Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Continuously adjustable dielectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

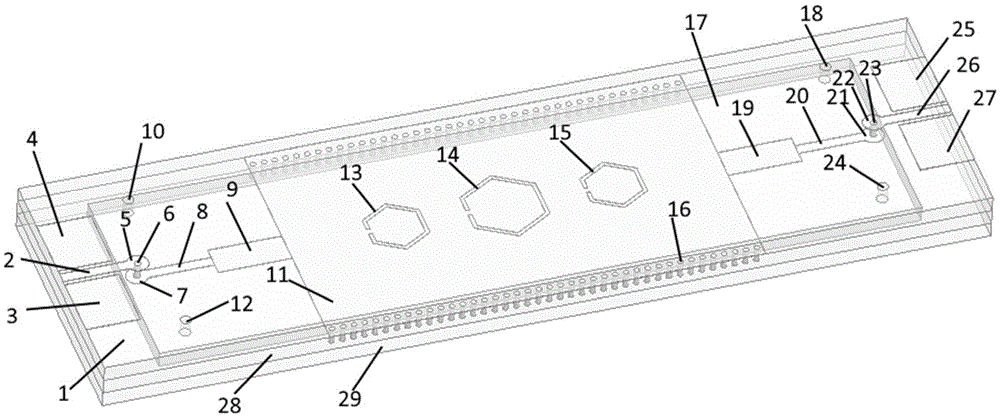

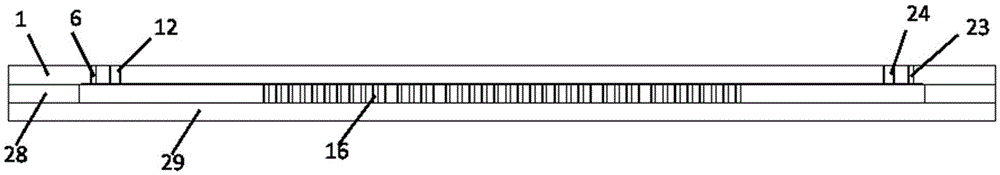

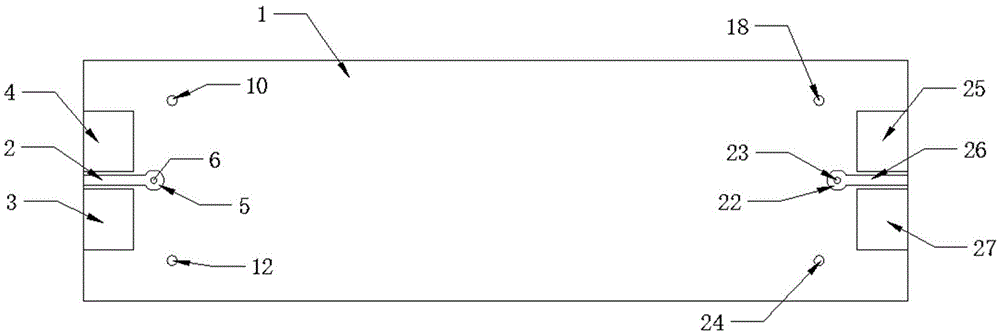

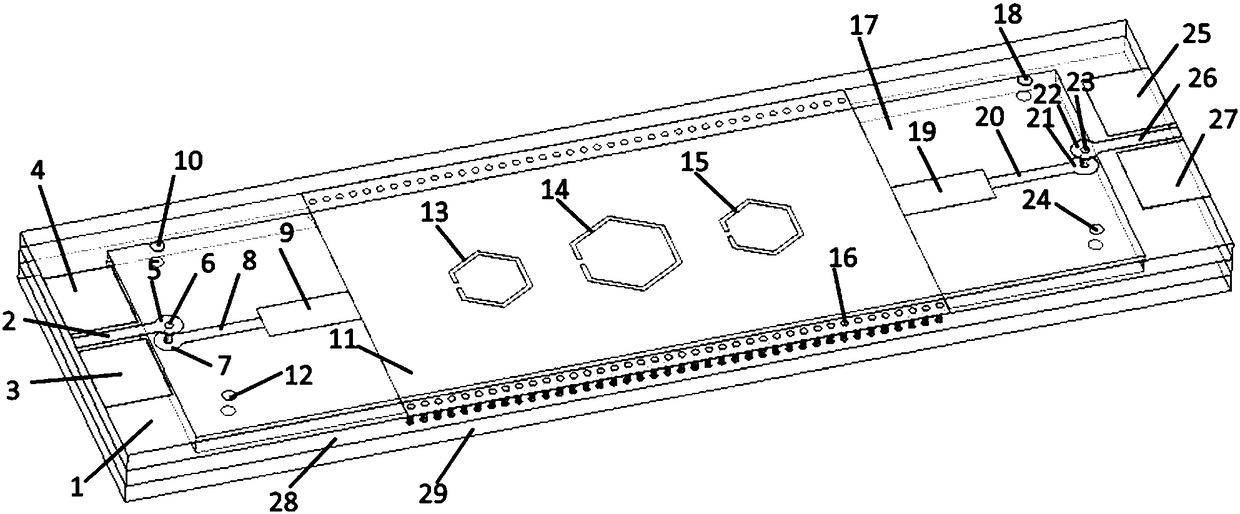

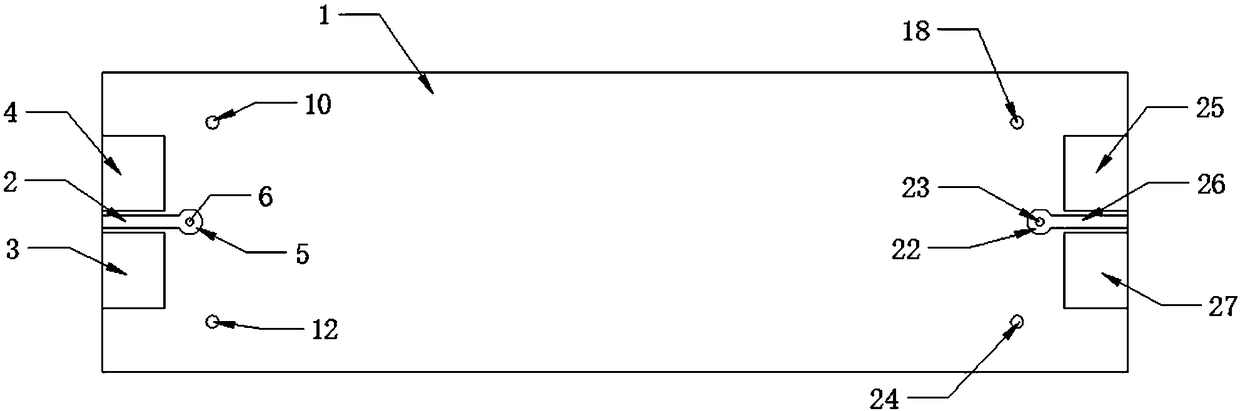

Substrate integrated waveguide microwave tunable filter based on liquid crystal material

InactiveCN105489987AOvercome Impedance MismatchAddressing Impedance MismatchesWaveguide type devicesSatelliteLiquid crystal

The invention discloses a substrate integrated waveguide microwave tunable filter based on a liquid crystal material, wherein the substrate integrated waveguide microwave tunable filter belongs to the technical fields of wireless communication, satellite communication, radar system, etc. Particularly the invention relates to a filter based on the liquid crystal material. The filter settles a problem of liquid crystal material leakage in an existing packaging process. The filter settles a problem of impedance mismatch in manners of interlayer through hole interconnection and strip line stepped impedance transformation. A modulating voltage is added through direct contact type feeding. A bandpass filter is realized through etching an open resonance ring structure on an upper-surface metal layer of a substrate integrated waveguide. The upper-surface metal layer of the substrate integrated waveguide is reversed for contacting with the liquid crystal material, thereby forming the substrate integrated waveguide tunable filter based on the liquid crystal material. The substrate integrated waveguide microwave tunable filter settles the problem of liquid crystal leakage in a traditional packaging method and has effects of impedance matching and continuous adjustable frequency response of the filter.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

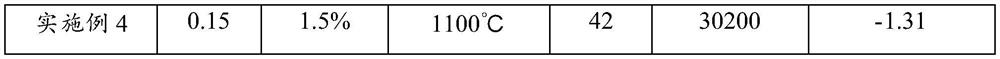

Dielectric adjustable material of ceramics burned together at low temperature, and preparation method

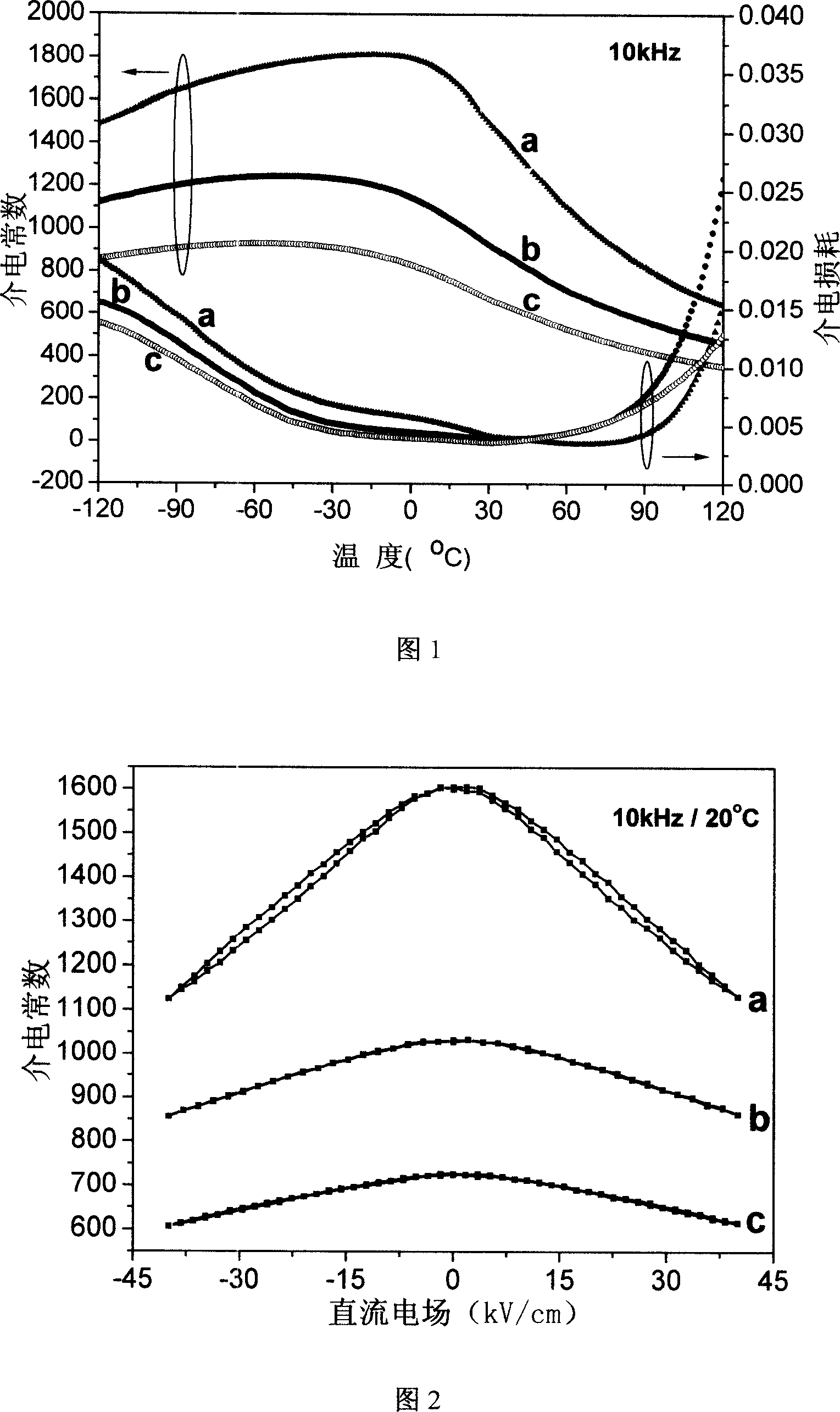

This invention relates to a method for preparing ceramic material with a sintering temperature below 950 deg.C. The ceramic material is composed of Ba1-xSrxTiO3 (x = 0.2 -0.6) 75.0-95.0 wt. %, MgO 0.15-15 wt. %, B2O3 0-1.0 wt. %, Li2CO3 3.0-10.0 wt. %. The method utilizes MgO and B2O3-Li2O sintering aid to dope and modify BST ceramic material, and the obtained ceramic material has such advantages as adjustable dielectric constant (100-2000) and low sintering temperature (850-950 deg.C). The ceramic material can be used in LTCC technique and microwave adjustable devices.

