Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

253 results about "Standard material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

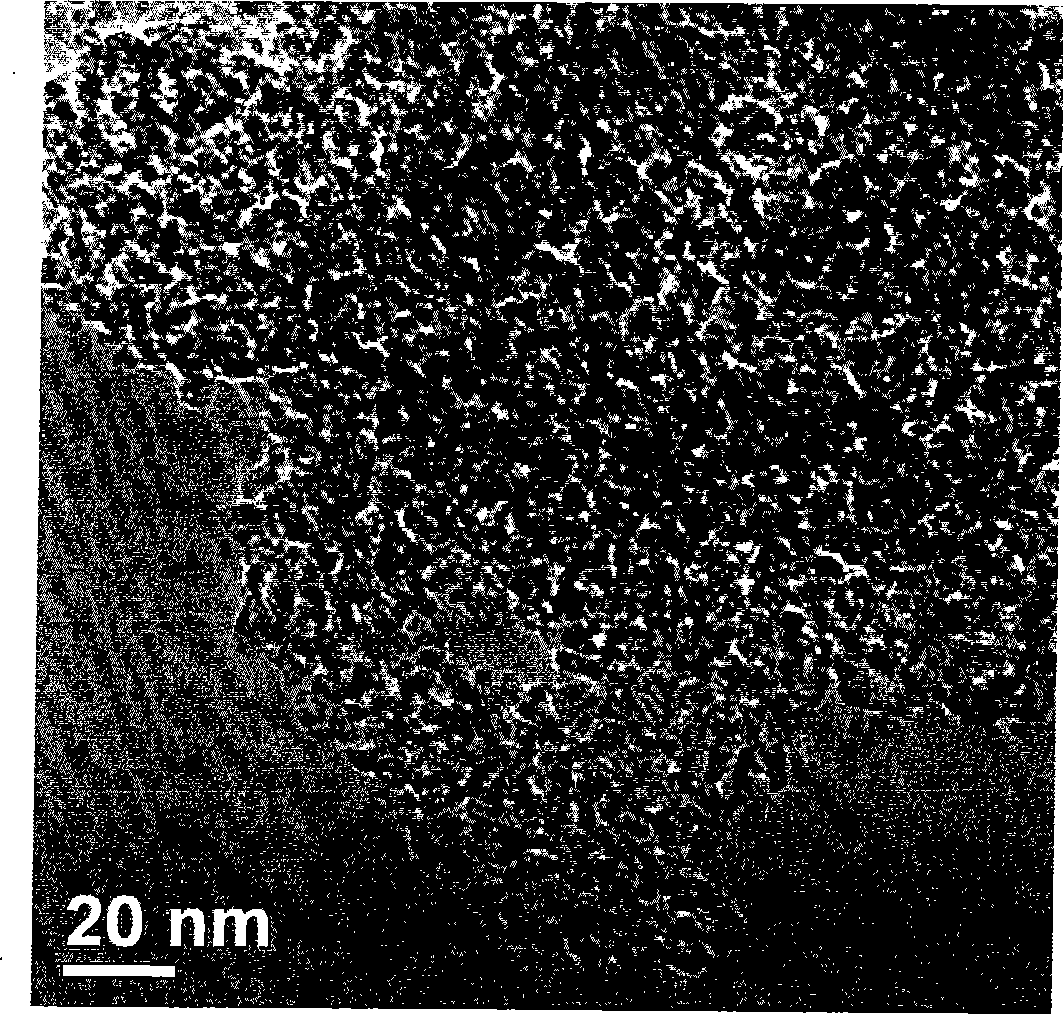

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

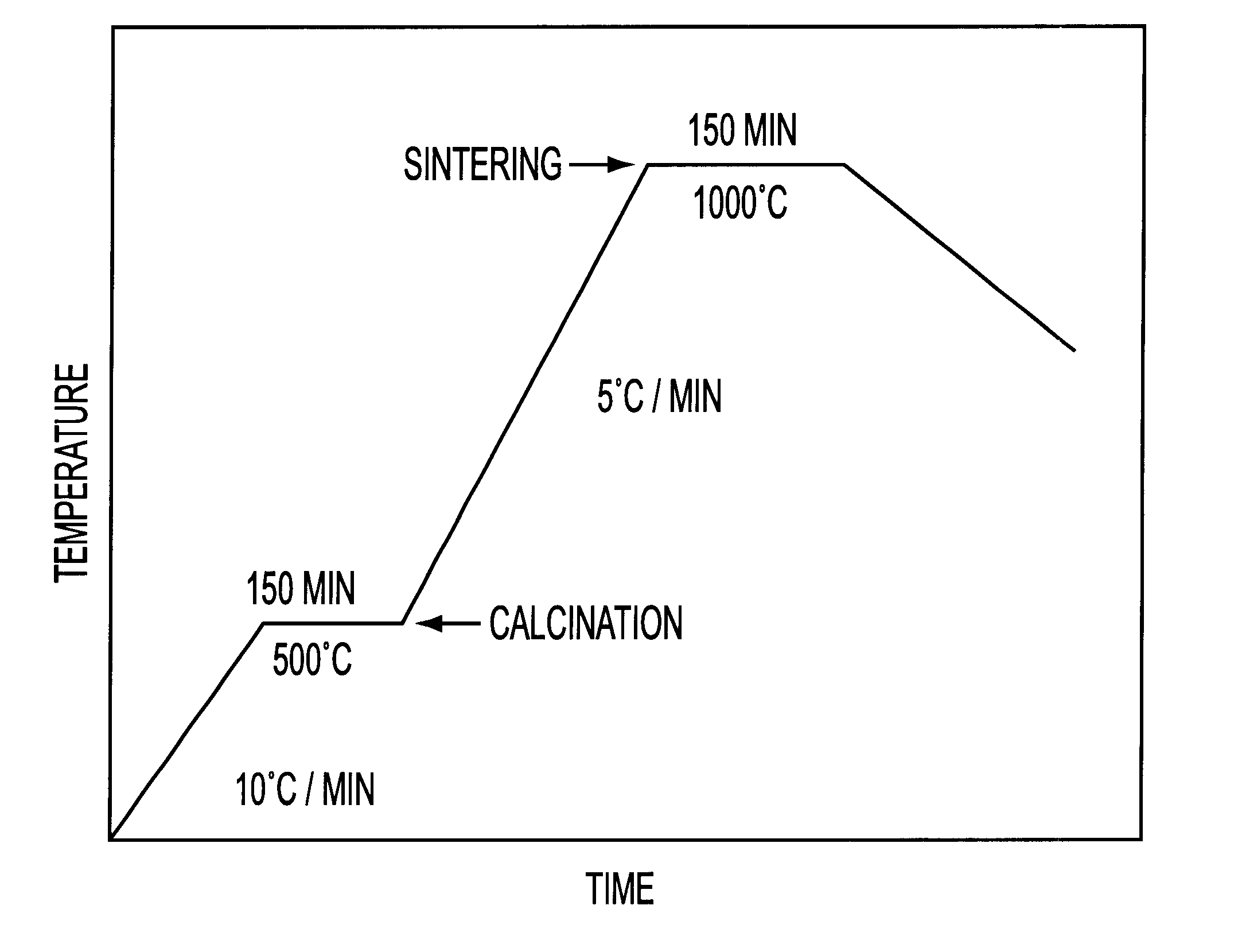

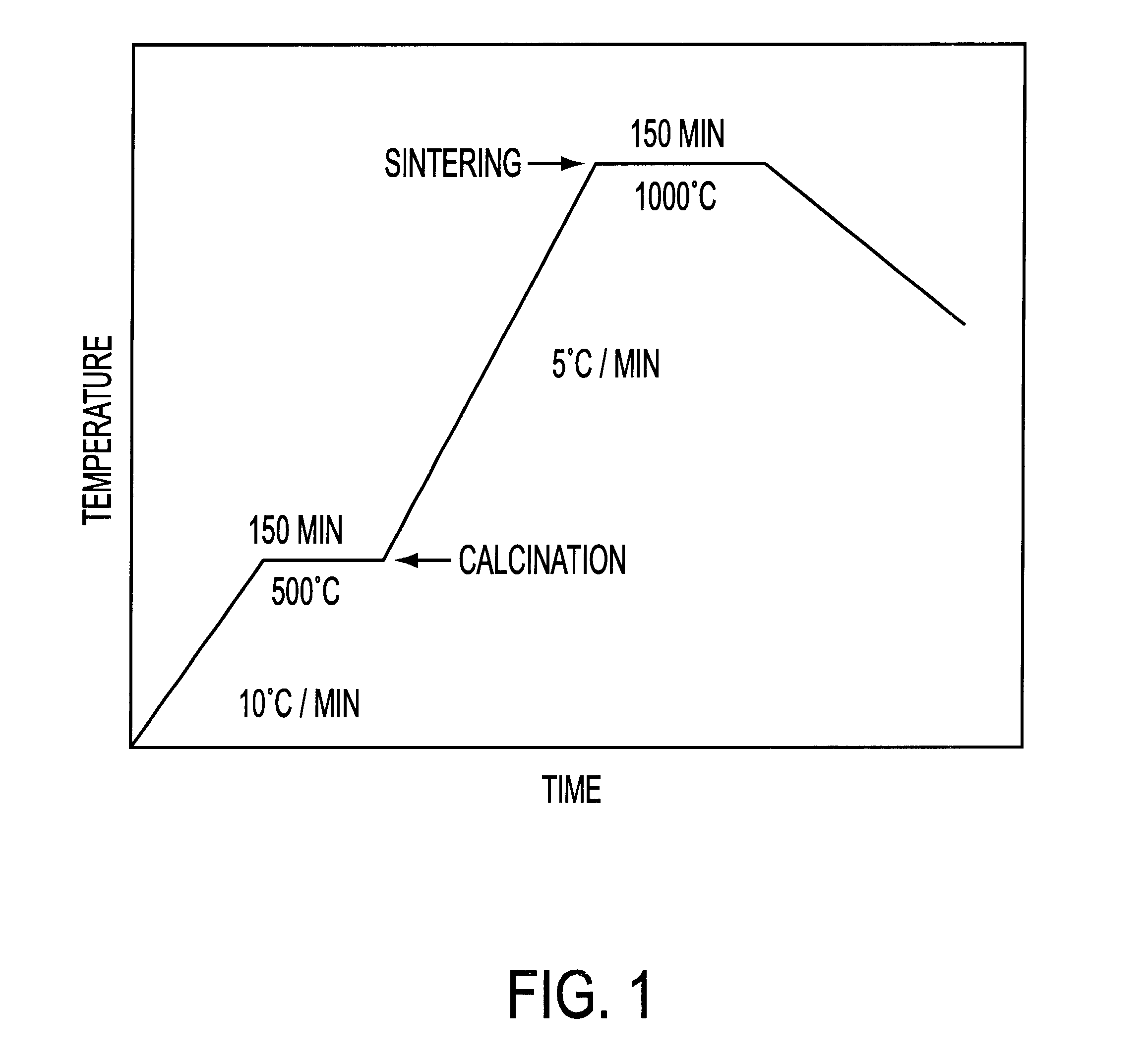

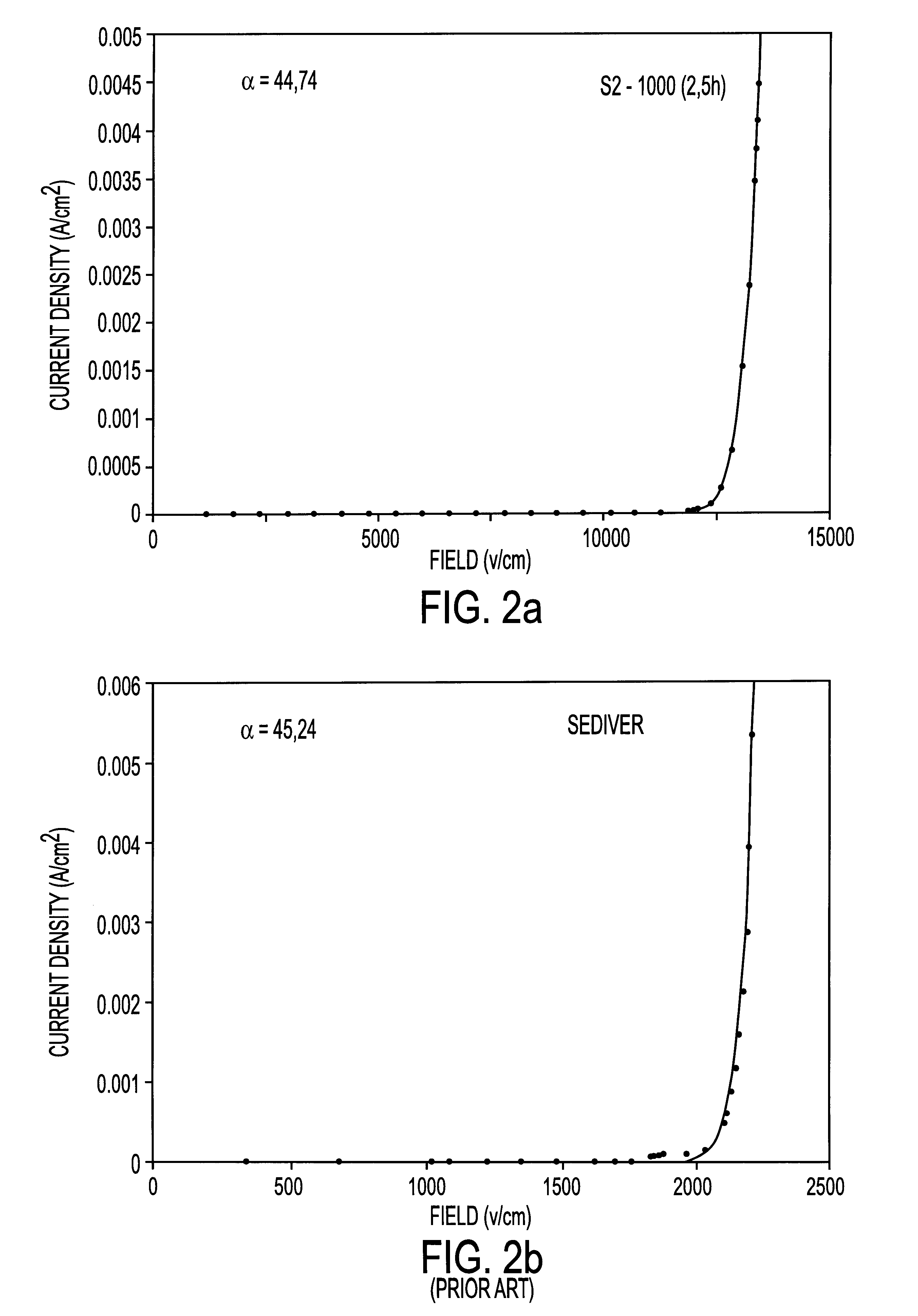

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

Oriented chipboard and processing technology

ActiveCN102198684ASave resourcesReduce consumptionWood working apparatusDomestic articlesWood shavingsSurface layer

The invention discloses an oriented chipboard and a processing technology. The chipboard is composed of three layers including two surface layers and one intermediate core layer, which are adhered together by adhesives; the processing technology uses rotary cut veneer wastes remained in a plywood production process as raw materials to substitute small-diameter standard materials, so that a large volume of wood is saved, and production cost is saved; and simultaneously, the length of the oriented chipboard can be increased by using the method, consequently, inherent mechanical property indexes of the oriented chipboard can be improved, and the oriented chipboard has higher carrying capacity; the oriented chipboard and the processing technology provided by the invention have the advantages that the rotary cut veneer wastes can be used as the raw materials, so that the large volume of wood is saved, the production cost is saved, the static bending strength and the elastic modulus of the produced oriented chipboard are synchronously increased, and the carrying capacity of the oriented chipboard is greatly improved.

Owner:寿光市鲁丽木业股份有限公司

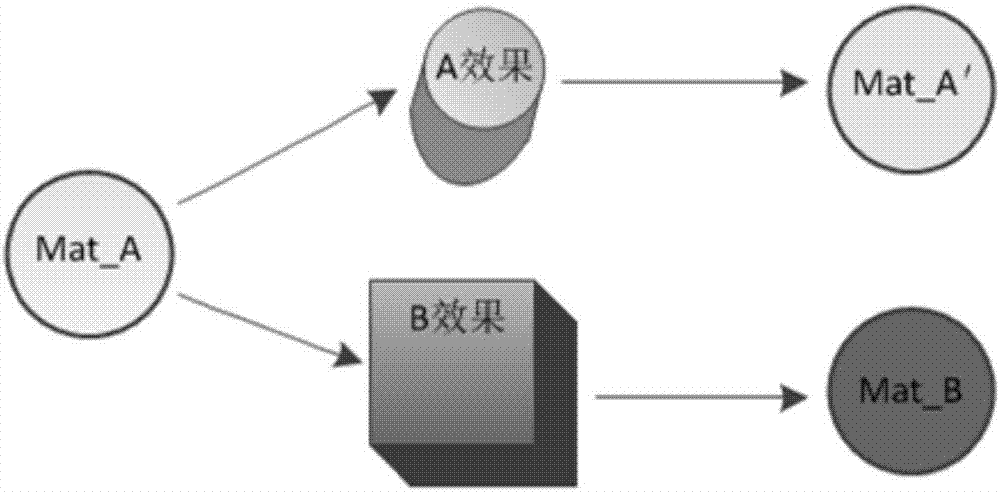

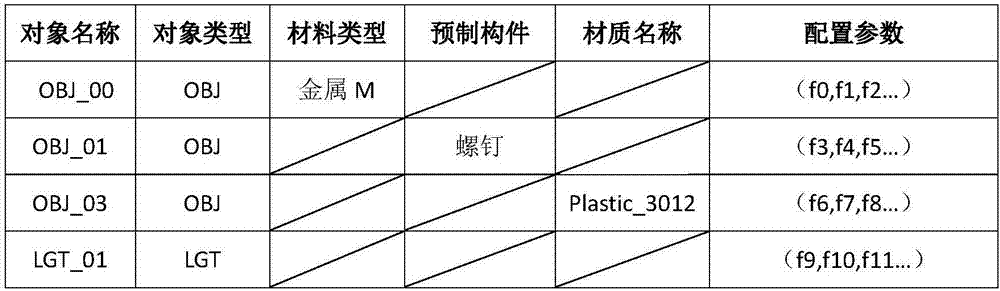

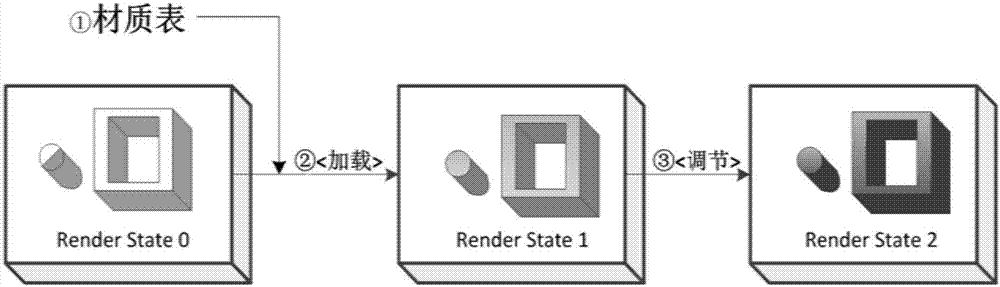

Fast rendering method for virtual scene and model

ActiveCN107103638AMaterial parameters can be modifiedImprove efficiencyImage rendering3D-image renderingUV mapping3D modeling

The invention discloses a fast rendering method and device for a virtual scene and a model. The method comprises steps of firstly obtaining the rendering request of the virtual scene and the model to be rendered and the standard material library; creating a read and write file including the corresponding relation among the scene parameter, the model and the material according to the rendering request, and selecting a material corresponding to the model to be rendered from the pre-established standard material library after loading; setting and adjusting the scene parameter according to the rendering request, rendering the model according to the selected material and adjusting the material parameter to complete the rendering satisfying the specified rendering request; when a single model corresponds to a plurality of materials, directly subjecting the plurality of materials to a three-dimensional presence UV mapping on the surface of the three-dimensional model; and generating a high light effect and its corresponding material by the hand-drawn trajectory according to the rendering request, and rendering the model's high light effect. The method has the advantages of high efficiency, openness, automation, integration of tools, light weight, sustainability, and the like on the basis of greatly improving the efficiency of virtual scene and model rendering.

Owner:HANGZHOU VERYENGINE TECH CO LTD

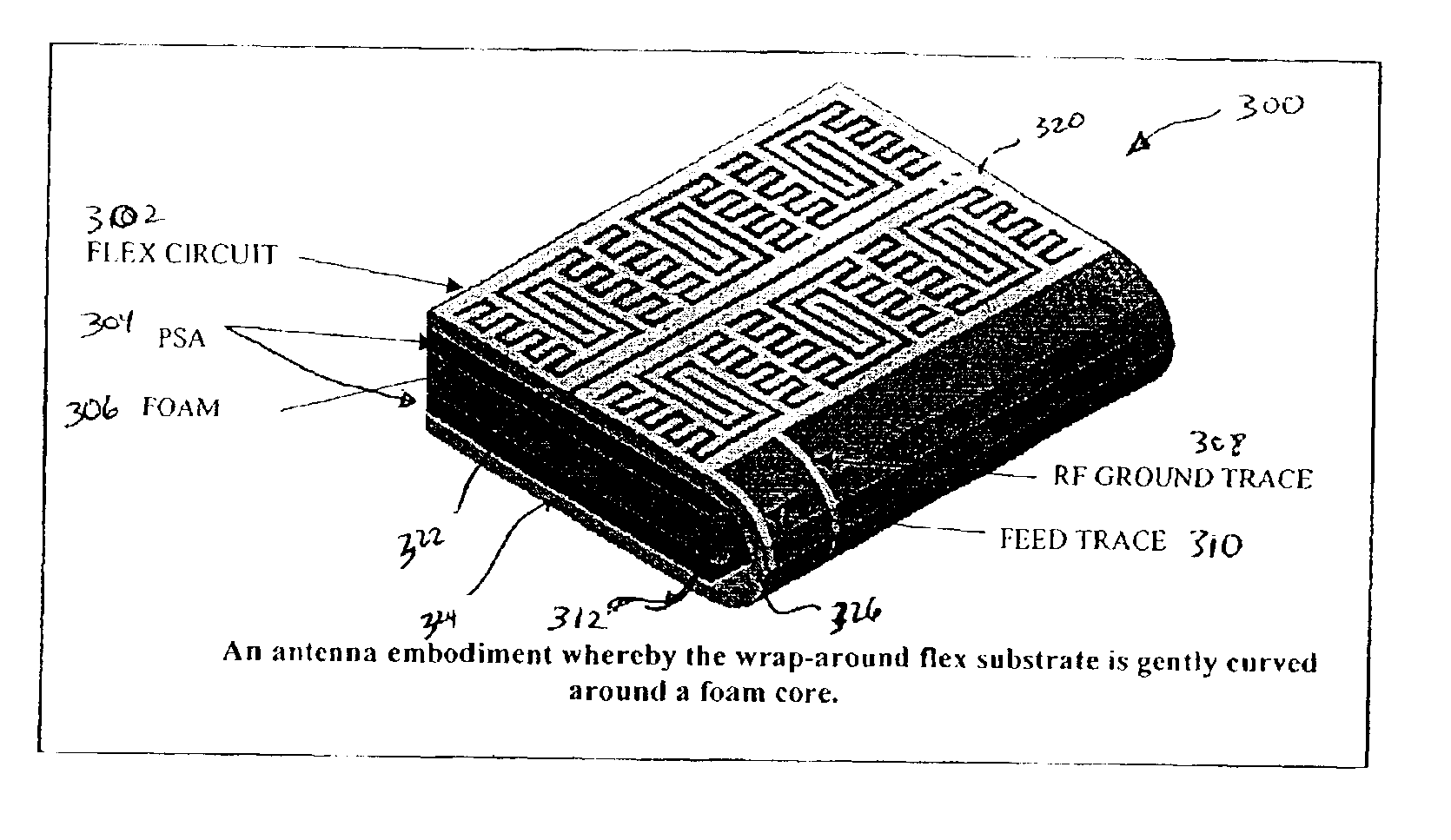

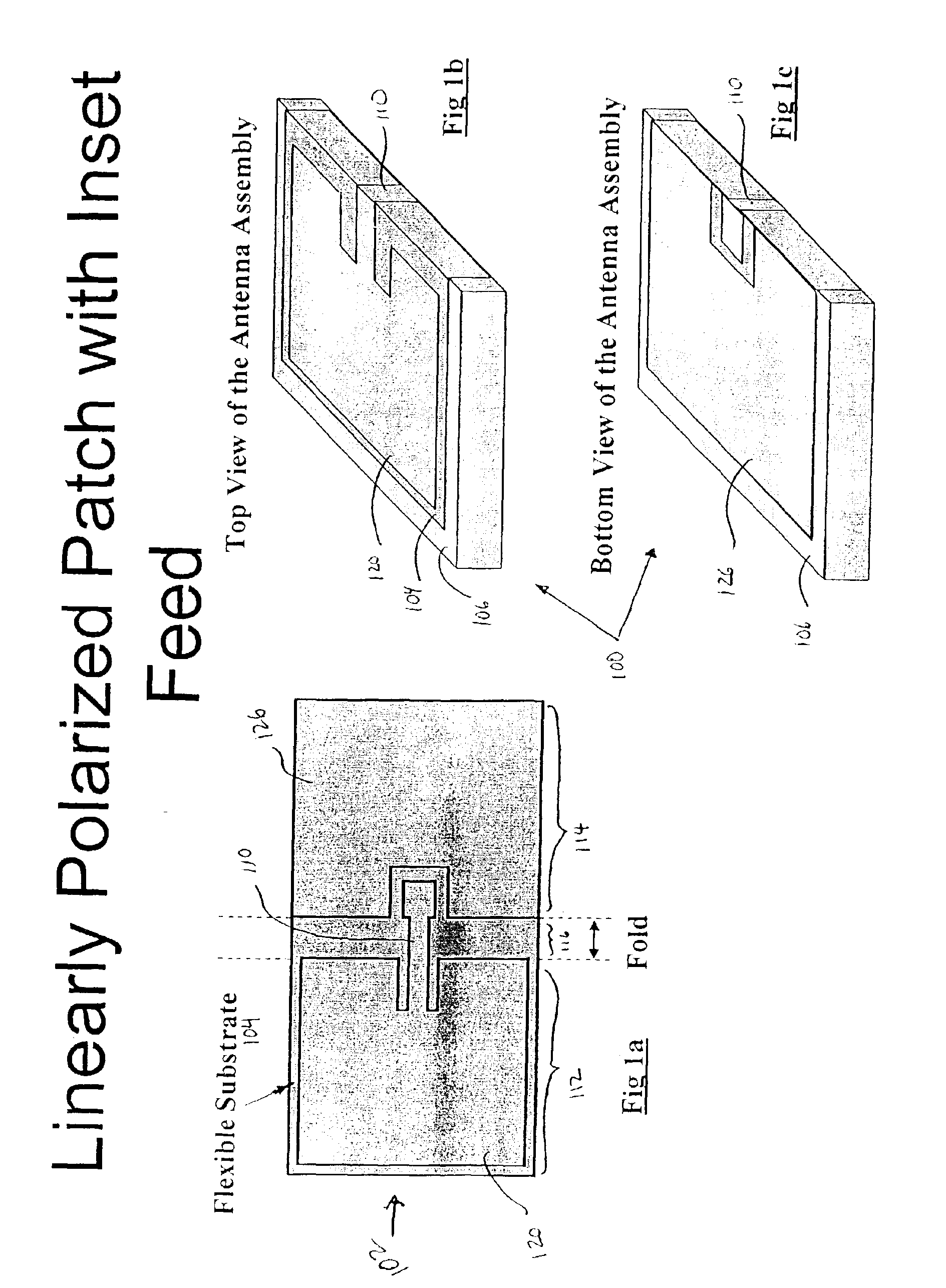

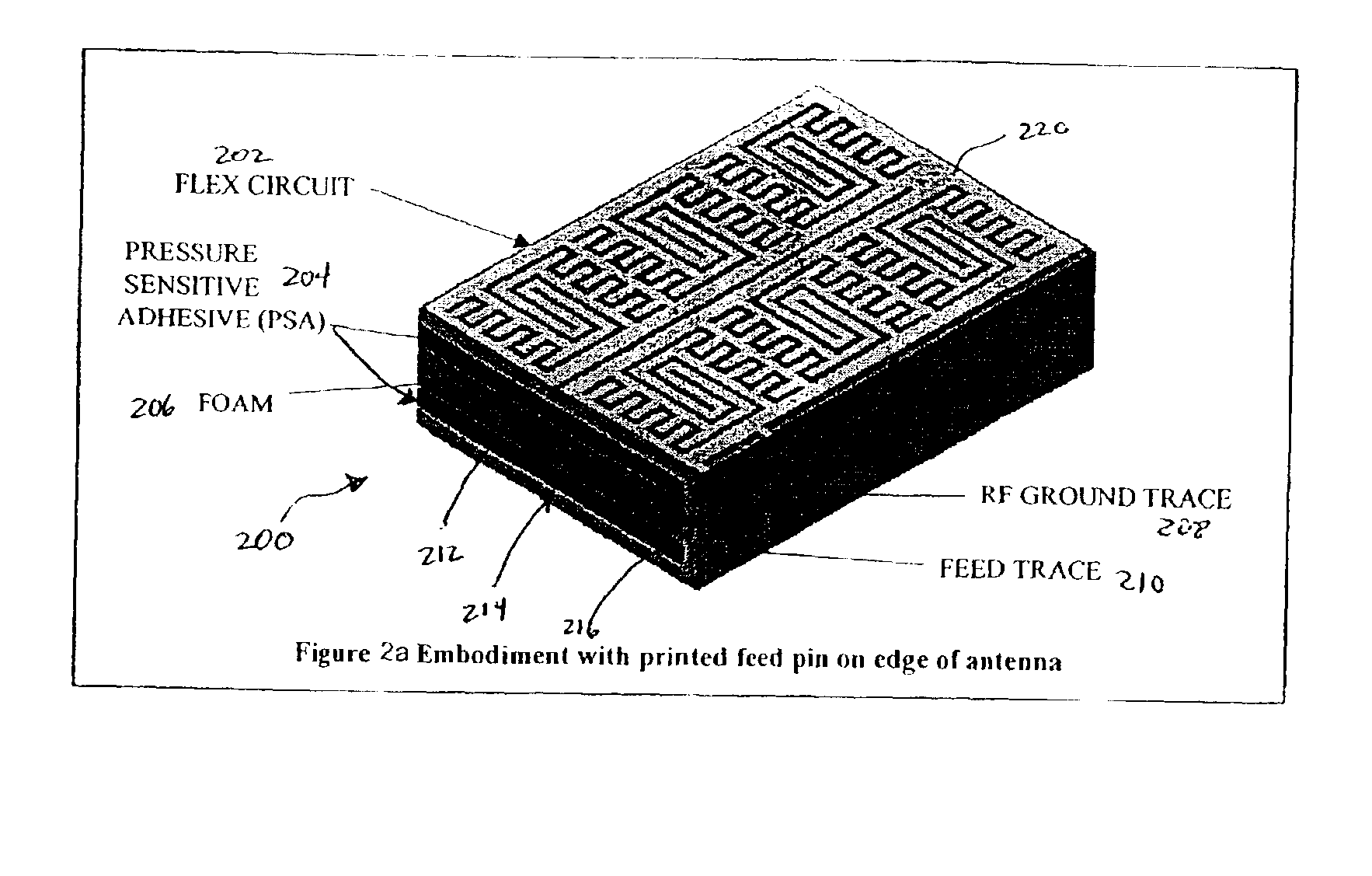

Method for fabrication of miniature lightweight antennas

InactiveUS6937192B2Low costReduce assembly labor costsSimultaneous aerial operationsAntenna supports/mountingsManufacturing technologyHigh volume manufacturing

Lightweight, small antennas are described that have decreased material and fabrication / processing cost. The antennas may be used in consumer electronics products such as cellular phones, laptops and PDA's. Some of the antennas and fabrication techniques also provide lower part count and increased reliability. All antennas are fabricated with standard materials currently available in high volume production.

