Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improved ohmic contact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface treatment method of metal oxide and preparation method of thin film transistor

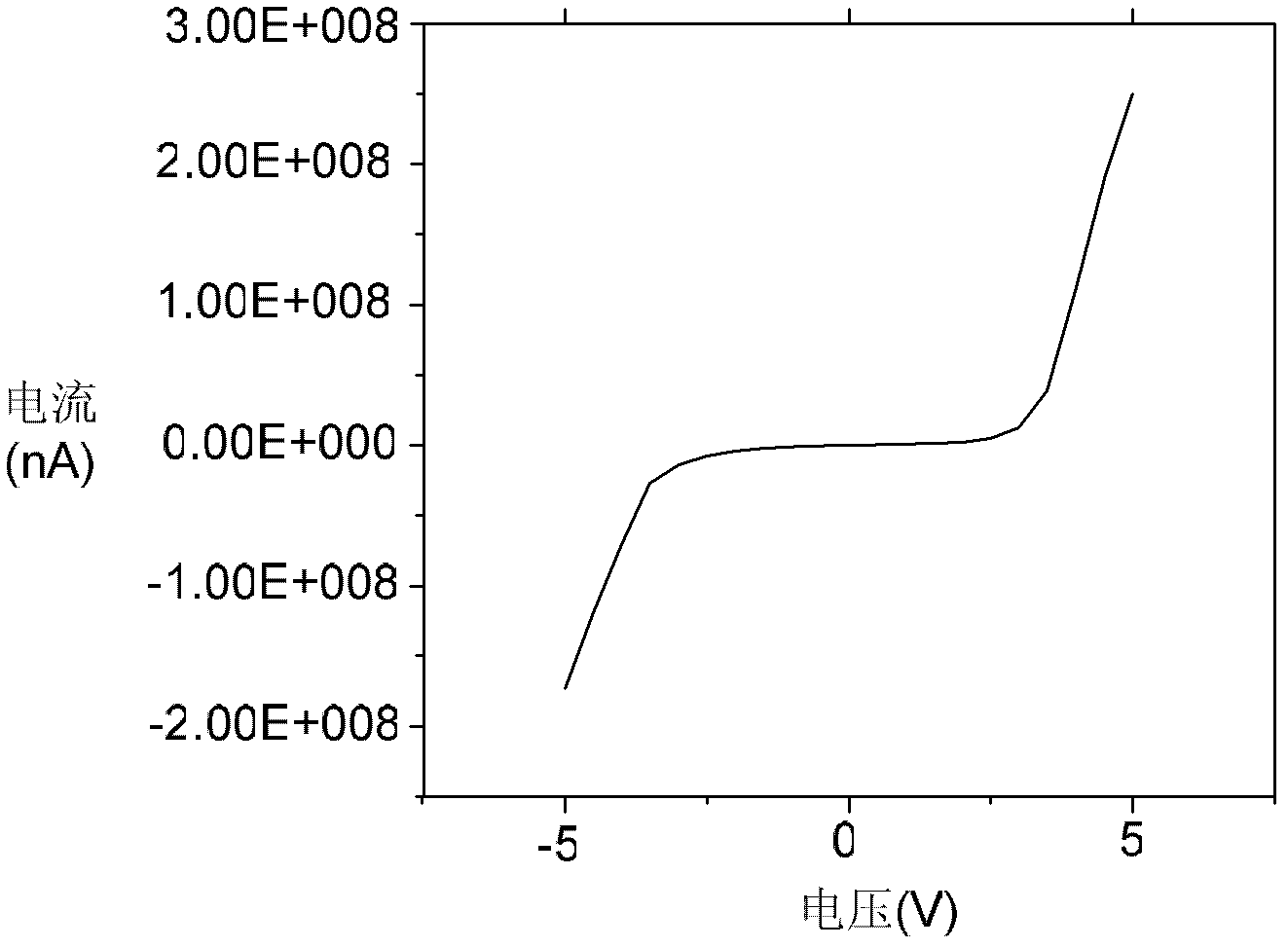

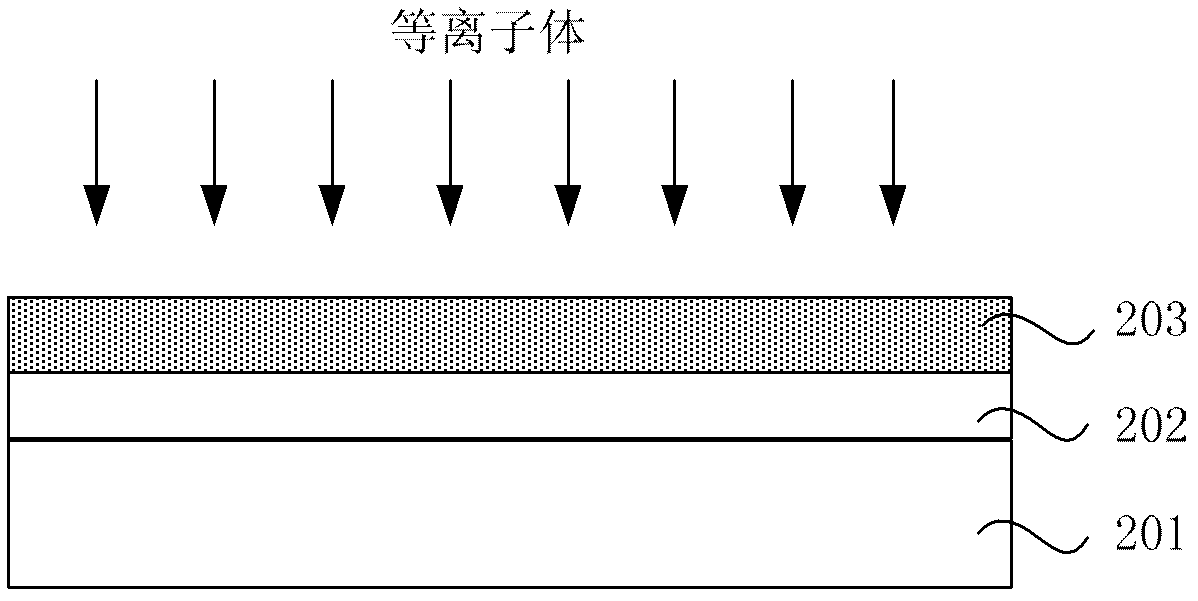

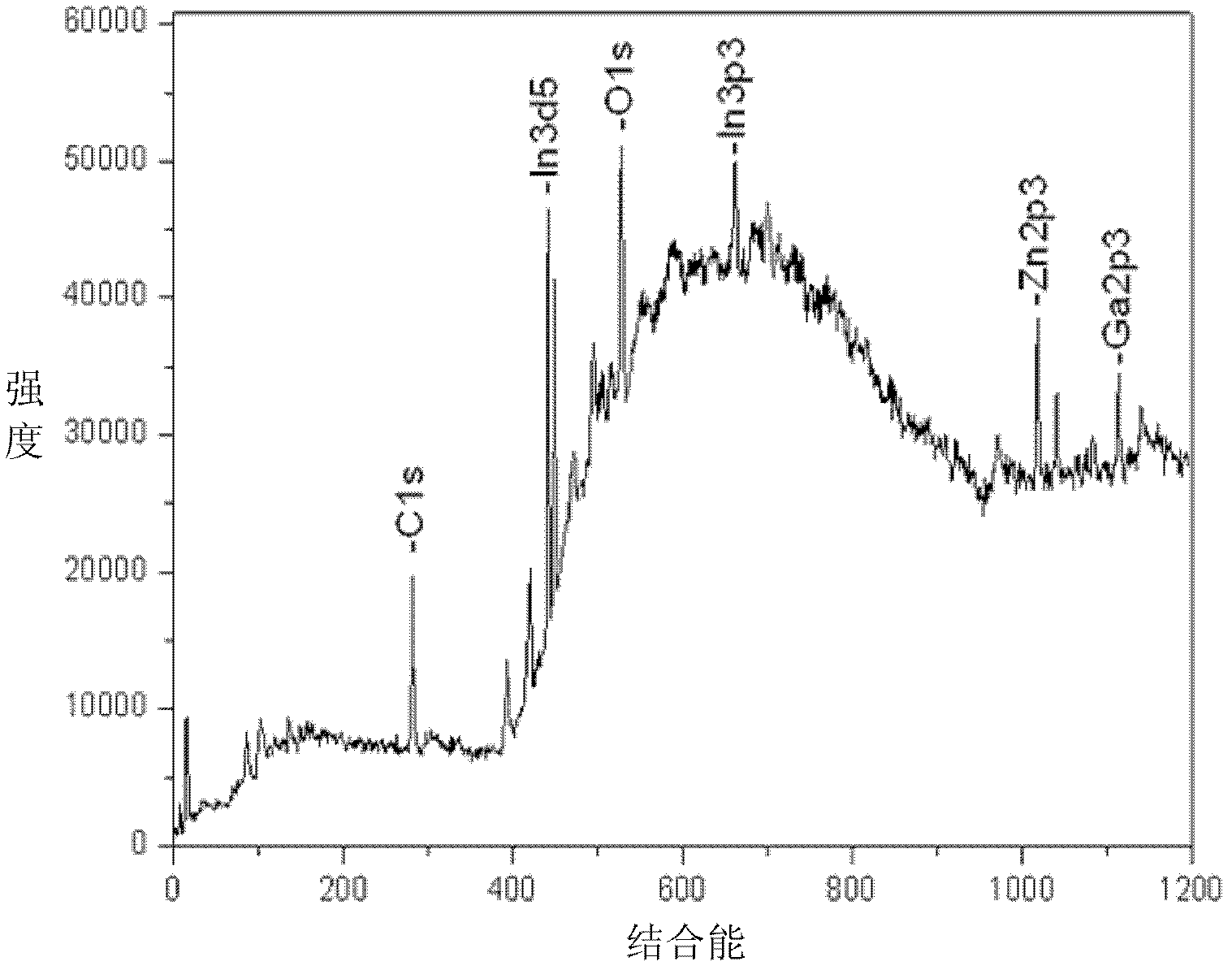

InactiveCN102651317AIncrease concentrationReduce contact resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxygen vacancy

The invention provides a surface treatment method of metal oxide semiconductor and a preparation method of a thin film transistor, wherein the surface treatment method of the metal oxide comprises the following steps that: plasmas are utilized for carrying out surface treatment on a device to be treated; and the plasmas comprise mixed gas of F-base gas and O2, and the device to be treated is a metal oxide semiconductor product or a product plated with the metal oxide semiconductor. In the embodiment provided by the invention, the plasmas obtained by using the mixed gas of F base gas and O2 are used for treating the metal oxide for enhancing the oxygen vacancy concentration in the metal oxide, reducing the contact resistance between the metal oxide and other electrodes and improving the ohm contact effect of the metal oxide.

Owner:BOE TECH GRP CO LTD

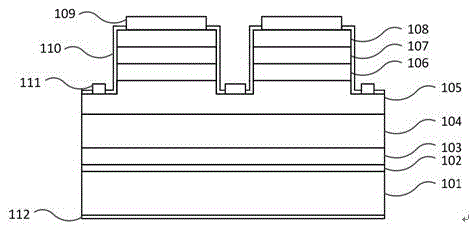

Deep ultraviolet light emitting diode chip with high luminous efficiency and preparation method thereof

InactiveCN105679910AImproved ohmic contact performanceImprove surface light extraction efficiencySemiconductor devicesOhmic contactUltraviolet lights

The invention relates to the technical field of a semiconductor device, in particular to an inverted deep ultraviolet light emitting diode chip with high luminous efficiency and a preparation method of the chip. In the inverted deep ultraviolet light emitting diode chip with high luminous efficiency, provided by the invention, a Ni / Al material with high ultraviolet reflectivity is selected and used as a p-type electrode material, the ohmic contact performance between a metal electrode and p-type GaN can be partially improved, and ultraviolet light also can be reflected to a sapphire surface. According to the preparation method of the inverted deep ultraviolet light emitting diode chip with high luminous efficiency, provided by the invention, a sapphire substrate of an epitaxial wafer is thinned to a specific thickness, an Al thin film with an appropriate thickness is evaporated, and the surface luminous efficiency of the inverted deep ultraviolet light emitting chip is partially improved by coupling of TM-mode ultraviolet light and surface plasmon.

Owner:HUAZHONG UNIV OF SCI & TECH

Leadless ohmic electrode silver coating for PTC ceramic and its preparation method

InactiveCN1870179AReliable bondingExcellent aging resistanceNon-conductive material with dispersed conductive materialResistor manufactureCeramicOhm

A method for preparing silver size pole of lead free ohm electrode used on PTC ceramic includes mixing and grinding silver micro powder, zinc powder and organic carrier together to obtain silver size pole material then firing obtained material at temperature of 480-580deg.c to let electrode layer attached on surface of ceramic body tightly for forming excellent ohm contact property.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

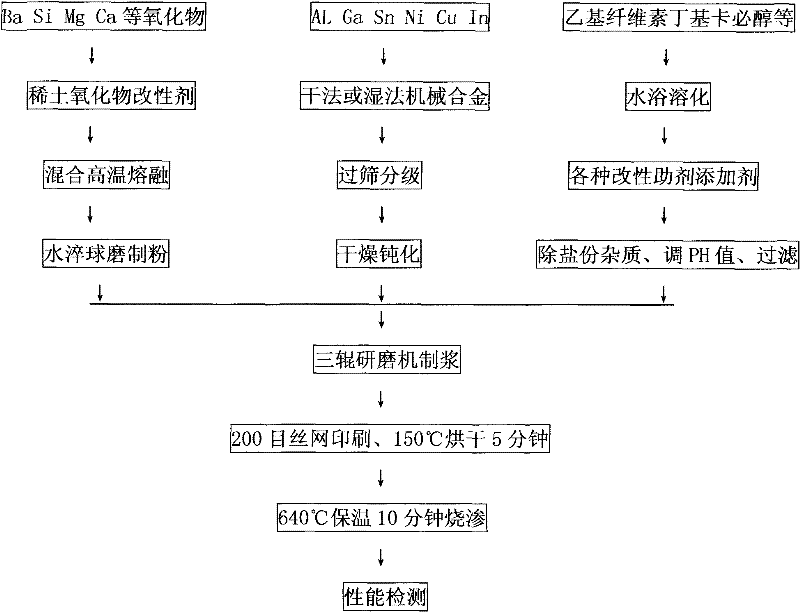

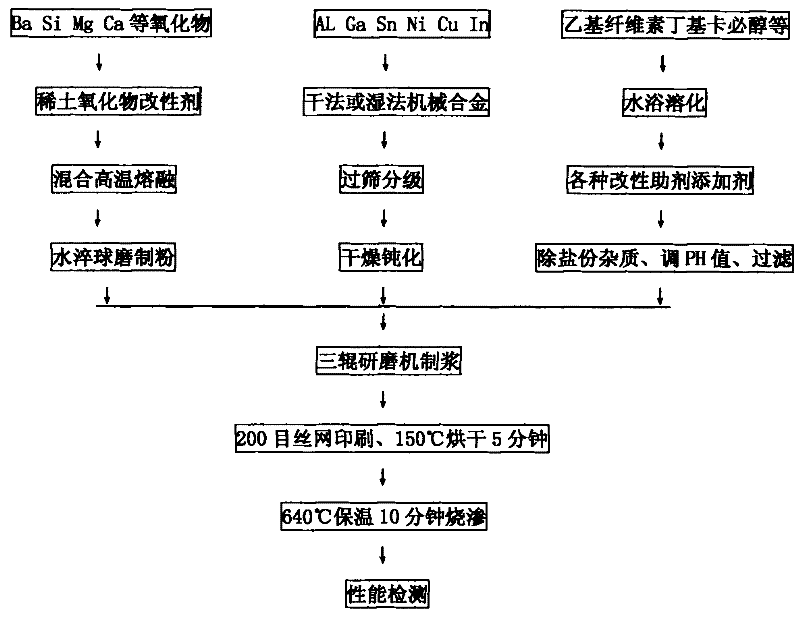

Environmental friendly lead-free aluminum slurry and preparation method thereof

InactiveCN101840744AAchieve stabilityAchieving printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureHazardous substanceFerrosilicon

The invention relates to an environmental friendly lead-free aluminum slurry and a preparation method thereof. The environmental friendly lead-free aluminum slurry comprises the following components: antioxidant ultrafine aluminum alloy micropowder, barium ferrosilicon borate composite frit and a composite organic carrier. The invention has the advantages that the prepared lead-free aluminum slurry is an environmental friendly electronic slurry without harmful substances including lead, cadmium, mercury and hexavalent chromium, is used as a function material, completely replaces lead containing aluminum slurry, is stable and reliable, and has excellent performance, favorable ohmic contact quality, wide sintering temperature range, low sheet resistance, water boiling resistance, long ageing life and favorable replaceability to noble metals.

Owner:WUHAN YILAI RUIER HIGH TECH

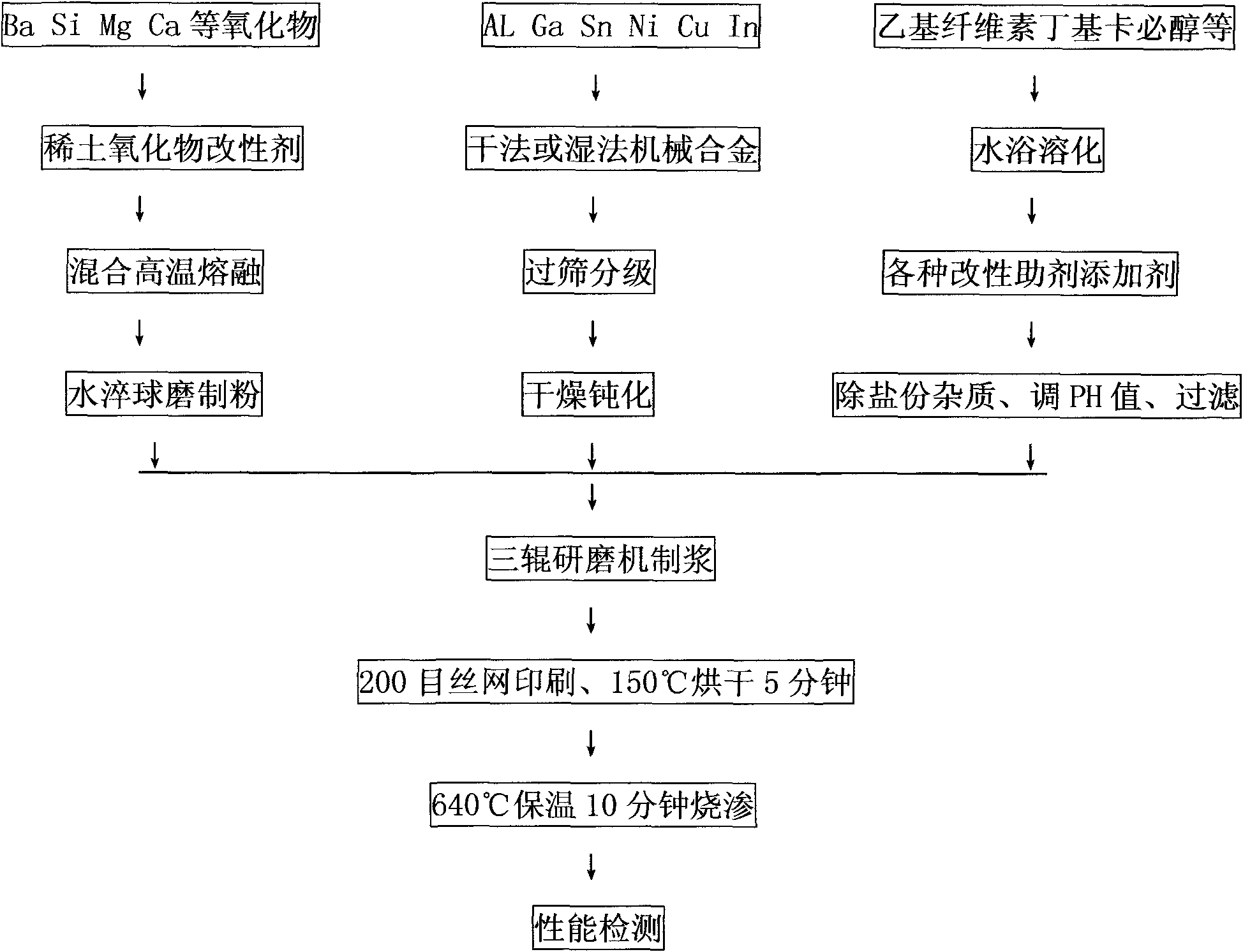

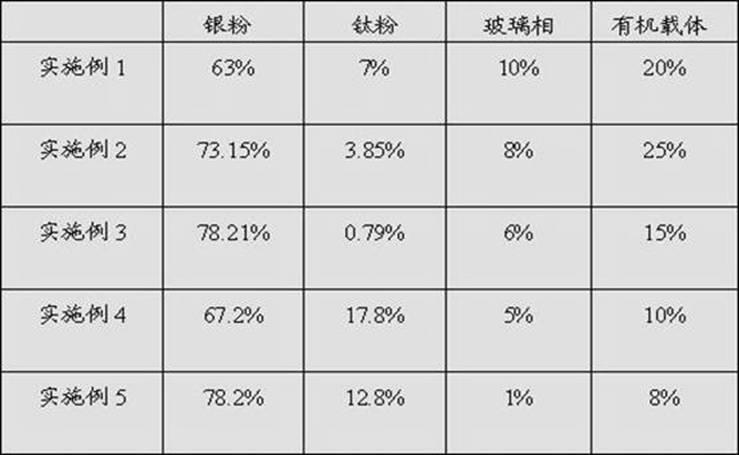

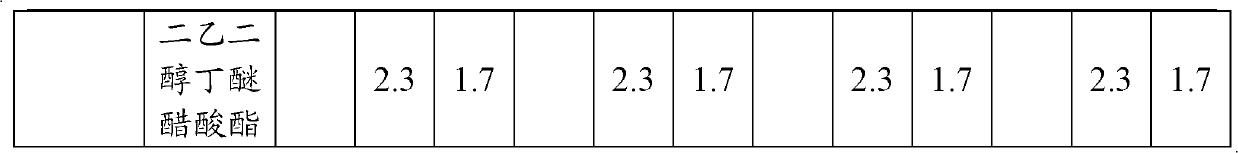

Conductive paste for front electrode of silicon crystal solar battery

InactiveCN102637467ALow costIncrease contactNon-conductive material with dispersed conductive materialSemiconductor devicesSodium stearateAcrylic resin