Owner:TONGJI UNIV

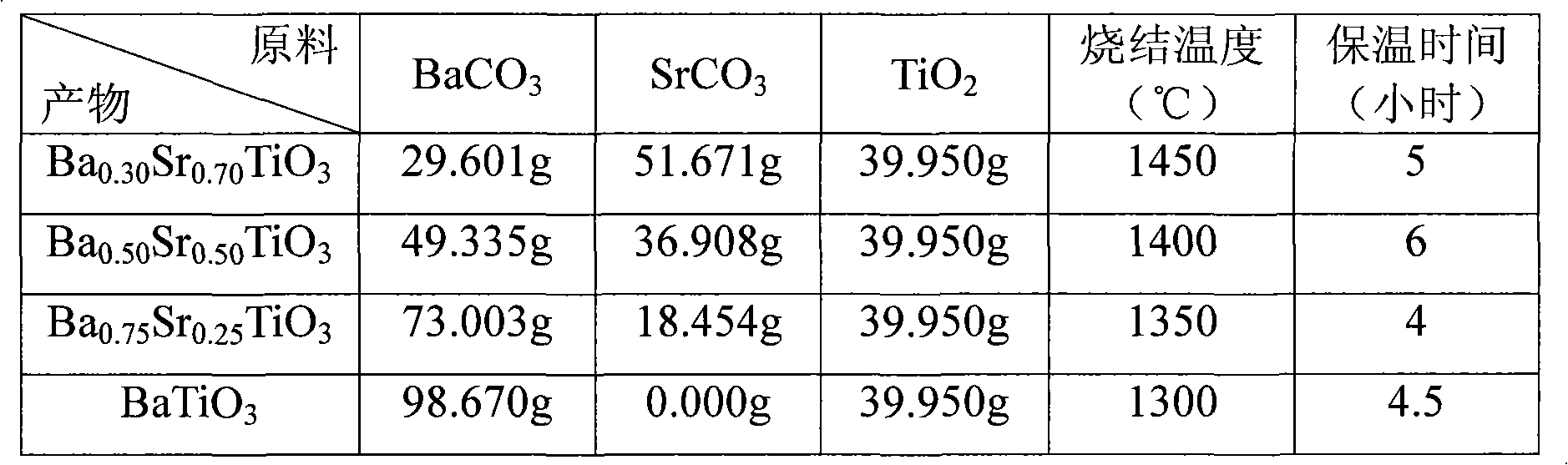

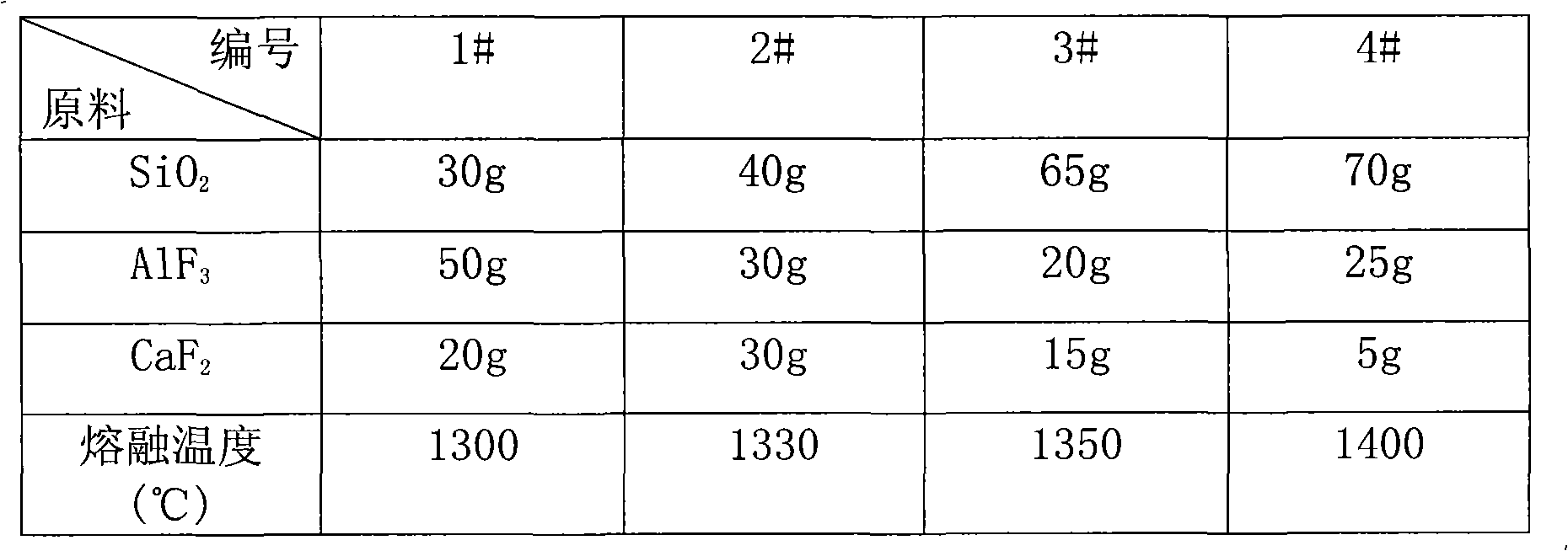

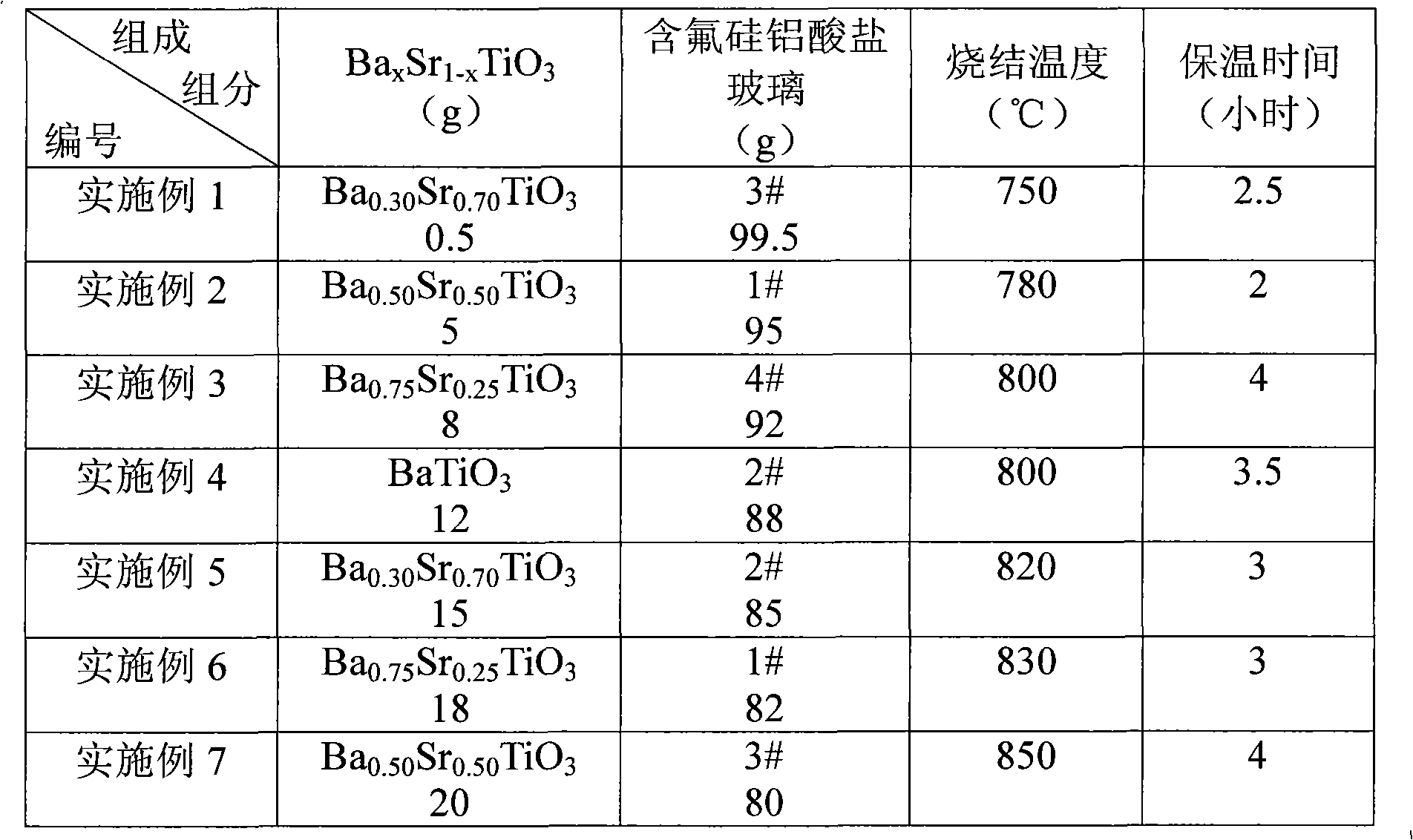

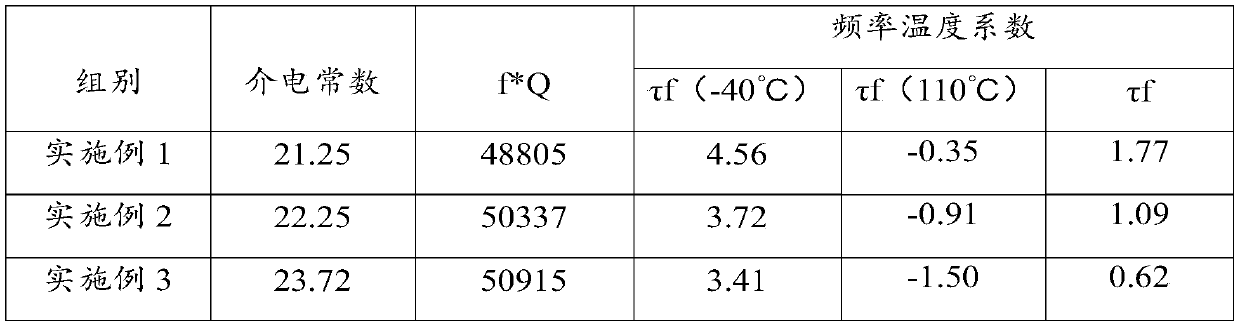

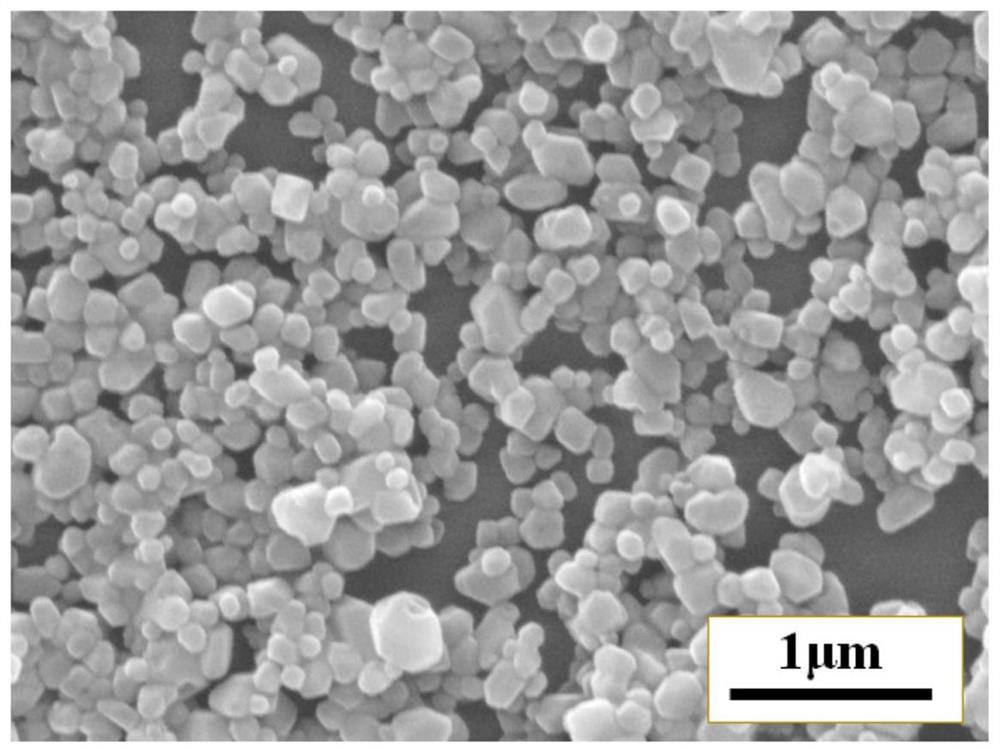

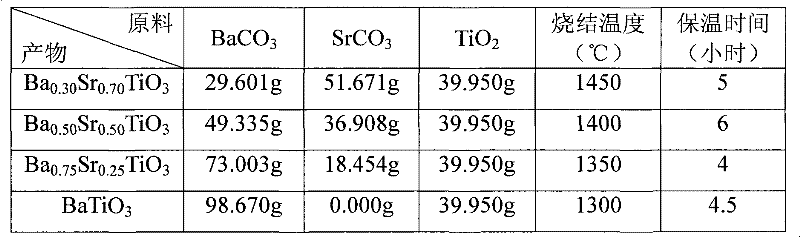

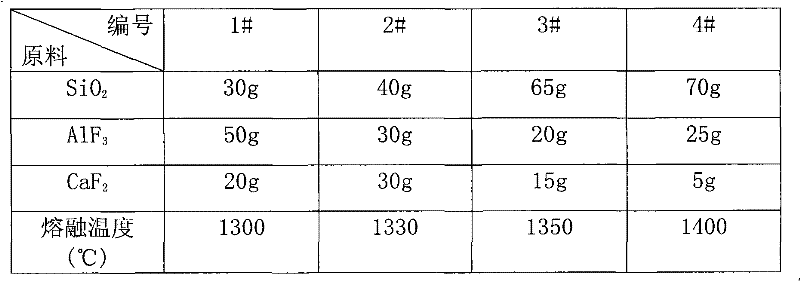

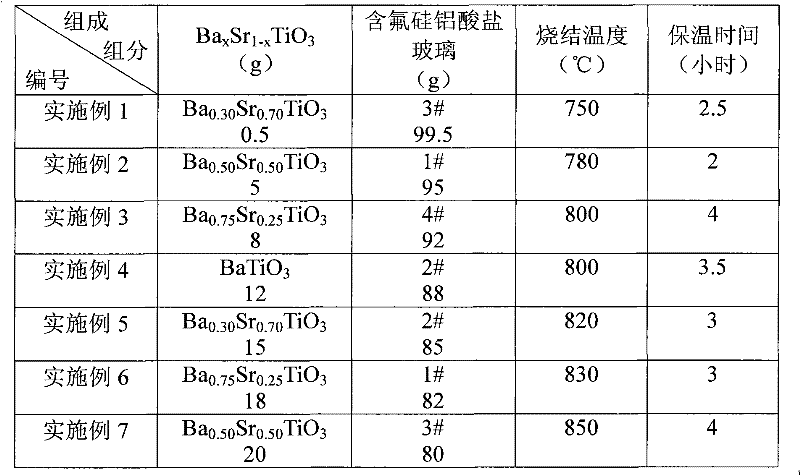

Low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and preparation method thereof

The invention discloses a low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by mass: 0.5 to 20 percent of BaxSrl-xTiO3(x=0.3-1) and 80 to 99.5 percent of fluorinated aluminosilicate glass; wherein, the fluorinated aluminosilicate glass is prepared from the following raw materials in percentage by mass: 30 to 70 percent of SiO2, 20 to 50 percent of AlF3, and 5 to 30 percent of CaF2. After being mixed by the ratio, the components are added with ethanol or water, ball milled for 24h and dried to obtain low-temperature co-fired glass ceramic powder. The low-temperature co-fired glass ceramic composite material has the advantages that: (1) the sintering temperature is low (750 to 850DEG C) and the sintering shrinkage rate is 8 to 15 percent; and (2) the dielectric constant is adjustable from 8 to 50 (1GHz), and the dielectric loss is below 0.002 and the mechanical strength is higher. Consequently, the invention is applicable to low-temperature co-fired ceramic materials and electronic packaging materials.

Owner:TSINGHUA UNIV

Microwave dielectric ceramic material, preparation method and application thereof, microwave dielectric ceramic body, preparation method and application of microwave dielectric ceramic body, and microwave device

ActiveCN110668795AGood temperature characteristicsImprove temperature stabilityElectronic ceramicsCeramic materials

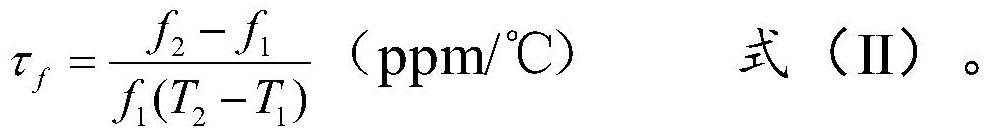

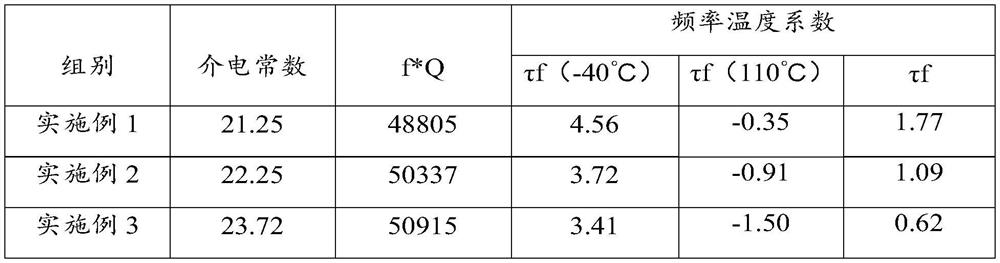

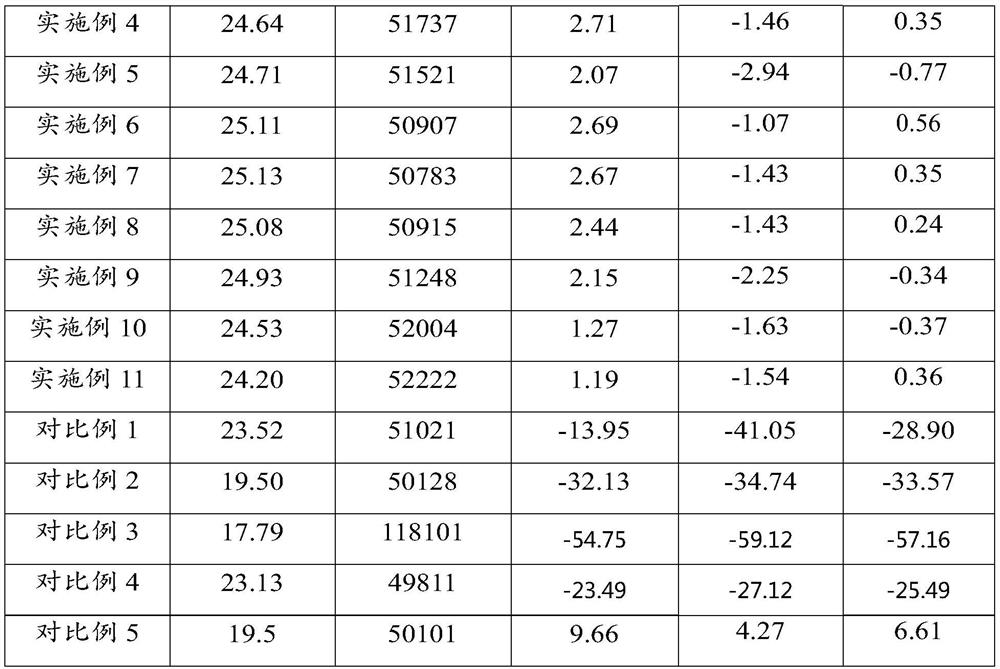

The invention relates to the field of electronic ceramics, and provides a microwave dielectric ceramic material, a preparation method and application thereof, a microwave dielectric ceramic body, a preparation method and application of the microwave dielectric ceramic body, and a microwave device. The microwave dielectric ceramic material is mainly prepared from ceramic main materials and optionaladditives, the ceramic main materials comprise the specific weight percentage of MgO, CaO, SiO2, Nd2O3, Sm2O3 and TiO2, the additives comprise the specific weight percentage of oxide of R, R comprises one or more of Nb, Zn, Zr, Mn, Y, Ni, Cu, Mo or Al, wherein the sum of the weight percentage of all the components is 100%. The dielectric constant of the microwave dielectric ceramic body is continuously adjustable within 15-30, f*Q at the temperature of 25 DEG C is greater than 45000, the good temperature characteristics are achieved, the frequency temperature coefficients at the temperaturesof minus 40 DEG C, 25 DEG C and 110 DEG C are each close to zero, and temperature stability is high.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Dielectric-constant adjustable houghite-like membrane and preparation method thereof

InactiveCN101538018ALow dielectric constantImprove bindingOxide/hydroxide preparationZinc oxides/hydroxidesDielectricOctahedron

The invention relates to a dielectric-constant adjustable houghite-like membrane and a preparation method thereof, belonging to the technical field of controllable preparation of inorganic functional membrane. A pure aluminium sheet is taken as a substrate; an LDH membrane grows on the surface of the aluminium sheet; the houghite-like membrane is a compound generated by orderly assembling of interlayer anions and a plywood with positive charges; the chemical general formula of the membrane layer is (M<2+>1-xAl<3+>x(OH)2)<x+> (CO3<2->)x / 2 mH2O, wherein, M<2+> stands for any one or two of divalent metal ions of Mg<2+>, Co<2+>, Ni<2+>, Cu<2+>, Fe<2+>, Mn<2+> or Zn<2+>. The numeric ranges of x and m are that x is more than or equal to 0.2 and less than or equal to 0.4 and m is more than or equal to 0 and less than or equal to 2. The structure of the houghite-like membrane is similar to brucite Mg(OH)2, and MO6 octahedron shares a seamed edge to form a plywood main body. The prepared LDH membrane is then roasted at 400 DEG-550 DEG C to obtain a composite metal oxide membrane. The dielectric-constant adjustable houghite-like membrane has the advantage that continuous adjustment for the membrane dielectric constant is realized.