Owner:OAE TECH INC

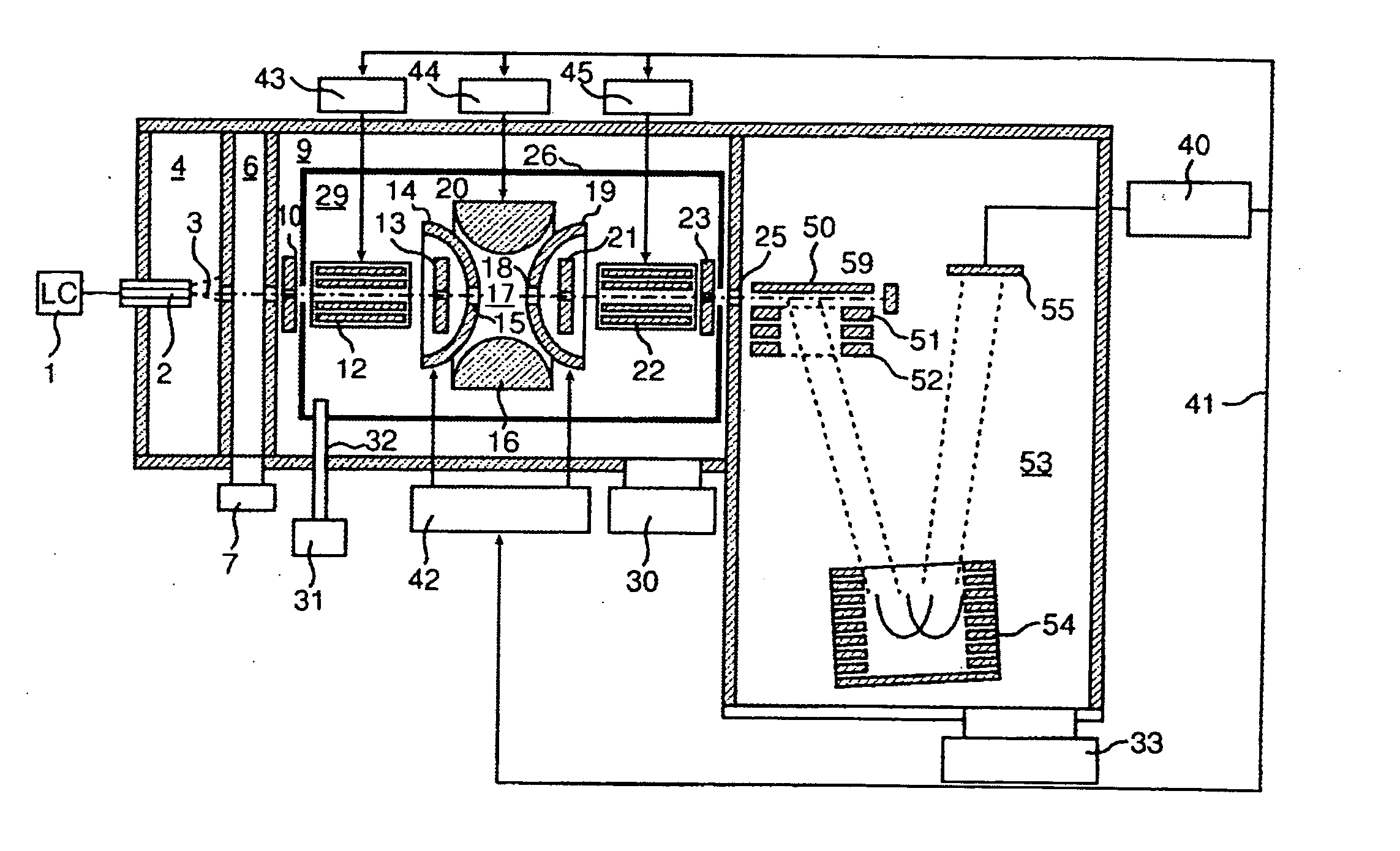

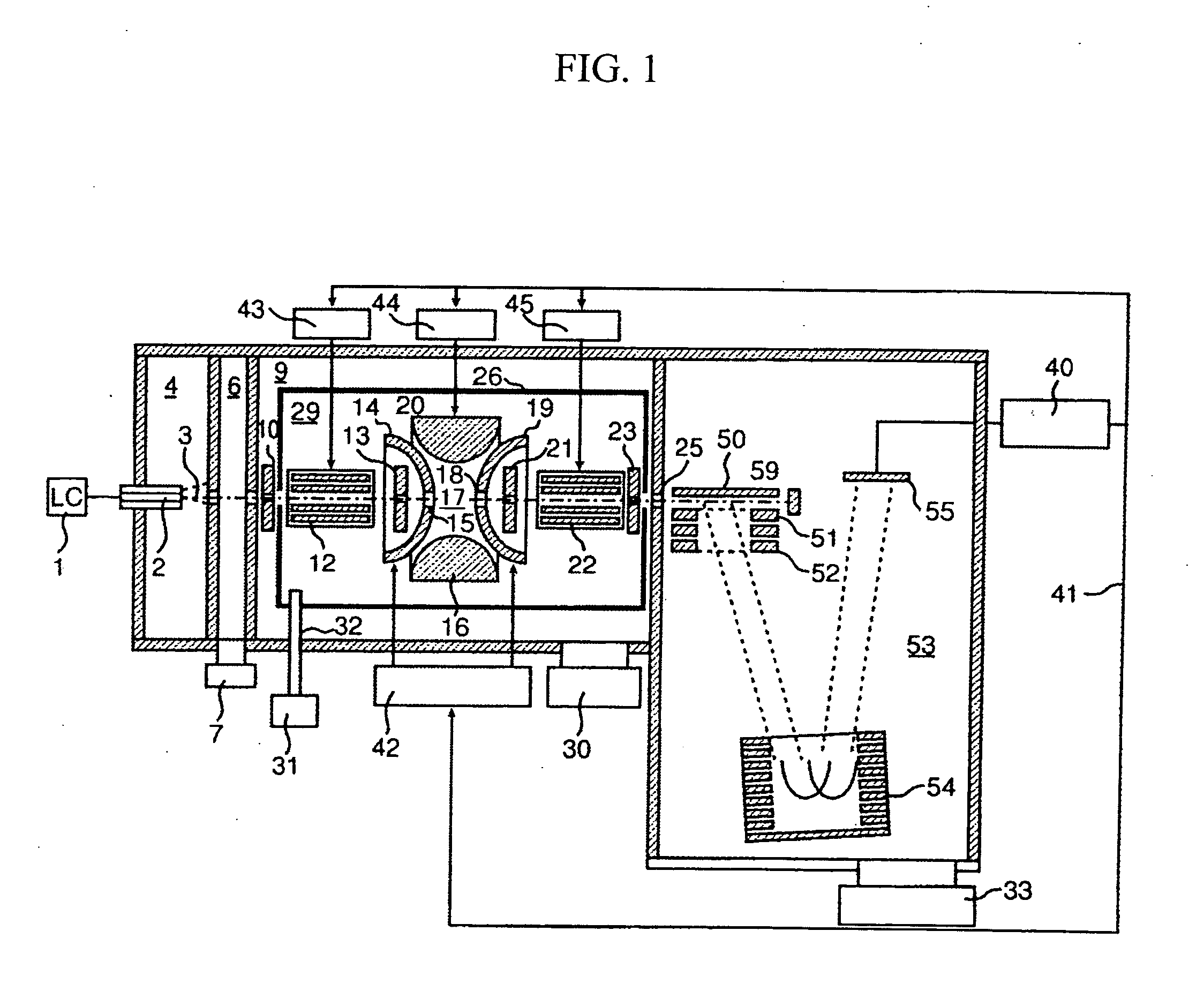

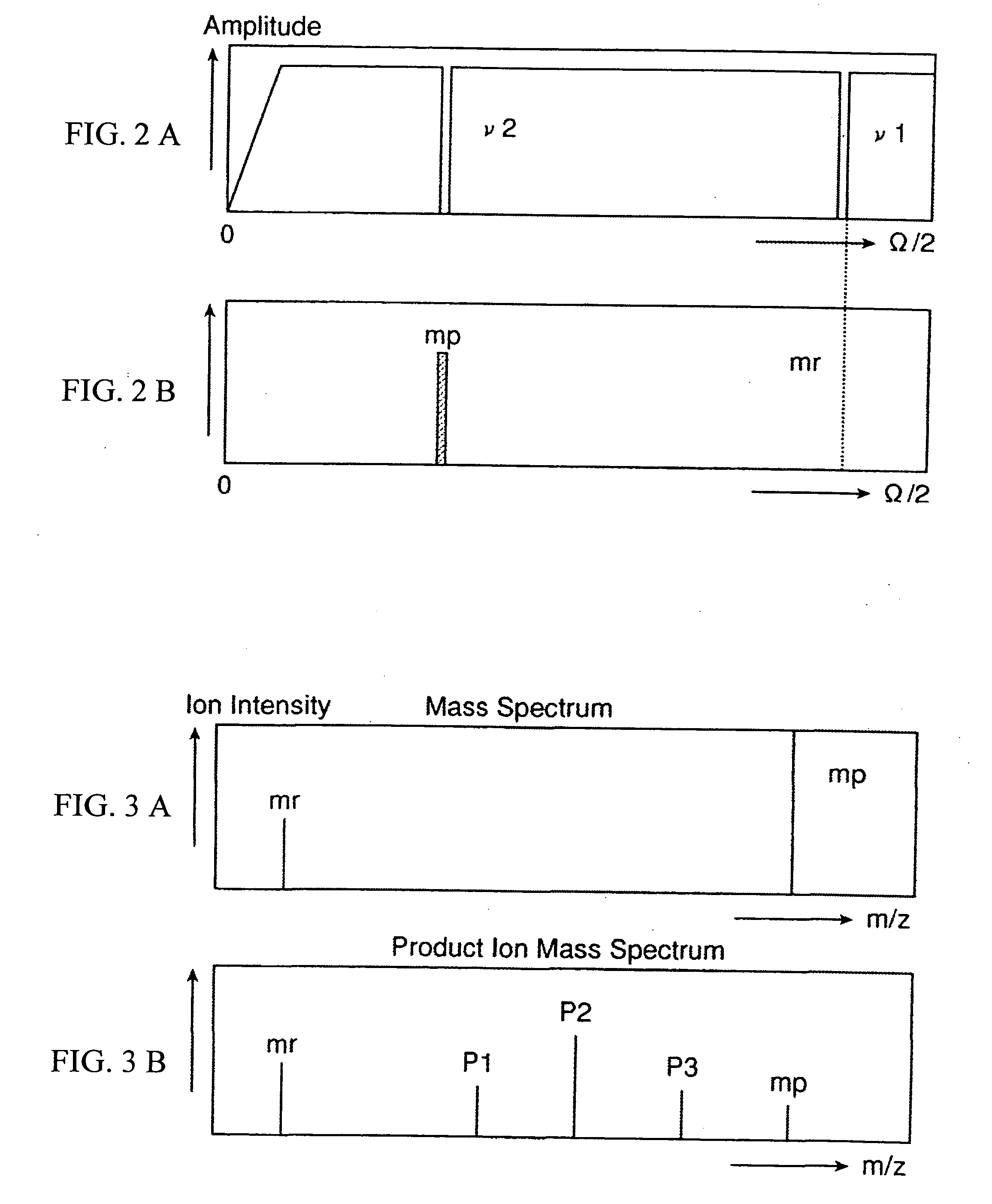

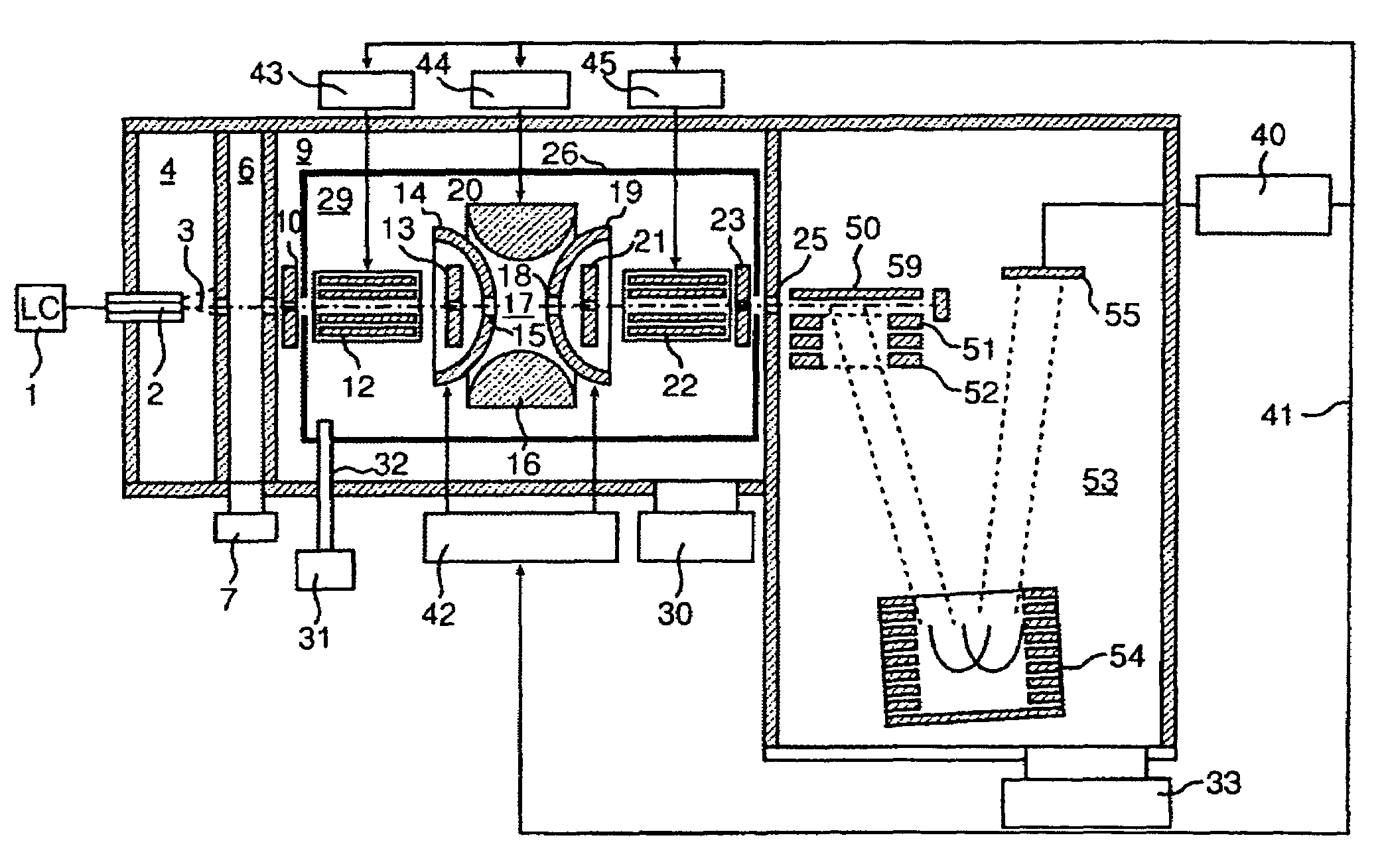

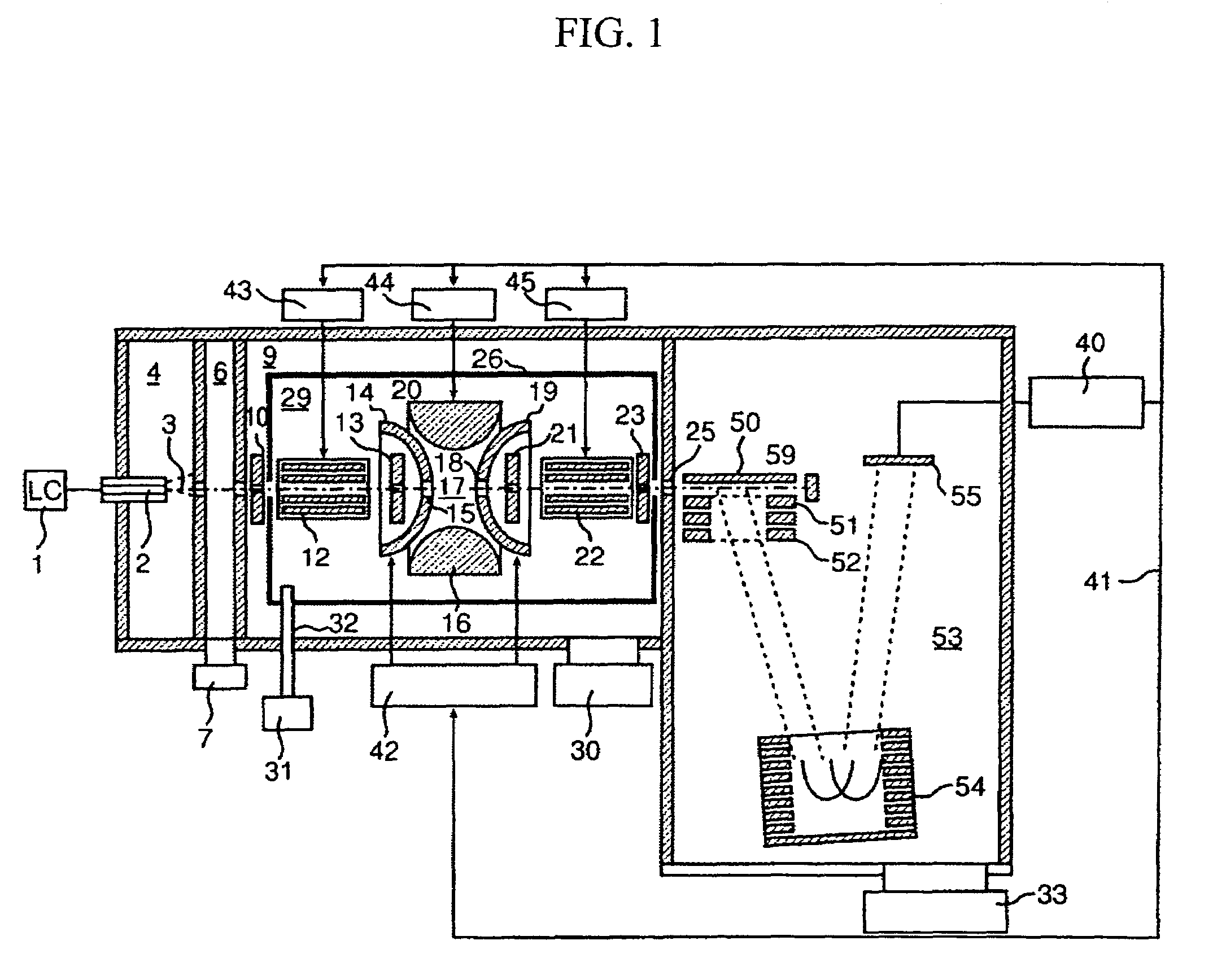

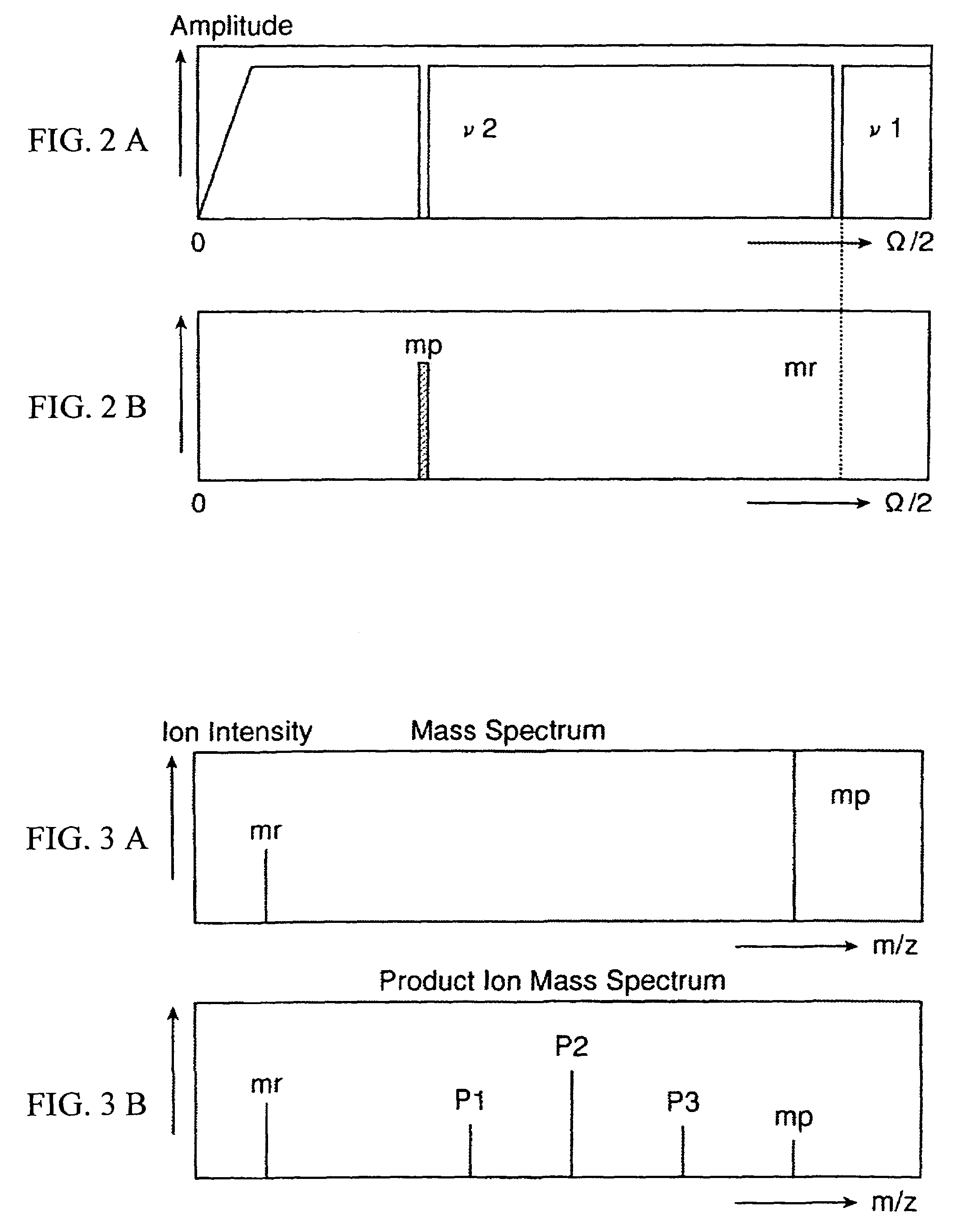

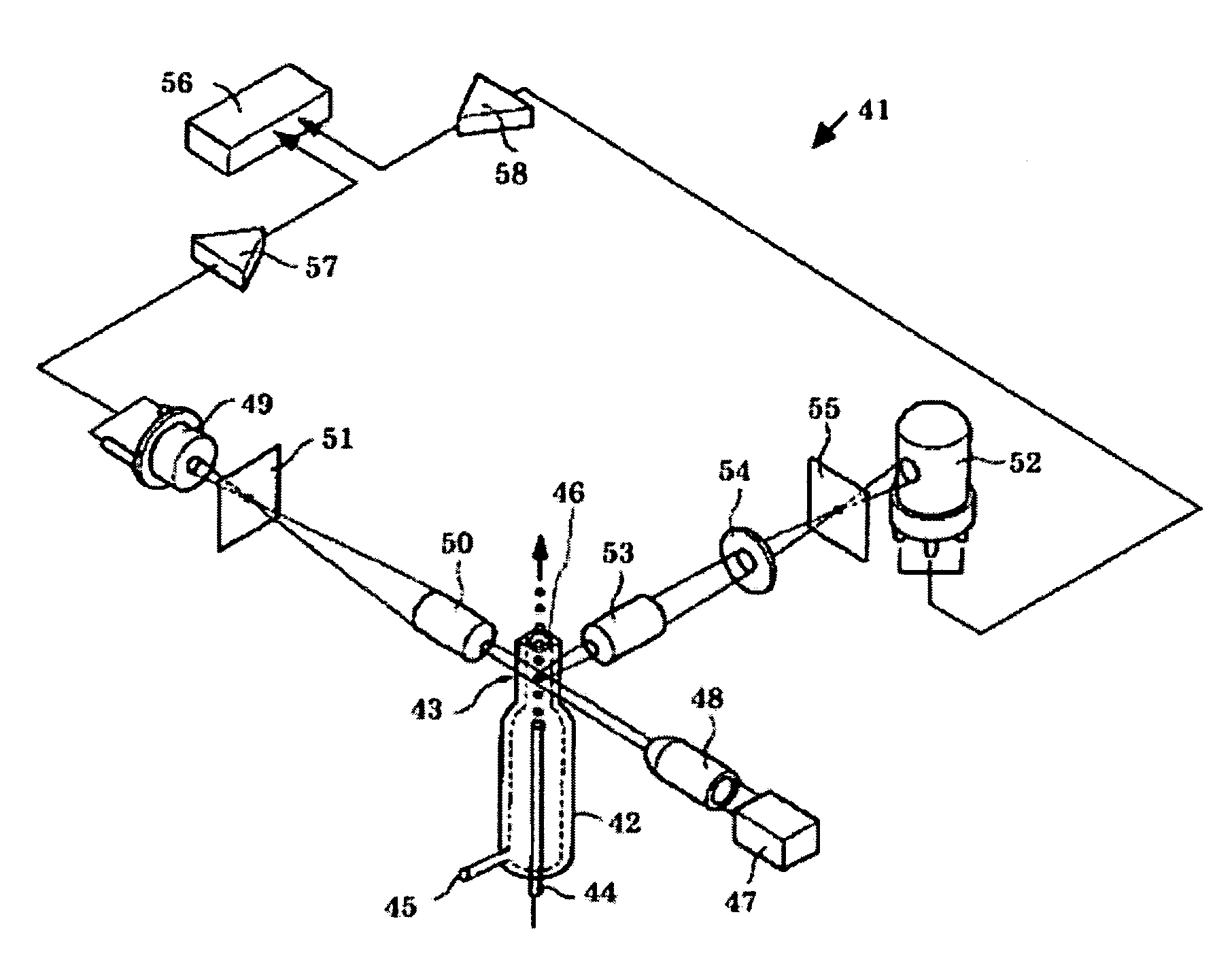

Method for accurate mass determination with ion trap/time-of-flight mass spectrometer

ActiveUS20050151073A1Accurate mass determinationImprove accuracyStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryAnalyte

Accurate mass measurement is carried out for product ions of a sample. A method for accurate mass determination of ions with Trap-TOF / μs includes steps of generating ions of an analyte sample and a standard material; introducing the ions of the analyte sample and the standard material together into an ion trap to trap them; selecting a precursor ion from the ions of the analyte sample to leave the precursor ion and a standard material ion in the ion trap and eliminate other ions; exciting and dissociating the precursor ion to generate product ions; ejecting the precursor ion, its product ions, and the standard material ion trapped in the ion trap to introduce these ions into the TOF mass spectrometer; and measuring a mass spectrum with the TOF mass spectrometer, where correction for accurate masses of the product ions is carried out based on the standard material ion measured.

