Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Lower Frequency Temperature Coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

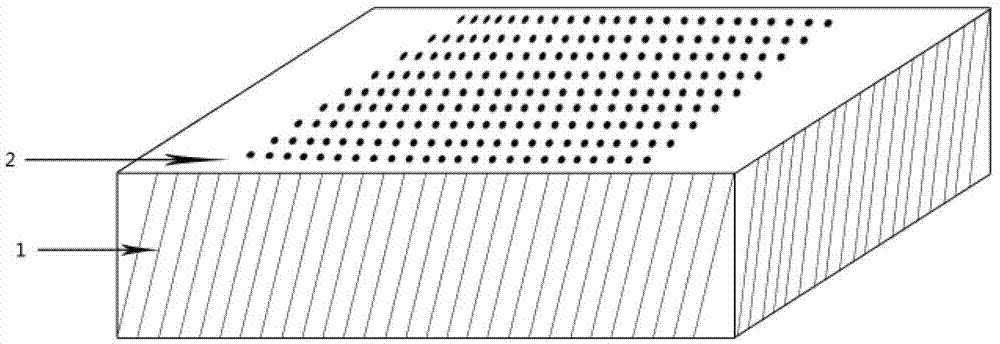

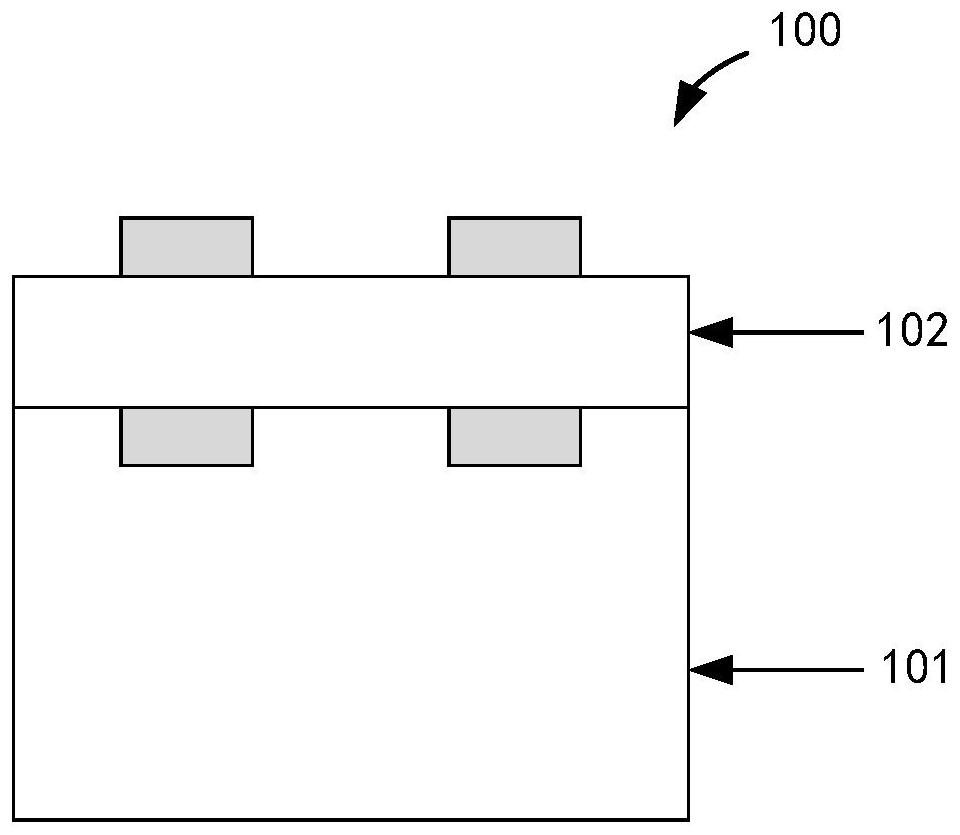

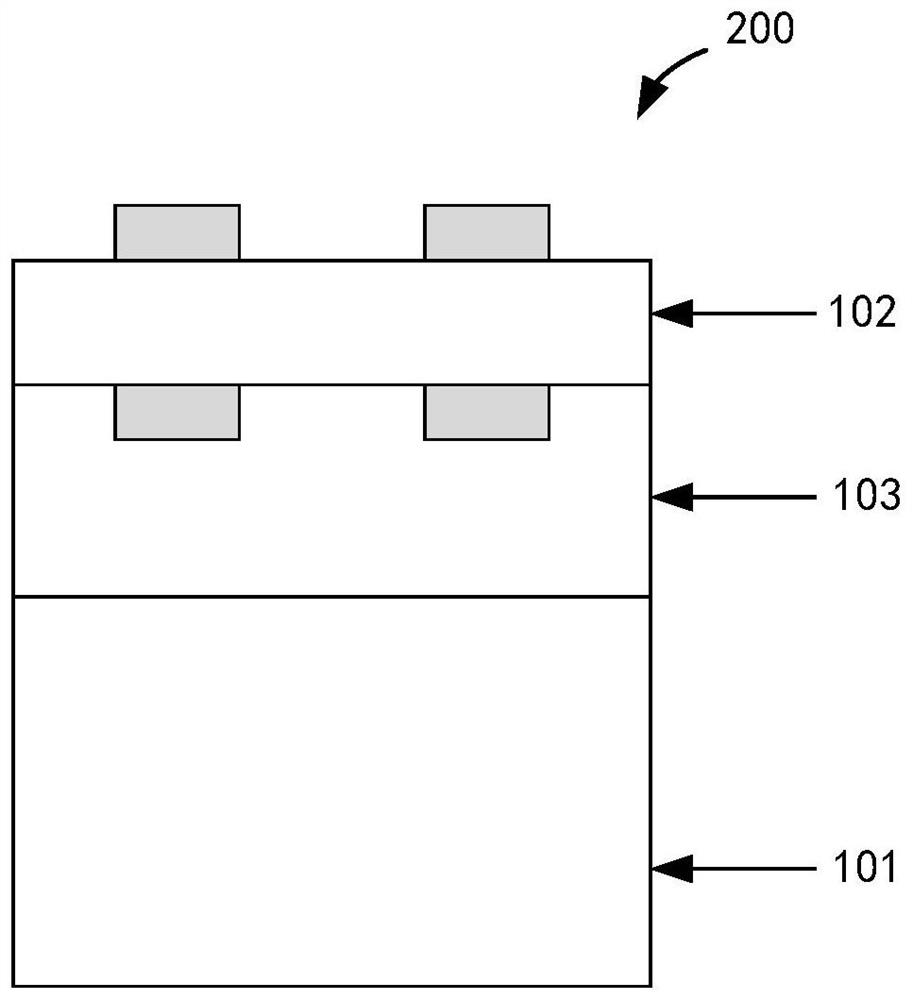

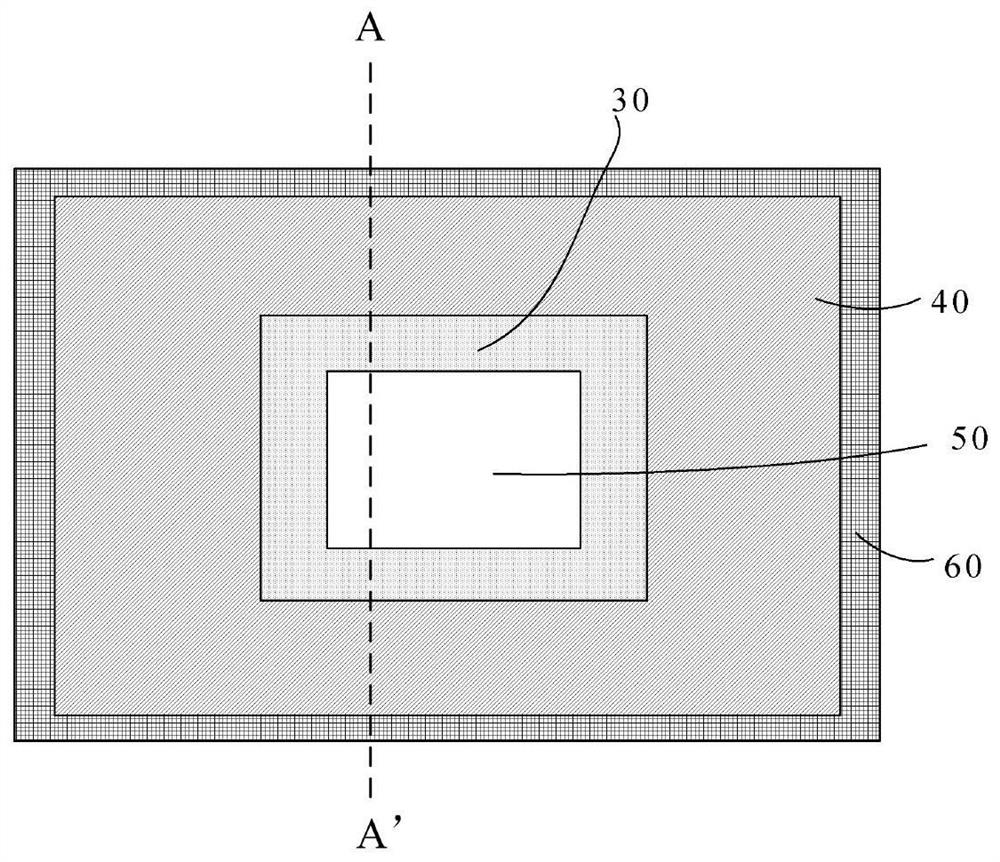

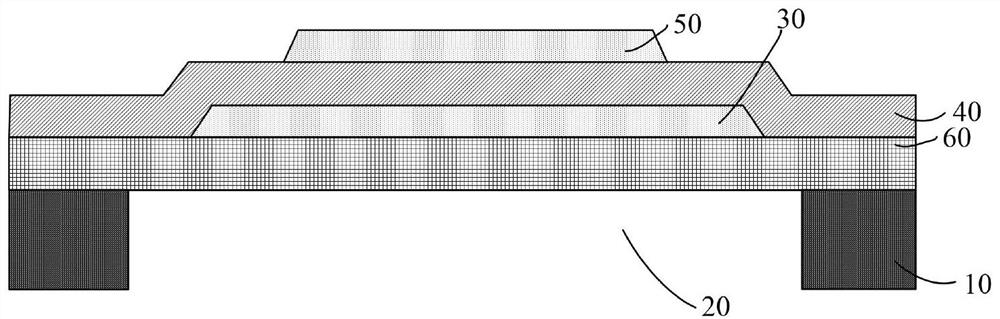

FBAR (film bulk acoustic resonator) substrate and preparation method thereof

InactiveCN102931941AGood frequency stabilityHigh frequencyImpedence networksWireless communication systemsThin-film bulk acoustic resonator

The invention discloses a FBAR (film bulk acoustic resonator) substrate and a preparation method thereof. The FBAR substrate is of a W / piezoelectric film / W / DLC / air gap / Si structure. The FBAR substrate with a W / piezoelectric film / W / DLC / air gap / Si structure has the characteristics of high frequency, high Q (quality) and good frequency stability. The FBAR substrate can be used for manufacturing filters and duplexers and the like in wireless communication systems, and also can be used for manufacturing high-performance sensors in combination with sensitive films.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

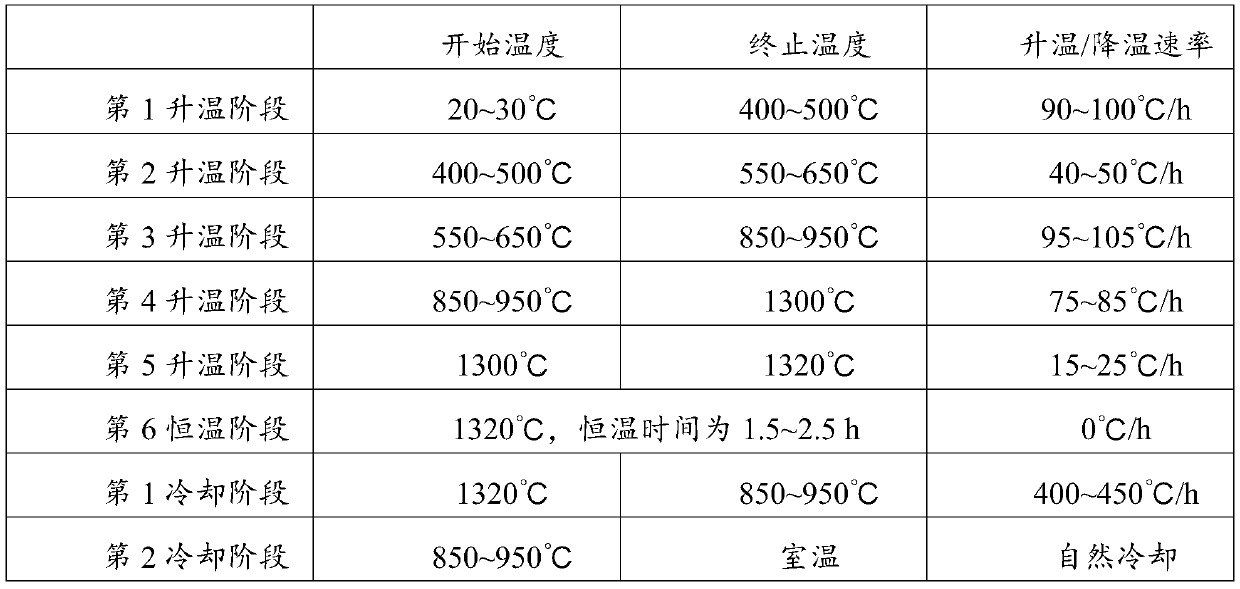

B-substituted BNT microwave dielectric ceramic material and preparation method

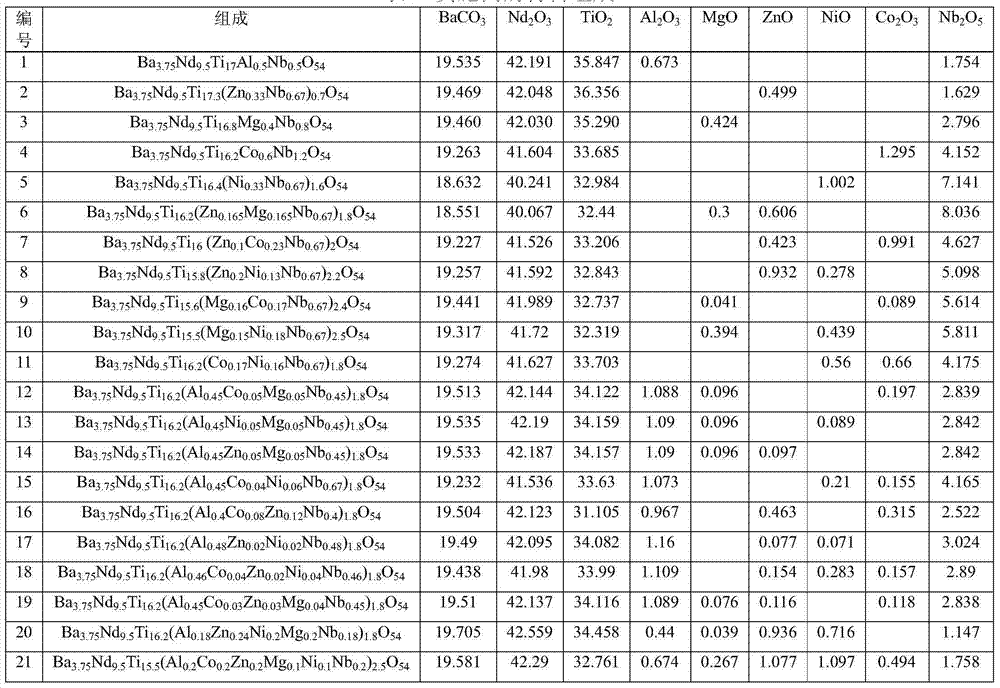

A B-substituted BNT microwave dielectric ceramic material and its preparation method belong to the technical field of a functional material. The general chemical formula of the microwave dielectric ceramic material is Ba3.75Nd9.5Ti18-y(M,N)yO54, wherein y is less than or equal to 2.5 and greater than or equal to 0.6; the microwave dielectric ceramic material is prepared by steps of: burdening BaO, Nd2O3, TiO2, oxides of metallic elements M and N according to mole ratio of the general chemical formula, carrying out ball-milling, presintering and sintering; an oxide of the element M is Nb2O5; and an oxide of the element N is one or more compounds selected from Al2O3, MgO, ZnO, Co2O3 and NiO. According to the invention, simultaneous substitution of high and low valence elements is carried out in the B position of Ba6-3xNd8+2xTi18O54. The microwave dielectric ceramic material prepared by a one-step synthesis process has high dielectric constant, low loss characteristic and low frequency-temperature coefficient, can meet requirements in the microwave communication industry, and is especially suitable for manufacturing of RFID tags.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Dielectric material with low dielectric constant and low loss for microwave functional module and its prepn process

InactiveCN1609025ASpeed up the development processDielectric properties comparable toGlass shaping apparatusInorganic insulatorsMicrowaveLow-pass filter

The present invention relates to the dielectric material with low dielectric constant and low loss for microwave functional module and its preparation process. The preparation process includes mixing material including MgO, Al2O3, SiO2, ZnO and B2O3 and founding glass; quenching glass to obtain transparent vitreous body without recrystallization; wet ball grinding, adding TiO2 as temperature coefficient regulating agent, mixing, ball milling, drying, pressing into disc and sintering to obtain the material of the present invention. The MgO-Al2O3-SiO2-ZnO-B2O3 system with TiO2 temperature coefficient regulating agent has low dielectric constant, low loss, low temperature coefficient of frequency, low thermal expansion coefficient and other advantages, and may be used in producing various microwave modules.