The invention discloses a conductive paste for a front electrode of a silicon crystal solar battery. The conductive paste is composed of the following materials in percentage by weight: 70%-92% of conductive phase, 1%-10% of glass phase and 5%-25% of organic phase; the conductive phase is composed of 80-99% of silver powder and 1-20% of titanium powder; the organic carrier is composed of the following constituents in parts by weight: 0.2-1 part of thickening agent, 6-9.2 parts of solvent, 0.1-1 part of thixotropic agent, 0.05-0.5 part of surface active agent, 0.3-2 parts of plasticizing agent and 0.05-0.2 parts of coupling agent; the thickening agent is at least one of ethyl cellulose, hydroxyethylcellulose, rosin, acrylic ester and phenolic resin; the thixotropic agent comprises at least one of acrylic resin, hydrogenated castor oil and polyethylene wax; and the surface active agent generally is at least one of lecithin, sorbitan tristearate, zinc stearate, sodium stearate and dodecanol ester. The conductive paste disclosed by the invention can be used for not only maintaining the existing technical performance, but also greatly reducing the cost of the conductive paste, thereby improving the competitive power of the silicon crystal solar battery.

Owner:SEMITEL ELECTRONICS

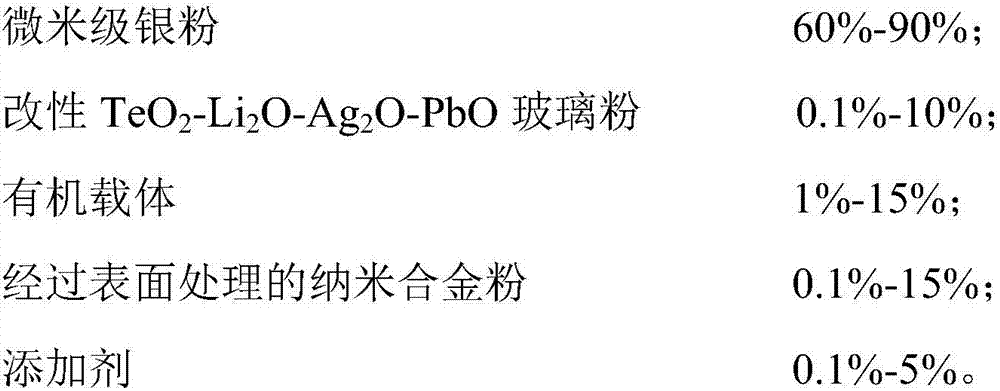

Silicon solar energy cell right side conductive silver slurry and preparation method thereof

ActiveCN107274963AIncrease the area of actionRapid responseNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver plateAlloy

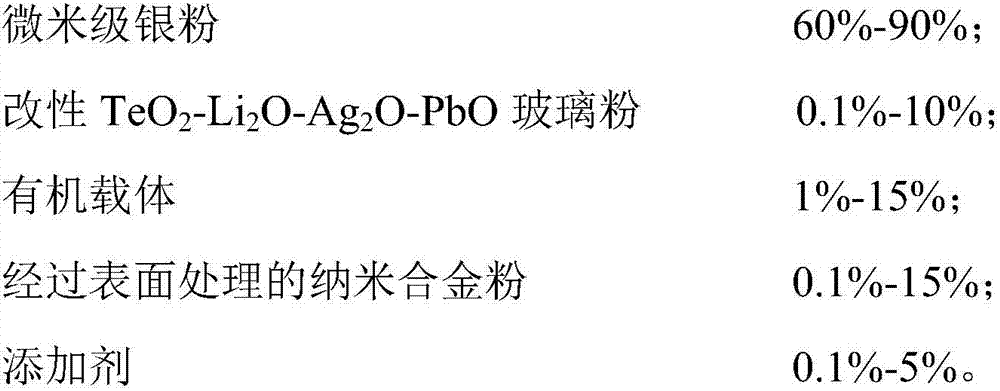

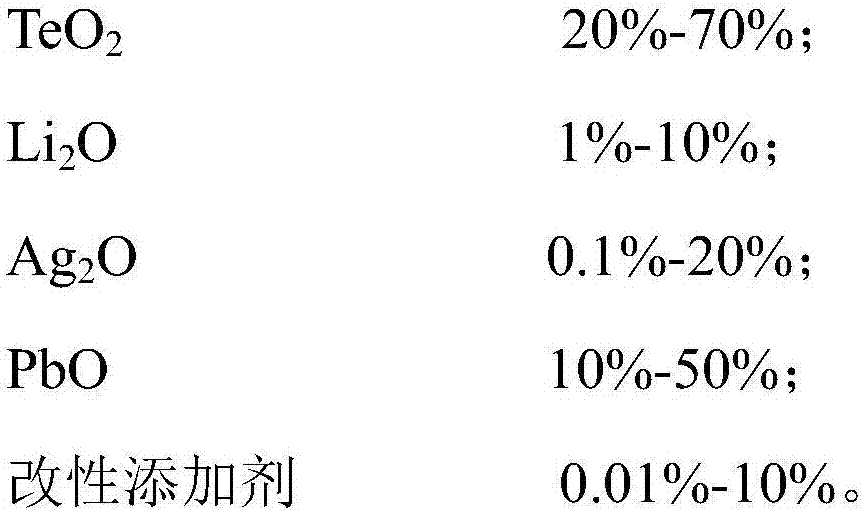

The invention provides a silicon solar energy cell right side conductive silver slurry. The silicon solar energy cell right side conductive silver slurry comprises silver powder, glass powder, an organic carrier, nanometer alloy powder after surface treatment and an additive, wherein the silver powder is micron-level silver powder, the glass powder is modified TeO2-Li2O-Ag2O-PbO glass powder, the nanometer alloy powder after surface treatment is Ag-Pb-Bi-Si alloy powder of which the surface is wrapped in an organic matter, the additive is alkali metal salt treated through silver plating on the surface, if total weight of the silicon solar energy cell right side conductive silver slurry is taken as 100%, weight percents of components of the silicon solar energy cell right side conductive silver slurry are as follows, micron-level silver 60-90%, the modified TeO2-Li2O-Ag2O-PbO glass powder 0.1-10%, the organic matter 1-15%, the nanometer alloy powder after surface treatment 0.1-15% and the additive 0.1-5%.

Owner:深圳磐汩新能源有限公司

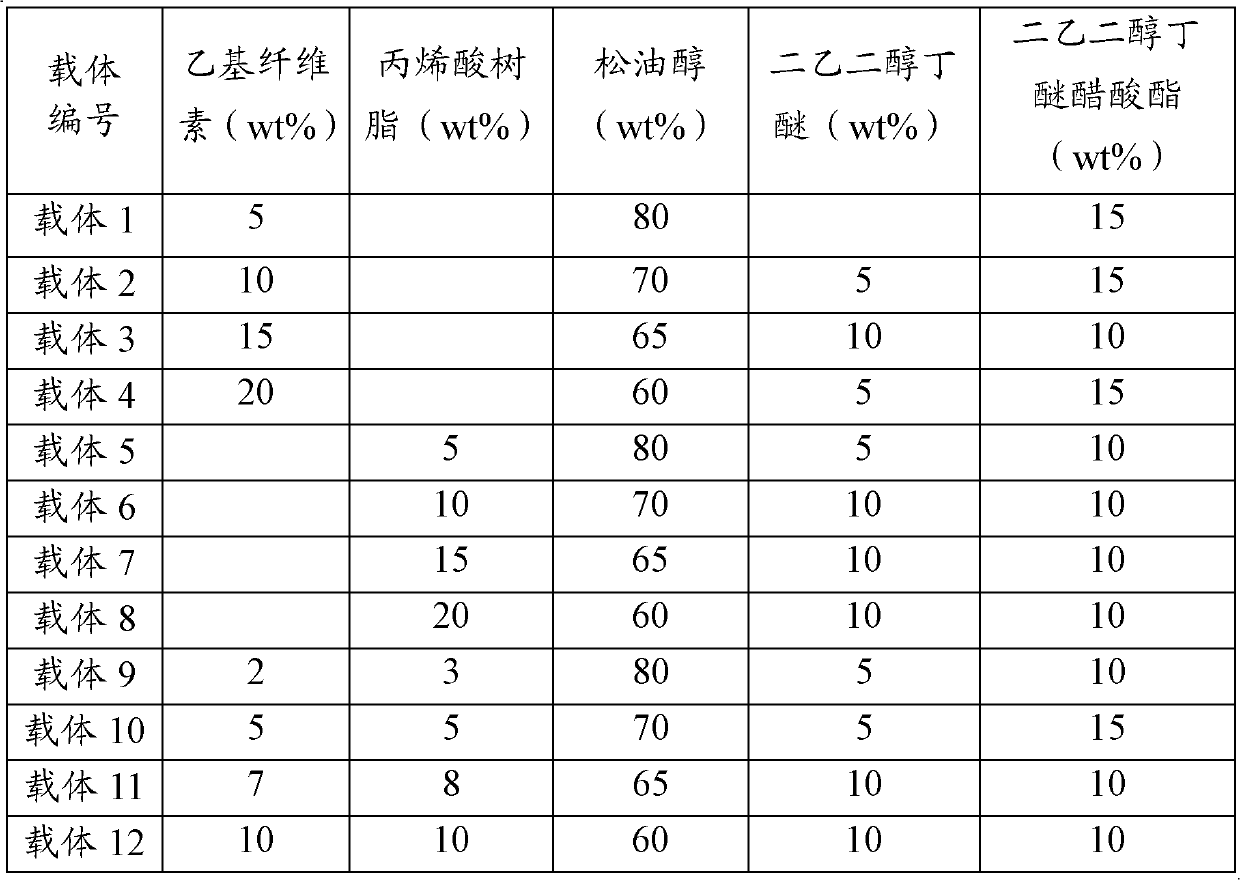

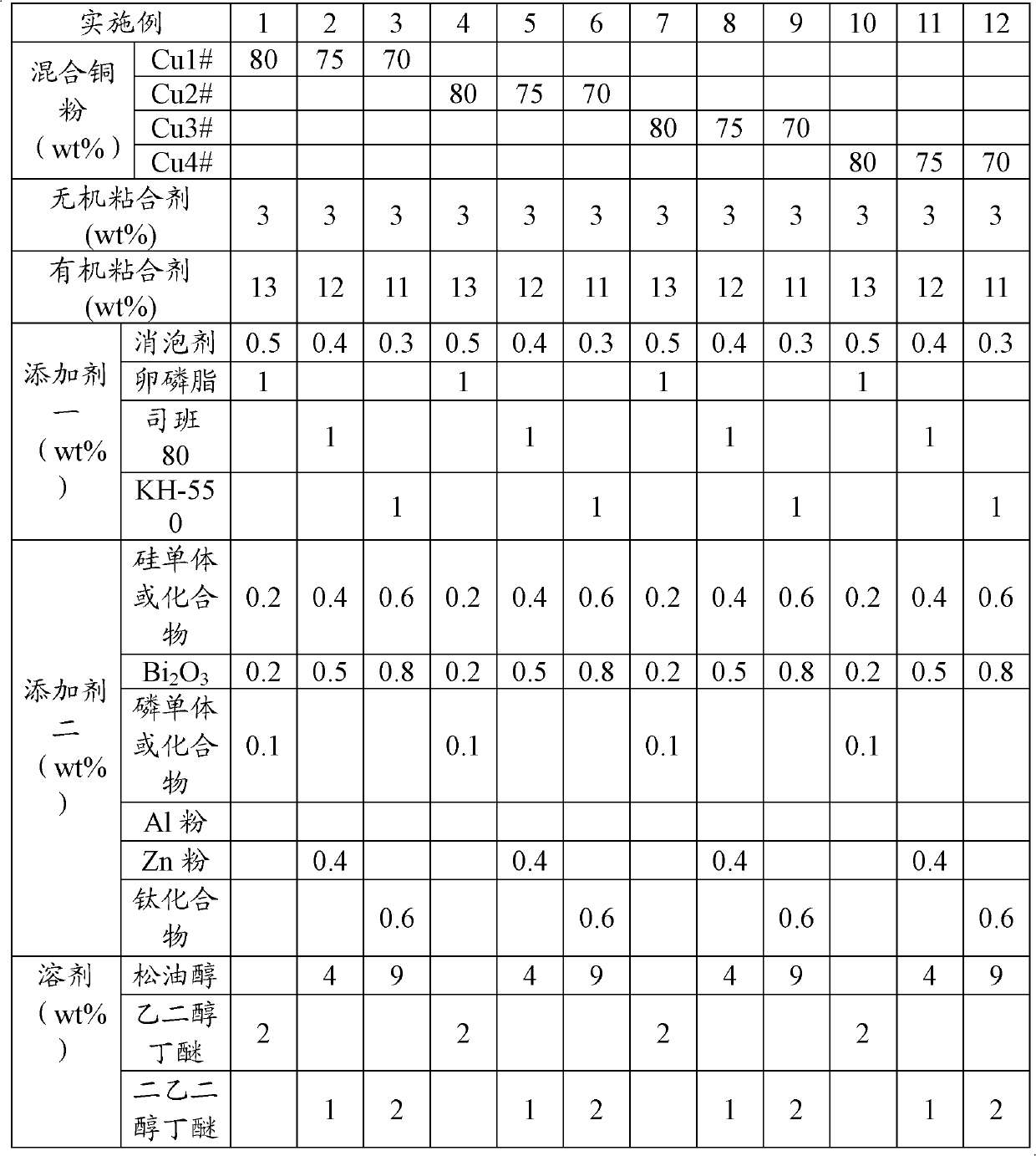

Lead-free copper slurry applied to silicon solar battery electrode and preparation method thereof

InactiveCN103310870AWide variety of sourcesLow priceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellSlurry

The present invention provides lead-free copper slurry applied to a silicon solar battery electrode and a preparation method thereof. The lead-free copper slurry is prepared from, by mass, 60% to 85% of mixed copper powder, 1% to 10% of inorganic binder, 10% to 30% of organic binder, 1% to 30% of mixed additive and 5% to 20% of organic solvent. The mixed copper powder comprises copper powder A whose particle diameter distribution is 0.5 to 2 microns, copper powder B whose particle size distribution is 1 to 3 microns and copper powder C whose particle diameter distribution is 4 to 7 microns, wherein the mass ratio of the three kinds of copper powder is 5 to 8:1 to 4:1. The mixed additive is composed of a first additive and a second additive. The first additive is the mixture of one or more than two of a defoaming agent, a silane coupling agent KH-550 and lecithin or span. The second additive is one or more of elements or compounds of transition family or III, IV and V family elements. Ratio restriction on the additive amount of the first additive and the second additive does not exist, and adding is carried out according to the actual situation. The lead-free copper slurry has the advantages of low cost and excellent conductivity, weldability and ohmic contact property, and can be used as universal electrode slurry of electrodes on front and back of a solar battery.