Owner:HITACHI HIGH-TECH CORP

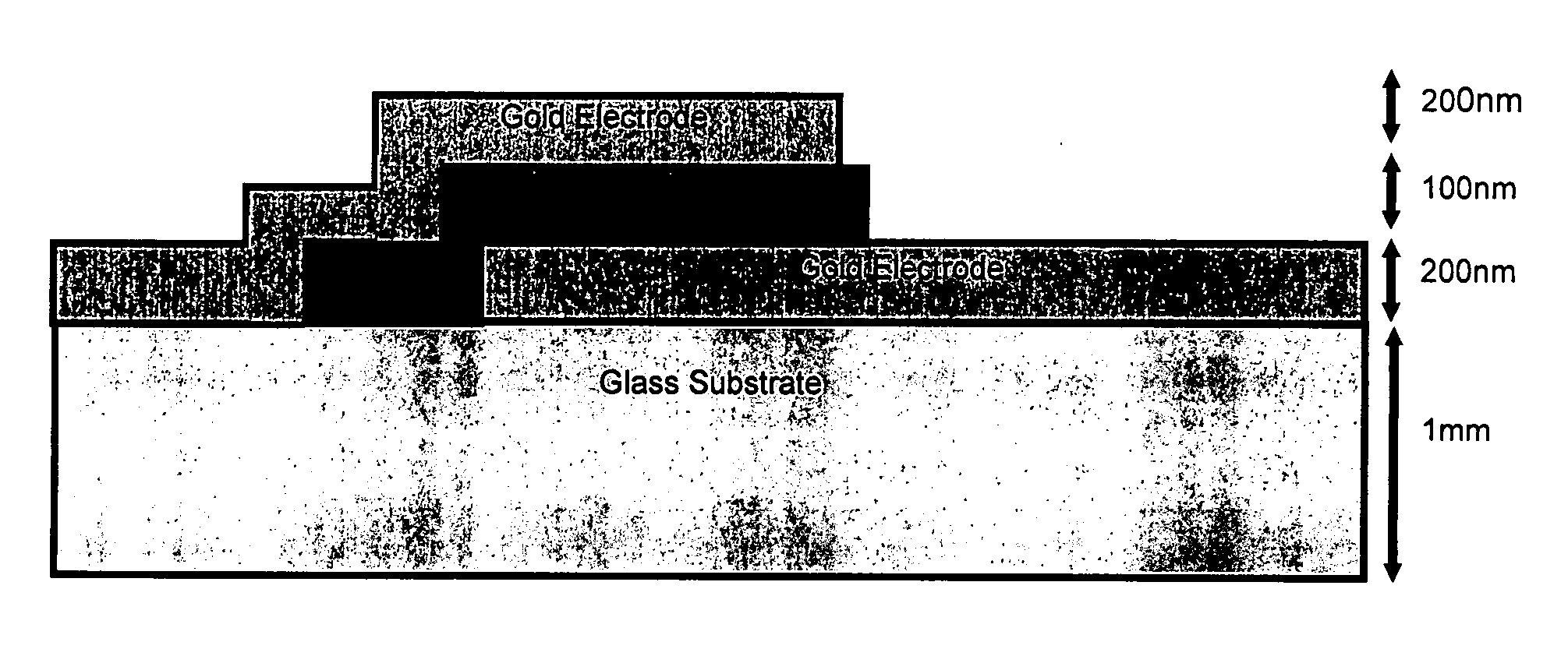

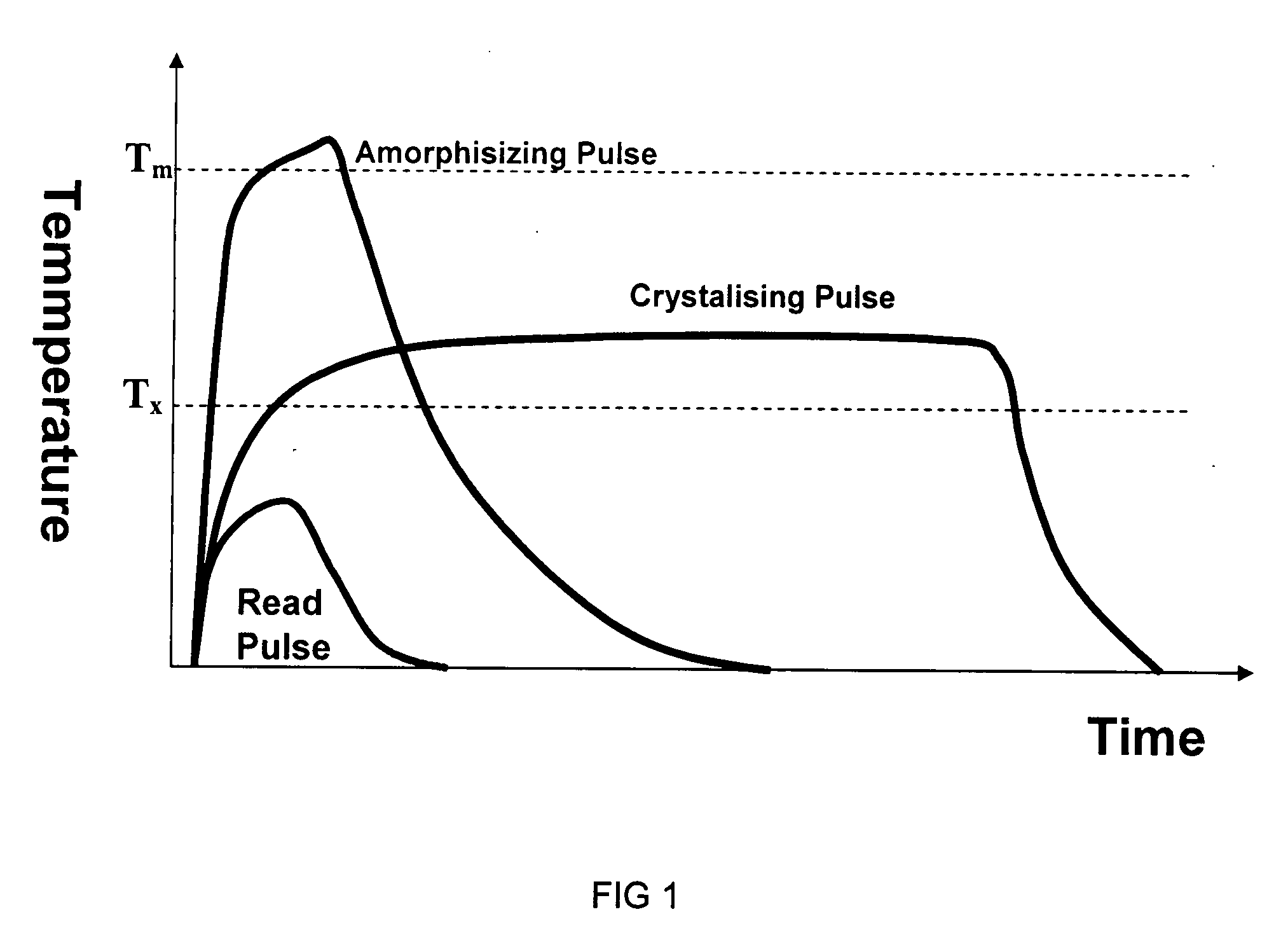

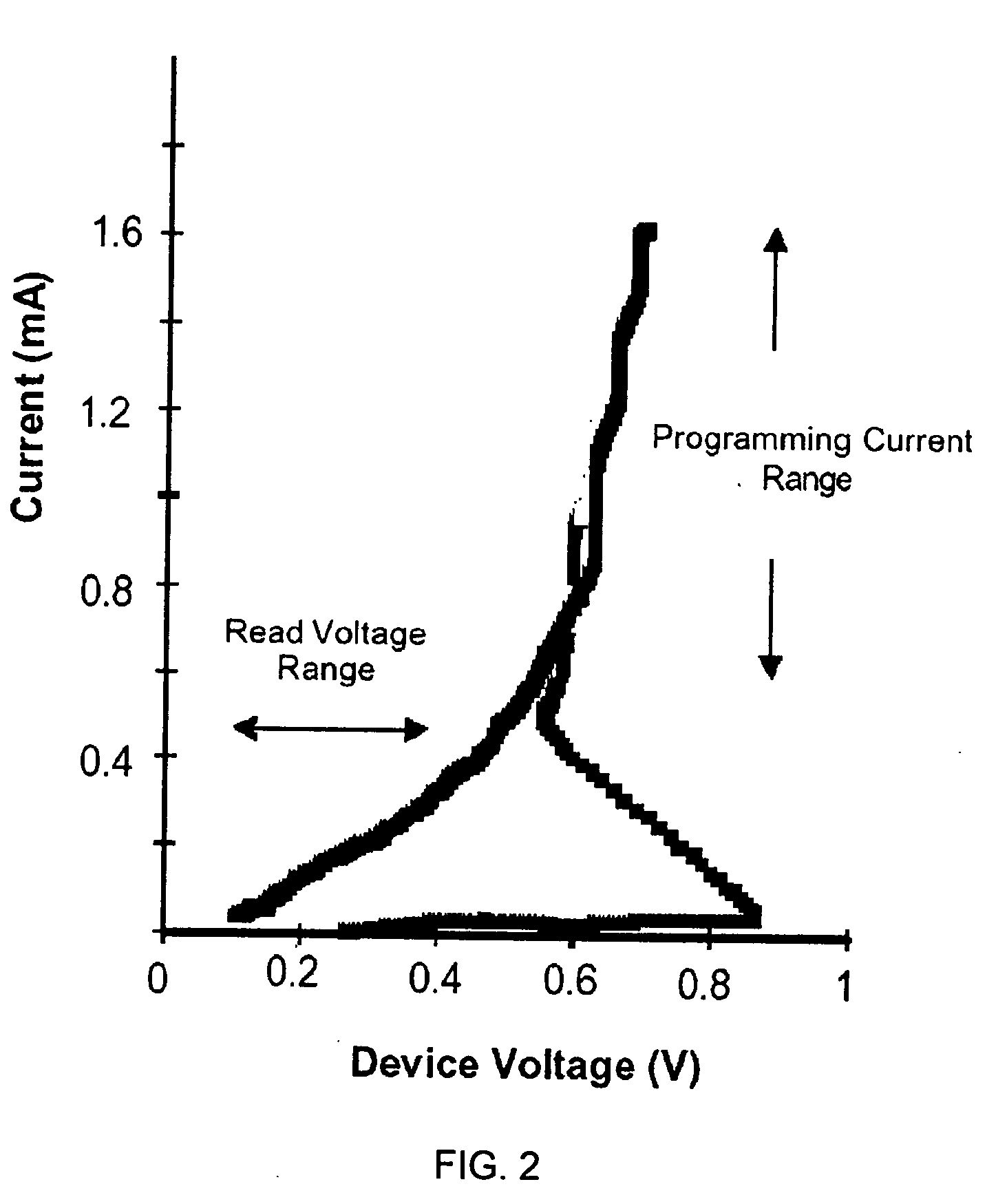

Phase change memory materials, devices and methods

InactiveUS20070181867A1Weaken energyImprove erasabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryLanthanide

A new class of phase change materials has been discovered based on compounds of: Ga; lanthanide; and chalcogenide. This includes compounds of Ga, La, and S (GLS) as well as related compounds in which there is substitution of S with O, Se and / or Te. Moreover, La can be substituted with other lanthanide series elements. It has been demonstrated that this class of materials exhibit low energy switching. For example, the GLS material can provide an optical recording medium with erasability 3-5 dB greater than the erasability of GeSbTe (GST) material which is the standard material for phase change memories.

Owner:UNIV OF SOUTHAMPTON

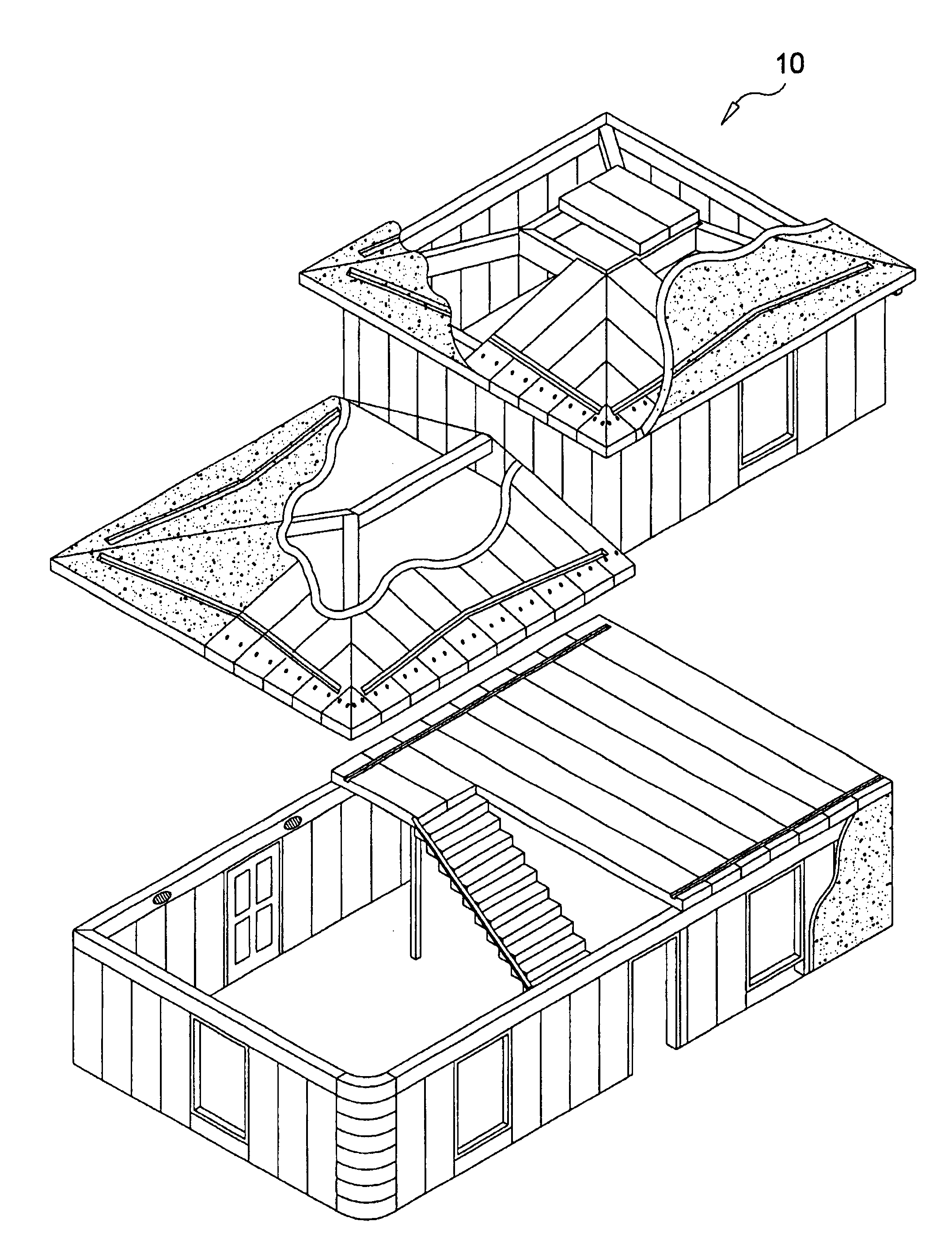

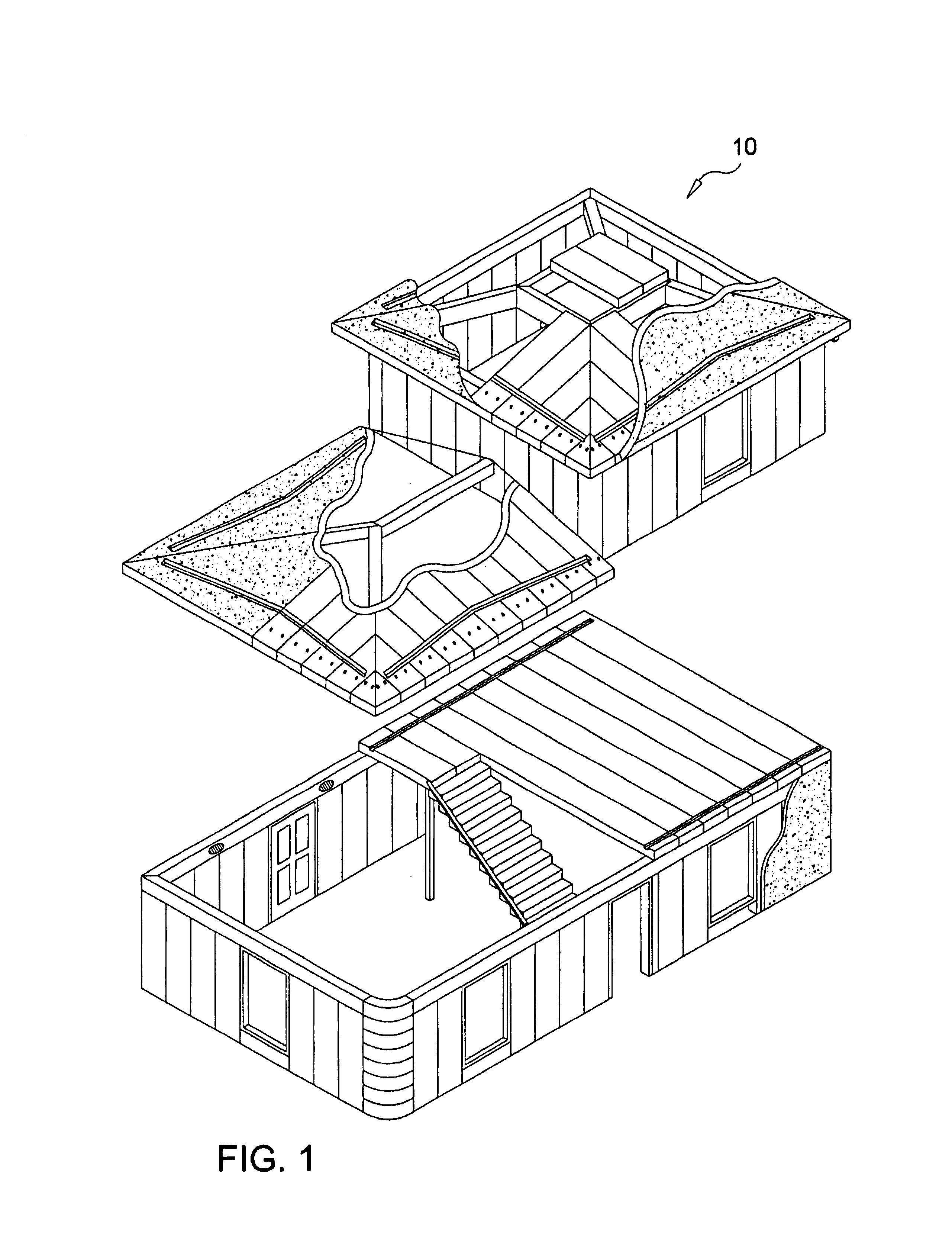

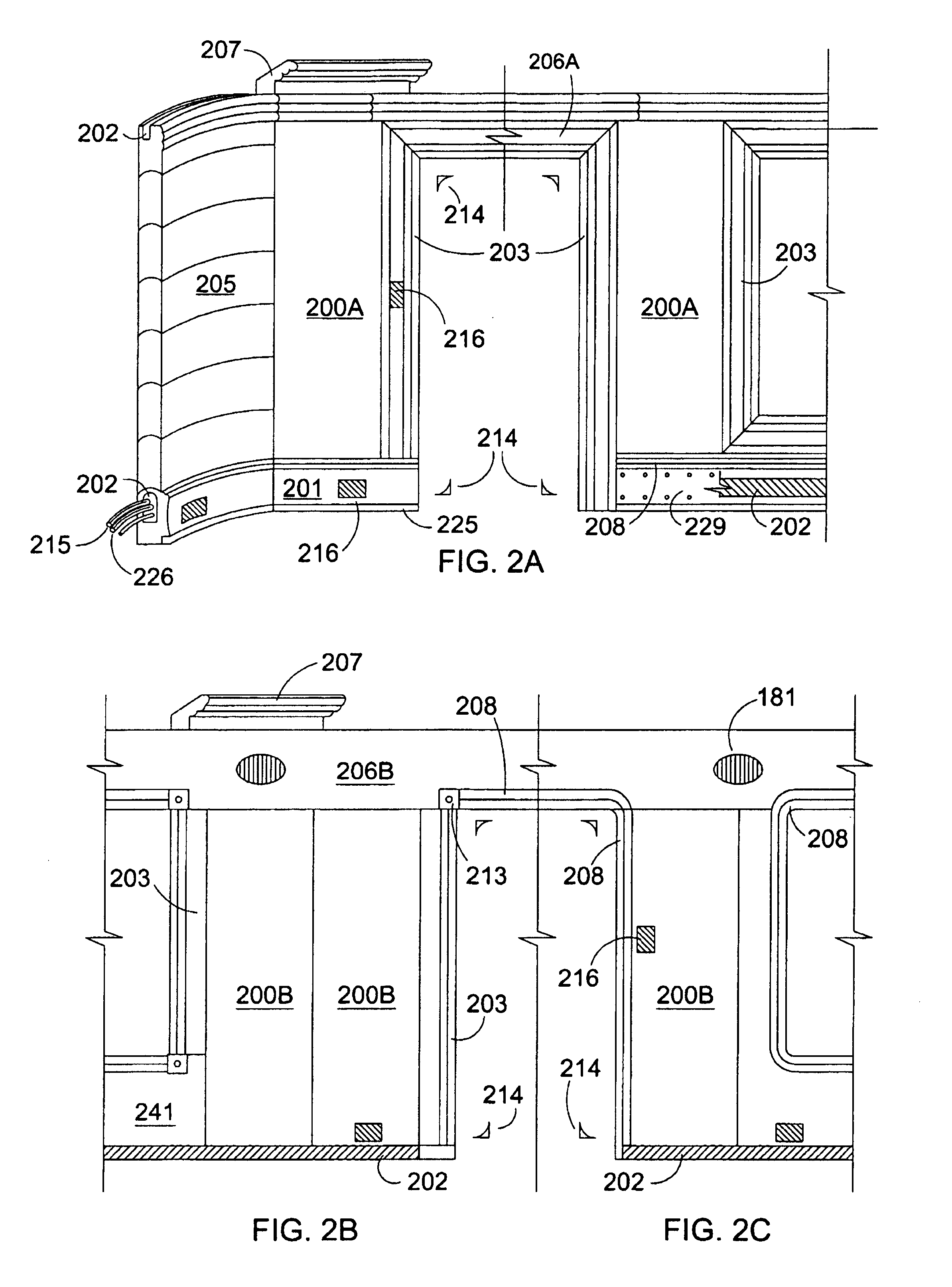

System for manufacturing structures of cementitious materials

InactiveUS7204060B2Overcome problemsBuilding roofsSolar heating energyHigh pressureAutoclaved aerated concrete

Owner:HUNT CHRISTOPHER M

Method for preparing high specific surface area nano alumina material

InactiveCN101391786ASimple production processLow costAluminium oxides/hydroxidesNano al2o3Petrochemical

The invention relates to a method for preparing nano-alumina material with high specific surface area; the method mixes oil phase, surfactant, and cosurfactant in accordance with a certain volume ratio and adds aluminum salt solution, precipitant drop into the organic phase, then a microemulsion system is formed, a reaction is generated in a tiny water droplet by stirring, and later aluminum hydroxide precipitation is obtained. By washing, drying and calcining, nano-alumina is finally formed. The nano-alumina is a Gamma-alumina phase, with the average particular diameter of 5 to 100nm, the specific surface area of 200 to 500m <2> / g, the pore volume of 1.5 to 2.5cm <3> / g, and the average pore diameter of 5 to 60nm. The preparation method has the advantages of simple production process, low cost, strong repeatability, extremely high purity, uniformity and stability of obtained alumina product, can carry out batch production, can be applied to scientific research, petrochemical and building industries, and can also be used as standard material of the specific surface area.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

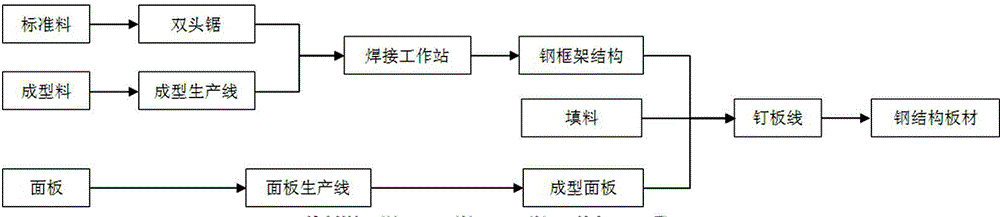

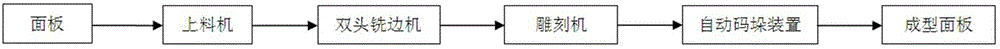

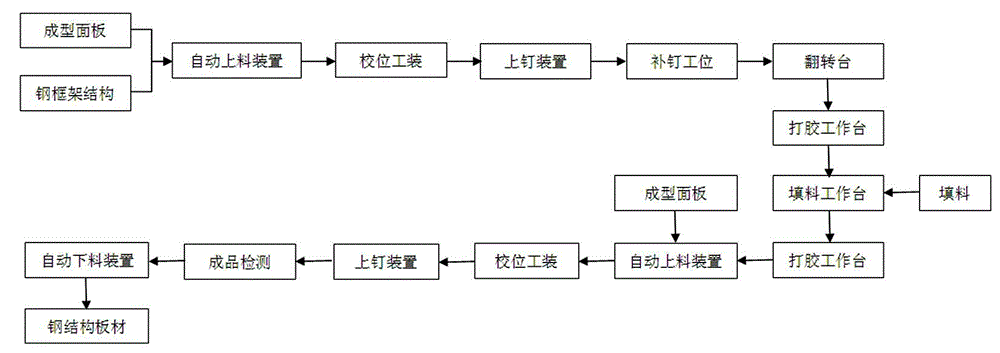

Production line and production method for steel structure plates

ActiveCN104405073AImprove stabilityReduce welding errorsConstruction materialOther manufacturing equipments/toolsProduction lineMetallurgy

The invention discloses a production line and production method for steel structure plates. The production line comprises a panel production line for processing panels, a double-end saw used for cutting standard materials, a steel structure forming production line used for steel structure processing, a welding operation station used for welding steel frame structures, and a plate nailing production line used for combining the steel structure plates. The production line for steel structure plates, provided by the invention, has the characteristics of high automation degree, and stable quality of produced steel structure plate products.

