Method for preparing superfine spherical silver powder for barium-titanate-based semiconductor ceramic ohmic electrode slurry

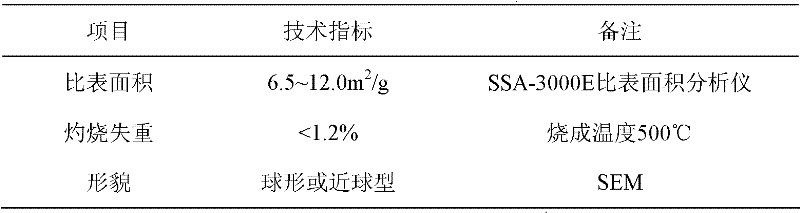

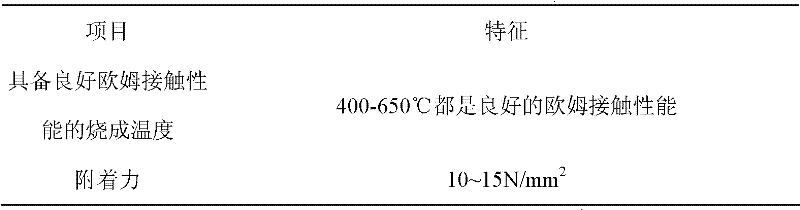

An electrode slurry and semiconductor technology, which is applied in the field of industrialized preparation of ultrafine silver powder for barium titanate-based ceramic ohmic electrode slurry, can solve the problem that the process is complicated and cannot meet the performance requirements of barium titanate-based semiconductor ceramic ohmic electrode slurry , the particle size of ultra-fine silver powder is too large, and the effect of high purity, excellent ohmic contact performance and wide firing temperature range is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A preparation method of ultrafine spherical silver powder for barium titanate-based semiconductor ceramic ohmic electrode slurry

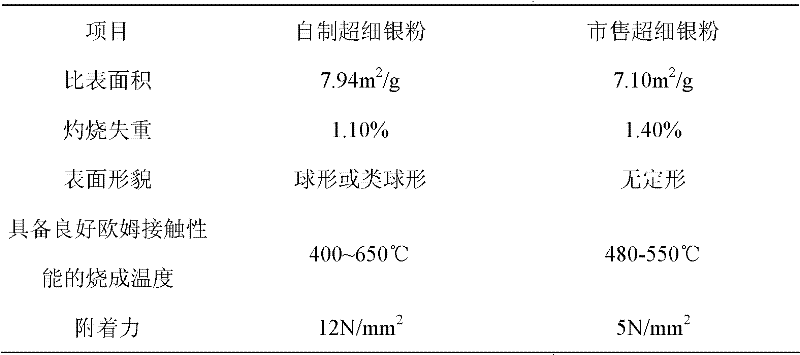

[0026] Weigh 90gAgNO 3 Dissolve in 300ml deionized water, place in a 2000ml beaker with stirring device; add 1.3g polymer resin, and AgNO 3 Solution emulsification; dropwise adding 10wt% Na at room temperature and high rotation speed 2 CO 3 to pH8-12; add 1.2-2.0 times the amount of reducing agent, and carry out the reduction reaction for 1.5 hours. During the reaction, add 20ml of alcohol for defoaming; adjust the stirring speed to 80r / min, keep warm, and form ultra-fine silver powder particle aggregates. The reaction was kept for 2.0 hours; the natural sedimentation method was used to wash the reacted precipitate 6 times according to the volume ratio of powder to deionized water of 1:10, and then dried at 50°C. The ultrafine silver powder with complete sphericity is obtained, the specific surface area is 7.94m2 / g, the dispers...

Embodiment 2

[0029] Example 2: A preparation method of ultrafine spherical silver powder for barium titanate-based semiconductor ceramic ohmic electrode slurry

[0030] Weigh 90gAgNO 3 Dissolve in 300ml deionized water, place in a 2000ml beaker with stirring device; add 1.3g polymer resin, and AgNO 3 Solution emulsification; dropwise adding 10wt% Na at room temperature and high rotation speed 2 CO 3 to pH8-12; add 0.2g polymer surfactant, add 1.2-2.0 times the amount of reducing agent, and carry out the reduction reaction for 1.5h; adjust the stirring speed to 80r / min, keep warm, and form ultra-fine silver powder particle aggregates, react Insulate for 2.0 hours; use the natural sedimentation method to wash the reacted precipitate 6 times according to the volume ratio of powder to deionized water of 1:10, and dry it at 60°C. Obtain ultra-fine silver powder with good sphericity, and the specific surface area is 8.14m 2 / g, good dispersibility, narrow particle size distribution range, pu...

Embodiment 3

[0032] Example 3: A preparation method of ultrafine spherical silver powder for barium titanate-based semiconductor ceramic ohmic electrode slurry

[0033] Weigh 90gAgNO 3 Dissolve in 300ml deionized water, place in a 2000ml beaker with stirring device; add 1.3g polymer resin, and AgNO 3 Solution emulsification; dropwise adding 10wt% Na at room temperature and high rotation speed 2 CO 3to pH8-12; add 1.0g long carbon chain organic reagent, add 1.2-2.0 times the amount of reducing agent, and carry out the reduction reaction for 1.5h; adjust the stirring speed to 80r / min, keep warm, form ultrafine silver powder particle aggregates, and react Insulate for 2.0 hours; use the natural sedimentation method to wash the reacted precipitate 6 times according to the volume ratio of powder to deionized water of 1:10, and dry it at 60°C. Obtain ultra-fine silver powder with good sphericity, and the specific surface area is 7.95m 2 / g, good dispersibility, narrow particle size distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com