Owner:SHENZHEN SENLONT ELECTRONICS

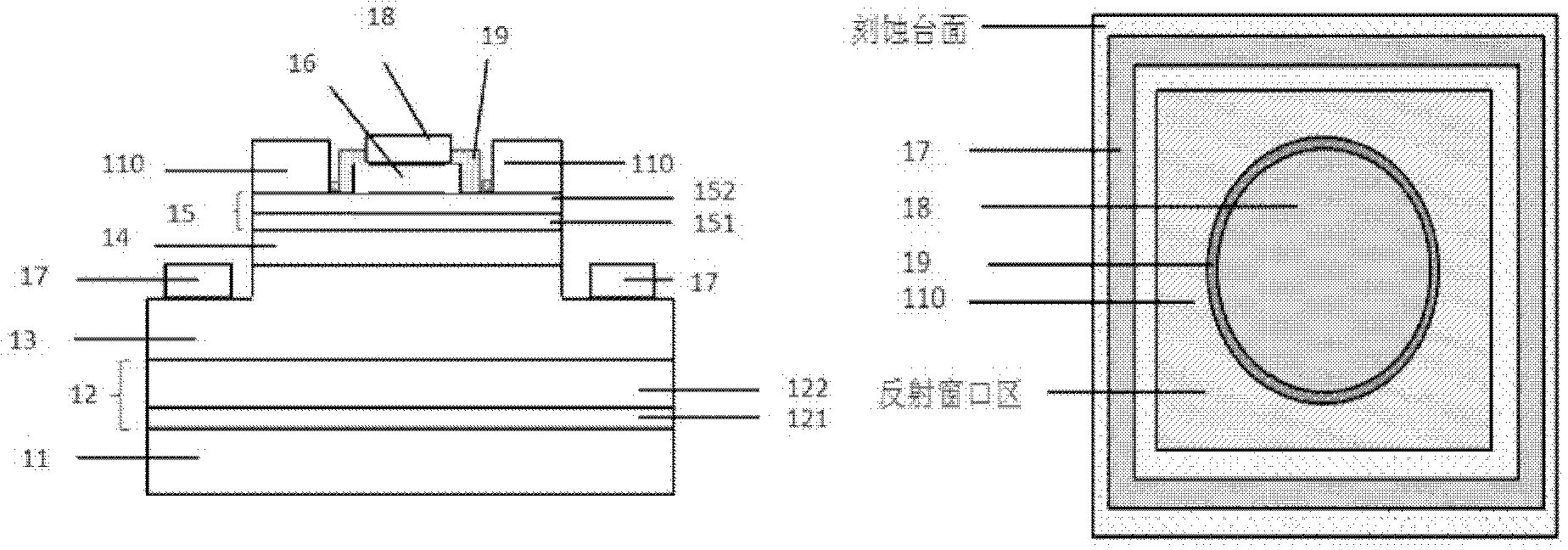

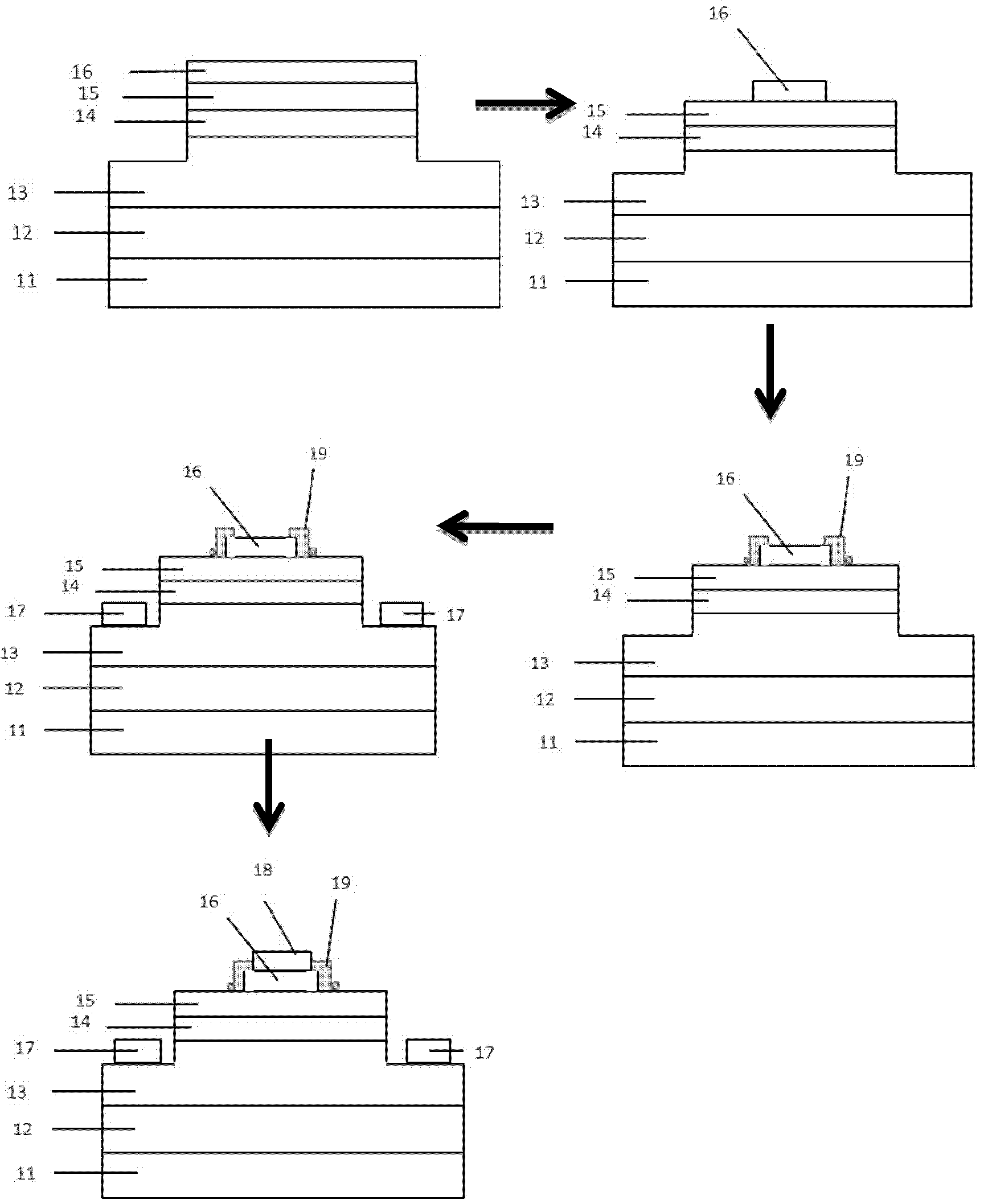

Ultraviolet light-emitting diode with high reflection film and manufacturing method of ultraviolet light-emitting diode

InactiveCN103165775AImprove light extraction efficiencyGood electrical propertiesSemiconductor devicesUltraviolet lightsUltraviolet light emitting diodes

The invention discloses an AlGaN-based ultraviolet light-emitting diode device with a high reflection film structure and a manufacturing method of the ultraviolet light-emitting diode, relates to the technical field of micro-electronics, and mainly solves the problem of low luminous efficiency of a back light-emitting structure of an ultraviolet light-emitting diode. The device sequentially comprises a substrate, an AlN nucleating layer, an n-type AlGaN potential barrier layer, an active area, a p-type AlGaN potential barrier layer and a p-type GaN cap layer, and a high reflection film is manufactured on the p-type AlGaN potential barrier layer and used for emitting light from the bottom of the device after reflecting the light. The light absorbed by the p-type GaN cap layer in the ultraviolet light-emitting diode is emitted from the bottom of the ultraviolet light-emitting diode, so that the power and the efficiency of the emergent light are greatly improved. The device is simple in process, fine in repeatability and high in reliability, and can be used for the field of air / water purification, medical treatment, biomedicine, white-light illumination, space communication and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