Owner:广东耀达房屋科技股份有限公司

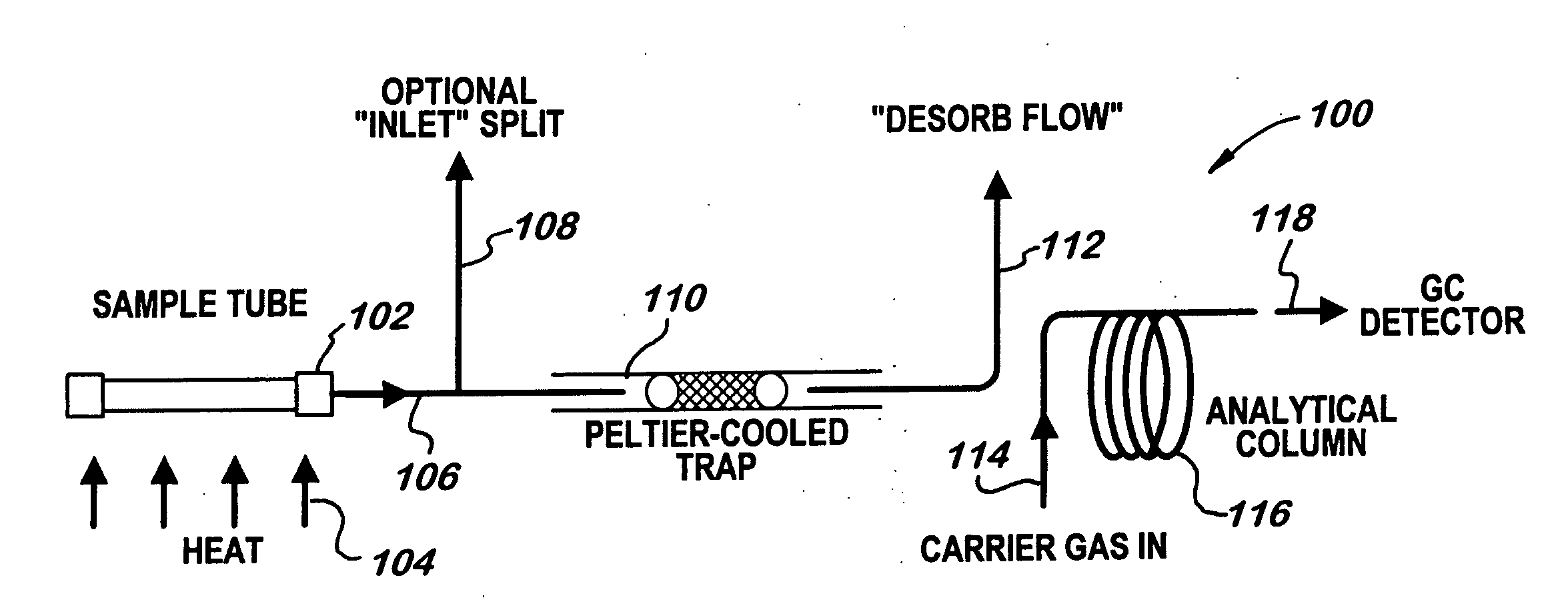

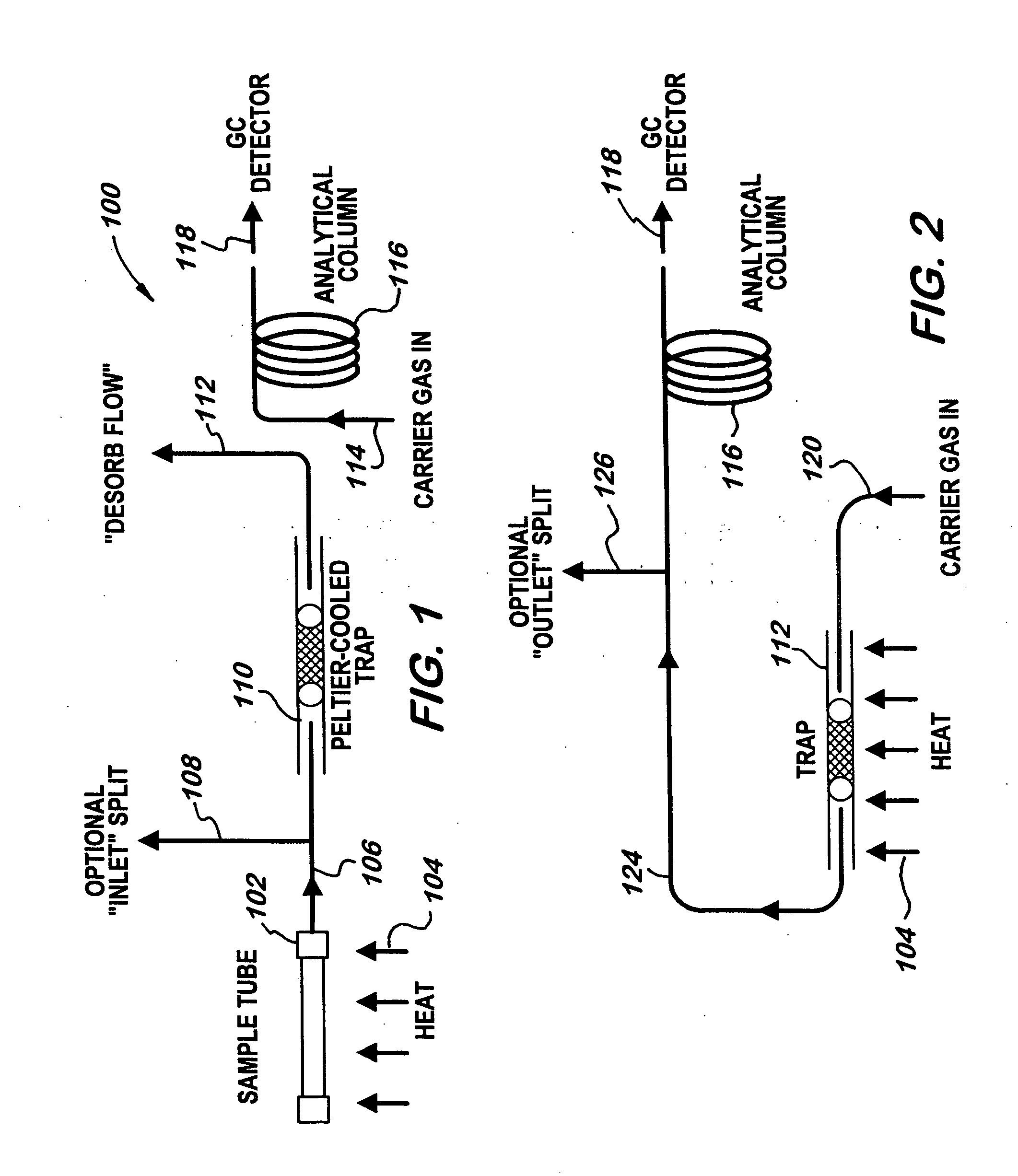

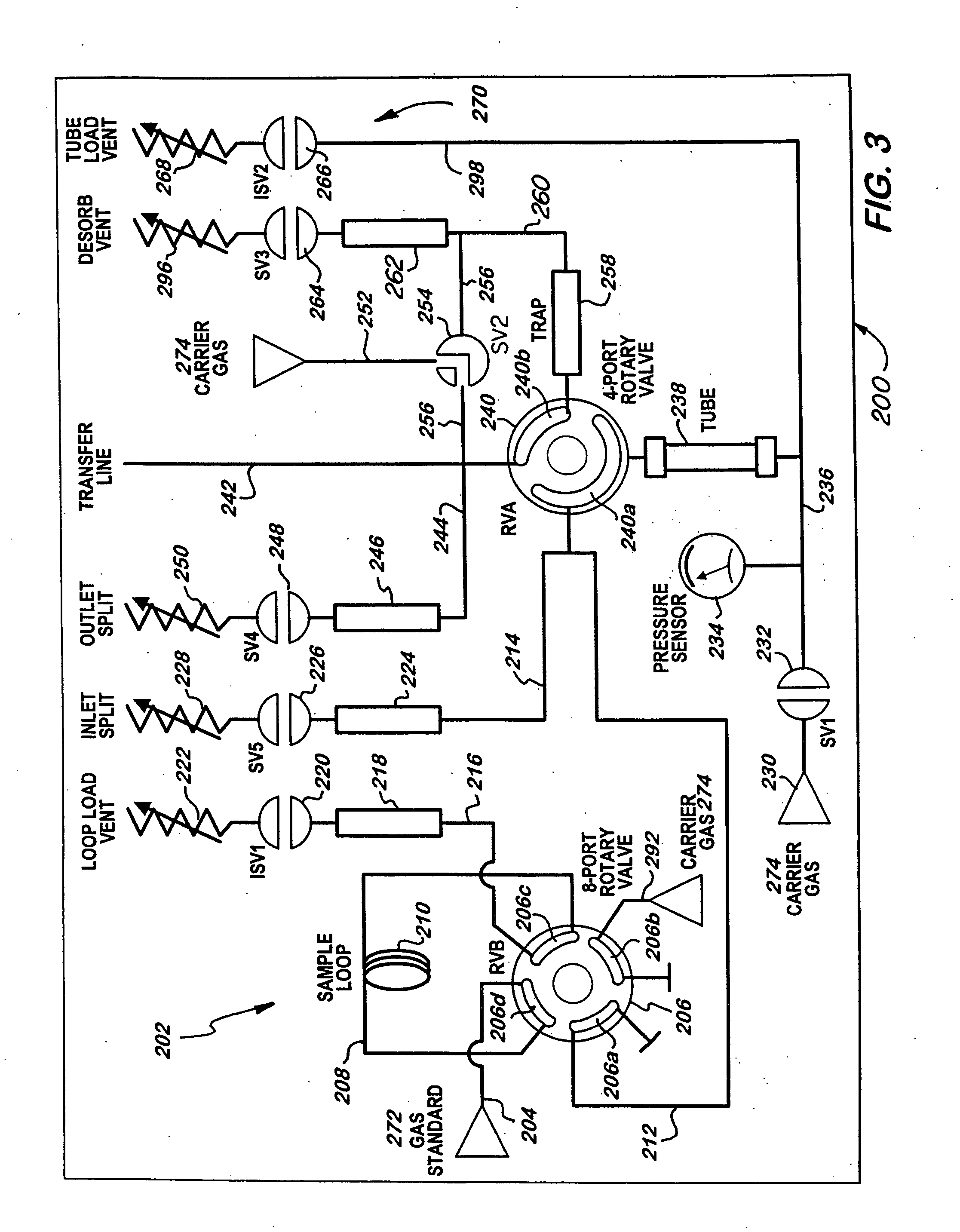

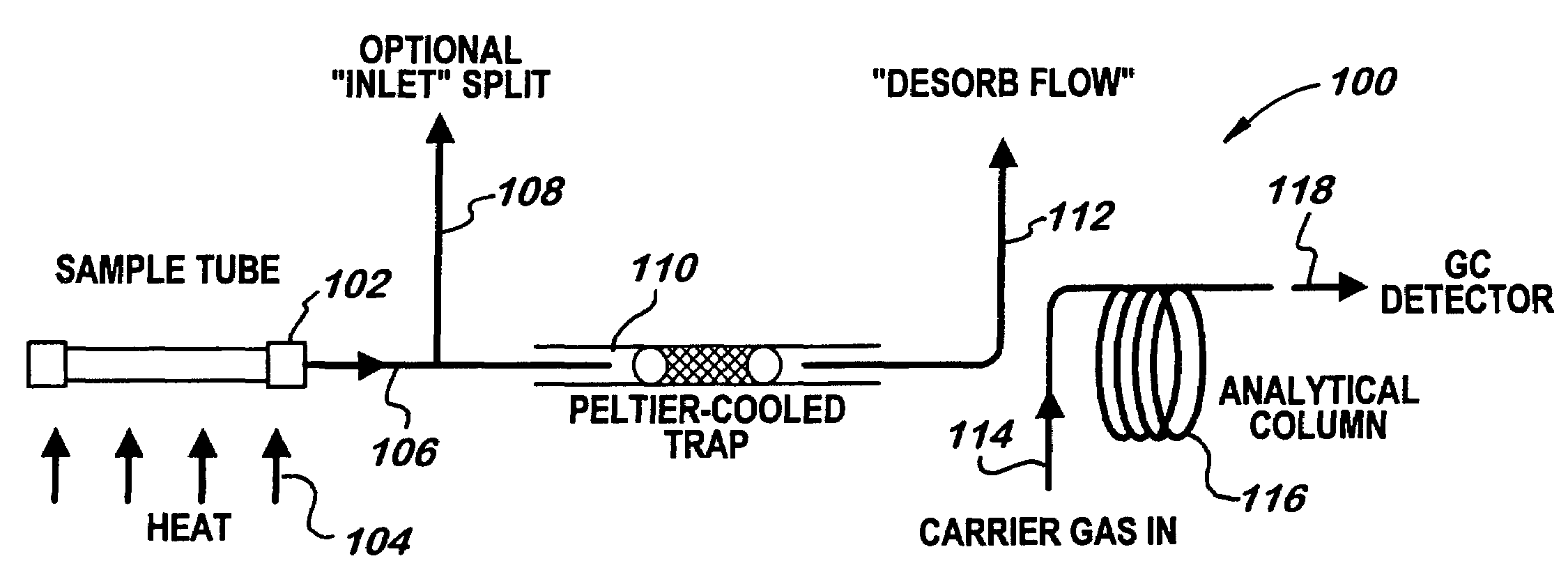

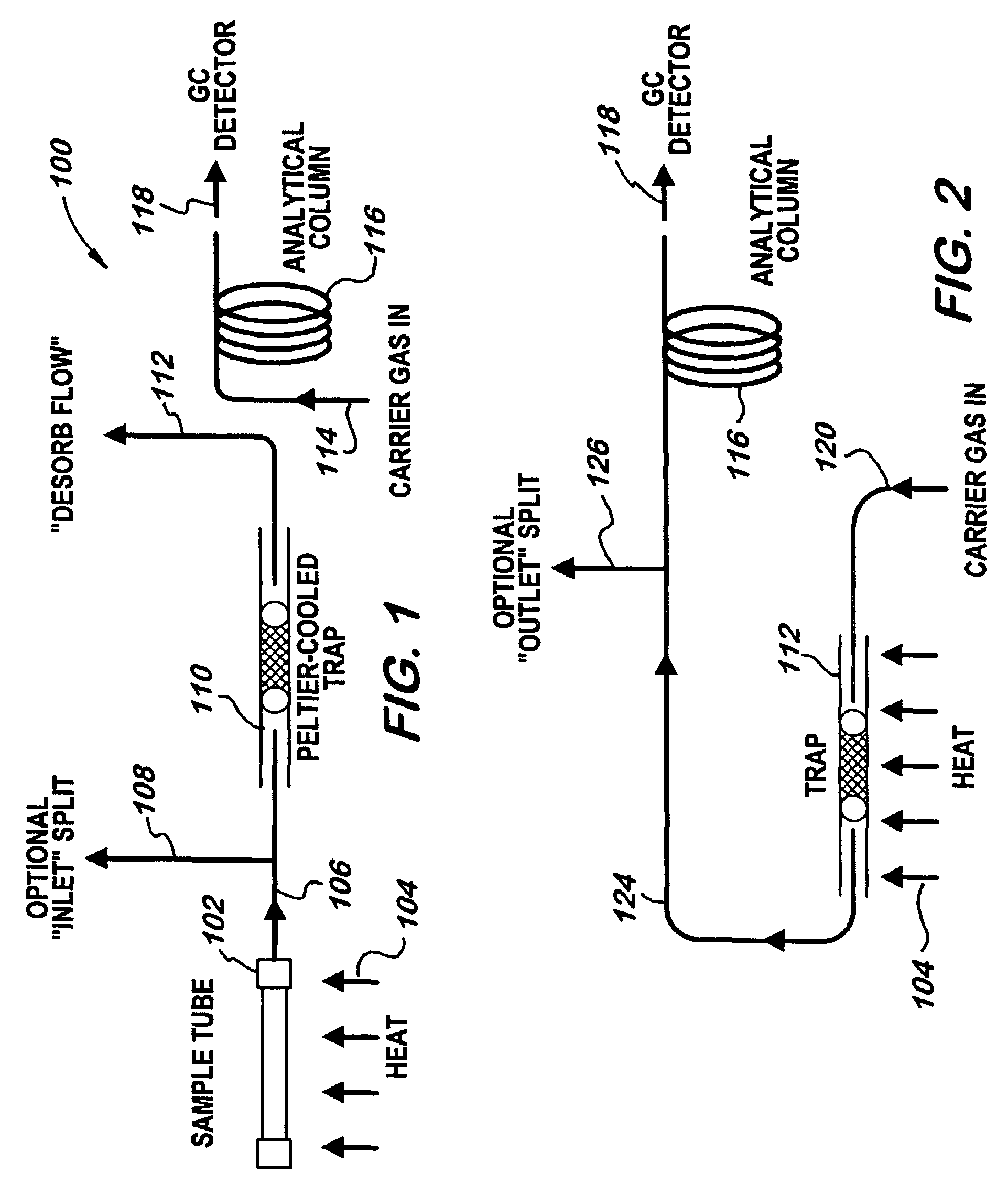

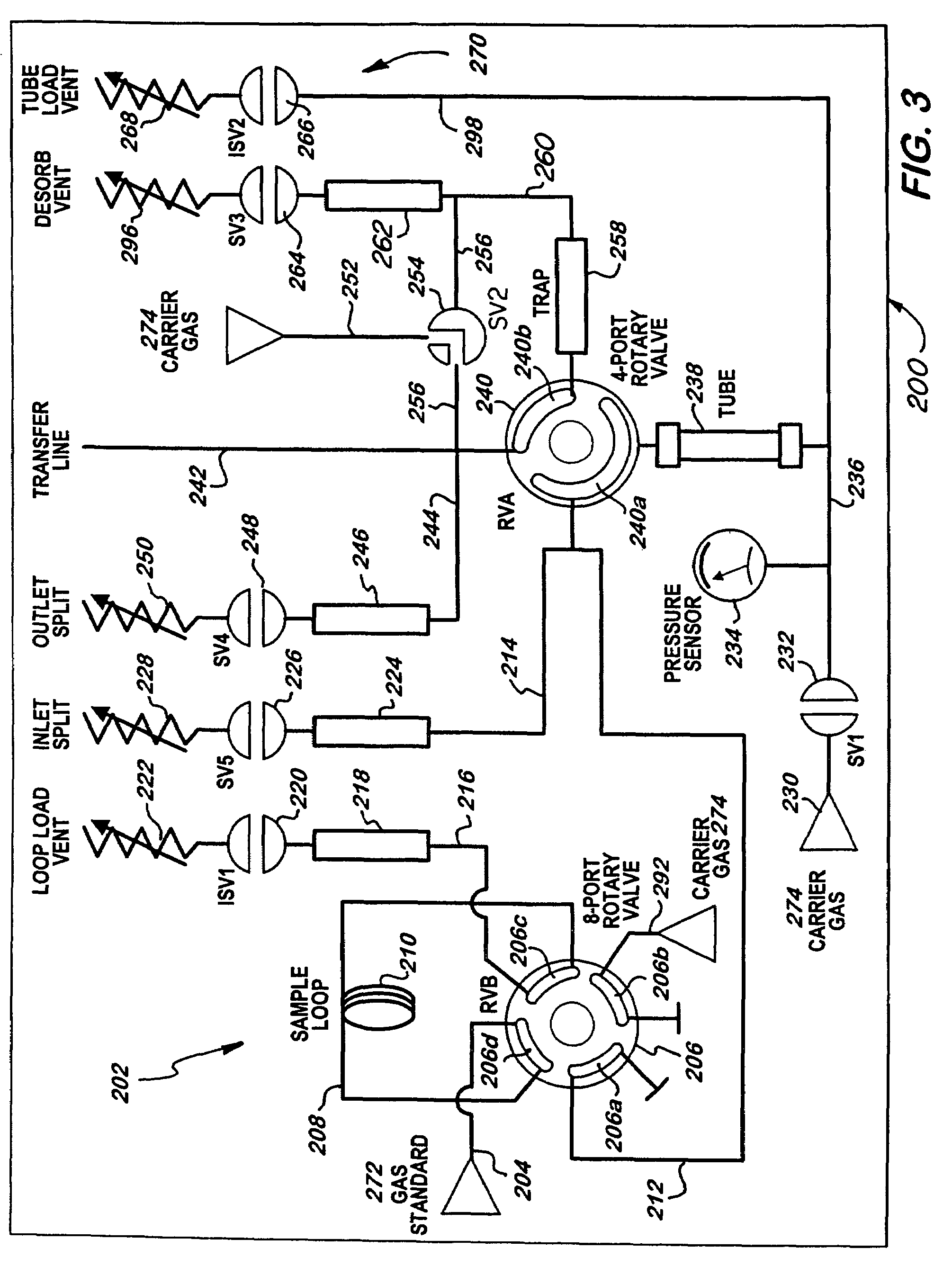

Method for verifying the integrity of thermal desorption sampling tubes

ActiveUS20060094118A1Fast loadingComponent separationWithdrawing sample devicesAnalyteCompound (substance)

An analyte of a sample is transferred to an analytical instrument by introducing a quantity of a compound of a standard material into a vessel containing an adsorbent material; introducing a quantity of the analyte of the sample into the vessel; and transferring the analyte of the sample and the compound of the standard material to the analytical instrument.

Owner:PERKINELMER U S LLC

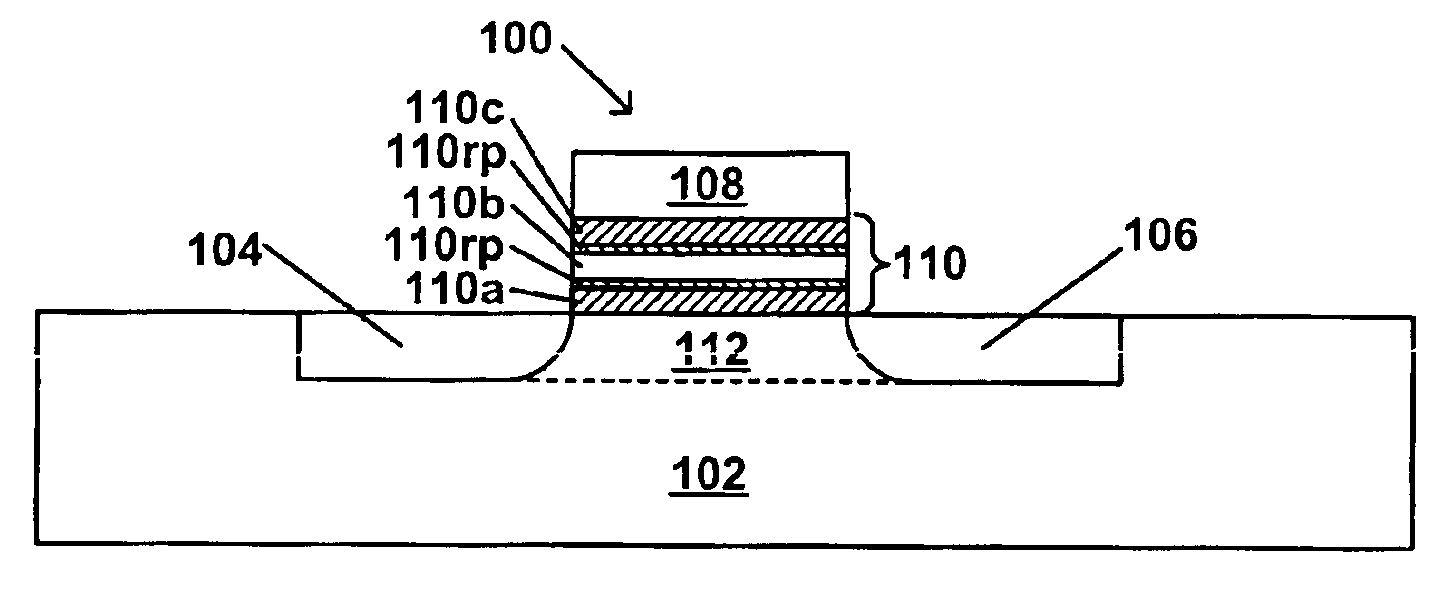

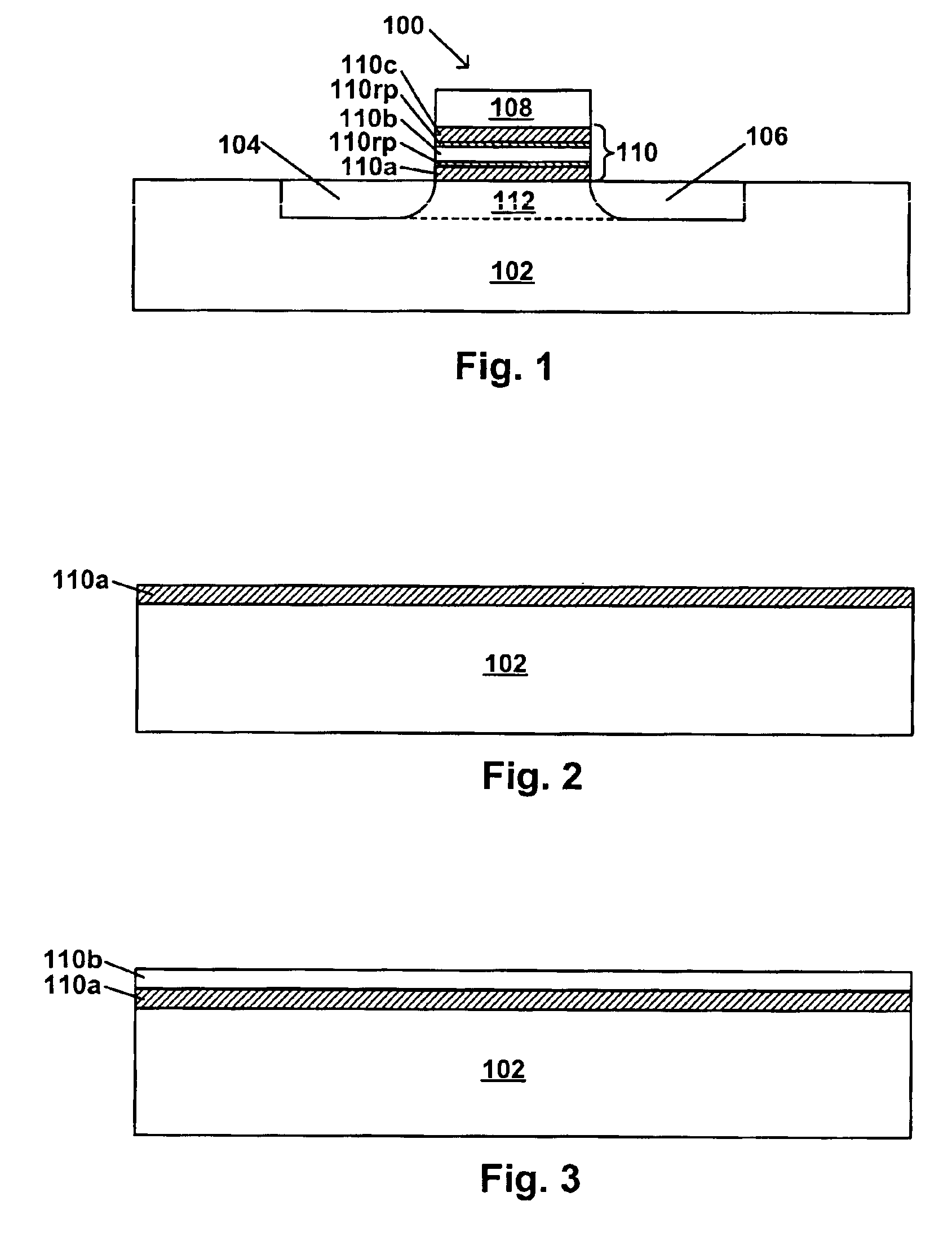

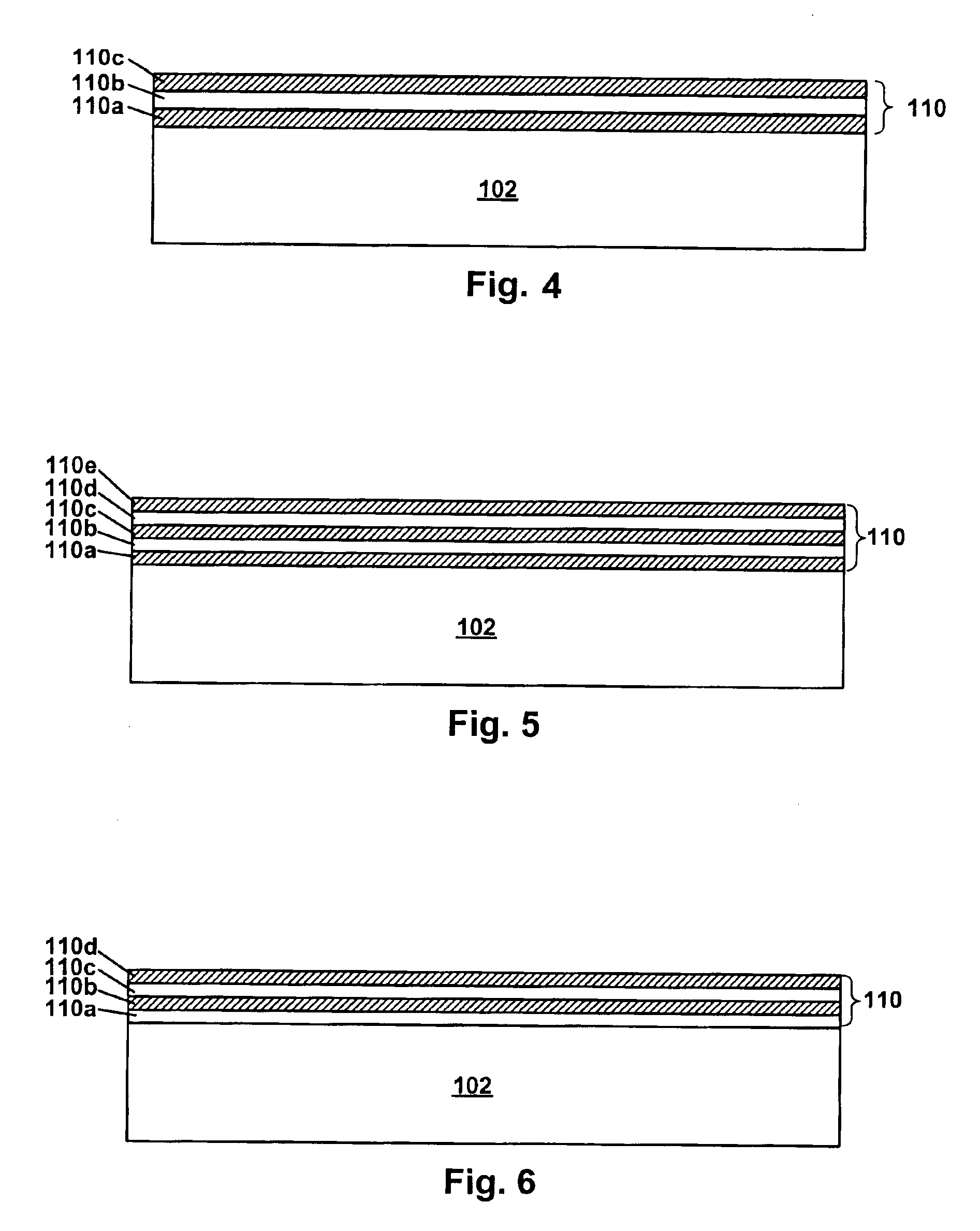

Preparation of composite high-K/standard-K dielectrics for semiconductor devices

A semiconductor device having a composite dielectric layer, including a semiconductor substrate, alternating sub-layers including a first dielectric material and a second dielectric material on the semiconductor substrate, the sub-layers forming a composite dielectric layer having at least two sub-layers of at least one of the first dielectric material and the second dielectric material, in which one of the first dielectric material and the second dielectric material is a high-K dielectric material and an other of the first dielectric material and the second dielectric material is a standard-K dielectric material comprising aluminum oxide; and the composite dielectric layer includes a reaction product of the high-K dielectric material and the standard-K dielectric material. In one embodiment, the composite dielectric layer includes a substantially uniform layer of the reaction product of the first dielectric material and the second dielectric material.

