Low-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature sintering technology is applied in the field of composite microwave dielectric ceramic materials, low-temperature sintered composite microwave dielectric ceramic materials and their preparation, which can solve problems such as restricting applications and achieve the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

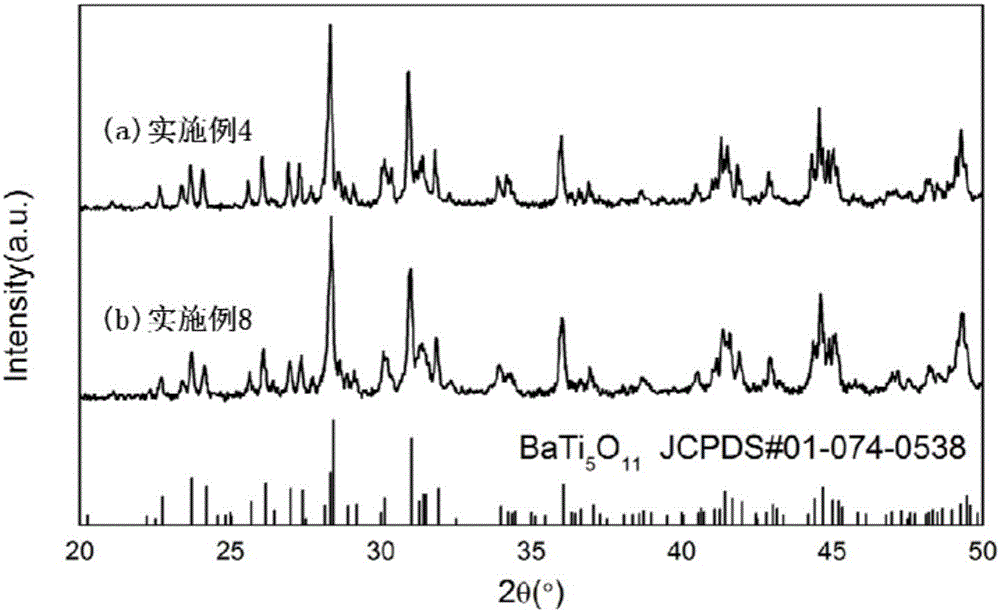

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

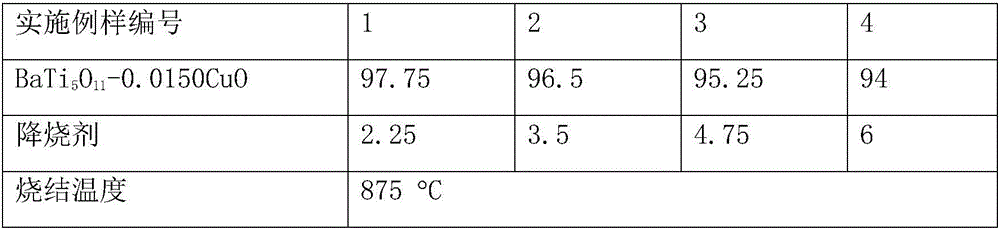

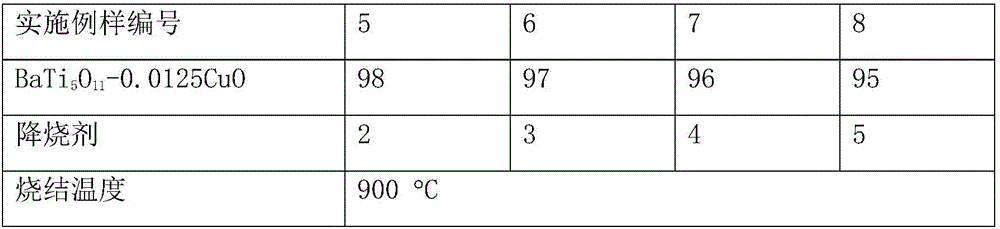

[0021] The material of the present invention is composed of BaTi with a mass percentage of 92.5% to 97.5%. 5 o 11 Composition of base material and a fever reducer with a mass percentage of 1% to 7.5%, BaTi 5 o 11 The composition of the base material is BaTi 5 o 11 -nCuO, wherein: 0.005≤n≤0.020 weight ratio, fever reducer composition is 27.25%≤Ba 2 CO 3 ≤46.74%, 4.25%≤Li 2 CO 3 ≤7.47%, 8.65%≤SiO 2 ≤9.19%, 25.59%≤B 2 o 3 ≤38.29%, 20.88%≤ZnO≤32.95%, 1.58%≤Al 2 o 3 ≤9.83%, 0.29%≤MnCO 3 ≤0.95%.

[0022]Table 1 shows the data of several specific examples of the composition content of the present invention, and Table 2 shows the microwave dielectric properties of each example.

[0023] Its preparation method is:

[0024] Step 1, the BaCO 3 , CuO, TiO 2 Raw powder by BaTi 5 o 11 -nCuO composition ingredients, wherein: 0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com