Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Wide firing temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

Leadless environmentally-friendly glass glaze, preparation method thereof, and glazed surface preparation method

The invention relates to a leadless environmentally-friendly glass glaze. The leadless environmentally-friendly glass glaze comprises base glaze, and the base glaze comprises 25-60wt% of SiO2, 5-30wt% of ZnO, 1-8wt% of CaO + MgO, 0-10wt% of BaO, 0-10wt% of SrO, 5-33wt% of B2O3, 0.5-11wt% of Al2O3, 0.5-10wt% of TiO2, 0-10wt% of ZrO2, 1-22wt% of K2O +Na2O and 1-10wt% of Li2O. The environmentally-friendly glass glaze contains no lead, can avoid damages to human bodies and the environment, can substitute traditional lead-containing glazes, has a lower price than leadless bismuth-containing glazes, is suitable for common flat glass, and can be toughened or sintered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

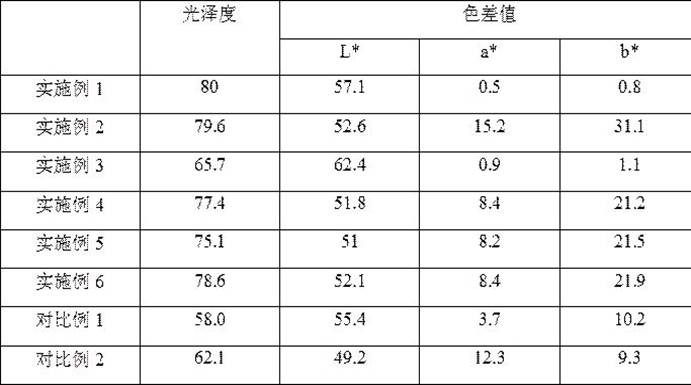

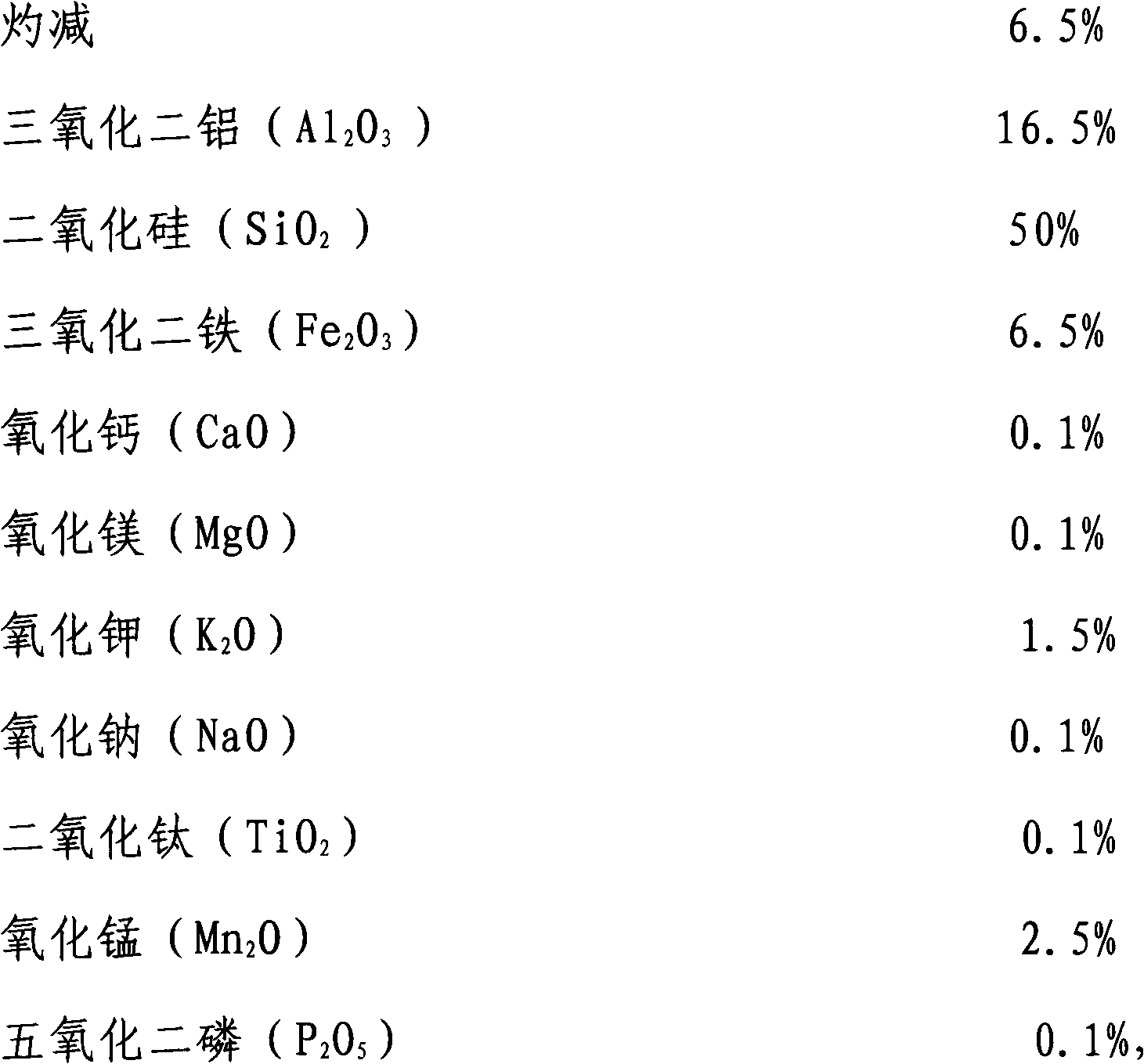

Method for preparing iron tailing into ceramic frit glaze

Provided is a method for preparing iron tailing into ceramic frit glaze. The method for preparing iron tailing into ceramic frit glaze regards iron tailing as raw materials, is free of adding other ceramic pigment or, colorant except for iron, and prepares ceramic frit glaze which is abundant in color and good in effect. The method for preparing iron tailing into ceramic frit glaze explores a novel path for iron tailing resources with high technology and high added value. The dosage of the iron tailing in the ceramic frit glaze is large, and the iron tailing is in integral utilization. The method for preparing iron tailing into ceramic frit glaze utilizes affluent iron and other microelements in the iron tailing to tint for glaze, replaces the expensive ceramic pigments, greatly lowers the cost of the ceramic frit glaze, selects and provides novel direction for ceramic frit glaze raw materials and the ceramic pigments, and lowers the dependent degree to high quality non-metal mineral resources compared with the current ceramic glaze production. The iron tailing and parts of the raw materials are initially melted to frits to use, so that firing temperature range of the glaze is expanded, and ceramic glaze surface quality is improved. A series of unfavorable influences to the preparation process in the process of applying the iron tailing in a ceramic green body are overcome. The method for preparing iron tailing into ceramic frit glaze has the advantages of being simple in process, optimum in glaze quality, and applicable to industrialized mass production.

Owner:UNIV OF SCI & TECH BEIJING +2

Guangdong Jun Blue glaze prepared from commonly used raw materials in ceramics factory and preparation method of Guangdong Jun Blue glaze

The invention belongs to the preparation field of traditional Guangdong Jun glaze in Foshan Shiwan art ceramics, and discloses a Guangdong Jun Blue glaze prepared from commonly used raw materials in a ceramics factory and a preparation method of the Guangdong Jun Blue glaze. The method comprises the following steps: using common glaze raw materials widely applied in the existing ceramics factory such as feldspar, quartz, limestone, calcined talc, black clay, cattle and sheep ashes and chemical toners CuO, CoO, Fe2O3 and the like to replace the lead-containing traditional raw materials such as ramulus mori ashes, miscellaneous wood ashes, straw ashes, canal mud, jade powder, carnelian cobble, copper ore, yellow stone, star cinnabar, graphite and Lion mountain ashes which are complex or expensive in treatment, or nearly exhausted, or large in toxicity to the environment. The Guangdong Jun glaze disclosed by the invention is wide in raw material resource, low in cost, simple in preparation process, and unnecessary to renovate the equipment, the obtained Guangdong Jun glaze formula is simple in composition, smooth in glaze, high in stability, and has the color characteristics of the Guangdong Jun glaze.

Owner:FOSHAN UNIVERSITY

Frit used for producing Longquan celadon, Longquan celadon frit glaze and production method of frit glaze

The invention discloses a frit used for producing Longquan celadon, a Longquan celadon frit glaze and a production method of the frit glaze. Raw materials of the frit comprise, by weight, 45-95% of rare earth tailings, 1-30% of Longquan porcelain clay, 1-25% of alumina powder, 1-15% of kaolin, 1-30% of yellow glaze soil, 0-25% of potash feldspar, 0-20% of quartz and 0-10% of talcum. The rare earth tailings are adopted as a main raw material of the frit, so the recycling of the rare earth tailings is realized, and the use amounts of other routine Longquan celadon raw materials are greatly reduced; and trace rare earth elements in the rare earth tailings have an obvious color development promoting effect on the celadon glaze, so extra addition of a coloring agent or a ceramic coloring chemical engineering raw material to the glaze is prevented, thereby the manufacturing cost of the Longquan celadon frit glaze is reduced, the color appearance of the glaze is stable, and industrial large-scale production is facilitated.