Owner:BEIJING UNIV OF CHEM TECH

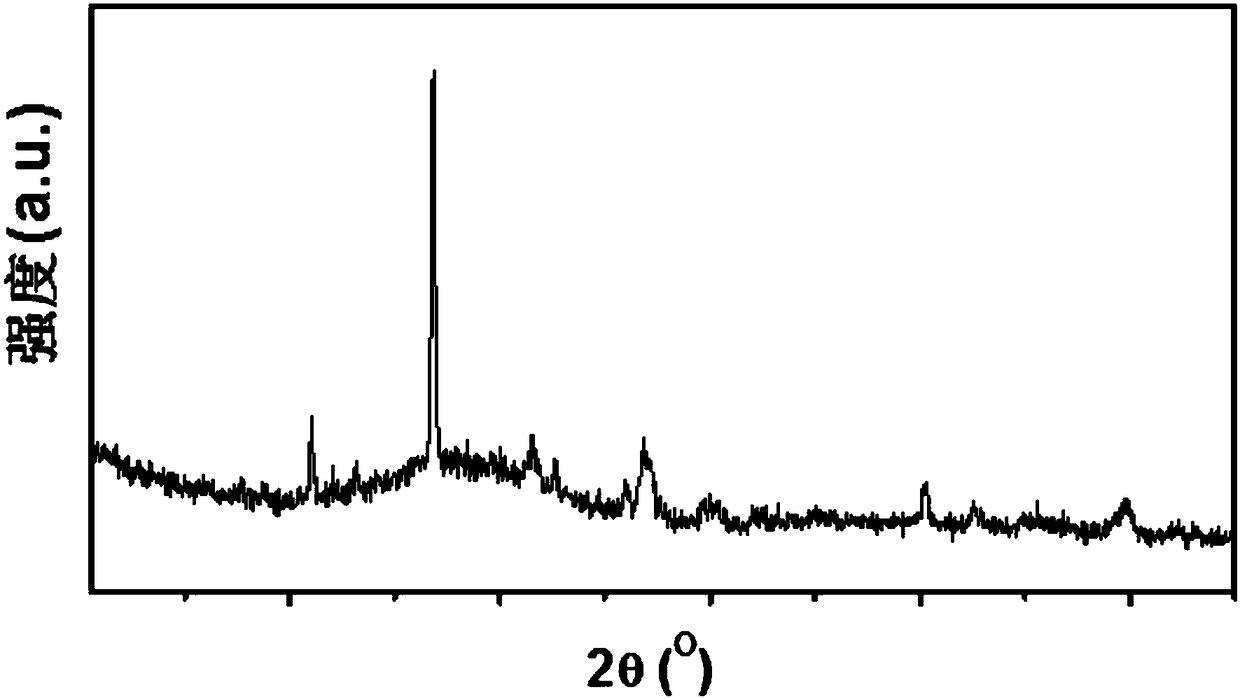

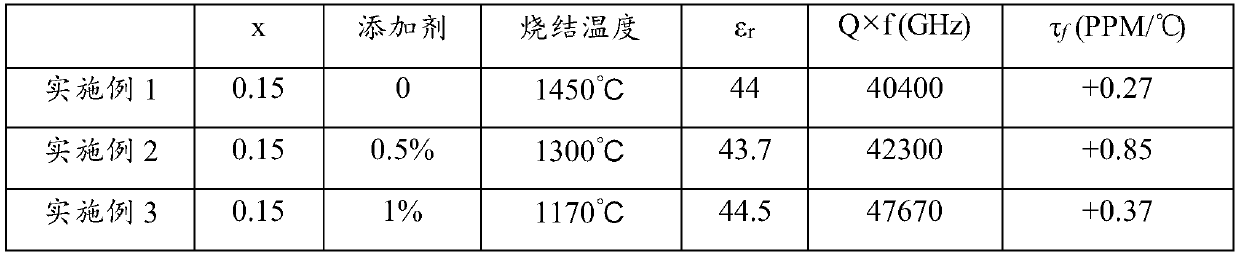

Microwave dielectric ceramic material and preparation method thereof

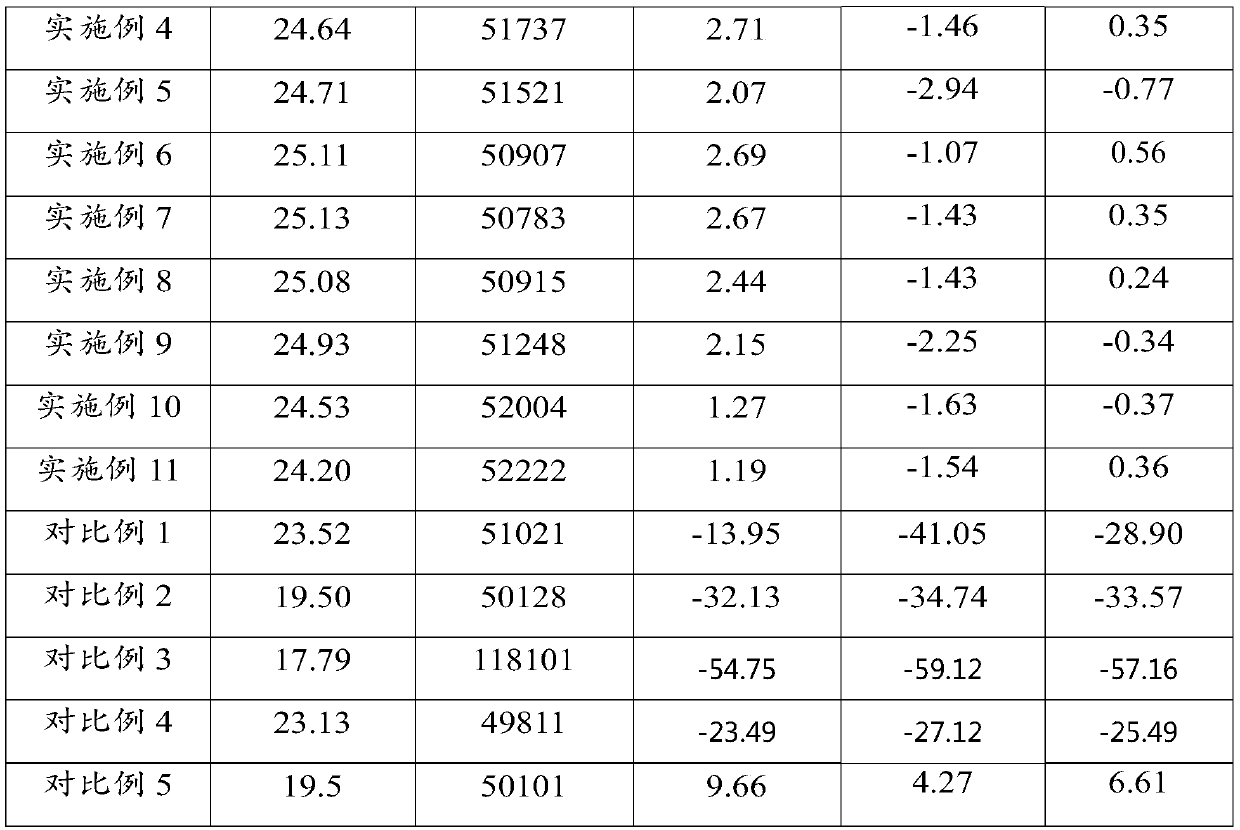

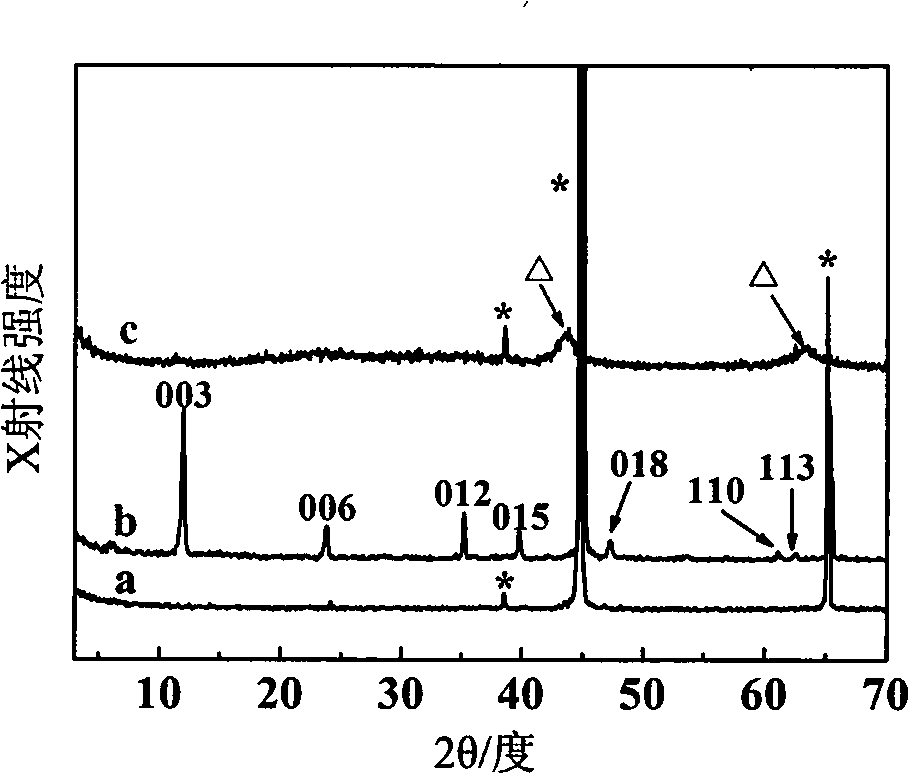

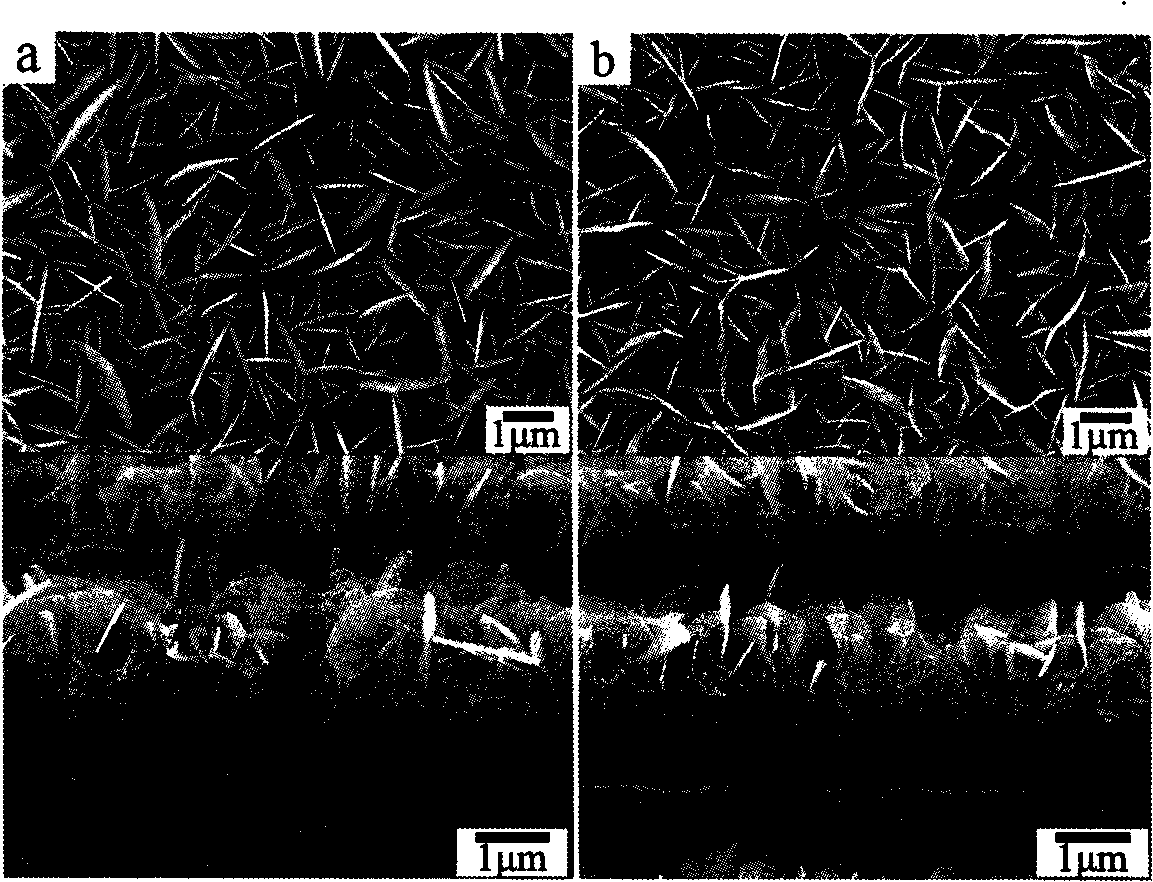

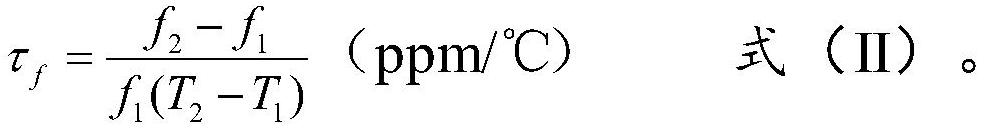

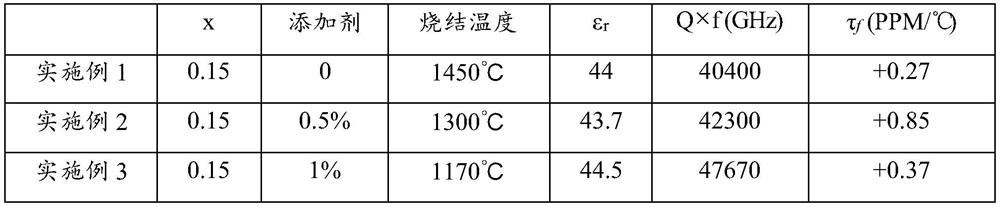

The invention provides a microwave dielectric ceramic material prepared by a composite oxide and an additive. The composite oxide is represented by the following general formula: MLa4Ti3M'O15, whereinM is Ca, Ba or Mg, and M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the invention is prepared by the compound oxide represented by a specificgeneral formula and the additive and is a medium-dielectric-constant microwave dielectric ceramic; the microwave dielectric ceramic material satisfies the dielectric constant near 45 and is continuously adjustable, has an extremely high Q*f value and good sintering stability, and also can achieve continuous adjustment of temperature drift to meet various needs. Experimental results show that therelative dielectric constant [epsilon]r of the microwave dielectric ceramic material provided by the invention is 43.2-46.8, the quality factor Q*f value is more than or equal to 46200 GHz, and the sintering is stable; at the same time, the temperature drift adjusting range is from -8 to +13 ppm / DEG C and can be continuously adjustable to meet various needs, and the microwave dielectric ceramic material has excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

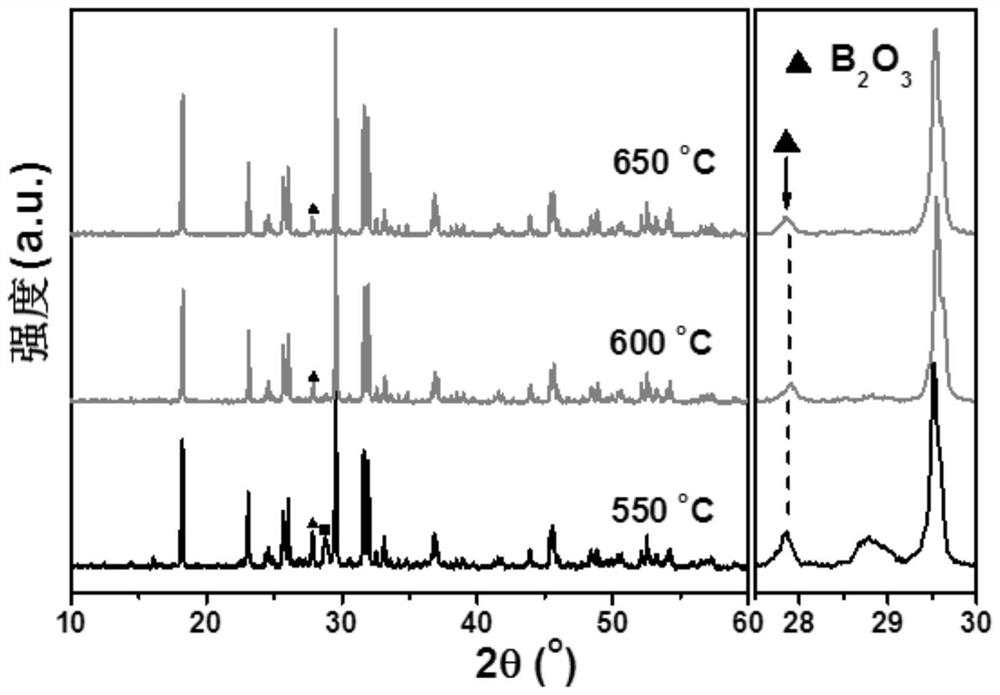

Dielectric-adjustable low-temperature co-firing ceramic material and preparation method thereof

The invention relates to the technical fields of electronic materials and devices, and particularly relates to a composite microwave ceramic material with dielectric adjustable characteristic and low-temperature co-firing characteristic and a preparation method of a low-temperature co-firing ceramic device. The composite microwave ceramic material with dielectric adjustable characteristic and low-temperature co-firing characteristic comprises the following components in percentage by weight: 50-88wt% of Ba[1-x]SrxTiO3 (x=0.4-0.6), 10-48wt% of AMoO4(A=Ba, Sr or Ca) and 2-10wt% of yB2O3.zLi2O (y / z=0.5-1). The composite material disclosed by the invention is characterized in that the Ba[1-x]SrxTiO3 is simultaneously subjected to compound doping modification by a AMoO4 modifying agent and a yB2O3.zLi2CO3 glass sintering additive so as to obtain the composite microwave ceramic material with low sintering temperature (900-950DEG C). The composite microwave ceramic material is suitable for being applied to a low-temperature co-fired ceramic (LTCC) technology and a microwave adjustable device.

