High dielectric microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and high-dielectric technology, which is applied in the field of high-dielectric Ca-Li-Nd-Ti-based microwave dielectric ceramic materials and its preparation, can solve the problems of restricting large-scale applications and the frequency temperature coefficient cannot meet actual needs, and achieve Effects of improved performance, reduced temperature coefficient of resonance frequency, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

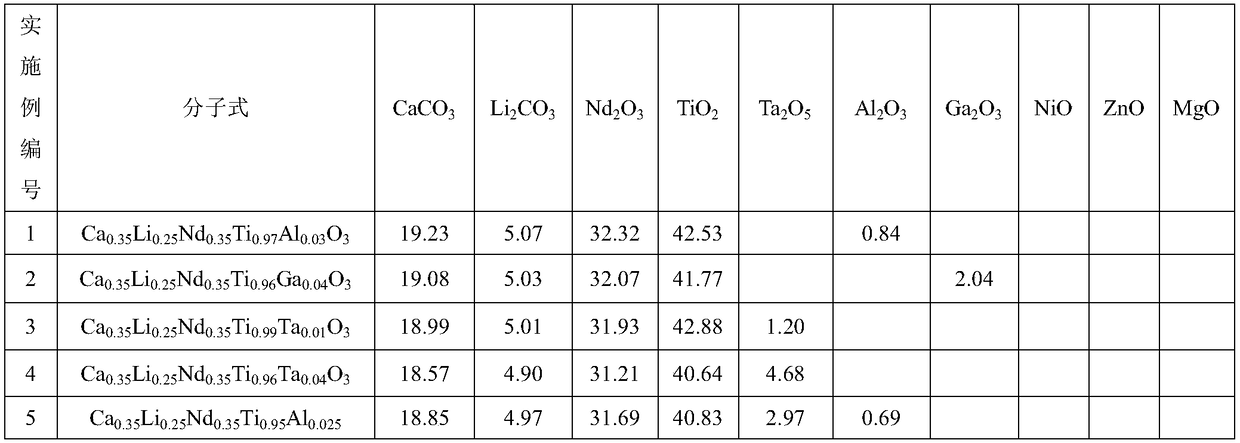

[0035] A high dielectric and low loss microwave dielectric ceramic material substituted by a B position, the general chemical formula is (Ca 0.35 Li 0.25 Nd 0.35 )(Ti 1- x D. x )O 3 , where 0.01≤x≤0.05, the composition of D is VW, V represents Ta with a valence state higher than tetravalent, W represents a valence state lower than tetravalent and the average ionic radius is close to Ti 4+ Single or multiple elements of V and W are substituted simultaneously or individually. When substituted alone, W is one of Al, Ga, Mg, Zn, Ni, or D is directly Ta. When VW is substituted at the same time, if W is one of Al and Ga, then the molar ratio V:W=1:1, if W is one of Mg, Zn, Ni, then the molar ratio V:W= 2:1.

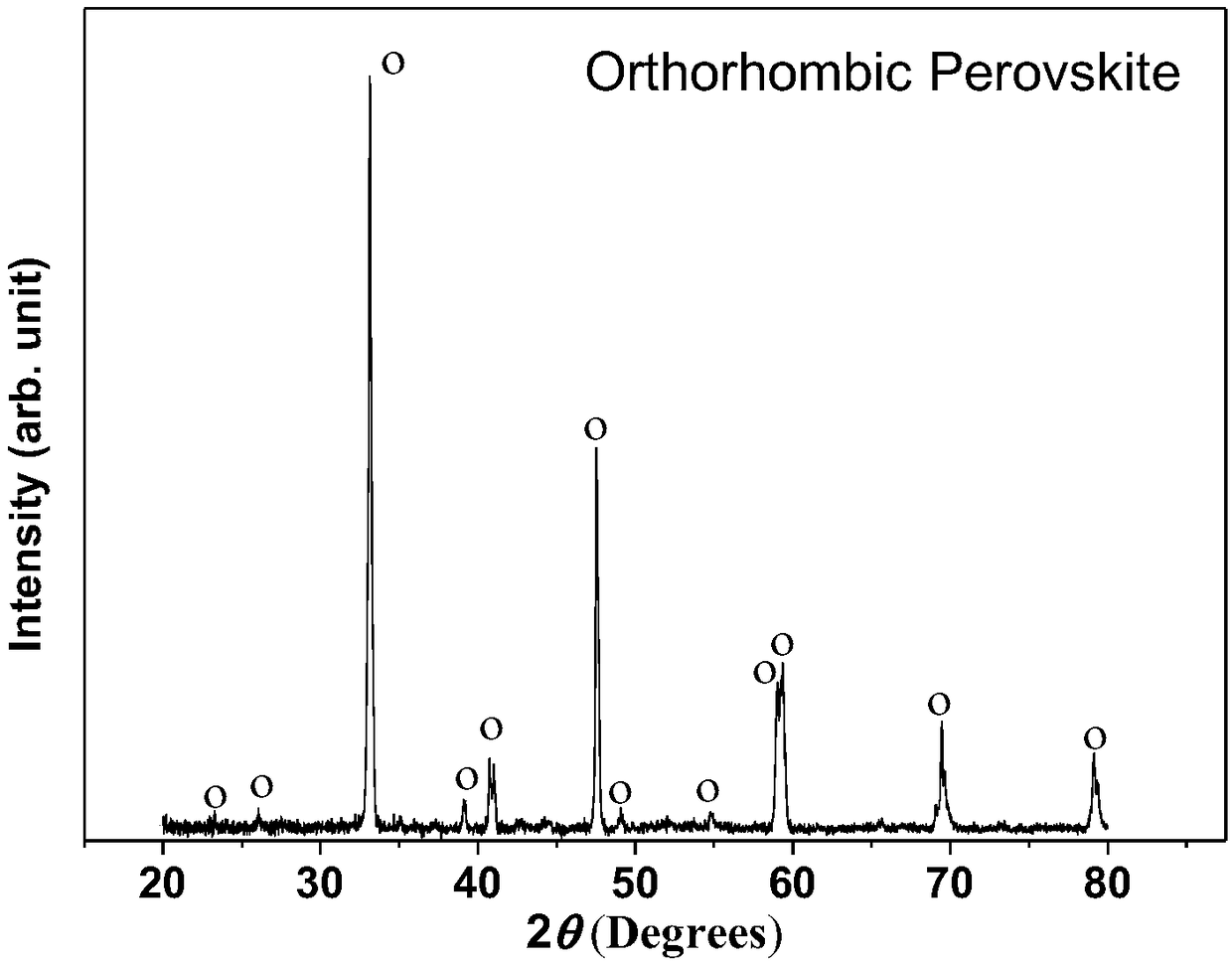

[0036] The crystal phase of the microwave dielectric ceramic material is an orthorhombic perovskite structure. The relative permittivity ε of the microwave dielectric ceramic material r Between 120 and 140, the Q×f value is between 2700 and 4000GHz, and the resonant f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com