Owner:ZHEJIANG UNIV +1

High-dielectric low-loss microwave dielectric ceramic material and preparation method thereof

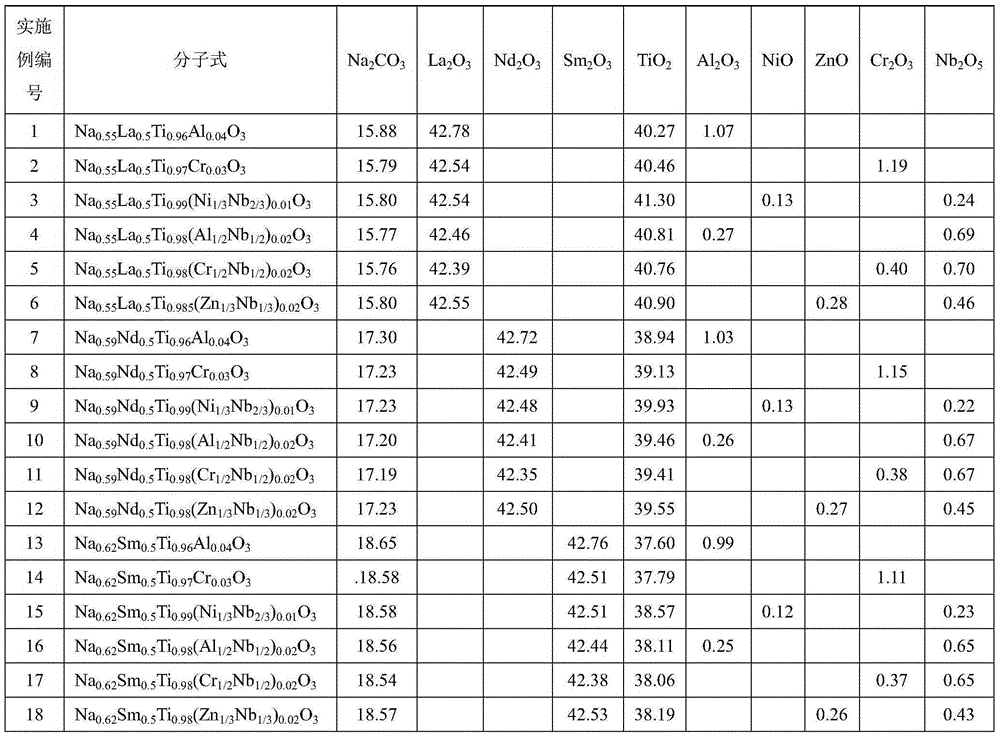

The invention provides a high-dielectric low-loss microwave dielectric ceramic material. The general chemical formula of the material is (Na0.5+yLn0.5)(Ti1-xCx)O3, Ln=La or Nd or Sm, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.04, y is larger than or equal to 0.05 or is smaller than or equal to 0.12, the composition of C is VW, V represents Nb with the valence state higher than four, W represents a single ion or compound ions with the valence state lower than or equal to four and the average ion radius approximating to Ti4+, and V and M achieve simultaneous replacement or independent replacement. The invention further provides a preparation method of the high-dielectric low-loss microwave dielectric ceramic material. The preparation method comprises the steps of burdening, ball grinding, drying and sieving, presintering, pelleting, compression molding and sintering. The prepared material has the high dielectric constant and high Q*f value, contains no Pb or Cd or other volatile toxic metals in the formula, and is stable in performance and capable of meeting application requirements of modern microwave devices, raw materials are sufficiently supplied in China, the cost is relatively low, and the high-performance microwave ceramic can be low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

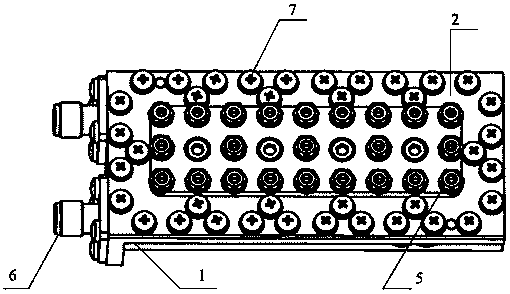

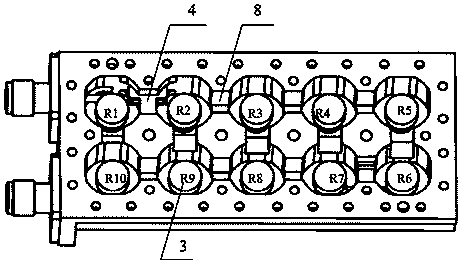

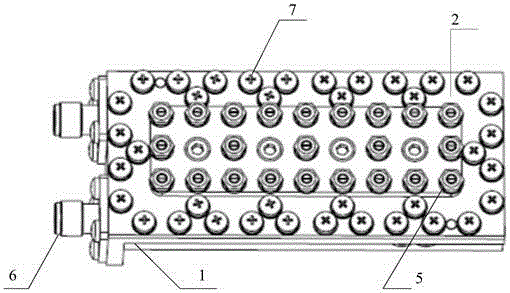

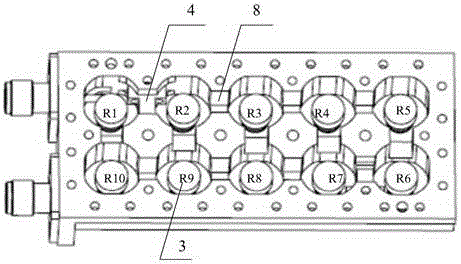

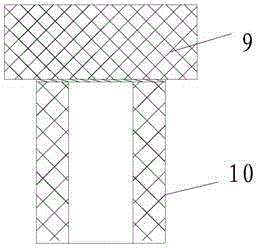

TE01 mode dielectric filter

ActiveCN104218281AReduce the amount of debuggingCompact structureWaveguide type devicesEngineeringDielectric resonator

A TE01 mode dielectric filter comprises a cavity, a cover plate, dielectric resonators, T-shaped coupling rods, tuning screws, SMA electric connectors and fastening screws. The TE01 mode dielectric filter is characterized in that cross couplings of the filter are all positive, and a main coupling is provided with two negative couplings positioned between the dielectric resonators R1 and R2 and between the dielectric resonators R6 and R7 respectively by the aid of the novel T-shaped coupling rods. Due to the fact that all cross couplings of the filter are positive and implemented through coupling holes, compared with a traditional dielectric filter with negative cross couplings implemented through probes, the TE01 mode dielectric filter has the advantages that introduced parasitic couplings are small, introducing redundant cross couplings for overcoming influences of the parasitic couplings is not needed, and reliability of the filter is improved. In addition, the novel T-shaped coupling rods are low in chromatic dispersion and simple in processing, fine tuning of coupling can be realized by the aid of the tuning screws, repeatedly demounting the cover for altering the sizes of the coupling rods during debugging of the filter is avoided, and accordingly debugging workload is reduced.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

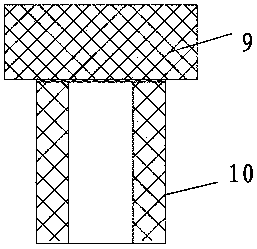

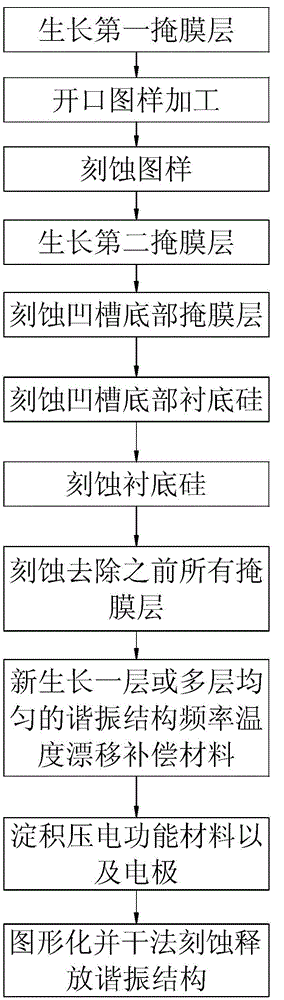

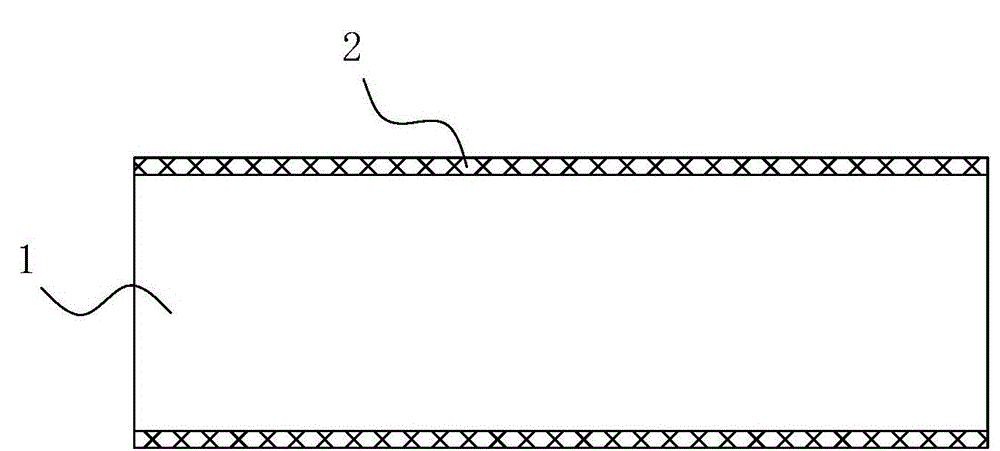

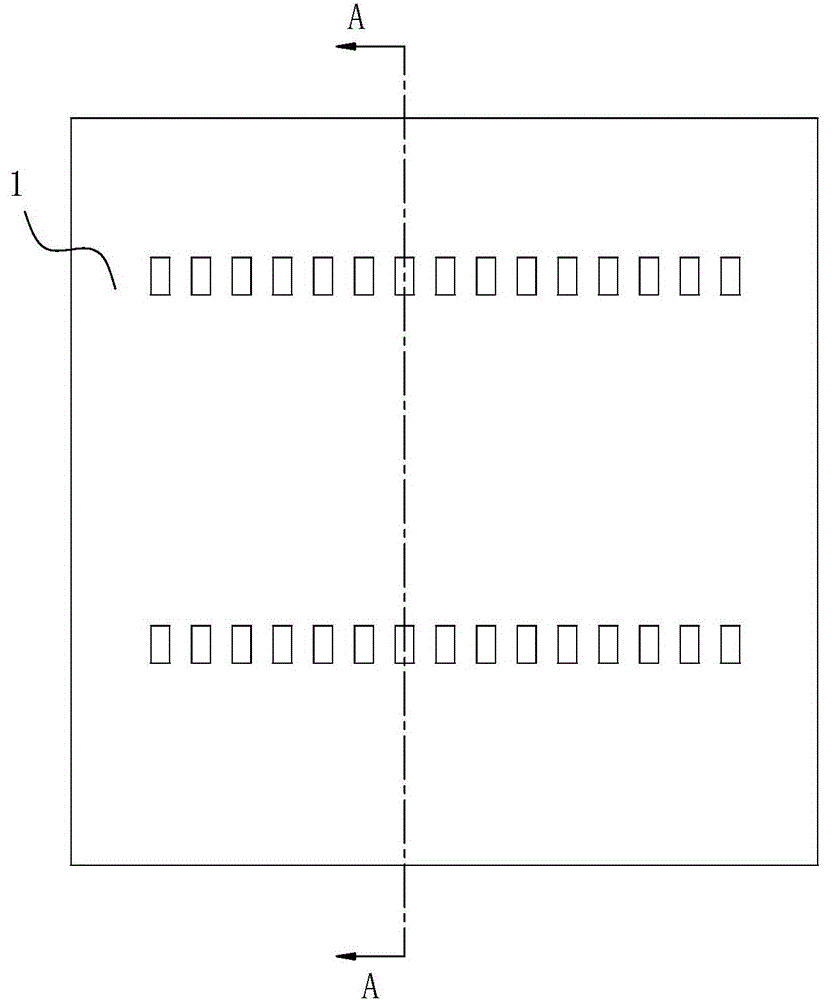

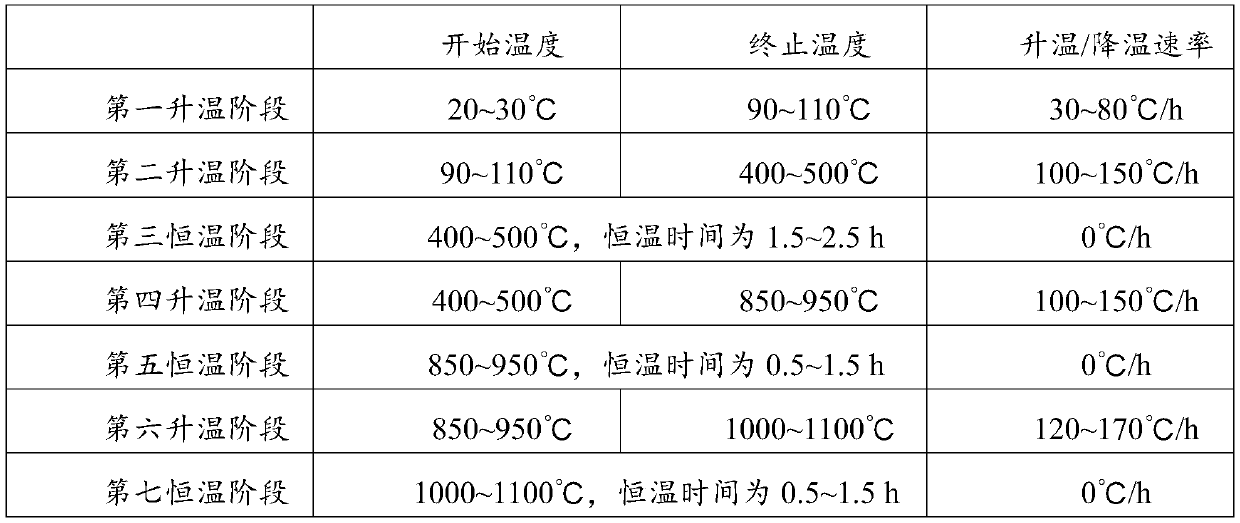

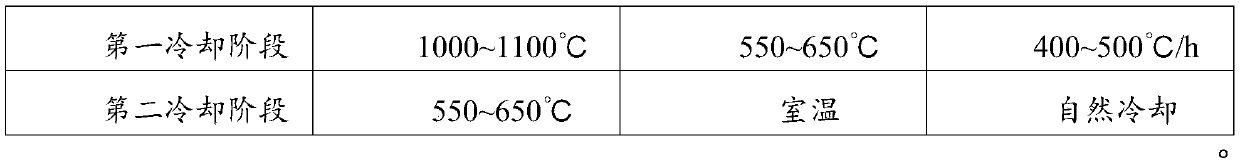

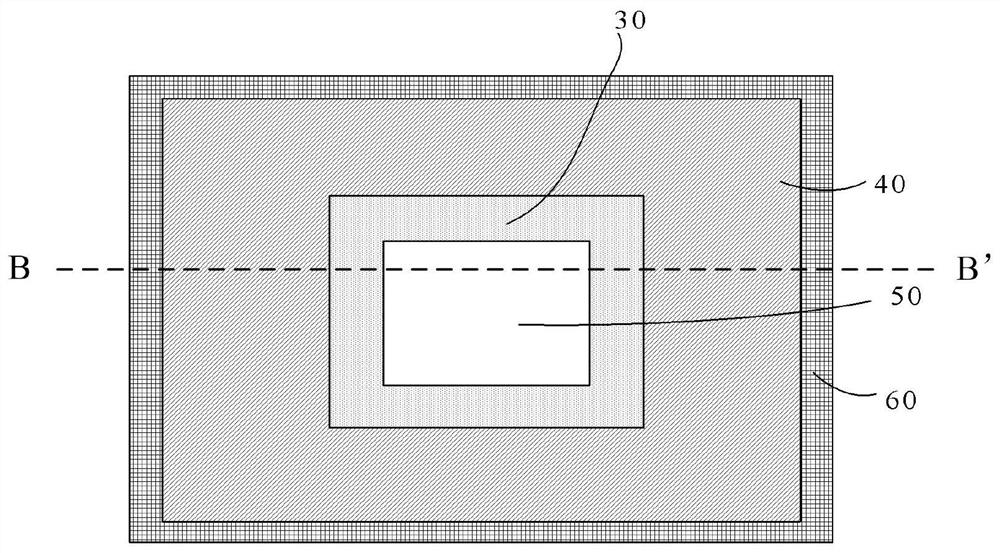

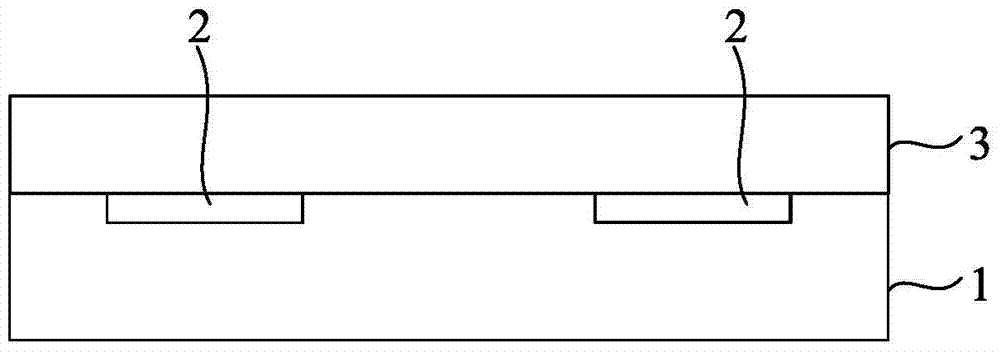

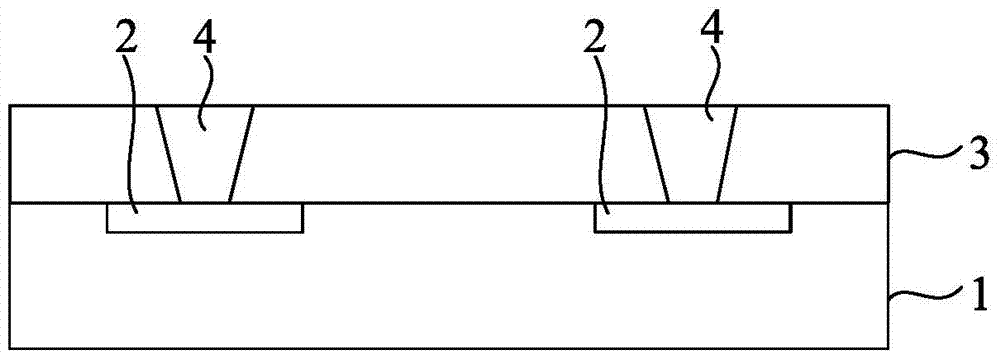

Method for machining MEMS resonant structure

ActiveCN104993804ALower Frequency Temperature CoefficientEasy to controlImpedence networksDry etchingSilicon