Owner:LISHUI UNIV

Crystal ceramic and preparation method thereof

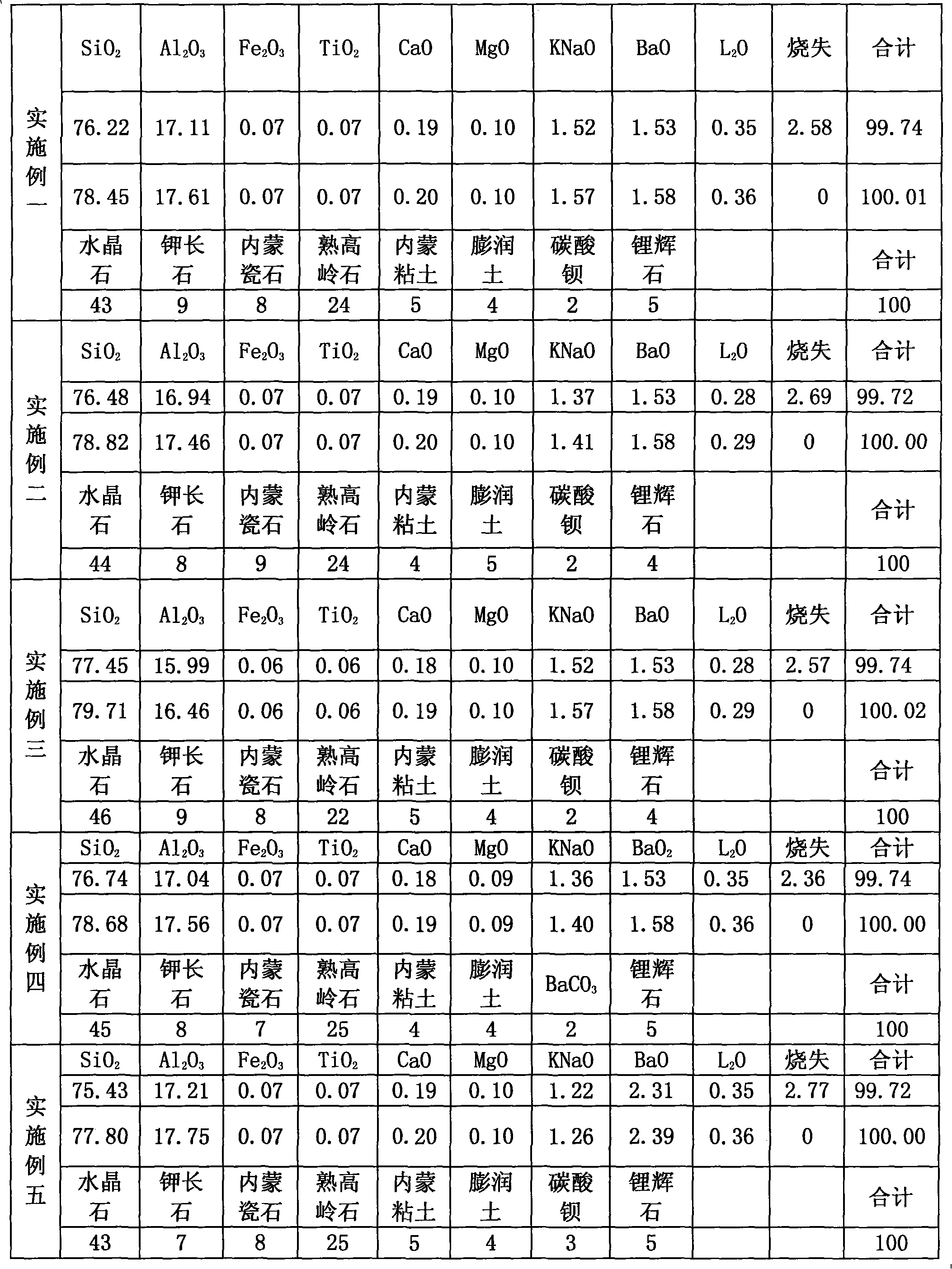

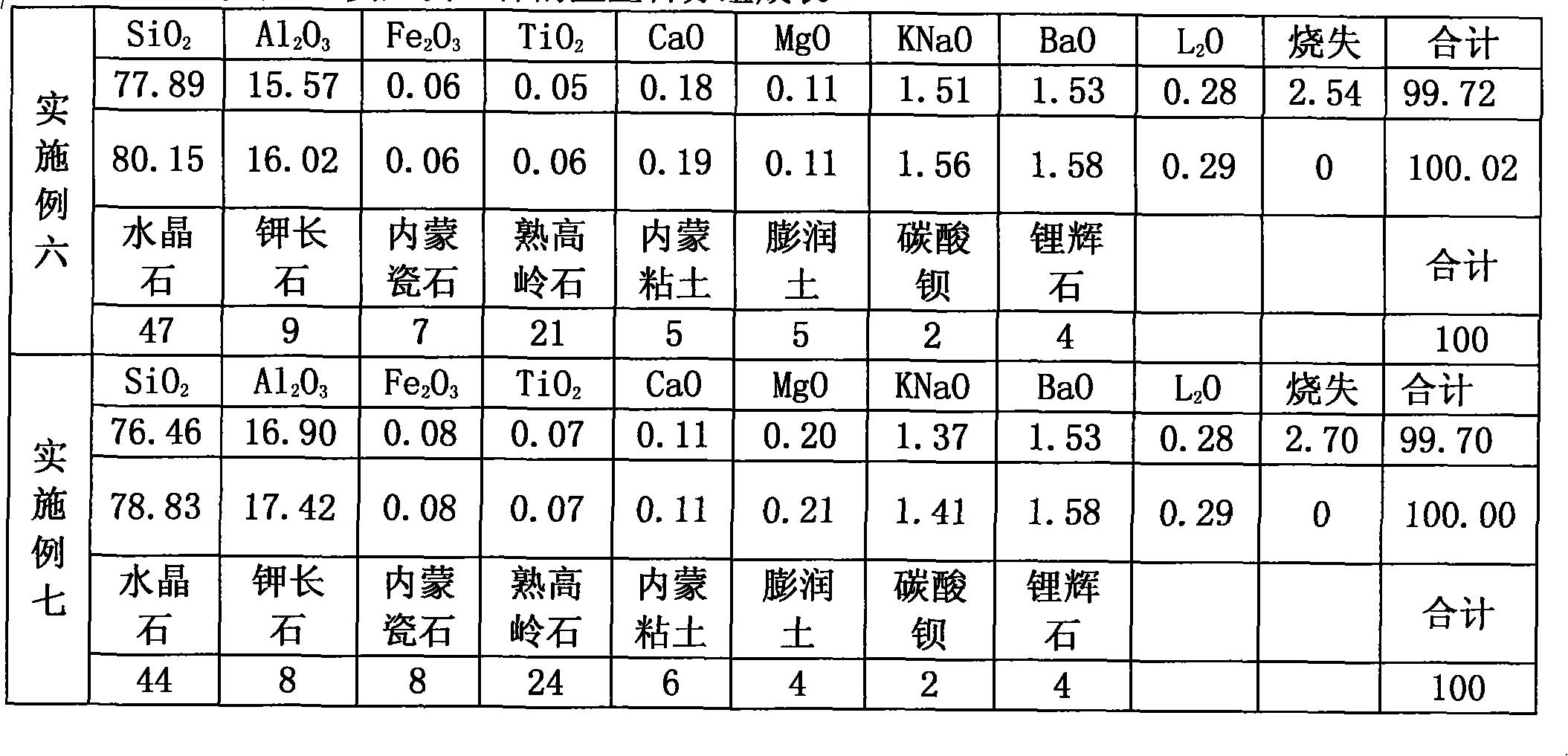

The invention relates to a crystal ceramic which is a new product of ceramic products, or a new ceramic type. Glaze is coated on a green body which is prepared from the following components by weightpercent: 75-82 percent of SiO2, 15-21 percent of Al2O3, 0-0.1 percent of Fe2O3, 0-0.1 percent of TiO2, 0-0.5 percent of CaO, 0-0.9 percent of MgO, 0.5-2.6 percent of KNaO, 0.1-0.8 percent of Li2O and0.1-0.5 percent of BaO. The invention has the characteristics of wide range of firing temperature, easy firing control, high whiteness, favorable translucency, high mechanical strength and favorable thermal stability. The invention also provides a preparation method comprising the steps of preparing materials, dosing, molding, biscuiting, enamelling and glaze firing, wherein the crystal needs to be preprocessed, and the preprocessing comprises the steps of calcining at 1250-1300 DEG C, washing with acid, washing with water to neutrality and separately grinding and controlling the grain diameter ranges from 5 to 20 microns. The invention is scientific and reliable, is easy to implement and ensures the quality and qualification rate of products.

Owner:淄博泰山瓷业有限公司

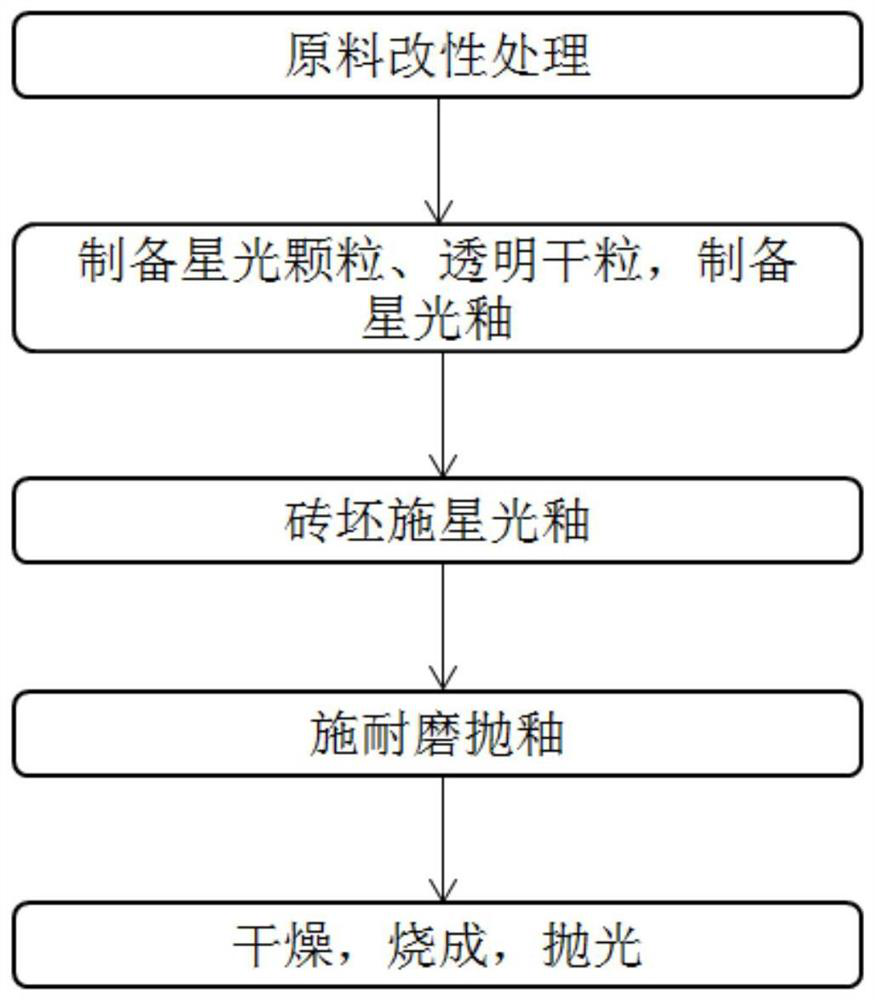

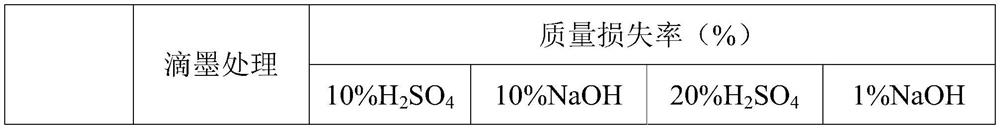

Wear-resistant antifouling ceramic starlight glazed brick and preparation method thereof

ActiveCN112979349AWide firing temperature rangeMild conditions for crystallizationBrickWear resistance

The invention relates to the technical field of preparation of ceramic glazed bricks, and provides a wear-resistant antifouling ceramic starlight glazed brick and a preparation method thereof. The glittering effect is achieved through multiple reflection, dispersion and refraction methods of crystals in the glaze, a glaze layer of the glazed brick has the multi-layer glittering effect and the three-dimensional decoration effect, and the grade and decoration of the product are improved; and an excellent flashing effect can be achieved only by polishing according to a conventional polishing process of a glazed product. The glazed brick disclosed by the invention has relatively high hardness and excellent antifouling property and wear resistance.

