Ultraviolet light-emitting diode chip with reflection ohmic contact electrode

A technology for ohmic contact electrodes and light-emitting diodes, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of difficult to obtain ohmic contact between aluminum and P-type layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

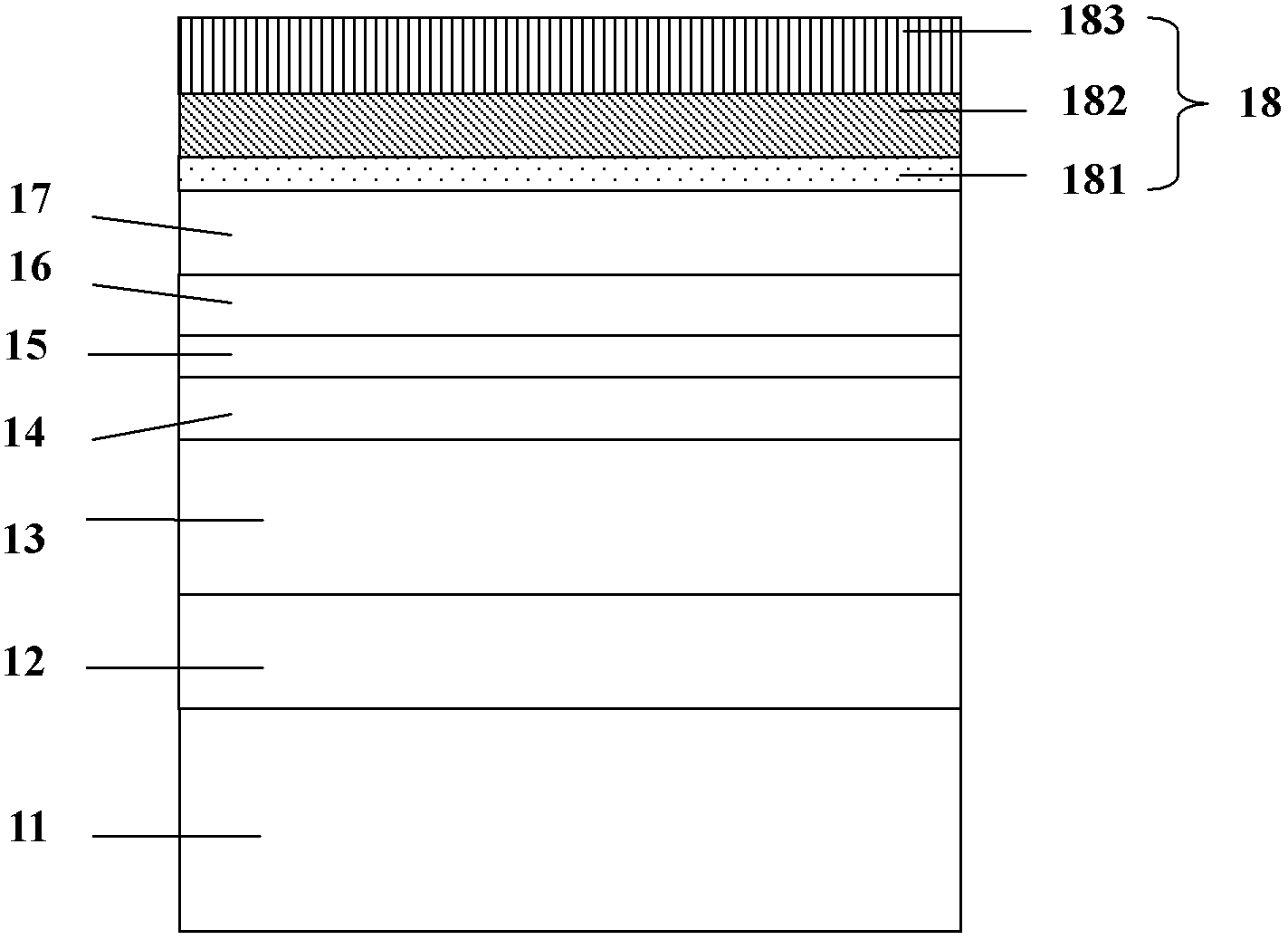

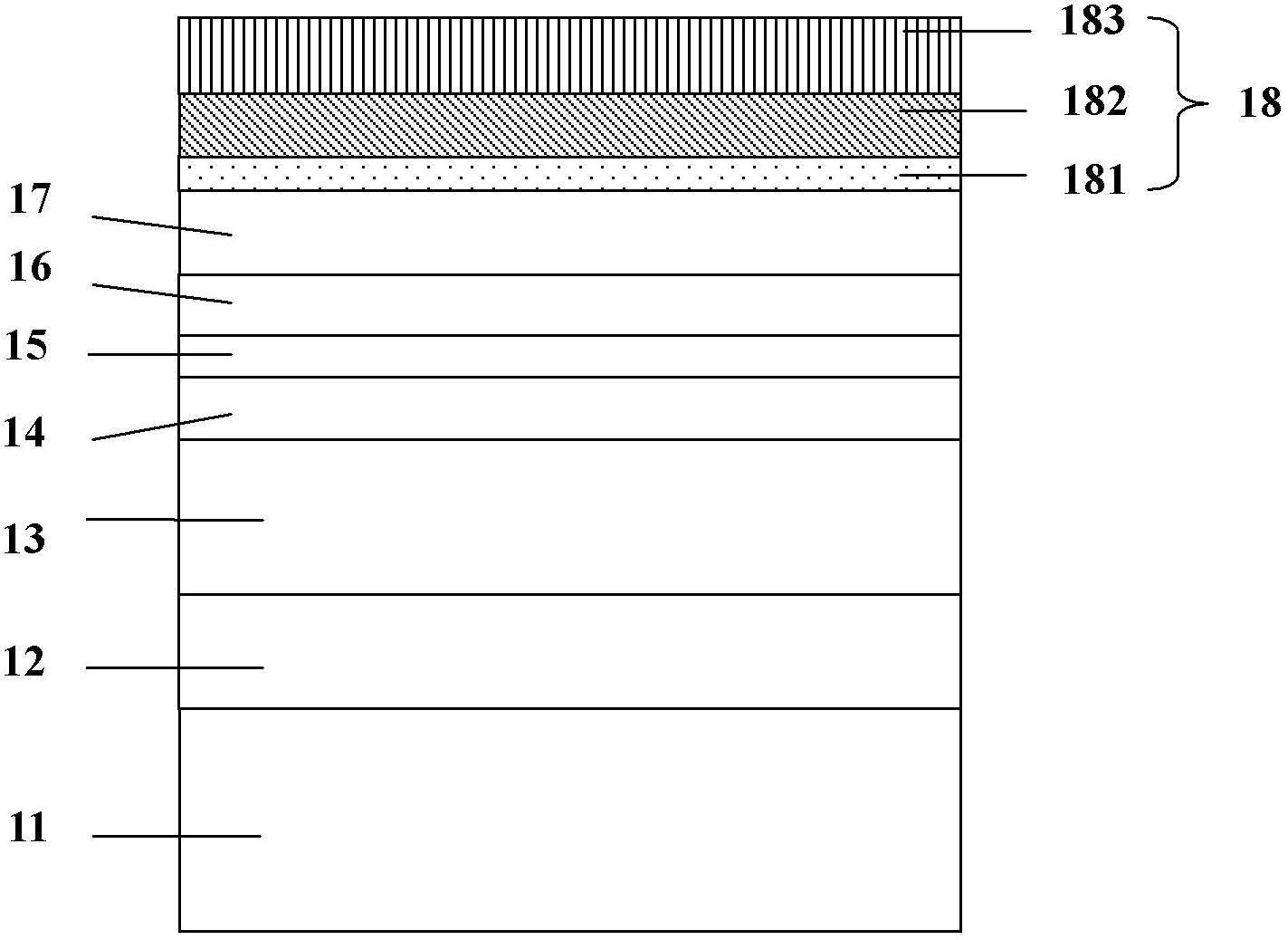

[0016] Please refer to figure 1 Shown, a kind of substrate of the ultraviolet light-emitting diode with reflective ohmic contact electrode of the present invention comprises:

[0017] A substrate 11, the material of the substrate 11 is sapphire or AlN;

[0018] An AlN template layer 12, which is grown on the substrate 11 by metal organic compound vapor deposition (MOCVD), and has a thickness of 0.1-10 μm;

[0019] An N-type AlGaN layer 13, grown on the AlN template layer 12 by MOCVD, with a thickness of 1-5 μm;

[0020] An active region 14 of multiple quantum wells, which is grown on the N-type AlGaN layer 13 by MOCVD, and its material is Al x Ga 1-x N / Al y Ga 1-y N-based materials, where 0≤x<y≤1;

[0021] An electron blocking layer 15, which is grown on the active region 14 of the multi-quantum well by MOCVD method, and its material is an AlGaN material with a high Al composition, and its Al composition is higher than that of the multi-quantum well active region 14, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com