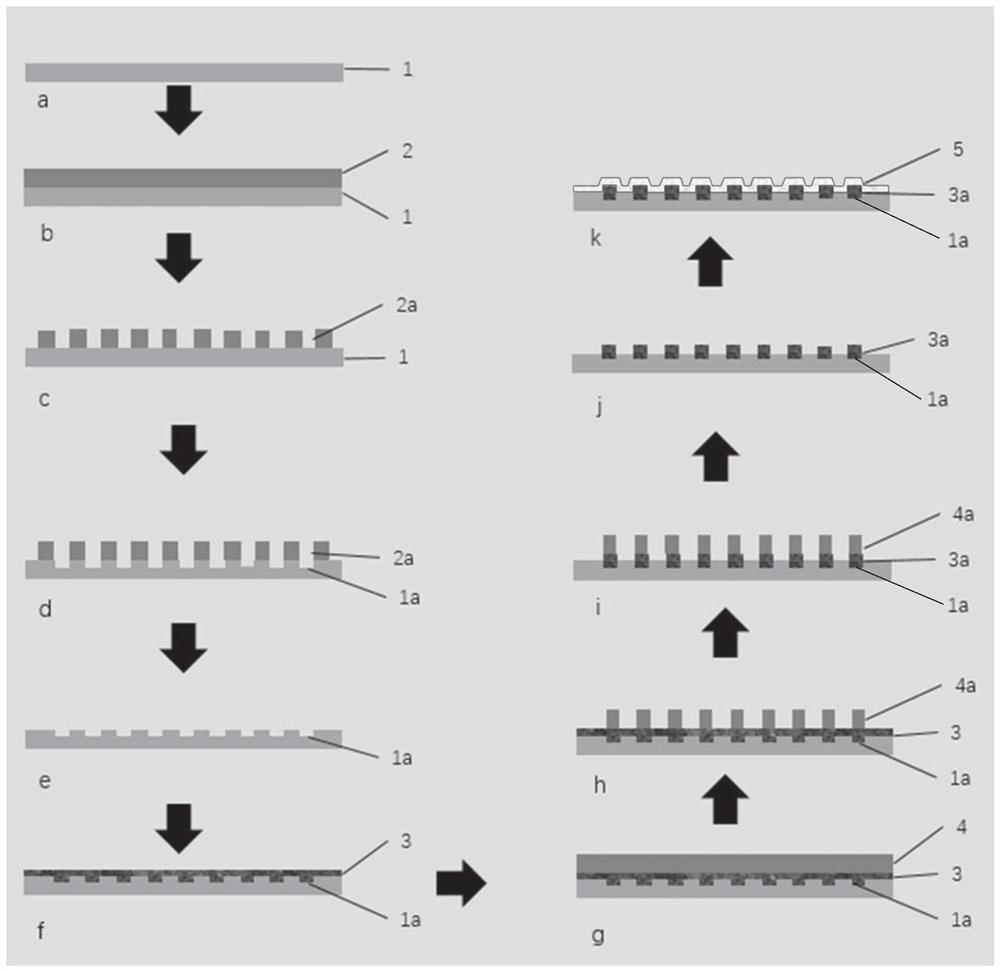

The invention discloses a method for machining an MEMS resonant structure. The method includes: providing silicon wafer as substrate silicon, and growing a first mask layer on the surface of the substrate silicon; machining open patterns on the first mask layer; removing parts of the first mask layer and the substrate silicon which are corresponding to the open patterns by dry etching, and forming groove structures on the substrate silicon; growing second mask layers, forming the second mask layers on groove side walls of the groove structures and the groove bottoms, and forming a composite mask layer on the surface of the substrate silicon; removing the second mask layers by dry etching, and completely removing the second mask layers of the groove bottoms; etching the substrate silicon again by dry etching, enabling the groove structures to be deepened, and enabling newly etched groove side walls not to be covered by mask layers; by wet etching, enabling the inside of the substrate silicon to be communicated with the open pattern to form a cavity; depositing lower electrodes, piezoelectric function materials and upper electrodes; and patterning and releasing the resonant structure by dry etching.

Owner:GUANGDONG HEWEI INTEGRATED CIRCUIT TECH

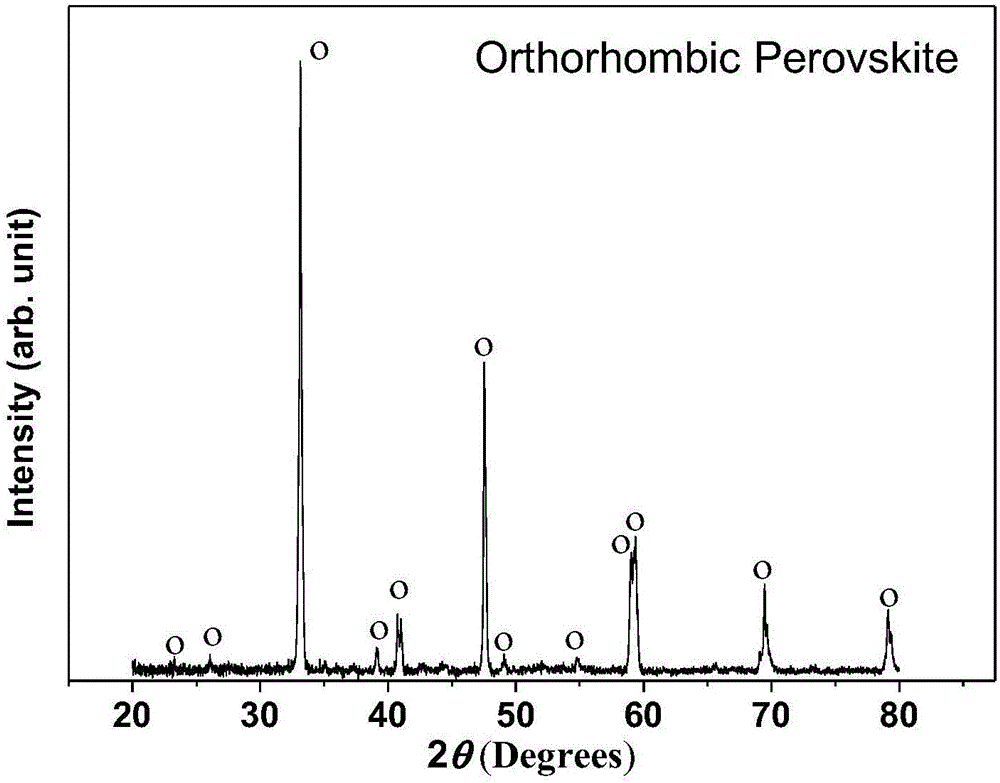

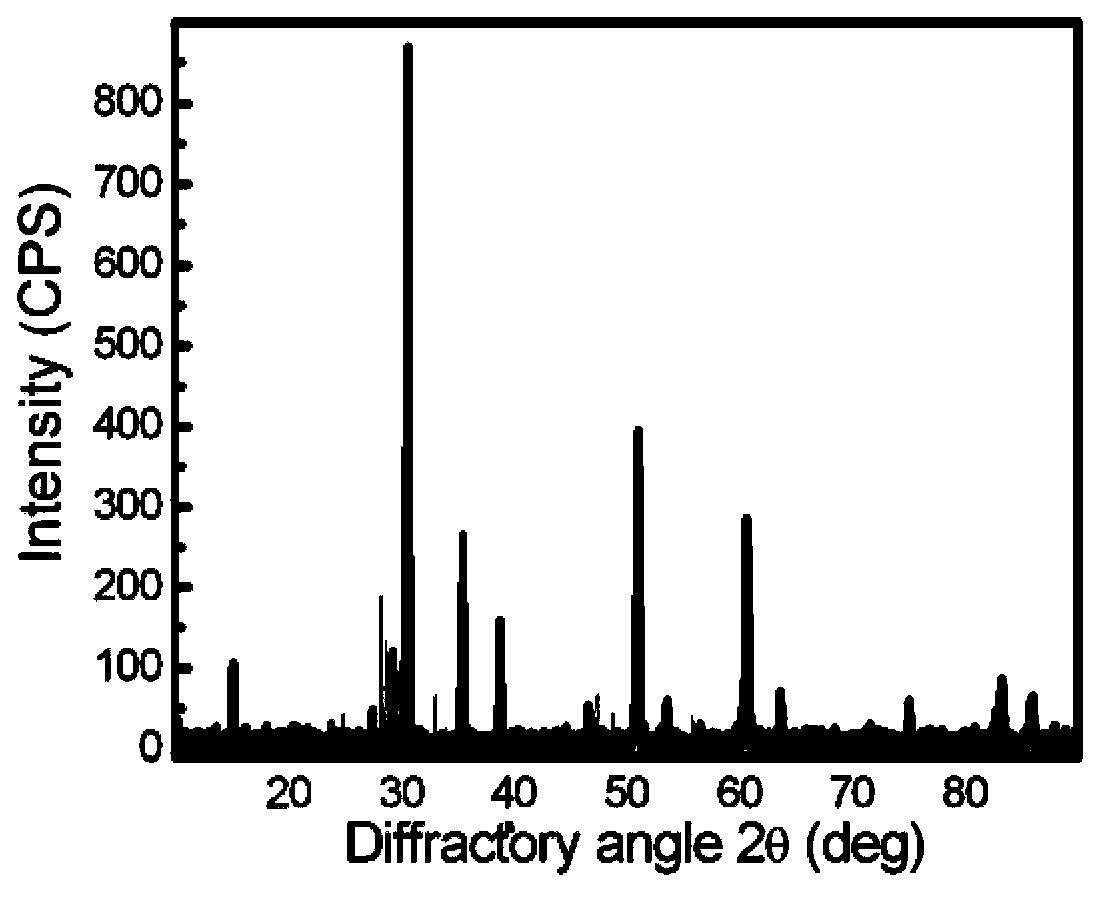

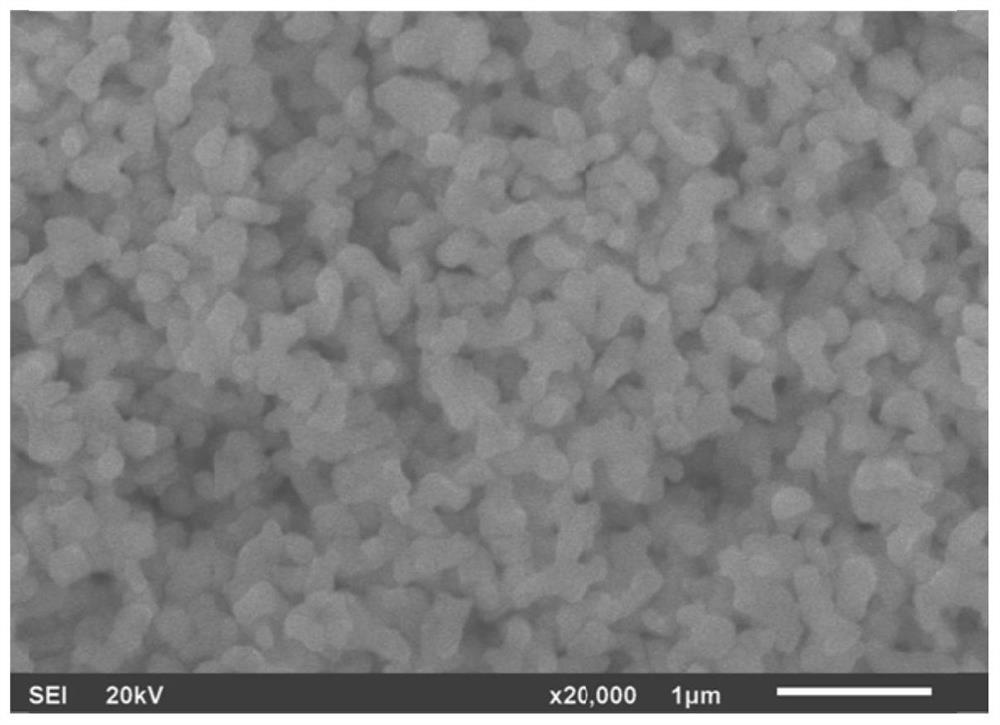

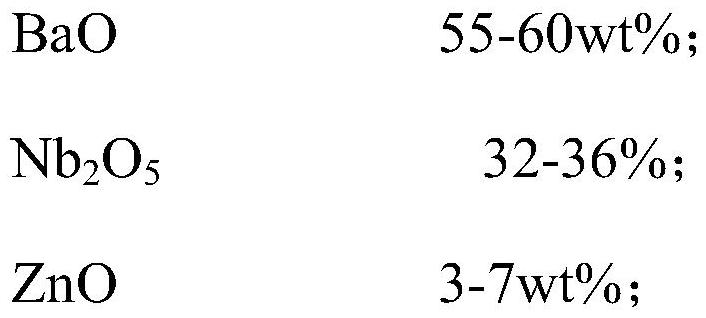

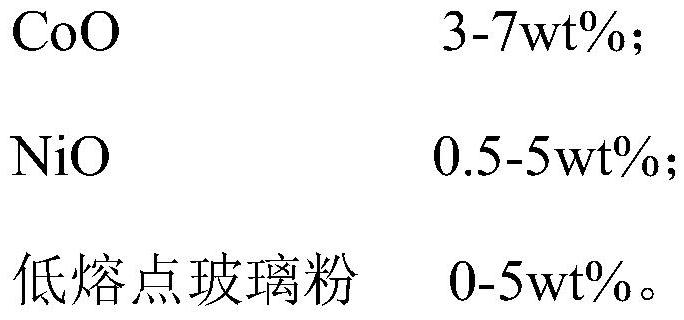

Barium niobate system microwave dielectric ceramic material and preparation method and application thereof

ActiveCN111116197ALower sintering temperatureImprove Microwave PerformanceResonatorsDielectricMicrowave

The invention belongs to the technical field of microwave dielectric ceramic materials, and particularly relates to a barium niobate system microwave dielectric ceramic material. BaCO3, Nb2O5, ZnO, CoO and NiO are used as raw materials to synthesize a main sintering block, SiO2, BaO, CaO, B2O3 and Li2O are used as raw materials to synthesize low-melting-point glass powder, and then the main sintering block and the low-melting-point glass powder are mixed and dispersed to obtain the required barium niobate system microwave dielectric ceramic material. The dielectric constant of the microwave dielectric ceramic material reaches 33-36, f*Q at 25 DEG C is larger than 80000, the frequency temperature coefficient calculated by testing the resonant frequencies f at -40 DEG C, 25 DEG C and 110 DEGC is low and is only -5 ppm / DEG C to 5 ppm / DEG C, and the performance of the microwave dielectric ceramic material meets the requirements of microwave dielectric ceramic devices. Meanwhile, the material also has relatively good dielectric properties in a millimeter wave frequency band, and the method can be used for producing ceramic devices such as filters and resonators.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

