Dielectric constant series adjustable low-temperature co-fired dielectric material and preparation method thereof

A dielectric material and low-temperature co-firing technology, applied in ceramics, inorganic insulators, etc., can solve problems such as deviation of glass powder components, sample performance not as good as expected, unsuitable glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

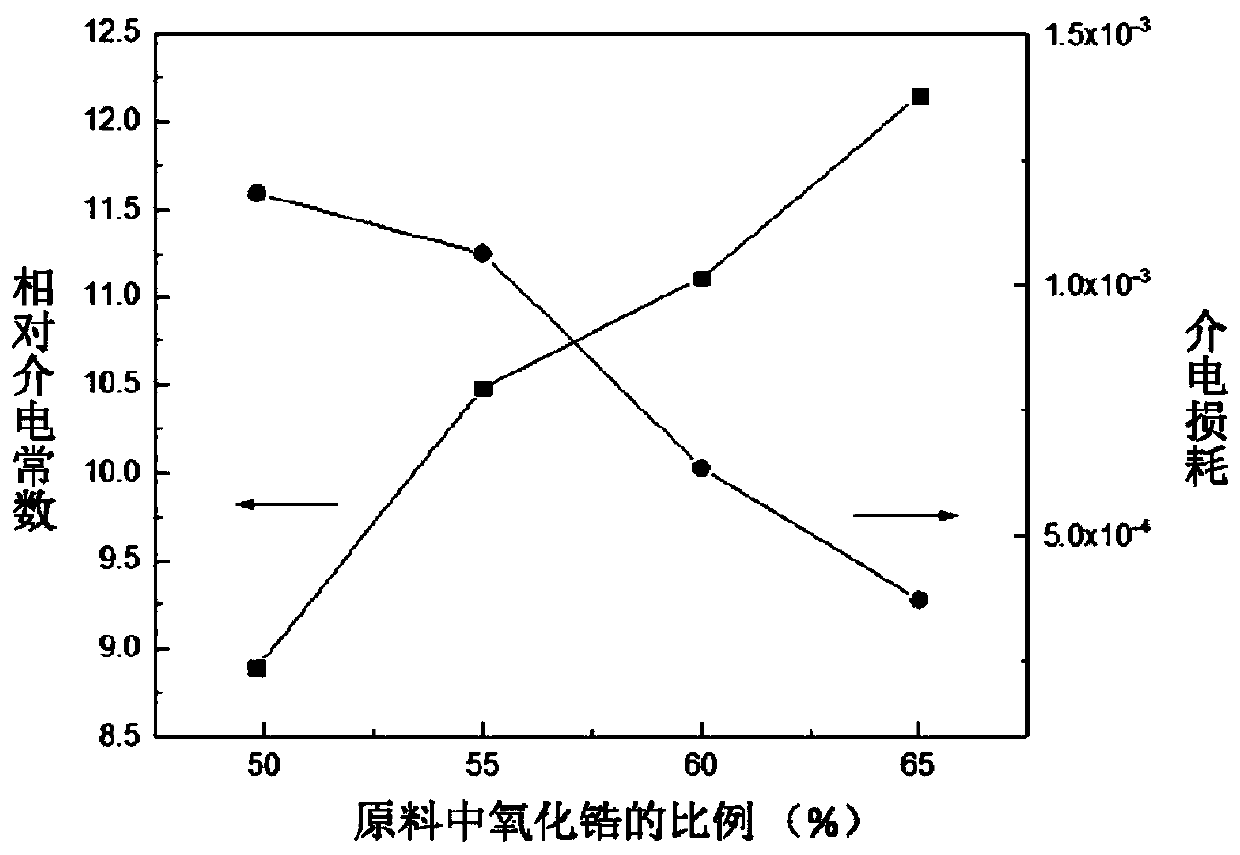

Image

Examples

Embodiment 1

[0026] An embodiment of the preparation method of the low-temperature co-fired dielectric material described in the present invention, the preparation method of the low-temperature co-fired dielectric material described in this embodiment includes the following steps:

[0027] Dissolve 9.3mL of tetraethyl orthosilicate in a mixed solution of alcohol (100mL) and deionized water (9.3mL); to promote hydrolysis, add nitric acid to adjust the pH of the solution to about 1 and stir; after the solution is clarified, add 0.07 g NaNO 3 , 0.24gKNO 3 , 0.28g Ca(NO 3 ) 2 4H 2 O and 0.92g HBO 3 solution, stirred vigorously and heated at 75°C, and then added ammonia water to adjust the pH to about 7 to form a gel. The resulting gel was dried and calcined at 700°C for 2 hours to obtain a silicon-based amorphous phase filler; finally weighed 49.81% ZrO 2 (particle size of 5 μm) and 50.19% silicon-based amorphous phase filler were ball-milled for 18 hours, dried and pressed into sheets at...

Embodiment 2

[0030] An embodiment of the preparation method of the low-temperature co-fired dielectric material described in the present invention, the preparation method of the low-temperature co-fired dielectric material described in this embodiment includes the following steps:

[0031] Dissolve 9.3mL of tetraethyl orthosilicate in a mixed solution of alcohol (93mL) and deionized water (9.3mL); in order to promote hydrolysis, add nitric acid to adjust the pH of the solution to about 1 and stir. After the solution is clarified, add 0.07 g NaNO 3 , 0.24g KNO 3 , 0.28g Ca(NO 3 ) 2 4H 2 O and 0.92g HBO 3 solution, stirred vigorously and heated at 80°C; then added ammonia water to adjust the pH to about 7 to form a gel, and the resulting gel was dried and calcined at 700°C for 2 hours to obtain a silicon-based amorphous filler; finally weighed 55% ZrO 2 (particle size of 5 μm) and 45% silicon-based amorphous phase filler were ball-milled for 15 hours. After drying, it was dry-pressed a...

Embodiment 3

[0034] An embodiment of the preparation method of the low-temperature co-fired dielectric material described in the present invention, the preparation method of the low-temperature co-fired dielectric material described in this embodiment includes the following steps:

[0035] Dissolve 9.3mL of tetraethyl orthosilicate in a mixed solution of alcohol (100mL) and deionized water (9.3mL); to promote hydrolysis, add nitric acid to adjust the pH of the solution to about 1 and stir; after the solution is clarified, add 0.07 g NaNO 3 , 0.24gKNO 3 , 0.28g Ca(NO 3 ) 2 4H 2 O and 0.92g HBO 3 solution, stirred vigorously and heated at 60°C; then added ammonia water to adjust the pH to about 7 to form a gel, and the resulting gel was dried and calcined at 700°C for 2 hours to obtain a silicon-based amorphous phase filler; finally weighed 60% ZrO 2 (particle size of 5 μm) and 40% silicon-based amorphous phase filler were ball-milled for 16 hours, dried and pressed into sheets at 7 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com