Owner:TONGJI UNIV

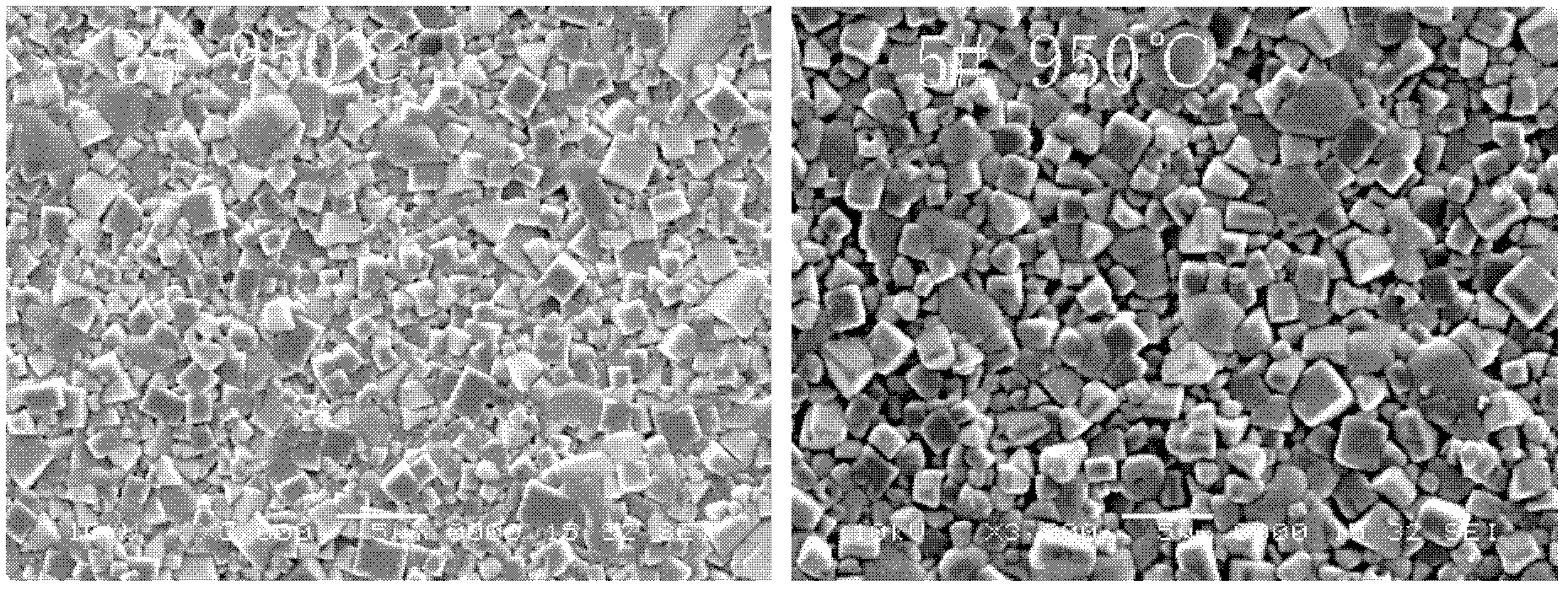

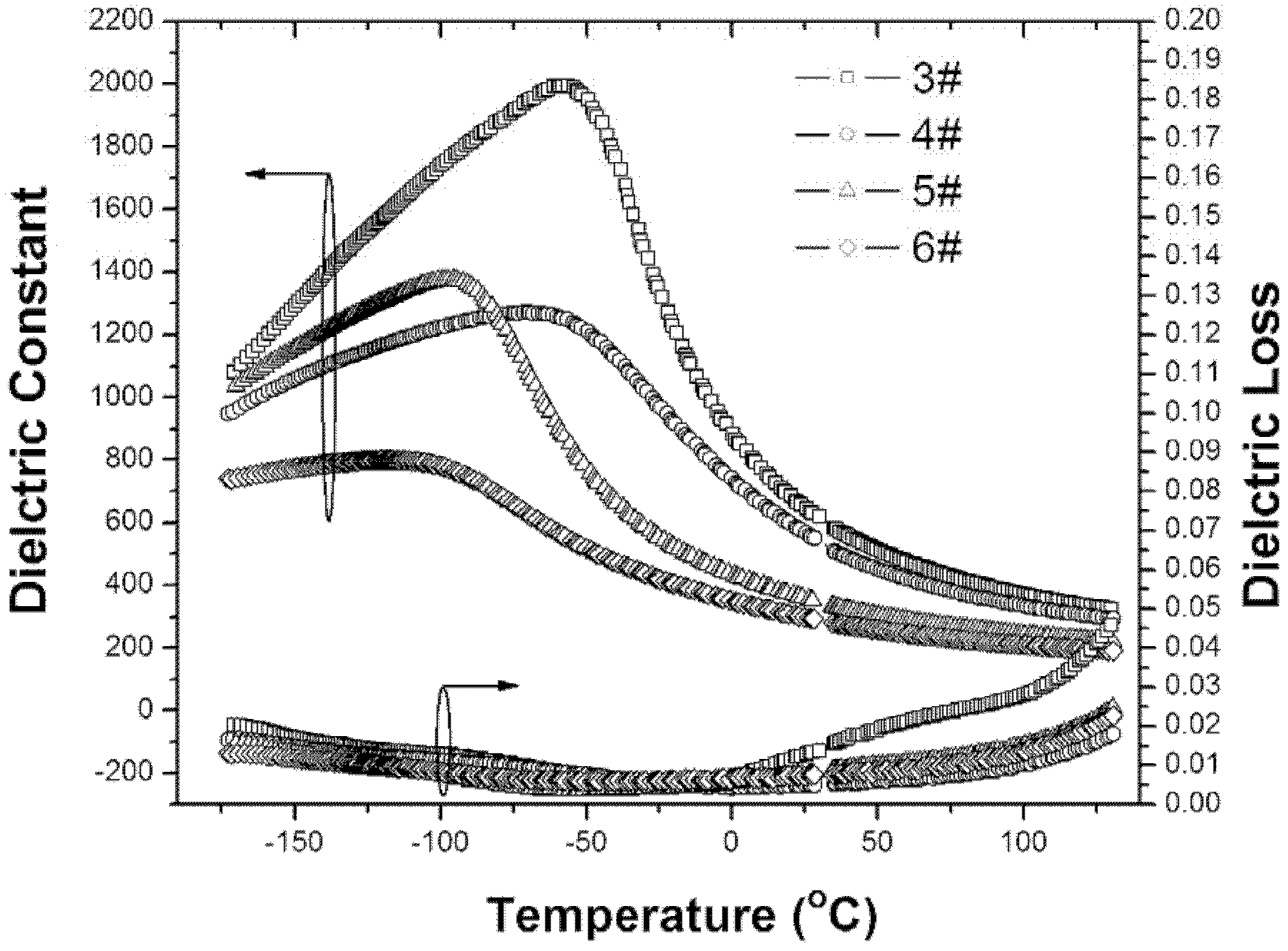

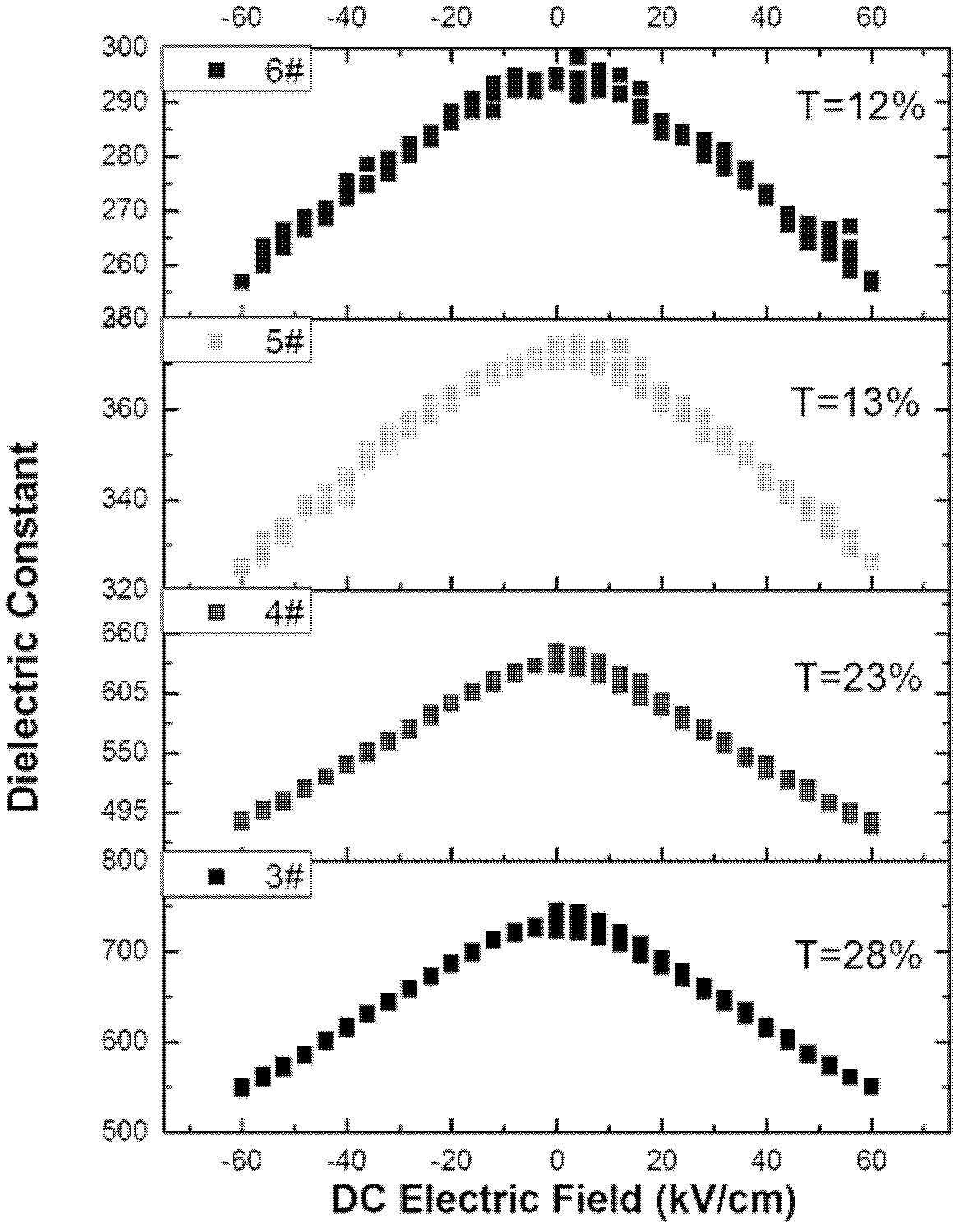

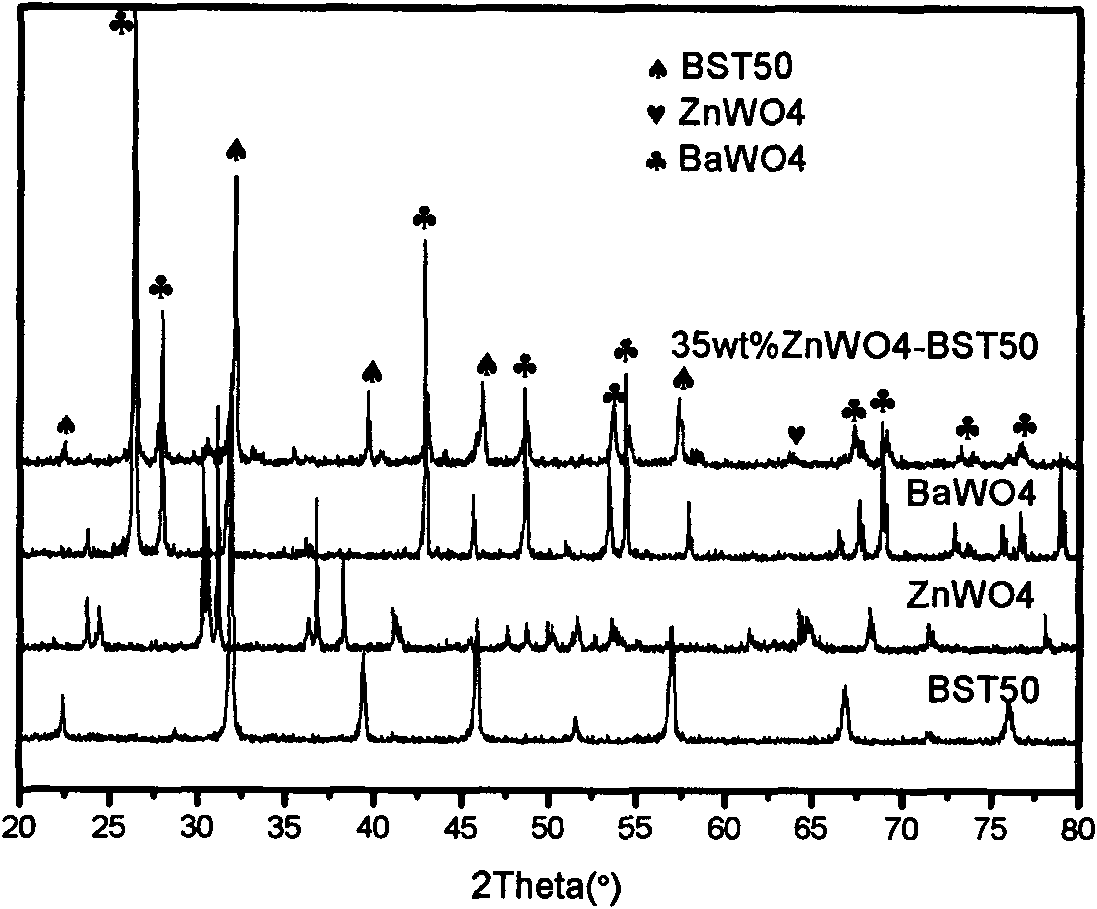

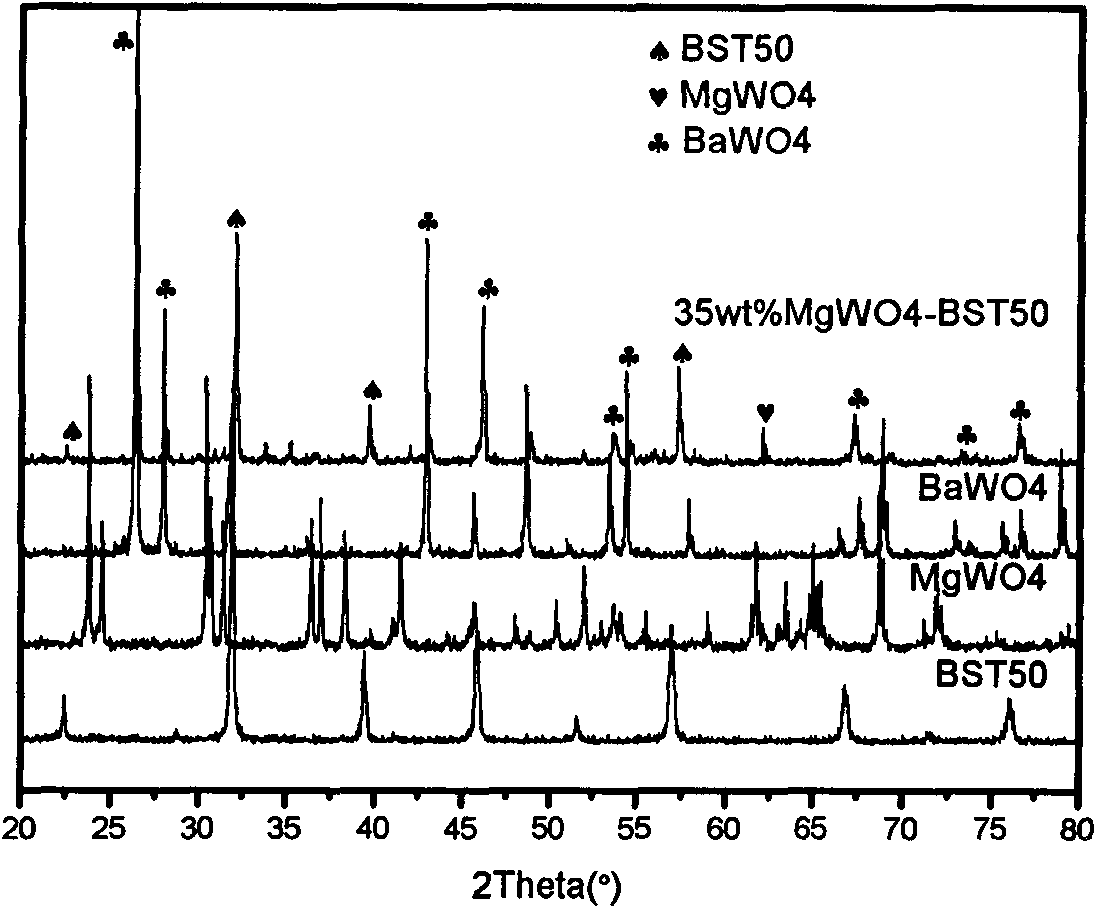

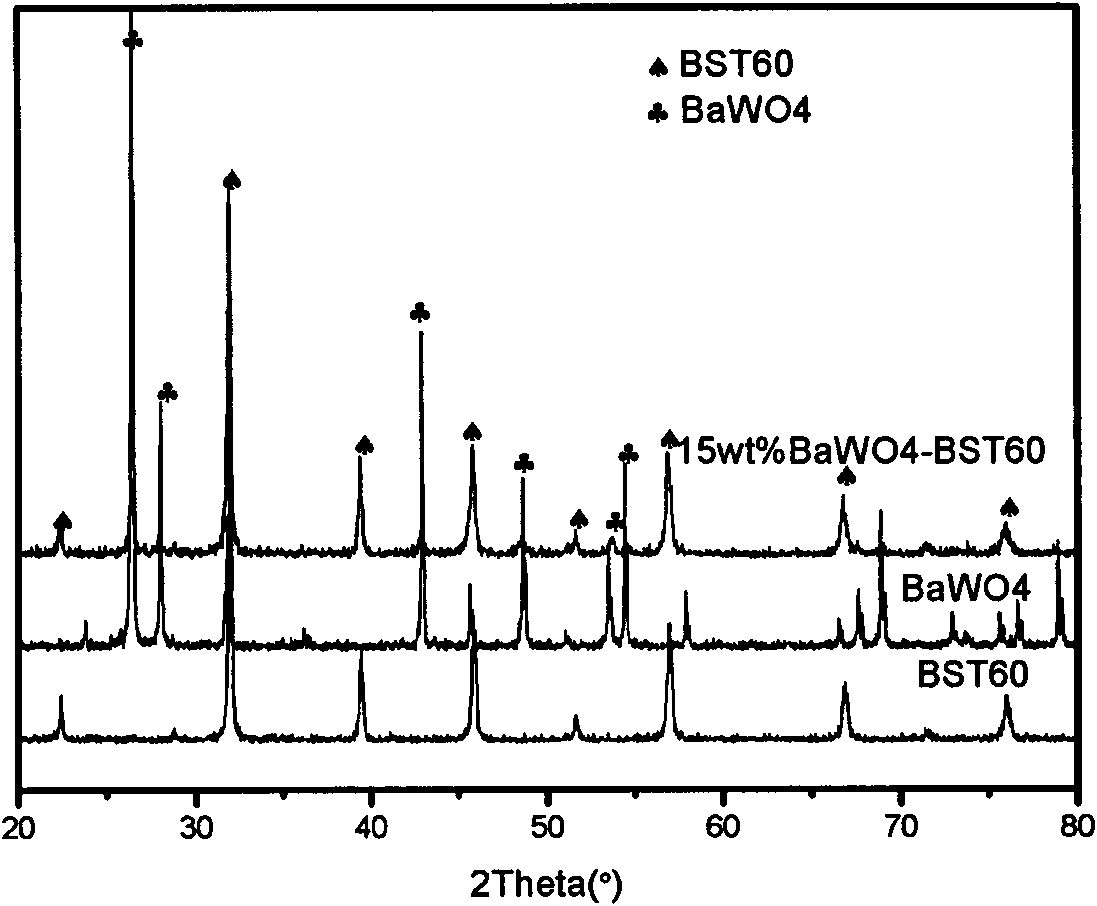

Dielectric tunable barium-strontium titanate-based composite tungstate microwave dielectric material and preparation thereof

The invention belongs to the technical field of electronic materials and parts, particularly relates to a dielectric tunable barium-strontium titanate-based composite tungstate ceramic dielectric material and preparation thereof. The components of the dielectric tunable barium-strontium titanate-based composite tungstate ceramic dielectric material are as follows: (1-x%)Ba(1-y)SryTiO3 plus x%AWO4,wherein A is selected from Ba, Ca, Mg or Zn; the value range of x is that x% is more than 0wt% and less than 100wt%; and the value range of y is more than or equal to 0.4 and less than or equal to 0.6. The dielectric tunable barium-strontium titanate-based composite tungstate ceramic dielectric material has high Q value, low dielectric constant and a certain dielectric turnable ratio, and can bebroadly used for preparing tunable microwave devices such as electric tuning microwave resonators, filters, mirowave polyrod antennas and the like.