Owner:江西金唯冠建材有限公司

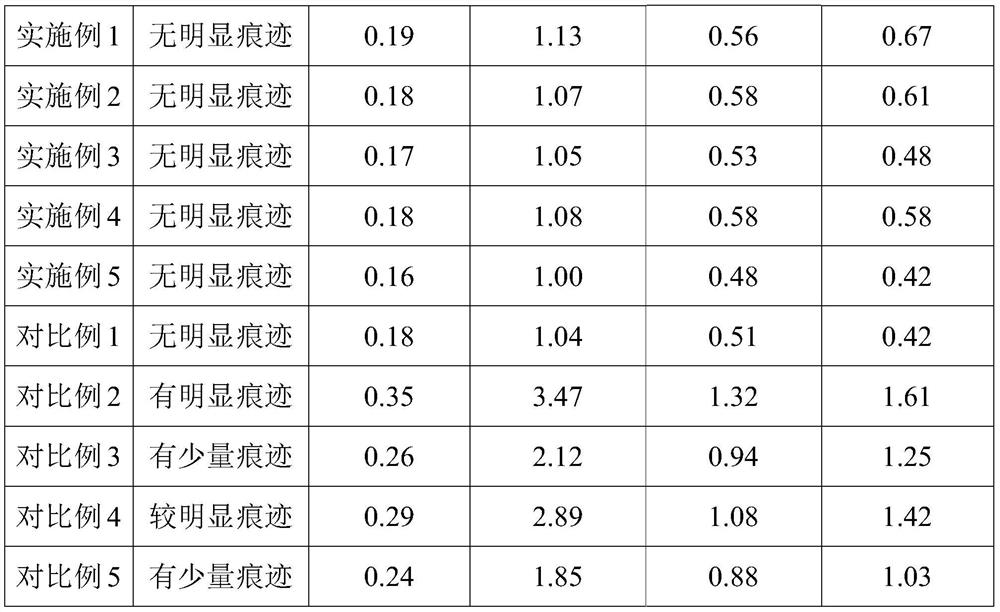

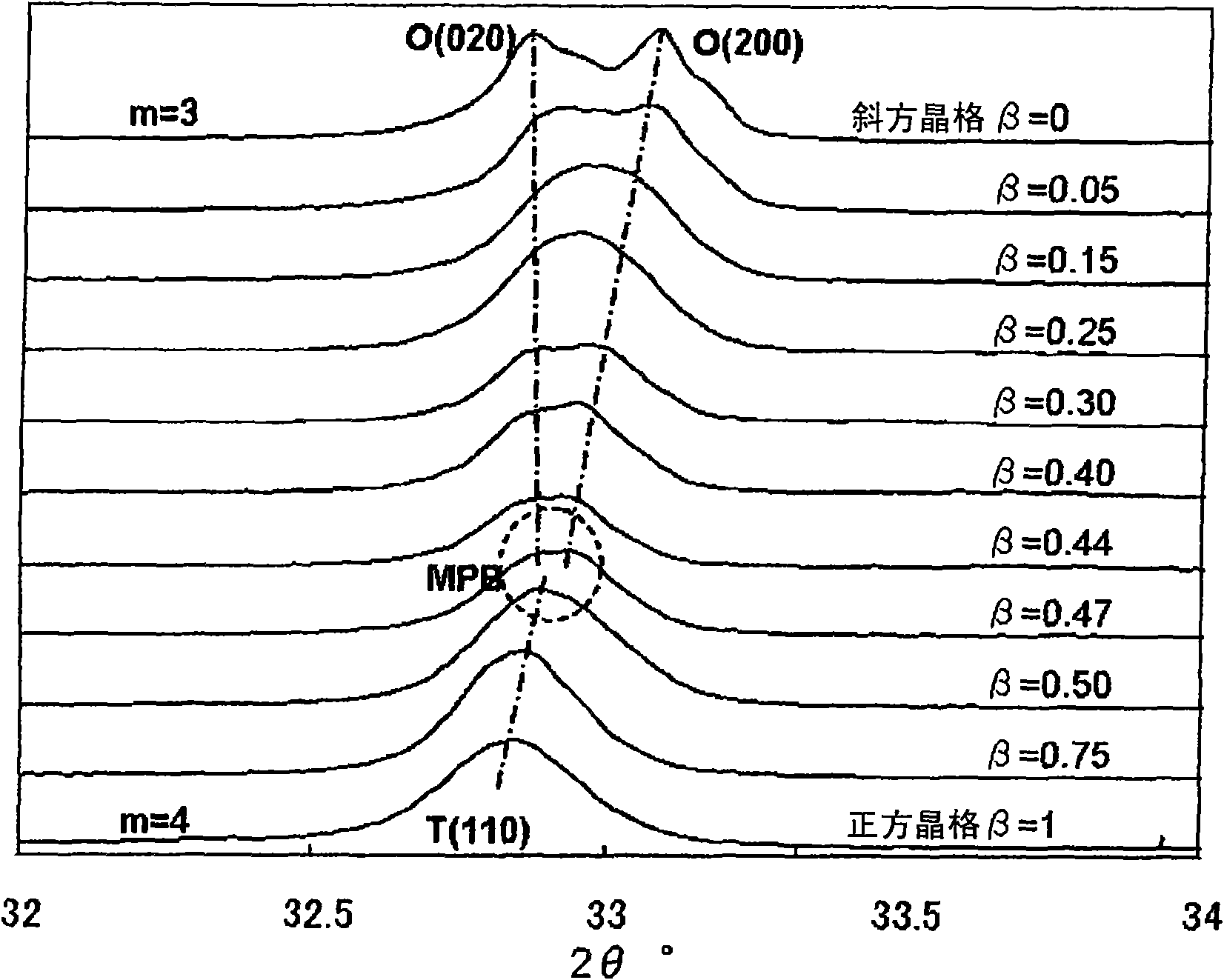

Piezoelectric ceramic and piezoelectric element

ActiveCN101578248AImprove temperature stabilityHigh curie temperaturePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRoom temperatureBismuth

The present invention provides a piezoelectric ceramic and a piezoelectric element, which have a large dynamic d33 (dynamic piezoelectric coefficient d33 ), can be used even under an elevated temperature of 200 DEG C, and exhibit a small variation between the dynamic d33 at room temperature and the dynamic d33 at 200 DEG C. The piezoelectric ceramic of the present invention is characterized by containing 100 parts by mass of a bismuth layered compound as a main component and a total of 0.05 to 1 part by mass, in terms of oxides (MnO2 and Fe2O3), of at least one of Mn and Fe, the bismuth layered compound being represented by a compositional formula of Bi 4 Ti3O12.beta [(1-gamma )M1TiO3.gamma M2M3O3], wherein and satisfy the following formulae: 0.405 <=beta <=0.498 and 0 <=gamma <=0.3, M1 represents at least one selected from Sr, Ba, Ca, (Bi0.5 Na0.5 ), (Bi0.5 Li0.5 ) and (Bi0.5 K0.5 ), M2 is at least one selected from Bi, Na, K and Li, and M3 is at least one of Fe and Nb.

Owner:KYOCERA CORP

Method for preparing positioning iron red crystal glaze

The present invention discloses a preparation method for positioning ferreous crystal; the preparation of the base glaze is that: potassic feldspar, quartz, kaoline, ocher, steatite, limestone and bone ash are mixed with ferric oxide for grilling; the proportion of the glaze slurry is 1.6-1.7 g / cm3; the preparation method of the crystal core is that: kaoline is mixed with ferric oxide for grilling and calcining and cooling to become grain powder; and then crystal core is pre-buried in the position for the blank body to form the crystal flower; the size Phi of the preburied hole is about 1mm; the quantity and distribution are adjusted according to the actual requirement; the base glaze is put on the ceramic blank body preburied with crystal core evenly; the thickness of the glaze level is controlled on 0.7-1.0mm; the semi finished product of the ceramic glaze is baked to the maximum temperature with oxidation blaze, and then is cooled into the room temperature. The present invention uses the common ceramic raw material and the positioning crystal measure to produce the positioning ferreous crystal glaze, which solves the shortcoming that the size and the distribution for the ferreous crystal flower is hard to be controlled; the method is a stable preparation method with simple process technical, wide baking temperature range, good stability, without needing middle temperature heat preservation; the produce cost is much lower.

Owner:SHAANXI UNIV OF SCI & TECH

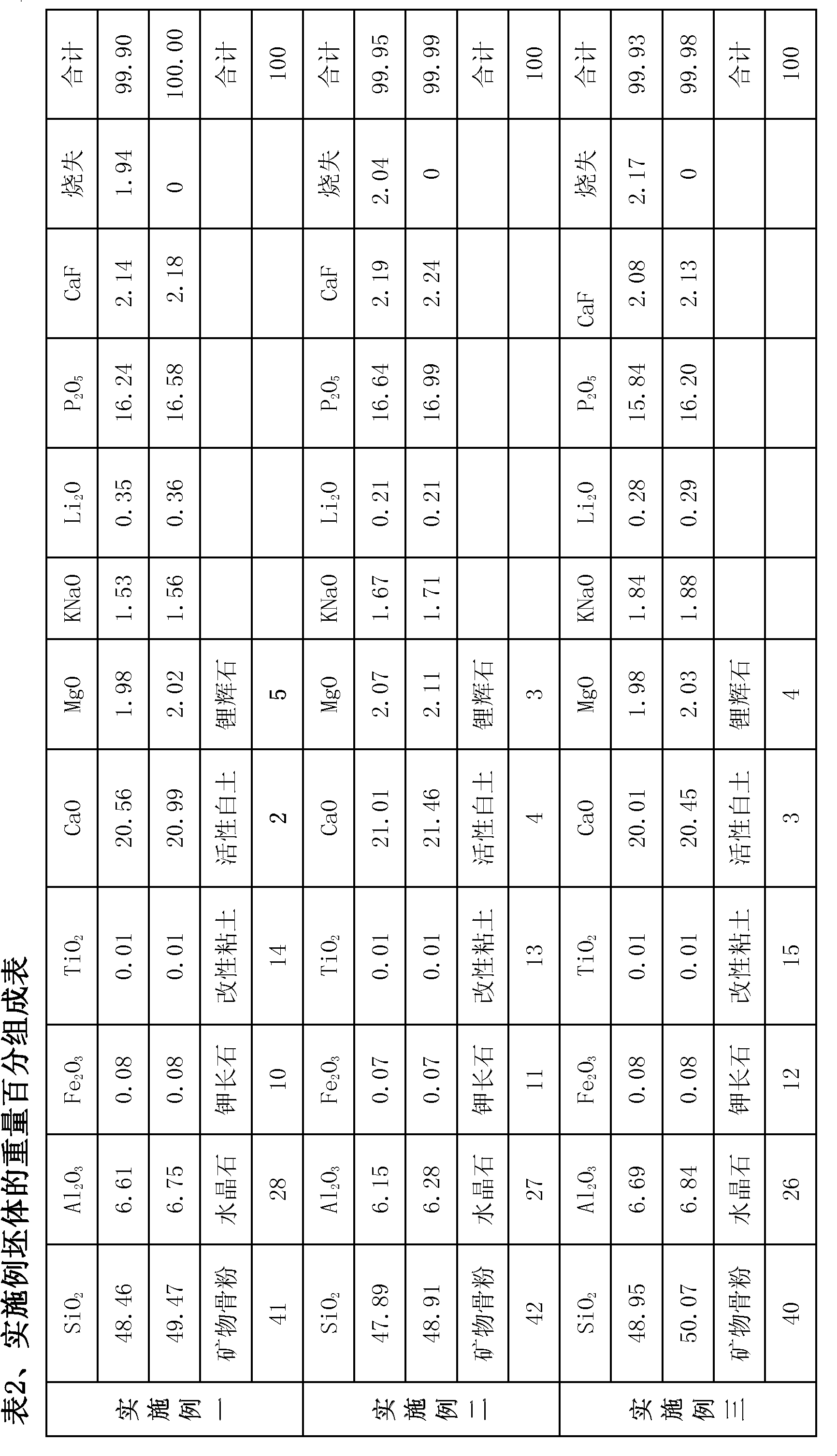

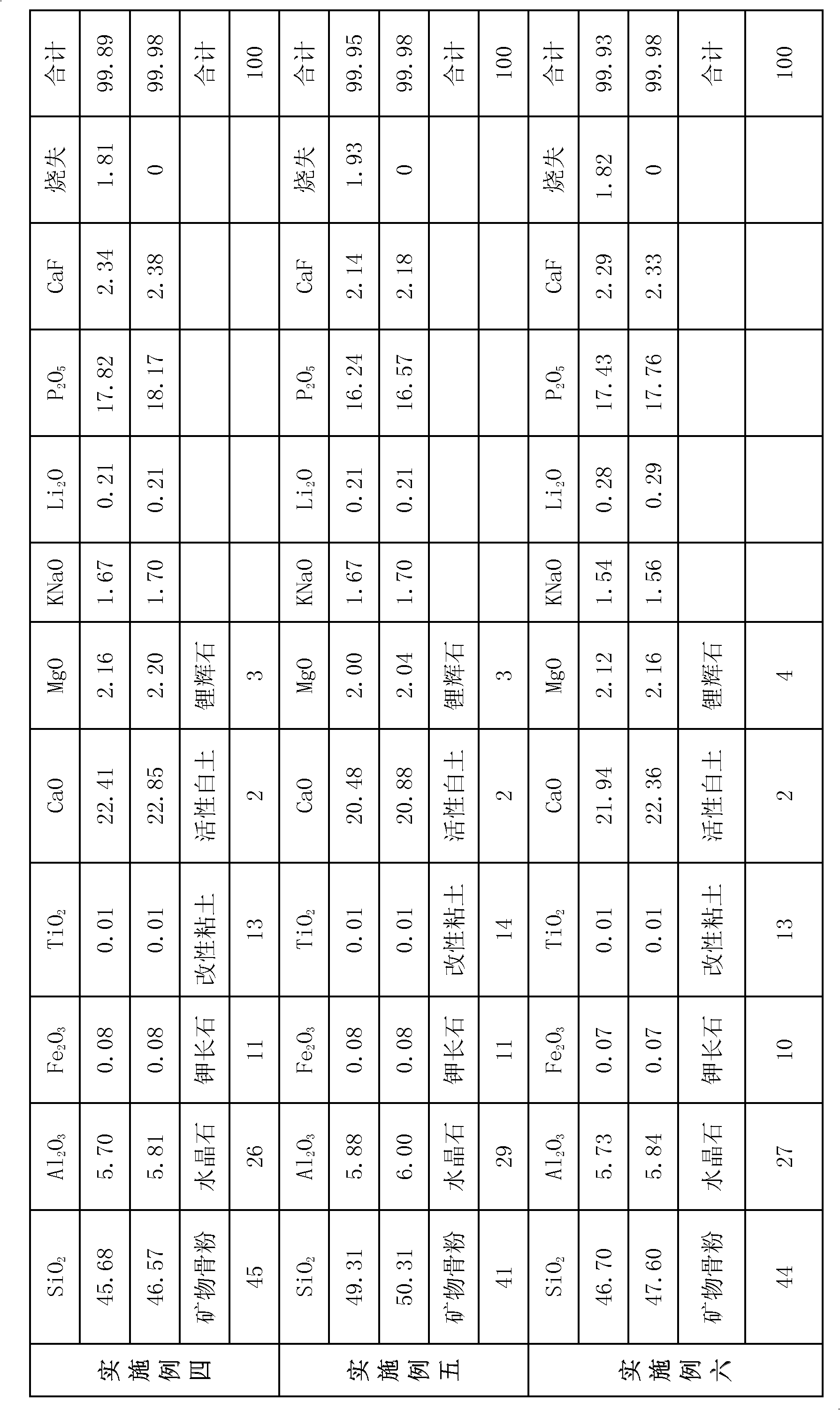

Mineral bone powder, crystal bone china and production method of the crystal bone china