Owner:GLOBALFOUNDRIES INC

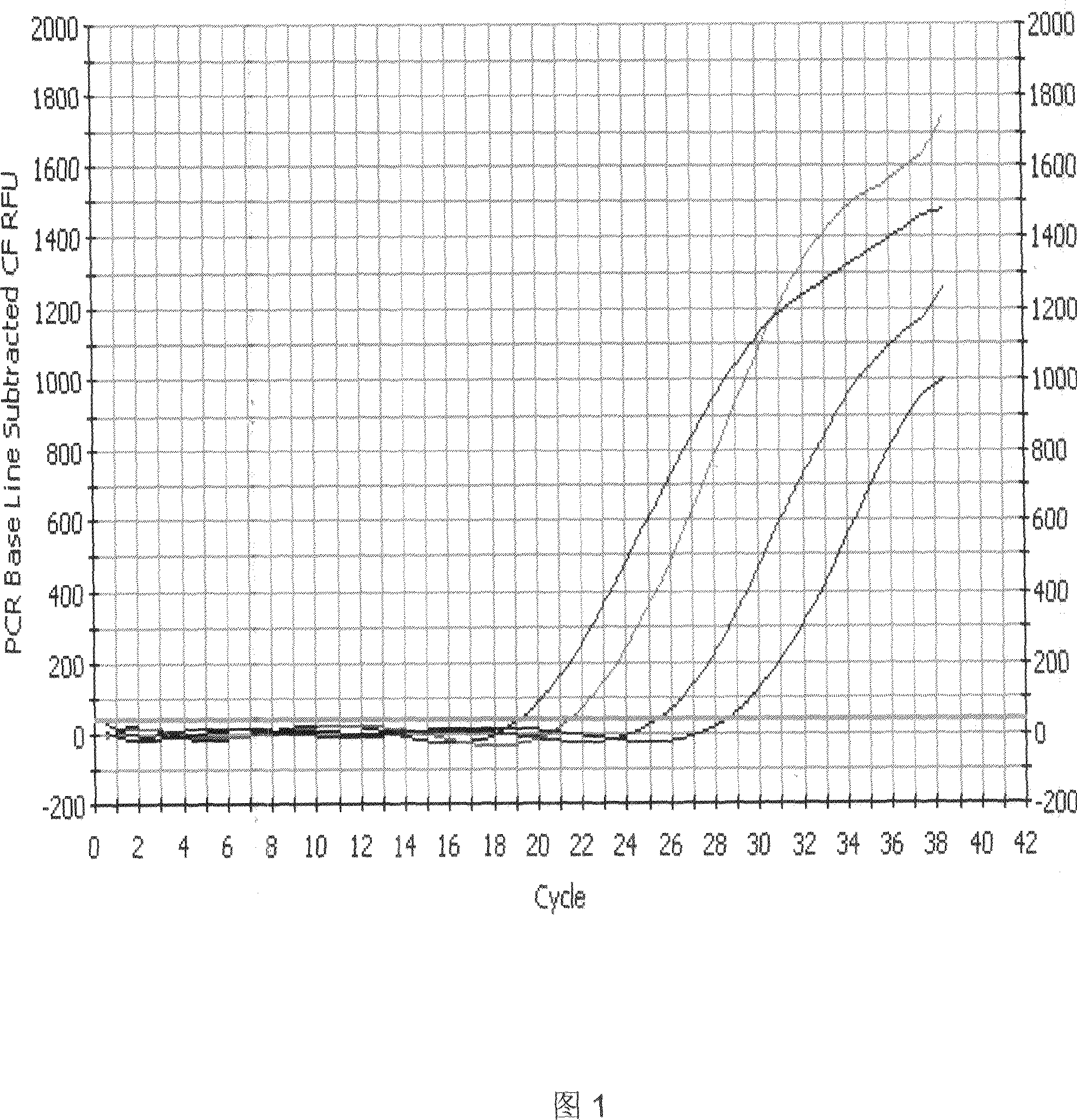

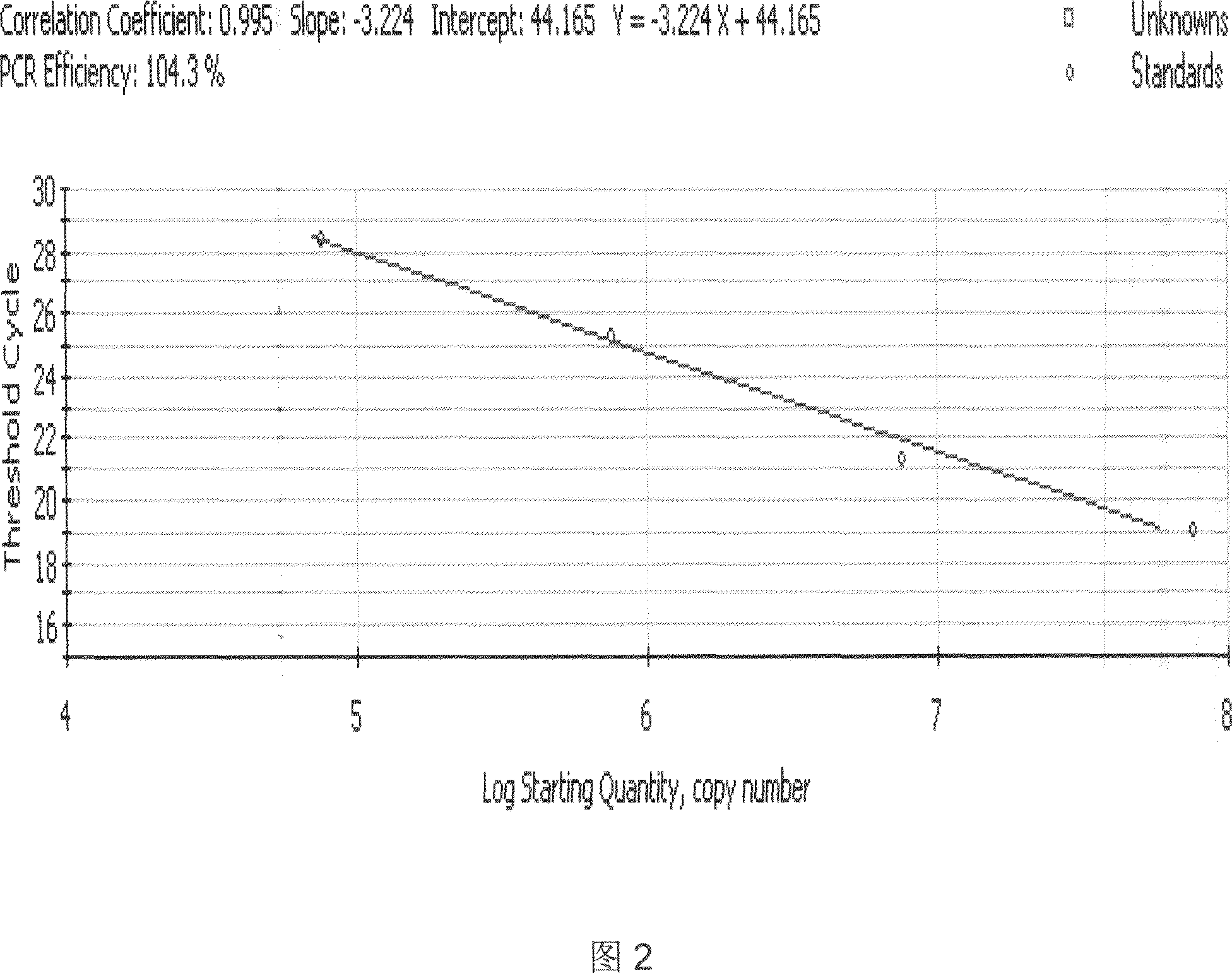

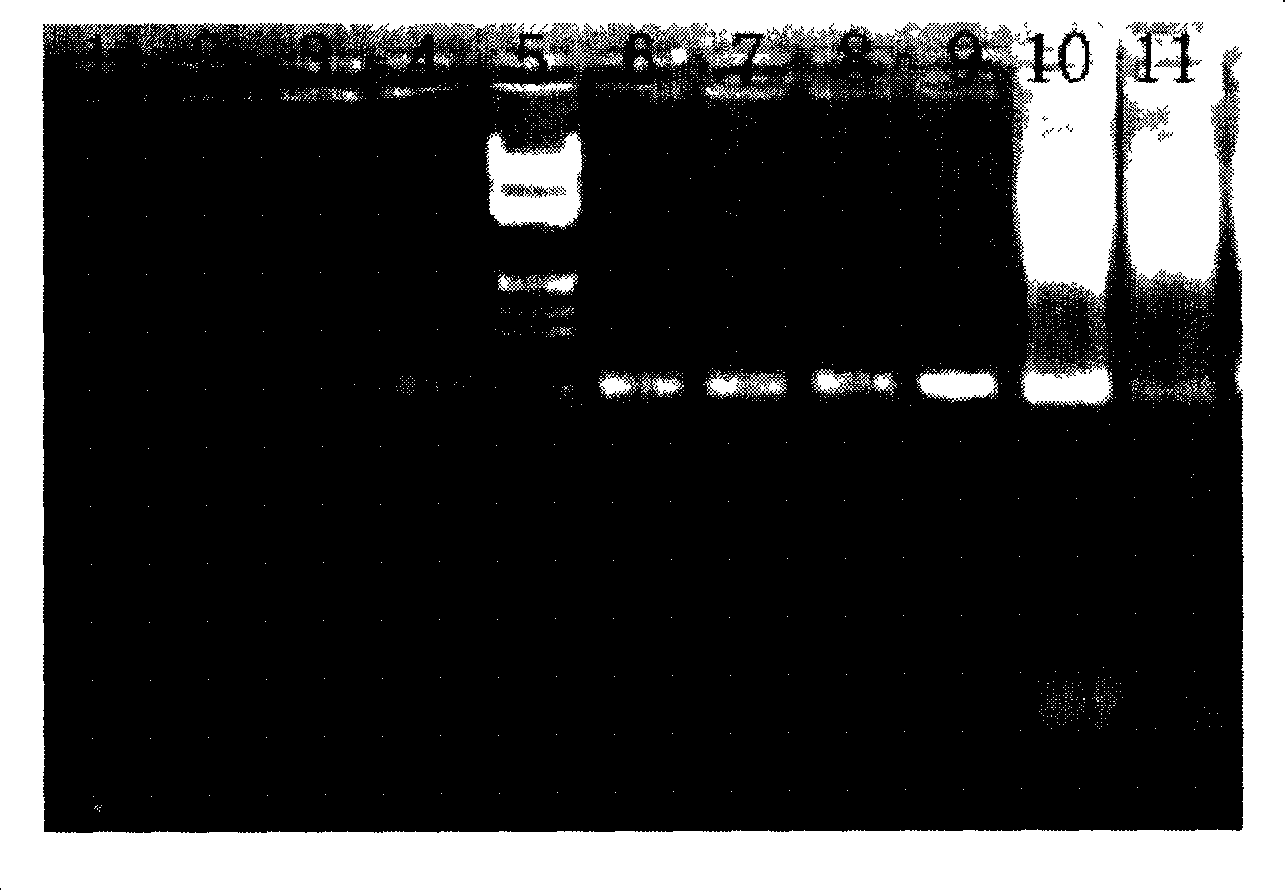

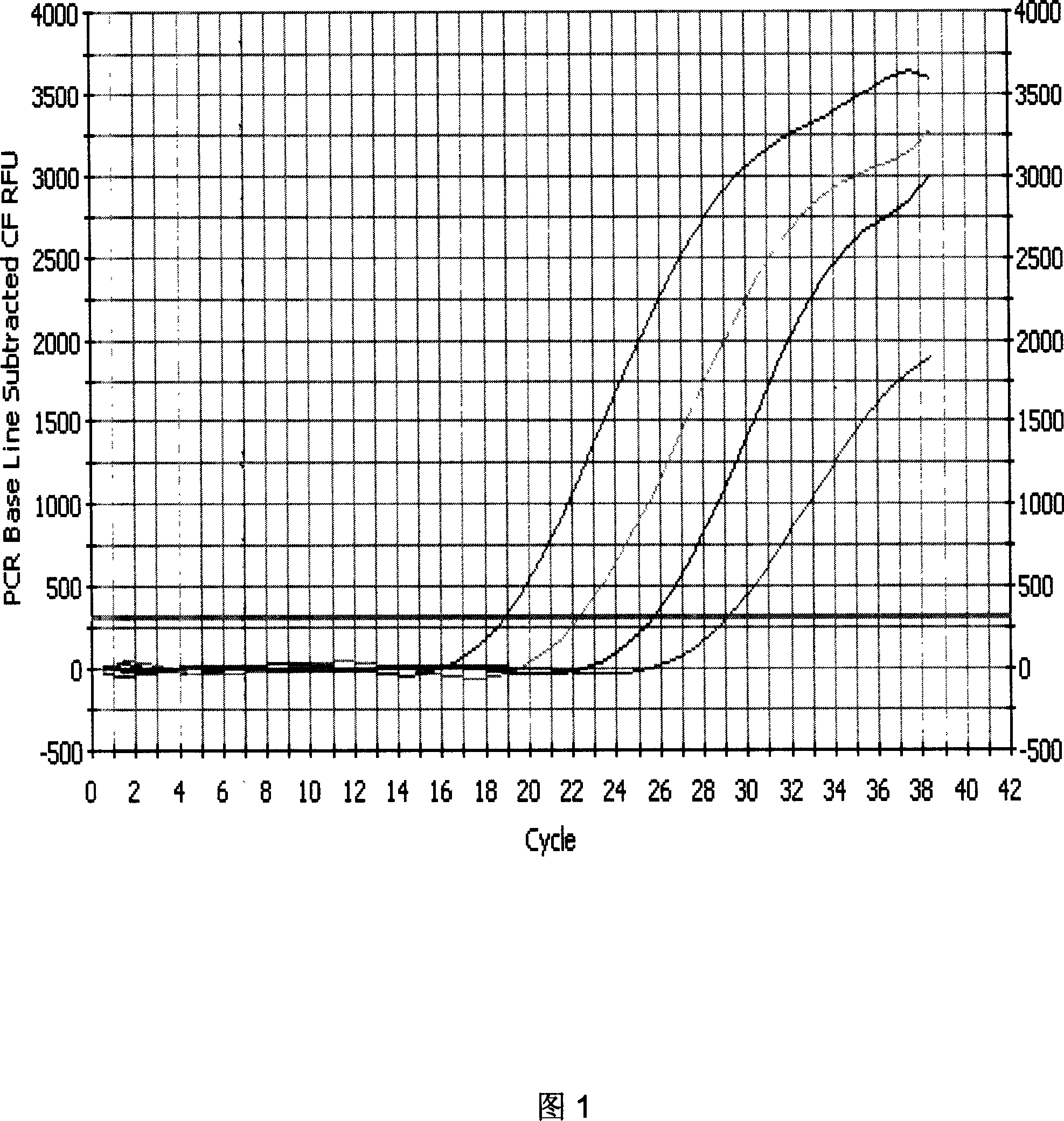

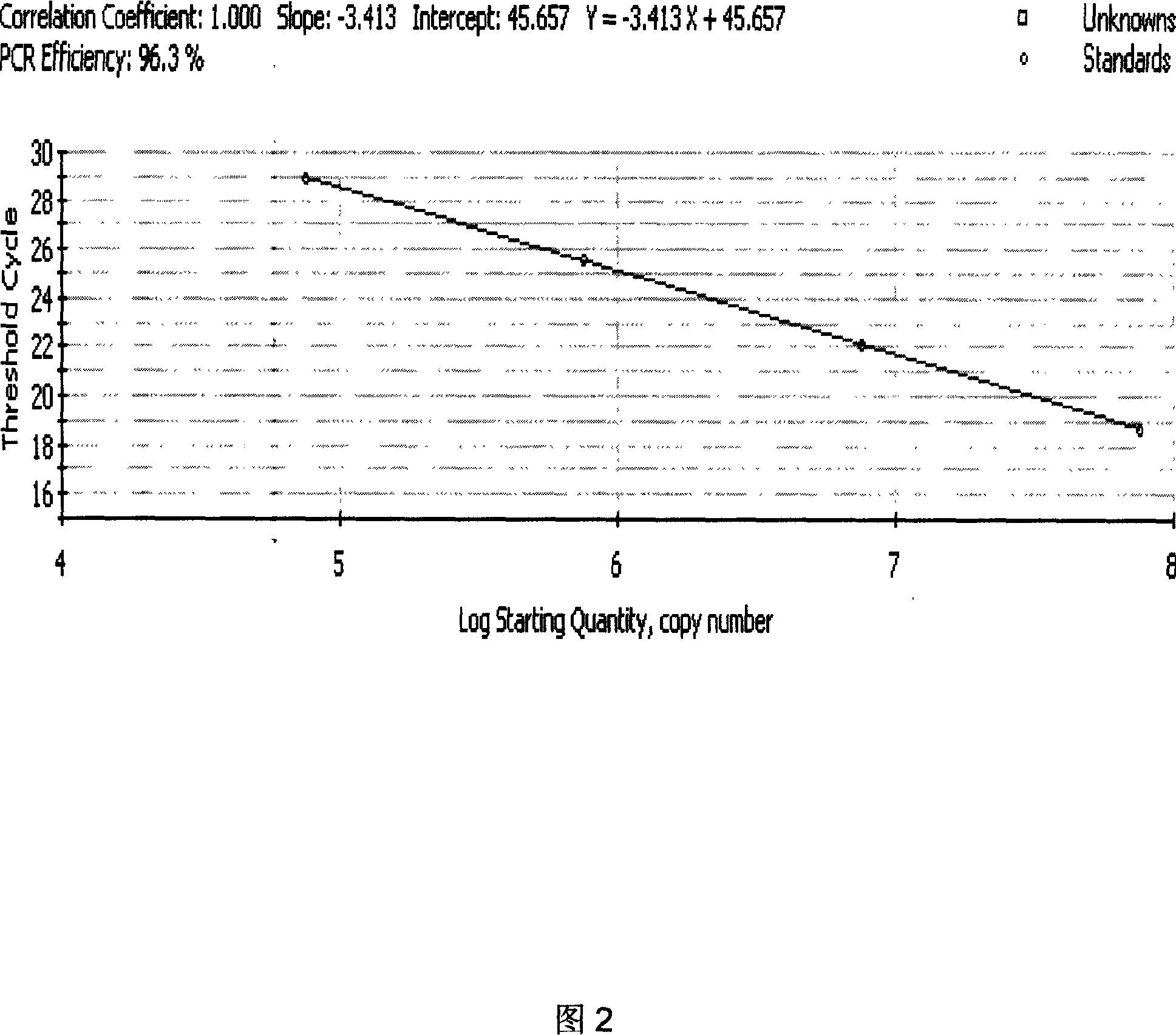

BCR-ABL gene fluorescence quantitative RT-PCR primer and probe and reagent kit

InactiveCN1995386AEasy to detectImprove featuresMicrobiological testing/measurementReference genesAgricultural science

The invention discloses a quantitative RT-PCR primer and probe and agent box of BCR-ABL fusing gene mRNA fluorescence with BCR-ABL fusing gene primer and probe sequence as SEQ ID NO1-4 and internal reference gene primer and probe sequence as SEQ ID NO5-7, wherein the agent box contains cell cracking liquid, water, RT-PCR reacting liquid, internal reference TBP RT-PCR reacting liquid, BCR-ABL fusing gene detecting probe, TBP internal reference gene testing probe, composite enzyme, standard material and comparing material; the box can test the expressive level of mRNA of P210BCR / ABL and P190BCR / ABL in the specimen, which provides the reference to diagnose, recurrent and treat chronic granulocytic leukemia and acute lymphocyte leukemia.

Owner:SHANGHAI FOSUN PHARMA (GROUP) CO LTD +1

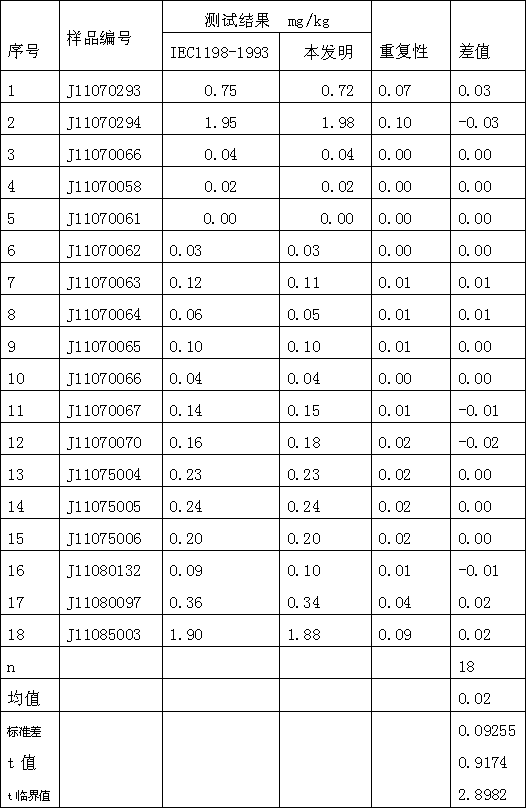

Measuring method for the furfural content of transformer oil

The invention relates to an analysis method for transformer oil. A measuring method for the furfural content of transformer oil comprises: a step of preparation of furfural standard oil, a step of preparation of a standard sample and a sample, and a step of sample analysis. The step of the preparation of the furfural standard oil comprises 1) preparation of a general solution: weighing 0.01g-0.03g standard material 2-furfural, placing in a brown volumetric flask, fully dissolving and diluting to the mark with new oil containing no furfural to obtain a furfural general solution with a certain concentration which is stored away from light for two days for use; 2) preparation of the standard solution: diluting one equal part of general solution with a certain amount of new oil containing no furfural to prepare a standard solution of a desired concentration, wherein the desired concentration includes 0.5 mg / kg, 1.0 mg / kg, 5.0 mg / kg and 10.0 mg / kg, and the standard solution is stored away from light and in brown reagent bottle. The method provided by the invention has the characteristics of low toxicity, and convenient operating, and can meet the production requirements.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Method for verifying the integrity of thermal desorption sampling tubes

ActiveUS7662630B2Fast loadingComponent separationWithdrawing sample devicesAnalyteThermal desorption

An analyte of a sample is transferred to an analytical instrument by introducing a quantity of a compound of a standard material into a vessel containing an adsorbent material; introducing a quantity of the analyte of the sample into the vessel; and transferring the analyte of the sample and the compound of the standard material to the analytical instrument.

Owner:PERKINELMER U S LLC

Fiber reinforced magnesium oxychloride red mud plate and preparation method

The invention discloses a fiber reinforced magnesium oxychloride red mud plate and a preparation method, and belongs to the utilization technology of waste material-red mud produced in alumina industry. The plate mainly comprises a solid blending material and brine, wherein the weight ratio of the brine is 15-30%, and the solid blending material comprises the following components by weight ratio: 30-70% of red mud, MgO of 25-60 % and 5-10% of reinforcing fiber; and 0.5-5% of modifier is added into the brine. The wet red mud, the magnesium oxide, the reinforcing fiber and the brine added with the modifier are subjected to extrusion molding by roller pressure after being uniformly mixed, naturally harden after solidification, and form a standard material or profile after shear processing. The plate is of a high-strength solidification plate with high content of red mud, has the advantages of fireproof, waterproof and anti-static performances, heat and noise insulation, strong pressure resistance, good fracture resistance, good corrosion resistance and the like, is widely used in construction, decoration and other industries, and can digest a lot of red mud to truly turn waste into wealth.

Owner:NUCLEAR IND YANTAI TONCIN IND GRP CO LTD

Method for accurate mass determination with ion trap/time-of-flight mass spectrometer

ActiveUS7138624B2Accurate mass determinationImprove accuracyStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryTime-of-flight mass spectrometry

Owner:HITACHI HIGH-TECH CORP

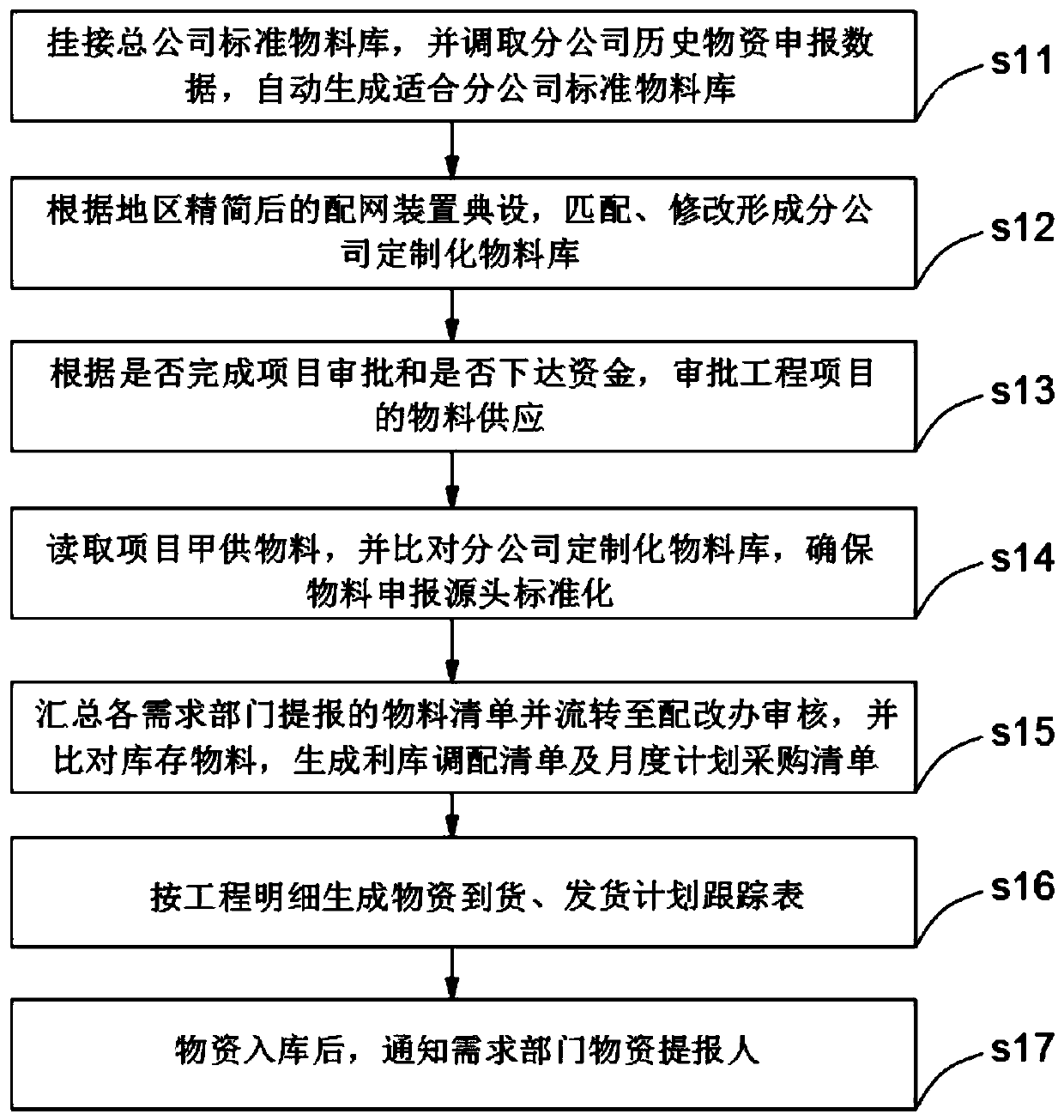

A distribution network material plan management method and system

ActiveCN109697550AA wide variety of solutionsSolve complexityResourcesLogisticsDesign standardProgram planning

The invention provides a distribution network material plan management method and system, and the method comprises the steps: carrying out the matching of a network province company standard materiallibrary according to the simplified distribution network device typesetting of a region, and forming a branch company customized standard material library; predicting an annual material demand plan according to materials such as an annual comprehensive plan, a project feasibility plan and the like; determining a monthly object demand plan according to the engineering project comprehensive plan, the implementation progress of the engineering and the determined engineering construction scheme and the supply period of the unified purchase and distribution materials; according to the final matching result of the province company, an order is created in time, and the matching result is imported to form a material arrival and delivery tracking table; material change caused by engineering designchange and the like is coordinated in time by tracking the actual performance condition of unified purchased materials in time; and the design standard is reversely improved by comparing the difference between the material utilization and the plan in the project. The invention provides a distribution network material plan management method and system which can improve the material plan managementlevel of a unit and improve the professional operation capability of materials.

