Piezoelectric ceramic and piezoelectric element

A technology of piezoelectric ceramics and piezoelectric elements, applied in electrical components, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. problems, to achieve the effect of superior temperature stability, high yield, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

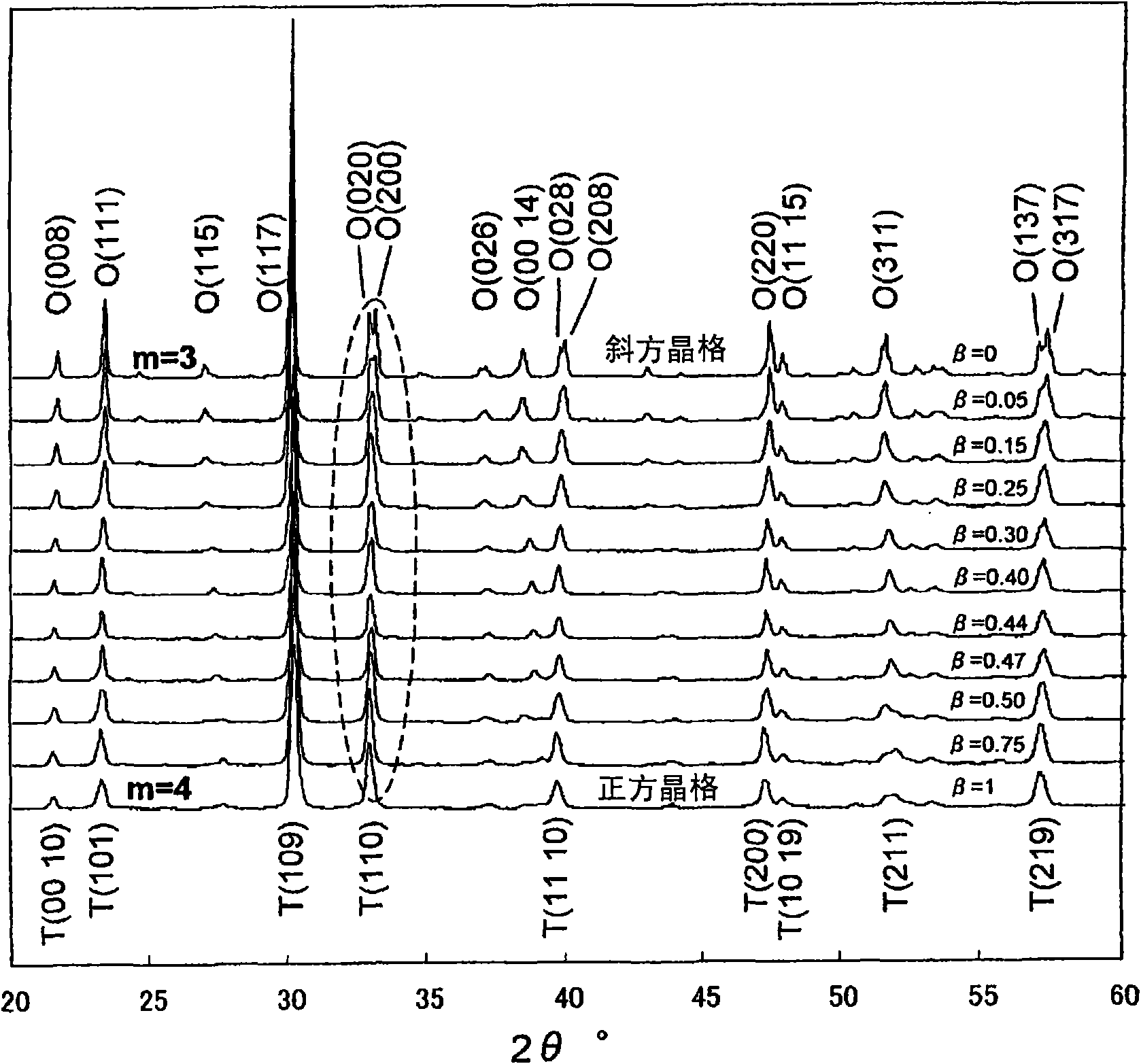

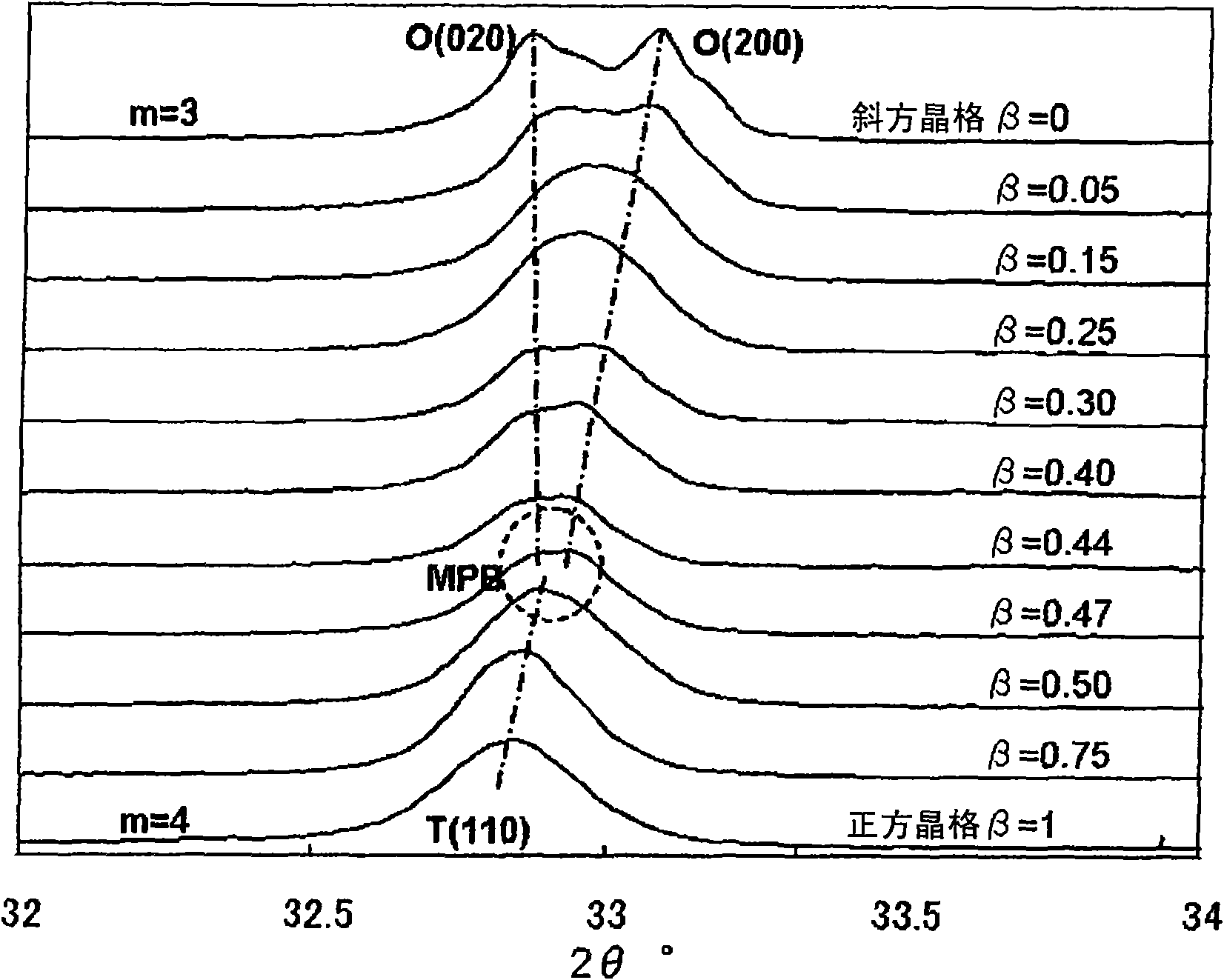

[0026] In the piezoelectric ceramics of the present invention, the piezoelectric ceramics mainly contain a bismuth layered compound, and the bismuth layered compound is expressed as Bi in a composition formula based on a molar ratio. 4 Ti 3 o 12 · β[(1-γ)M1TiO 3 · γM2M3O 3 ], satisfy 0.405≤β≤0.498, 0≤γ≤0.3, and M1 is selected from Sr, Ba, Ca, (Bi 0.5 Na 0.5 ), (Bi 0.5 Li 0.5 ) and (Bi 0.5 K 0.5 ), M2 is at least one selected from Bi, Na, K and Li, M3 is at least one selected from Fe and Nb, relative to the bismuth layered compound, that is, the main component 100 mass parts, as oxide (MnO 2 , Fe 2 o 3 ) conversion, at least one selected from Mn and Fe is contained in an amount of 0.05 to 1 part by mass.

[0027] Here, the reason for setting β as a coefficient to the above-mentioned range will be described. In the above composition formula, the reason for setting 0.405≤β≤0.498 is as follows: When β is greater than 0.498, the dynamic d at 200°C 33 Constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com