ActiveCN102153340AThe chemical composition of the green body is stableGood formabilityApatitePotassium

The present invention relates to a mineral bone powder, crystal bone china and a production method of the crystal bone china. The mineral bone powder is synthesized by mineral apatite and dolomite. A crystal bone china green body consists of ingredients in weight percent as follows: 39-46% of mineral bone powder, 25-32% of crystal, 9-15% of potassium feldspar, 12-18% of synthetic clay, 1-5% of nano-activated clay, and 2-6% of spodumene. The production method of the crystal bone china includes the steps of ingredient mixing, molding, biscuiting, glazing and glaze firing; the crystal needs calcination acid treatment; and the product is formed by biscuiting and glaze firing. For the crystal bone china, by reasonable ingredient mixing, mineral bone powder and crystal are adopted as main materials for producing high-grade china, the firing temperature range is wide, the firing control is easy, and the crystal bone china integrates the characteristics of high white degree, good semi-transparency, high mechanical strength and good thermal stability; and the scientific and rational production method which is easy to implement effectively ensures the quality and the qualified rate of the product and is conducive to industrial production.

Owner:淄博泰山瓷业有限公司

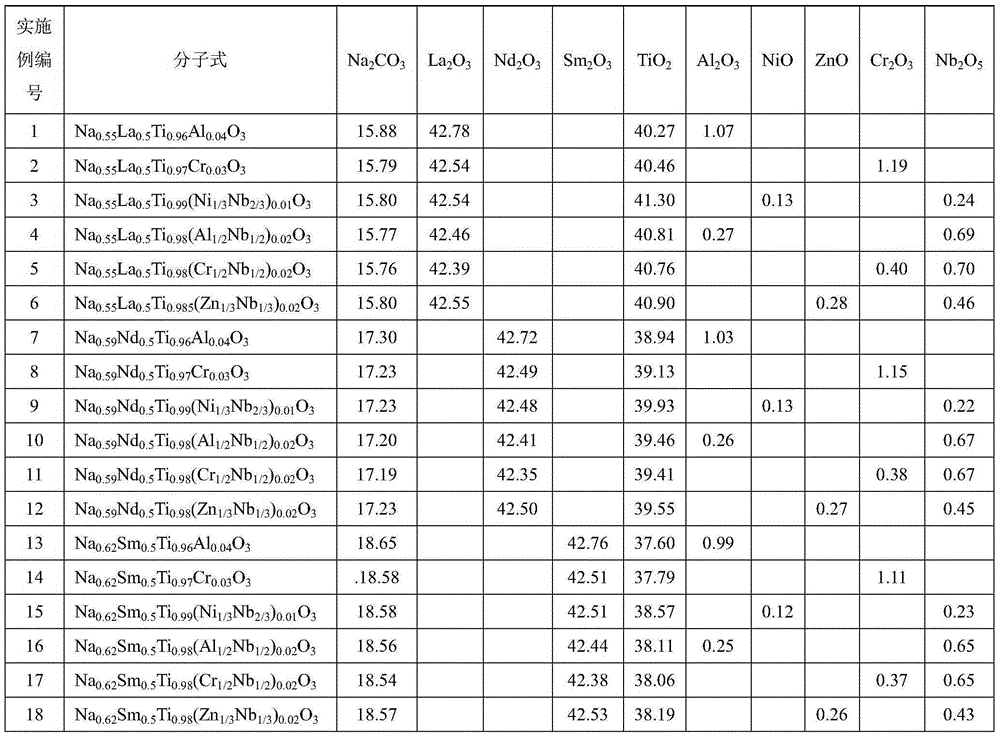

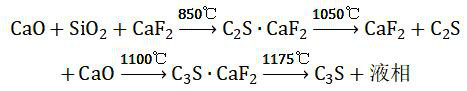

High-dielectric low-loss microwave dielectric ceramic material and preparation method thereof

The invention provides a high-dielectric low-loss microwave dielectric ceramic material. The general chemical formula of the material is (Na0.5+yLn0.5)(Ti1-xCx)O3, Ln=La or Nd or Sm, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.04, y is larger than or equal to 0.05 or is smaller than or equal to 0.12, the composition of C is VW, V represents Nb with the valence state higher than four, W represents a single ion or compound ions with the valence state lower than or equal to four and the average ion radius approximating to Ti4+, and V and M achieve simultaneous replacement or independent replacement. The invention further provides a preparation method of the high-dielectric low-loss microwave dielectric ceramic material. The preparation method comprises the steps of burdening, ball grinding, drying and sieving, presintering, pelleting, compression molding and sintering. The prepared material has the high dielectric constant and high Q*f value, contains no Pb or Cd or other volatile toxic metals in the formula, and is stable in performance and capable of meeting application requirements of modern microwave devices, raw materials are sufficiently supplied in China, the cost is relatively low, and the high-performance microwave ceramic can be low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

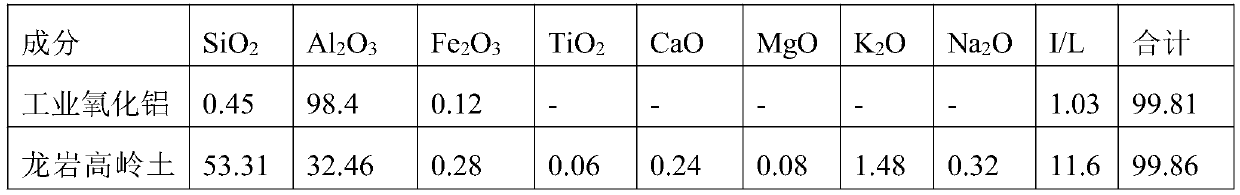

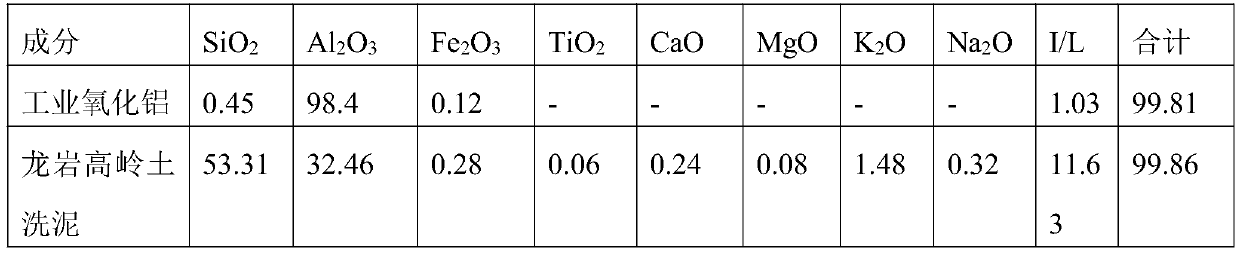

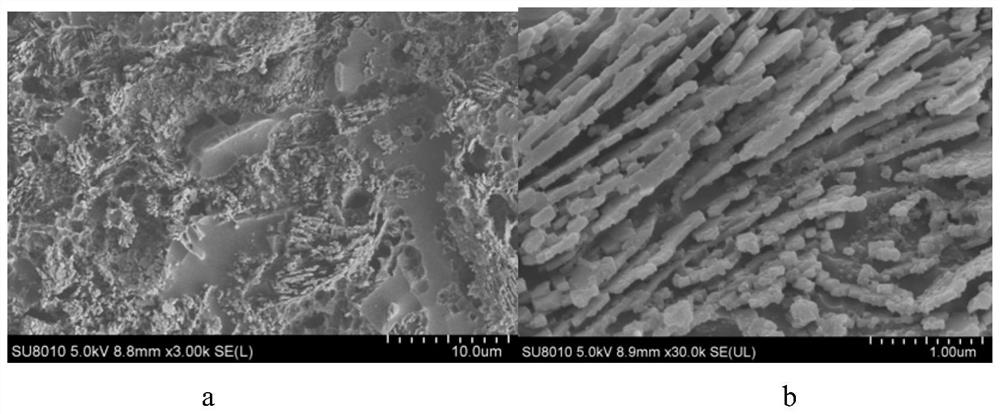

Preparation method of high strength high aluminum ceramic thin plate

The invention relates to a preparation method of a high strength high aluminum ceramic thin plate. The preparation method comprises following steps: (1) processing raw materials: ball-milling coal based kaolin, calcined bauxite, common kaolin, potash feldspar, soda feldspar, and talcum in a ball-milling machine, sieving, and saving the powder for later use; (2) proportioning and mixing raw materials: weighing raw materials according to percentages by weight, adding a blank enhancer, and mixing to obtain a mixture; (3) carrying out granulation and aging; (4) carrying out semi-dry pressing and moulding; (5) drying; (6) glazing; and (7) sintering: placing a dried blank in a roller kiln, and sintering to obtain the high strength high aluminum ceramic thin plate. Calcined bauxite is used to replace industrial alumina to introduce Al2O3 into the system; densely grown short rod like mullite of coal based kaolin is used to enhance the strength of the thin plate; the impurity namely TiO2 of calcined bauxite and added TiO2 are used to reduce the sintering temperature; the prepared thin plate has the characteristics of high strength and low sintering temperature, and the cost is reduced.

