A kind of composite microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and adhesives, which is applied in the direction of ceramics and inorganic insulators, can solve the problems of low reliability and achieve the effects of meeting environmental protection requirements, simple preparation methods, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the composite microwave dielectric ceramic described in the above technical solution, comprising the following steps:

[0046] a) According to the chemical formula Mg x Zn y Al 2 o 4 MgO, Al 2 o 3 After mixing with ZnO, the first grinding treatment is carried out to obtain the MZA raw material; then the MZA raw material is calcined for the first time to obtain the MZA calcined material;

[0047] b) According to the chemical formula Sr 2 TiO 4 SrCO 3 and TiO 2 After mixing, carry out the second grinding treatment to obtain the ST raw material; then carry out the second calcining of the ST raw material to obtain the ST calcined material;

[0048] c) After mixing the above-mentioned MZA calcined material and ST calcined material, perform the third grinding treatment to obtain MZA-ST powder;

[0049] d) adding a binder to the MZA-ST powder obtained in step c) for granulation and molding to obtain the MZA-S...

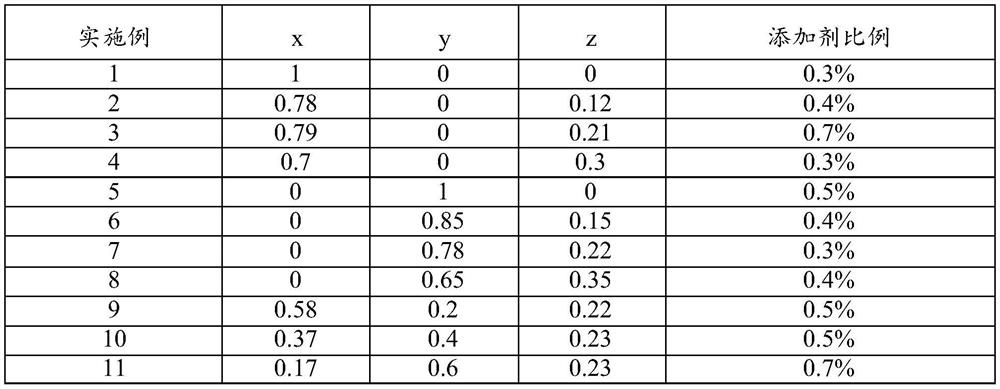

Embodiment 1~11

[0088] (1) According to the chemical formula Mg x Zn y Al 2 o 4 MgO, Al 2 o 3 After mixing with ZnO, mix the mixed raw materials, water, and zirconium balls at a mass ratio of 1:2:2, ball mill at a speed of 250r / min for 8 hours, and then dry at 120°C to obtain MZA raw materials; The MZA raw material is heated up to the pre-burning temperature at a heating rate of 3°C / min for the first pre-burning for a certain pre-burning time to obtain the MZA pre-fired material;

[0089] At the same time, according to the chemical formula Sr 2 TiO 4 SrCO 3 and TiO 2 After mixing, mix the mixed raw materials, water, and zirconium balls at a mass ratio of 1:2:2, ball mill for 8 hours at a speed of 250r / min, and then dry at 120°C to obtain ST raw materials; The ST raw material is heated up to the pre-burning temperature at a heating rate of 3°C / min for the second pre-burning for a certain pre-burning time to obtain the ST pre-fired material;

[0090] (2) After mixing the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com