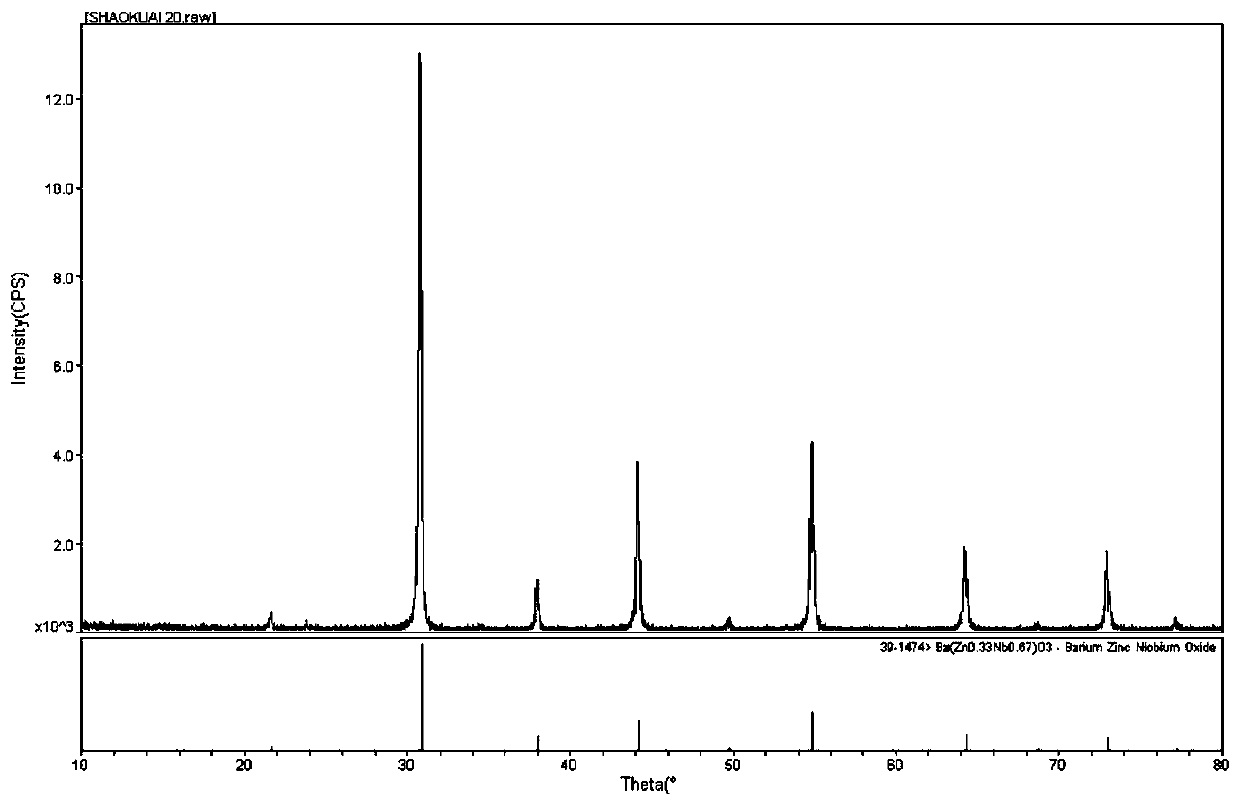

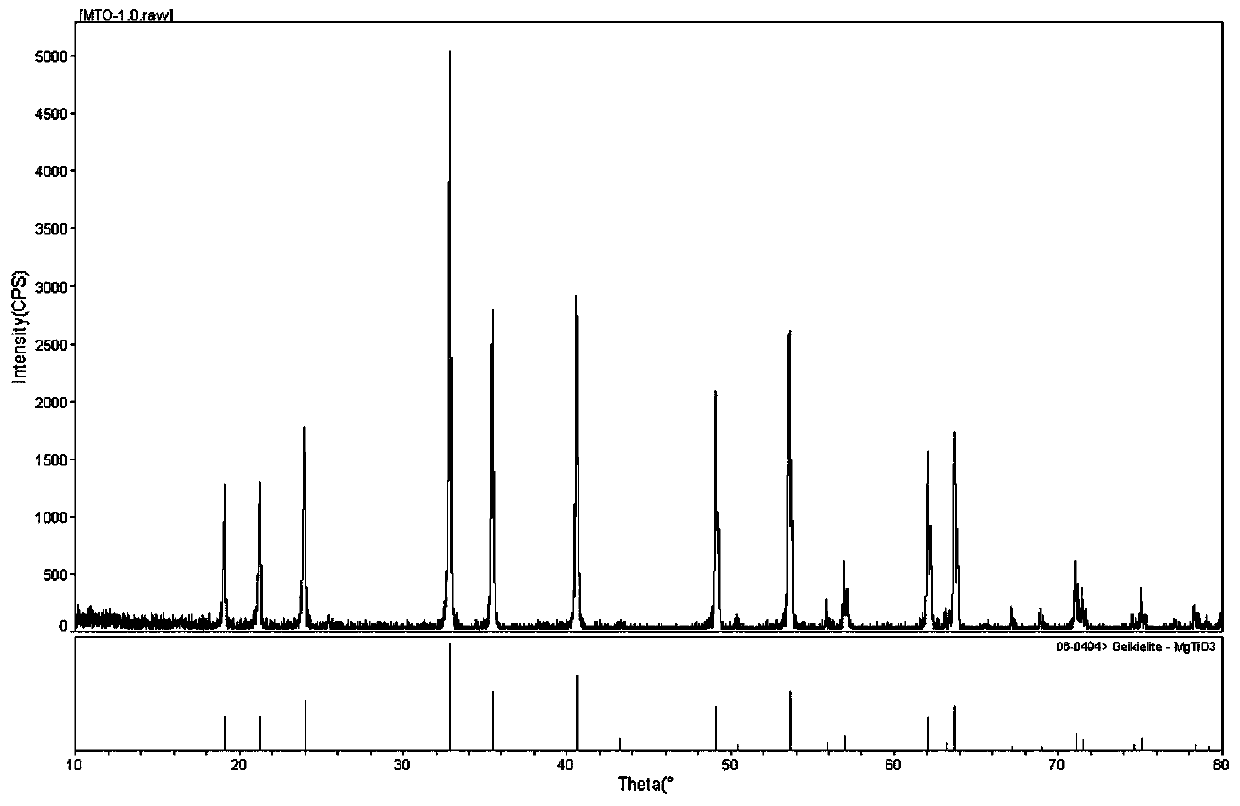

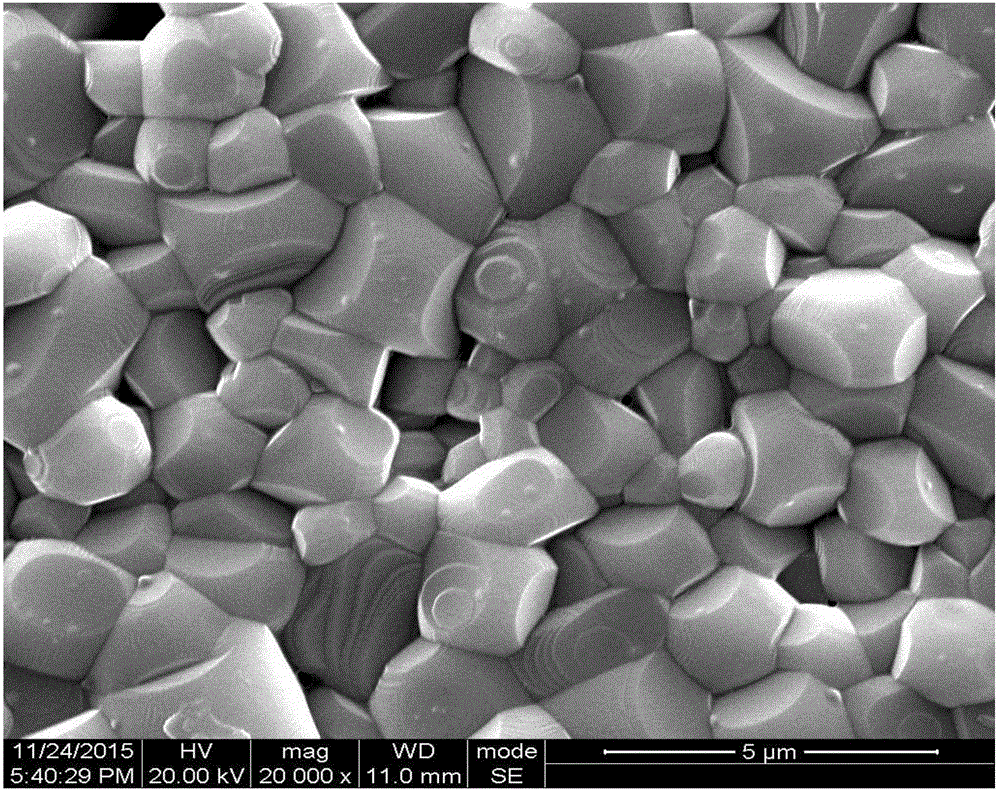

Two-phase composite microwave dielectric ceramic material, and preparation method and application thereof

InactiveCN111170738AGood dielectric propertiesThe synthesis method is simpleResonatorsCeramicResonator

The invention belongs to the technical field of microwave dielectric ceramic materials, and particularly relates to a two-phase composite microwave dielectric ceramic material. The two-phase compositemicrowave dielectric ceramic material is prepared from Ba(Zn<1 / 3>Nb<2 / 3>)O<3>, MgTiO<3> and a selectively-added oxide additive through solid-phase synthesis; the obtained microwave dielectric ceramicmaterial can be sintered into ceramic at a sintering temperature of 1320 to 1370 DEG C; the dielectric constant of a test wafer reaches 30-35, the value of f*Q at 25 DEG C is larger than 60000, a frequency temperature coefficient calculated by testing resonant frequencies f at -40 DEG C, 25 DEG C and 110 DEG C is low and ranges from -5 ppm / DEG C to 5 ppm / DEG C, and the performance of the test wafer meets the requirements on microwave dielectric ceramic devices; meanwhile, the material also has relatively good dielectric properties in a millimeter wave frequency band; and the material can be used for producing ceramic devices such as filters and resonators.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

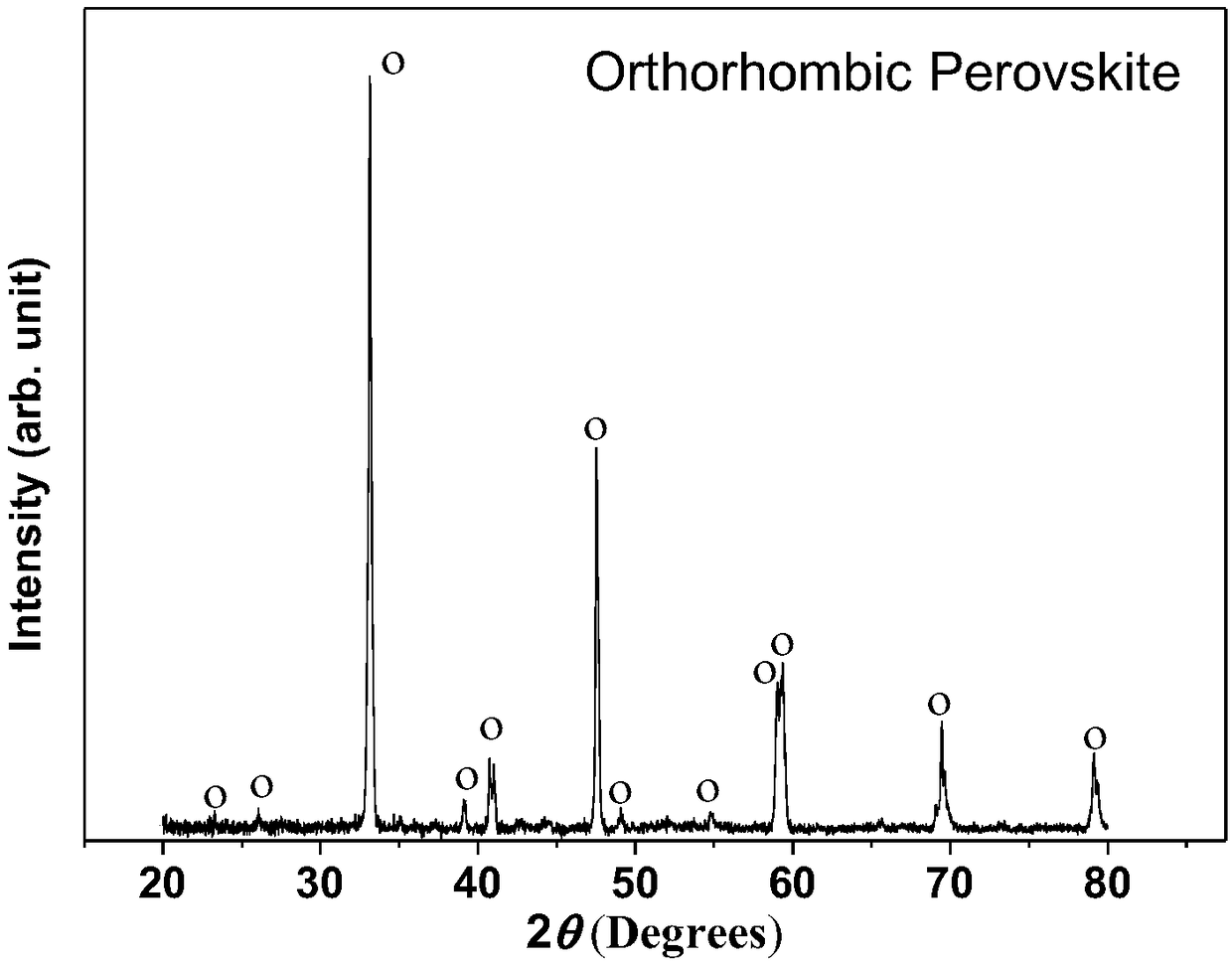

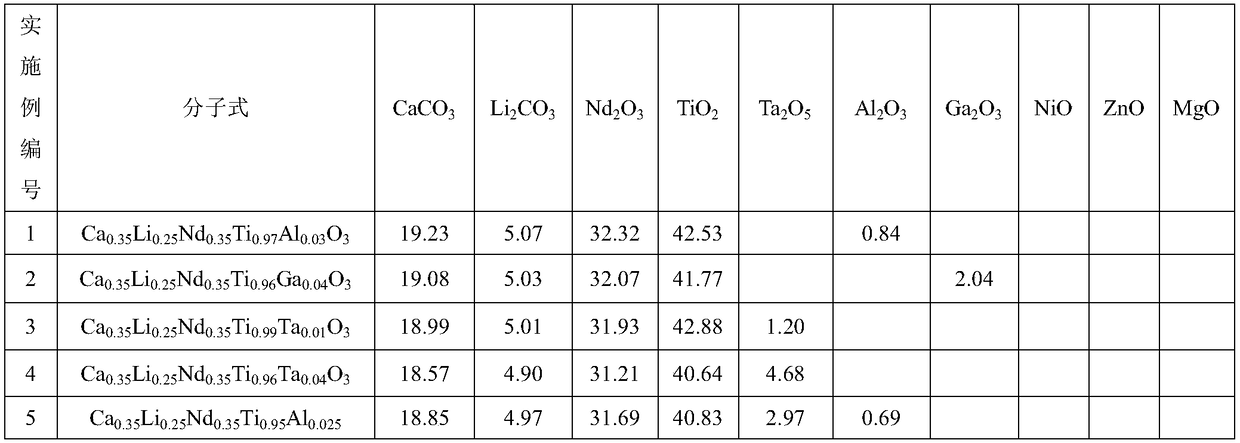

High-permittivity microwave dielectric ceramic material and preparation method thereof

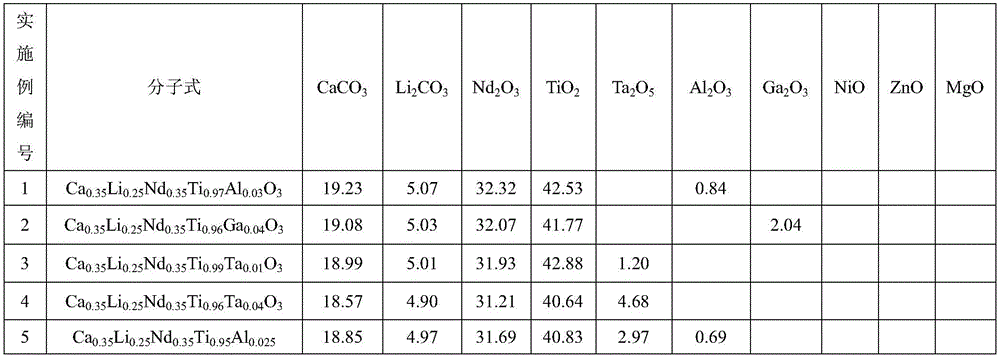

The invention provides a high-permittivity microwave dielectric ceramic material. The material has the material chemical formula (Ca0.35Li0.25Nd0.35)(Ti1-xDx)O3, wherein x is larger than or equal to 0.01 and smaller than or equal to 0.05, the composition of D is VW, V represents Ta with the valence state higher than 4, W represents one or more elements with the valence state lower than four and the average ion radius close to Ti4+, and V and W can be substituted at the same time or independently. The invention further provides a preparation method of the high-permittivity microwave dielectric ceramic material. The method includes the steps of material mixing, ball grinding, drying, screening, pre-sintering, granulating, compression molding forming and sintering. The prepared material has a high dielectric constant, a high Q*f value and an adjustable frequency and temperature coefficient. Volatile toxic metal such as Pb and Cd is not contained in the formula, performance is stable, application requirements of modern microwave devices can be met, the raw materials can be sufficiently supplied in China, the price is relatively low, and low cost of high-performance microwave ceramic is made possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