Owner:XIANGYANG GAOMING MINING IND CO LTD

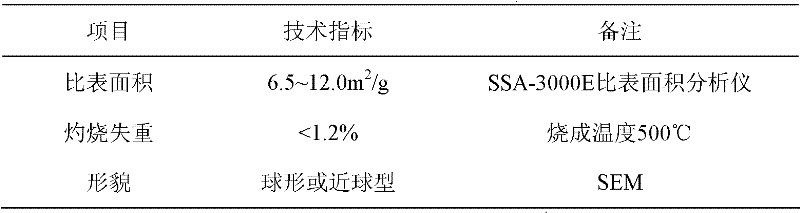

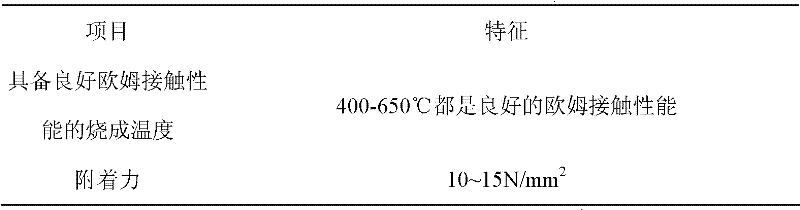

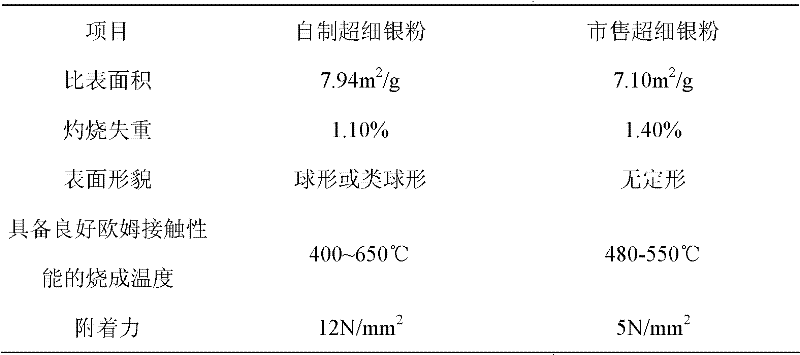

Method for preparing superfine spherical silver powder for barium-titanate-based semiconductor ceramic ohmic electrode slurry

The invention discloses a method for preparing superfine spherical silver powder for barium-titanate-based semiconductor ceramic ohmic electrode slurry, which comprises the following steps of: preparing silver nitrate solution, adding a polymer dispersant with high-speed stirring, and regulating the pH value of the silver nitrate solution to be between 8 and 12; and adding another polymer dispersant, a reducing agent and an antifoaming agent in turn, washing by using deionized water, and drying to obtain a finished product. By skillfully utilizing the change of high and low stirring rotating speeds and adding stirring heat preservation, superfine silver powder particle aggregate with an organic surface is formed, and the settling speed of the silver powder is greatly increased; an organicreagent with a dispersion function, and a polymer surfactant are selected as the antifoaming agent, so that the dispersion function and an antifoaming function are enhanced simultaneously; suitable polymer dispersants, reducing agent, antifoaming agent and alcohol are selected, so that the superfine silver powder with high purity and complete sphericity is prepared, and the barium-titanate-based semiconductor ceramic ohmic electrode slurry prepared from the superfine silver powder has high adhesion and ohmic contact performance and a wide firing temperature range; and the preparation method is nontoxic, low in cost and environment-friendly.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Azure jun porcelain glaze and preparation method thereof

The invention relates to an azure jun porcelain glaze. The azure jun porcelain glaze is prepared from components in parts by weight as follows: 50-60 parts of potassium feldspar, 15-18 parts of calcite, 13-15 parts of talc, 8-12 parts of fluorite, 8-12 parts of clay, 8-13 parts of a wanyao glaze stone, 0.3-1 part of tin oxide and 0.2-0.8 parts of copper oxide. The formula composition is simple, a preparation method is simple and easy, sintering temperature range is wide, the prepared azure jun porcelain glaze has smooth and flat glaze surface, is high in stability and has bright azure color which is greenish blue, and the glaze surface is even and clean.

Owner:崔松伟

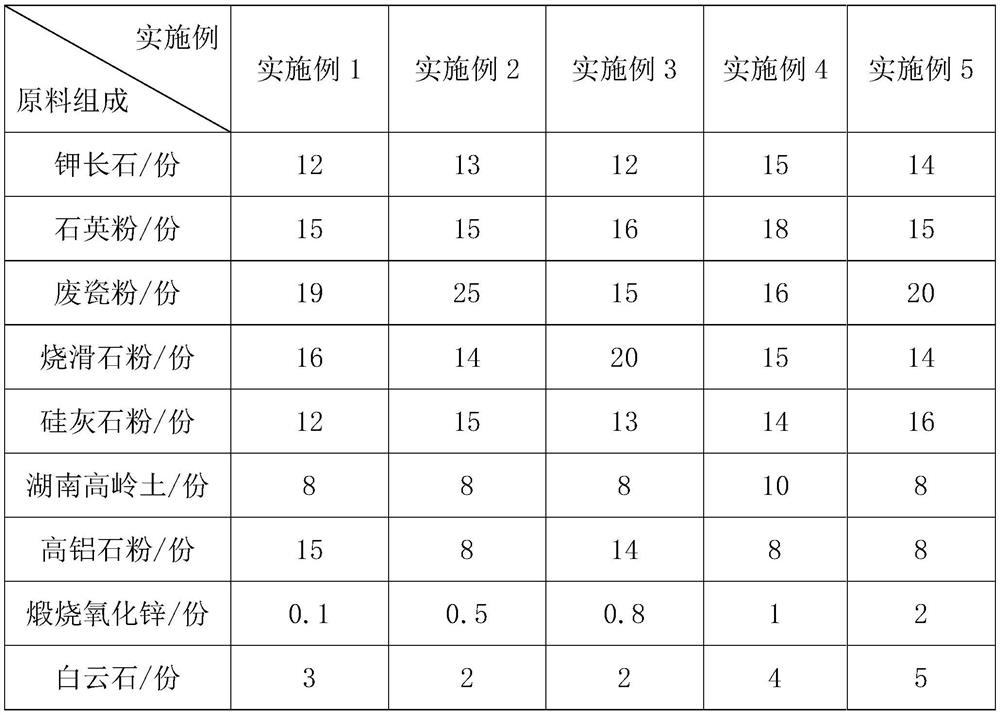

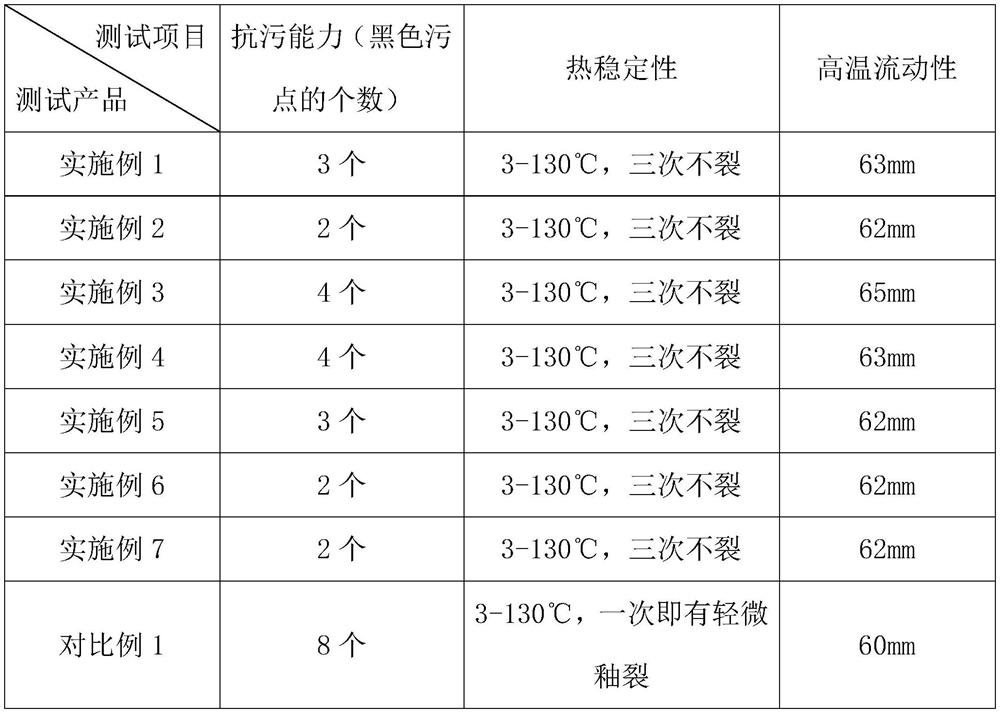

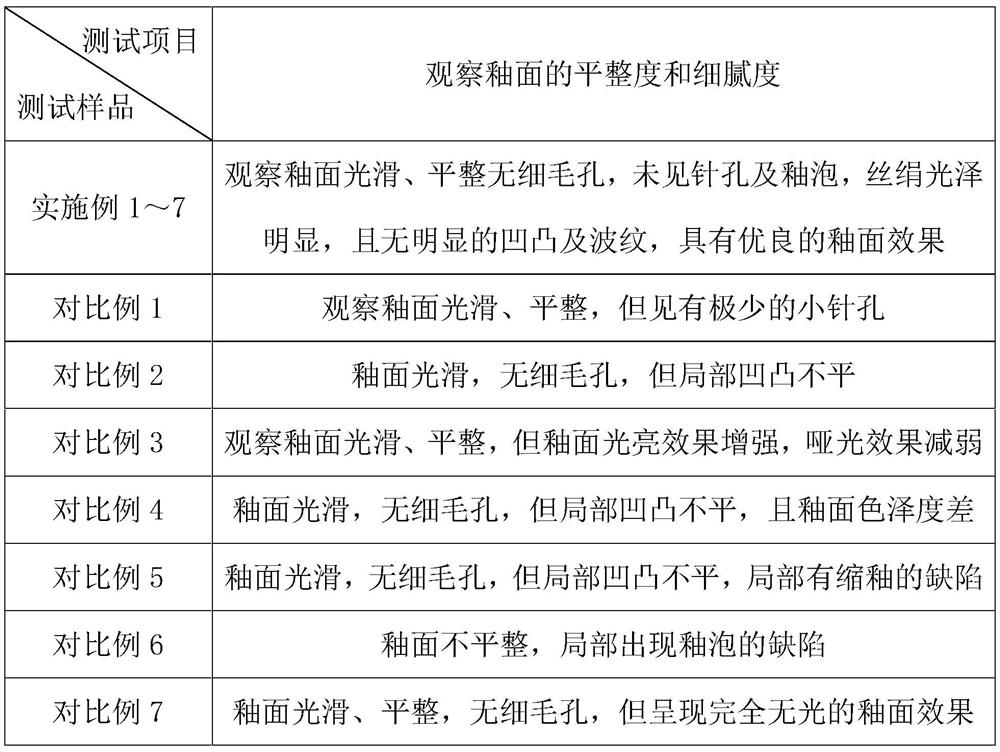

Matt glaze for sanitary ceramics and preparation method of sanitary ceramics

ActiveCN113511922AImprove thermal stabilitySolution rangeCeramic materials productionClaywaresKaolin clayStone dust

The invention relates to the technical field of sanitary ceramics, in particular to matte glaze for sanitary ceramics and a preparation method of the sanitary ceramics. The ceramic tile is prepared from the following raw materials in parts by weight: 12-15 parts of potassium feldspar, 15-18 parts of quartz powder, 15-25 parts of waste porcelain powder, 14-20 parts of burnt talcum powder, 12-16 parts of wollastonite powder, 8-10 parts of Hunan kaolin, 8-15 parts of high-aluminum stone powder, 0.1-2 parts of calcined zinc oxide and 2-5 parts of dolomite. The silica-alumina ratio of the matte glaze for the sanitary ceramics is 4.8-6.2. The matt glaze for the sanitary ceramics can show a silky and glossy matt effect and has the characteristics of fineness, stain resistance, wide firing temperature range and good glaze heat stability, the preparation method of the sanitary ceramics using the matt glaze for the sanitary ceramics is simple in preparation process, the glaze surface of the product is smooth, flat and free of fine pores, and the glaze surface is smooth and smooth. The problems that bubbles and pinholes are prone to occurring on an existing sanitary ceramic glaze surface, and the flatness of the glaze surface is poor are solved.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +3

Method and apparatus for calcining mineral materials difficult to be treated

The invention opened a roasting method of the intractable mineral. The mineral is put into the roasting pipe of the roasting furnace to roast for 1.0-5.0h, and then heated by the coal, the gas or the residual heat. The temperature of the pipe is 400-1150 DEG C. It mixes the mineral by turning the pipe continuously or intermittently. The roasting furnace includes the dispenser, the petticoat pipe collector, the flue, the rectangular parallelepiped furnace body, bag-type dust collector, the eluting gas wash tower, the receiver bin, the fueling equipment, the fuel discharge device and the draught fan. The ratio of the long to the diameter of the roasting pipe is 2-15:1. the method has the low cost and high production.