Owner:STATE GRID ZHEJIANG HANGZHOU CITY FUYANG DISTRICT POWER SUPPLY CO LTD +2

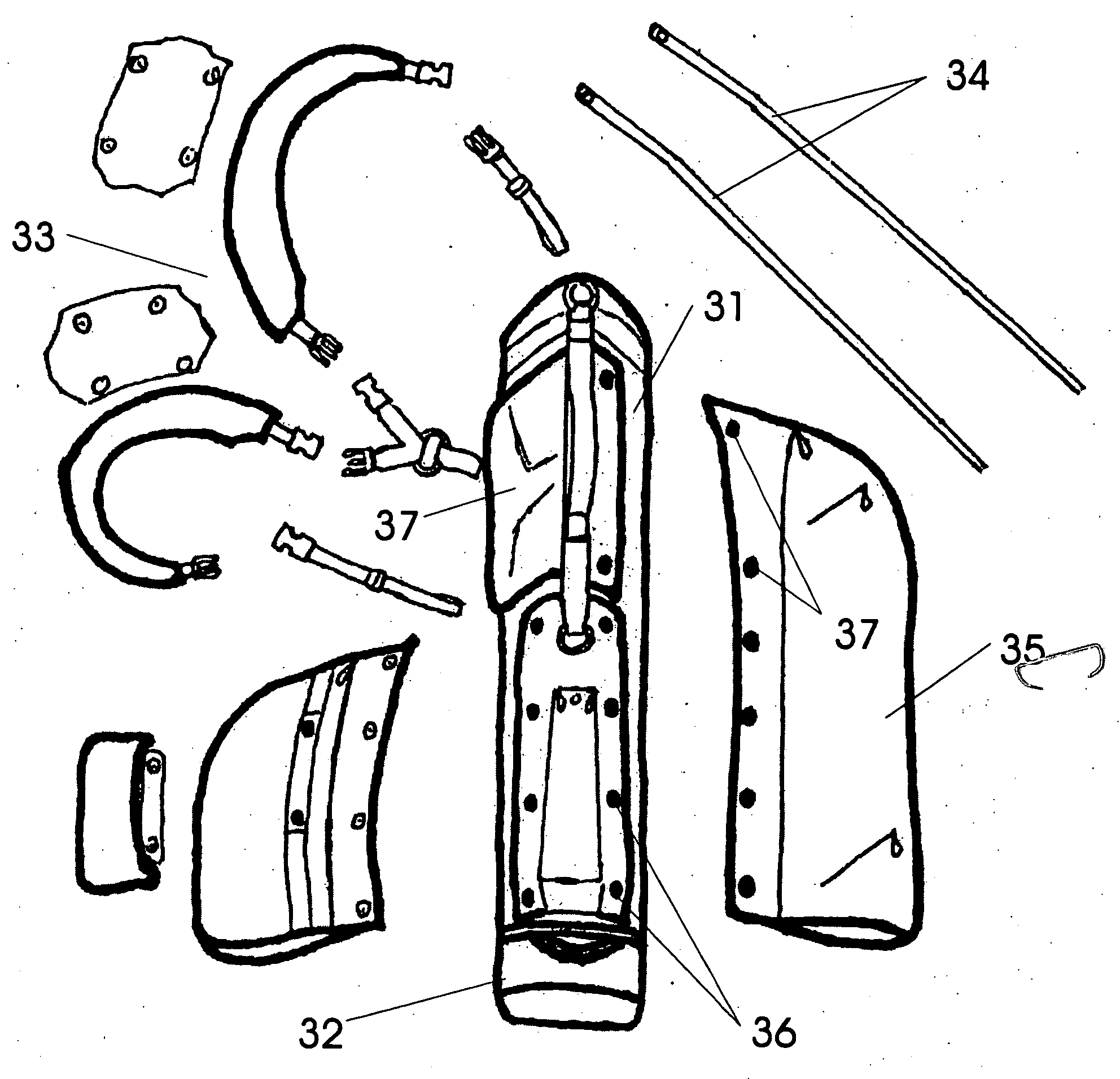

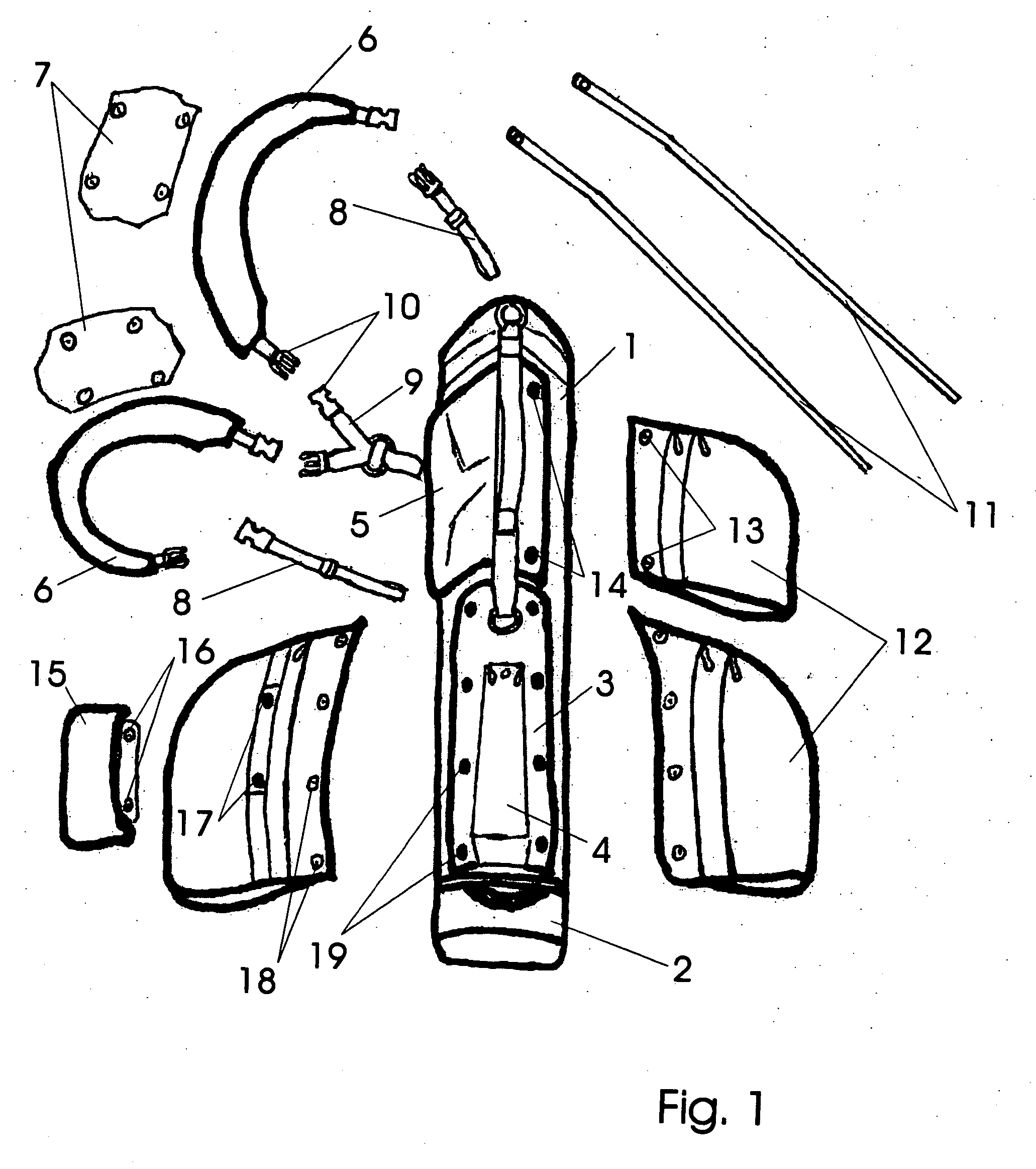

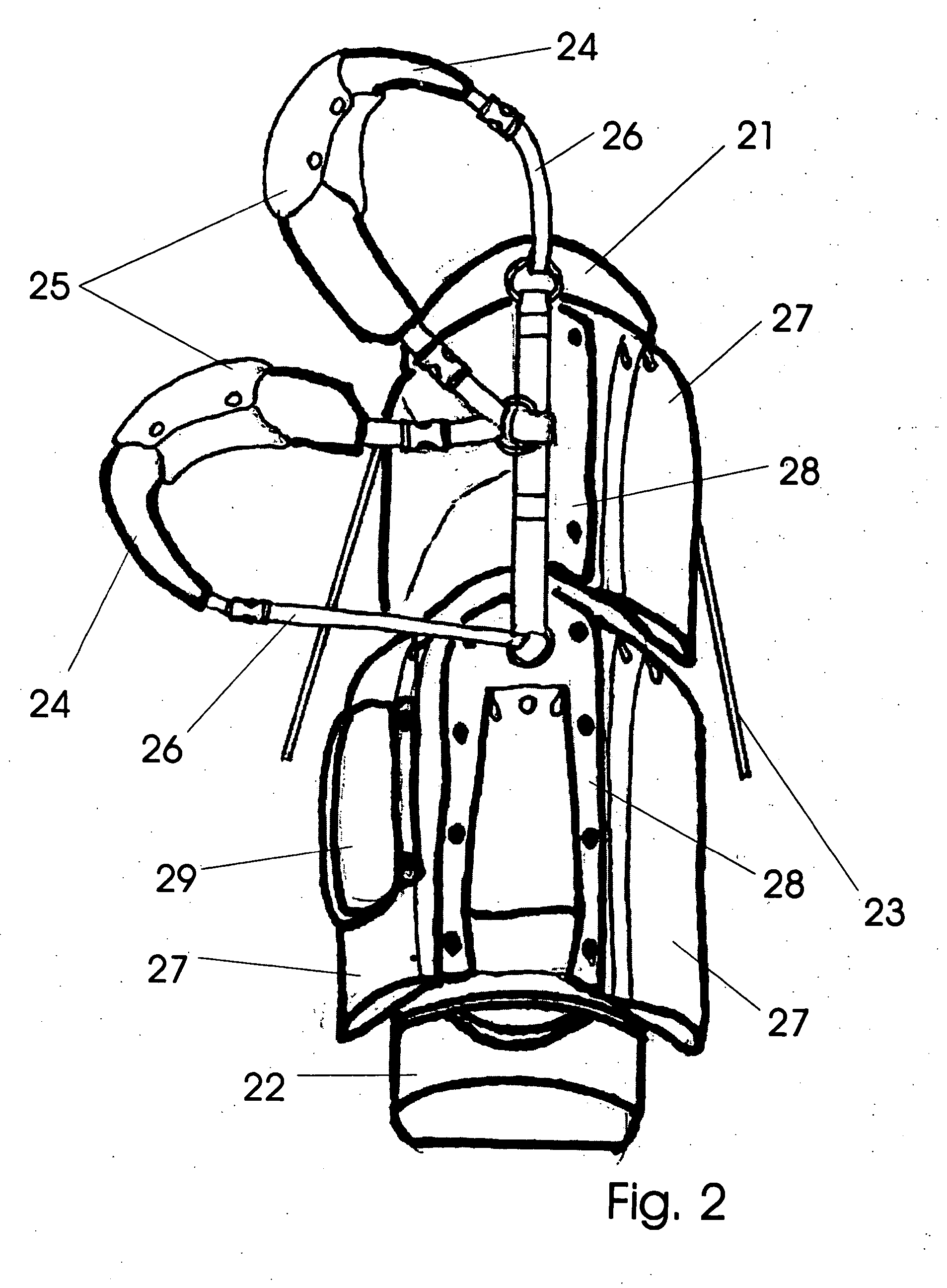

Modular stand bag for golf clubs

InactiveUS20050040059A1Easy to disassembleEasily change their appearance and styleTravelling sacksHandbagsModularityEngineering

These inventions provide for golf bags, in particular stand type golf bags used in game play are arranged with modular components. These components can be easily switched by a golfer whereby the component may be replace with one having an alternative function or style. In addition, components subject to damage may be quickly and easily replaced with new components. Golf bags are configured with special fasteners which allow parts to be removably affixed to the bag for the switchable components. Standard materials and fasteners might be used elsewhere on the bag. Golf bag components which are arranged to be changeable include at least: the stand element, a back pad, shoulder straps and shoulder moulds, and pockets. Kits comprising an upgrade theme are also arranged to cooperate with these bags and to be sold as stand alone products in support of extended uses of the bags.

Owner:HEROLD JEFFREY

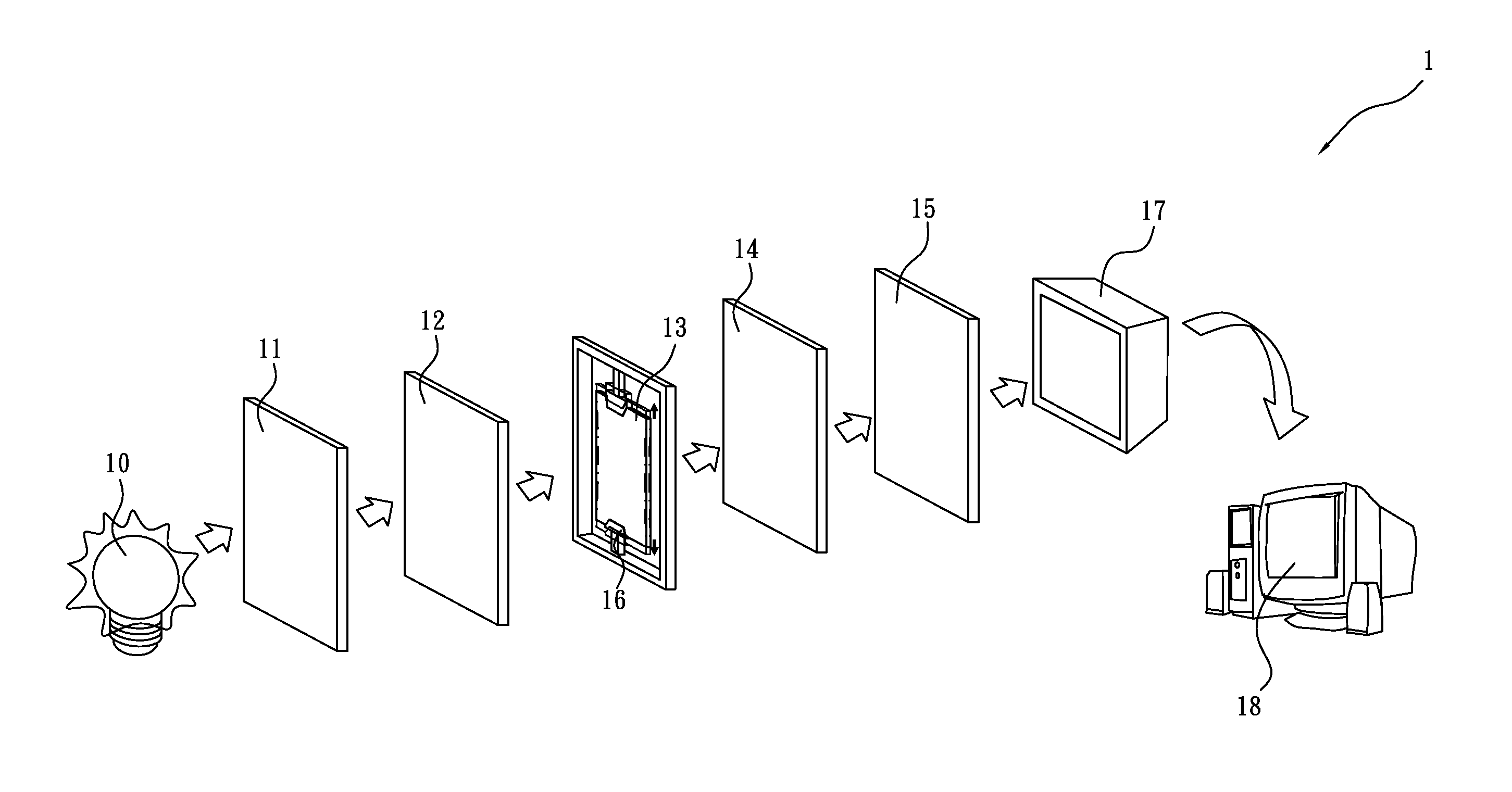

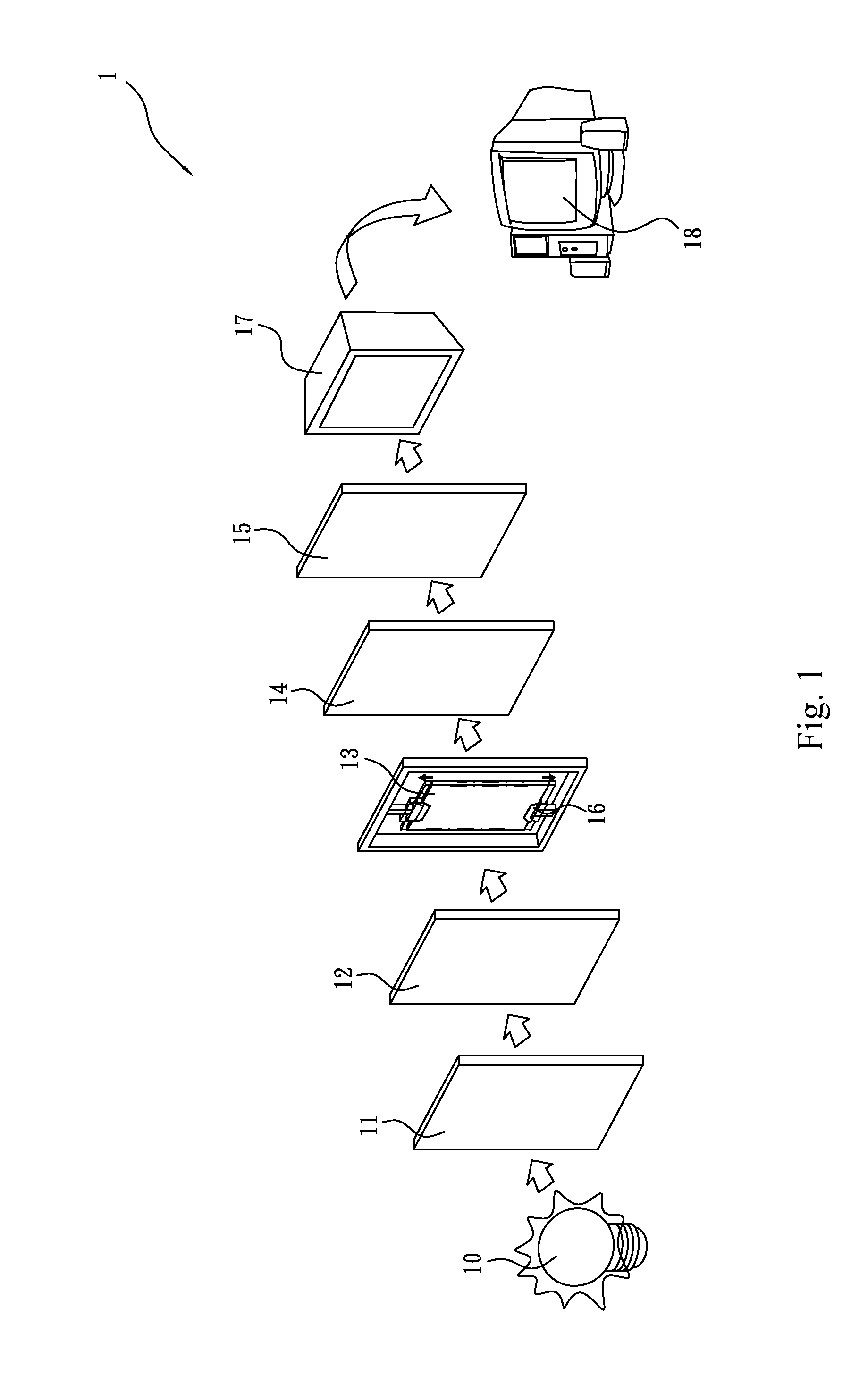

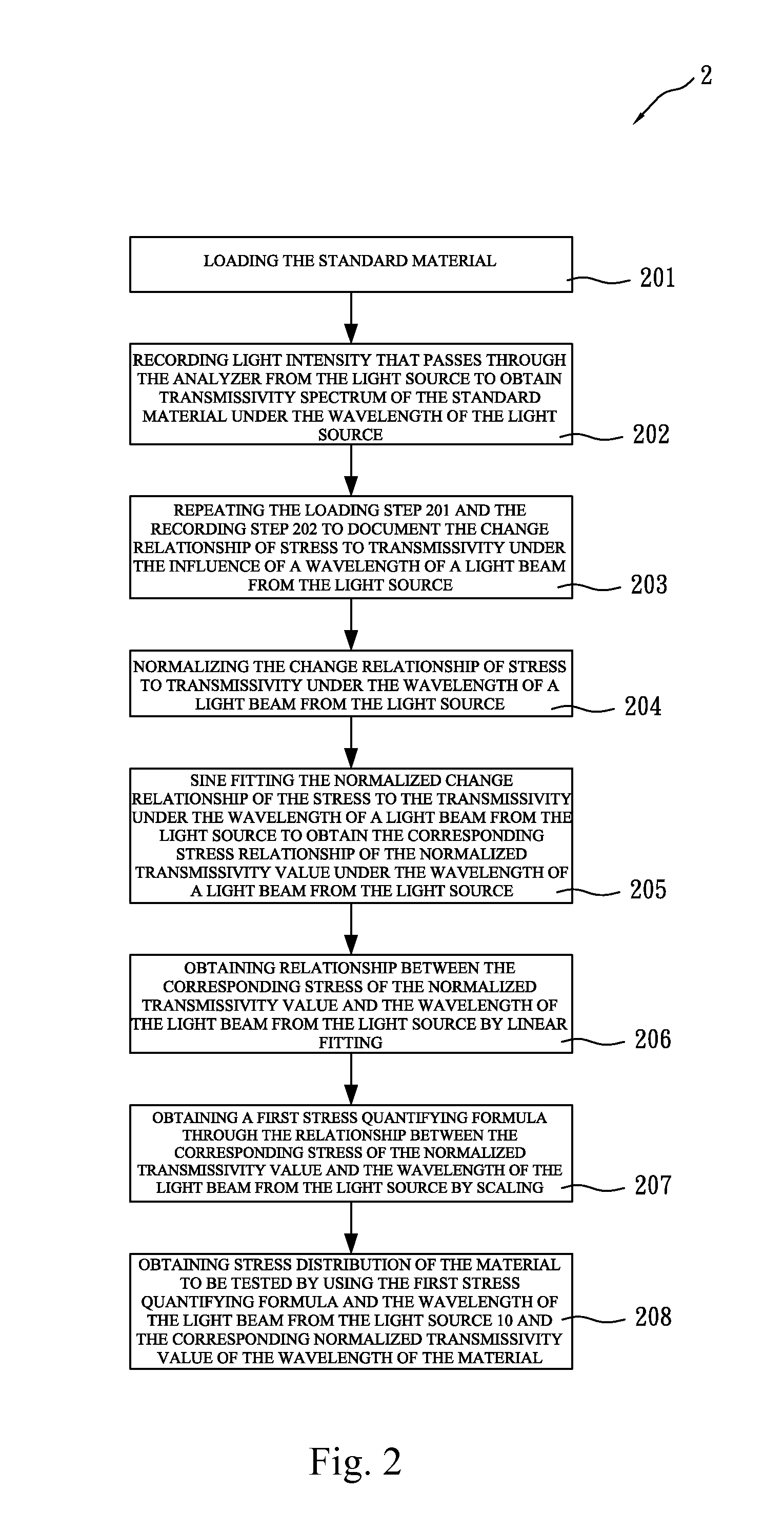

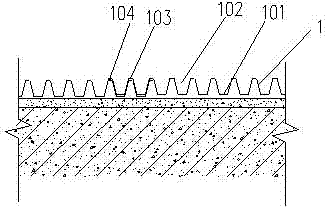

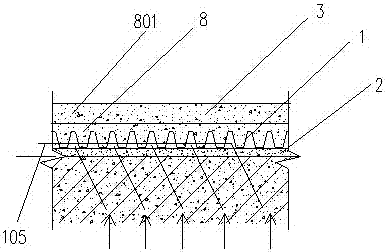

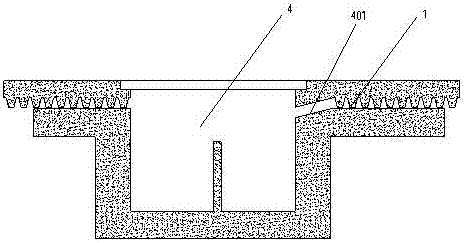

Apparatus for quantifying unknown stress and residual stress of a material and method thereof

ActiveUS20130250277A1Force measurement by measuring optical property variationMaterial analysis by optical meansLight beamTransmittance

An apparatus for quantifying unknown stress and residual stress of a material to be tested, the material being a birefringent or temporary birefringent material, which includes a light source, a polarizer in front of the light source for converting a light beam from the light source into a beam with linear polarization, a first quarter-wave plate in front of the polarizer for generating circular polarization, a standard material, a second quarter-wave plate, an analyzer, a loading unit, a spectrometer for obtaining transmissivity spectrum of the standard material under the wavelength of the light source and a detecting module connected to the spectrometer to have the transmissivity spectrum of the material to be tested and consequently a stress quantifying formula for the standard material.

Owner:NATIONAL TSING HUA UNIVERSITY

Basement drainage plate and construction method

PendingCN107059946AReduce consumptionReduce energy consumptionProtective foundationBasementSurface layer

The invention discloses a basement drainage plate and a construction method. The basement drainage plate comprises a drainage plate; the drainage plate is arranged at the upper part of a basement baseplate, and is provided with hollow convex points outwards projected; hollow grooves are formed in the other surface of the drainage plate; the drainage plate is buckled and joined with the hollow grooves through the hollow convex points; the hollow convex points are downwards paved; a gap drainage sandwich layer is arranged among the hollow convex points; and concrete is cast in the hollow grooves. The construction method of the basement drainage plate comprises the steps of deep design, construction preparation, substrate treatment, pavement of the drainage plate, casting of the concrete on the drainage plate, construction of reinforcements and surface-layer concrete, and inspection and acceptance. The drainage plate is joined in a basement to achieve large-area standard construction, convenient and fast operation and low cost; the next procedure can be performed after the pavement is finished; the standard material and the standard construction are achieved; the material consumption and the construction energy consumption are reduced; and the national policy requirements of energy conservation and emission reduction are met.