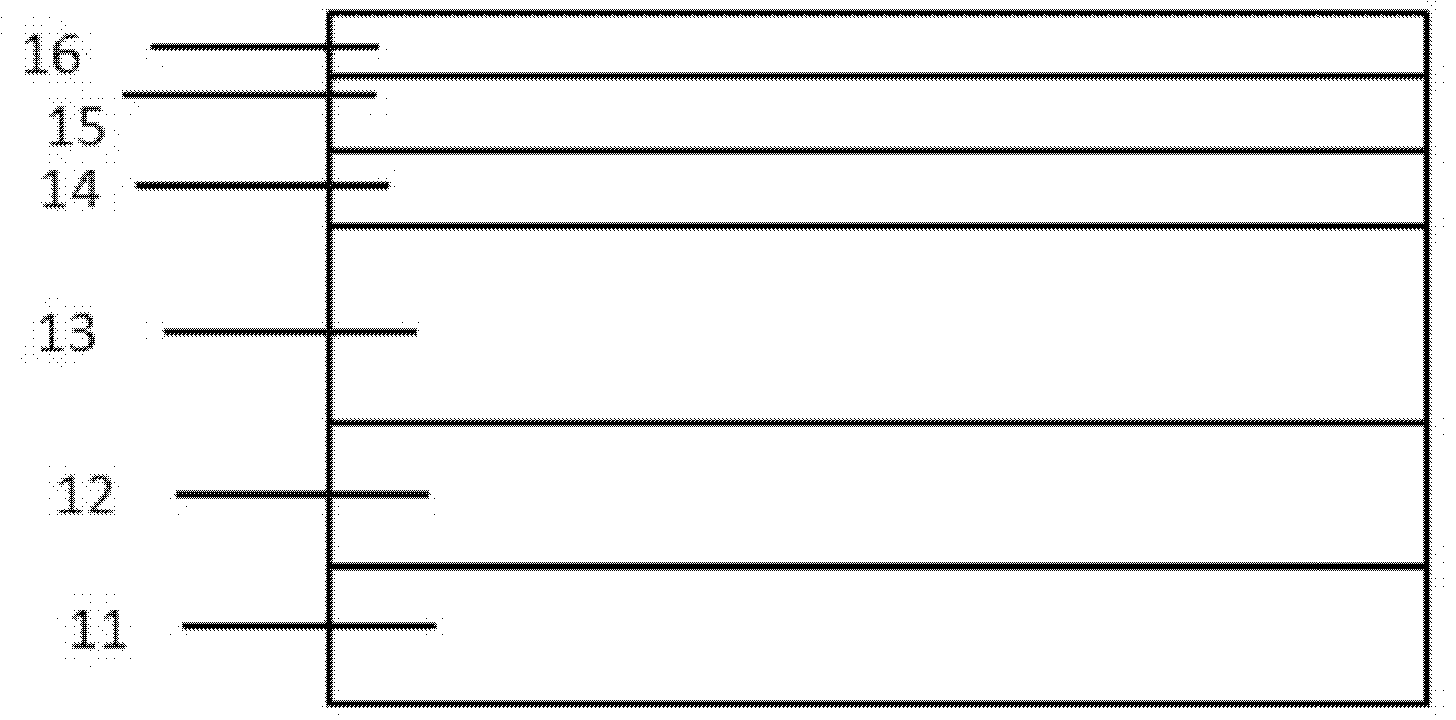

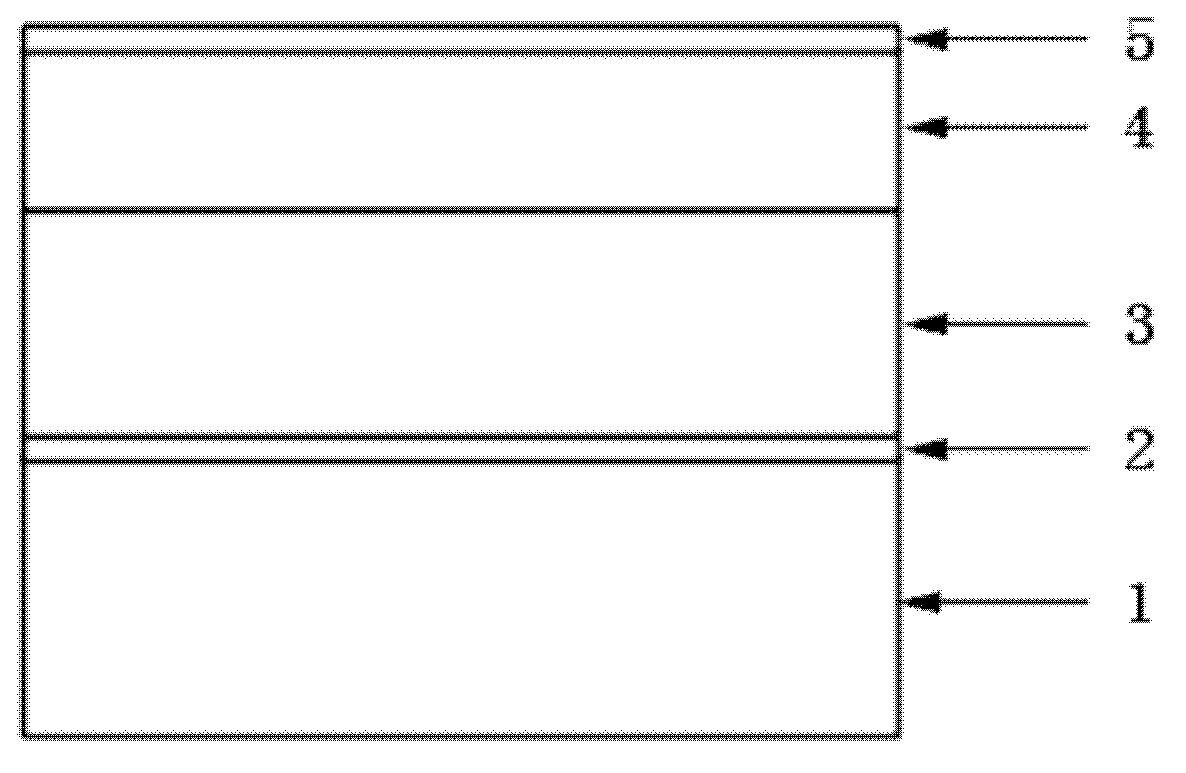

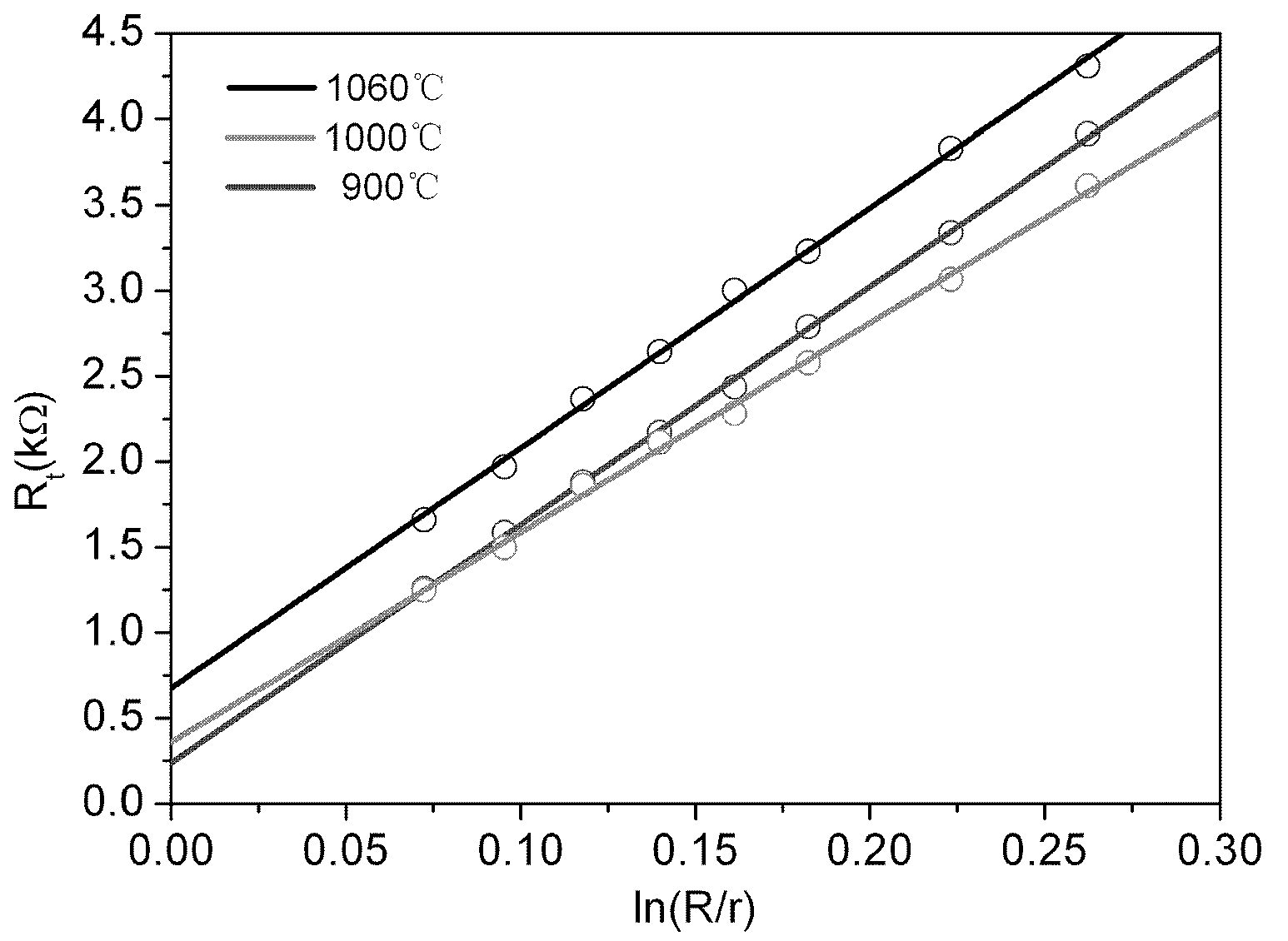

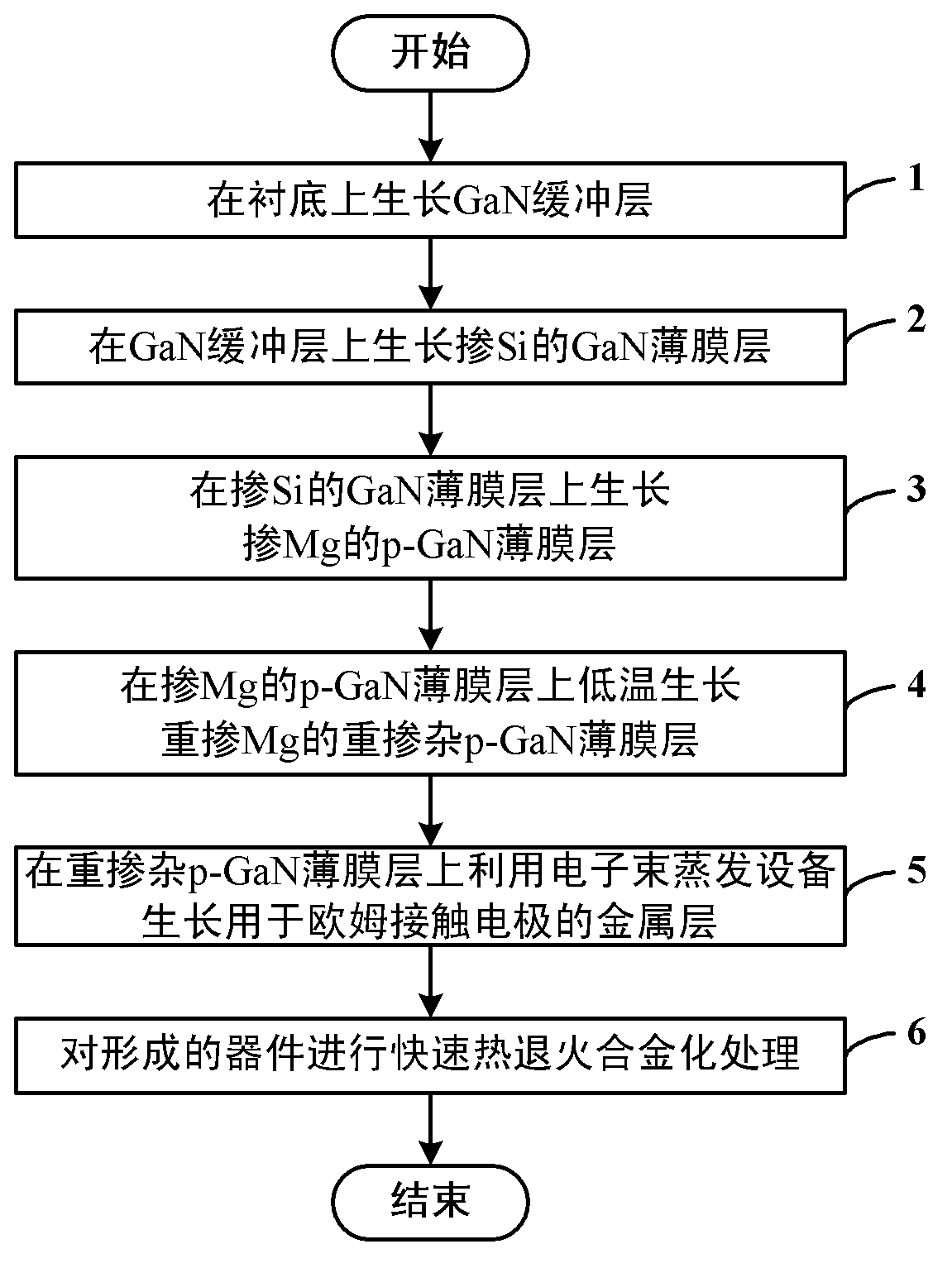

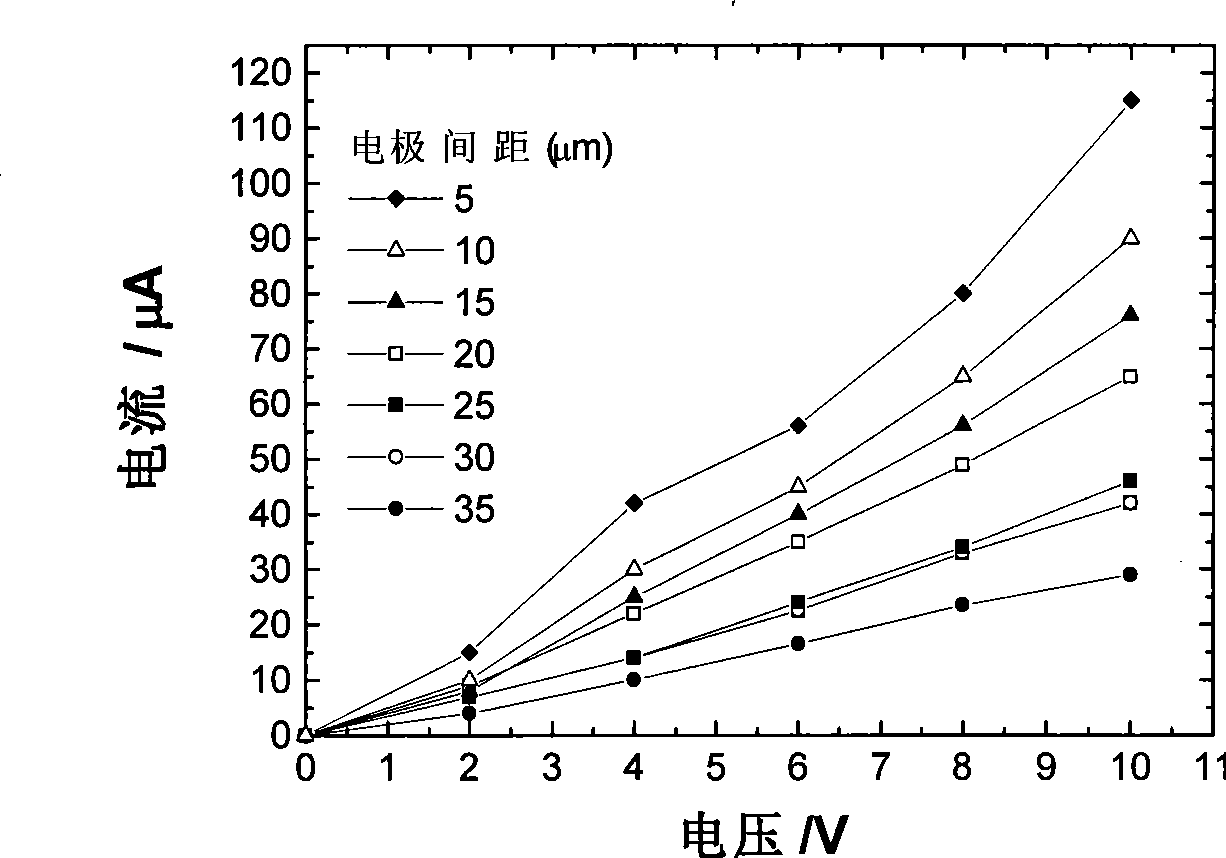

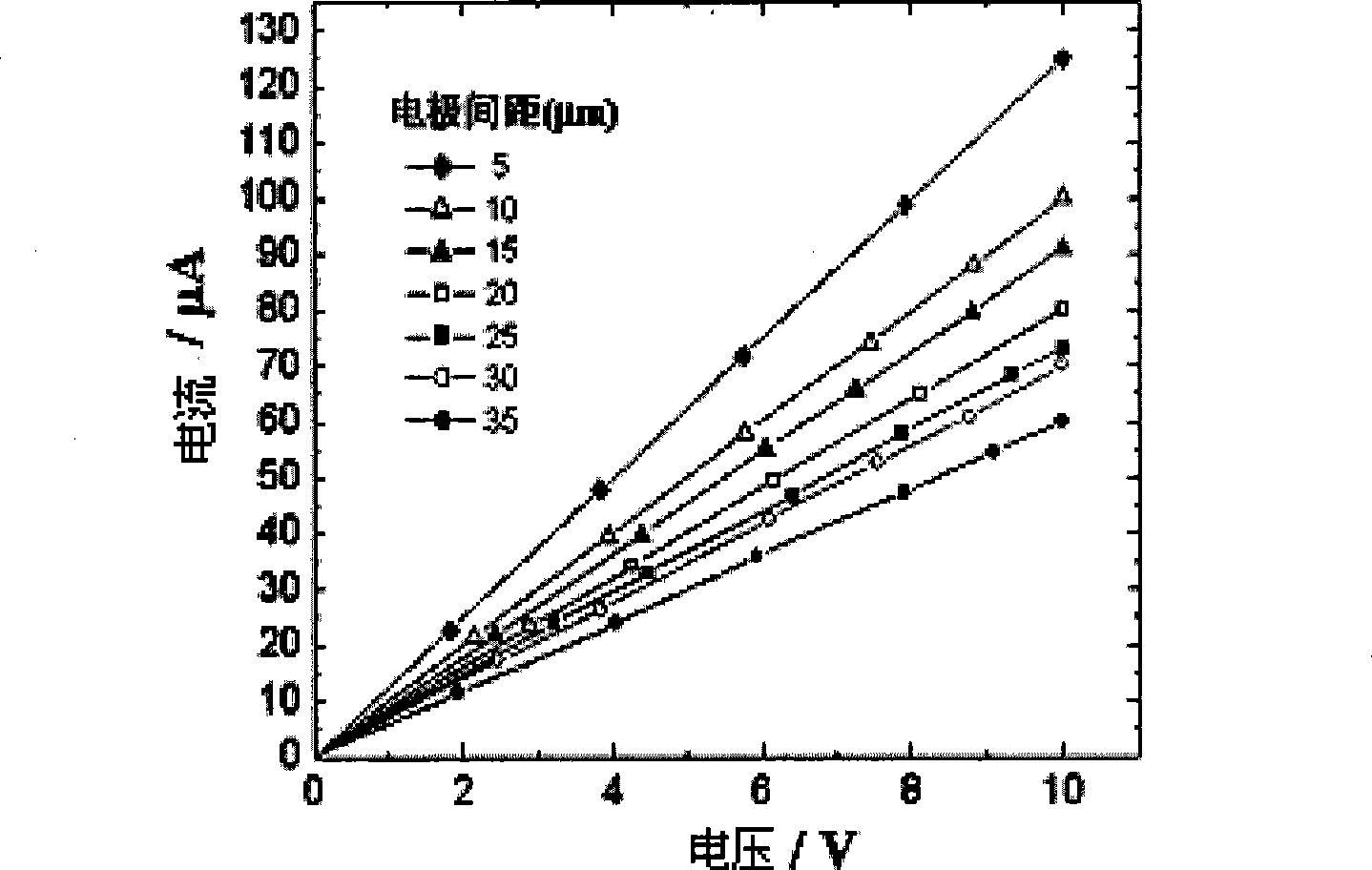

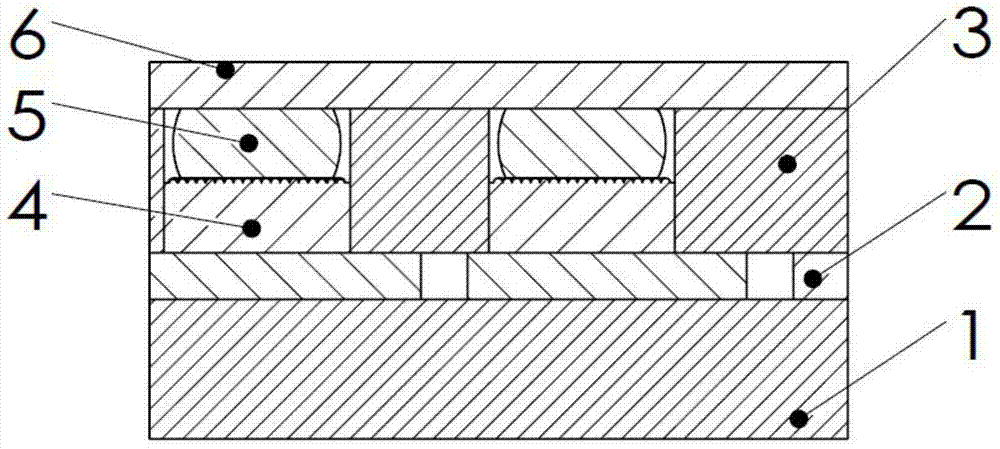

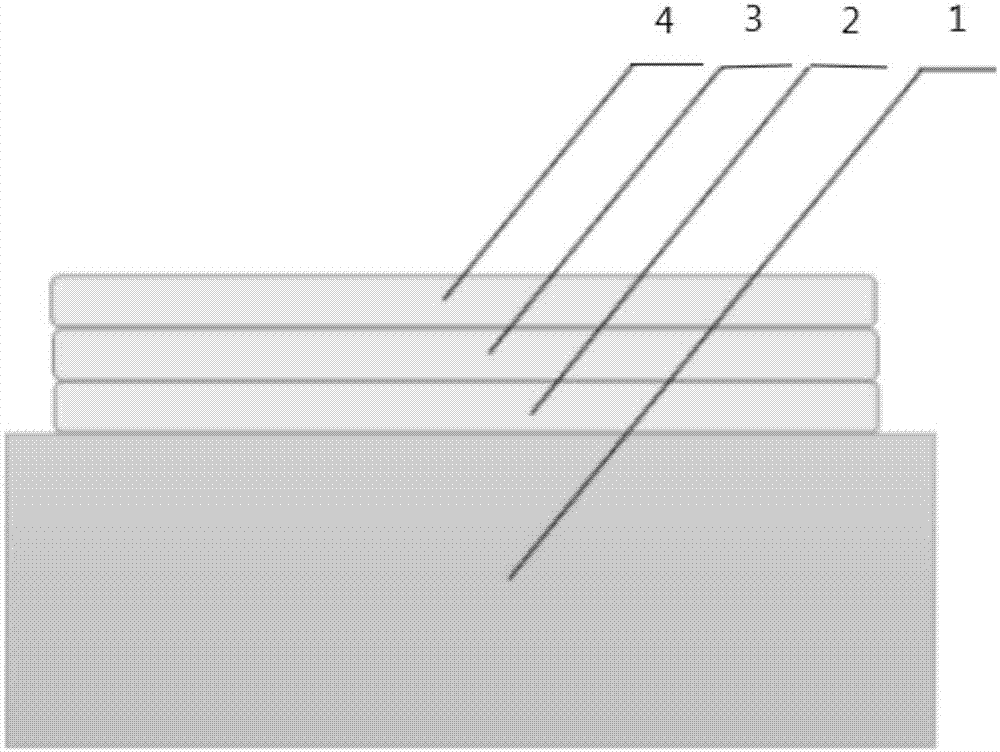

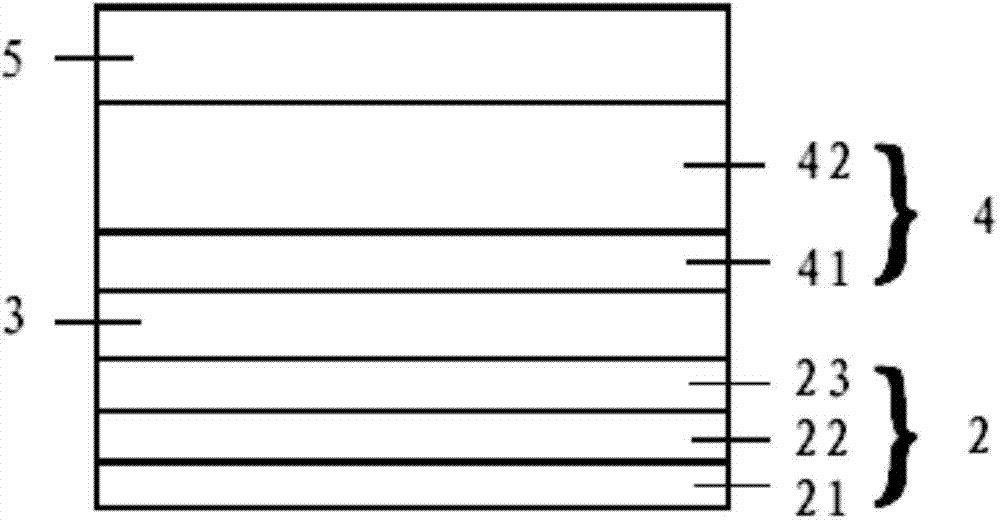

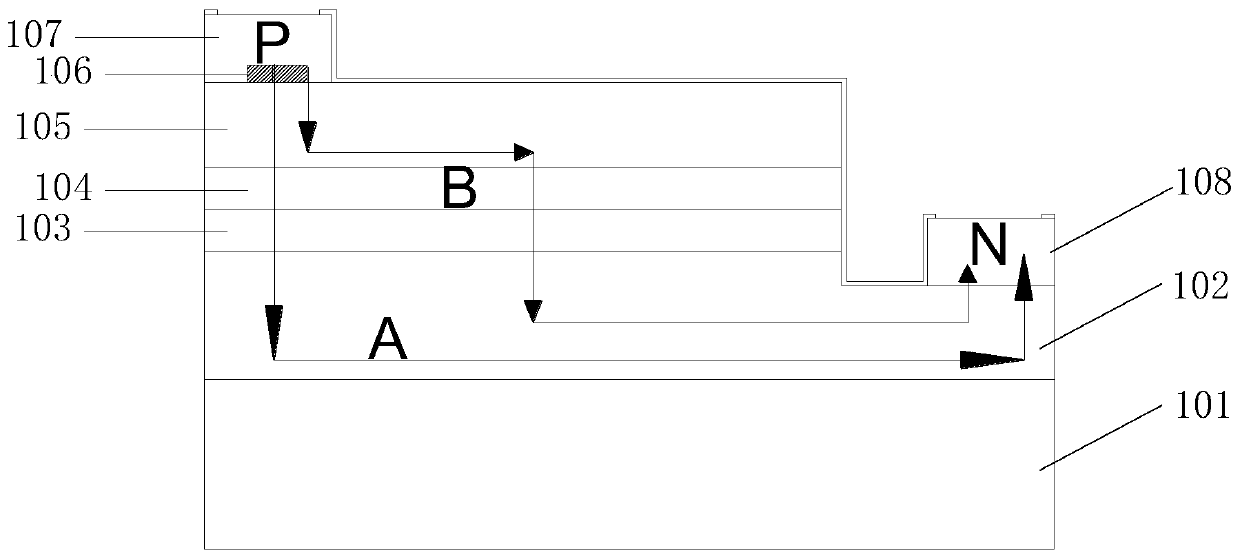

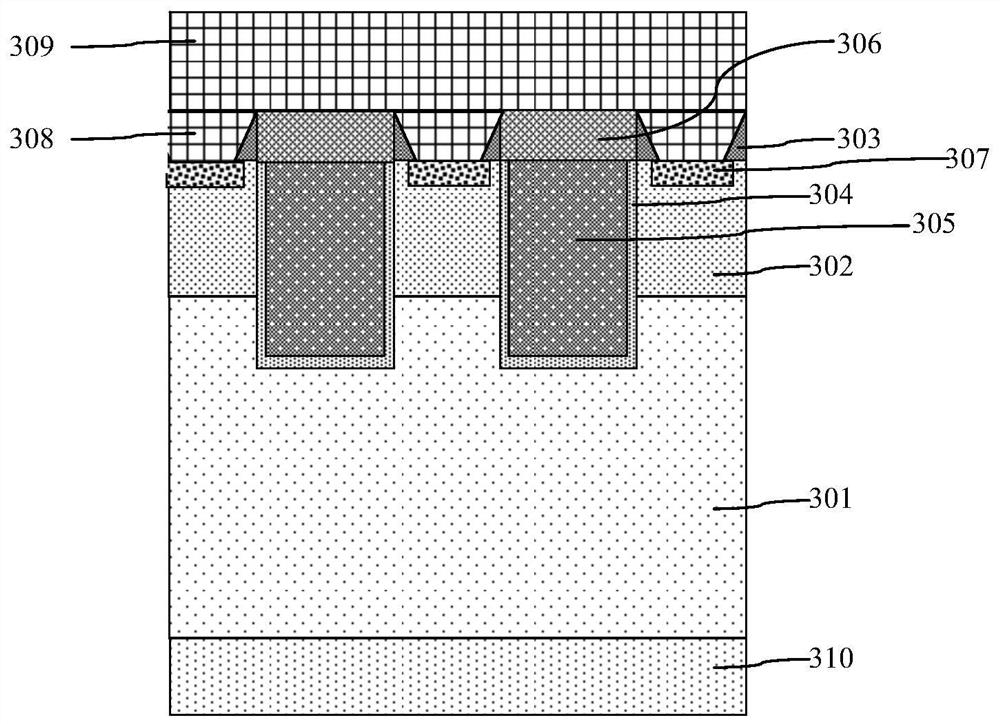

Material structure for improving ohmic contact of p-GaN film and preparation method thereof

InactiveCN103077964AImproved ohmic contact performanceLower specific contact resistivitySemiconductor devicesOptoelectronicsOhmic contact

The invention discloses a material structure for improving the ohmic contact of a p-GaN film and a preparation method thereof, wherein the material structure comprises a substrate (1), a buffer layer (2), an n-GaN film layer (3), a p-GaN film layer (4) and a heavily-doped p-GaN film layer (5), wherein the buffer layer (2) grows on the substrate (1); the n-GaN film layer (3) grows on the buffer layer (2); the p-GaN film layer (4) grows on the n-GaN film layer (3); and the heavily-doped p-GaN film layer (5) grows on the p-GaN film layer (4). According to the invention, the thin heavily-doped p-GaN layer with a large number of defects is inserted between the p-GaN film and a metal, and the heavily-doped p-GaN layer is enabled to have a large number of defect-energy levels by the methods of low-temperature growth or ion injection and the like, so that the transportation of current carriers can be finished through variable-range hopping or defect-energy level assistance, and furthermore, the specific contact resistivity of the p-GaN film and the contacted metal can be decreased, and the ohmic-contact performance of the p-GaN film is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

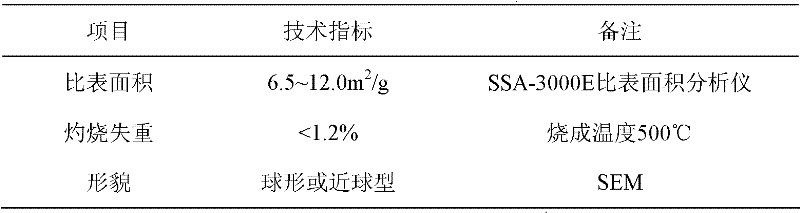

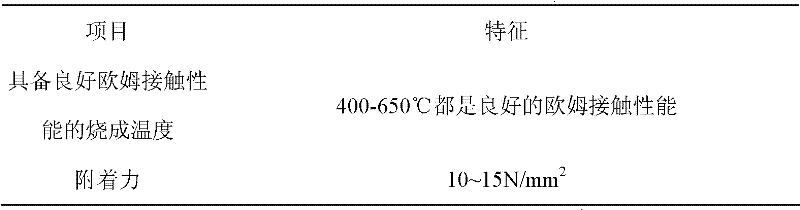

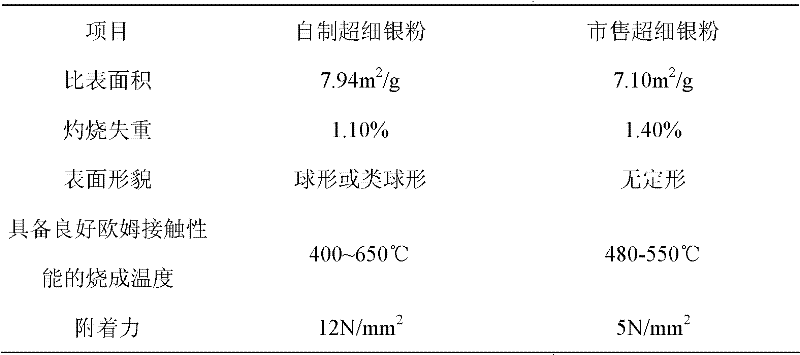

Method for preparing superfine spherical silver powder for barium-titanate-based semiconductor ceramic ohmic electrode slurry