Owner:ZIJIN MINING GROUP

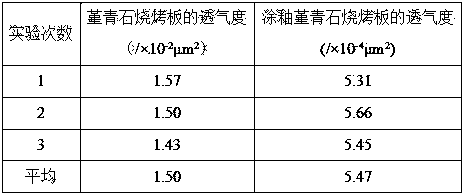

Low expansion mat glaze and cordierite barbecue plate coated with glaze

ActiveCN104193412AWide firing temperature rangeGood thermal shock resistanceCordieriteLithium carbonate

The invention discloses low expansion mat glaze and a cordierite barbecue plate coated with the glaze. The glaze comprises bottom glaze and surface glaze, wherein the bottom glaze is made from spodumene, quartz, dolomite, talc, lithium carbonate, kaolin and barium carbonate, and the surface glaze is made from spodumene, quartz, dolomite, kaolin and zinc oxide. The preparation method of the cordierite barbecue plate coated with the glaze comprises the following steps: uniformly mixing a bottom glaze raw material and adding an adhesive, a dispergator and water, and ball-milling to obtain bottom glaze slurry; uniformly mixing the surface glaze raw material and adding an adhesive, a dispergator and water, and ball-milling to obtain surface glaze slurry; spraying the bottom glaze slurry to the surface of the cordierite barbecue plate, and then applying the surface glaze slurry to the plate; and firing for 40-60 minutes at 1200-1260 DEG C and cooling. The glaze layer formed by the glaze is good in thermal shock resistance, high in compactness and fine and smooth and can be used for effectively preventing harmful matters from internally permeating.

Owner:广东道氏陶瓷材料有限公司

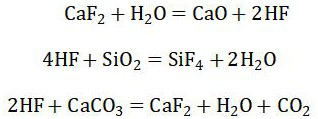

Portland cement clinker and preparation method thereof

The invention discloses Portland cement clinker and a preparation method thereof, and belongs to the field of building material preparation. The Portland cement clinker comprises the following components by weight percentage: 52%-58% of limestone, 23%-26% of coal gangue, 8%-12% of iron tailings, 5%-10% of fly ash, 1.2%-1.8% of fluorgypsum and 0.8%-1.2% of calcium fluoride. Limestone is used as a calcareous raw material, coal gangue is used as a silicon-aluminum raw material, iron tailings and fly ash are used as correction materials, fluorgypsum and calcium chloride are used as a mineralizer,a large amount of solid waste can be consumed to produce the Portland cement clinker, and the mineralizer is introduced at the same time to improve the burnability of raw materials and improve the quality and yield of the clinker. According to the method, waste can be turned into wealth, accumulation of a large amount of solid waste is effectively reduced, the raw material supply problem is relieved, and meanwhile the cost is saved.

Owner:张延年

Porcelain glaze and glazing method of porcelain

The invention relates to porcelain glaze and a glazing method of porcelain at normal temperature. The porcelain glaze comprises the following components in percentage by weight: 45%-55% of potassium feldspar, 3%-10% of MgO, 35%-40% of SiO2 and 5%-12% of Suzhou clay. The glazing method comprises the following steps of: weighing raw materials, and then carrying out ball-milling to obtain glaze slurry; deironing and filtering the glaze slurry to obtain glaze slurry; carrying out glaze spraying on the porcelain at the pressure of 0.06-0.08 MPa, wherein the thickens of a glaze layer is 0.15-0.20 mm; sintering the glazed surface of the porcelain subjected to the glaze spraying at a temperature of 1350-1400 DEG C; and keeping the temperature for 2-2.5 hours. The porcelain glaze disclosed by the invention is not precipitated after prepared into the glaze slurry and has strong adhesive force; according to the glaze disclosed by the invention, the porcelain can be glazed without being heated, the range of sintering temperature is wide, and the sintered glazed surface has uniform vitrification and good glossiness, and therefore, the mechanical strength and the heat stability of the porcelain are enhanced and the product quality is obviously improved.

Owner:HENAN GENGSHENG HIGH TEMPERATURE MATERIALS CO LTD

Low-temperature adherence strength highly-firing amplitude broad glass lining bottom glaze

The present invention relates to a enamel glass ground glaze with wide sintering amplitude and low-temperature adherence strength, which comprises A hardened materials, B medium materials, C soft materials, mill additions and water; calculated according to the weight percentage, the C soft materials are mainly composed of the following raw materials such as 34.19 to 36.79 percent of SiO2, 3.5 to 4.0 percent of Al2O3, 20.00 to 21.0 percent of B2O3, 4.00 to 15.00 percent of Na2O, 3.00 to 4.00 percent of K2O, 2.5 to 3.0 percent of CaF2, 5.5 to 6.5 percent of MnO2, 1.8 to 2.2 percent of Fe2O3, 1.8 to 2.2 percent of CuO, 1.70 to 1.90 percent of CoO, 4.5 to 5.5 percent of Li2O and 1.8 to 2.2 percent of TiO2; calculated according to the mill addition mixture ratio, the A hardened materials take 35 to 45 percent, the B medium materials take 25 to 35 percent, the C soft materials take 25 to 35 percent, the clays take 5.5 to 6.5 percent, the Alpha-Al2O3 takes 2.8 to 5.0, the zircon powders ZrO2 take 4.0 to 7.5 percent, the nepheline powders take 2.8 to 5.2 percent, the sintering quartz powders take 4 to 8 percent, the borax decathydrates take 0.8 to 1.2 percent, the magnesium oxides take 1.8 to 2.2 percent and the distilled water takes 65 to 75 percent. The present invention can strengthen the low-temperature adherence strength of the ground glaze and increase the sintering amplitude.

Owner:JIANGYIN SILICON GENERAL ENAMEL

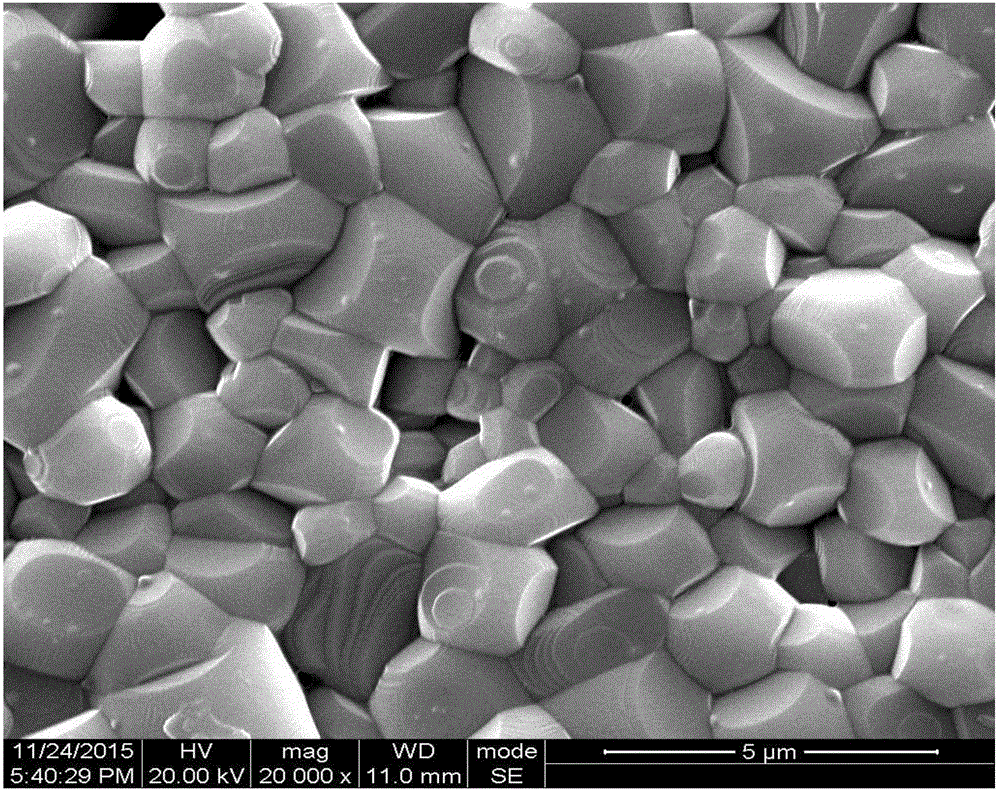

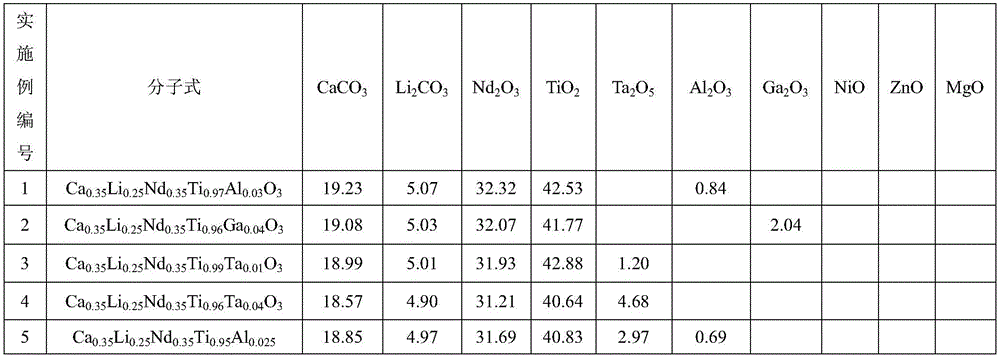

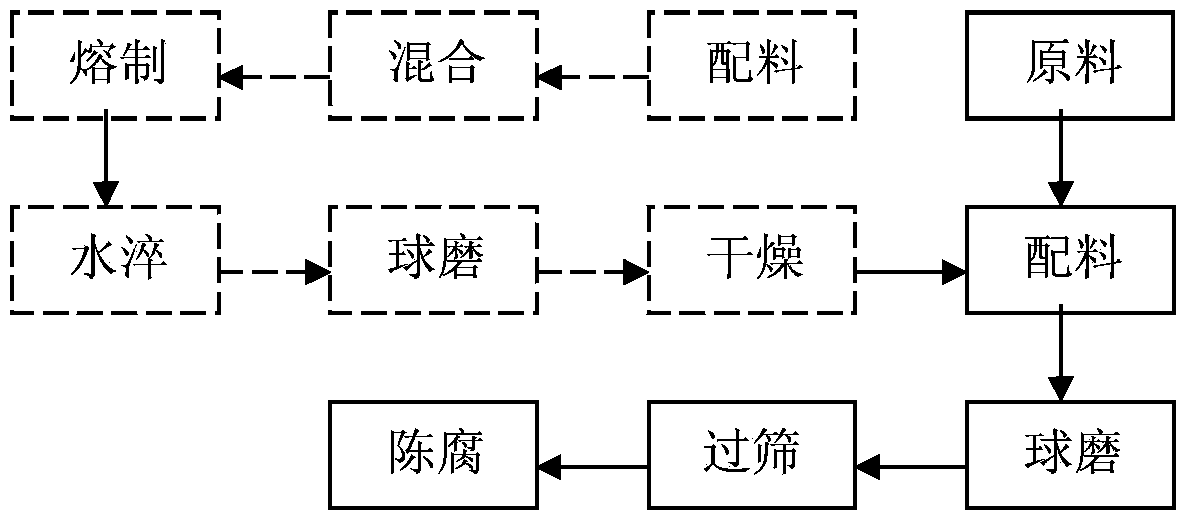

High-permittivity microwave dielectric ceramic material and preparation method thereof

The invention provides a high-permittivity microwave dielectric ceramic material. The material has the material chemical formula (Ca0.35Li0.25Nd0.35)(Ti1-xDx)O3, wherein x is larger than or equal to 0.01 and smaller than or equal to 0.05, the composition of D is VW, V represents Ta with the valence state higher than 4, W represents one or more elements with the valence state lower than four and the average ion radius close to Ti4+, and V and W can be substituted at the same time or independently. The invention further provides a preparation method of the high-permittivity microwave dielectric ceramic material. The method includes the steps of material mixing, ball grinding, drying, screening, pre-sintering, granulating, compression molding forming and sintering. The prepared material has a high dielectric constant, a high Q*f value and an adjustable frequency and temperature coefficient. Volatile toxic metal such as Pb and Cd is not contained in the formula, performance is stable, application requirements of modern microwave devices can be met, the raw materials can be sufficiently supplied in China, the price is relatively low, and low cost of high-performance microwave ceramic is made possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing iron tailing into ceramic frit glaze

Provided is a method for preparing iron tailing into ceramic frit glaze. The method for preparing iron tailing into ceramic frit glaze regards iron tailing as raw materials, is free of adding other ceramic pigment or, colorant except for iron, and prepares ceramic frit glaze which is abundant in color and good in effect. The method for preparing iron tailing into ceramic frit glaze explores a novel path for iron tailing resources with high technology and high added value. The dosage of the iron tailing in the ceramic frit glaze is large, and the iron tailing is in integral utilization. The method for preparing iron tailing into ceramic frit glaze utilizes affluent iron and other microelements in the iron tailing to tint for glaze, replaces the expensive ceramic pigments, greatly lowers the cost of the ceramic frit glaze, selects and provides novel direction for ceramic frit glaze raw materials and the ceramic pigments, and lowers the dependent degree to high quality non-metal mineral resources compared with the current ceramic glaze production. The iron tailing and parts of the raw materials are initially melted to frits to use, so that firing temperature range of the glaze is expanded, and ceramic glaze surface quality is improved. A series of unfavorable influences to the preparation process in the process of applying the iron tailing in a ceramic green body are overcome. The method for preparing iron tailing into ceramic frit glaze has the advantages of being simple in process, optimum in glaze quality, and applicable to industrialized mass production.

