Portland cement clinker and preparation method thereof

A Portland cement and clinker technology, applied in cement production and other directions, can solve the problems of large stacking volume, occupying large land, polluting the environment, etc., and achieve the effect of saving costs and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

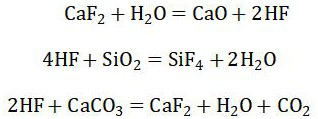

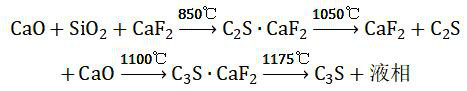

Method used

Image

Examples

Embodiment 1

[0033] A Portland cement clinker, comprising 52% limestone, 26% coal gangue, 12% iron tailings, 7% fly ash, 1.5% fluorogypsum, 1.5% calcium fluoride, prepared according to the following method:

[0034] (1) Break the raw materials separately, and control the particle size of the incoming abrasive to be less than 15mm;

[0035] (2) The raw materials are evenly mixed in proportion, and then ground, and the final particle size greater than 0.08mm does not exceed 10% of the total weight;

[0036] (3) Add the raw materials pulverized in step (2) into a rotary kiln for calcination, the calcination temperature is 1400°C, and the calcination time is 40 minutes;

[0037] (4) Cool the raw materials calcined in step (3) to room temperature to obtain Portland cement clinker.

Embodiment 2

[0039] A Portland cement clinker, comprising 55% limestone, 25% coal gangue, 10% iron tailings, 7.5% fly ash, 1.5% fluorogypsum, 1% calcium fluoride, prepared according to the following method:

[0040] (1) Break the raw materials separately, and control the particle size of the incoming abrasive to be less than 15mm;

[0041] (2) The raw materials are evenly mixed in proportion, and then ground, and the final particle size greater than 0.08mm does not exceed 10% of the total weight;

[0042] (3) Add the raw materials pulverized in step (2) into a rotary kiln for calcination, the calcination temperature is 1400°C, and the calcination time is 45 minutes;

[0043] (4) Cool the raw materials calcined in step (3) to room temperature to obtain Portland cement clinker.

Embodiment 3

[0045] A Portland cement clinker, comprising 58% limestone, 23% coal gangue, 11% iron tailings, 5% fly ash, 1.8% fluorogypsum, 1.2% calcium fluoride, prepared according to the following method:

[0046] (1) Break the raw materials separately, and control the particle size of the incoming abrasive to be less than 15mm;

[0047] (2) The raw materials are evenly mixed in proportion, and then ground, and the final particle size greater than 0.08mm does not exceed 10% of the total weight;

[0048] (3) Add the raw materials pulverized in step (2) into a rotary kiln for calcination, the calcination temperature is 1400°C, and the calcination time is 50 minutes;

[0049] (4) Cool the raw materials calcined in step (3) to room temperature to obtain Portland cement clinker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com