Owner:TONGJI UNIV

Microwave medium ceramic with low dielectric constant and low loss and preparation method thereof

ActiveCN101817674ASimple preparation processFacilitate mass production and application promotionCeramicsTemperature coefficientLithium carbonate

The invention discloses a microwave medium ceramic with a low dielectric constant and a low loss and a preparation method thereof and belongs to the technical field of a microwave medium ceramic material. The microwave medium ceramic has the characteristics of low dielectric constant, low loss, high temperature stability, continuously adjustable dielectric constant and high machining property. The composition of the microwave medium ceramic is expressed by a general formula: (Zn1-xLi2x)O.ySiO2+a weight percent of TiO2, wherein x is more than or equal to 0 and less than or equal to 1; y is more than or equal to 0.5 and less than or equal to 1; a is more than or equal to 0 and less than or equal to 20; and a is mass percentage in (Zn1-xLi2x)O.ySiO2. The microwave medium ceramic is prepared by the following steps of: 1) confecting zinc oxide, lithium carbonate and silicon dioxide according to the general formula (Zn1-xLi2x)O.ySiO2+a weight percent of TiO2, mixing and pre-burning the mixture to synthesize a main component and crushing the main component into powder; 2) putting powdery TiO2 into the main component and mixing to obtain a powdery mixture; and 3) blanking and sintering the powdery mixture. A specific tau f modifier TiO2 is selected, so the material has a dielectric constant of between 7 and 9, a high quality factor value of Q*f0 and adjustable frequency temperature coefficient tau f. Simultaneously, the material has the advantages of simple preparation process, no special requirement on equipment and workshop environment and contribution to batch production, application and popularization.

Owner:JIANGSU JIANGJIA ELECTRONICS

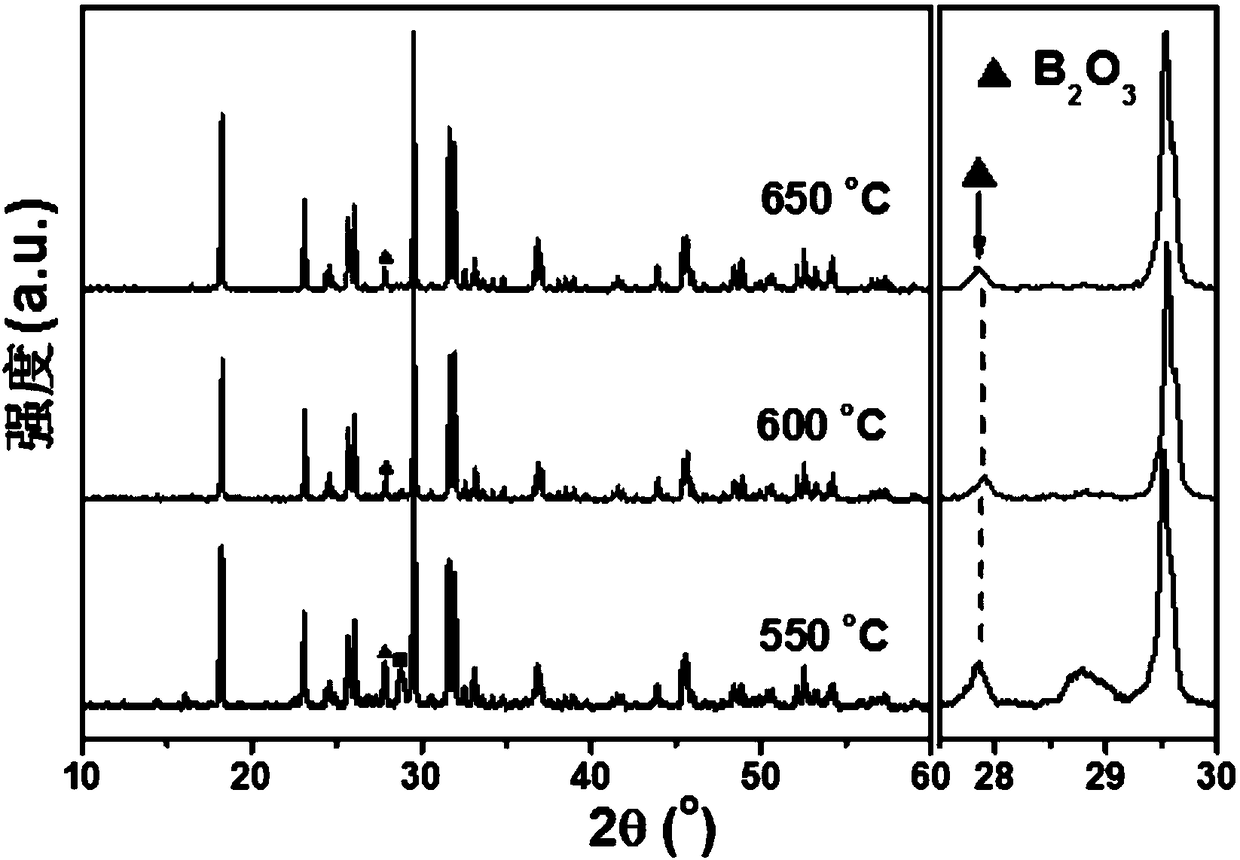

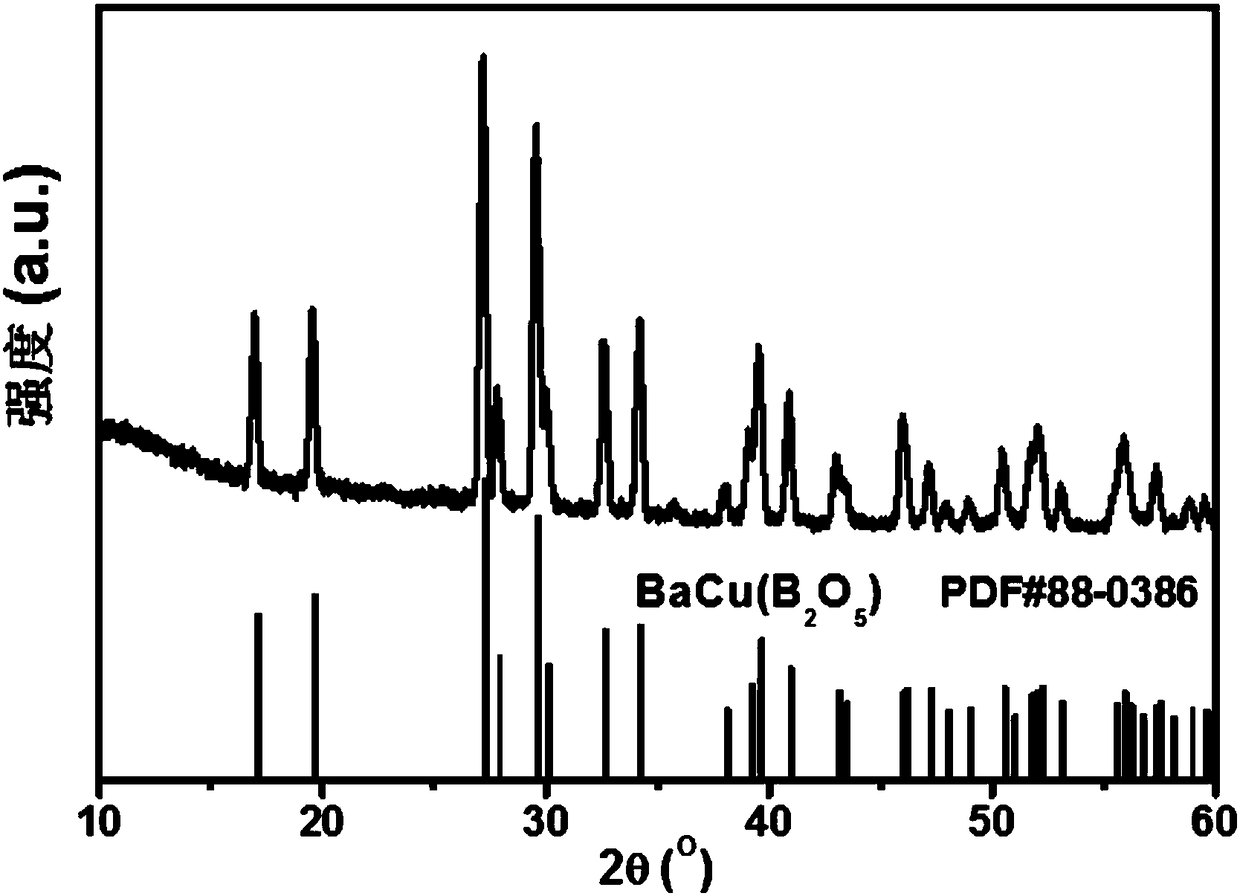

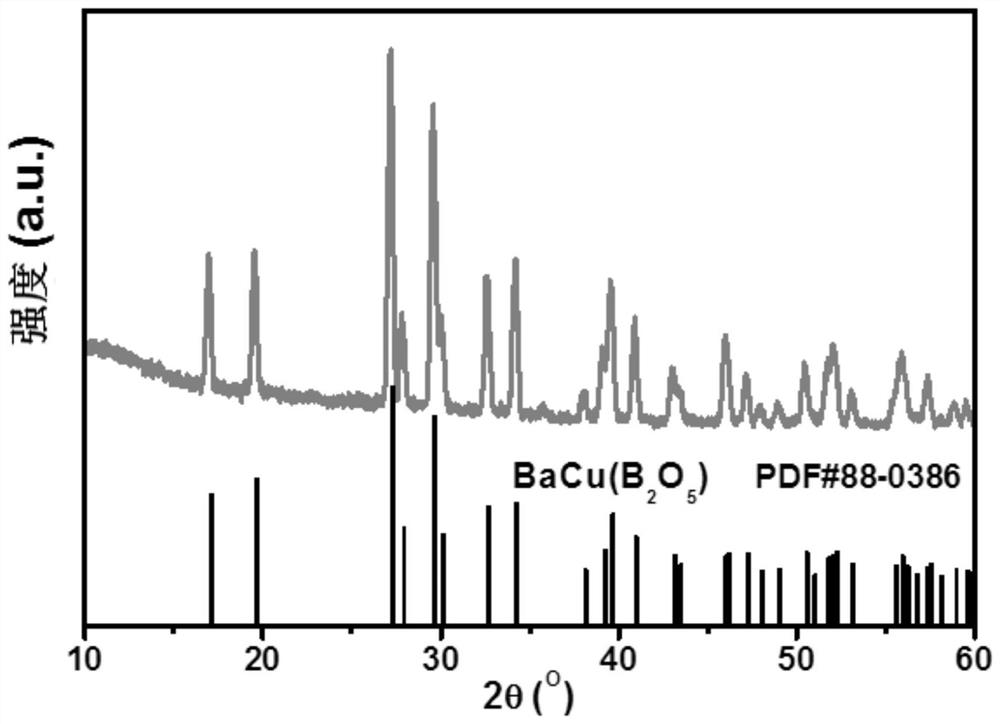

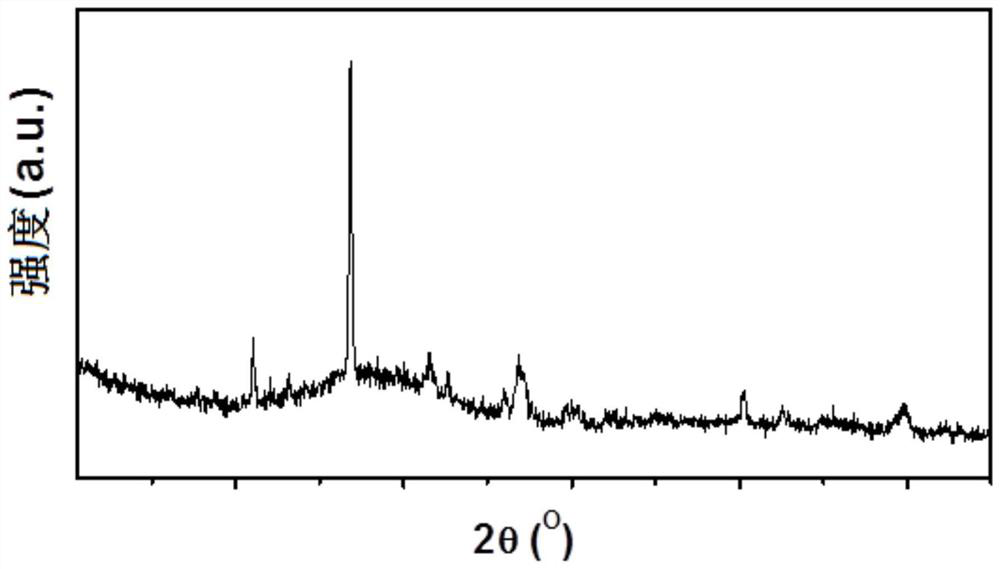

Low-dielectric constant low-loss low-temperature co-fired ceramic material and preparation method thereof

ActiveCN108218406AImprove Microwave PerformanceReduce manufacturing costDielectric lossCo-fired ceramic

The invention discloses a low-dielectric constant low-loss low-temperature co-fired ceramic material and a preparation method thereof. The ceramic material comprises the following components in partsby mass: 10-40 parts of Al2O3, 0-40 parts of SiO2, 0-60 parts of powder A, 0-60 parts of powder B, and 8-30 parts of powder C, and the material has at least one of the powder A and the powder B; the powder A comprises the following raw materials by parts: 40-70 parts of Bi2O3, 10-30 parts of ZnO, and 15-45 parts of H3BO3; the powder B comprises the following raw materials: a BaO precursor, CuO andH3BO3 which have a mol ratio being 1:1:2; and the powder C comprises the following raw materials: MgO and SiO2 which have the mol ratio being 2:1. The preparation method comprises the following steps: mixing the raw materials in proportion, performing steps of ball milling, drying, granulation, tabletting, glue discharging and sintering, and finally preparing the low-temperature co-fired ceramicmaterial which has the advantages that the dielectric constant is adjustable in a scope of 5.2-10, the dielectric loss is less than 0.002, and the insulation resistivity is higher than 1*1014 omega.cm.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

MAS-LT composite microwave dielectric ceramic and preparation method thereof

ActiveCN110357607AStable structureContinuously adjustable dielectric constantDielectric lossDielectric ceramics

The invention provides an MAS-LT composite microwave dielectric ceramic, which has a general formula shown in the following formula: Mg2-xBaxAl4Si5O18-Li2TiO3; wherein x = 0 ~ 0.16; the MAS-LT composite microwave dielectric ceramic contains 6-24% of Li2TiO3 by mass. Compared with the prior art, the MAS-LT composite microwave dielectric ceramic takes a composite oxide with the specific general formula as a main material, and can realize the dielectric constant between 4 and 6 and the continuous adjustment of the frequency temperature coefficient by adjusting the content of the Li2TiO3. Moreover, the MAS-LT composite microwave dielectric ceramic has a stable structure, a specific dielectric constant and a higher Q * f value, and the resonant frequency temperature coefficient is continuouslyadjustable. Experimental results show that the dielectric constant of the MAS-LT composite microwave dielectric ceramic is 4-5.8, the Q * f is more than or equal to 35,800 GHz, and the dielectric constant can reach 87,600 GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, the system has high Q * f value and low dielectric loss; at the same time, the resonantfrequency temperature coefficient is continuously adjustable between -12 ppm / DEG C to +13 ppm / DEG C, the sintering temperature is as low as 950 DEG C, and the formula can be flexibly adjusted.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Microwave dielectric ceramic and preparation method thereof

ActiveCN110372370AContinuously adjustable dielectric constantStable structureMicrowaveDielectric loss

The invention provides a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic has the following general formula: (1-x)Ca2Sm4Ti5O18-xSmAlO3, wherein x=0.05 to0.25. Compared with the prior art, the microwave dielectric ceramic provided by the invention uses a composite oxide represented by the above specific general formula as a main material, and throughadjustment of a content of SmAlO3, the dielectric constant is about 45, and the frequency temperature coefficient is continuously adjustable; the microwave dielectric ceramic has a stable structure, aspecific dielectric constant, a higher Q x f value, and a continuously-adjustable resonant frequency temperature coefficient; experimental results show that the microwave dielectric ceramic providedby the invention has the dielectric constant of 40 to 46.1, the Q x f value is >30000 GHz and can be as high as 49700 GHz, compared with other microwave dielectric ceramic system with the same dielectric constant, the system provided by the invention has a high Q x f value and low dielectric loss; and at the same time, the resonant frequency temperature coefficient is continuously adjustable in the range from -7.4 PPM / DEG C to +6.7 PPM / DEG C, and the microwave dielectric ceramic provided by the invention is suitable for large-scale commercial use.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