Owner:UNIV OF SCI & TECH BEIJING +2

Low-temperature bright red ceramic glaze and preparation method thereof

The invention relates to low-temperature bright red ceramic glaze and a preparation method thereof. The glaze comprises the main components of, by weight, 50-60 parts of PbO, 15-30 parts of SiO2, 10-20 parts of B2O3, 1-5 parts of Na2O, 1-5 parts of ZnO, 0.5-1.5 parts of CaO and 5-6 parts of inclusion red; the binder comprises red lead powder, quartz powder, sodium borate, boracic acid, calcium carbonate, zinc oxide and sodium silicate, the inclusion red is taken as a coloring agent, and the non-frit low-temperature bright red ceramic glaze is prepared. The glaze overcomes the defects that the preparation technology of frit glaze is complex, the melting temperature is high, the appearance and the performance of the glaze are unstable, and the glaze have to be fired in a reducing atmosphere. The low-temperature bright red ceramic glaze has the advantages that the color tone is pure, the glaze face is smooth and level, the glossiness is high, the glazing method is simple, and the sintering temperature range is wide. The glaze is ideal glaze for firing high-quality ceramic products.

Owner:LUOYANG NORMAL UNIV

Metal glaze as well as preparation method and application method thereof

The invention belongs to the technical field of ceramic glaze, and relates to metal glaze as well as a preparation method and an application method thereof. The metal glaze comprises the following raw materials in percentage by weight: 30-37% of albite, 8-15% of quartz, 0-4% of wollastonite, 9-16% of calcined kaolin, 4-6% of calcined zinc oxide, 19-23% of calcined iron phosphate and 13-20% of self-made high-phosphorus frit powder. On the basis of calcined iron phosphate, self-made high-phosphorus frit powder is added as a crystallization accelerant into the metal glaze, so that the metal luster is more easily presented. The element P is introduced into the self-made high-phosphorus frit powder in a frit form, and compared with a high-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, and the metal effect is more stably presented. By finely adjusting the ratio of the self-made high-phosphorus frit powder to the silicon-aluminum of the metal glaze, the adjustment of metal to different colors can be realized. In addition, the metal glaze is combined with a roller printing process, so that the glaze surface can present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

Curing agent for dry iron tailing stack and preparation method of curing agent

The invention discloses a curing agent for a dry iron tailing stack and a preparation method of the curing agent, belonging to the technical field of mine safety. The curing agent is composed of curing agent clinker and an excitant, wherein the curing agent clinker comprises the basic components in parts by mass: 46-50 parts of CaO, 12-18 parts of MgO, 20-25 parts of SiO2, 8-12 parts of Al2O3 and 1-2 parts of mineralizing agent. The preparation method comprises the steps of firstly, grinding a CaO and MgO enriched raw material, an Al2O3 and SiO2 enriched raw material and the mineralizing agent; then, feeding the ground powder into a balling dish to prepare curing agent clinker powder; and finally, adding excitant powder into the curing agent clinker powder, stirring and uniformly mixing to obtain the curing agent for the dry iron tailing stack. The curing agent prepared by the invention is strong in curing capacity, relatively low in raw material cost and favorable in large-scale popularization and application prospects.

Owner:罗强

Thick white glaze ceramics and preparation method thereof

The invention belongs to the technical field of domestic ceramics, and particularly relates to thick white glaze ceramics and a preparation method thereof. The thick white glaze ceramics comprise thefollowing materials: crystal frit, potassium feldspar, Longyan kaolin, zinc oxide, Guangfeng calcined talc, strontium carbonate and titanium dioxide. The process method is adopted, through the fact that raw material selecting, formulation optimizing and preparation technique controlling are conducted, a glaze of the prepared ceramic glaze is thick, glossiness is high, and the thickness can reach 2-3mm. Under oxidation flame, the burned glaze is white and yellowish with lard white colors, the glaze is crystal clear with oil but not greasy, and particularly noble, glaze materials are applied tohigh white green bodies, the effect is especially obvious, the ratio of fishing products is high, and the glaze materials are suitable for promotion and application of the domestic ceramics and display ceramics.

Owner:FUJIAN QUANZHOU SHUNMEI GROUP

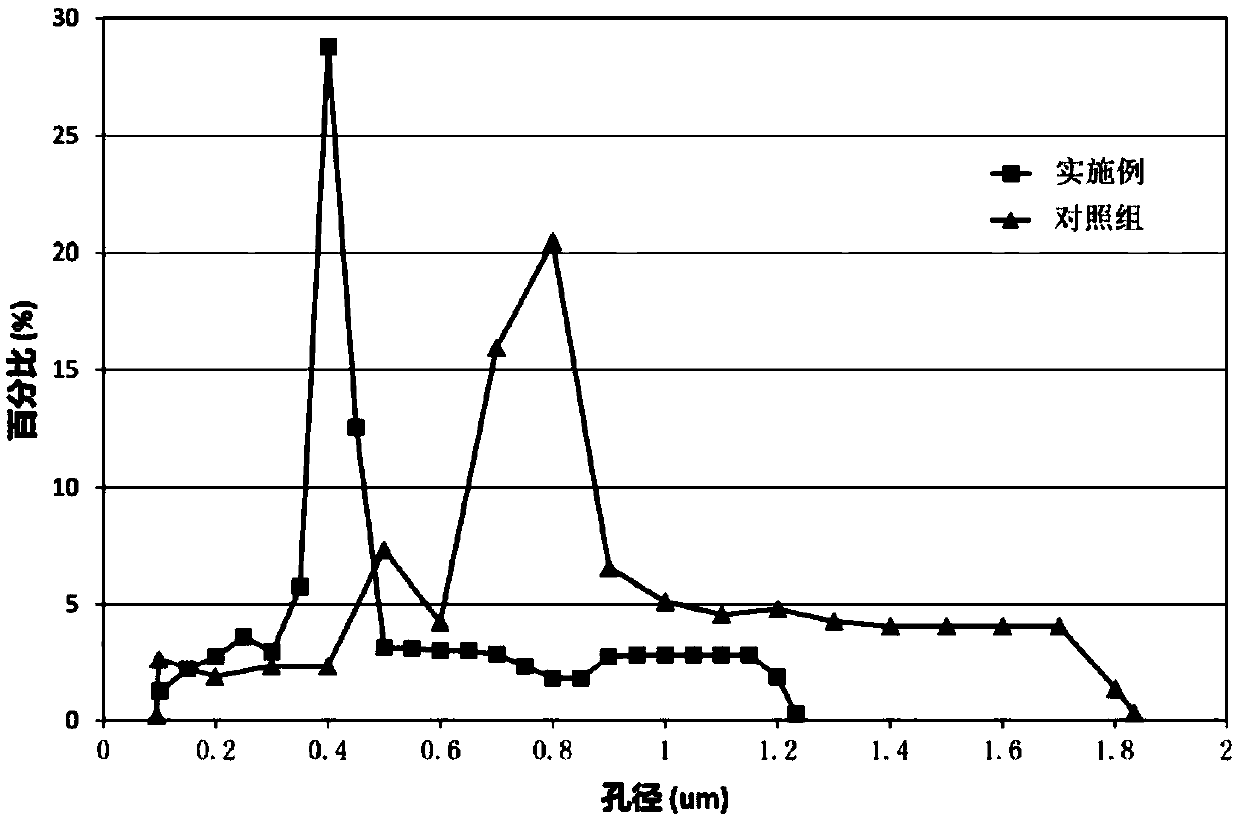

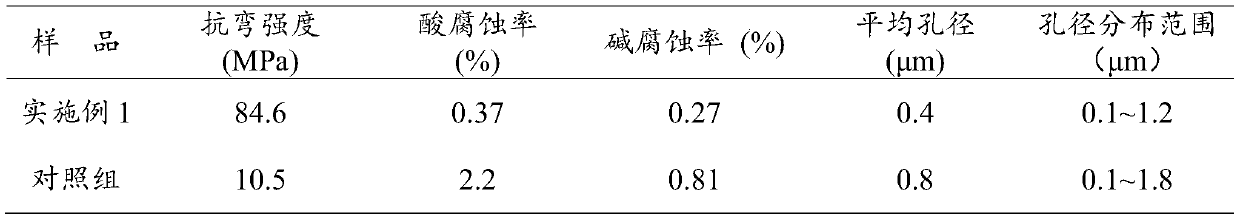

Preparation method of aluminum oxide porous material

ActiveCN109516831AImprove hydrophilicityImprove chemical reactivityCeramicwareMagnesium phosphateMagnesium orthophosphate

The invention discloses a preparation method of an aluminum oxide porous material. The preparation method comprises the following steps of modifying an aluminum oxide powder by a magnesium phosphate sol, adding a manganese oxide micropowder as a sintering additive, and reducing the firing temperature of the aluminum oxide porous material to the temperature of 1200 to 1400 DEG C. The preparation method has the advantage that the good pore structure can be obtained for the porous material within the wide firing temperature range. The aluminum oxide porous material prepared by the preparation method has excellent mechanical property.