Owner:CHINA HUASHI ENTERPRISES

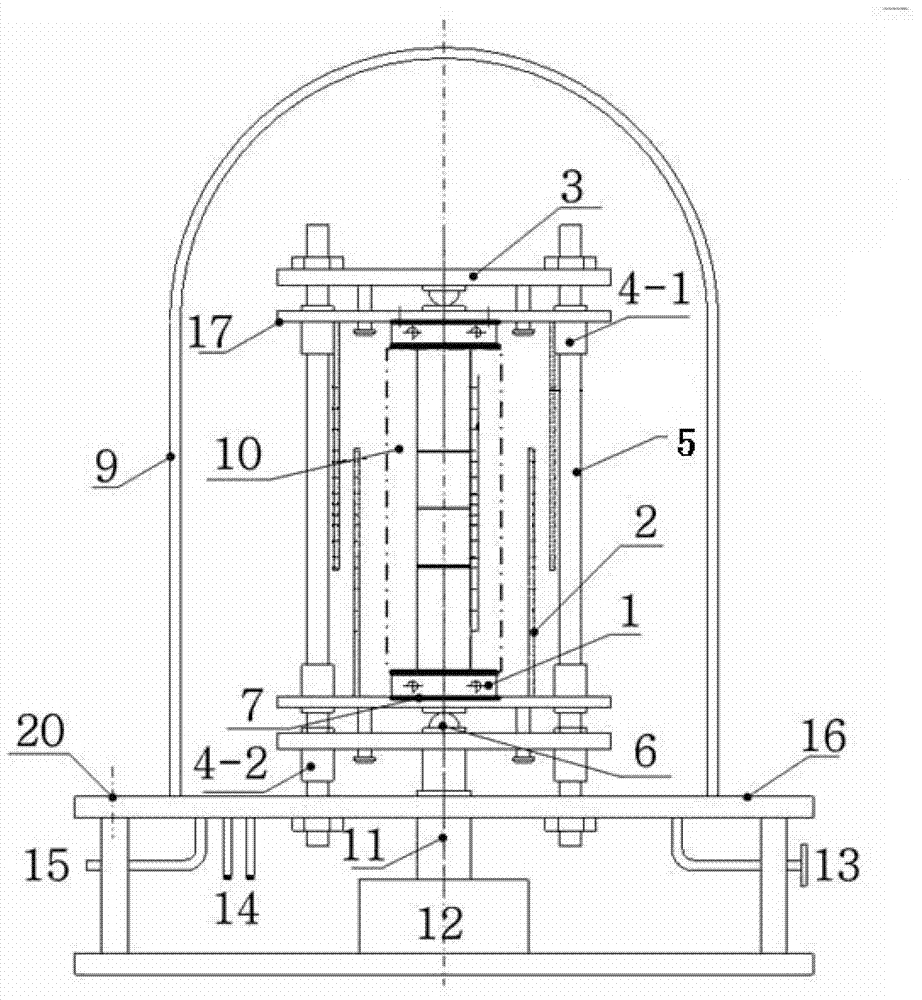

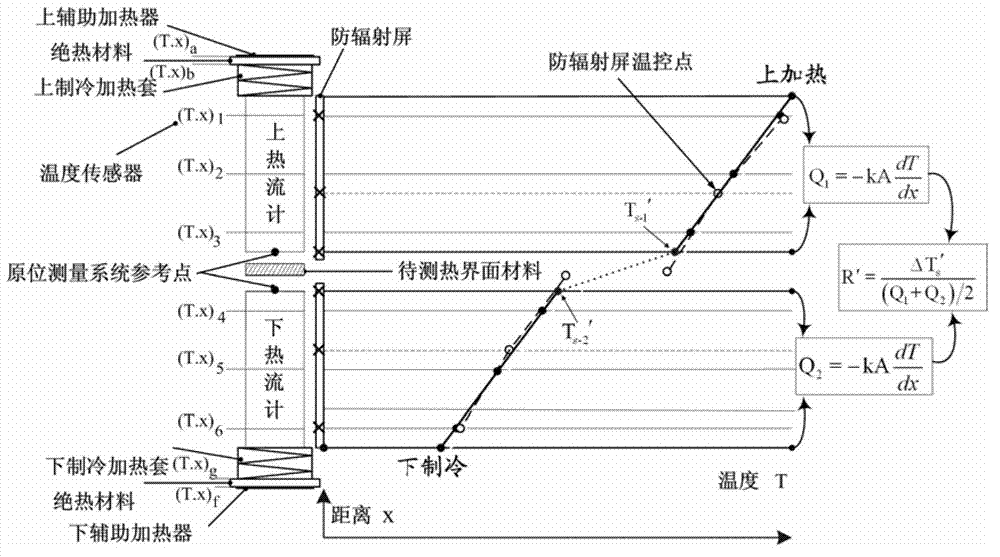

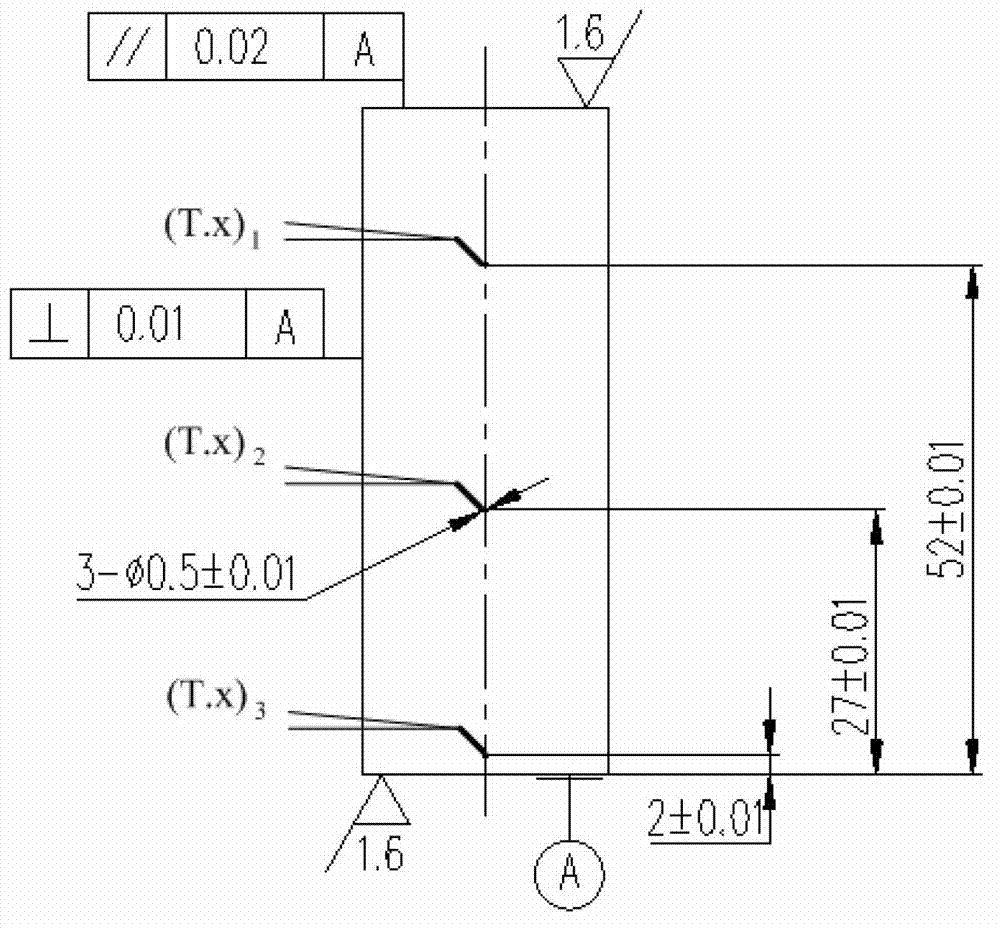

Up-and-down constant-temperature parameter identifying method for testing thermal interface material performance

ActiveCN102830134AGuaranteed accuracyMeasured with high precisionMaterial heat developmentHeat conductingEngineering

The invention discloses an up-and-down constant-temperature parameter identifying method for testing the thermal interface material performance. The up-and-down constant-temperature parameter identifying method comprises the following steps: step one, preparing a standard material thermal flow meter; step two, placing a thermal interface material between contact interfaces of two thermal flow meters, loading pressure stress, and heating the thermal flow meters forward; step three, amending measuring temperature of a test point; step four, calculating a contact thermal resistance R; and step five, measuring the thickness L of the thermal interface material, and calculating the equivalent heat conducting coefficient of the thermal interface material. According to the invention, a symmetrical testing structure which is amended by up-and-down constant-temperature parameter identification is adopted for measuring, the inconsistent error of temperature measurement caused by different contact thermal resistance of each temperature sensor and the thermal flow meters or incomplete linearity of temperature and the like can be eliminated, and further the performance of the thermal interface material with high accuracy can be measured on the premise that the thermal flow rate is ensured.

Owner:NANJING UNIV OF SCI & TECH

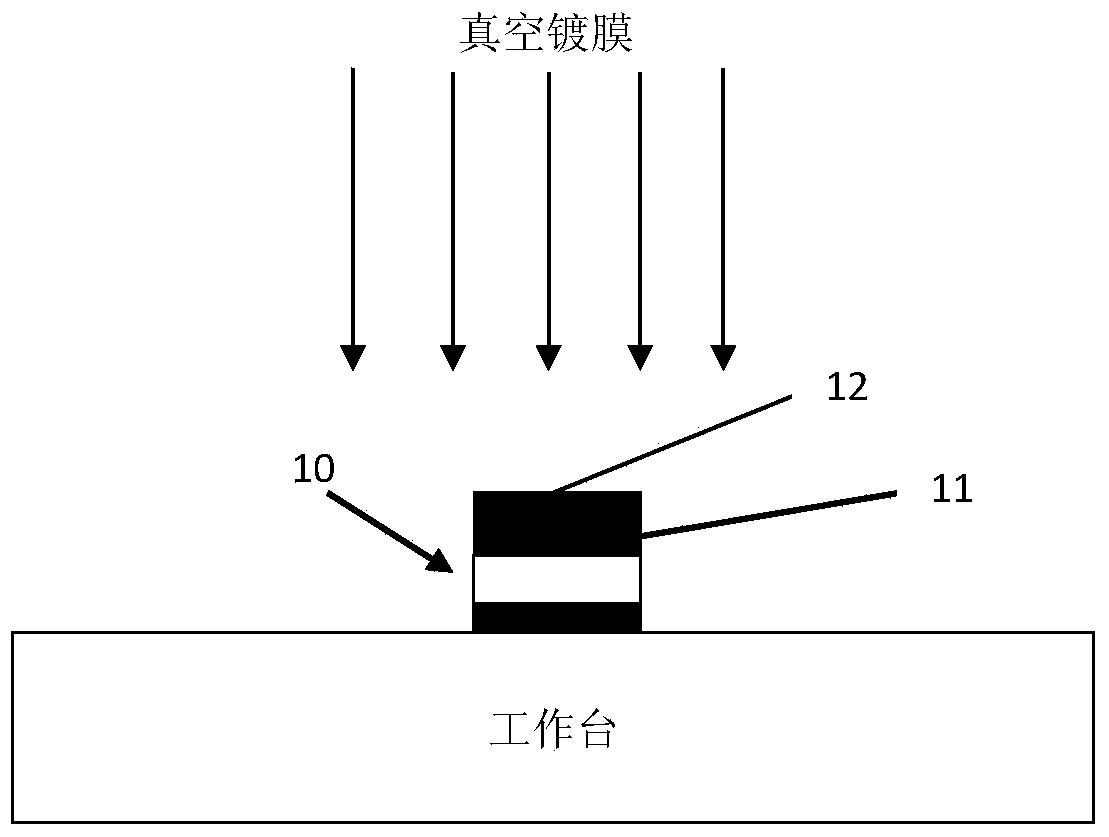

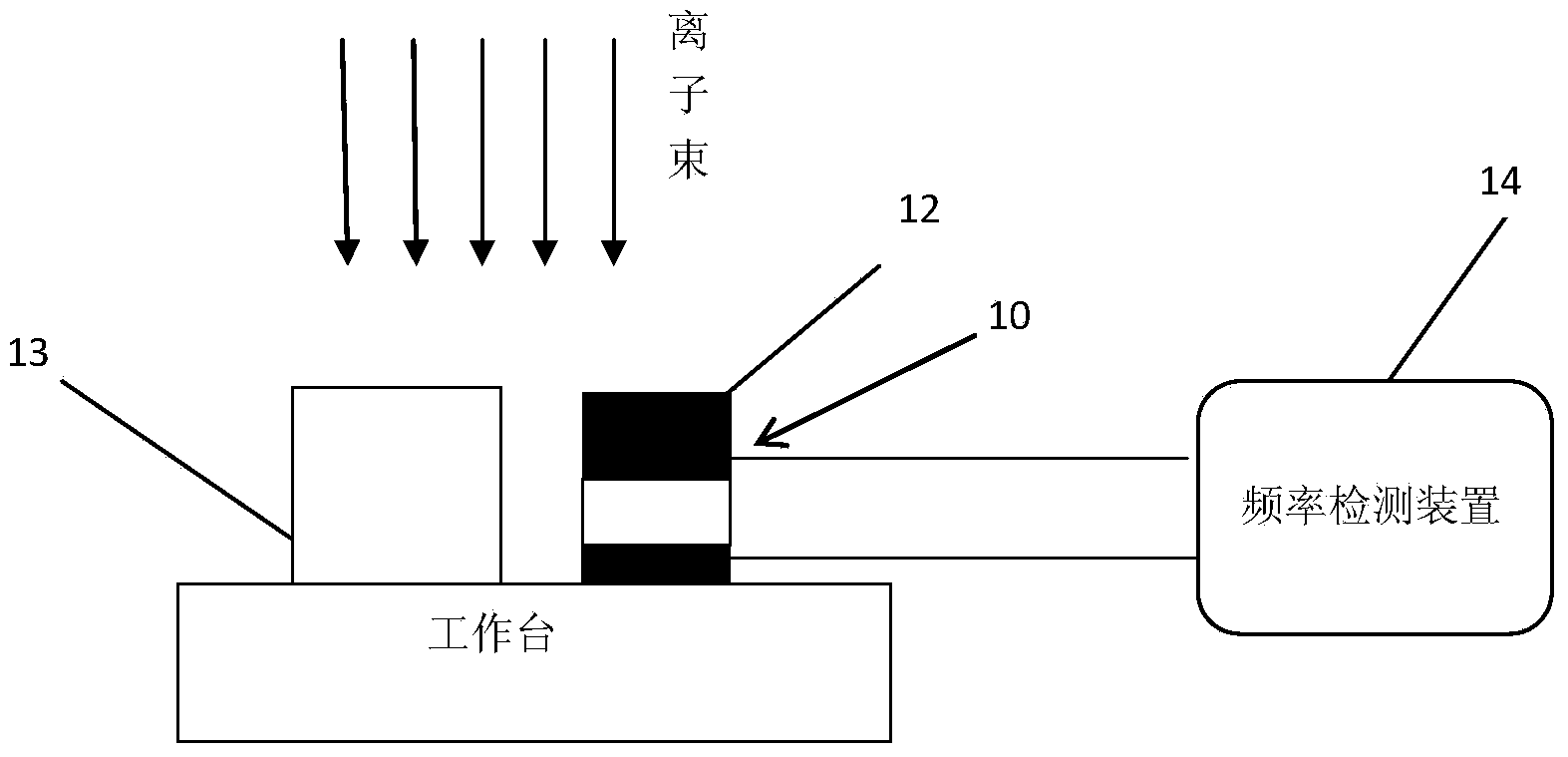

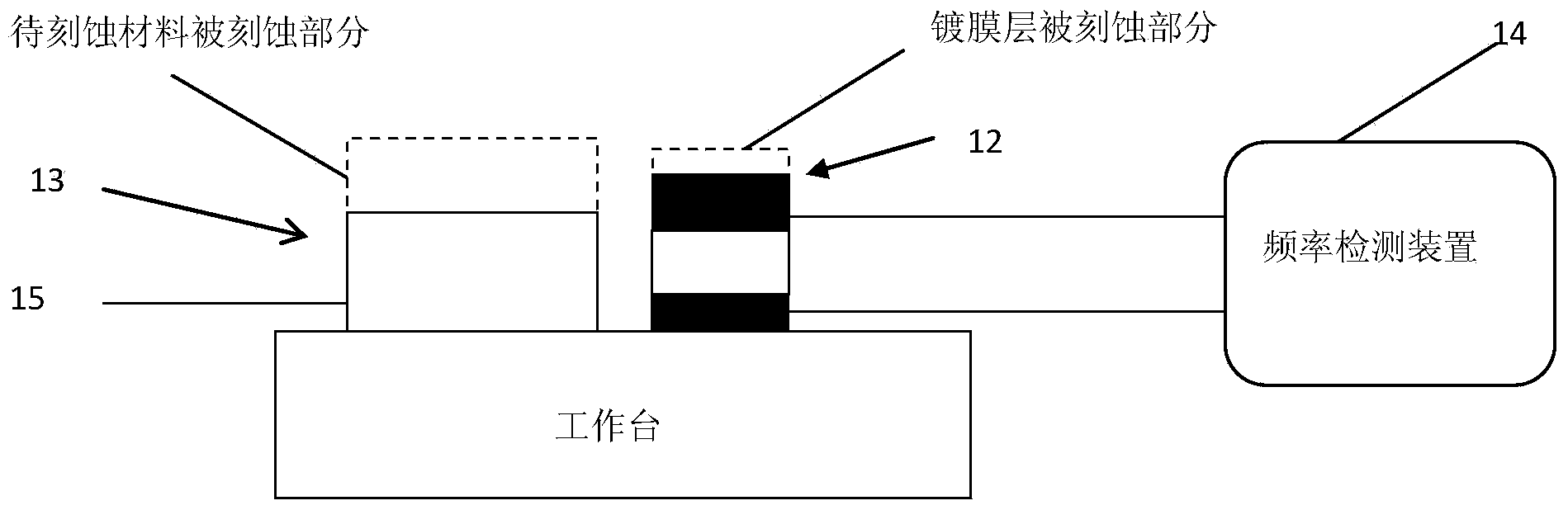

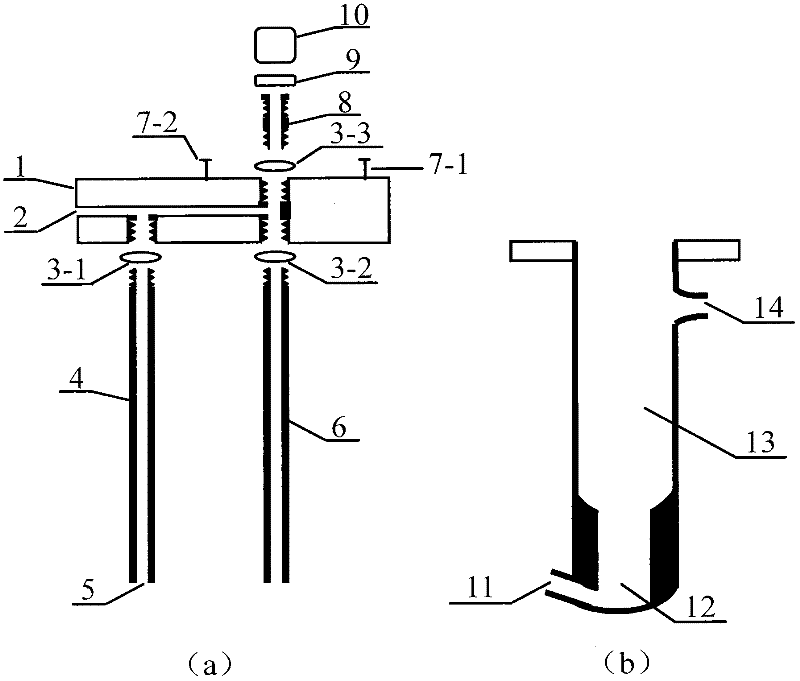

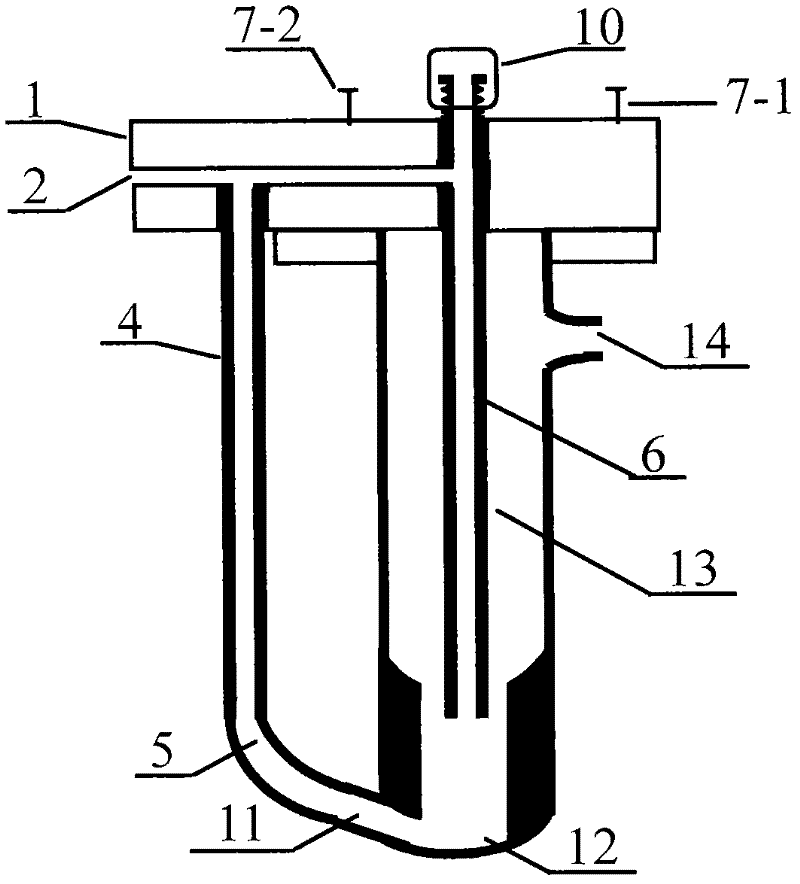

Ion beam etching depth monitoring method

InactiveCN103824790ARealize real-time monitoringThe experimental method is simpleSemiconductor/solid-state device testing/measurementDevice MonitorOptoelectronics

The invention provides an ion beam etching depth monitoring method. The ion beam etching depth monitoring method is characterized in that the ion beam etching depth monitoring method comprises the following steps that: step one, a layer of a standard material is plated on an electrode surface of a quartz crystal and is adopted as a plated film layer, such that a plated film quartz crystal can be obtained; step two, the plated film quartz crystal and a material to be etched are put in an ion beam etching machine, the plated film quartz crystal is connected with a frequency detection device; step three, the material to be etched and the plated film layer are etched simultaneously, and the frequency detection device monitors the etching depth of the plated film layer in real time, and when the frequency detection device monitors that the etching depth of the plated film layer achieves predetermined depth, etching is stopped, and an etched material that satisfies target etching depth can be obtained. The ion beam etching depth monitoring method provided by the invention is advantageous in simple devices, operational easiness, high precision and low cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Liquid organic atomization and gasification device

InactiveCN102172504AThe result is accurateReliable resultsAlarmsChemical/physical/physico-chemical processesGas phaseEquation of state

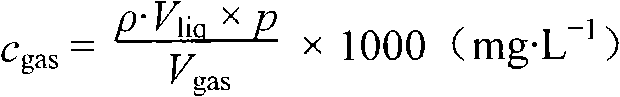

The invention discloses a liquid organic atomization and gasification device, which is mainly used for preparing a standard gas required in processes of manufacturing, production, verification and calibration of gas alarms from a liquid organic material. A liquid standard material is atomized in an atomizing air pipe through the inlet of an injector and is evaporated and gasified in an evaporating tube under the action of the gas in a blowing air pipe, and thus, the liquid standard organic substance is converted into a gaseous substance. The pushing rate of the injector is controlled by using an injection pump, so that the pushing rate of the injector is smaller than the maximum evaporation rate of the liquid standard substance. The temperature and pressure in an atomizing and gasifying system are measured, the concentration of the standard material from the outlet of the atomization and gasification device in a gas phase can be obtained by using the pushing rate of the injector and the flow metered by a flowmeter, and by conversion according to an equation of state of gas.

Owner:中国人民解放军防化指挥工程学院

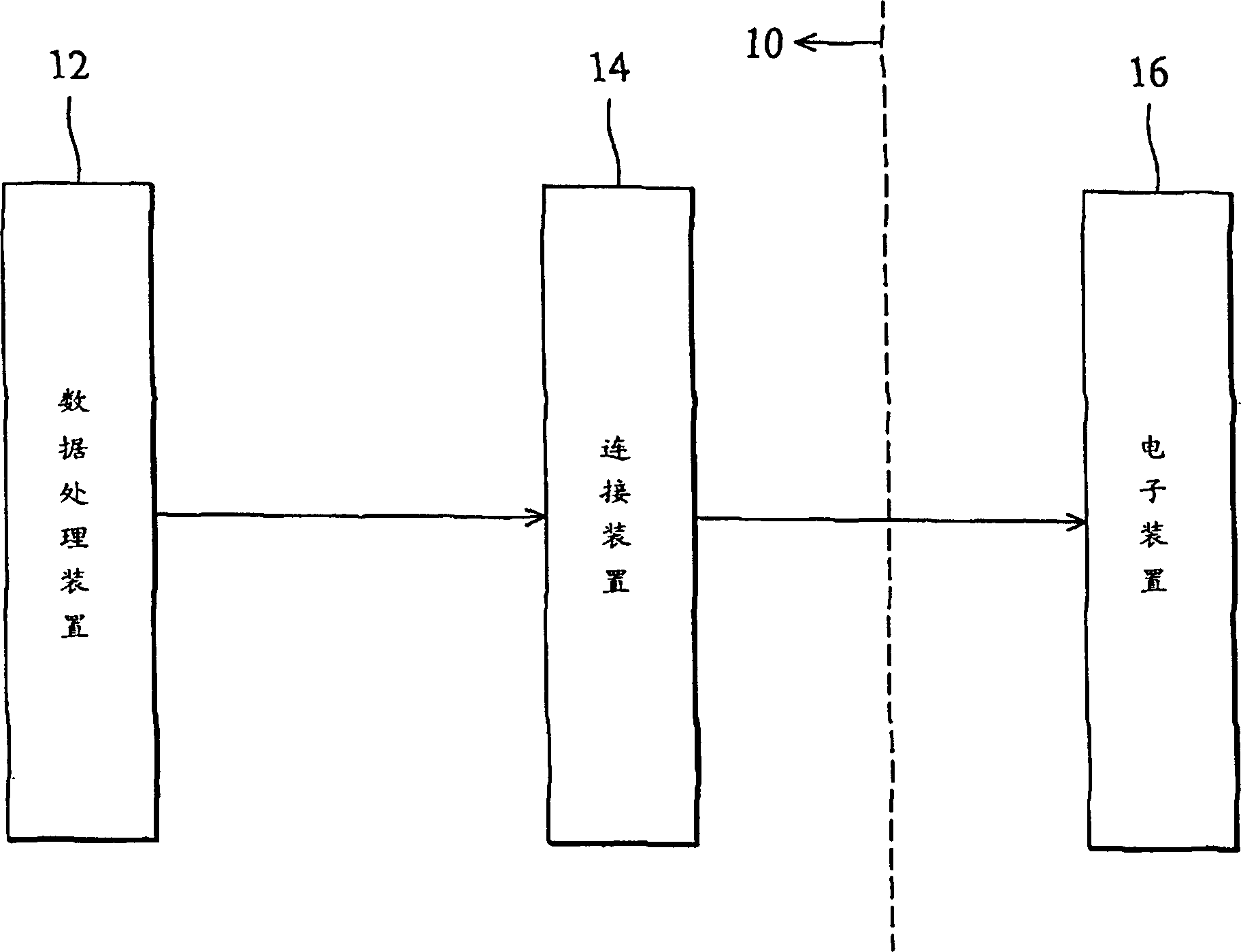

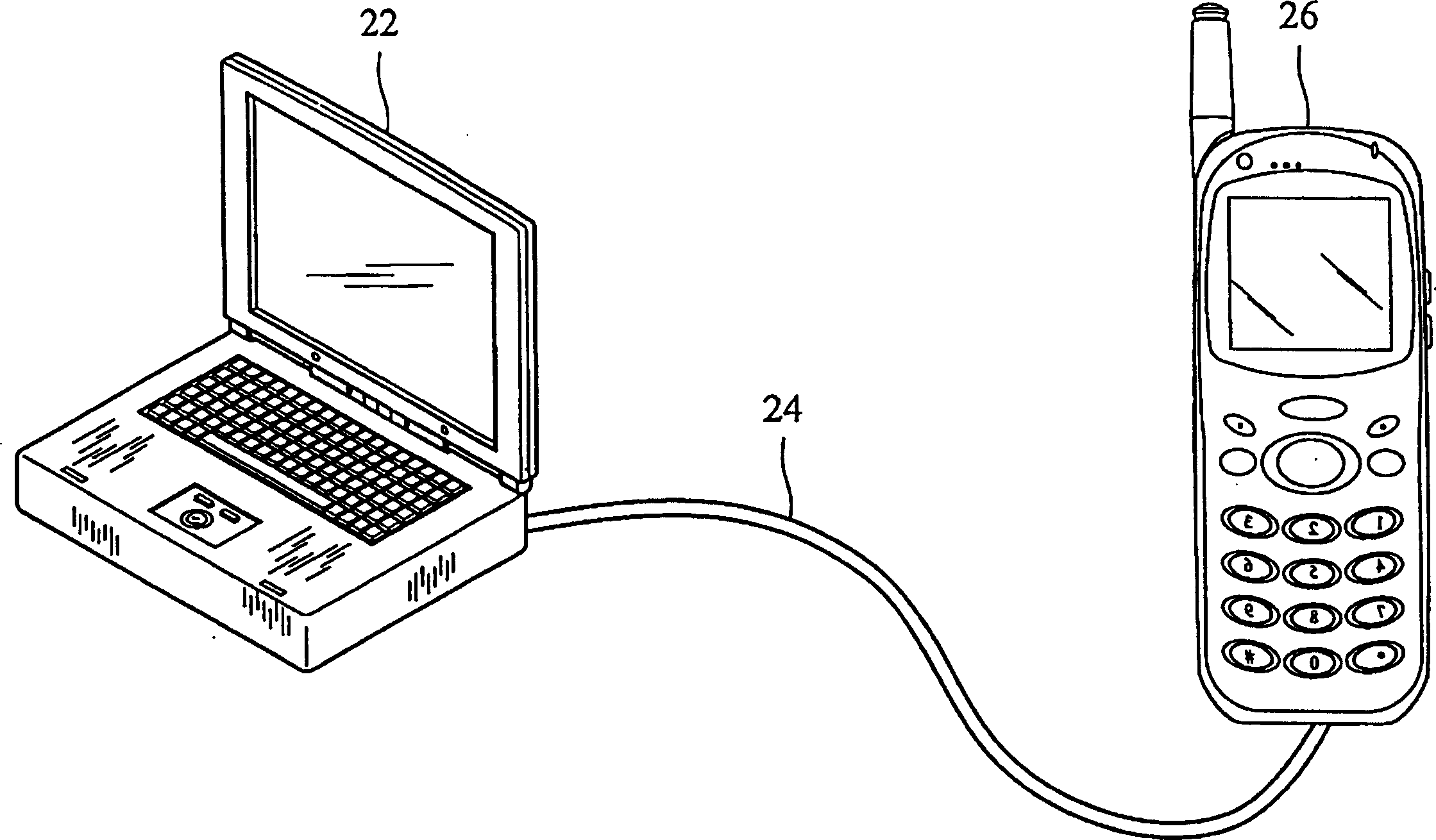

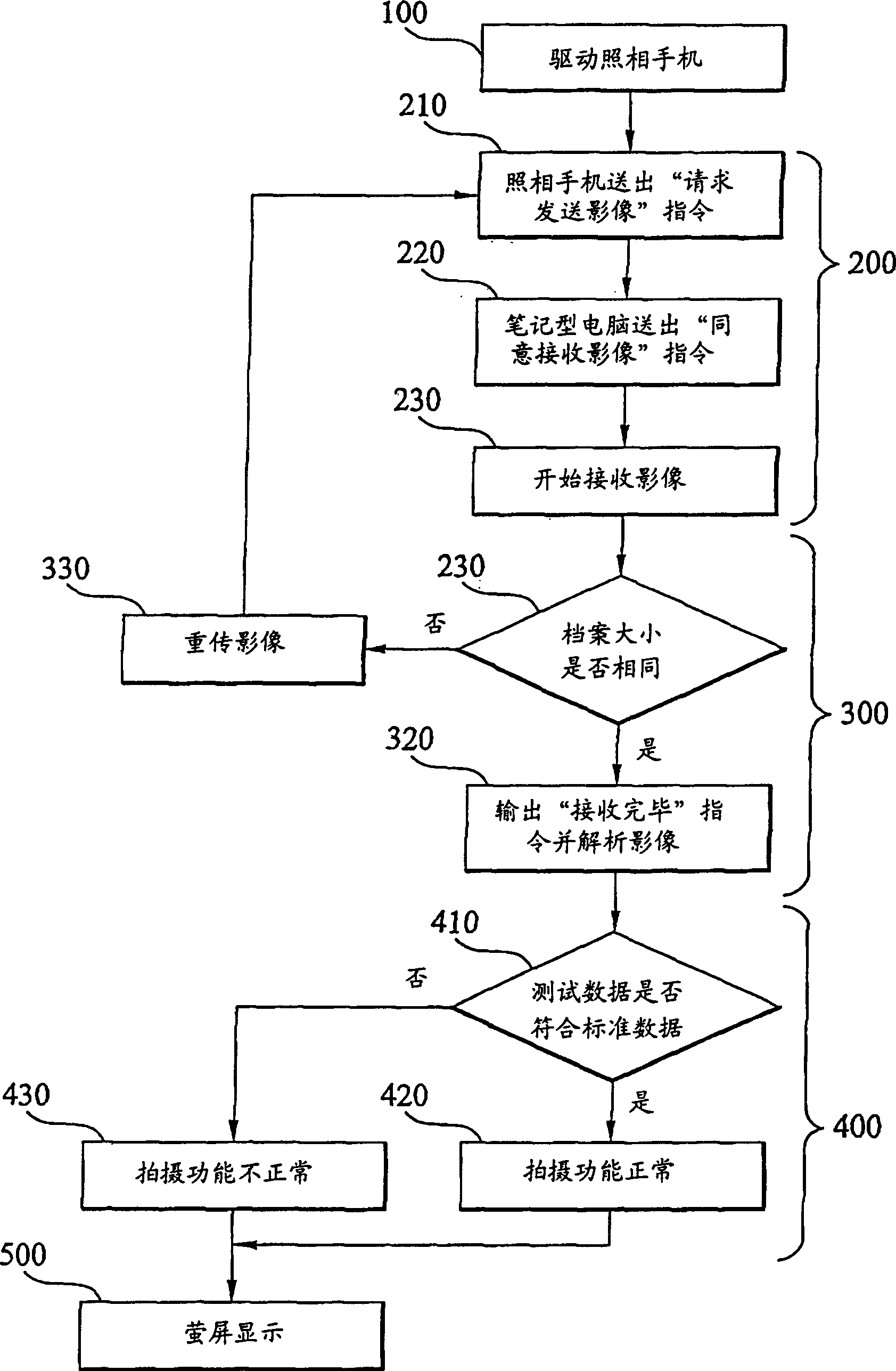

Method for automatic testing camera, testing system and storing media

InactiveCN1661456ATelevision system detailsColor television detailsComputer hardwareAutomatic testing

