Intermediary electric constant low temperature cofiring ceramic material and preparation method

A low-temperature co-fired ceramic and electrical constant technology, applied in the field of ceramic materials, can solve the problems of difficult grinding and fine processing, high energy consumption, low melting point glass composition and complex process, and achieve stable resonant frequency temperature coefficient and resonant frequency temperature coefficient. Small, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

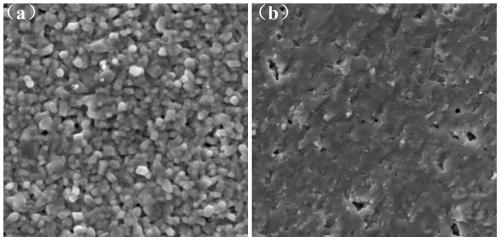

Image

Examples

Embodiment

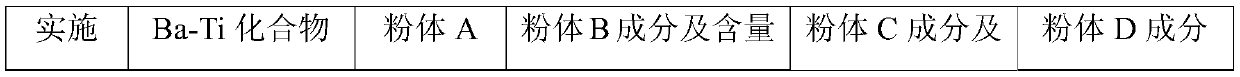

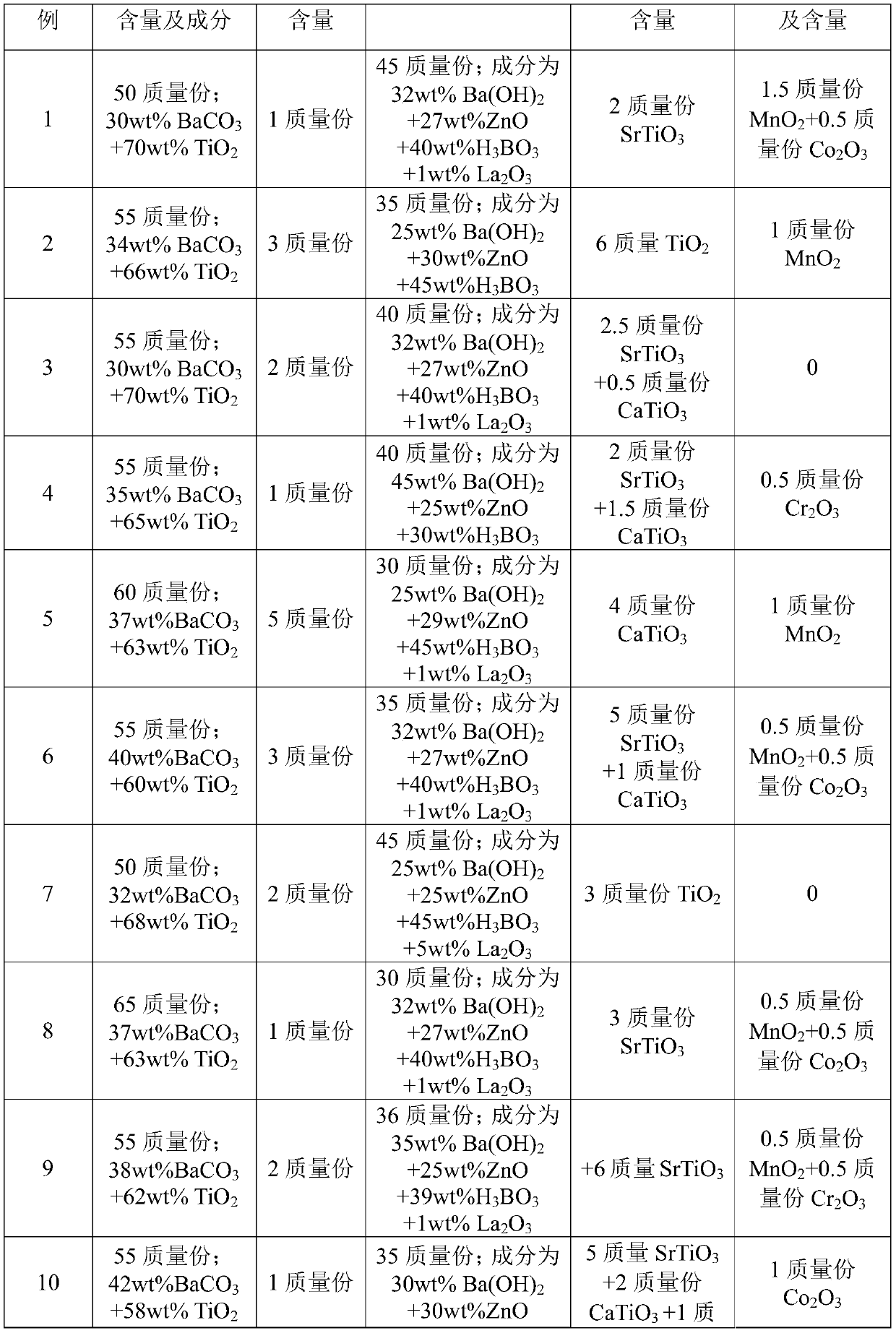

[0019] The present invention calculates the formula according to the number of parts by mass, using solid-phase synthesized Ba-Ti compound, powder A, powder B, powder C and analytically pure powder D, specific examples are shown in Table 1. Among them, the Ba-Ti compound is a calcined body, which consists of 30 to 50 parts by mass of BaCO 3 and 50-70 parts by mass of TiO 2 composition. Powder A is calcined body, its chemical composition is BaZn 2 Ti 4 o 11 . Powder B is a calcined body, and its composition is 20 to 45 parts by mass of Ba(OH) 2 , 20-40 parts by mass of H 3 BO 3 , 25-50 parts by mass of ZnO and 0-5 parts by mass of La 2 o 3 . The powder C is SrTiO 3 、TiO 2 and CaTiO 3 one or more of. The powder D is MnO 2 、Co 2 o 3 and Cr 2 o 3 one or more of.

[0020] In Table 1, the synthesis temperature of Ba-Ti compound is 1150℃, BaCO 3 and TiO 2 The relative mass parts of the powder A are shown in Table 1, and other mass parts and other synthesis tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com