Ceramic-based double-layer structure radome and its preparation method

A double-layer structure, radome technology, applied in the fields of aerospace and aviation vehicles, can solve the problems of single material, long process cycle, unsuitable for large-size radomes, etc., and achieve mechanical properties that resist catastrophic damage and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

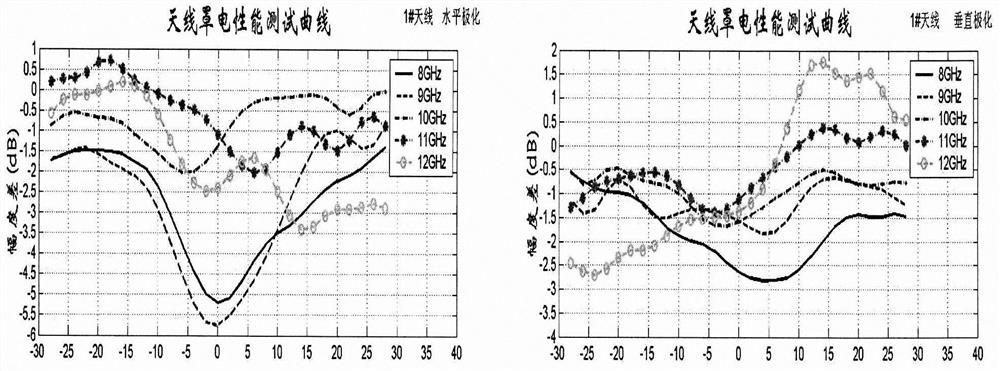

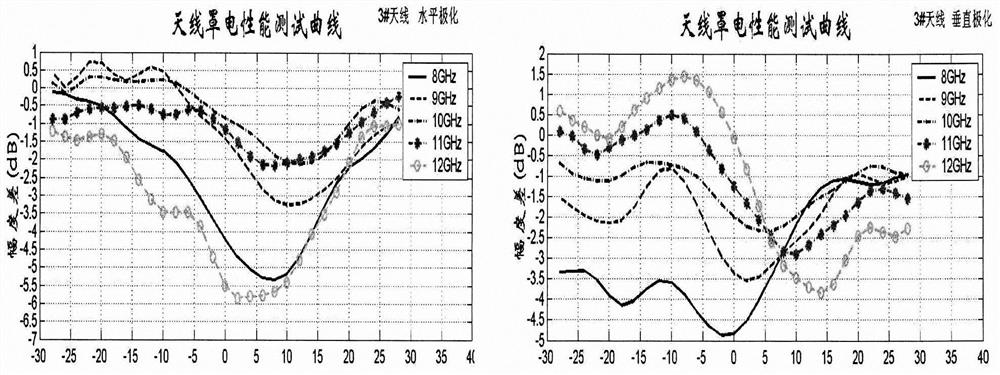

[0031] The dielectric constant of the core layer of the broadband double-layer radome is 2.30±0.05, and the dielectric constant of the surface layer is 4.50±0.05. According to the operating frequency of the antenna and the shape and structure of the radome, the thickness of the core layer and the surface layer of the radome are determined to be 7.3mm and 1.2mm respectively.

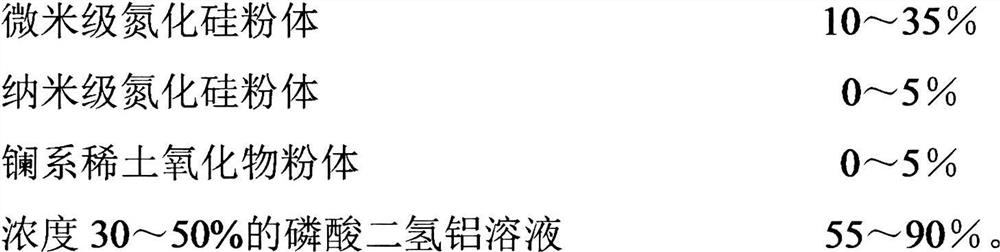

[0032] (1) Preparation of core material

[0033] a pretreatment of fiber preform

[0034] The core layer material adopts B-type 195Tex (Tex refers to the weight of a certain length of yarn, generally refers to the quality of 1000m fiber, the unit is g / 1000m) quartz fiber, and the fiber prefabricated body is prepared by weaving 2.5D normal yarns with a volume fraction of 45 %; The preform is heat-treated in a muffle furnace, heated to 460°C at a rate of 10°C / min, kept for 2 hours, and the wetting agent on the surface is removed, then cooled with the furnace, and then soaked in high-purity silica sol soluti...

Embodiment 2

[0050] The dielectric constant of the core layer of the broadband double-layer radome is 2.3±0.05, and the dielectric constant of the surface layer is 4.5±0.05. According to the operating frequency of the antenna and the shape and structure of the radome, the thickness of the core layer and the surface layer of the radome are determined to be 7.1mm and 1.0mm respectively.

[0051] (1) Preparation of core material

[0052] a pretreatment of fiber preform

[0053] The core layer material uses B-type quartz fiber as raw material, and the fabric adopts a three-dimensional four-way weaving structure with a fiber volume fraction of 42%. 2h, remove the wetting agent on the surface, then cool with the furnace, and then soak in the high-purity silica sol solution for more than 6 hours.

[0054] b liquid phase impregnation

[0055] Place the pretreated quartz fiber prefabricated body in a vacuum tank, evacuate to less than 10Pa, and then inhale the quartz slurry, which is prepared by ...

Embodiment 3

[0075] The dielectric constant of the core layer of the broadband double-layer radome is 2.3±0.05, and the dielectric constant of the surface layer is 4.5±0.05. According to the operating frequency of the antenna and the shape and structure of the radome, the thickness of the core layer and the surface layer of the radome are determined to be 14.6mm and 1.8mm respectively.

[0076] (1) Preparation of core material

[0077] a pretreatment of fiber preform

[0078] The core material is made of B-type quartz fiber, the fabric adopts a 2.5D weaving structure, and the fiber volume fraction is 42%. The prefabricated body is heat-treated in a muffle furnace, and the temperature is raised to 520°C at a heating rate of 10°C / min and kept for 2 hours. , remove the wetting agent on the surface, then cool with the furnace, and then soak in the high-purity silica sol solution for more than 6 hours.

[0079] b liquid phase impregnation

[0080] Put the pretreated quartz fiber prefabricated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com