The invention discloses a method for preparing superfine spherical silver powder for barium-titanate-based semiconductor ceramic ohmic electrode slurry, which comprises the following steps of: preparing silver nitrate solution, adding a polymer dispersant with high-speed stirring, and regulating the pH value of the silver nitrate solution to be between 8 and 12; and adding another polymer dispersant, a reducing agent and an antifoaming agent in turn, washing by using deionized water, and drying to obtain a finished product. By skillfully utilizing the change of high and low stirring rotating speeds and adding stirring heat preservation, superfine silver powder particle aggregate with an organic surface is formed, and the settling speed of the silver powder is greatly increased; an organicreagent with a dispersion function, and a polymer surfactant are selected as the antifoaming agent, so that the dispersion function and an antifoaming function are enhanced simultaneously; suitable polymer dispersants, reducing agent, antifoaming agent and alcohol are selected, so that the superfine silver powder with high purity and complete sphericity is prepared, and the barium-titanate-based semiconductor ceramic ohmic electrode slurry prepared from the superfine silver powder has high adhesion and ohmic contact performance and a wide firing temperature range; and the preparation method is nontoxic, low in cost and environment-friendly.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

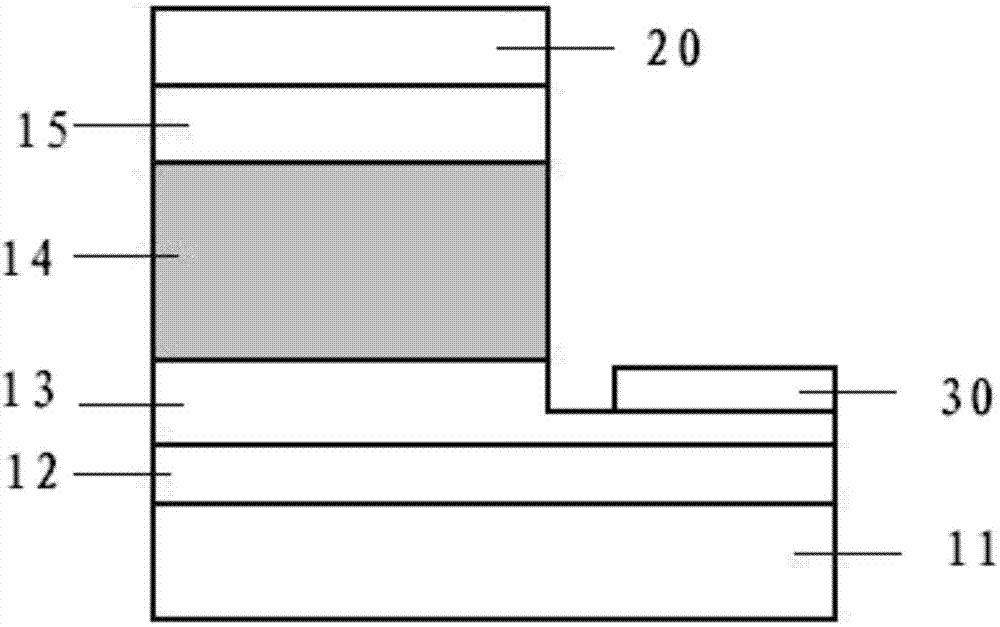

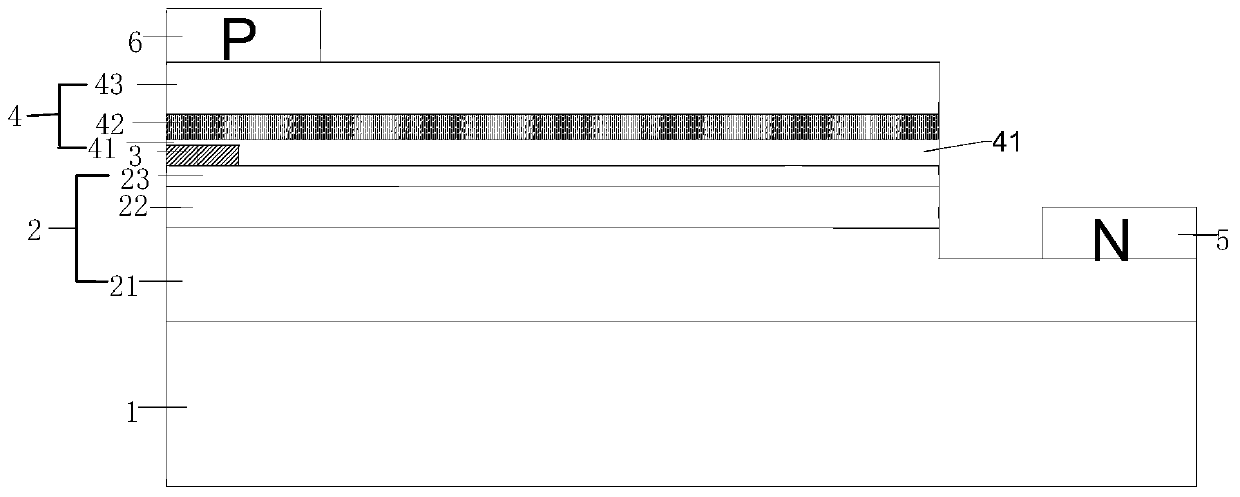

Ultraviolet light-emitting diode chip with reflection ohmic contact electrode

InactiveCN102709429AImprove electrical performanceGood electrical propertiesSemiconductor devicesQuantum wellOhmic contact

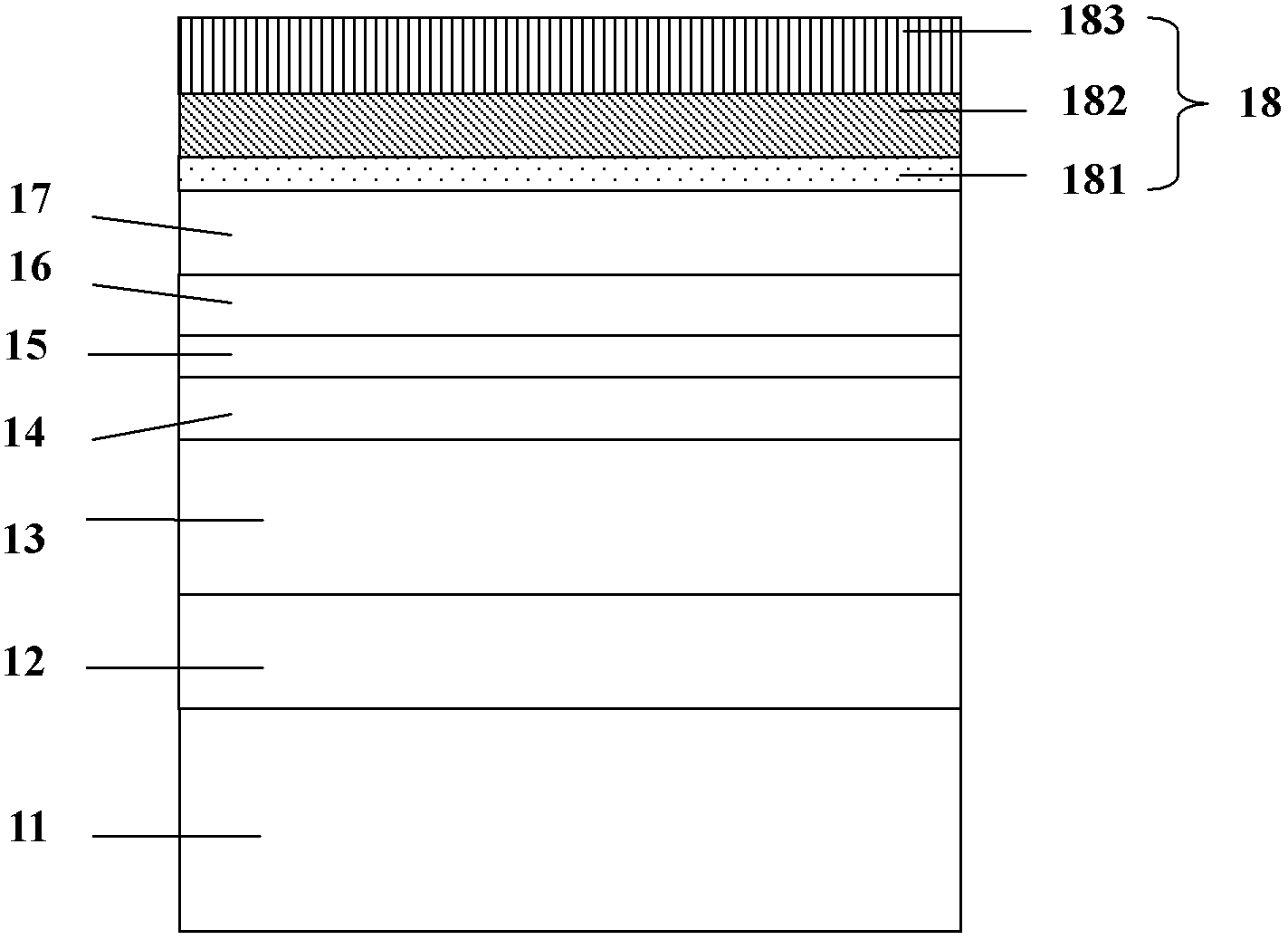

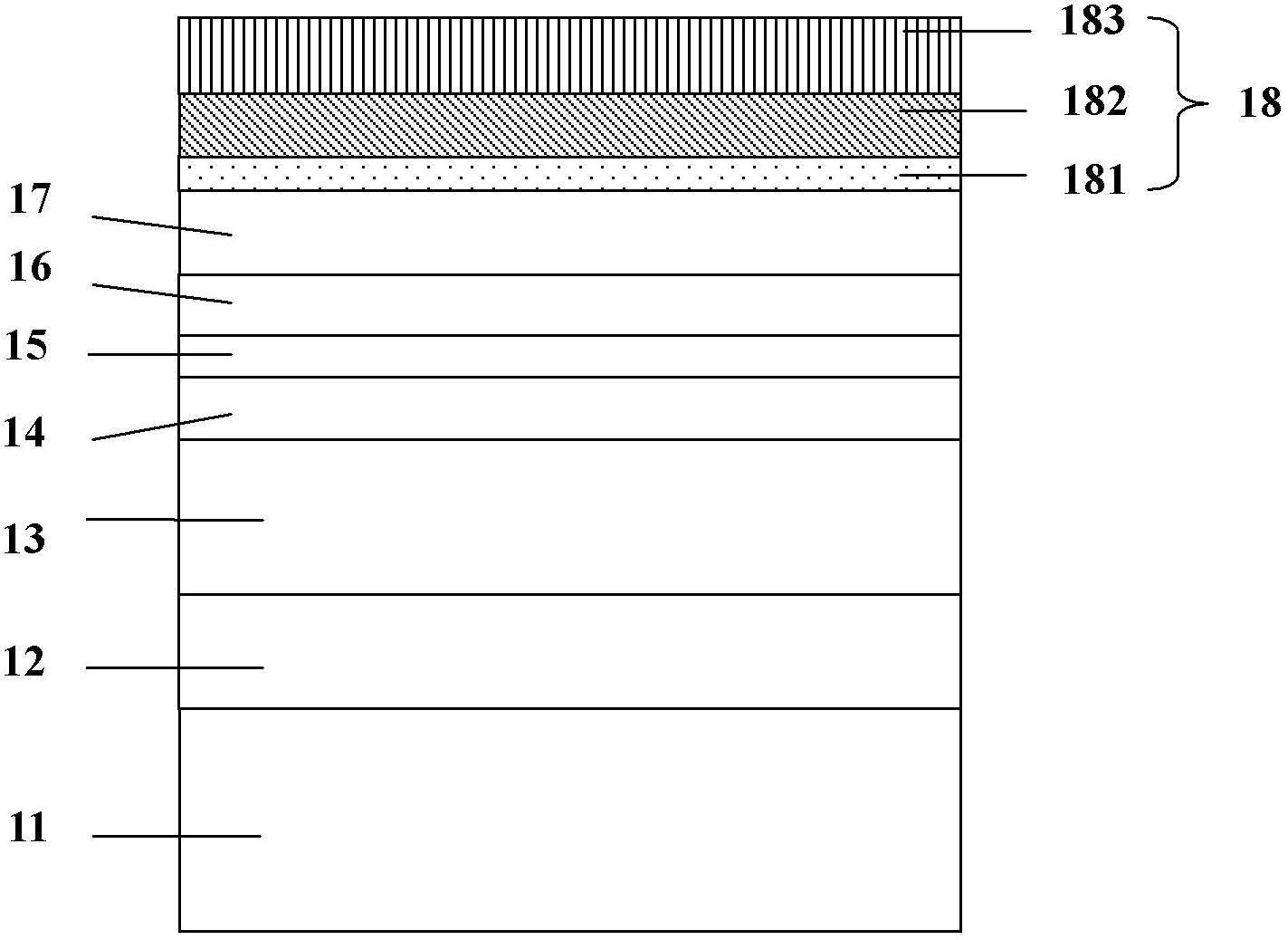

The invention relates to an ultraviolet light-emitting diode chip with a reflection ohmic contact electrode. The ultraviolet light-emitting diode chip comprises a substrate, an AlN template layer, an N-type AlGaN layer, a multiquantum-well active region, an electronic barrier layer, a P-type transition layer, a P-type contact layer and the reflection ohmic contact electrode, wherein the AlN template layer grows on the substrate; the N-type AlGaN layer grows on the AlN template layer; the multiquantum-well active region grows on the N-type AlGaN layer; the electronic barrier layer grows on the multiquantum-well active region; the P-type transition layer grows on the electronic barrier layer; the P-type contact layer grows on the P-type transition layer; and the reflection ohmic contact electrode is made on the P-type contact layer. An ultraviolet light-emitting diode prepared from the chip has the light emitting wavelength range of 200nm to 365nm. The chip has high ultraviolet reflectivity, so that the light extraction efficiency of the ultraviolet light-emitting diode is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

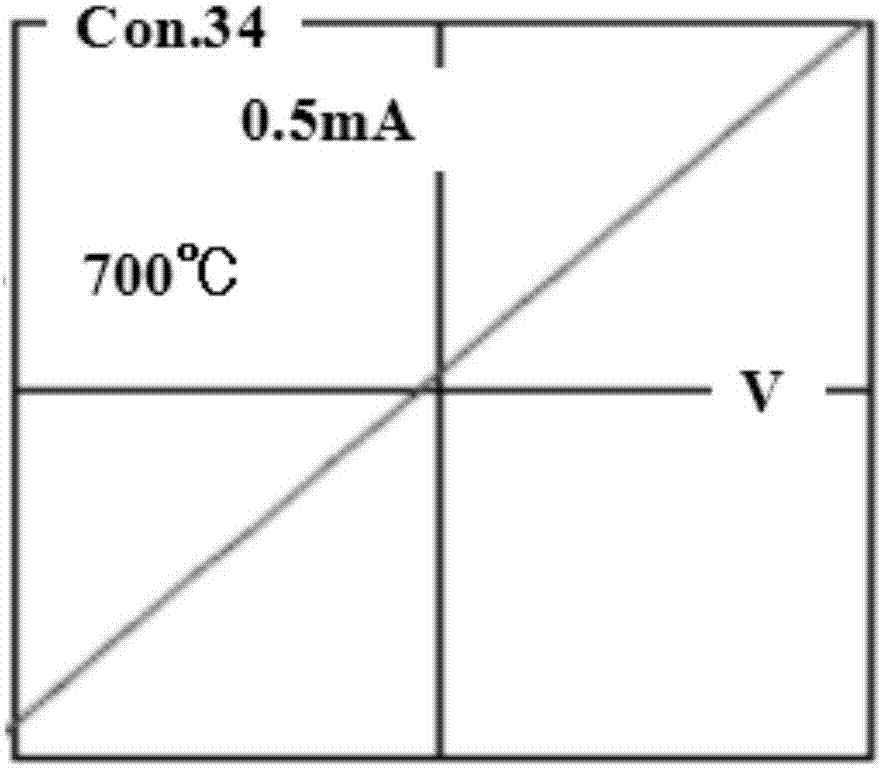

P type silicon carbide device and preparation thereof

InactiveCN101369600AImproved ohmic contact performanceSemiconductor devicesNanoparticleOhmic contact

The invention discloses a P-type silicon carbide apparatus and a manufacturing method thereof. The P-type silicon carbide apparatus comprises a silicon carbide layer and an aluminum electrode layer; a gold nano-particle layer is arranged between the silicon carbide layer and the aluminum electrode layer. The manufacturing method comprises: firstly, depositing the gold nano-particle layer on the silicon carbide layer by using a sputtering method, and carrying out annealing treatment, wherein, the depositing thickness is 100 nanometers, the temperature of the annealing treatment is 450 to 710 DEG C, the annealing time is 8 to 10 minutes, and the protective gas is nitrogen; and then, manufacturing the aluminum electrode layer on the gold nano-particle layer. The manufactured P-type silicon carbide apparatus has better ohmic contact performance.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Circuit device used for back contact solar module and preparation method

ActiveCN104851926AImprove conductivityReduce usageFinal product manufacturePhotovoltaic energy generationMetal foilAdhesive

The invention discloses a method for preparing a circuit device used for a back contact solar module. The method includes the steps of: manufacturing a perforated insulating adhesive film 3; gluing a copper foil, an aluminum foil or another metal foil with excellent conductivity to the perforated insulating adhesive film 3; machining in a position in a hole of the perforated insulating adhesive film 3 to generate an electrode cluster point, wherein the thickness of the electrode cluster point 4 does not exceed that of the perforated insulating adhesive film 3, and the electrode cluster point 4 is electrically connected with positive and negative poles of a silicon wafer of the solar module through a conductive silver adhesive; machining the metal foil to generate a circuit; and gluing a solar module back plate on the other side of the metal foil. The invention also provides a product produced by the abovementioned method. The method and the product provided by the invention improve ohmic contact performance of a back contact solar cell flexible circuit device, remarkably saves the usage amount of the conductive silver adhesive, and can improve a conductive effect and machining efficiency and reduce machining cost of the circuit device used for the back contact solar module.

Owner:上海翌晶储能科技有限公司

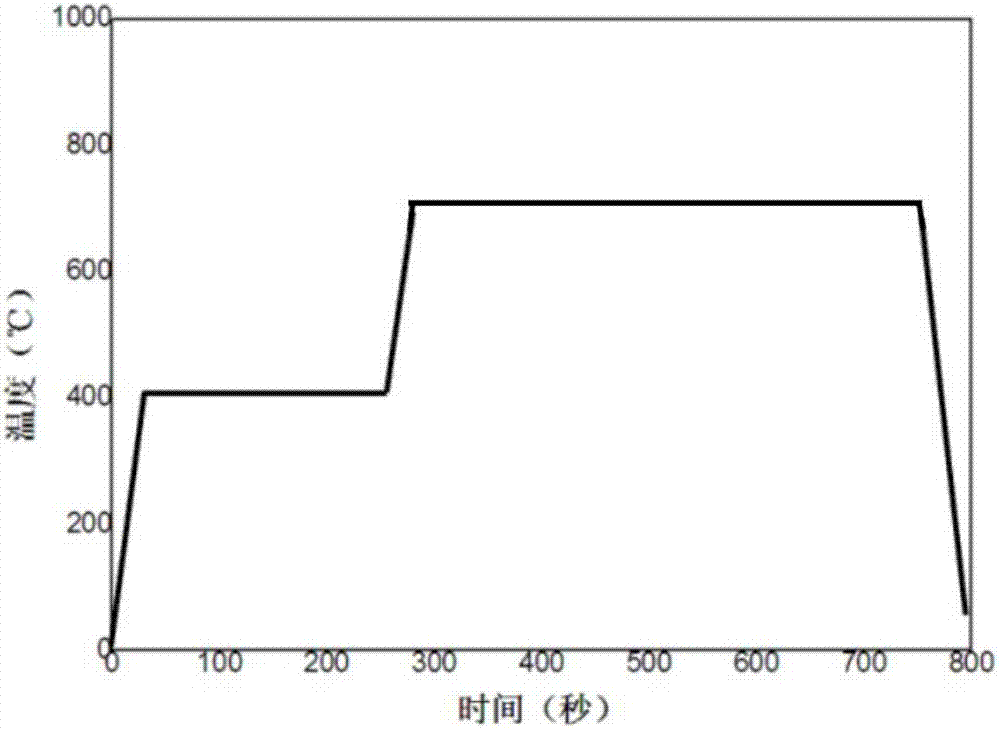

Formation method for germanium-doped SiC ohmic contact

InactiveCN107123593AImproved ohmic contact performanceIncrease contactSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactTwo temperature

The invention relates to a formation method for germanium-doped SiC ohmic contact. The method comprises the steps of forming a Ti / Pt / Au metal electrode on a germanium-doped SiC wafer by electron beam evaporation; performing rapid annealing on the germanium-doped SiC wafer after the electrode is formed to form ohmic contact, wherein rapid annealing is divided into two temperature-rising steps, the temperature of the first stage is risen to 300-500 DEG C and heat preservation is performed for 3-5 mixtures, and the temperature of the second stage is risen to 600-800 DEG C and heat preservation is performed for 5-10 mixtures; and finally, reducing the temperature to a range not higher than 60 DEG C. By doping germanium element, ohmic contact with high quality and low contact resistance is formed; and meanwhile, by changing the concentration of the doped germanium element, germanium-doped SiC products with different ohmic contact properties can be prepared.