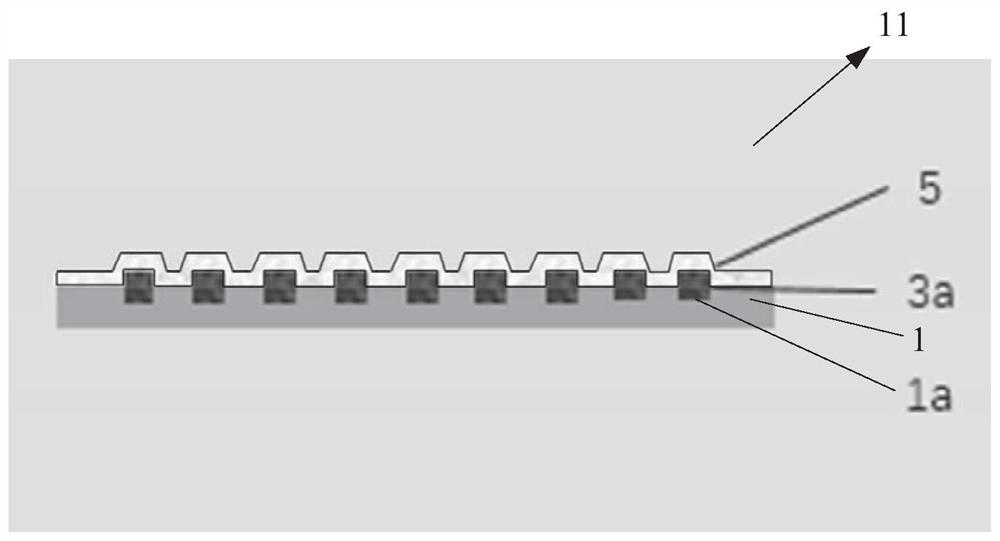

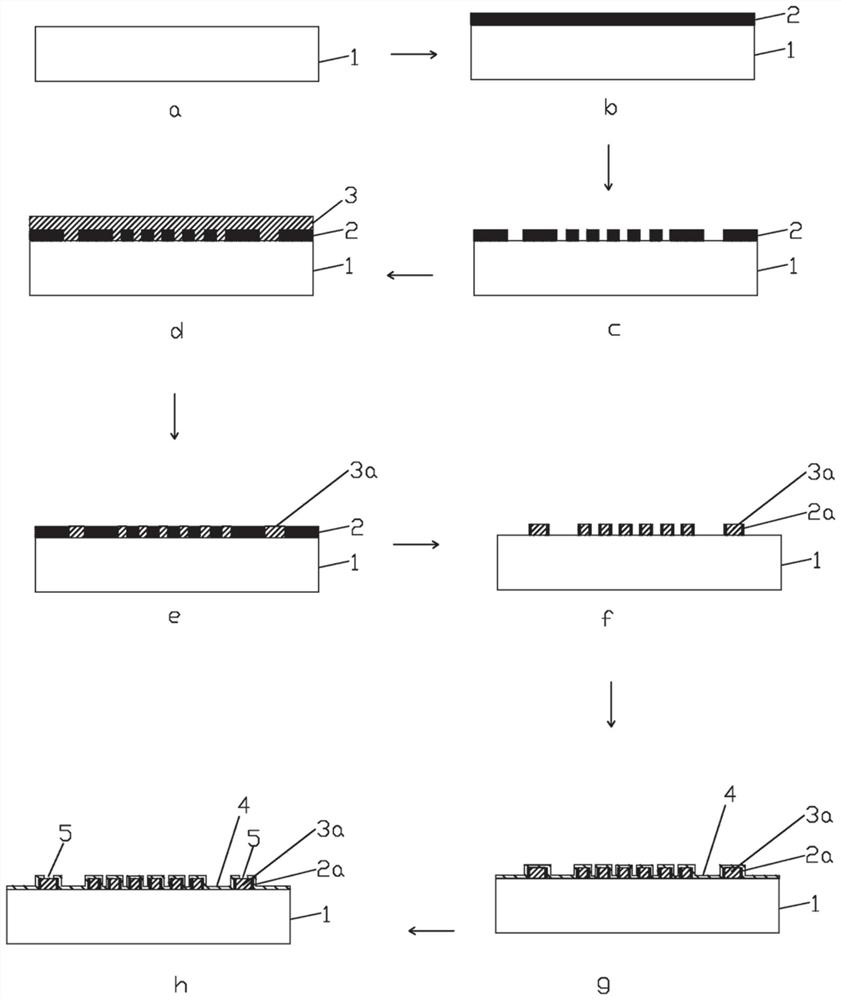

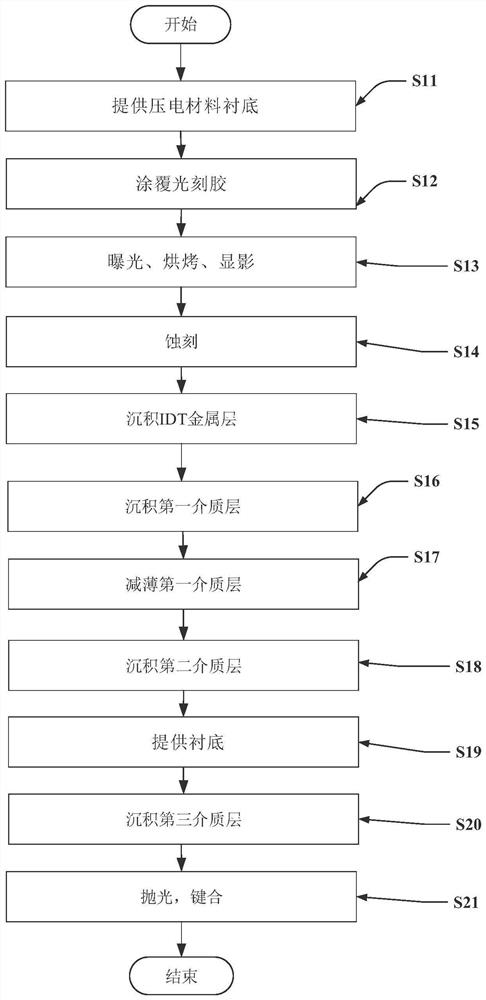

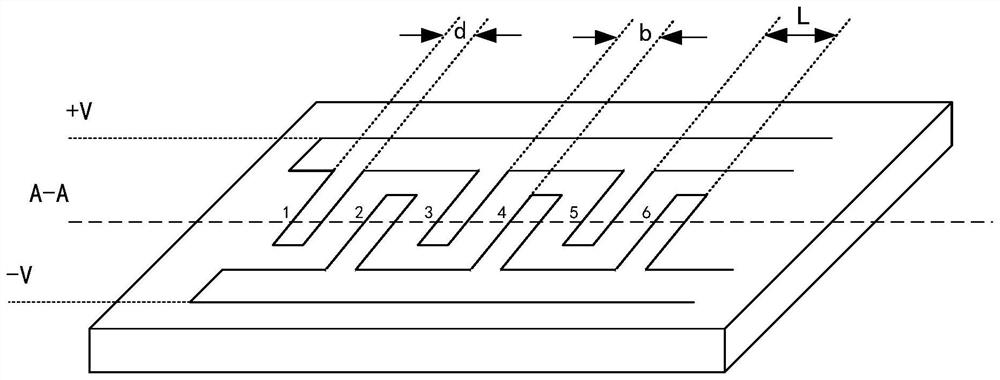

Temperature compensation type surface acoustic wave device and manufacturing method thereof

PendingCN112436816AInhibit temperature driftSuppression of spurious effectsImpedence networksSurface acoustic wavePhotoresist

The invention provides a temperature compensation type surface acoustic wave device and a manufacturing method thereof. The manufacturing method comprises the following steps: providing a piezoelectric material substrate; coating a first photoresist on the piezoelectric material substrate, exposing and developing the first photoresist, and defining an IDT metal layer semi-buried gully pattern; etching the piezoelectric material substrate to form an IDT metal filling trench corresponding to the IDT metal layer semi-buried trench pattern, and removing the first photoresist; depositing metal on the etched piezoelectric material substrate to form an IDT metal layer, and enabling the IDT metal layer to fill the IDT metal filling trench and overflow the IDT metal filling trench; coating a secondphotoresist on the IDT metal layer, exposing and developing the second photoresist, and defining an IDT pattern; etching the IDT metal layer to form an IDT metal finger strip structure correspondingto the IDT pattern, and removing the second photoresist; and depositing a dielectric material on the piezoelectric material substrate and the IDT metal finger strip structure to form a dielectric layer.

Owner:GUANGDONG CANCHIP TECH CO LTD

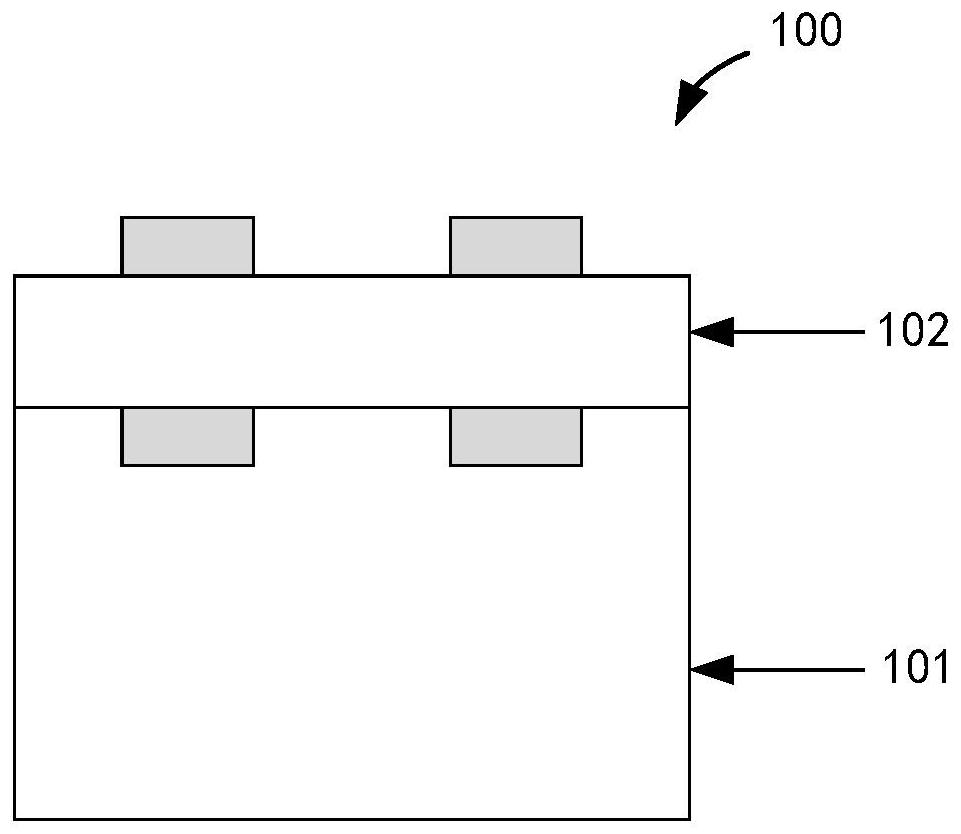

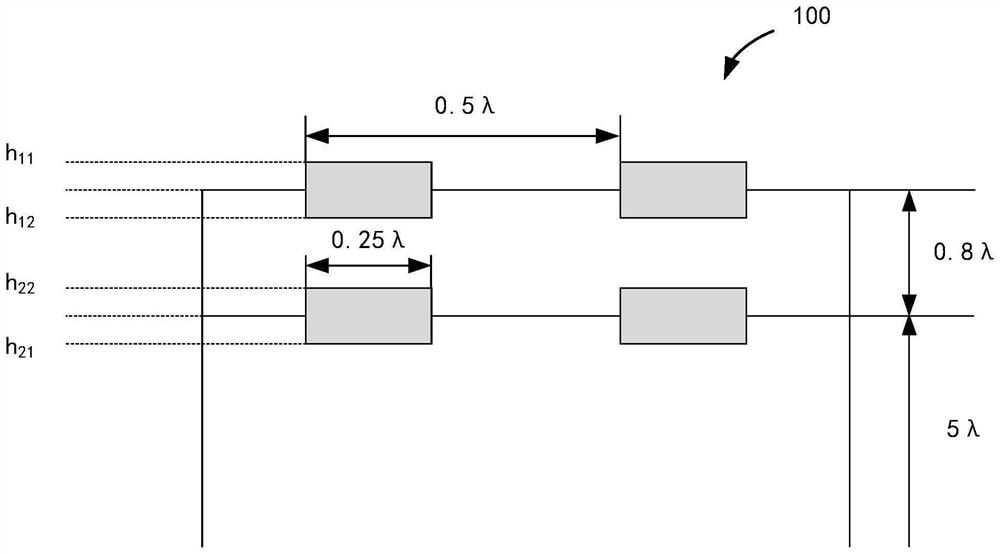

Lamb wave resonator with POI structure

The invention provides a Lamb wave resonator with a POI structure. The Lamb wave resonator may include: a substrate of high acoustic velocity material; a piezoelectric layer located above the substrate made of the high-sound-velocity material, wherein a first interdigital transducer and a second interdigital transducer are arranged on the upper surface and the lower surface of the piezoelectric layer respectively, and interdigital electrodes of the first interdigital transducer and the second interdigital transducer are opposite to each other in the stacking direction across the piezoelectric layer. The first interdigital transducer and the second interdigital transducer have same electrode width, electrode thickness, electrode pitch, duty cycle p, and excitation sound wave wavelength lambda, where the duty cycle p = electrode width / (electrode width + electrode pitch), and where the duty cycle p is set to 0.2-0.5.

Owner:GUANGDONG CANCHIP TECH CO LTD

Microwave dielectric ceramic material, preparation method and application thereof, and filter ceramic material

The invention provides a microwave dielectric ceramic material, a preparation method and application thereof, and a filter ceramic material, and belongs to the technical field of electronic materials.The microwave dielectric ceramic material provided in the invention includes, by mass, a component A, a component B, a component C, a component D and a component E, wherein the component A is BaTi4O9, the component B is Ba2Ti9O20, the component C is BaWO4, the component D is a mixture of ZnTiO3, SnTiO3, LaTiO3, NdTiO3, BaSm2Ti4O12 and PrTiO3, and the component E is obtained by sintering and cooling CaO, MgO and SiO2 in sequence. The microwave dielectric ceramic material provided by the invention is relatively high in dielectric constant, small in dielectric loss, relatively high in quality factor Q and relatively small in frequency temperature coefficient.

Owner:福建省德化县华瓷新材料科技有限公司

A te01 mode dielectric filter

ActiveCN104218281BReduce the amount of debuggingSmall parasitic couplingWaveguide type devicesCouplingEngineering

A TE01 mode dielectric filter comprises a cavity, a cover plate, dielectric resonators, T-shaped coupling rods, tuning screws, SMA electric connectors and fastening screws. The TE01 mode dielectric filter is characterized in that cross couplings of the filter are all positive, and a main coupling is provided with two negative couplings positioned between the dielectric resonators R1 and R2 and between the dielectric resonators R6 and R7 respectively by the aid of the novel T-shaped coupling rods. Due to the fact that all cross couplings of the filter are positive and implemented through coupling holes, compared with a traditional dielectric filter with negative cross couplings implemented through probes, the TE01 mode dielectric filter has the advantages that introduced parasitic couplings are small, introducing redundant cross couplings for overcoming influences of the parasitic couplings is not needed, and reliability of the filter is improved. In addition, the novel T-shaped coupling rods are low in chromatic dispersion and simple in processing, fine tuning of coupling can be realized by the aid of the tuning screws, repeatedly demounting the cover for altering the sizes of the coupling rods during debugging of the filter is avoided, and accordingly debugging workload is reduced.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

