Back contact solar battery and preparing method thereof

A technology for a solar cell and a manufacturing method, which is applied in the field of solar cells, can solve the problems of high cost, complicated manufacturing process, shortened life of a silicon substrate body, etc., and achieves the effect of reducing manufacturing cost and simplifying manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

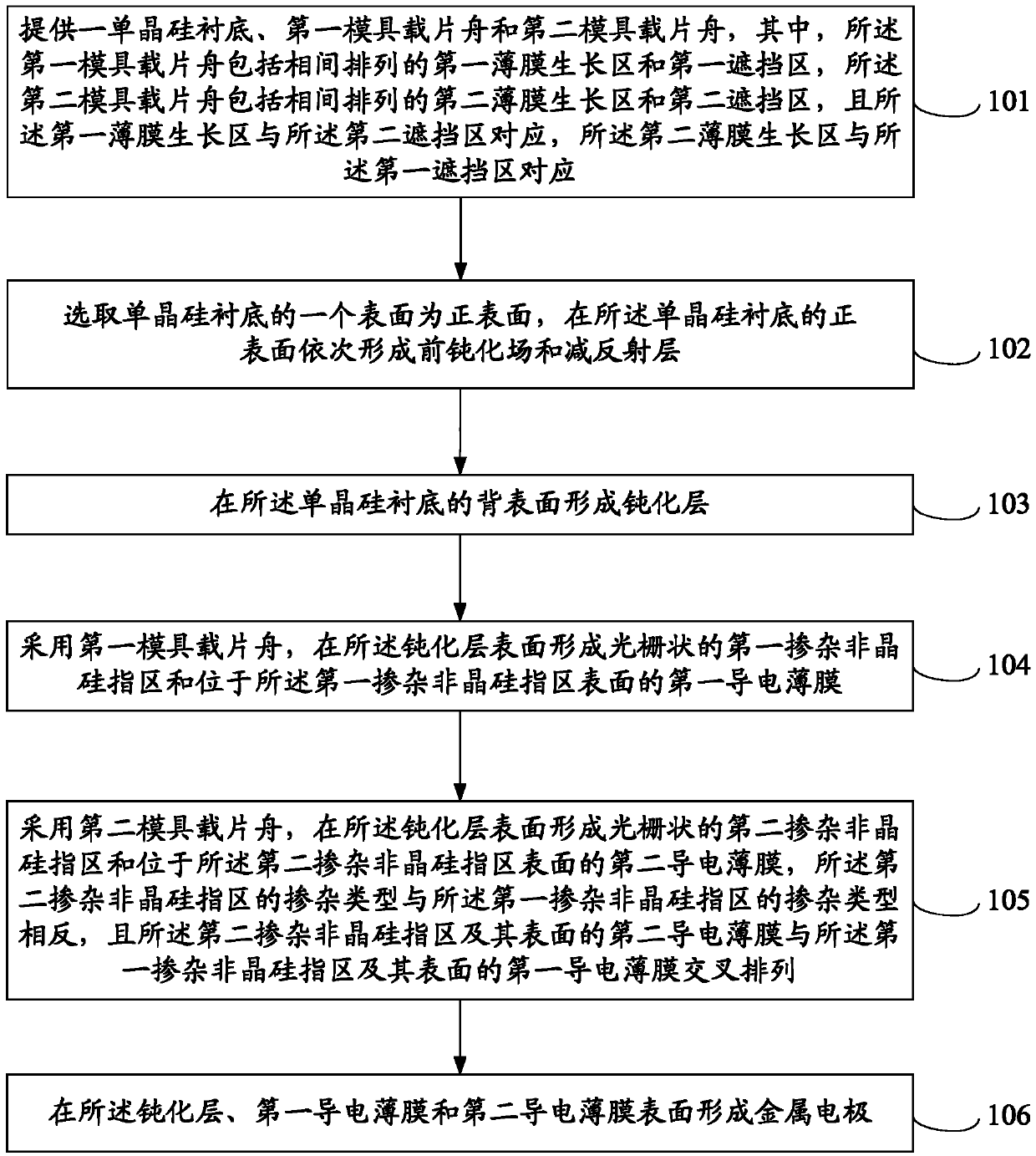

[0043] This embodiment provides a method for fabricating a back contact solar cell, such as figure 1 shown, including the following steps:

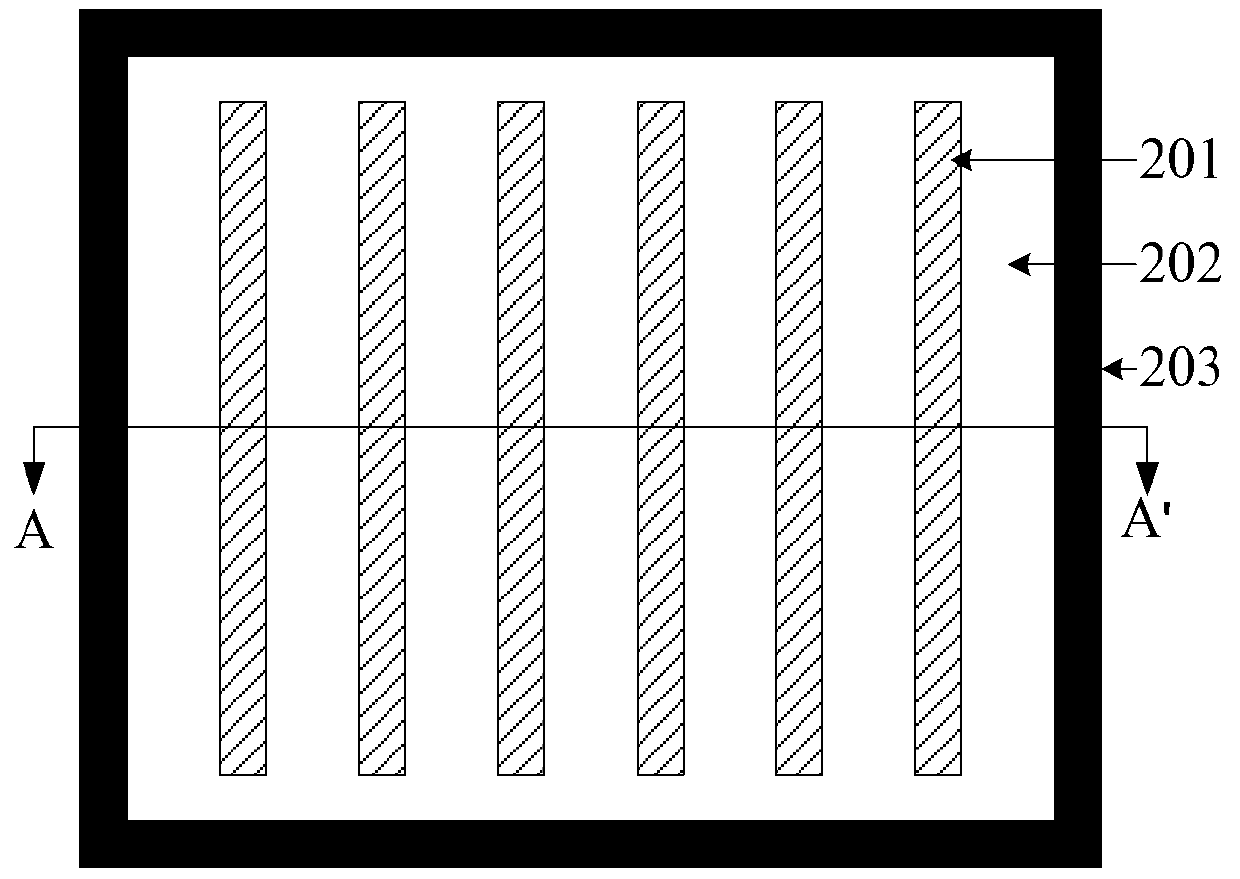

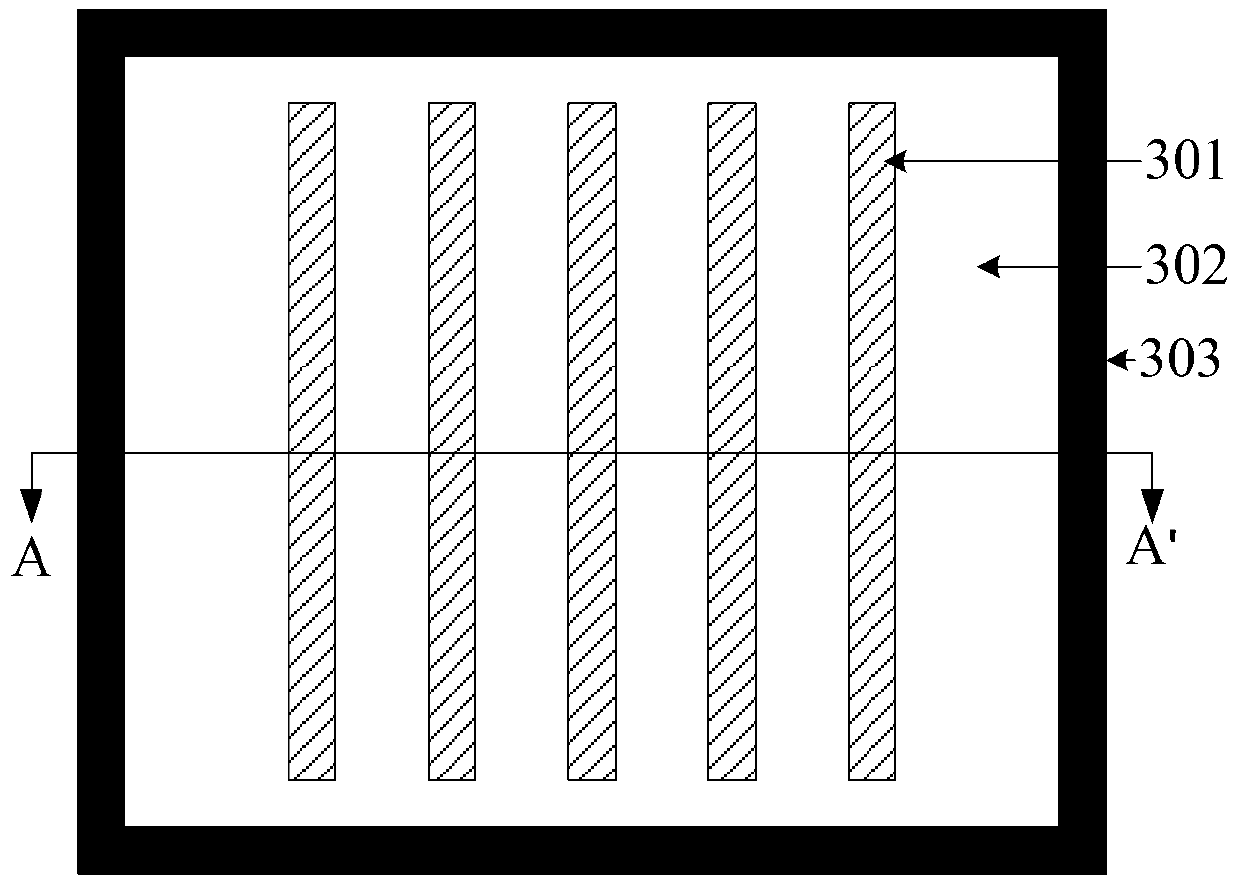

[0044] Step 101: Provide a single crystal silicon substrate, the first mold carrier boat 20 and the second mold carrier boat 30, wherein the top view of the first mold carrier boat 20 is as follows figure 2 As shown, the top view of the second mold carrier boat 30 is as image 3 As shown, while the cross-sectional view of the first mold carrier boat 20 and the second mold carrier boat 30 along AA' is as Figure 4 shown.

[0045] Such as figure 2 As shown, the first mold carrier boat 20 includes first thin film growth regions 201 and first shielding regions 202 arranged alternately, and the first thin film growth region 201 is a hollowed-out region located between the first shielding regions 202 . Such as image 3 As shown, the second mold carrier boat 30 also includes a second film growth region 301 and a second shielding region 30...

Embodiment 2

[0072] This embodiment provides a back contact solar cell, the back contact solar cell is formed by the manufacturing method described in Embodiment 1, such as Figure 12 As shown, the back contact solar cell includes: a single crystal silicon substrate 1201; a passivation layer 1205 located on the back surface of the single crystal silicon substrate 1201; a first doped amorphous silicon substrate located on the surface of the passivation layer 1205 The silicon finger region 1206 and the first conductive film 1207 on its surface; the second doped amorphous silicon finger region 1206 and the first conductive film 1207 on its surface are arranged crosswise on the surface of the passivation layer 1205 The doped amorphous silicon refers to the region 1208 and the second conductive film 1209 on its surface.

[0073] Wherein, the thickness d of the first doped amorphous silicon finger region 1206 and the second doped amorphous silicon finger region 1208 is 1 3nm to 30nm, including ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com