Owner:SHANDONG UNIV +2

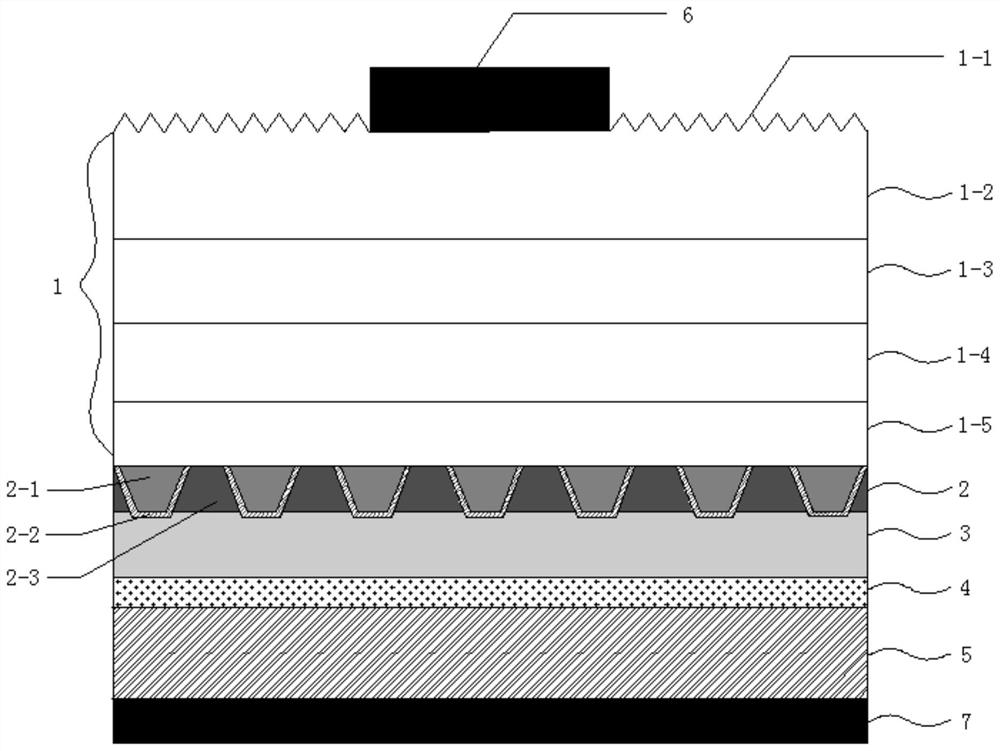

LED chip based on graphical reflector and manufacturing method of LED chip

InactiveCN111710767AImprove light extraction efficiencyImprove adhesionSemiconductor devicesDielectricOhmic contact

The invention provides an LED chip based on a graphical reflector and a manufacturing method of the LED chip. A dielectric film layer grows on the surface of a second type window layer, the dielectricfilm layer comprises a dielectric film and an adhesion layer which are sequentially stacked in the first direction, and the dielectric film layer is provided with a plurality of dielectric holes usedfor forming ohmic contact; the metal reflector is in ohmic contact with the second type window layer through the ohmic contact material in the dielectric hole; good ohmic contact between the metal reflector and the second type window layer is ensured; the adhesion layer is additionally arranged between the dielectric film and the metal reflector, so that the adhesion between the metal material ofthe metal reflector and the dielectric film is improved, the surface of one side, close to the epitaxial laminated layer, of the metal reflector is smoother, the reflection effect of the metal reflector is enhanced, and the high light extraction rate of light is realized. Meanwhile, patterning of the metal reflector can be achieved, so that the reflection path of light is changed, and the light emitting efficiency of the LED chip is improved.

Owner:YANGZHOU CHANGELIGHT

Environmental friendly lead-free aluminum slurry and preparation method thereof

InactiveCN101840744BGood substitutionImprove performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureHazardous substanceFerrosilicon

The invention relates to an environmental friendly lead-free aluminum slurry and a preparation method thereof. The environmental friendly lead-free aluminum slurry comprises the following components: antioxidant ultrafine aluminum alloy micropowder, barium ferrosilicon borate composite frit and a composite organic carrier. The invention has the advantages that the prepared lead-free aluminum slurry is an environmental friendly electronic slurry without harmful substances including lead, cadmium, mercury and hexavalent chromium, is used as a function material, completely replaces lead containing aluminum slurry, is stable and reliable, and has excellent performance, favorable ohmic contact quality, wide sintering temperature range, low sheet resistance, water boiling resistance, long ageing life and favorable replaceability to noble metals.

Owner:WUHAN YILAI RUIER HIGH TECH

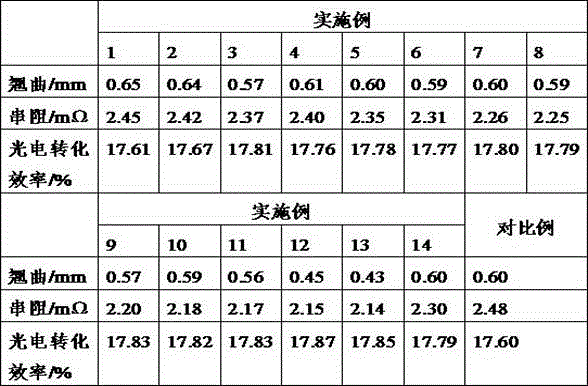

Method for preparing solar cells

ActiveCN103746004BImprove fill factorImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationOhmic contactEngineering

Owner:YINGLI GRP

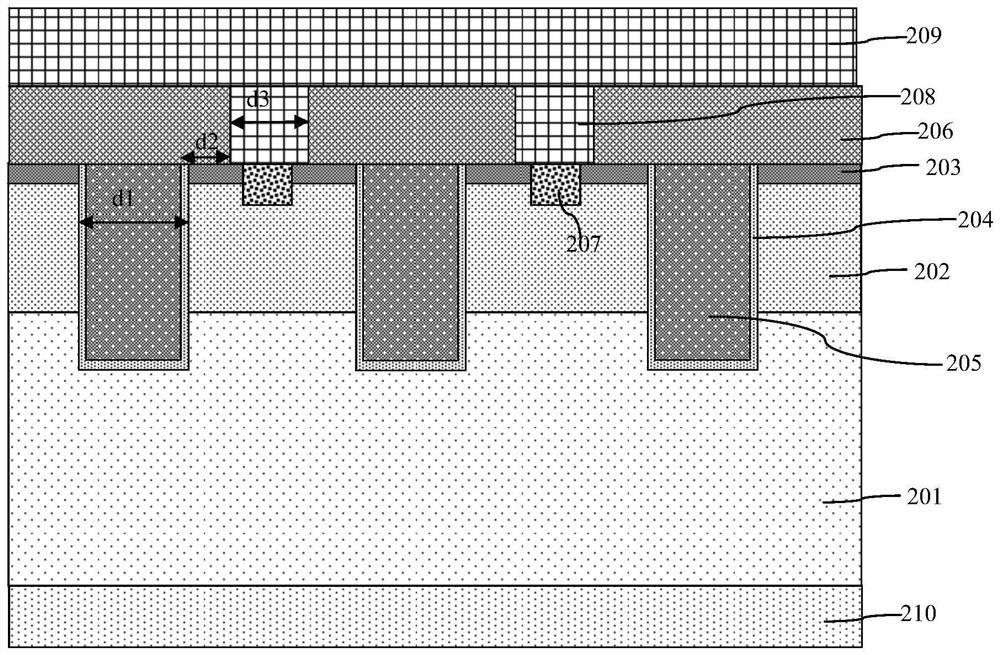

Preparing method of solar cell piece

ActiveCN103746004APrevent contact deformationImproved ohmic contact performanceFinal product manufacturePhotovoltaic energy generationSizingEngineering

The invention discloses a preparing method of a solar cell piece. The preparing method comprises the steps of passivating an emitter and plating an antireflection film, wherein the antireflection film plating operation comprises the steps of, before the step of the emitter passivating, performing plating on the back surface of a silicon wafer for the first time to form a back surface antireflection film; after the emitter passivating step, performing plating on the front surface of the silicon wafer for the second time to form a front surface antireflection film. By the method in which the reflection films are respectively plated on the front surface and the back surface of the silicon wafer before and after the emitter passivating, the passivating layer material in the emitter passivating step is effectively prevented from adhering to the back surface of the silicon wafer, so the contact deformation phenomenon caused by the fact that a metal sizing agent cannot penetrate through the passivating material during sintering is effectively prevented, the ohmic contact performance of the metal sizing agent with the silicon wafer base body is improved, the filling factor of the solar cell piece is enhanced and the photoelectric conversion efficiency of the solar cell piece is improved.

Owner:YINGLI GRP

Double-laminated-layer electrode light-emitting device

ActiveCN103594575AIncrease the restrictive effectImprove luminous efficiencySemiconductor devicesQuantum wellP type doping

The invention discloses a double-laminated-layer electrode light-emitting device which is characterized by being provided with a sapphire substrate. A low-temperature buffer layer, an n-type doping layer, a multi-quantum-well layer, a p-type doping layer and a laminated p electrode are sequentially arranged on the sapphire substrate, wherein the n-type doping layer is of a step structure, a laminated n electrode is arranged on the step structure, and the laminated p electrode and the laminated n electrode are of the same structure.

Owner:LIYANG TECH DEV CENT

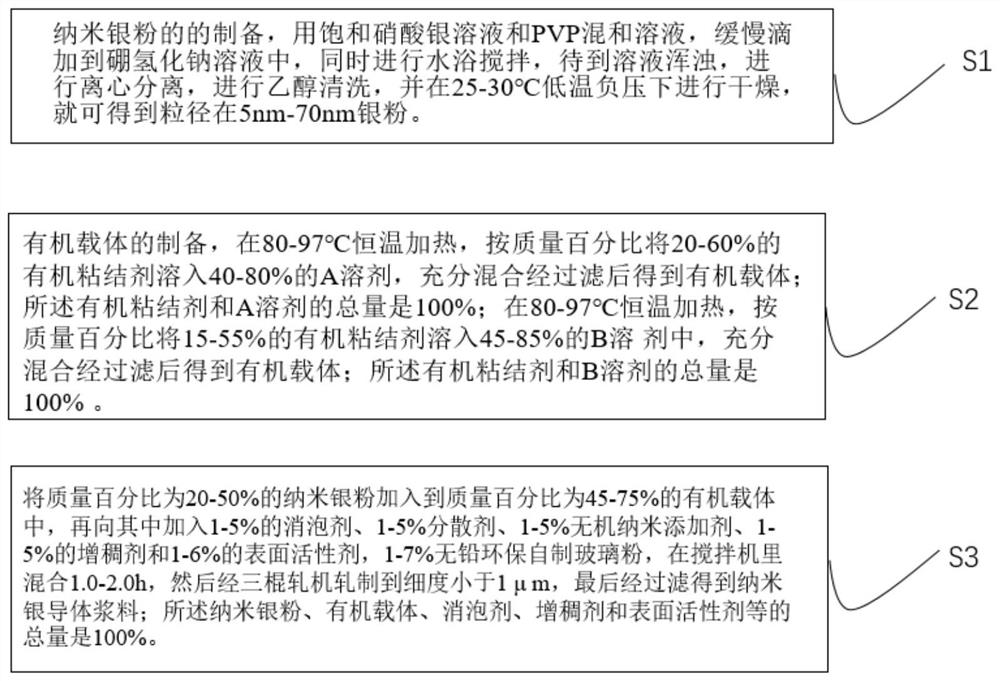

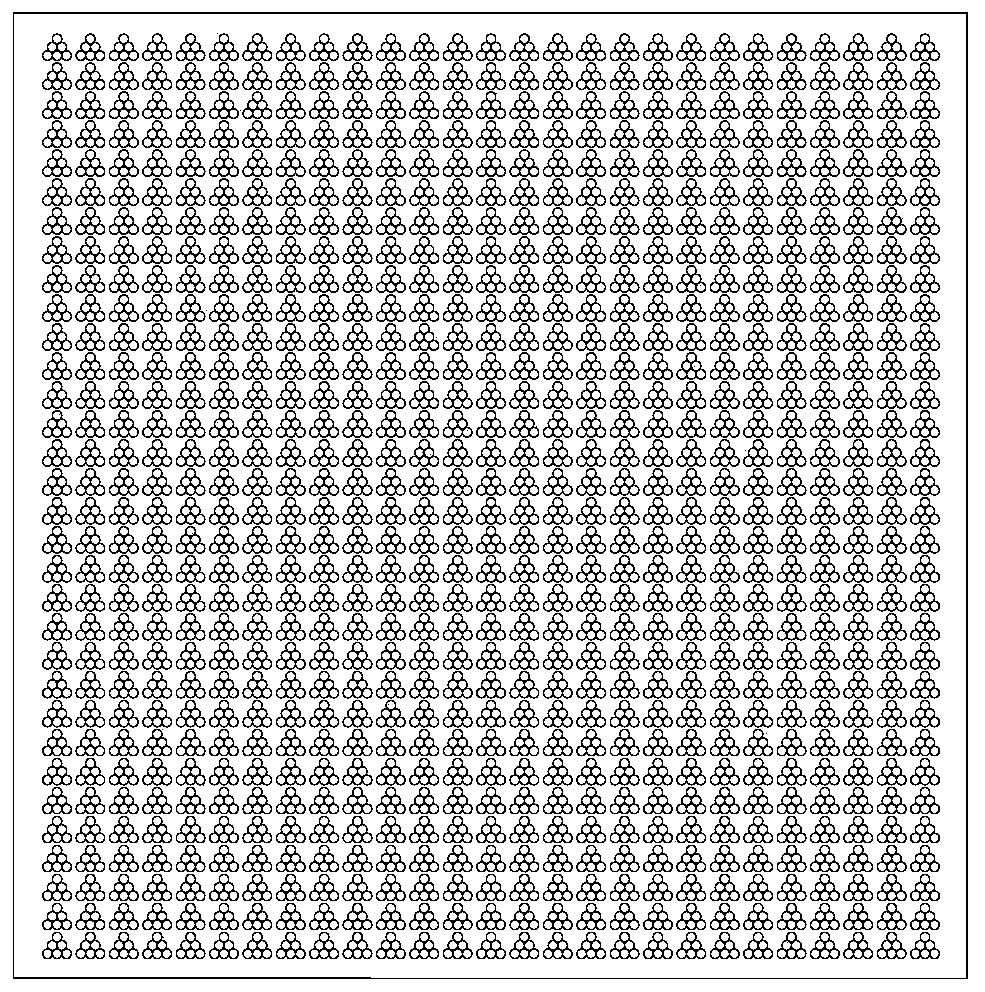

Preparation method of nano low-silver high-efficiency positive silver conductor paste for crystalline silicon solar energy

InactiveCN112420239AChange the electrical conductivityGood aspect ratioNon-conductive material with dispersed conductive materialSemiconductor devicesCrystalline siliconPhotoelectric conversion efficiency

The invention discloses a preparation method of nano low-silver high-efficiency positive silver conductor paste for crystalline silicon solar energy, and the method comprises the following steps: S1)preparing nano silver powder: dropwise adding a saturated silver nitrate and PVP mixed solution into a sodium borohydride solution, performing stirring in a water bath at 30-55 DEG C, performing centrifuging, performing washing with alcohol, and performing drying at a low temperature of 25-30 DEG C and a negative pressure to obtain the nano silver powder; adding a catalyst at 180 + / -5 DEG C for thermal decomposition to obtain silver powder with the particle size of 5-70nm; S2) preparing an organic carrier; S3) preparing nano-silver conductor paste. According to the method, self-made nano silver powder is used for replacing micron-sized silver powder in existing positive silver conductor paste, the microstructure of the silver conductor paste is changed due to reduction of the particle sizeof silver, and therefore the conductivity, the printing performance and the crystalline silicon substrate adhesion performance of the paste are changed, and printed conductor lines have the excellentheight-width ratio; the lines tend to be semitransparent, so that the light transmittance is improved, the photoelectric conversion efficiency is improved, and the application of the positive silverconductor paste in crystalliane silicon solar energy is greatly expanded.

Owner:陕西彩虹新材料有限公司 +1

LED chip and manufacturing method thereof

ActiveCN110571315AImprove light utilizationIncrease brightnessSemiconductor devicesDot matrixComposite film

The embodiment of the invention provides an LED chip and a manufacturing method thereof. The LED chip comprises a substrate, an epitaxial structure, a current blocking layer, a composite film layer, afirst electrode and a second electrode, wherein the epitaxial structure is located on the first surface of the substrate and comprises a first gallium nitride layer, an active layer and a second gallium nitride layer, and the first gallium nitride layer and the second gallium nitride layer are different in doping type; the current blocking layer is located in a preset region on the side, which isaway from the substrate, of the second gallium nitride layer; the composite film layer is located on the side, which is away from the second gallium nitride layer, of the current blocking layer and covers the second gallium nitride layer, the composite film layer comprises an ohmic contact layer, an insulating dot matrix layer and a first conducting layer which are laminated, and the insulating dot matrix layer comprises a plurality of discontinuous insulating units; the first electrode is electrically connected with the side, which is away from the substrate, of the first gallium nitride layer; and the second electrode is electrically connected with the side, which is away from the second gallium nitride layer, of the composite film layer. The LED chip has relatively high current transverse expansion capability and relatively high light-emitting brightness.