Owner:浙江昕明环境科技有限公司

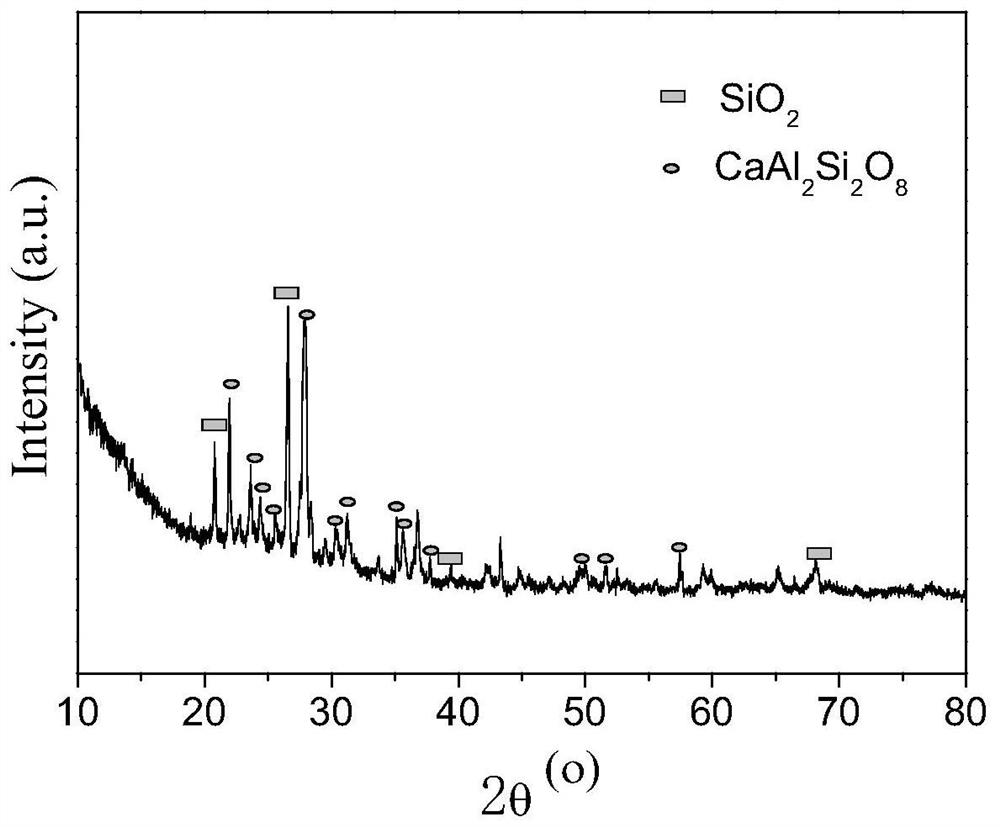

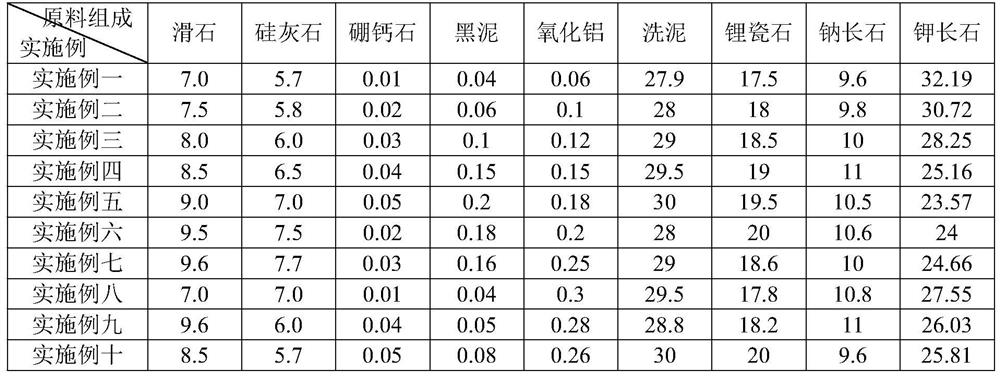

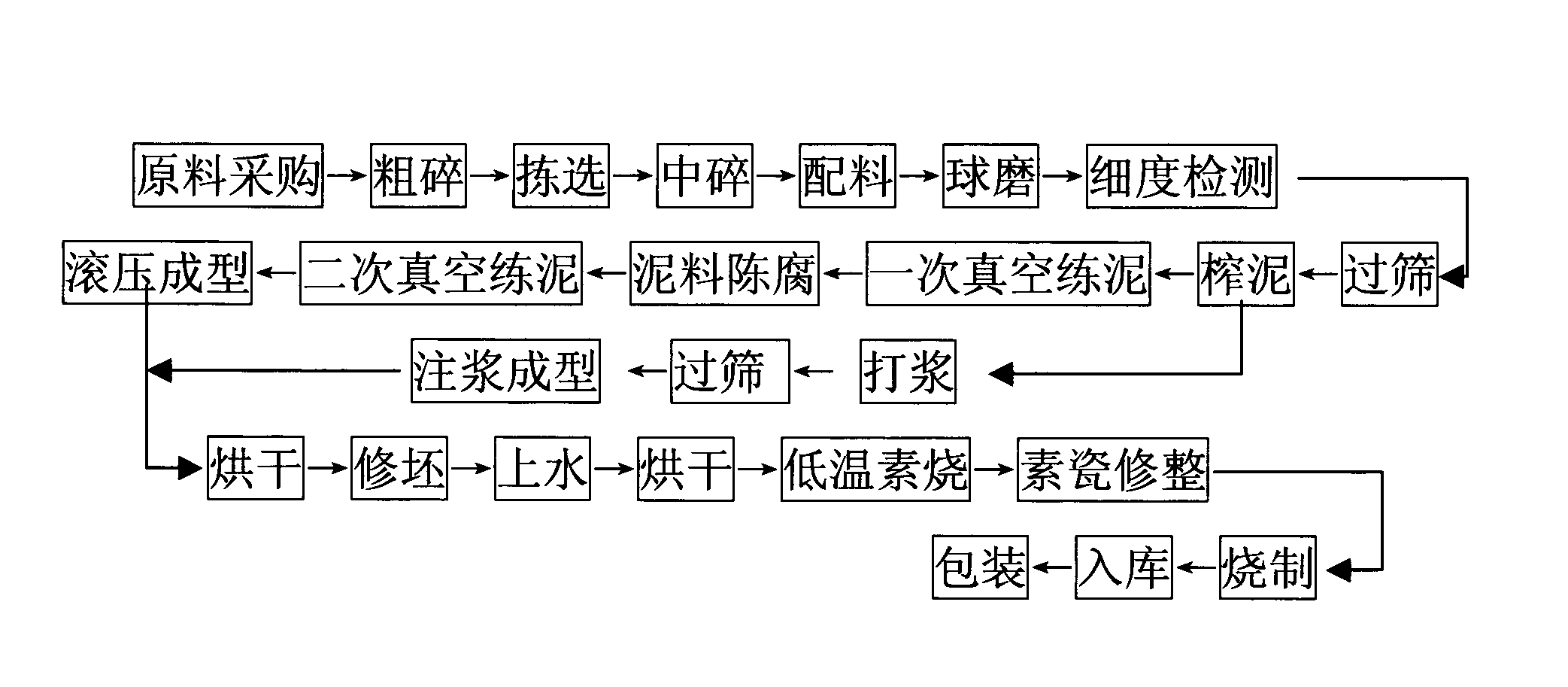

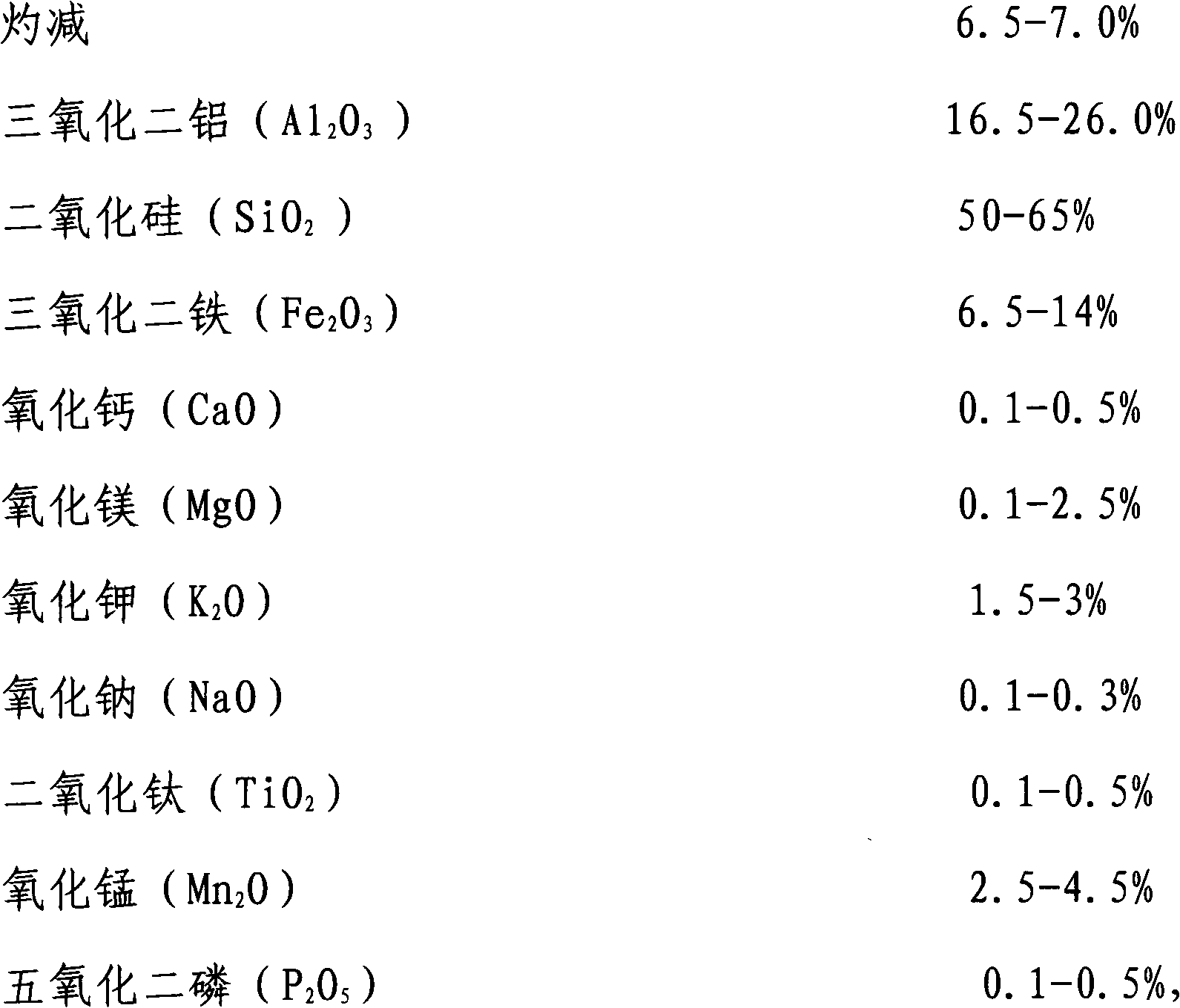

High-performance ceramic rock plate and preparation method thereof

The invention discloses a high-performance ceramic rock plate, which is prepared from the following raw materials in percentage by weight: 7.0 to 9.6 percent of talc, 5.7 to 7.7 percent of wollastonite, 0.01 to 0.05 percent of borocalcite, 0.04 to 0.2 percent of black mud, 0.06 to 0.3 percent of aluminum oxide, 27.9 to 30 percent of washing mud, 17.5 to 20 percent of lithium chinastone, 9.6 to 11 percent of albite and 24 to 32.19 percent of potassium feldspar. In addition, the invention further discloses a preparation method of the high-performance ceramic rock plate. Through formula design, a large number of layered anorthite crystals are separated out from a system, and the thermal expansion coefficient with a glass phase can be reduced by regulating and controlling the anorthite / quartz crystal phase proportion and increasing the anorthite content, so that internal stress formed in the cooling process is avoided, and the problems that a rock plate product is prone to cracking and edge breakage, high in splicing difficulty and the like are effectively solved; and the purpose of easy processing is achieved while good stability is achieved. The preparation method disclosed by the invention is based on a general traditional ceramic glaze and a ceramic production process, and has a promotion effect on technical progress and application development of the architectural ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method of heat-preservation foam glass

InactiveCN107892483AReduce viscosity change rateUniform and stable bubble diameterGlass shaping apparatusPotassiumFoam glass

The invention discloses a preparation method of heat-preservation foam glass, and relates to the technical field of glass processing. The heat-preservation foam glass is prepared from quartz glass, nanometer zeolite powder coated with bismuth oxide, potassium chloride, sodium carbonate, calcium oxide, aluminium oxide, zinc oxide, acidized bentonite and a foaming agent. By adopting the nanometer zeolite powder coated with bismuth oxide, the foaming temperature and crystallization tendency within the foaming temperature range can be reduced effectively, the synergistic effect of the nanometer zeolite powder and the acidized bentonite can be achieved, the viscosity change rate of the glass within the foaming temperature range can be substantially decreased, and therefore the firing temperature range is widened; the prepared foam glass has an even and stable foam diameter, and the heat preservation performance of the foam glass can be effectively improved.

Owner:蚌埠承永玻璃制品有限公司

Iron-manganese heat resistant cooker and production technology thereof

The invention belongs to the technical field of ceramic materials, and provides a novel iron-manganese heat resistant cooker and a production technology thereof. A low expansion coefficient raw material such as spodumene is not required in the formula of the product; the heat conductivity coefficient of the ceramic ware is greatly improved by improving the heat conductivity coefficient and the thermal shock resistance of ceramic; the sintering temperature is low, and the maturing temperature is wide in range and is 1,160 to 1,230 DEG C; the product is high in superior quality, can be quickly sintered, can tolerate the heat exchange of 500 to 20 DEG C without cracking, has the advantages of low energy consumption, high heat conductivity, high impact strength, thermal shock resistance and the like, and can be used for directly steaming, boiling, stewing and stir-frying food over a heat source; and the cooker keeps the cooking flavor of the conventional ceramic ware, does not decompose nutritional components in the food, and is an ideal multifunctional cooking ware for modern families, hotels and restaurants.

Owner:邱东烽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com