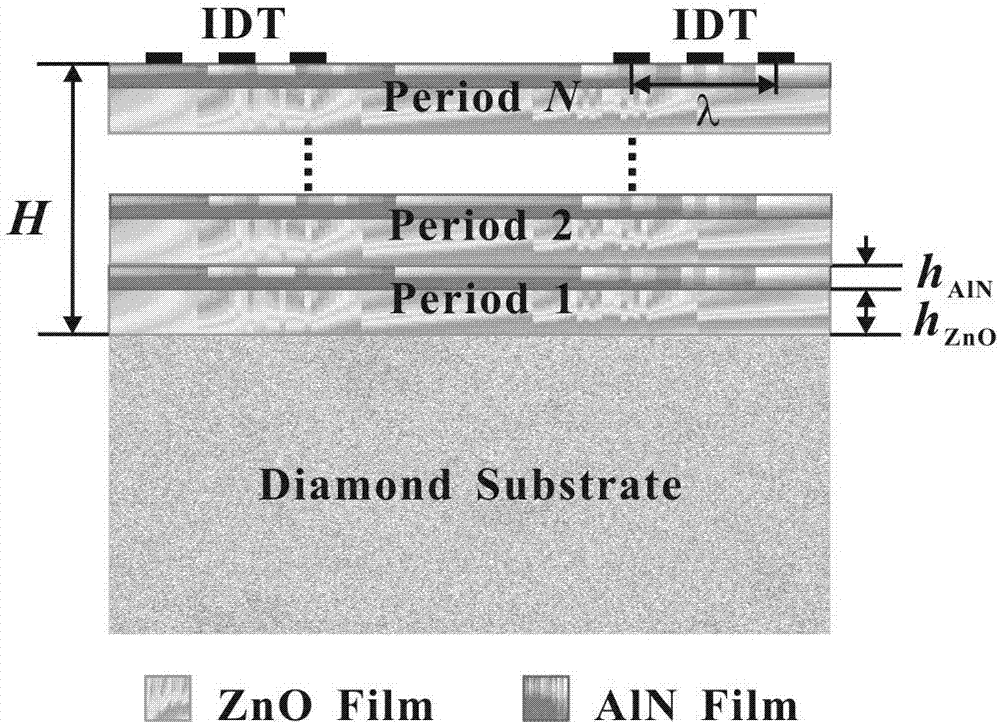

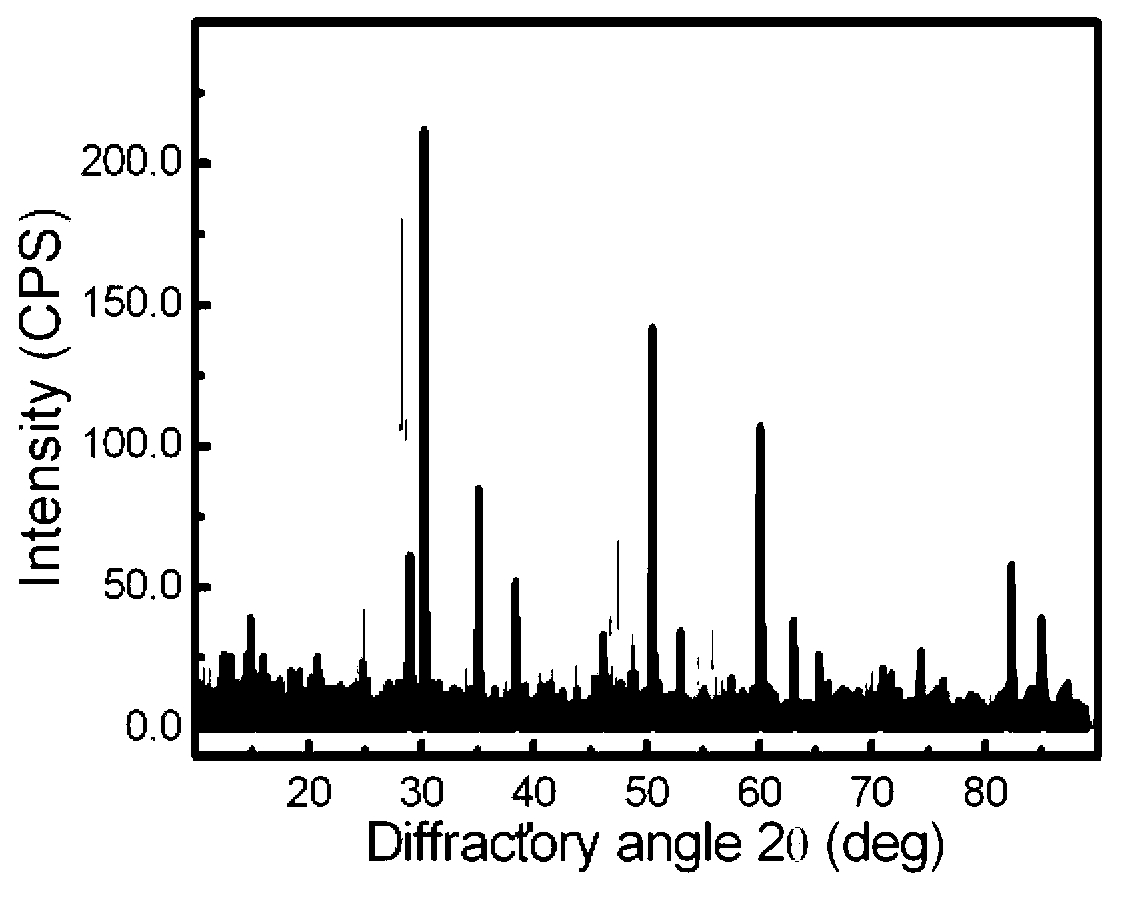

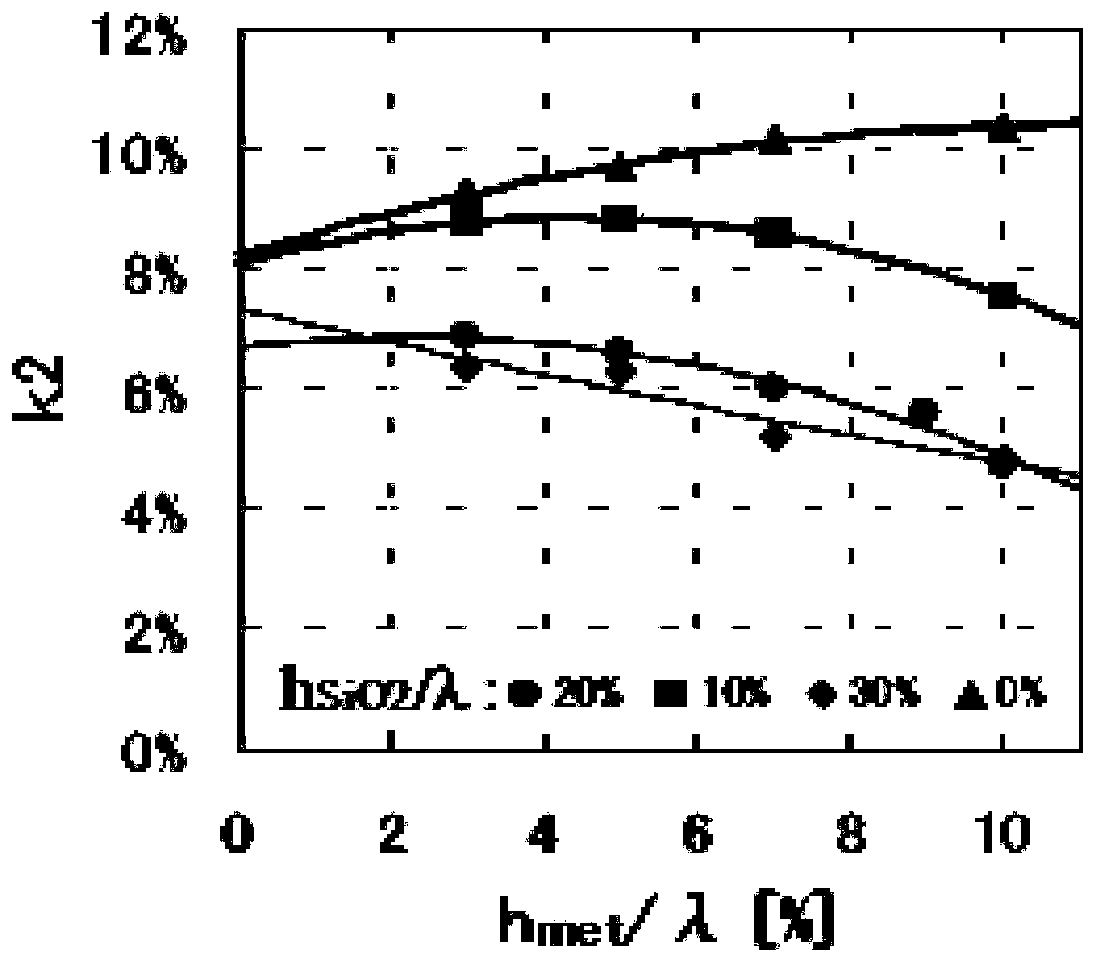

Surface acoustic wave (SAW) device having high electromechanical coupling coefficient and high centre frequency

InactiveCN107171653AImprove performanceImprove stabilityImpedence networksElectromechanical coupling coefficientSurface acoustic wave sensor

The invention relates to a surface acoustic wave (SAW) device having high electromechanical coupling coefficient and high centre frequency. The SAW device adopts a diamond film as the substrate, and adopts an AlN and ZnO film periodically stacked structure (AlN / ZnO)<N> as the piezoelectric layer; the period N of the stacked structure is 2-5; and the thickness ratio of R<h> of an AlN film to a ZnO film is 0.2-5. According to the SAW device disclosed by the invention, respective advantages and disadvantages of two piezoelectric materials including AlN and ZnO are considered; the cooperative effect of the two is utilized, so that the comprehensive performance of the device is improved; under the same interdigital width, compared with the ZnO and AlN double-piezoelectric-layer structure, the structure has the advantages that: the electromechanical coupling coefficient of the device can be maximally increased by two times; furthermore, the centre frequency cannot be reduced; simultaneously, the temperature stability of the device is also improved; the frequency temperature coefficient is reduced; in addition, when the SAW device is designed, more adjustable parameters of the structure exist; the performance parameter adjusting range of the device is relatively wide; and thus, the application field of the device is enlarged.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

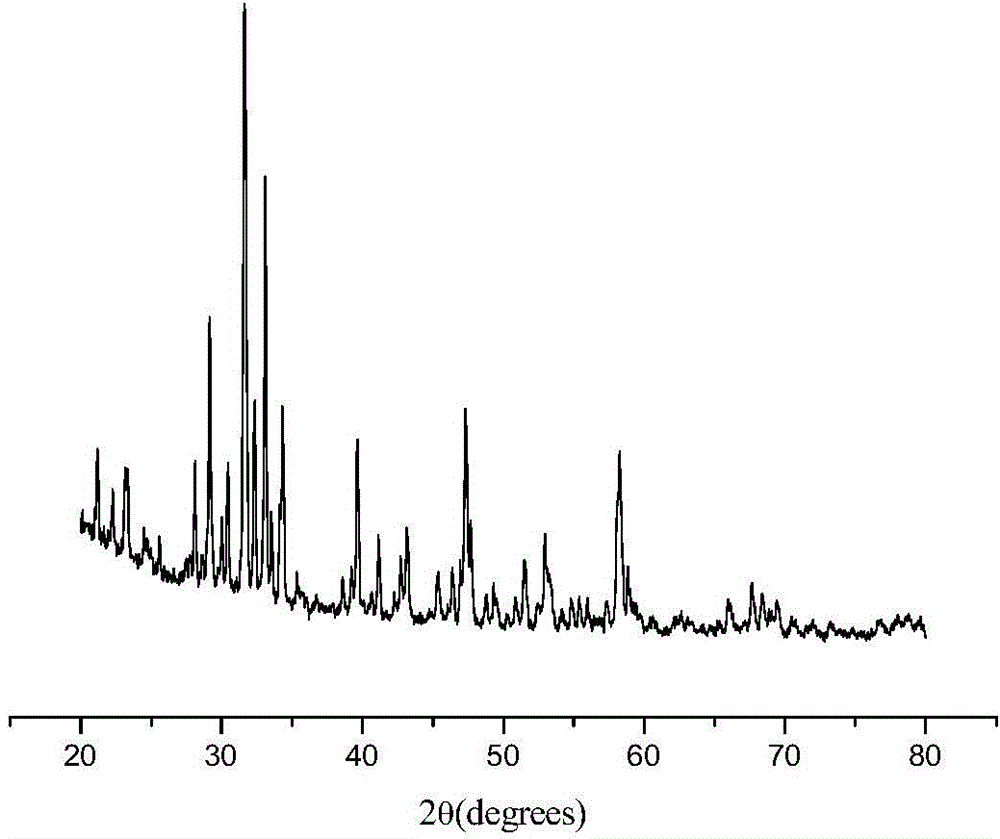

A kind of ceramic material and its preparation method, polytetrafluoroethylene-ceramic composite material and its preparation method and substrate

The invention provides a ceramic material and a preparation method thereof. The ceramic material has the general formula shown in formula I. The invention provides a polytetrafluoroethylene-ceramic composite material, which is prepared from ceramic powder and polytetrafluoroethylene, and the ceramic powder has the general formula shown in formula I. The invention provides a preparation method of a polytetrafluoroethylene-ceramic composite material, comprising: under the action of a silane coupling agent, mixing ceramic powder, polytetrafluoroethylene and a demulsifier to obtain a polytetrafluoroethylene-ceramic Composite material, the demulsifier includes alcohol compound or ether compound; the ceramic powder has the general formula shown in formula I. The invention provides a substrate, which is prepared from the above-mentioned polytetrafluoroethylene-ceramic composite material. The polytetrafluoroethylene-ceramic composite material provided by the invention has higher dielectric constant, lower loss, higher quality factor and higher thermal conductivity. xLi2TiO3‑(1‑x)ZnNb2O6 Formula I.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD

Microwave dielectric ceramics and preparation process thereof

The invention discloses microwave dielectric ceramics and a preparation process thereof, belonging to the technical field of microwave dielectric materials and manufacture thereof. The microwave dielectric ceramics comprises carbonate, oxide and Na, Gd, Dy, Er, Lu and Ti organic matters, and has a chemical formula of Na0.5Re4.5Ti4O15, wherein Re=Gd, Dy, Er and Lu. The invention provides a novel rare-earth-containing microwave dielectric material, and the selection range of a microwave dielectric application material is enlarged; and aiming at the microwave dielectric ceramics, the invention provides a novel matched process, namely, the microwave dielectric ceramics with better ceramic formation is obtained by combination of a process of preparing a powder material by adopting a sol-gel process and a process of preparing the ceramics by adopting a solid-phase reaction process.

Owner:CHINA JILIANG UNIV

Quartz resonator based on piezoelectric film transduction and electronic equipment

ActiveCN113037245AHigh Q valueImprove frequency stabilityImpedence networksElectromechanical coupling coefficientEngineering

The invention discloses a quartz resonator based on piezoelectric film transduction, and the quartz resonator comprises a substrate, an acoustic mirror, a piezoelectric film transduction layer, a quartz resonance main body layer, a first electrode and a second electrode, wherein the electromechanical coupling coefficient of the piezoelectric film transduction layer is greater than that of the quartz resonance main body layer. The quartz resonator has the characteristics of high Q value, high electromechanical coupling coefficient, high frequency stability, simple manufacturing and the like.

Owner:TIANJIN UNIV

Microwave dielectric ceramic and preparation method thereof

A novel microwave dielectric ceramic and a preparation method of the novel microwave dielectric ceramic belong to a microwave dielectric material and the technical field of microwave dielectric material manufacture. The microwave dielectric ceramic is composed of K, Dy, Ho, Er, Yb, Lu and Ti in modes of carbonate and oxide, a chemical formula of the microwave dielectric ceramic is K0.5Re4.5Ti4O15, and the Re is equal to the Dy, Ho, Er, Yb, Lu in the formula. The novel microwave dielectric ceramic provides a new material containing a rare earth microwave dielectric and expands selecting ranges of microwave dielectric application materials. A matched process is provided for the microwave dielectric ceramic, and the microwave dielectric ceramic with a good ceramic forming ratio is obtained.

