B-substituted BNT microwave dielectric ceramic material and preparation method

A technology of microwave dielectric ceramics and metal elements, applied in the field of functional materials, to achieve stable performance, high Q value, and low price

Inactive Publication Date: 2014-07-16

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although so far, the research on B-site substitution has not been satisfactorily applied to microwave dielectric ceramics, but these studies have confirmed that in Ba 6-3x Nd 8+2x Ti 18 o 54 It is feasible to carry out B-position substitution in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0029] first step:

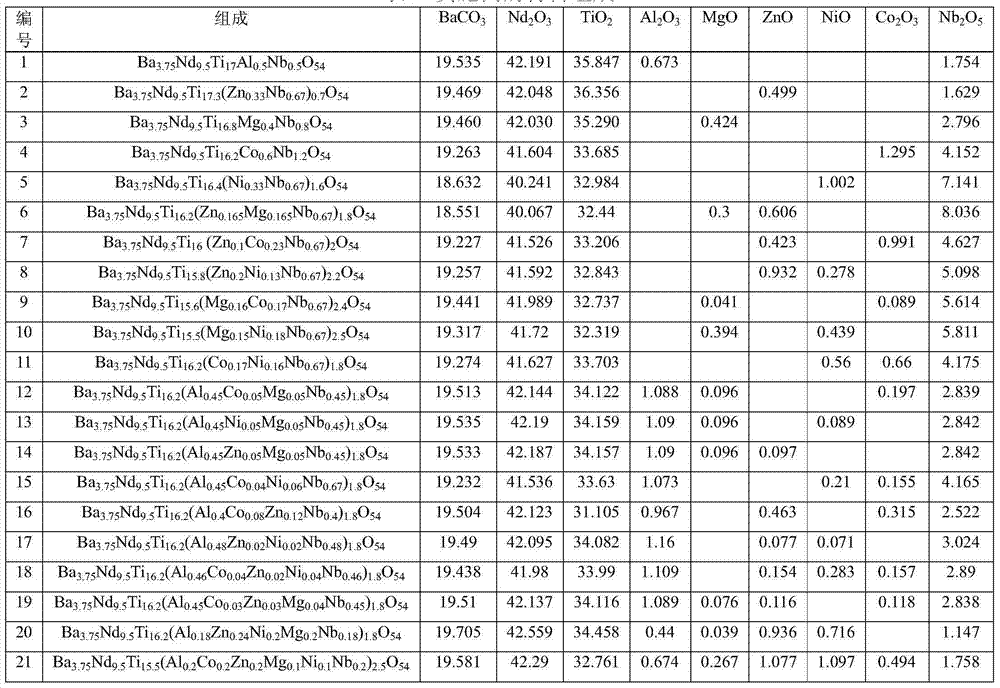

[0030] Accurately weigh various raw materials according to the mass percentage in Table 1, ball mill in deionized water for 6-8 hours, then dry and sieve, and pre-calcine at 1050-1150°C for 5-8 hours.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Login to View More