The present invention relates to a method for automatically detecting camera. Said method can compare the image short by electronic device built in the camera with a standard material, and can display compared result so as to make tester easily know that the shoot function of said electronic device is normal or not. Besides, said invention also provides the detection system of said detection method and storage medium for storing said detection method together.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

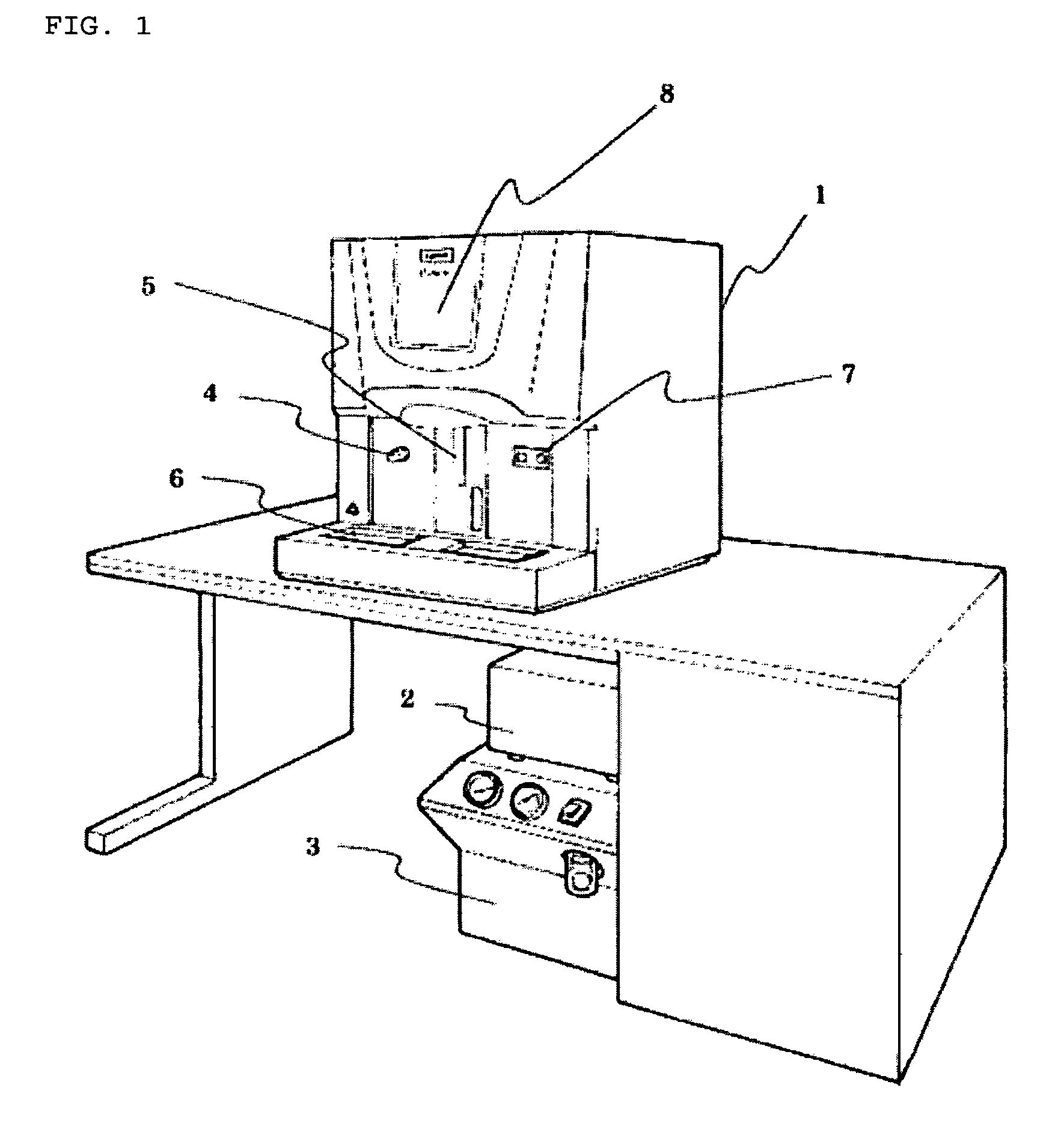

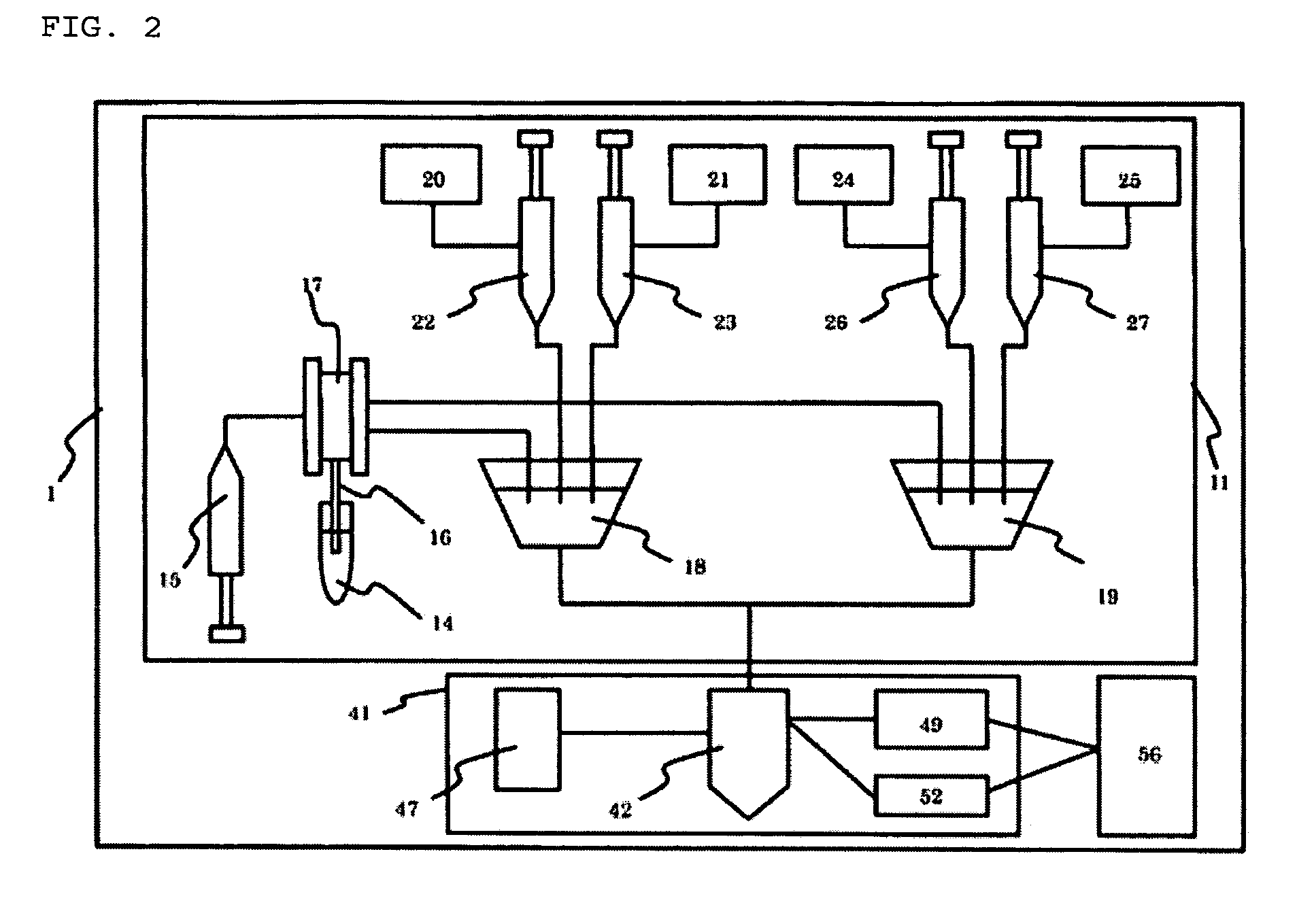

Standard material for particle analyzer

ActiveUS7601539B2Photometry using reference valueRadiation pyrometryFluorescenceFluorescence staining

Owner:SYSMEX CORP

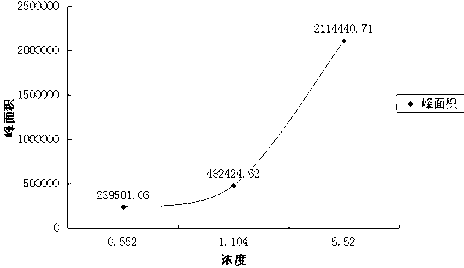

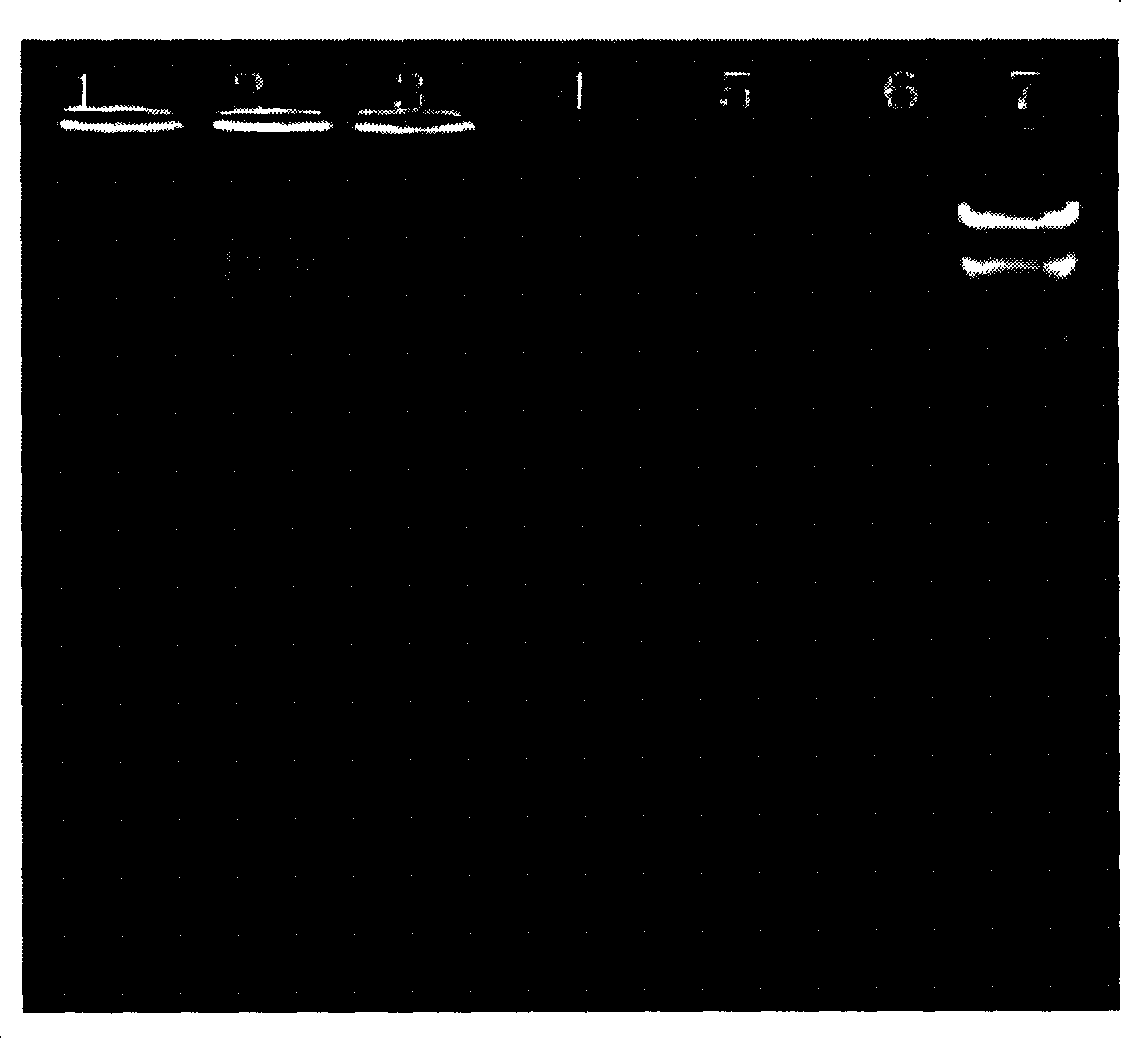

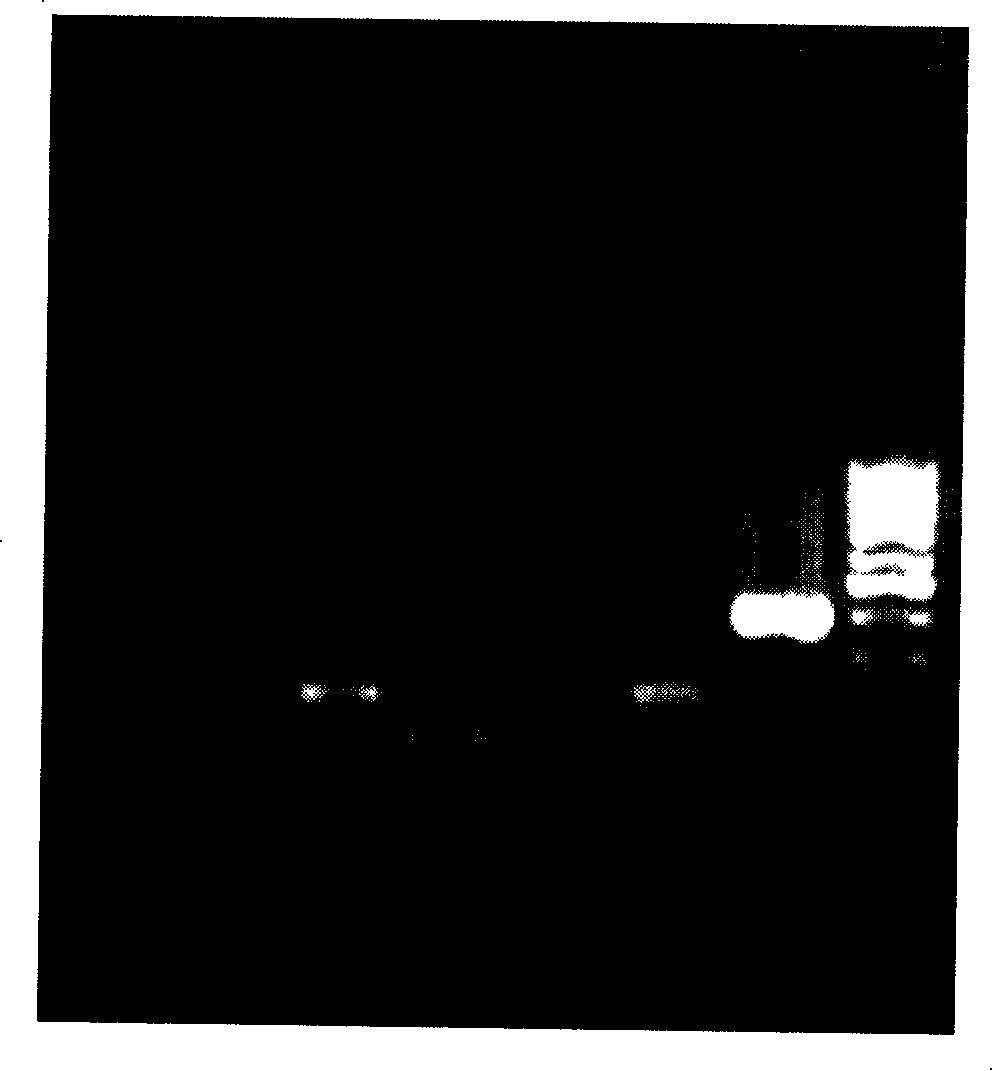

Armoured RNA and method for producing the same

InactiveCN101173252AImprove utilization efficiencyLow costMicrobiological testing/measurementViruses/bacteriophagesNegative strandNucleic acid detection

The invention relates to an armored RNA and a preparation method of the armored RNA, which is characterized in that the armored RNA is a RNA enwrapped by MS2 envelope protein. The invention also discloses the preparation method of the armored RNA. The armored RNA contains a plurality of virus RNA segments, and the armored RNA contains the negative or positive strand virus RNA, which provides the nucleic acid detection of multiplex viruses with safe and stable standard materials and quality control materials.

Owner:杭州市疾病预防控制中心

PML-RARa gene fluorescence quantitative RT-PCR primer and probe and reagent kit

InactiveCN1995385AImprove induction rateReduce early deathMicrobiological testing/measurementReference genesFluorescence

The invention discloses a quantitative RT-PCR primer and probe and agent box of PML-RARa fusing gene mRNA fluorescence with BCR-ABL fusing gene primer and probe sequence as SEQ ID NO1-4 and internal reference gene primer and probe sequence as SEQ ID NO5-7, wherein the agent box contains cell cracking liquid, water, RT-PCR reacting liquid, internal reference G6PDHRT-PCR reacting liquid, BCR-ABL fusing gene detecting probe, G6PDH internal reference gene testing probe, composite enzyme, standard material and comparing material; the invention measures the expressive level of L-pattern, S-pattern and V-pattern mRNA simultaneously, rapidly and precisely, which improves inducing buffer rate and lessens early bleeding death.

Owner:SHANGHAI FOSUN PHARMA (GROUP) CO LTD +1

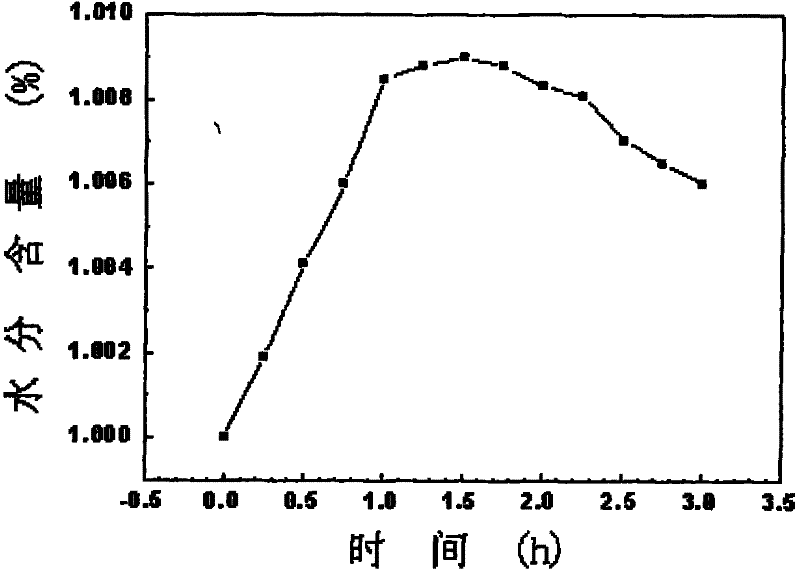

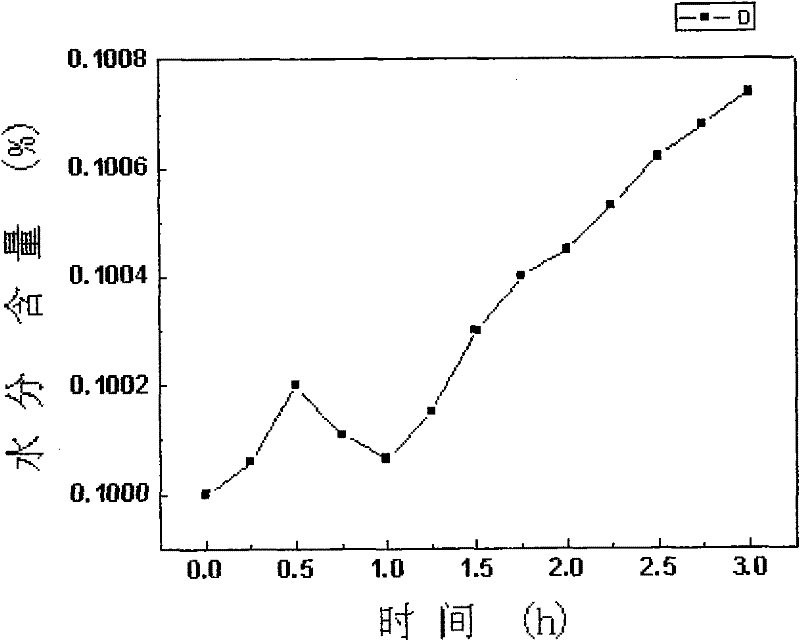

Preparation method of water content standard material

InactiveCN102252885AGood uniformity between bottlesStable moisture contentPreparing sample for investigationBottleVolumetric flask

The invention relates to a preparation method of a water content standard material. The method comprises the steps of: weighing the mass of a dried glass volumetric flask, adding propylene carbonate, 1-butanol and xylene in proportion, and weighing the mass of the mixed solution; measuring water in the mixed solution, and calculating the mass of water needing to be added according to a preparation target value; adding deionized water into the volumetric flask and mixing the solution well; shifting part of the mixed solution into an ampoule bottle, adjusting the humidity of a constant temperature and humidity chamber, monitoring water content variations over time under different humidity conditions; recording the humidity within the constant temperature and humidity chamber when the solution water content varies minimally; under a humidity condition with stable solution water content, charging ampoule bottles with the mixed solution separately, and sealing the ampoule bottles; taking the mean of the results measured by Coulometry and volumetric methods as the water content of a standard material; and evaluating the water uncertainty. The water content standard material prepared by the method of the invention is beneficial for improving the accuracy of a Karl Fischer water titrator measuring result.

Owner:NAT INST OF METROLOGY CHINA

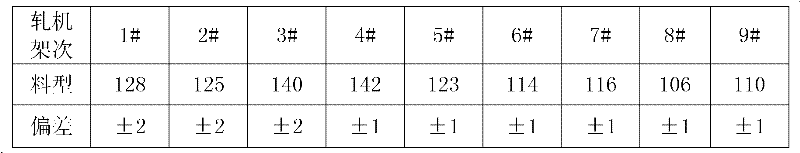

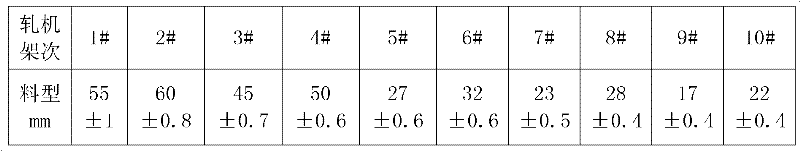

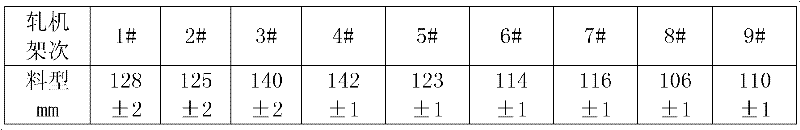

Rolling process of bismuth-containing free cutting steel

ActiveCN102389894AEnsure plastic deformationImprove organizationTemperature control deviceMetal rolling arrangementsMaterial typeDeformation control

The invention discloses a rolling process of bismuth-containing free cutting steel. The process comprises the following steps of: controlling the heating temperature at 1,150-1,230 DEG C; controlling the rolling temperature at 1,130-1,200 DEG C in a rough rolling step, wherein the standard material type size is used in each pass of rough rolling; controlling the rolling temperature at 1,000-1,060 DEG C in a medium rolling step, wherein the standard material size is used for rolling mill material types; controlling the rolling temperature at 900-950 DEG C in a pre-finish rolling step, wherein the standard material type size is used for rolling mill material types; controlling the rolling temperature at 930-980 DEG C in a finish rolling step, wherein the standard material type is used for rolling mill material types; and controlling the final rolling temperature at 810-830 DEG C. As the cooling water amount is controlled through process requirements and the deformation control temperature of each section is ensured in the rolling and deformation course, surface cracks and corner cracks generated in the rolling and deformation course and after deformation of a rolled piece can be prevented, a drawing steel accident caused by head splitting is avoided, the smooth rolling of the bismuth-containing free cutting steel is realized, the product surface quality is improved, medium wastes and inspection wastes are obviously reduced, the yield rate is greatly improved, and figured steel free cutting steel products, such as hexagonal steel, square steel, flat steel and the like can be directly produced through a caliber system.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

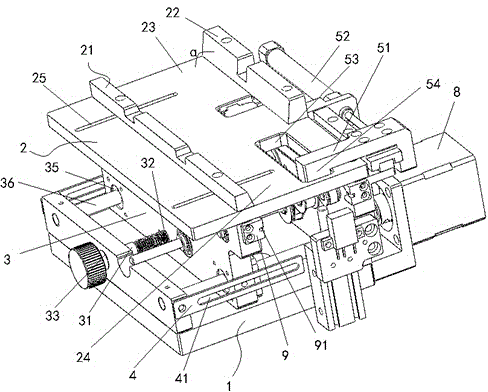

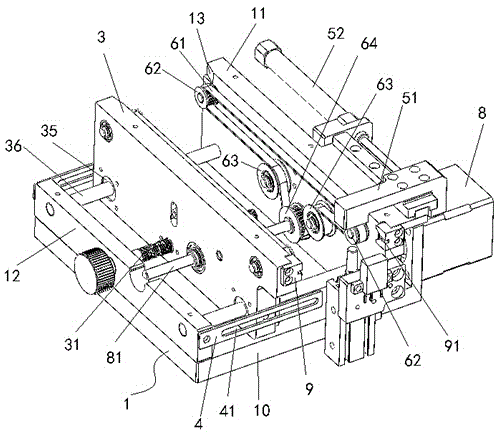

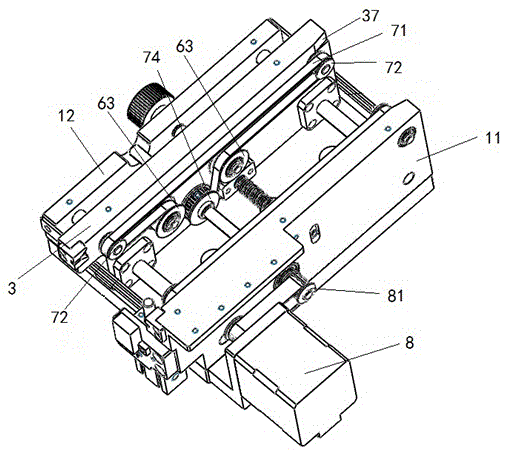

Conveying device

ActiveCN104828498AAdjustable widthFlexible width adjustmentMechanical conveyorsEngineeringMechanical engineering

The invention provides a conveying device. The conveying device comprises a supporting seat with a horizontal supporting surface, on which a first baffle plate and a second baffle plate arranged in parallel. A conveying channel is formed by the first baffle plate, the second baffle plate and the horizontal supporting surface. The conveying device further comprises an adjusting structure capable of adjusting the first baffle plate and / or the second baffle plate to move away from each other in order to adjust the width of the conveying channel. The conveying device has following beneficial effects: the conveying channel is adjustable such that a standard material box is unnecessarily adopted by the conveying device, namely, LED chip supports with different widths and sizes can be accurately pushed to corresponding positions of a machining mechanism; and therefore production cost is reduced and feeding efficiency is boosted.

Owner:深圳市佳思特光电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com