Owner:CHINA JILIANG UNIV

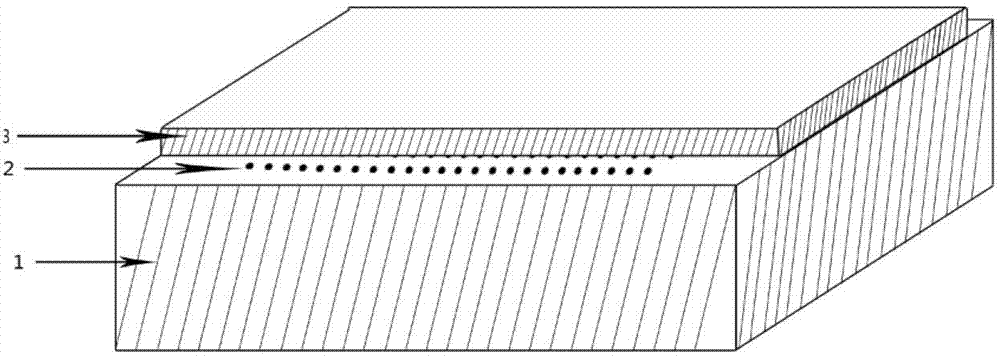

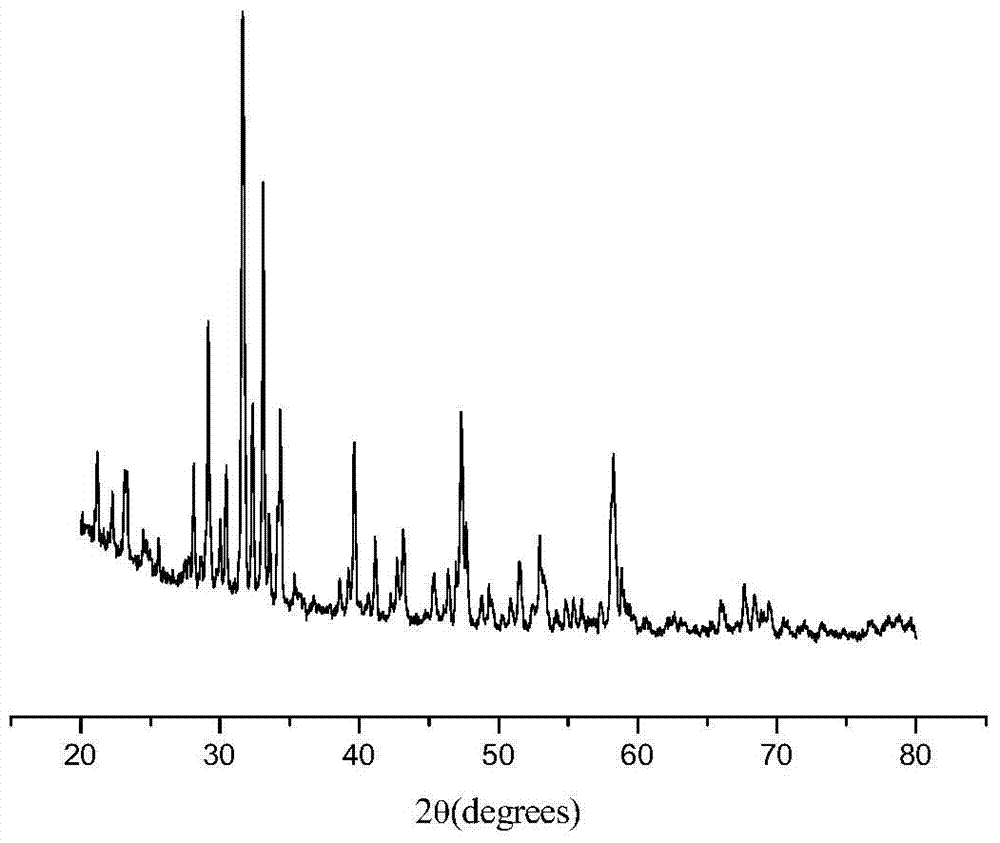

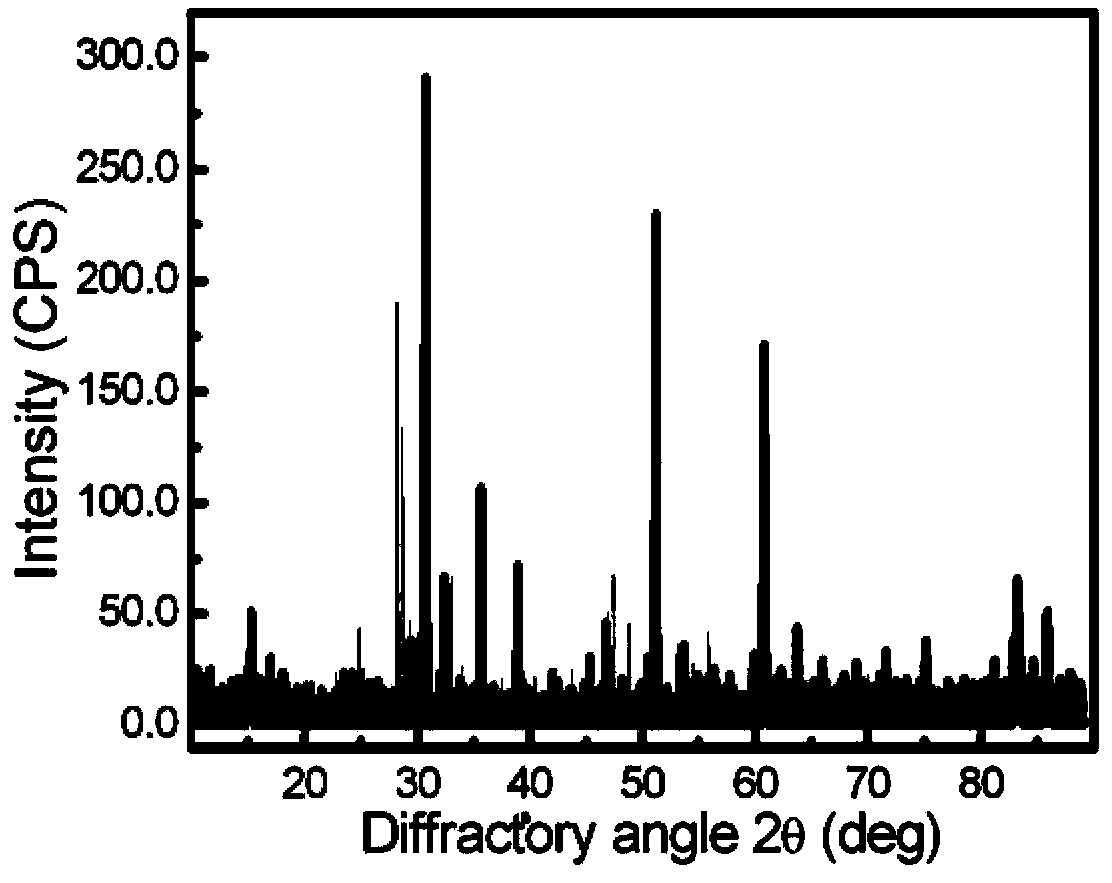

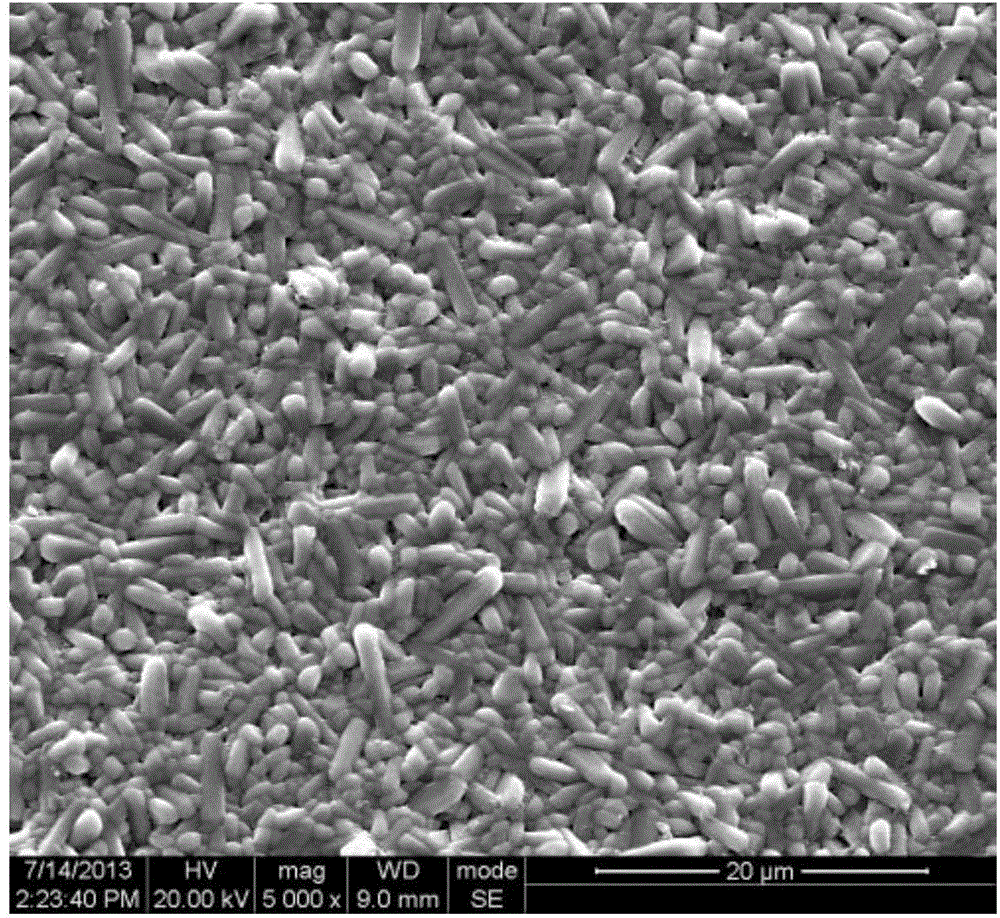

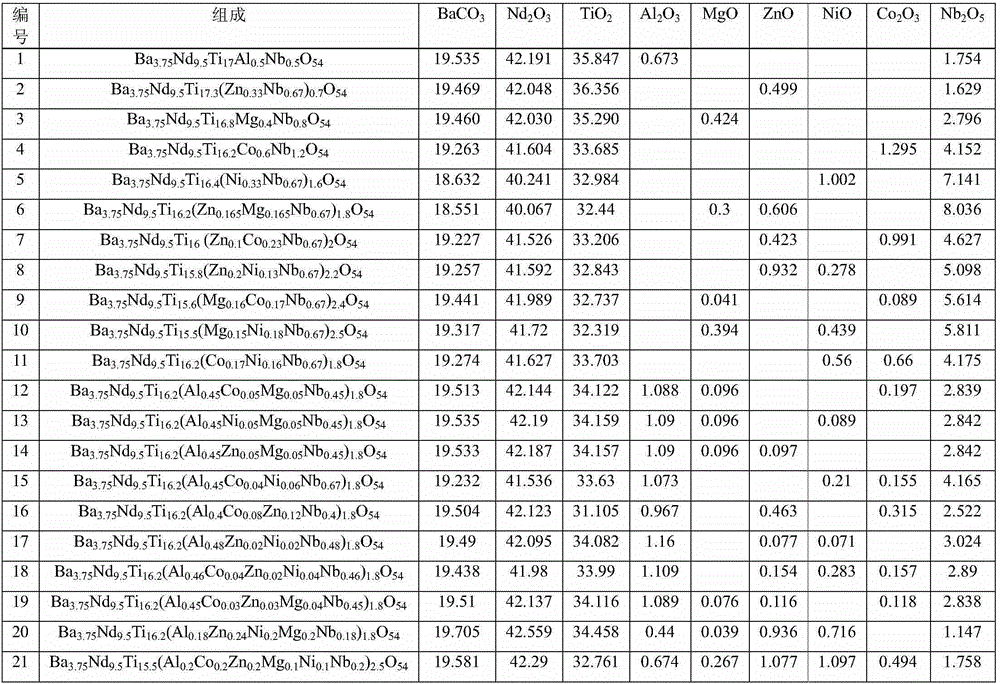

A kind of b-position substituted bnt microwave dielectric ceramic material and preparation method thereof

InactiveCN103922739BLower Frequency Temperature CoefficientHigh Q×f valueCommunication industryDielectric ceramics

A B-substituted BNT microwave dielectric ceramic material and its preparation method belong to the technical field of a functional material. The general chemical formula of the microwave dielectric ceramic material is Ba3.75Nd9.5Ti18-y(M,N)yO54, wherein y is less than or equal to 2.5 and greater than or equal to 0.6; the microwave dielectric ceramic material is prepared by steps of: burdening BaO, Nd2O3, TiO2, oxides of metallic elements M and N according to mole ratio of the general chemical formula, carrying out ball-milling, presintering and sintering; an oxide of the element M is Nb2O5; and an oxide of the element N is one or more compounds selected from Al2O3, MgO, ZnO, Co2O3 and NiO. According to the invention, simultaneous substitution of high and low valence elements is carried out in the B position of Ba6-3xNd8+2xTi18O54. The microwave dielectric ceramic material prepared by a one-step synthesis process has high dielectric constant, low loss characteristic and low frequency-temperature coefficient, can meet requirements in the microwave communication industry, and is especially suitable for manufacturing of RFID tags.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

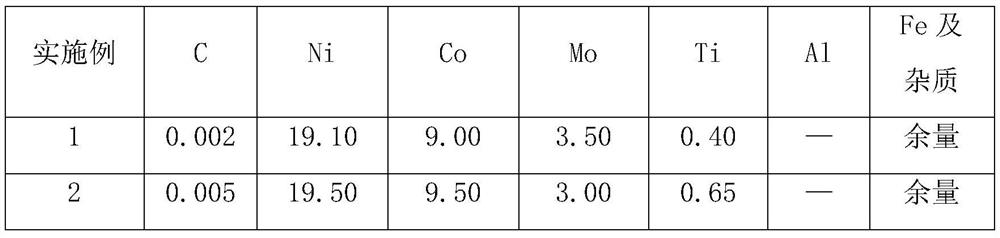

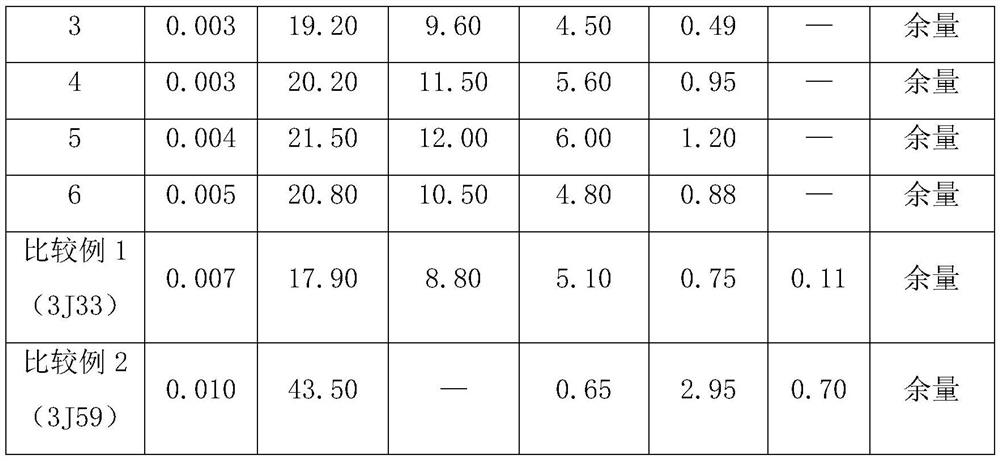

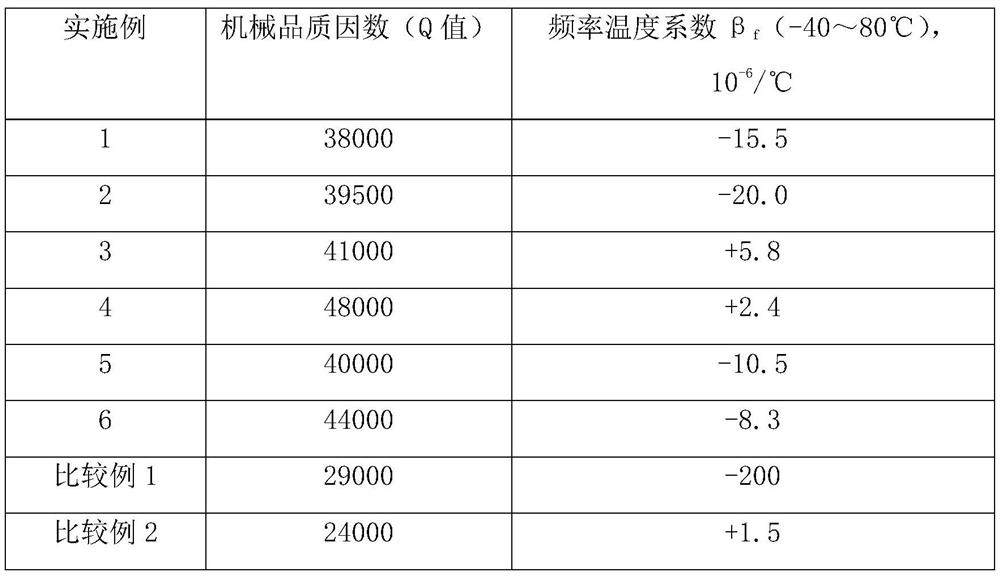

A kind of elastic alloy with high mechanical quality factor and its manufacturing method

ActiveCN109609860BHigh mechanical quality factorIncrease volume fractionSolution treatmentMetallurgy

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

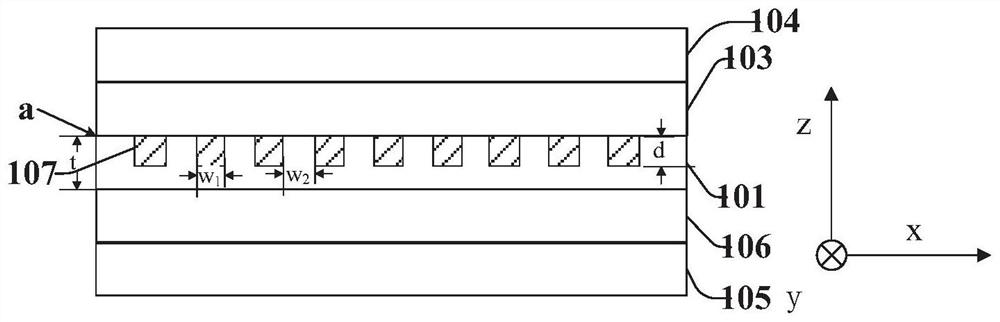

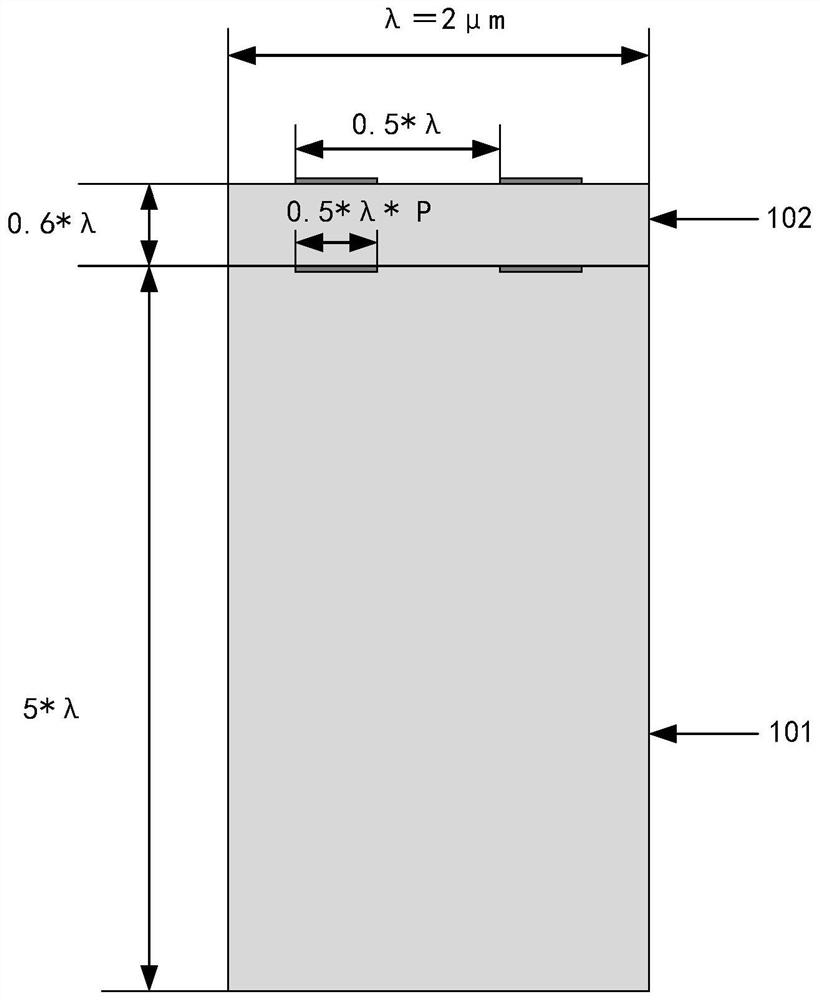

Surface acoustic wave resonator and method for manufacturing surface acoustic wave resonator

PendingCN112653417AHigh electromechanical coupling coefficientLower Frequency Temperature CoefficientImpedence networksAcousticsSurface acoustic wave resonators

The surface acoustic wave resonator of the present invention comprises: a substrate; a piezoelectric layer formed on the substrate and having a thickness of 0.8 [mu] m to 1.2 [mu] m; and an interdigital electrode having a plurality of electrode fingers formed in the piezoelectric layer, the thickness of the electrode fingers being 300 nm to 500 nm, and a duty ratio, which is a ratio of a width to a pitch of the electrode fingers, being 0.4 to 0.6.

