Dielectric powder for 5G filter and preparation method of dielectric powder

A filter and dielectric powder technology, which is applied in the field of dielectric ceramic raw material preparation, can solve problems such as inability to meet 5G filters, and achieve microscopic uniformity, uniform shrinkage, and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

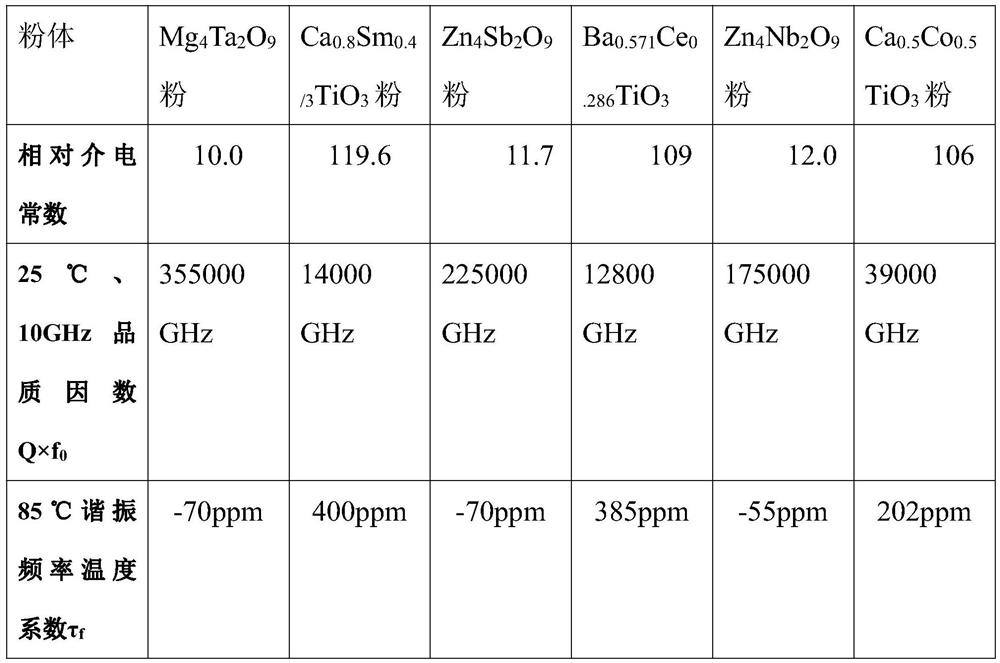

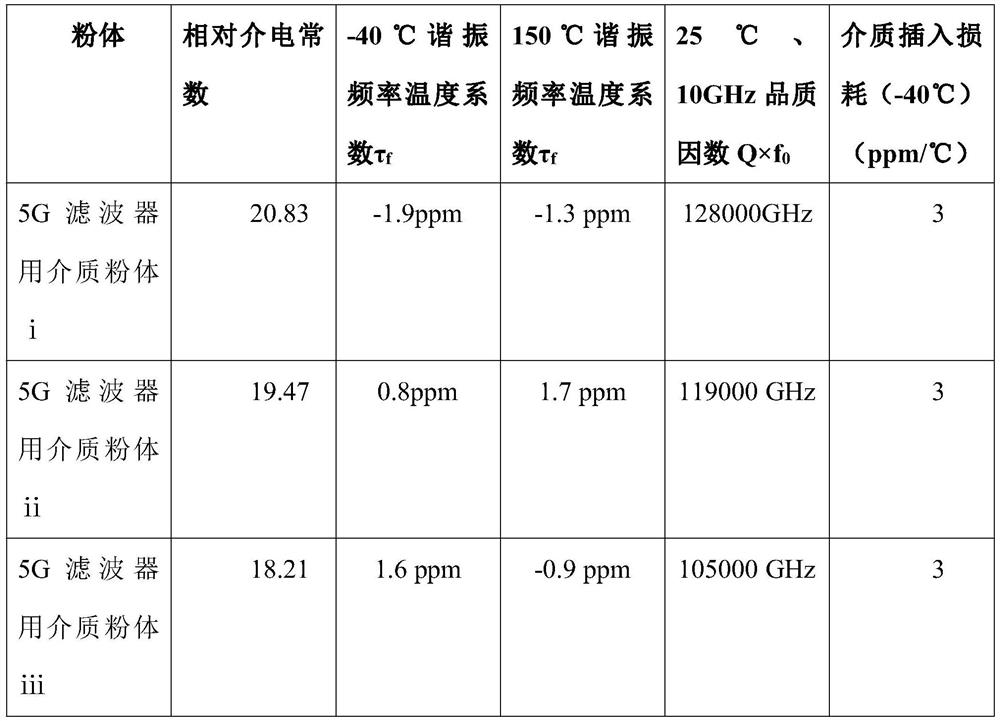

[0023] The chemical structural formula of a dielectric powder for 5G filters with high quality factor and near zero temperature drift is: 0.74Mg 4 Ta 2 o 9 -0.26Ca 0.8 SM 0.4 / 3 TiO 3 , its preparation method comprises the following steps:

[0024] (1) Synthesis of Mg 4 Ta 2 o 9 : First take by weighing respectively analytically pure magnesium carbonate (median particle diameter D50 is 0.6 μm) and analytical pure tantalum pentoxide (median particle diameter D50 is 1.2 μm) that the molar ratio is 4:1 to the mixing tank, then Add deionized water to form a mixed solution with a solid phase substance weight percentage of 15%, then add ammonium polyacrylate with 0.2% weight of deionized water into the mixing tank, stir and mix evenly to obtain slurry I, and then transfer slurry I Grind for 9 hours in a sand mill using zirconia balls as the grinding medium, until the D50 particle size is detected by a laser particle size analyzer to be less than 0.20 μm, use the spray drying ...

Embodiment 2

[0028] A high-quality factor, near-zero temperature drift dielectric powder for 5G filters. The chemical structural formula of Ⅱ is: 0.58Zn 4 Sb 2 o 9 -0.42Ba 0.571 Ce 0.286 TiO 3 , its preparation method comprises the following steps:

[0029] (1) Synthesis of Zn 4 Sb 2 o 9 : First weigh analytically pure zinc hydroxide (median particle size D50 is 1.2 μm) and analytically pure antimony trioxide (median particle size D50 is 1.0 μm) with a molar ratio of 4:1 respectively in the mixing tank, Then add deionized water to form a mixed solution with a solid phase substance weight percentage of 20%, then add CE-64 with 0.5% weight of deionized water into the mixing tank, stir and mix evenly to obtain slurry I, and then mix slurry I Transfer to a sand mill with zirconia balls as the grinding medium and grind for 11 hours until the D50 particle size is detected by a laser particle size analyzer to be less than 0.20 μm. The raw materials are granulated and dried by a spray dryi...

Embodiment 3

[0033] The chemical structural formula of a dielectric powder Ⅲ for 5G filters with high quality factor and near zero temperature drift is: 0.61Zn 4 Nb 2 o 9 -0.39Ca 0.5 co 0.5 TiO 3 , its preparation method comprises the following steps:

[0034] (1) Synthesis of Zn 4 Nb 2 o 9 : first weigh the analytically pure zinc oxide (median particle size D50 is 0.8 μm) and the analytically pure niobium pentoxide (median particle size D50 is 1.1 μm) with a molar ratio of 4:1 respectively in the mixing tank, then Add deionized water to form a mixed solution with a weight percentage of 18% of solid phase substances, then add 0.5% by weight of deionized water and NOF AKM-0531 grinding aid into the mixing tank, stir and mix evenly to obtain slurry I, Then transfer the slurry I to a sand mill with zirconia balls as the grinding medium and grind for 10 hours until the D50 particle size is detected by a laser particle size analyzer to be less than 0.20 μm. The raw materials are granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com