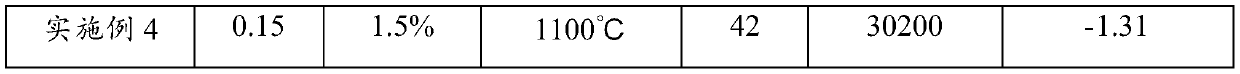

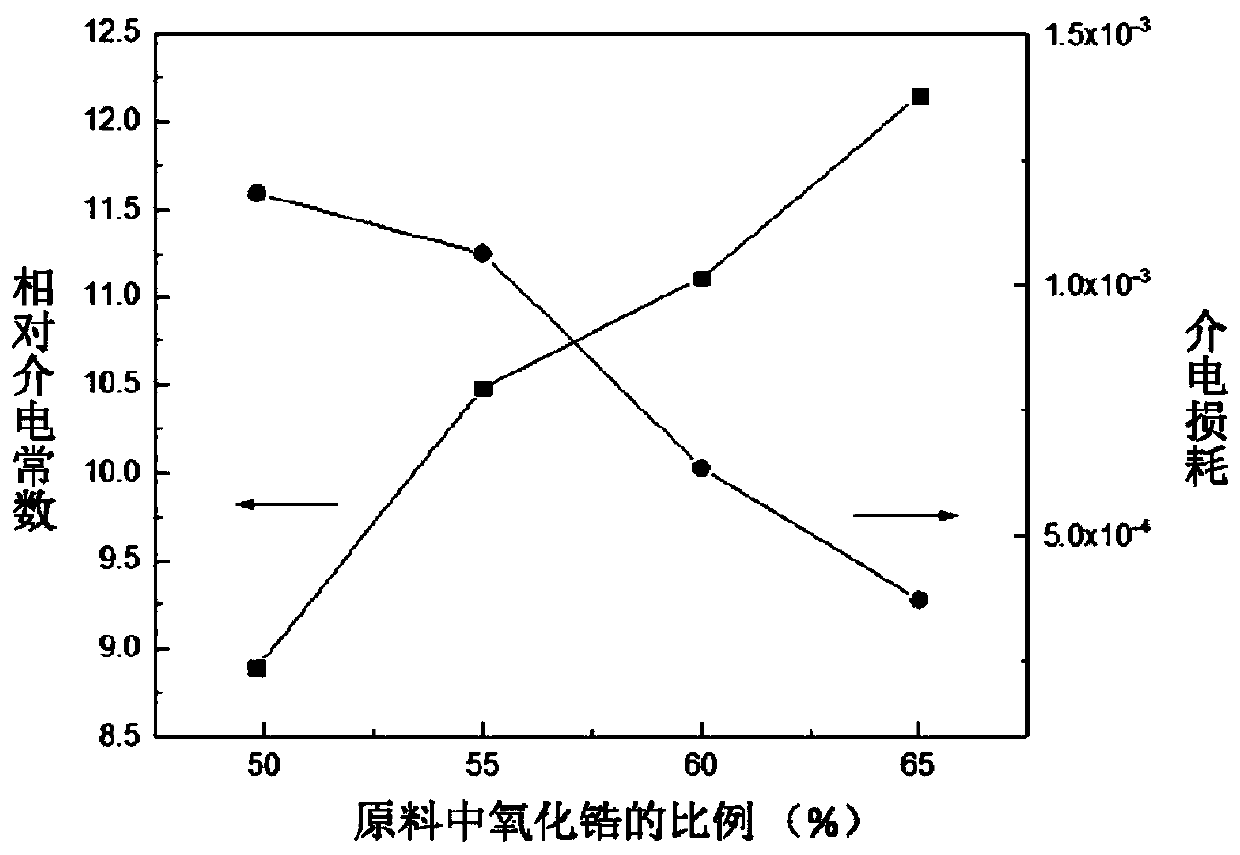

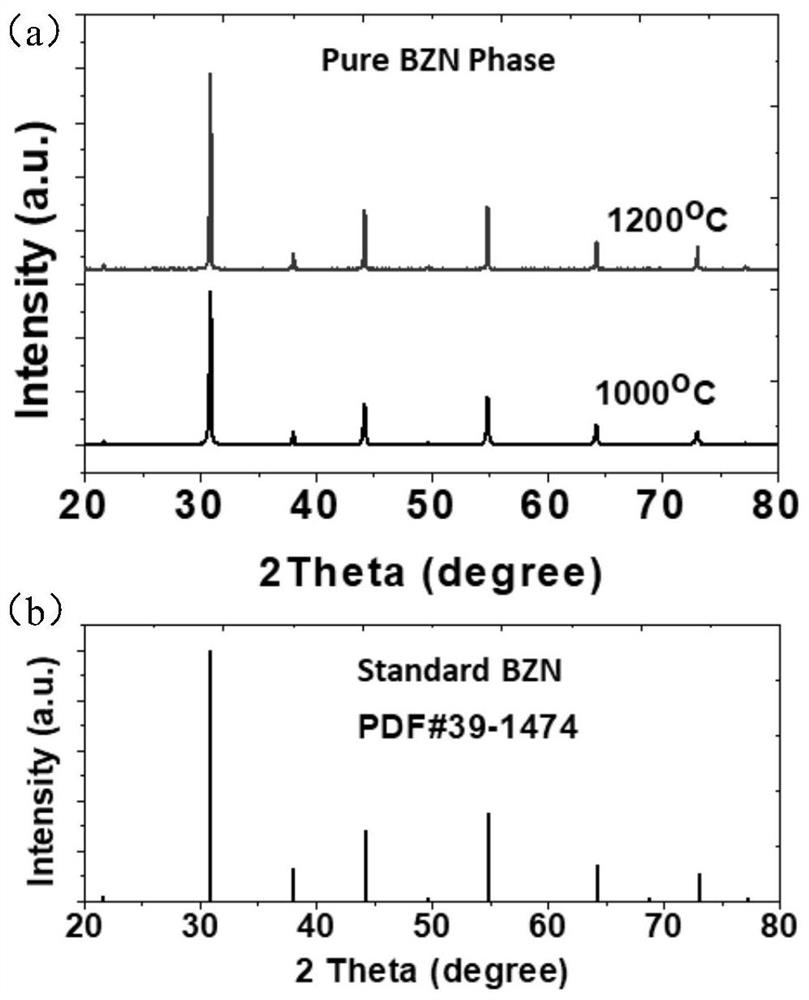

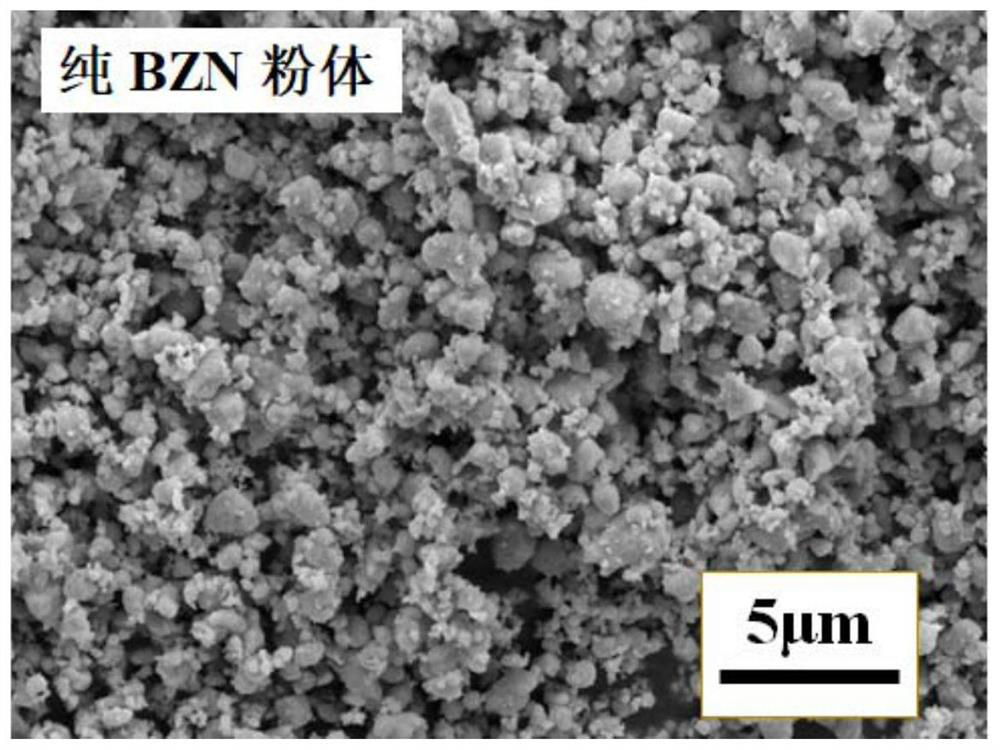

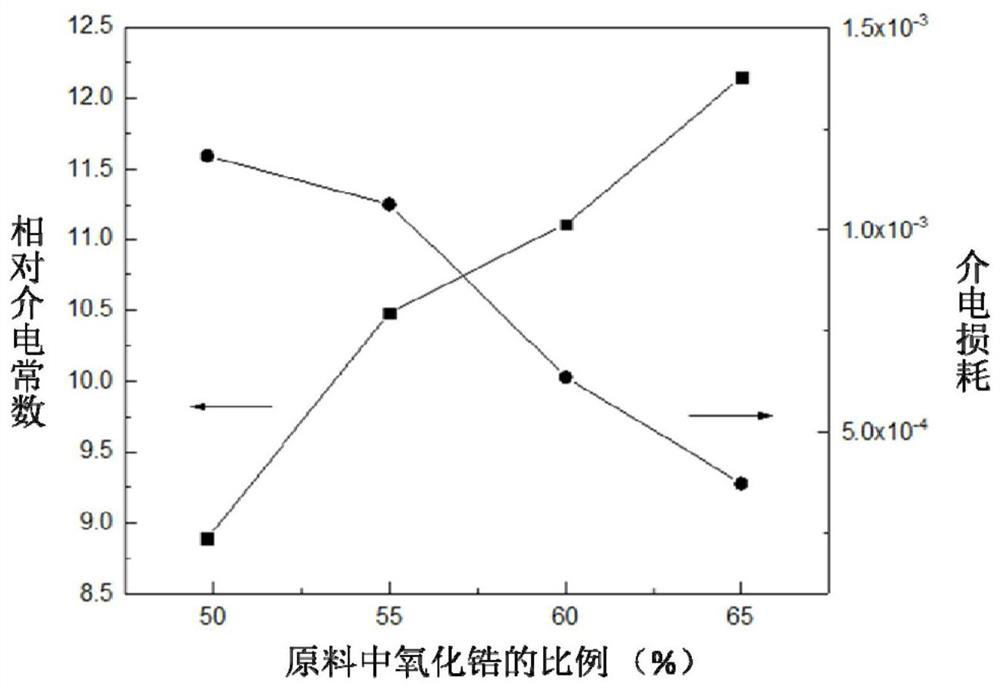

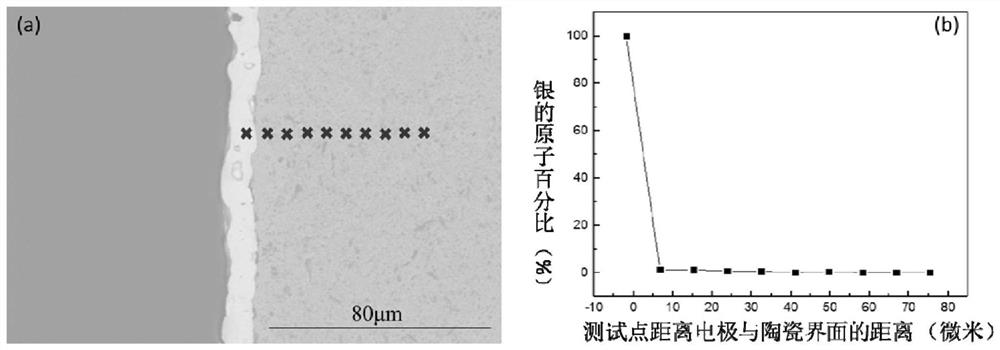

Dielectric constant series adjustable low-temperature co-fired dielectric material and preparation method thereof

ActiveCN111302792ADielectric constant series adjustableAdjustable dielectric constantCeramicsSilver electrodeDielectric loss

The invention discloses a dielectric constant series adjustable low-temperature co-fired dielectric material. The low-temperature co-fired dielectric material comprises a zirconia main phase and a silicon-based amorphous phase filler, wherein a weight ratio of the zirconia main phase to the silicon-based amorphous phase filler is (40-65): (35-60), and the weight percentage of SiO2 in the silicon-based amorphous phase filler is greater than or equal to 50%. By controlling the ratio of the zirconium oxide main phase to the silicon-based amorphous phase filler, the dielectric constant of the obtained material is continuously adjustable within a relatively wide range of 7-12, and dielectric loss can be as low as 0.1%@1 MHz. A material system obtained in the invention can be sintered at 800-900DEG C, can be compatibly co-sintered with a silver electrode, and can be used as a low-temperature co-sintered dielectric material. The invention also discloses a preparation method of the dielectricconstant series adjustable low-temperature co-fired dielectric material.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Microwave dielectric ceramic material, preparation method thereof and electronic device

PendingCN112707728ALow dielectric lossContinuously adjustable dielectric constantDivalent metalDielectric loss

The invention discloses a microwave dielectric ceramic material and a preparation method thereof, and an electronic device, the microwave dielectric ceramic material is prepared by sintering a raw material comprising a ceramic main crystal phase and a sintering aid, the sintering aid is a composite fluoride, the composite fluoride is selected from at least two of LF, MF2, ReF3 and NF4, L is an alkali metal element, M is a divalent metal element, Re is a rare earth metal element, Al, Ga or Bi, and N are valence metal elements. According to the invention, the composite fluoride with a low melting point is used as a sintering aid, and the microwave dielectric ceramic material with excellent microwave properties such as continuously adjustable medium dielectric constant, low dielectric loss and the like can be prepared by sintering at a lower temperature.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and preparation method thereof