Abstract

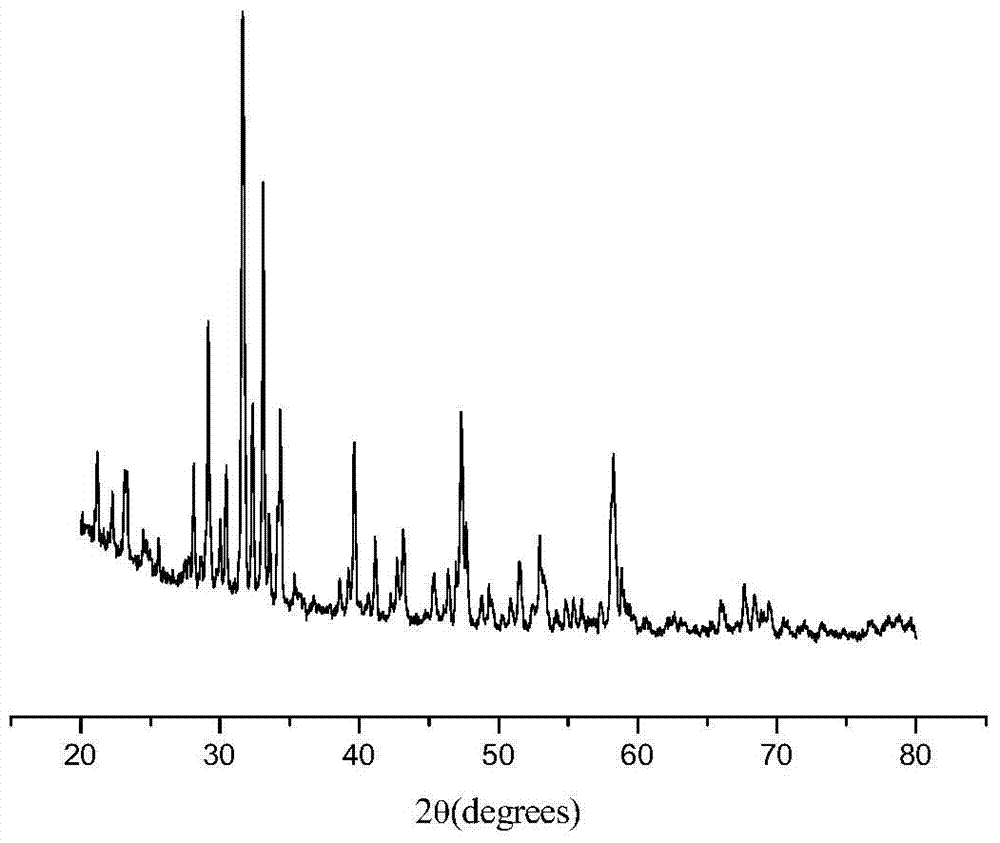

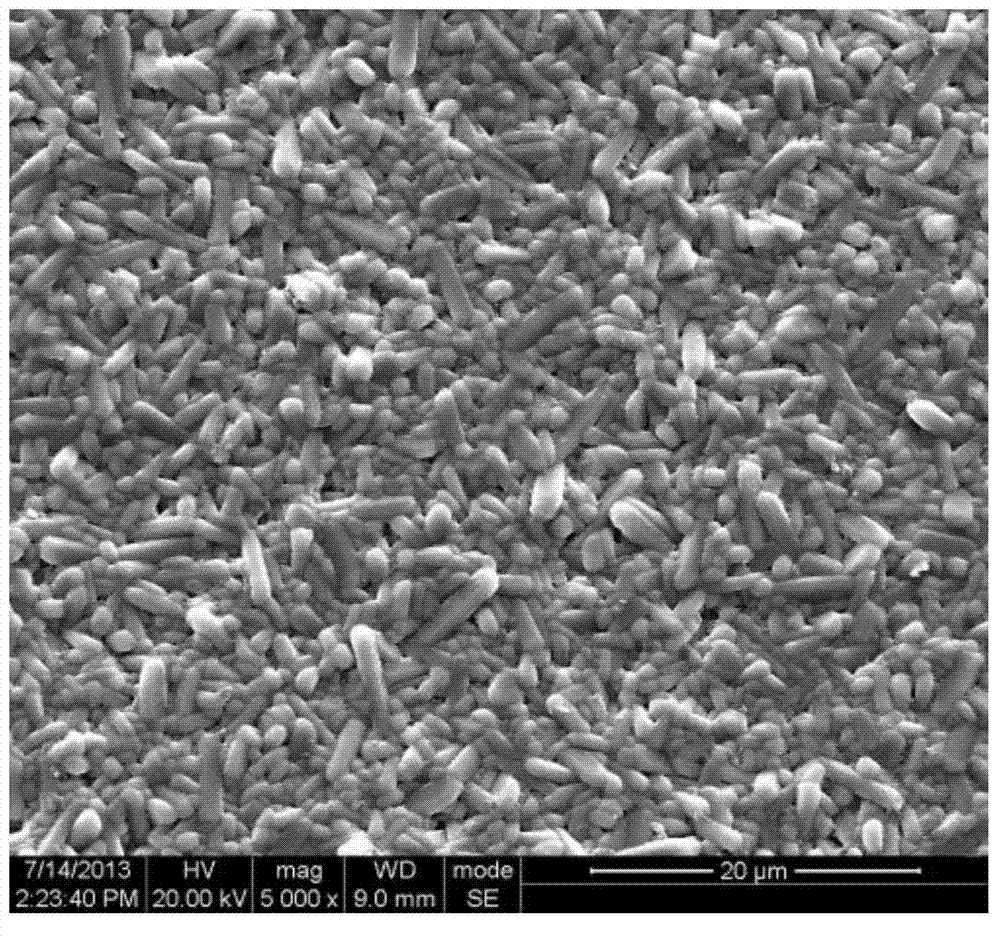

A B-substituted BNT microwave dielectric ceramic material and its preparation method belong to the technical field of a functional material. The general chemical formula of the microwave dielectric ceramic material is Ba3.75Nd9.5Ti18-y(M,N)yO54, wherein y is less than or equal to 2.5 and greater than or equal to 0.6; the microwave dielectric ceramic material is prepared by steps of: burdening BaO, Nd2O3, TiO2, oxides of metallic elements M and N according to mole ratio of the general chemical formula, carrying out ball-milling, presintering and sintering; an oxide of the element M is Nb2O5; and an oxide of the element N is one or more compounds selected from Al2O3, MgO, ZnO, Co2O3 and NiO. According to the invention, simultaneous substitution of high and low valence elements is carried out in the B position of Ba6-3xNd8+2xTi18O54. The microwave dielectric ceramic material prepared by a one-step synthesis process has high dielectric constant, low loss characteristic and low frequency-temperature coefficient, can meet requirements in the microwave communication industry, and is especially suitable for manufacturing of RFID tags.

Description

technical field [0001] The invention belongs to the technical field of functional materials, and relates to a microwave dielectric ceramic material and a preparation method thereof, in particular to a microwave dielectric ceramic material suitable for making radio frequency electronic tags and a preparation method thereof. Background technique [0002] In recent years, with the development of mobile communication technology and Internet of Things technology and the cross combination of the two, the development of radio frequency identification technology (radio frequency identification, RFID) has been promoted. Radio frequency identification technology is one of the core technologies of the perception layer of the Internet of Things; radio frequency identification technology is also a wireless communication technology, which consists of readers, antennas and electronic tags. Electronic tags, antennas and readers need to be used Microwave dielectric ceramics. Microwave diele...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/50C04B35/622

Inventor 唐斌陈鹤拓袁颖钟朝位张树人

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com