Dielectric adjustable material of ceramics burned together at low temperature, and preparation method

A technology for sintering ceramics and ceramic powders at low temperature, which is applied in the field of electronic materials and devices, can solve the requirements of spatial impedance matching of difficult composite microwave devices, reduce the sintering temperature of BST ceramics, and the high cost of BST powders. Low cost, environmentally friendly toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

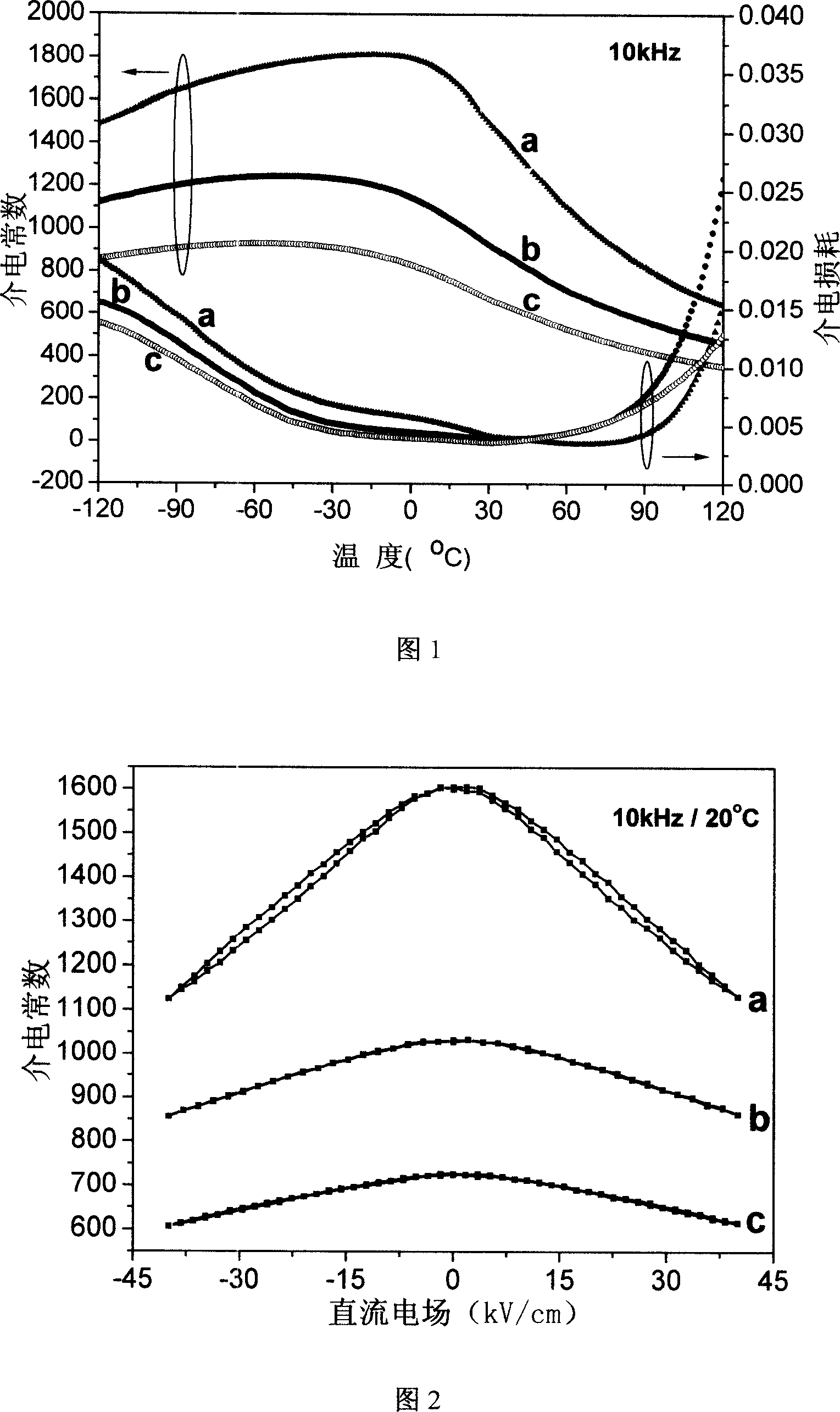

[0042] Preparation of Ba 0.6 Sr 0.4 TiO 3 -MgO low temperature co-fired ceramics:

[0043] Choose BaTiO 3 and SrTiO 3 (99.9%, 100nm, provided by Shandong Guoteng Functional Ceramic Material Co., Ltd.) as the main raw material, according to the ingredients of Ba:Sr=6:4 (molar ratio), the prepared raw materials are placed in a nylon ball mill jar, and zirconia balls are added Ball mill with absolute ethanol for 24 hours, pre-calcine at 1100°C for 4 hours after the discharge is dried, and Ba 0.6 Sr 0.4 TiO 3 The powder is ready for use.

[0044] Weigh the chemical reagents according to the following different component ratios:

[0045] experimental formula

[0046] Put the mixtures of the above formulas into nylon ball milling tanks respectively, add 20g of zirconia balls and 30g of absolute ethanol to ball mill for 24 hours, and pass through a 200-mesh sieve after drying. Polyvinyl alcohol (PVA) was used as a binder for granulation, and under a pressure of 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com