Owner:TSINGHUA UNIV

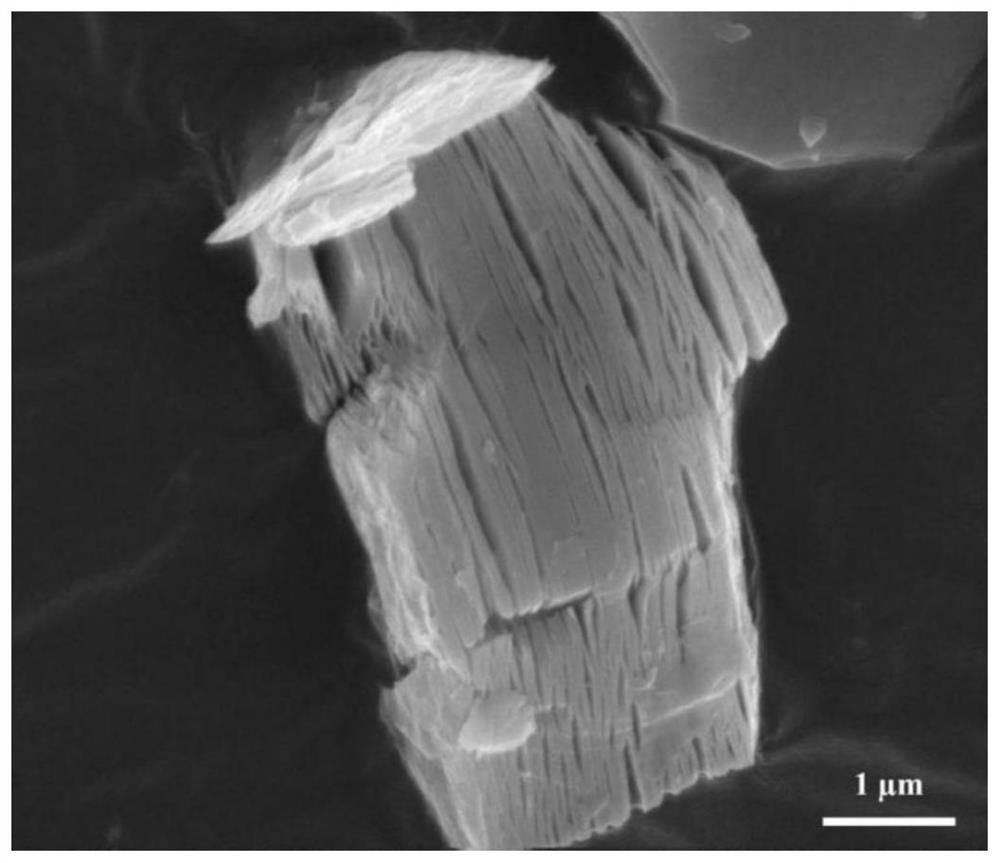

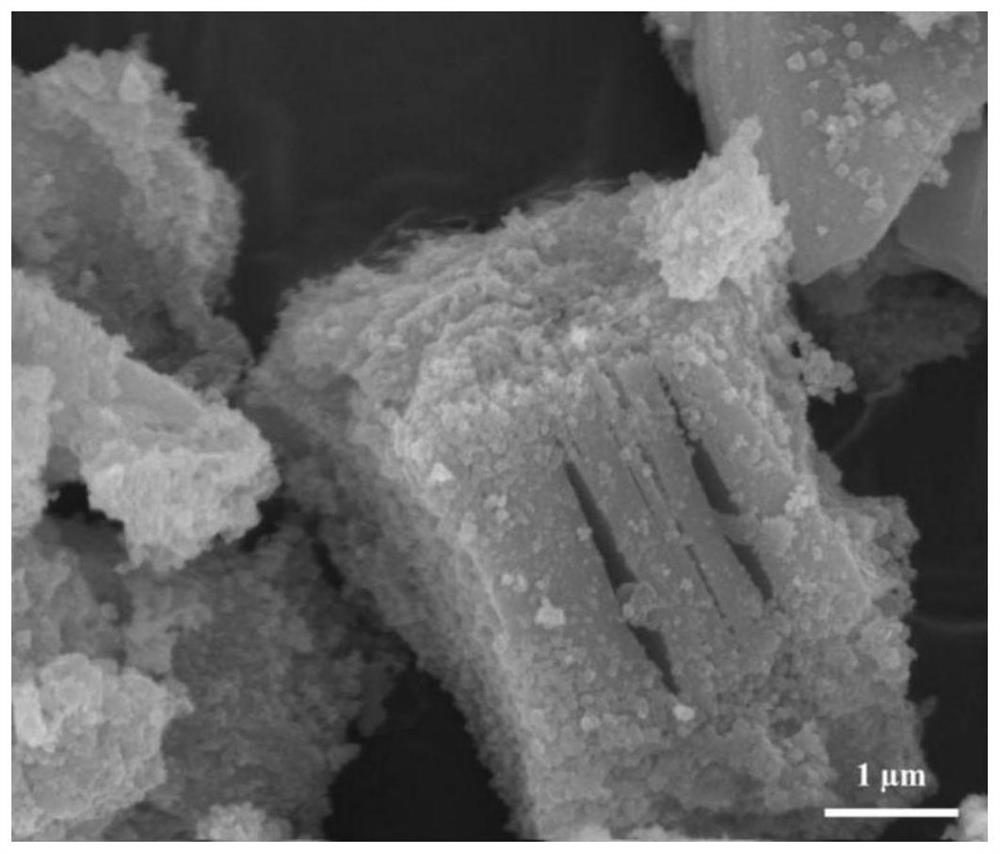

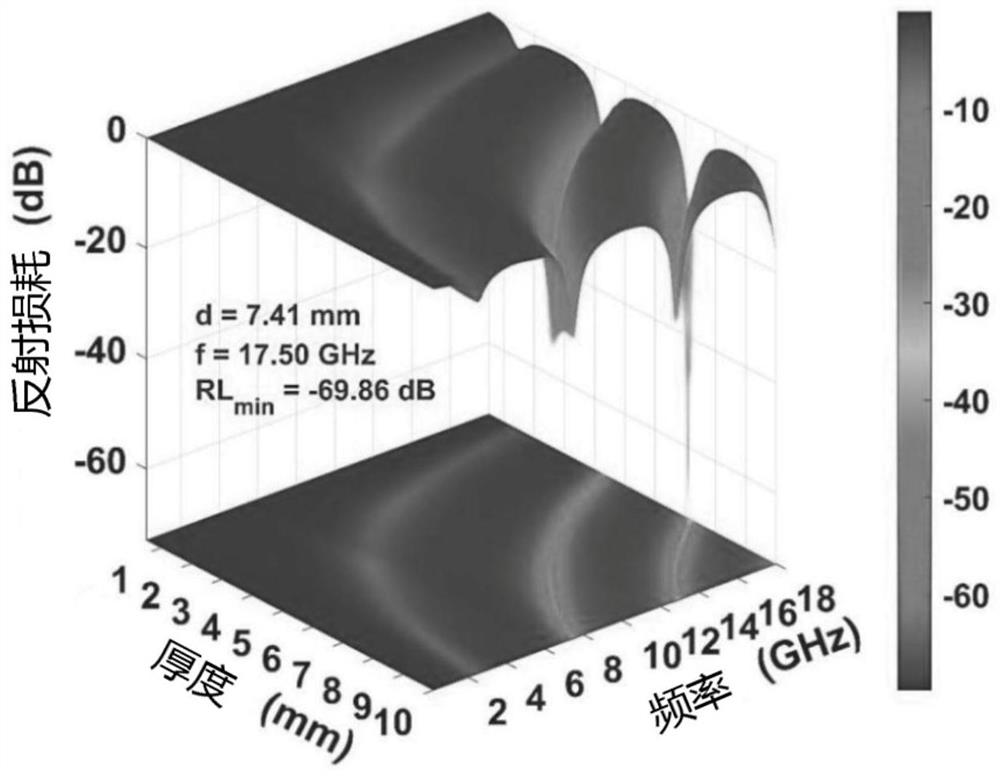

MXene/zinc-manganese ferrite/foamed silicone rubber wave-absorbing composite material as well as preparation method and application thereof

PendingCN114058186AContinuously adjustable structureContinuously adjustable dielectric constantMagnetic/electric field screeningBroadbandPlatinum catalyst

The invention discloses an MXene / zinc-manganese ferrite / foamed silicone rubber wave-absorbing composite material as well as a preparation method and application thereof. The composite material is prepared from an MXene / zinc-manganese ferrite hybrid wave-absorbing agent, vinyl silicone oil, hydrogen-containing silicone oil, hydroxyl silicone oil, a platinum catalyst and an inhibitor through heat vulcanization foaming. According to the MXene / zinc-manganese ferrite hybrid wave-absorbing agent, zinc-manganese ferrite grows on the surface of MXene and between sheet layers in situ. The composite material is a wave-absorbing composite material with light weight, broadband, strong absorption and flexibility, has certain functions of heat preservation, heat insulation, damping, noise reduction and the like, can be widely applied to the fields of electronics, electric appliances, communication, power batteries, military industry and the like, can be used for preparing low-density broadband wave-absorbing sheets through high-precision rolling and hot drying tunnel vulcanization processes, and is attached to the surfaces of electronic equipment and components needing to absorb waves.

Owner:SOUTH CHINA UNIV OF TECH +1

Low-temperature co-fired ceramic material with low dielectric constant and low loss and preparation method thereof

ActiveCN108218406BImprove Microwave PerformanceReduce manufacturing costDielectric lossDielectric permittivity

The invention discloses a low-dielectric constant low-loss low-temperature co-fired ceramic material and a preparation method thereof. The ceramic material comprises the following components in partsby mass: 10-40 parts of Al2O3, 0-40 parts of SiO2, 0-60 parts of powder A, 0-60 parts of powder B, and 8-30 parts of powder C, and the material has at least one of the powder A and the powder B; the powder A comprises the following raw materials by parts: 40-70 parts of Bi2O3, 10-30 parts of ZnO, and 15-45 parts of H3BO3; the powder B comprises the following raw materials: a BaO precursor, CuO andH3BO3 which have a mol ratio being 1:1:2; and the powder C comprises the following raw materials: MgO and SiO2 which have the mol ratio being 2:1. The preparation method comprises the following steps: mixing the raw materials in proportion, performing steps of ball milling, drying, granulation, tabletting, glue discharging and sintering, and finally preparing the low-temperature co-fired ceramicmaterial which has the advantages that the dielectric constant is adjustable in a scope of 5.2-10, the dielectric loss is less than 0.002, and the insulation resistivity is higher than 1*1014 omega.cm.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

A kind of microwave dielectric ceramic material and preparation method thereof

ActiveCN108821768BContinuously adjustable dielectric constantHigh Q*f valueDielectricDielectric permittivity

The invention provides a microwave dielectric ceramic material, which is prepared from composite oxides and additives; the composite oxide has the general formula shown in the following formula: MLa 4 Ti 3 M'O 15 ; Wherein, M is Ca, Ba or Mg; M' is Al, Sb or Bi. Compared with the prior art, the microwave dielectric ceramic material provided by the present invention is prepared from a composite oxide of a specific general formula and additives, and is a microwave dielectric ceramic with a medium dielectric constant; the microwave dielectric ceramic material satisfies a dielectric constant near 45 and It is continuously adjustable, and has a very high Q*f value and good sintering stability. At the same time, it can realize continuous adjustment of temperature drift to meet various needs. The experimental results show that the relative permittivity ε of the microwave dielectric ceramic material provided by the invention r 43.2~46.8, quality factor Q*f value ≥46200GHz, and sintering is stable; at the same time, the temperature drift adjustment range is ‑8~+13ppm / ℃, and can be continuously adjusted to meet various needs. It has very excellent application value and market potential.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

A substrate-integrated waveguide microwave tunable filter based on liquid crystal material

InactiveCN105489987BEfficient packagingImplement encapsulationWaveguide type devicesBandpass filteringRadar systems

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

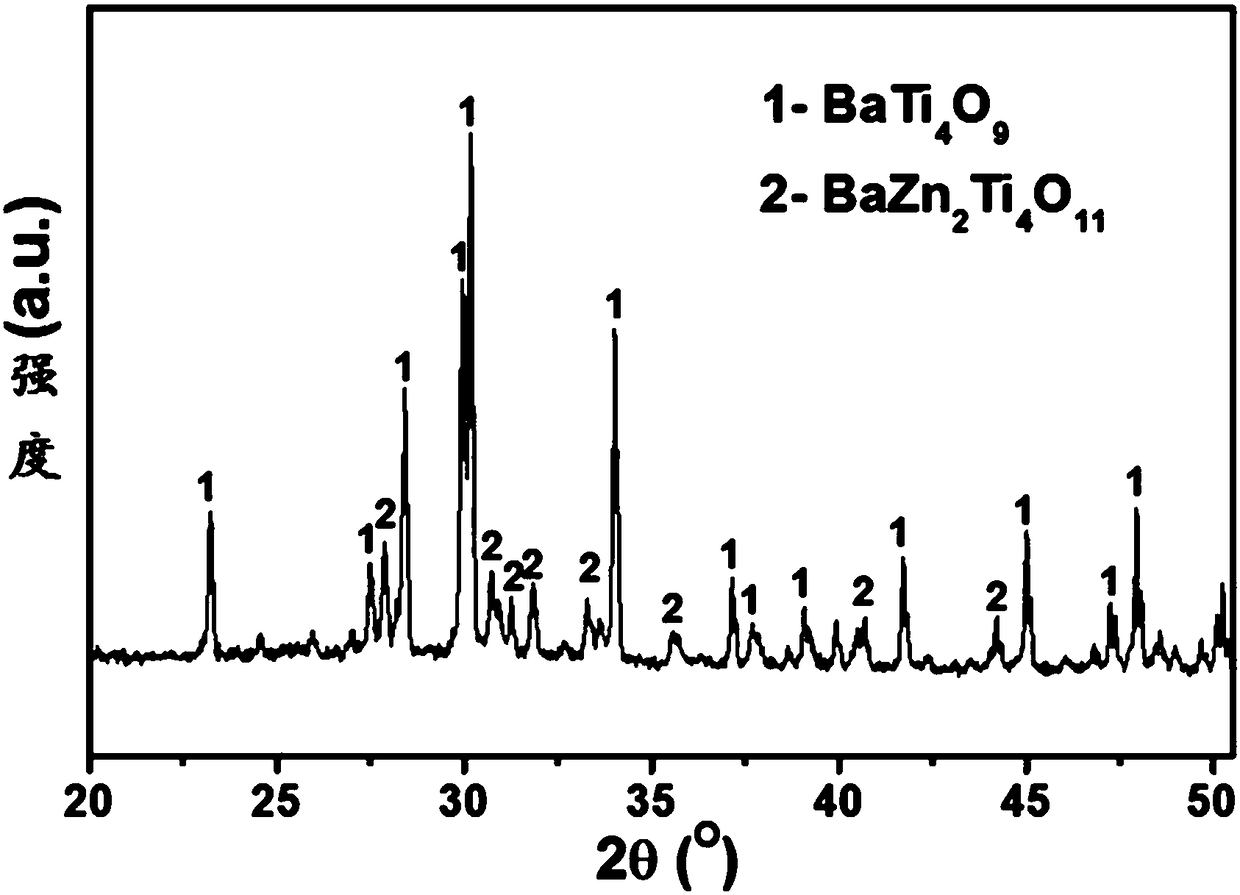

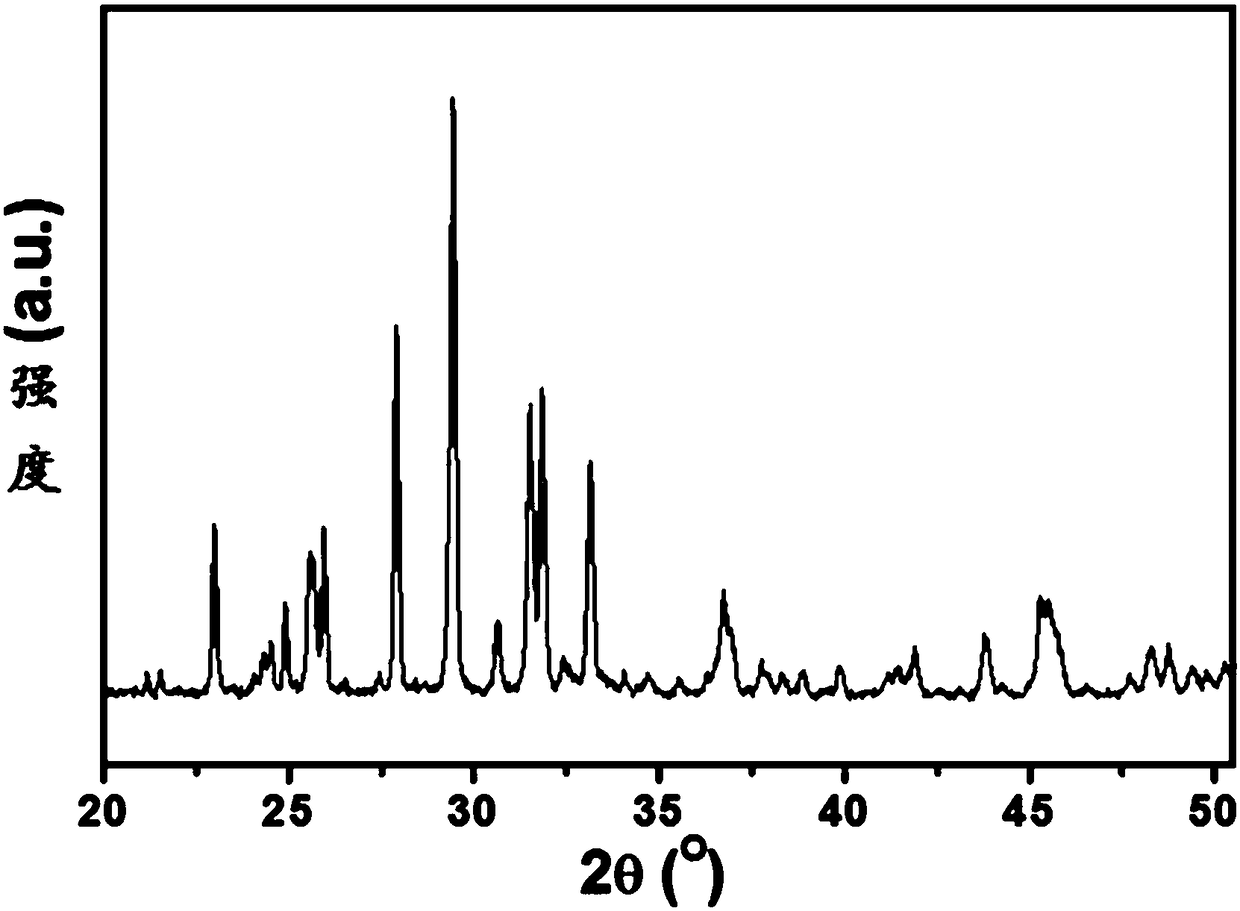

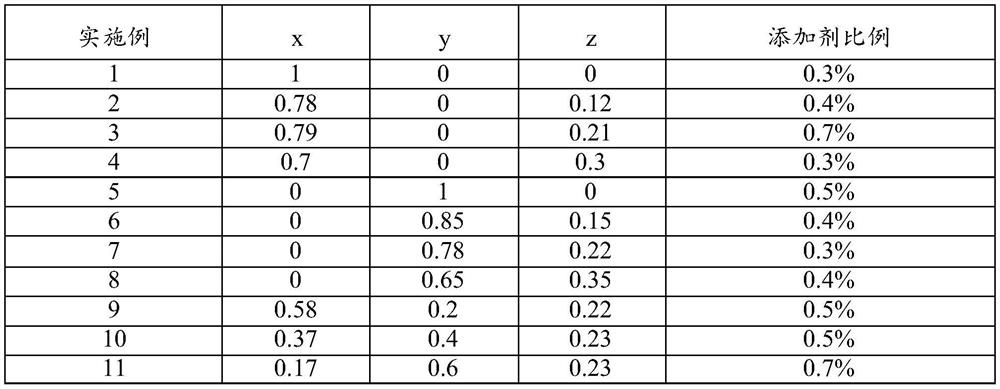

Medium low temperature co-fired ceramic material and preparation method thereof

The invention discloses a medium low temperature co-fired ceramic material and a preparation method thereof. The medium low temperature co-fired ceramic material comprises 40-65 parts by mass of a Ba-Zn-Ti compound, 35-55 parts by mass of powder A and 0-5 parts by mass of powder B, wherein the powder A is a pre-sintered body obtained by firing the following components in parts by mass: 0-15 partsof SiO2, 0-65 parts of BaCO3, 15-55 parts of H3BO3, 0-15 parts of ZnO and 0-70 parts of Bi2O3; and the powder B is one or a combination of more of Co3O4, MnCO3, SrTiO3, La2O3, CuO and Cr2O3. The material is not reacted with silver, and can be widely applied to manufacturing multilayered dielectric resonators, microwave antennas, filters and other microwave devices. Moreover, the raw materials usedby the material are rich, the cost is low, the preparation process is simple, and industrial production is facilitated.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

A kind of composite microwave dielectric ceramic and preparation method thereof

The invention provides a composite microwave dielectric ceramic, which has the general formula shown in the following formula: Mg x Zn y al 2 o 4 —zSr 2 TiO 4 ; Wherein, x+y+z=1, z≤0.35. Compared with the prior art, the present invention will have Mg with negative resonant frequency temperature coefficient x Zn y al 2 o 4 Ceramic and Sr with positive resonant frequency temperature coefficient 2 TiO 4 The ceramics are composited, so that the dielectric constant of the composite microwave dielectric ceramics can be adjusted between 8.5 and 18.63, and Q×f>59200GHz can be as high as 97534GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, the Q of this system is The value of ×f is large, and the dielectric loss is low; at the same time, the temperature coefficient of the resonant frequency is continuously adjustable between ‑77~+39PPM / ℃, the formula can be adjusted flexibly, there is no risk of titanium reduction, high reliability, and suitable for large-scale commercial use.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

A kind of zhts microwave dielectric ceramic and preparation method thereof

ActiveCN109761601BStable structureContinuously adjustable dielectric constantDielectric lossDielectric ceramics

