Low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and preparation method thereof

A low-temperature co-firing, glass-ceramic technology, applied in the field of electronic ceramic materials, can solve the problems of a single dielectric constant and a narrow adjustable range, and achieve the effects of a wide range of material applications, a simple and easy process, and a low dielectric loss coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

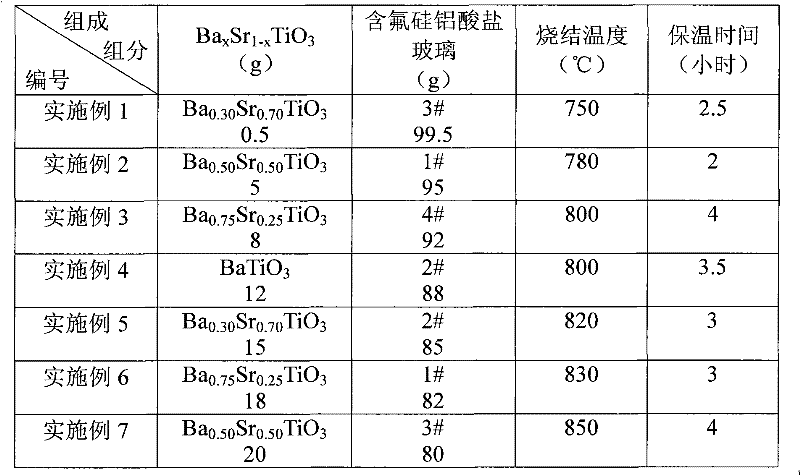

Embodiment 1-7

[0024] Embodiment 1-7, preparation of low temperature co-fired ceramic powder and its dielectric property test

[0025] 1) Ba x Sr 1-x TiO 3 (x=0.3-1) Preparation of powder

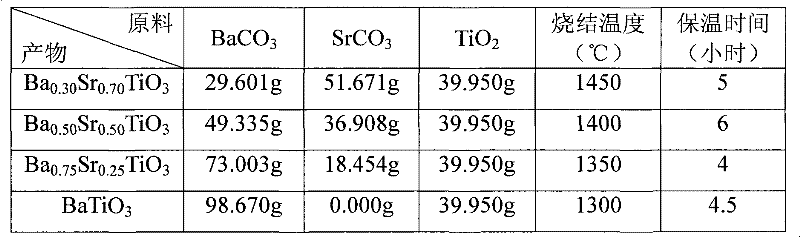

[0026] According to Ba x Sr 1-x TiO 3 The stoichiometric ratio of each component in the molecular formula, weigh the corresponding weight of BaCO 3 , SrCO 3 and TiO 2 , put it in a ball mill jar, add absolute ethanol or water, dry it after ball milling for 24 hours, pre-sinter at 1200°C for 4 hours, sinter at 1300-1450°C for 4-6 hours after grinding, pass through a 100-mesh sieve after grinding, that is Ba available x Sr 1-x TiO 3 Ceramic powder. BaCO weighed in preparation 3 , SrCO 3 and TiO 2 The quality, sintering temperature, holding time and the corresponding products obtained are shown in Table 1.

[0027] Table 1

[0028]

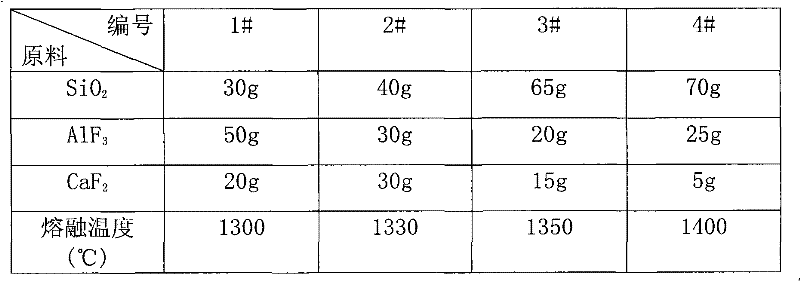

[0029] 2) Preparation of fluorine-containing aluminosilicate glass powder

[0030] SiO 2 , AlF 3 and CaF 2 After weighing according to the formula, put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com