Owner:XIAMEN CHANGELIGHT CO LTD

Trench gate semiconductor device and manufacturing method thereof

PendingCN112701164ASmall stepRemove restrictionsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialConductive materials

The invention discloses a trench gate semiconductor device, which comprises a body region formed in a first epitaxial layer, a gate trench passing through the body region, a gate conductive material layer completely filling the bottom region of the gate trench, and a source region formed on the side surface of the top region of the gate trench through angled ion implantation self-alignment; a top dielectric layer is formed on the surface of the gate conductive material layer, and first grooves are formed in the vertex angles of the two sides of the top dielectric layer; the bottom of a source contact hole is formed on the surface of the top dielectric layer in each first groove and between the first grooves in a self-aligning manner; and the top surfaces of the source region in the first grooves are in contact with the side surface of the source contact hole to realize source region leading-out. The invention further discloses a manufacturing method of the trench gate semiconductor device. According to the invention, the alignment of transverse isolation between the source contact hole and the trench gate is not required, the stepping of the device can be reduced, the base resistance of a parasitic triode can be reduced, and the process window and the producibility can be improved at the same time.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

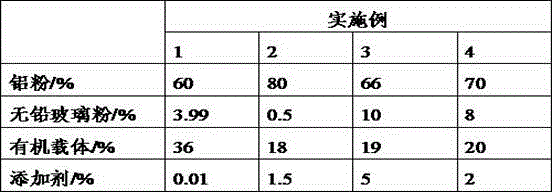

Solar aluminum conductor paste and preparation method thereof

ActiveCN106448805AImprove photoelectric conversion efficiencyImproved ohmic contact performanceNon-conductive material with dispersed conductive materialPhotovoltaic energy generationElectrical conductorOhmic contact

The invention discloses solar aluminum conductor paste. The solar aluminum conductor paste comprises the constituents based on percent by mass: 60-80% of aluminum powder, 0.5-10% of lead-free glass powder, 18-36% of organic carrier and 0.01-5% of additive, wherein the additive is selected from at least one of elements B, Ga and In, an inorganic compound containing Ga and In and a solid solution, and the additive is a coating additive of which a surface is coated with the lead-free glass powder by grinding. In the solar aluminum conductor paste, the additive is more uniformly dispersed in the aluminum paste by improving a morphology and contact mode of the additive in the aluminum paste, the glass powder is more stable to coat around the aluminum paste, a surface crystal boundary morphology of a solid solution crystal after smashing is maintained, ohmic contact performance of an aluminum layer and a silicon wafer is favorably improved, and the conductivity and the photoelectric conversion efficiency of a solar cell are further improved. The invention also discloses a preparation method of the solar aluminum conductor paste.

Owner:JIANGSU RUIDE NEW ENERGY TECH

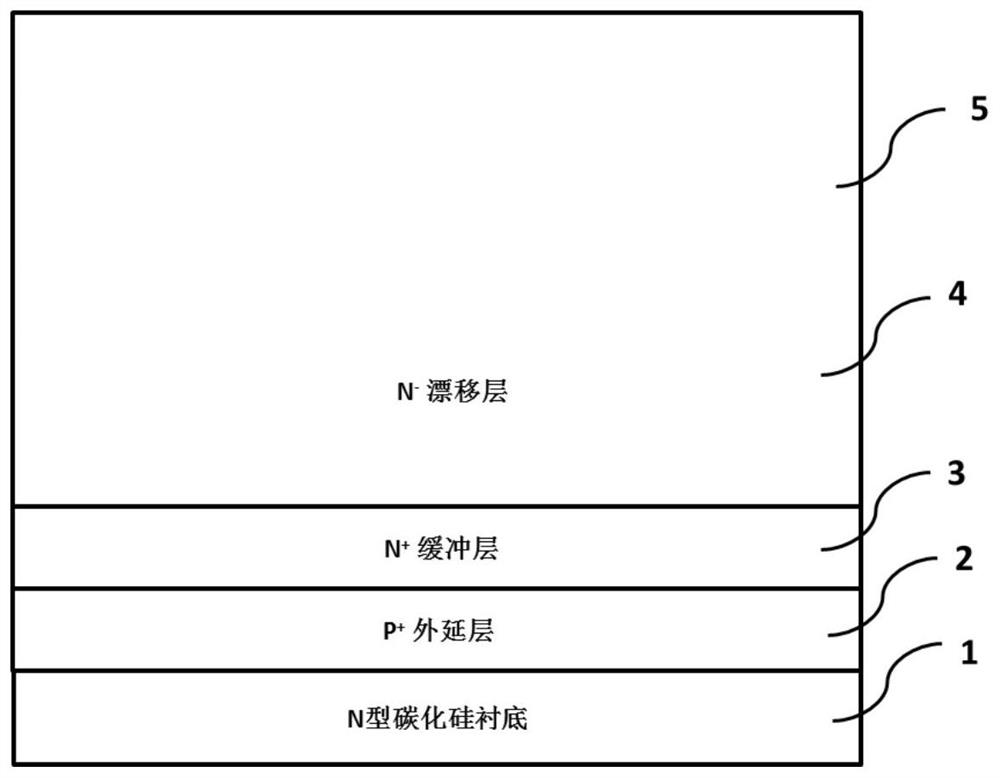

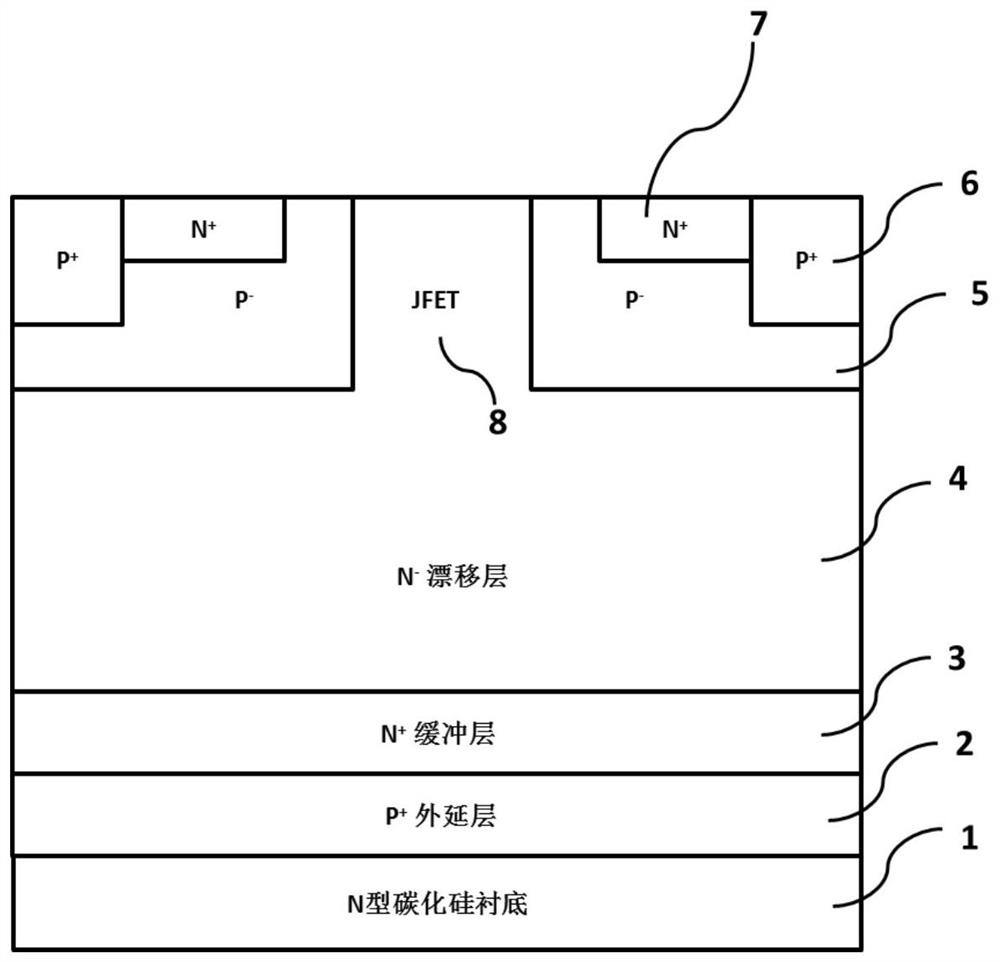

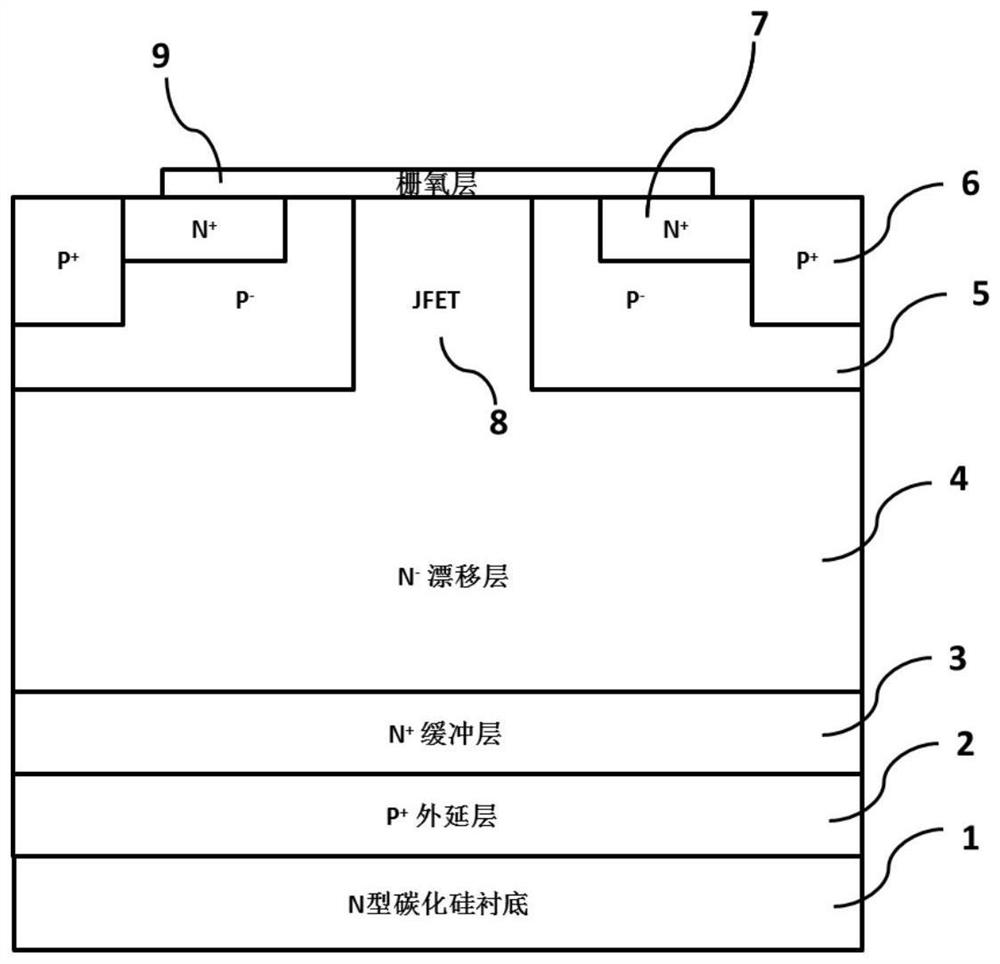

Preparation method of silicon carbide N-channel bipolar power device

InactiveCN113299552AGood ohmic contactLow costSemiconductor/solid-state device manufacturingSemiconductor devicesCarbide siliconMOSFET

The invention discloses a preparation method of a silicon carbide N-channel bipolar power device, and belongs to the field of semiconductor devices. According to the method, firstly, a P+ epitaxial layer, an N+ buffer layer and an N- drift layer are sequentially grown on an N-type silicon carbide substrate, secondly, a carrier lifetime prolonging process, a device front MOS preparation process, a device back substrate thinning process and a laser annealing process are introduced on an epitaxial wafer, and finally the preparation of the silicon carbide N-channel bipolar power device is achieved. According to the method, by introducing the carrier lifetime prolonging process, the conductivity modulation effect of the bipolar power device is enhanced, and the specific on-resistance and the conduction loss of the device are effectively reduced. Meanwhile, the method not only avoids the adoption of a high-resistance P-type silicon carbide substrate material, but also has the advantages that the front preparation process of the device is compatible with the preparation process of an MOSFET device, the cost is saved, the risk is smaller, and the industrial preparation is easier.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Crystalline silicon cell and conductive paste thereof

ActiveCN110580969AGuaranteed electrical conductivityReduce penetration depthNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteIndium

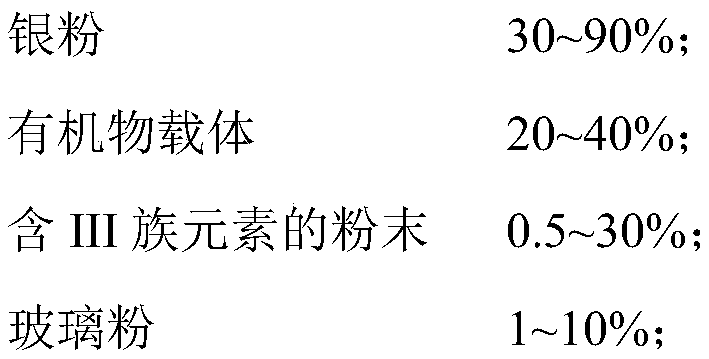

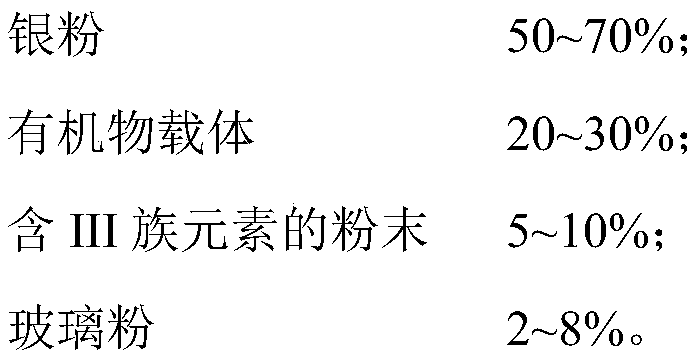

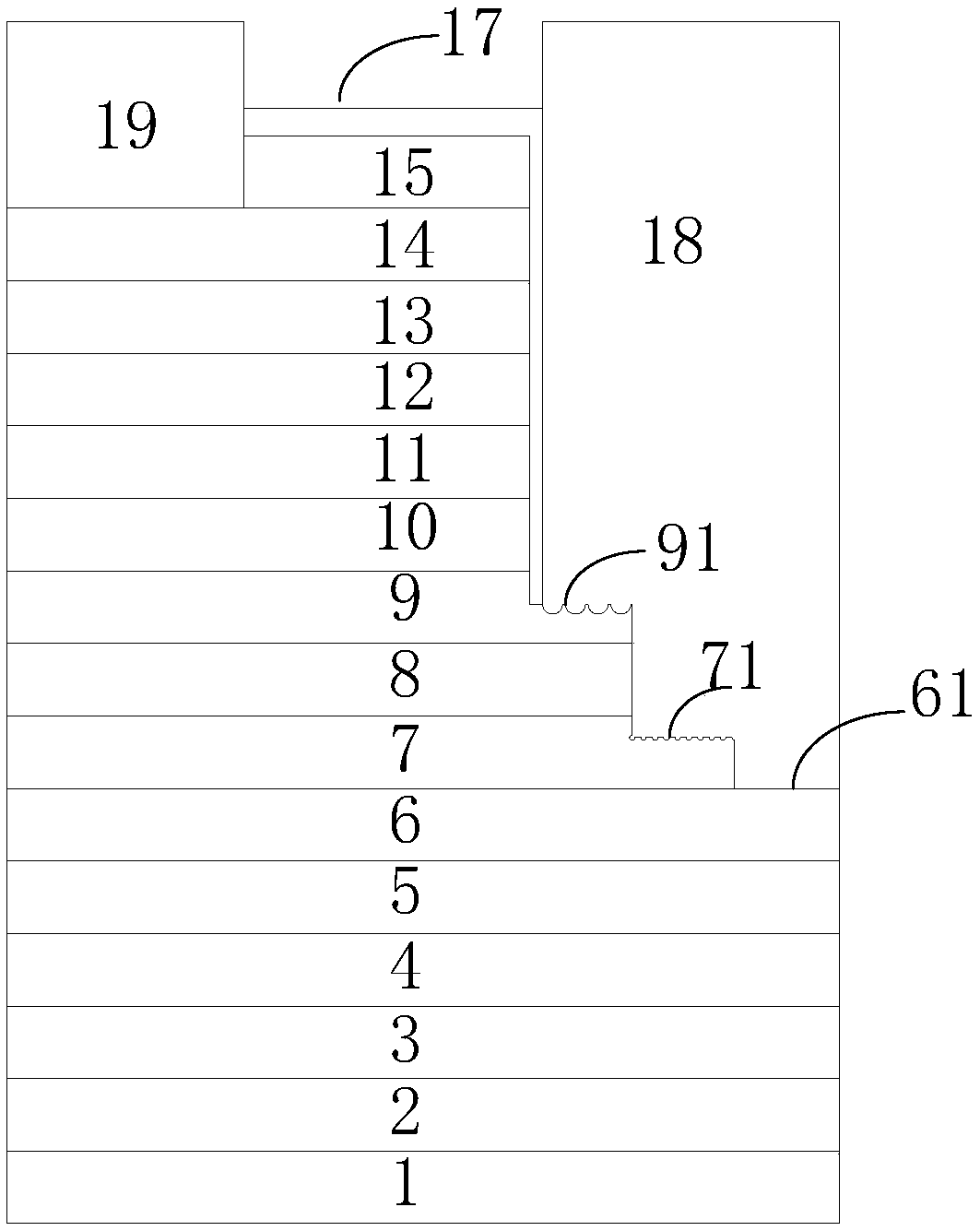

The invention discloses a crystalline silicon cell and conductive paste thereof. The conductive paste can be matched with a shallow junction process of a P-type doped surface of the crystalline silicon cell. The conductive paste of the crystalline silicon cell comprises the following components in percentage by mass: 30-90% of silver powders, 20-40% of organic carriers, 0.5-30% of powders containing group-III elements and 1-10% of glass powders, wherein the powders containing the group-III elements are one or a mixture of more of boron powders, gallium powders, indium powders and thallium powders; or, the powders containing the group-III elements are a mixture of group-III element powders and copper powders, and the group-III element powders being one or a mixture of more of boron powders,gallium powders, indium powders and thallium powders.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

Leadless ohmic electrode silver coating for PTC ceramic and its preparation method

InactiveCN100390905CSimple production processLow costNon-conductive material with dispersed conductive materialResistor manufactureZincSilver coating

A method for preparing silver size pole of lead free ohm electrode used on PTC ceramic includes mixing and grinding silver micro powder, zinc powder and organic carrier together to obtain silver size pole material then firing obtained material at temperature of 480-580deg.c to let electrode layer attached on surface of ceramic body tightly for forming excellent ohm contact property.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Light-emitting diode and method of making the same

ActiveCN107546307BReduce current crowdingImprove current blocking abilitySemiconductor devicesPower flowOhmic contact

The invention discloses a light emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate, a buffer layer, an unintentional doping layer, a first doping layer, a first heavy doping layer, a first ohmic contact layer, a first high doping layer, a first isolation layer, a second doping layer, a first current blocking layer, an active region, a second current blocking layer, a third doping layer, a second ohmic contact layer, a transparent conductive layer, a first electrode, a second electrode and a third electrode, wherein the second doping layer comprises a first platform, the first high doping layer comprises a second platform, the first ohmic contact layer comprises a third platform, the first platform, the second platform and the third platform are differentin surface roughness, the first electrode directly contacts with the first platform, the second platform and the third platform, and the first electrode and the second electrode realize electrical isolation through a second protection layer. The LED is advantaged in that the manufacturing process is simple, manufacturing cost of chips is reduced, and a current congestion problem of the LED is effectively solved.