Owner:GUANGDONG CANCHIP TECH CO LTD

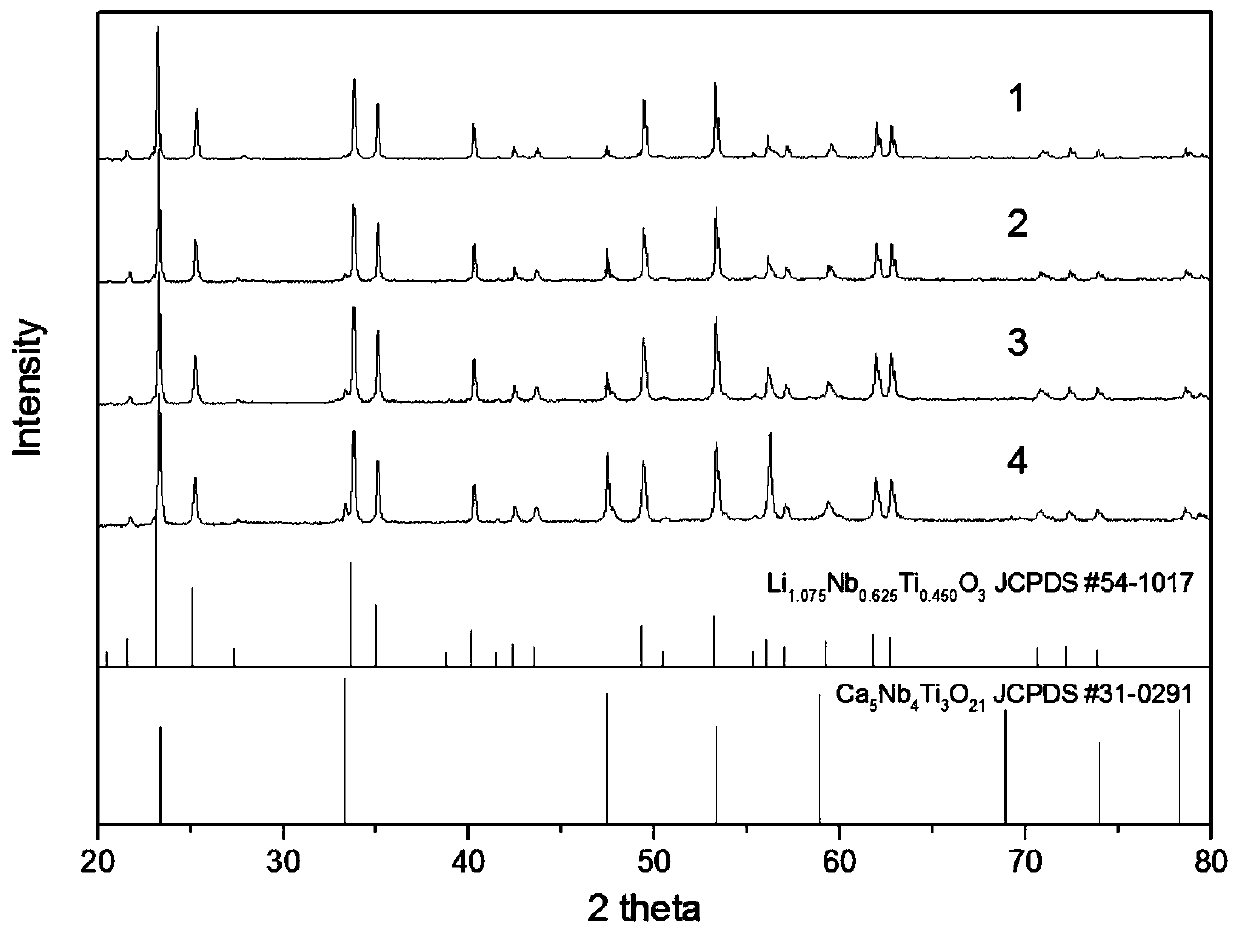

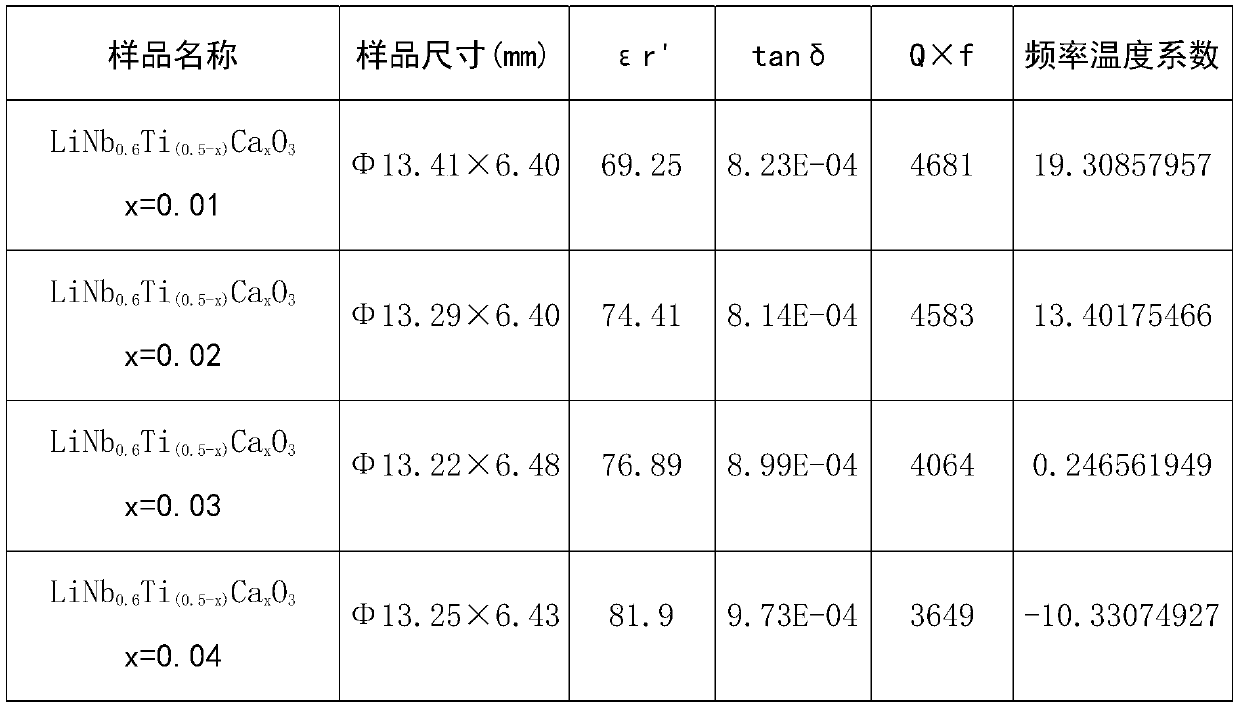

A kind of microwave dielectric ceramic material and preparation method thereof

The invention belongs to the field of electronic ceramics and its manufacture, in particular to a microwave dielectric ceramic material and its preparation method, which is LiNb 0.6 Ti 0.5 o 3 The system material is modified by doping to control its frequency temperature coefficient. Its raw material composition is LiNb formulated according to non-stoichiometric ratio 0.6 Ti (0.5‑x) Ca x o 3 , x=0.01-0.1. by LiNb 0.6 Ti 0.5 o 3 Microwave dielectric ceramic material doped with CaCO 3 Powder method to obtain the main crystal phase as Li 1.075 Nb 0.625 Ti 0.450 o 3 , the second phase is Ca 5 Nb 4 Ti 3 o 21 Microwave dielectric ceramic LiNb 0.6 Ti (0.5‑x) Ca x o 3 ; It has a high dielectric constant of 60-100 to facilitate the miniaturization of devices, a high quality factor Q×f value of 2000-5000GHz and a controllable and low frequency temperature coefficient of 20-78ppm / ℃.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method of forming mems devices

ActiveCN105329844BQuality is not affectedImprove qualityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCMOSGas phase

The invention discloses a forming method of an MEMS (Micro-Electro-Mechanical System) device. The method comprises the following steps: providing a substrate, wherein CMOS (Complementary Metal Oxide Semiconductor) devices are formed in the substrate; forming a sacrificial layer on the substrate; forming first through holes in the sacrificial layer, wherein the first through holes are positioned in the CMOS devices; forming a SiGe layer on the sacrificial layer and in the first through holes, wherein the first through holes are fully filled with the SiGe layer; generating a silicon oxide layer on the SiGe layer through a thermal oxide growth process; and after the silicon oxide layer is formed, removing the sacrificial layer. SiO<2> generated by the thermal oxide growth process is combined with SiGe by bonding, so that an interface characteristic between the silicon oxide layer and the SiGe layer can be enhanced, the bonding force between the silicon oxide layer and the SiGe layer is enhanced, and the problem of peeling is solved in comparison to SiO<2> formed by chemical vapor deposition.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Lamb wave resonator with POI structure

PendingCN112600529AHigh electromechanical coupling coefficientHigh high Q valueImpedence networksMechanical engineeringResonator

The invention provides a Lamb wave resonator with a POI structure. The Lamb wave resonator may include: a substrate of high acoustic velocity material; a piezoelectric layer which is located above thesubstrate made of the high-sound-velocity material, wherein a first interdigital transducer and a second interdigital transducer are arranged on the upper surface and the lower surface of the piezoelectric layer respectively, and interdigital electrodes of the first interdigital transducer and the second interdigital transducer are opposite to each other in the stacking direction across the piezoelectric layer, and have the same electrode width, electrode thickness, electrode spacing, duty ratio eta and excitation sound wave wavelength lambda, wherein the duty ratio eta = electrode width / (electrode width + electrode spacing), the material of the piezoelectric layer is YX-LiNbO3 with a cut angle theta, and the values of the cut angle theta and the duty ratio eta are 30 degrees < = theta <= 60 degrees respectively; and eta is equal to 0.2, 0.4 to 0.6 or 0.8 to 0.9.

Owner:GUANGDONG CANCHIP TECH CO LTD

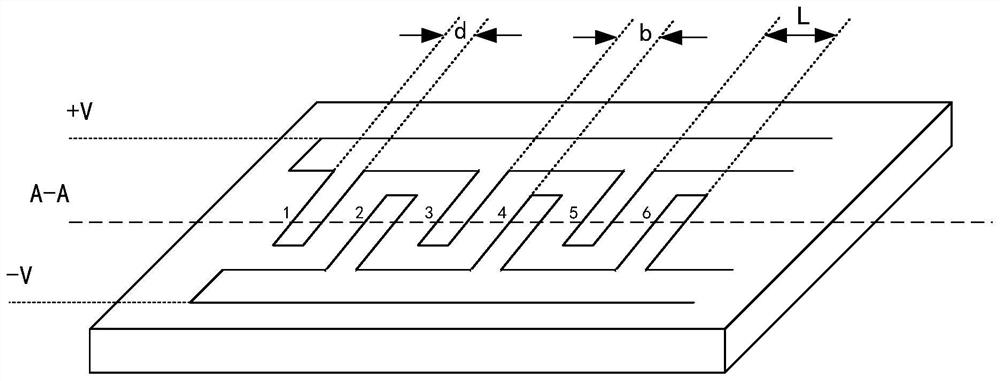

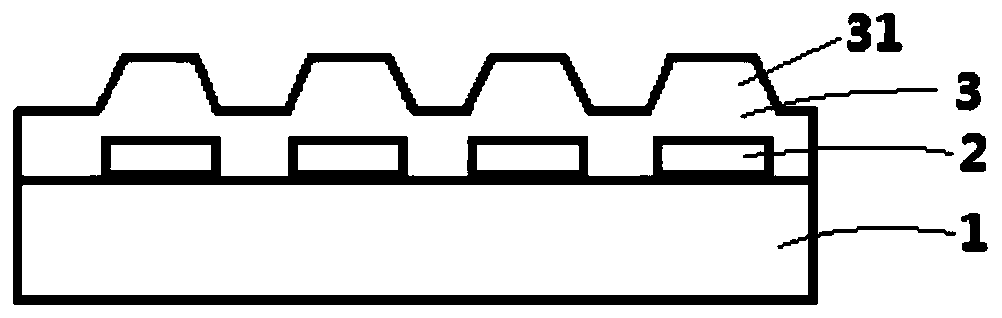

Surface acoustic wave filter with high temperature stability and preparation method and application thereof

PendingCN110601672ALower Frequency Temperature CoefficientReduce Rayleigh wave parasitic responseImpedence networksElectricityProcess conditions

The invention discloses a surface acoustic wave filter with high temperature stability and a preparation method and application thereof. The surface acoustic wave filter comprises a piezoelectric substrate which is provided with at least one plane; an interdigital transducer electrode, wherein the interdigital transducer electrode is fixedly arranged on the plane of the piezoelectric substrate; aninsulating protective layer provided with two opposite surfaces, wherein one surface of the insulating protective layer is laminated and combined on the plane of the piezoelectric substrate and covers the interdigital transducer electrode; and a plurality of bulges which are distributed at intervals are formed on the other surface. The surface acoustic wave filter has the advantages of low frequency temperature coefficient, low Rayleigh wave parasitic response phenomenon, stable working performance, long service life and the like. Moreover, the preparation method is controllable in process conditions, and can effectively ensure that the prepared surface acoustic wave filter with high temperature stability is stable in performance, high in yield and low in cost.

Owner:BEIJING ZHONGXUN SIFANG SCI & TECH +1

Lamb wave resonator with upper and lower buried electrodes in opposite proportions

The invention provides a Lamb wave resonator with upper and lower buried electrodes in opposite proportions. The Lamb wave resonator comprises a substrate made of a high-sound-velocity material; a piezoelectric layer which is located above the substrate made of the high-sound-velocity material, wherein a first interdigital transducer and a second interdigital transducer are arranged on the upper surface and the lower surface of the piezoelectric layer respectively, and interdigital electrodes of the first interdigital transducer and the second interdigital transducer are opposite to each other in the stacking direction across the piezoelectric layer, and have the same electrode width, the same electrode thickness, the same electrode distance and the same excitation sound wave wavelength lambda, wherein the proportions of the interdigital electrodes of the first interdigital transducer and the second interdigital transducer embedded into the piezoelectric layer in the thickness direction are h1 and h2 respectively, and h1 + h2 = 1.

Owner:GUANGDONG CANCHIP TECH CO LTD

High dielectric microwave dielectric ceramic material and preparation method thereof

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Coke green stone high frequency/microwave medium ceramic sintered by low temp. and preparation process thereof

InactiveCN100345795CLow dielectric constantLower Frequency Temperature CoefficientCeramicsElectricityDielectric

The invention discloses a low temperature sintering coke verd antique high frequency / microwave medium ceramics. The expression of the ceramics is Bi3xM2-3x)(ZnxNb2-x)O7, and M is Zn2+, Ca2+ or Cd2+, or Sr2+, and 0.5<=x<=0.64. The invention has the following feature: high dielectric constant, low medium consumption, wide covering range of temperature coefficient dielectric constant, low sintering temperature, simple technology, etc.

Owner:XI AN JIAOTONG UNIV

Microwave dielectric ceramics and preparation process thereof

The invention discloses microwave dielectric ceramics and a preparation process thereof, belonging to the technical field of microwave dielectric materials and manufacture thereof. The microwave dielectric ceramics comprises carbonate, oxide and Na, Gd, Dy, Er, Lu and Ti organic matters, and has a chemical formula of Na0.5Re4.5Ti4O15, wherein Re=Gd, Dy, Er and Lu. The invention provides a novel rare-earth-containing microwave dielectric material, and the selection range of a microwave dielectric application material is enlarged; and aiming at the microwave dielectric ceramics, the invention provides a novel matched process, namely, the microwave dielectric ceramics with better ceramic formation is obtained by combination of a process of preparing a powder material by adopting a sol-gel process and a process of preparing the ceramics by adopting a solid-phase reaction process.

Owner:CHINA JILIANG UNIV

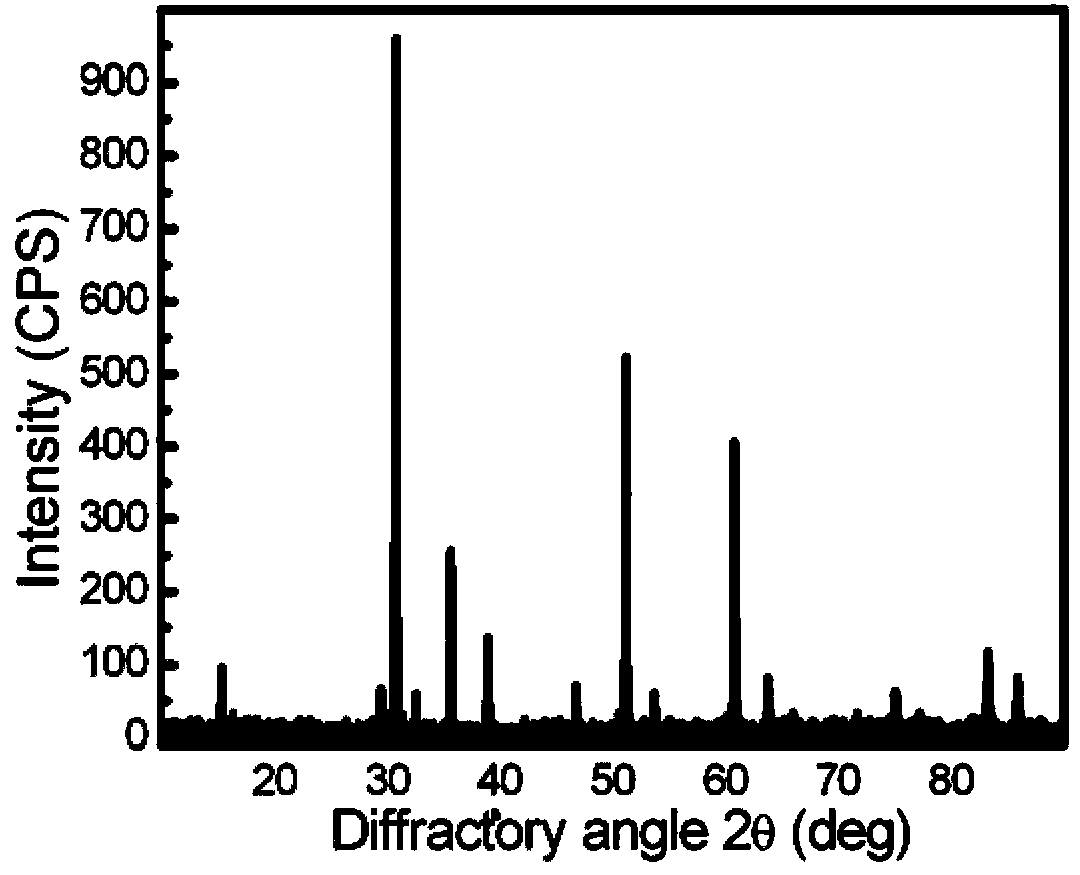

A kind of barium niobate system microwave dielectric ceramic material and its preparation method and application

ActiveCN111116197BLower sintering temperatureImprove Microwave PerformanceCeramicsResonatorsDielectricMicrowave

The invention belongs to the technical field of microwave dielectric ceramic materials, and in particular relates to a barium niobate system microwave dielectric ceramic material. The barium niobate system microwave dielectric ceramic material of the present invention, with BaCO 3 , Nb 2 o 5 , ZnO, CoO and NiO as raw materials to synthesize the main sintered block, and SiO 2 , BaO, CaO, B 2 o 3 , Li 2 O is used as a raw material to synthesize low-melting glass powder, and then the main sinter and the low-melting glass powder are mixed and dispersed to obtain the required barium niobate system microwave dielectric ceramic material. The dielectric constant of the microwave dielectric ceramic material reaches 33-36, f*Q>80000 at 25°C, and the frequency temperature coefficient calculated by testing the resonant frequencies f of -40°C, 25°C, and 110°C is low, only ‑5~5ppm / ℃, its performance meets the requirements of microwave dielectric ceramic devices; at the same time, the material also has good dielectric properties in the millimeter wave frequency band; it can be used to produce ceramic devices such as filters and resonators.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com