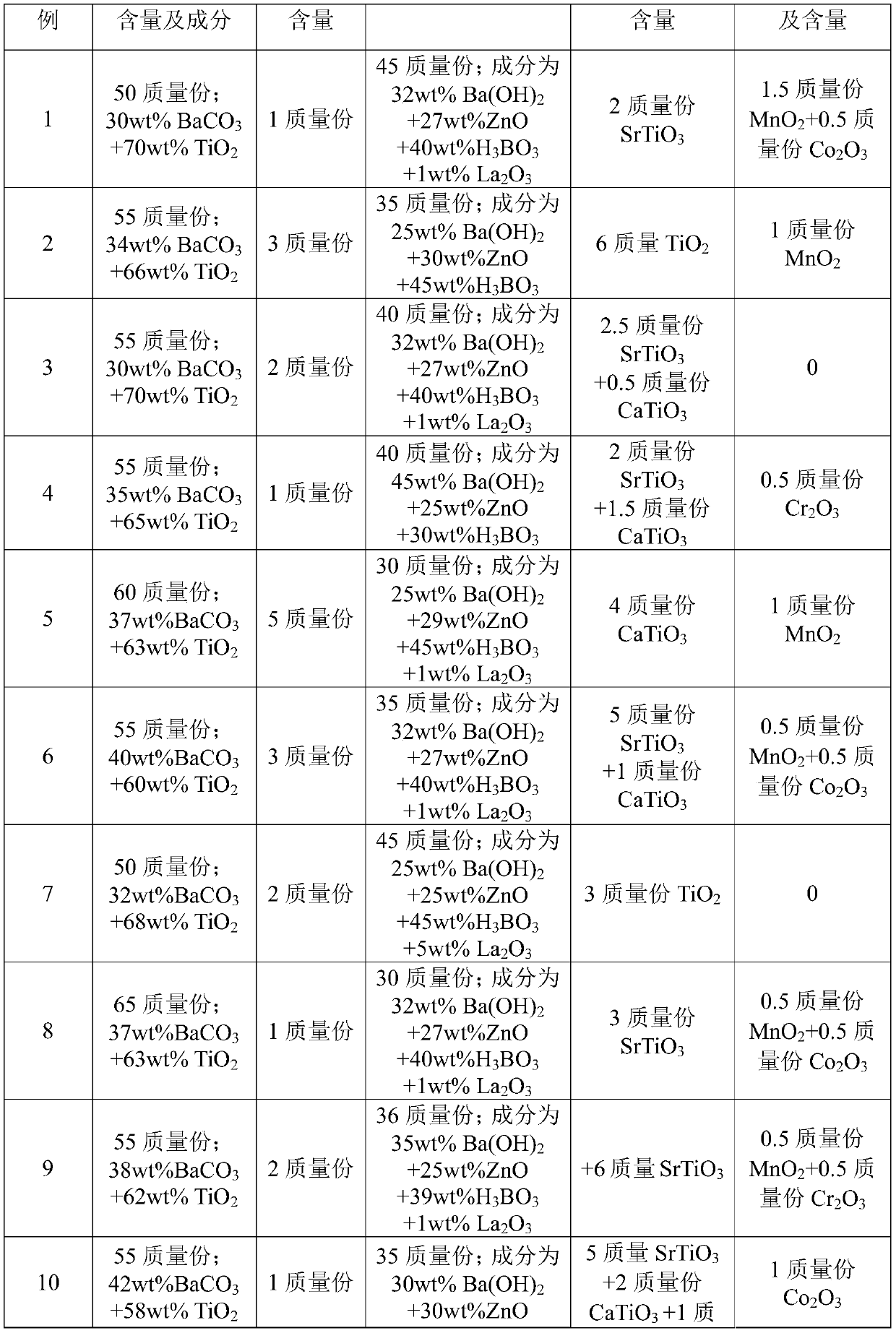

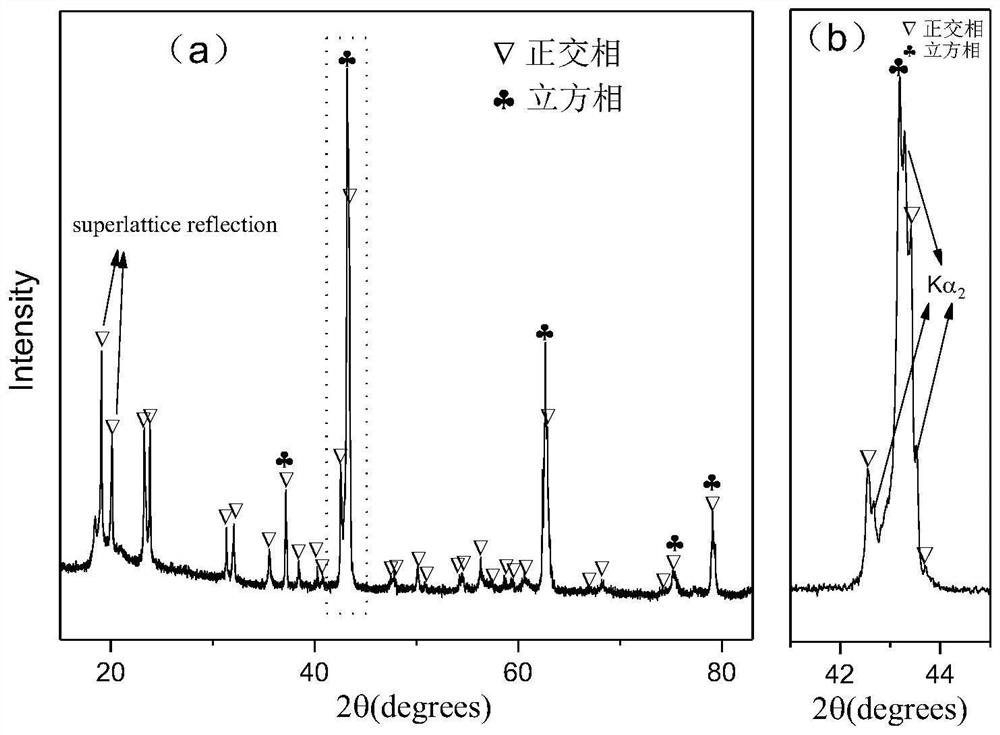

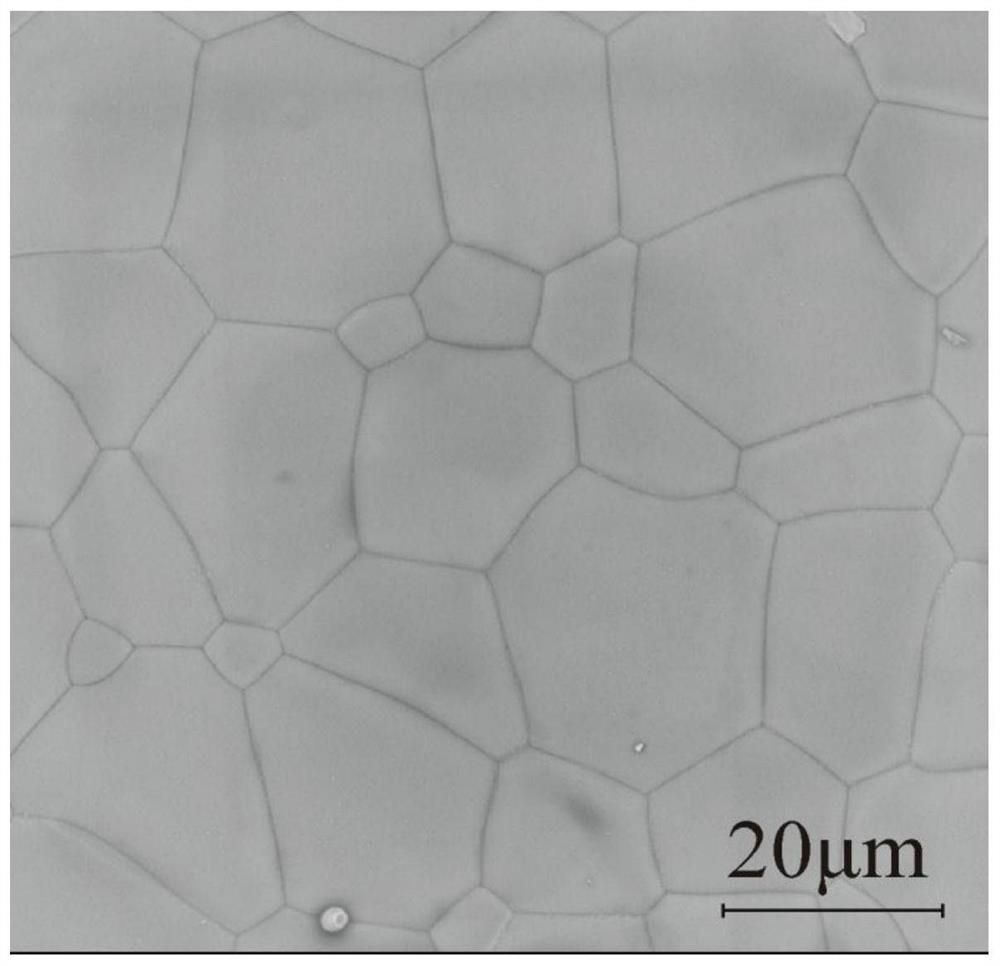

Multiphase rock-salt structure ultra-low loss microwave dielectric ceramic material and preparation method thereof

The invention provides a multi-phase rock-salt structure ultra-low loss microwave dielectric ceramic material and a preparation method thereof, the general formula of which is Li 3+ a Mg 2‑b / 3 x 1‑2b / 3 Y b+c o 6+2c · dZ, X is Nb 5+ or Ta 5+ , Y is Ti 4+ , Sn 4+ or Zr 4+ , Z is ZnO or LiF, 0.03≤a≤0.12, 0.12≤b≤0.38, 0≤c≤0.15, 0wt%≤d≤5wt%, the preparation method is according to the general formula ingredients, after the first ball mill mixing, drying, Screening, pre-calcination, and second ball milling, drying, granulation, debinding, and sintering in air; the crystal phase of the finished product is an ordered orthorhombic phase rock salt structure and a disordered cubic phase rock salt The composite phase of the structure; the microwave dielectric ceramic material provided by the present invention shows excellent performance under the condition of two different rock salt structural components adjustable: its relative permittivity ε r Adjustable between 8.8~17.9, Q×f value is 82000GHz~128000GHz, resonant frequency temperature coefficient τ f It can be adjusted between -33ppm / ℃~+11ppm / ℃, the preparation process is simple, and the performance is stable, which meets the application requirements of modern microwave devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com