Owner:XIAMEN CHANGELIGHT CO LTD

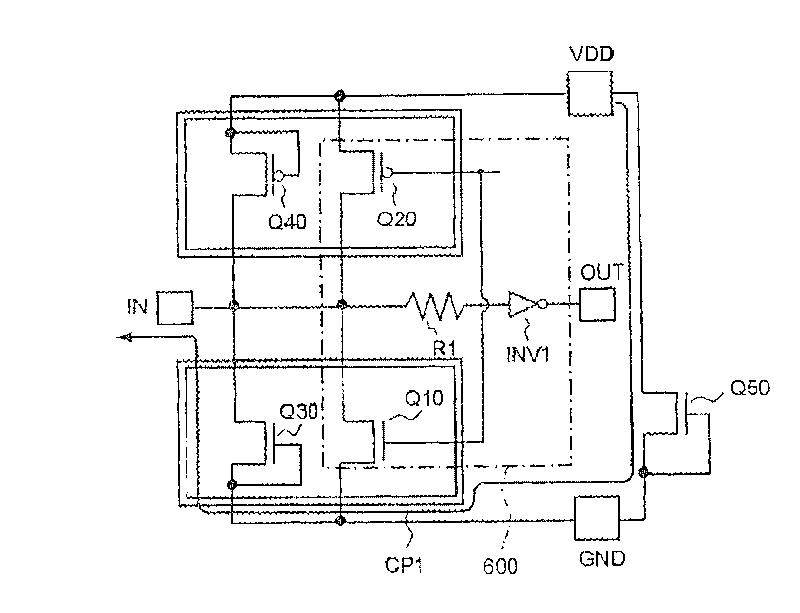

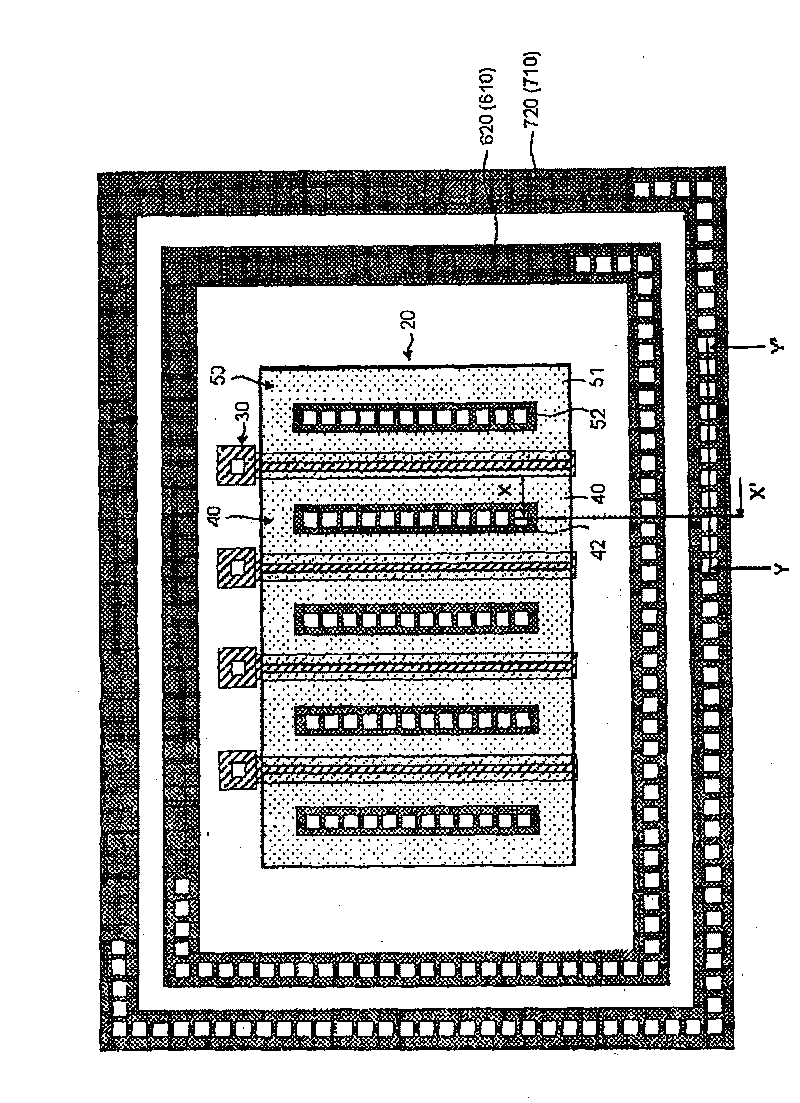

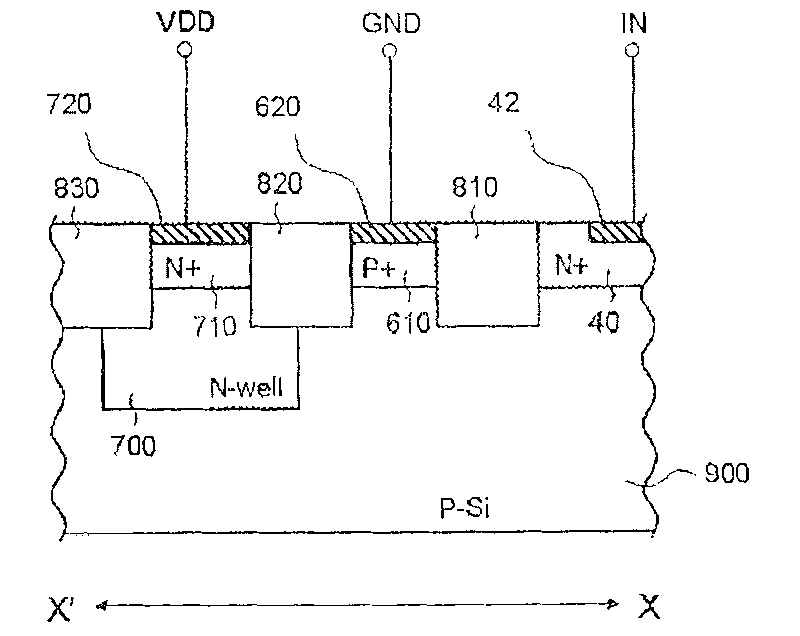

Semiconductor device

InactiveCN101022106BIncrease parasitic resistanceAvoid concentrationTransistorSemiconductor/solid-state device detailsProtection ringSemiconductor

The invention provides a semiconductor device. The semiconductor device forms a silicide on a protection ring for latch prevention, and avoids the protection ring from being damaged by an ESD surge. As a solving means, the semiconductor device has a structure that, a silicide with a width (W3) is not formed on a surface of a second protection ring for latch prevention, and at a side facing a transistor forming region (20).

Owner:OKI ELECTRIC IND CO LTD

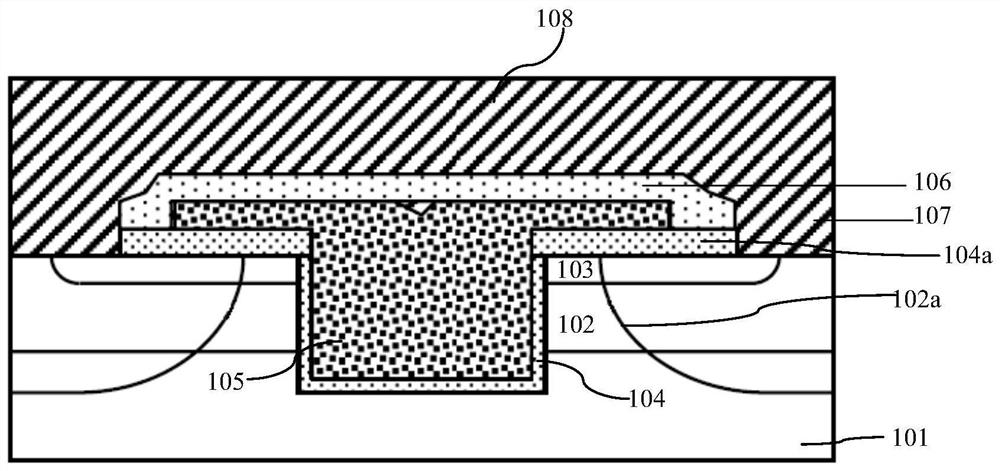

Thin-film transistor, method for manufacturing same, array substrate and display device

ActiveCN106898654AImprove job stabilityReduced ohmic contact resistanceTransistorSolid-state devicesOhmic contactDisplay device

The invention discloses a thin-film transistor, a method for manufacturing the same, an array substrate and a display device. An active layer is not in direct contact with the source metal layer and the drain metal layer in the thin-film transistor, thereby reducing the ohmic contact resistance between the active layer and the source metal layer and between the active layer and the drain metal layer, improving an ohmic contact effect between the active layer and the source metal layer and between the active layer and the drain metal layer in the vertical amorphous silicon thin-film transistor, and further improving the operating stability of the thin-film transistor. The embodiment of the invention provides a thin-film transistor comprising the source metal layer, a first ohmic contact layer on the top of the source metal layer, a first insulating layer on the top of the first ohmic contact layer, the active layer on the top of the first insulating layer and in contact with the first ohmic contact layer, a second ohmic contact layer on the top of the active layer; and the drain metal layer on the top of the second ohmic contact layer.

Owner:BOE TECH GRP CO LTD

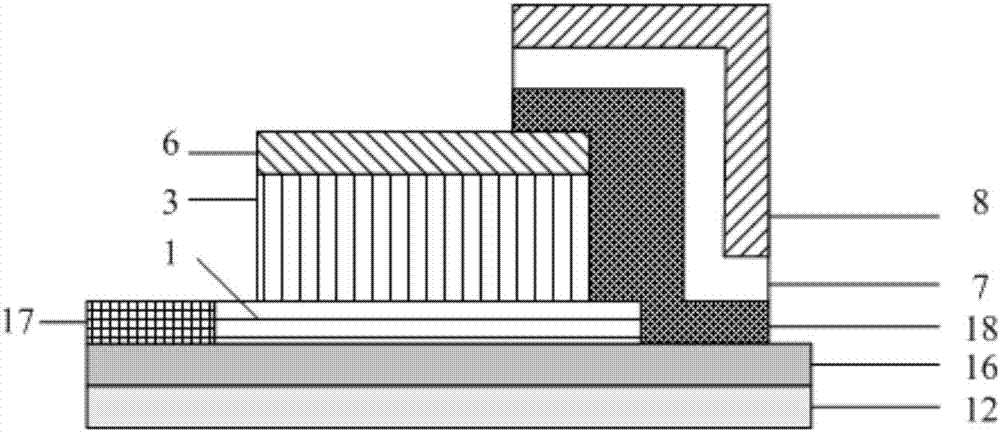

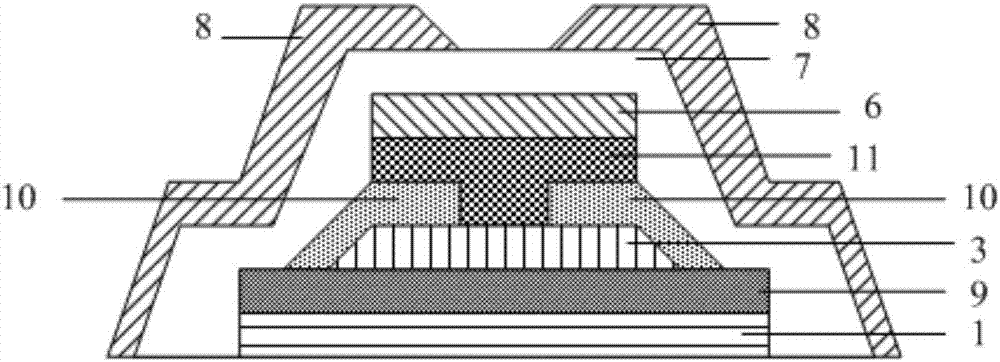

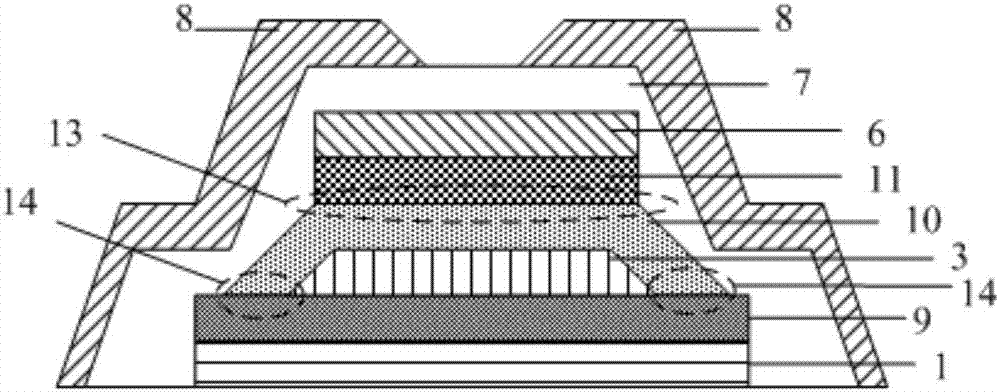

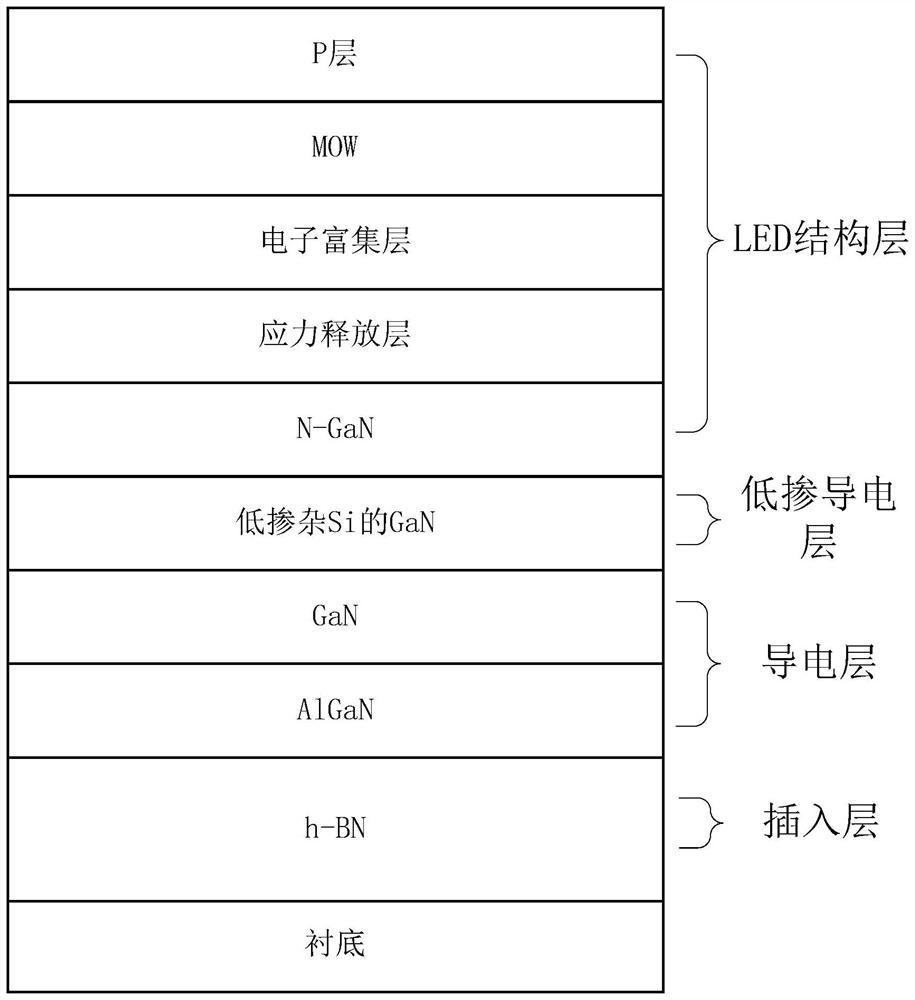

Vertical epitaxial structure LED chip and preparation method thereof

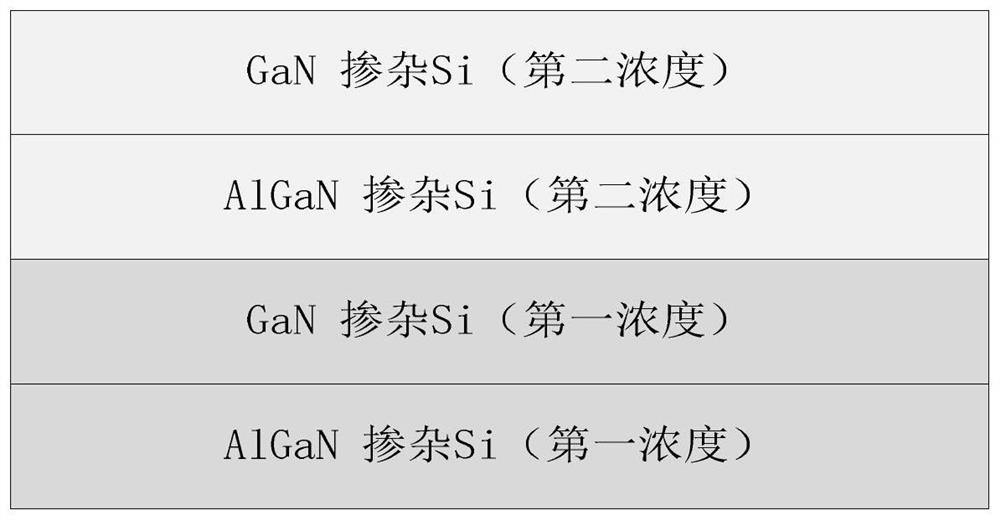

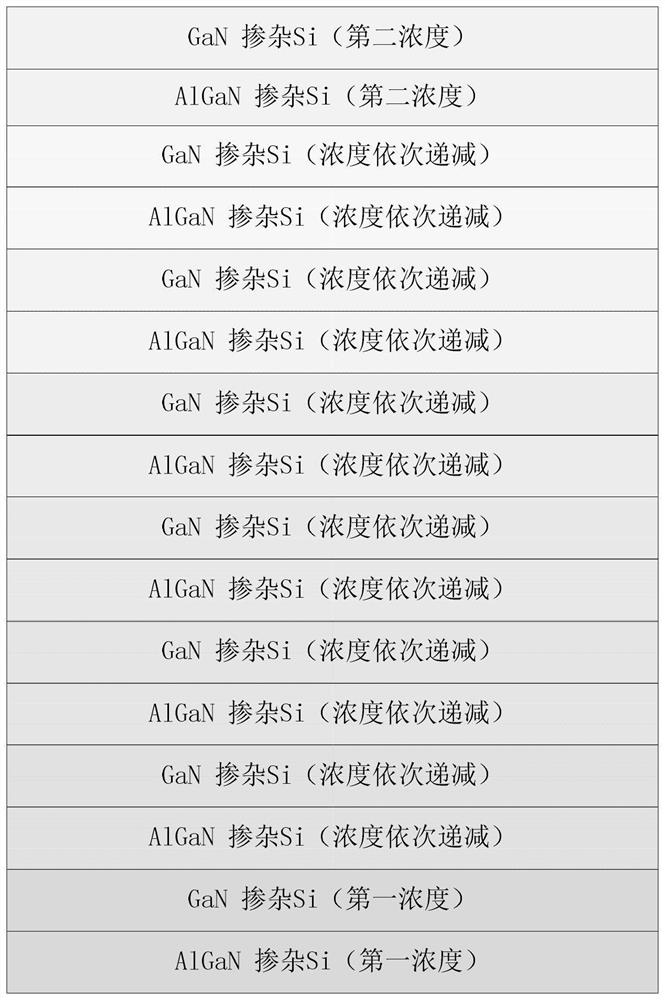

PendingCN114784158ADoes not affect electrical performanceImprove yieldSemiconductor devicesHeterojunctionHexagonal boron nitride

The invention provides a vertical epitaxial structure LED chip and a preparation method thereof, the vertical epitaxial structure LED chip comprises a substrate, an insertion layer, a conductive layer, a low-doped conductive layer and an LED structure layer which are sequentially arranged in a laminated manner, and the insertion layer is a hexagonal boron nitride layer; the conductive layer comprises a plurality of gallium nitride aluminum / gallium nitride heterojunction layers. The mutual acting force between the hexagonal boron nitride layered structures is small, and the damage of stripping to the upper epitaxial structure is small. And by utilizing the layered structure characteristic of the hexagonal boron nitride, the laser lift-off technology cannot damage the structure on the hexagonal boron nitride layer, so that the yield of the LED chip is improved. The gallium nitride aluminum / gallium nitride heterojunction structure can play a role similar to a chip DBR (Distributed Bragg Reflector) due to different materials. Moreover, through the design that the silicon-doped concentration of the gallium aluminum nitride / gallium nitride heterojunction layer is gradually reduced, the gallium aluminum nitride / gallium nitride heterojunction layer can be well matched with an electrode, and has good conductive and ohmic contact effects.

Owner:JUCAN PHOTOELECTRIC TECH (SUQIAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com