The invention provides a ZHTS microwave dielectric ceramic and a preparation method thereof. The ZHTS microwave dielectric ceramic has a general formula shown in formula (I): Zr x f y Ti 2 sn z o 8+2x+2y+2z ; wherein, 0≤y≤0.03, 0≤z≤0.5, x+y+z=1. Compared with the prior art, the ZHTS microwave dielectric ceramic provided by the present invention uses the compound oxide of the above-mentioned specific general formula as the main material, and by adjusting the content of Zr, Hf, and Sn, the dielectric constant can be around 40, and the temperature coefficient of frequency can be achieved. It is continuously adjustable; moreover, Hf partly replaces Zr to activate the lattice structure to increase the Qf value; the ZHTS microwave dielectric ceramic structure is stable, has a specific dielectric constant and a high Qf value, and the temperature coefficient of the resonant frequency is continuously adjustable. Experimental results show that the dielectric constant of ZHTS microwave dielectric ceramics provided by the present invention is between 38 and 43, Qf > 51500 GHz, and can be as high as 68600 GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, the Qf value of this system is larger , low dielectric loss; at the same time, the resonant frequency temperature coefficient is continuously adjustable between -10.9ppm / ℃~+23ppm / ℃.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

A kind of microwave dielectric ceramic and preparation method thereof

ActiveCN110372370BContinuously adjustable dielectric constantStable structureDielectric lossDielectric ceramics

The invention provides a microwave dielectric ceramic and a preparation method thereof, the microwave dielectric ceramic has a general formula shown in the following formula: (1-x)Ca 2 SM 4 Ti 5 o 18 ‑xSmAlO 3 ; Wherein, x=0.05~0.25. Compared with the prior art, the microwave dielectric ceramic provided by the present invention uses the compound oxide of the above-mentioned specific general formula as the main material, and adjusts SmAlO 3 The content of the dielectric constant can be around 45, and the frequency temperature coefficient can be continuously adjusted; moreover, the microwave dielectric ceramic has a stable structure, a specific dielectric constant and a high Q×f value, and the resonant frequency temperature coefficient can be continuously adjusted. Tune. Experimental results show that the dielectric constant of the microwave dielectric ceramic provided by the present invention is between 40 and 46.1, and Q×f>30000GHz, which can be as high as 49700GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, this system Q×f High f value and low dielectric loss; at the same time, the resonant frequency temperature coefficient is continuously adjustable between -7.4PPM / ℃~+6.7PPM / ℃, suitable for large-scale commercial use.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Dielectric-adjustable low-temperature co-firing ceramic material and preparation method thereof

InactiveCN102633500BChange and control dielectric propertiesPlay the role of liquid phase sinteringElectronic materialsCeramic

The invention relates to the technical fields of electronic materials and devices, and particularly relates to a composite microwave ceramic material with dielectric adjustable characteristic and low-temperature co-firing characteristic and a preparation method of a low-temperature co-firing ceramic device. The composite microwave ceramic material with dielectric adjustable characteristic and low-temperature co-firing characteristic comprises the following components in percentage by weight: 50-88wt% of Ba[1-x]SrxTiO3 (x=0.4-0.6), 10-48wt% of AMoO4(A=Ba, Sr or Ca) and 2-10wt% of yB2O3.zLi2O (y / z=0.5-1). The composite material disclosed by the invention is characterized in that the Ba[1-x]SrxTiO3 is simultaneously subjected to compound doping modification by a AMoO4 modifying agent and a yB2O3.zLi2CO3 glass sintering additive so as to obtain the composite microwave ceramic material with low sintering temperature (900-950DEG C). The composite microwave ceramic material is suitable for being applied to a low-temperature co-fired ceramic (LTCC) technology and a microwave adjustable device.

Owner:TONGJI UNIV

A low-temperature co-fired dielectric material with adjustable dielectric constant series and its preparation method

ActiveCN111302792BDielectric constant series adjustableAdjustable dielectric constantCeramicsSilver electrodeDielectric loss

The invention discloses a low-temperature co-fired dielectric material with adjustable dielectric constant series. The low-temperature co-fired dielectric material includes a zirconia main phase and a silicon-based amorphous phase filler. The weight ratio of the crystalline phase filler is: main phase of zirconia: silicon-based amorphous phase filler = 40-65: 35-60; the SiO 2 The weight percent content in the silicon-based amorphous phase filler is ≥50%. In the present invention, by controlling the ratio of the zirconia main phase and the silicon-based amorphous phase filler, the dielectric constant of the obtained material can be continuously adjusted within a wide range of 7-12, and the dielectric loss can be as low as 0.1%@1MHz. The material system can be sintered at 800-900°C, can be co-fired compatible with silver electrodes, and can be used as a low-temperature co-fired dielectric material. The invention also discloses a preparation method of the low-temperature co-fired dielectric material with adjustable dielectric constant series.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

A high-dielectric tunable barium strontium titanate-based composite aluminosilicate ceramic dielectric material

A high-dielectric adjustable strontium barium titanate-based composite aluminosilicate ceramic dielectric material is characterized in that the component general formula of the high-dielectric adjustable strontium barium titanate-based composite aluminosilicate ceramic dielectric material is is: (1‑m%)Ba 1‑z Sr z TiO 3 +m%(Sr 1‑x Ba x ) 2 Al 2 SiO 7 , where the value range of x is 0≤x≤0.9; the value range of z is 0.4≤z≤0.6; the value range of m is 10wt%≤m%≤90wt%, and BaCO 3 , SrCO 3 、TiO 2 , SiO 2 and Al 2 o 3 The powder is compounded, ball milled, dried, and pre-fired at high temperature to obtain a mixed powder. After tableting, it is pre-fired at a temperature of 550°C~600°C, and then fired at a temperature of 1200°C~1500°C. The highly dielectrically adjustable strontium barium titanate-based composite aluminosilicate ceramic dielectric material can be continuously adjusted in a wide range and has high comprehensive performance.

Owner:SHANDONG UNIV OF TECH

Microwave medium ceramic with low dielectric constant and low loss and preparation method thereof

ActiveCN101817674BHigh dielectric constantContinuously adjustable dielectric constantCeramicsElectricityMicrowave

The invention discloses a microwave medium ceramic with a low dielectric constant and a low loss and a preparation method thereof and belongs to the technical field of a microwave medium ceramic material. The microwave medium ceramic has the characteristics of low dielectric constant, low loss, high temperature stability, continuously adjustable dielectric constant and high machining property. The composition of the microwave medium ceramic is expressed by a general formula: (Zn1-xLi2x)O.ySiO2+a weight percent of TiO2, wherein x is more than or equal to 0 and less than or equal to 1; y is more than or equal to 0.5 and less than or equal to 1; a is more than or equal to 0 and less than or equal to 20; and a is mass percentage in (Zn1-xLi2x)O.ySiO2. The microwave medium ceramic is prepared by the following steps of: 1) confecting zinc oxide, lithium carbonate and silicon dioxide according to the general formula (Zn1-xLi2x)O.ySiO2+a weight percent of TiO2, mixing and pre-burning the mixture to synthesize a main component and crushing the main component into powder; 2) putting powdery TiO2 into the main component and mixing to obtain a powdery mixture; and 3) blanking and sintering the powdery mixture. A specific tau f modifier TiO2 is selected, so the material has a dielectric constant of between 7 and 9, a high quality factor value of Q*f0 and adjustable frequency temperature coefficient tau f. Simultaneously, the material has the advantages of simple preparation process, no special requirement on equipment and workshop environment and contribution to batch production, application and popularization.

Owner:JIANGSU JIANGJIA ELECTRONICS

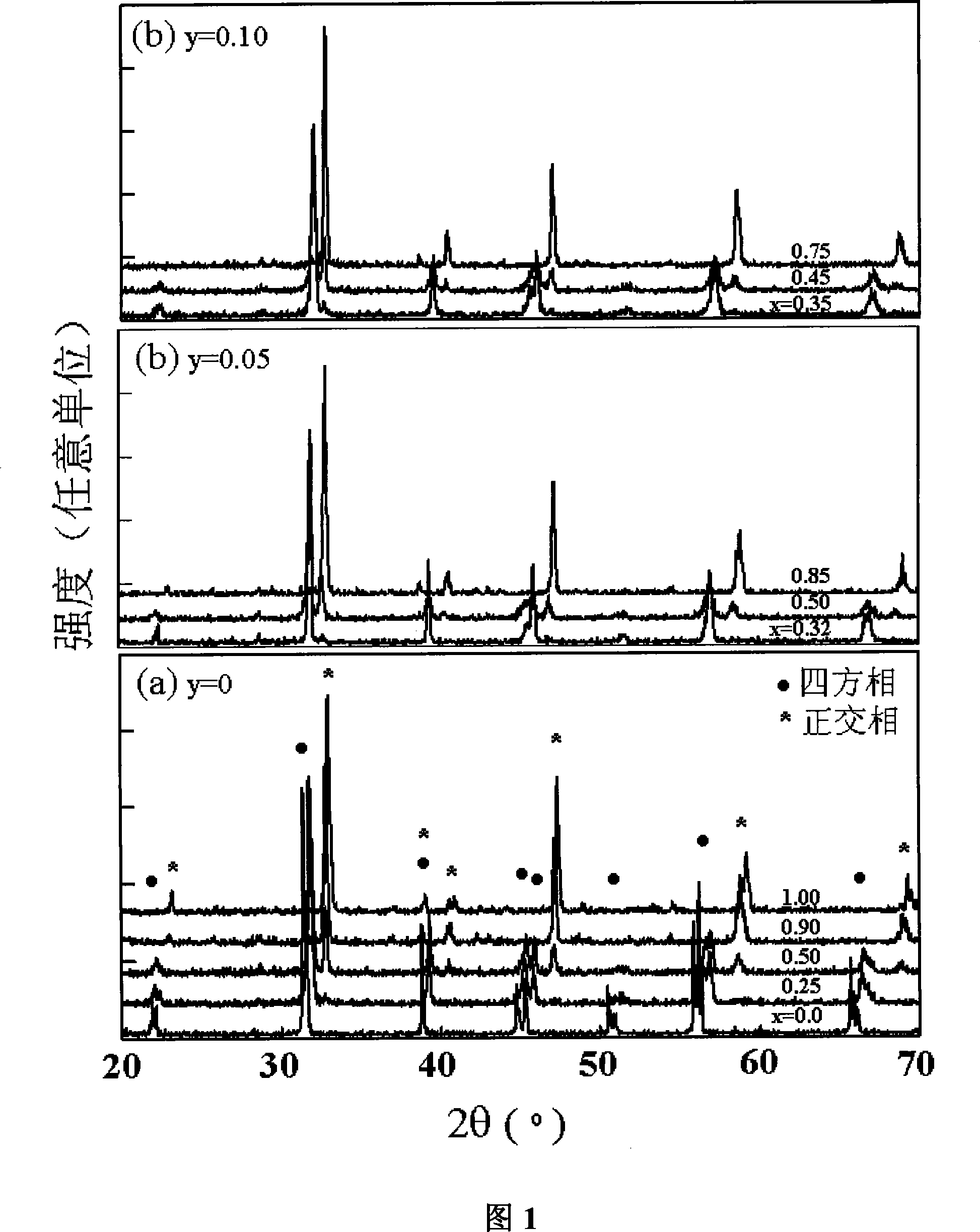

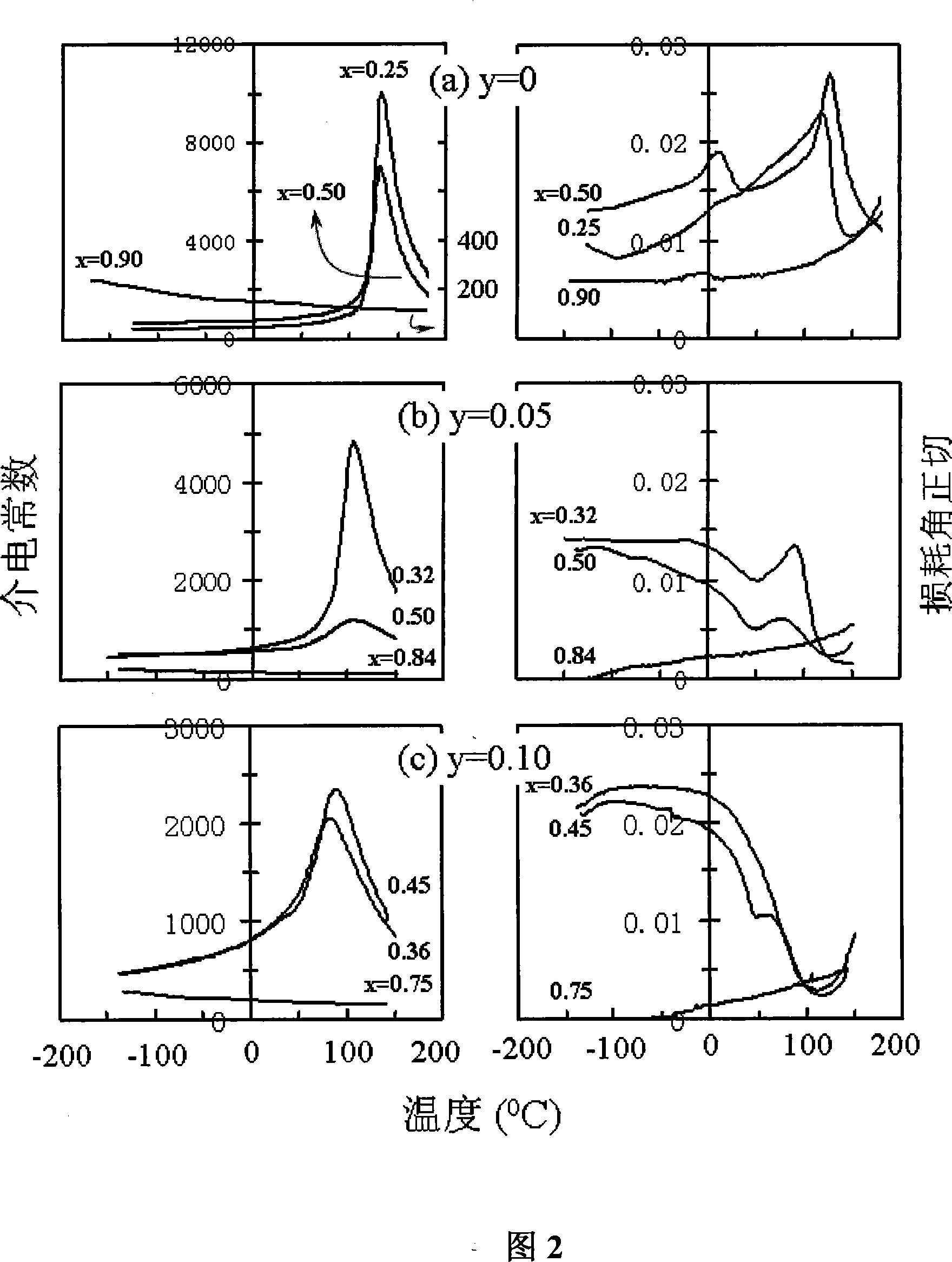

Multiple phase ceramic material with adjustable dielectric

The invention discloses complex phase ceramic material with adjustable dielectric property. The invention is characterized in that the component comprises two phases, wherein, the composing structural formula of the first phase is (Ba, Sr, Ca) TiO3, the content of each component is expressed according to the raw material that: (1-x-y)BaToO3-ySrTiO3-xCaTiO3, wherein, 0 is less than and equal to y which is less than and equal to 0.18, 0.21 is less than and equal to x which is less than and equal to 0.91 and the content of baric is bigger than the content of calcium; the composing structural formula of the second phase is (Ba, Sr, Ca)TiO3, the content of each component is expressed according to the raw material that: (1-x-y)BaTiO3-ySrTiO3-xCaTiO3, wherein, 0 is less than and equal to y whichis less than or equal to 0.18, and 0.21 is less than and equal to x which is less than and equal to 0.91. The content of calcium is bigger than the content of baric. The complex phase ceramic material with adjustable dielectric property disclosed in the invention has good dielectric capacity, small dielectric consumption, medium dielectric constant and much higher dielectric adjusting rate.

Owner:TONGJI UNIV

A kind of mas-lt composite microwave dielectric ceramic and preparation method thereof

ActiveCN110357607BStable structureContinuously adjustable dielectric constantMicrowaveDielectric loss

The invention provides a MAS-LT composite microwave dielectric ceramic, which has the general formula shown in the following formula: Mg 2‑x Ba x al 4 Si 5 o 18 -Li 2 TiO 3 ; In the formula, x=0~0.16; In the MAS‑LT composite microwave dielectric ceramics, Li 2 TiO 3 The mass percentage content is 6%~24%. Compared with the prior art, the MAS-LT composite microwave dielectric ceramic provided by the present invention takes the composite oxide of the above-mentioned specific general formula as the main material, and by adjusting Li 2 TiO 3 The content of the dielectric constant can be between 4 and 6, and the frequency temperature coefficient can be continuously adjusted; moreover, the MAS‑LT composite microwave dielectric ceramic has a stable structure, a specific dielectric constant and a high Q×f value, At the same time, the resonant frequency temperature coefficient is continuously adjustable. Experimental results show that the dielectric constant of the MAS-LT composite microwave dielectric ceramic provided by the present invention is 4-5.8, Q×f≥35800GHz, and can be as high as 87600GHz. Compared with other microwave dielectric ceramics with the same dielectric constant, this system High Q×f value and low dielectric loss; at the same time, the resonant frequency temperature coefficient is continuously adjustable between ‑12ppm / ℃~+13ppm / ℃, the sintering temperature is as low as 950 degrees, and the formula can be flexibly adjusted.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Microwave dielectric ceramic material and its preparation method and application, microwave dielectric ceramic body and its preparation method and application, microwave device

ActiveCN110668795BContinuously adjustable dielectric constantAchieve fine-tuningCeramicsDielectricMicrowave

The invention relates to the field of electronic ceramics, and provides a microwave dielectric ceramic material, a preparation method and application thereof, a microwave dielectric ceramic body, a preparation method and application thereof, and a microwave device. The microwave dielectric ceramic material is mainly prepared from ceramic main materials and optional additives: the ceramic main materials include MgO, CaO, SiO in specific weight percentages 2 、Nd 2 o 3 、Sm 2 o 3 and TiO 2 ; The additive includes oxides of R in a specific weight percentage, and R includes at least one of Nb, Zn, Zr, Mn, Y, Ni, Cu, Mo or Al; wherein, the sum of the weight percentages of each component is 100% . The dielectric constant of the above-mentioned microwave dielectric ceramic material is continuously adjustable between 15-30, f*Q>45000 at 25°C, and has good temperature characteristics. The temperature coefficient of frequency at -40°C, 25°C, and 110°C Close to zero, high temperature stability.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com