Formation method for germanium-doped SiC ohmic contact

An ohmic contact and silicon carbide technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to improve the actual effect of ohmic contact and low contact resistance, and achieve the effect of passivation and oxidation tendency and reducing contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation of the germanium-doped silicon carbide single crystal used in the examples is grown by the physical vapor transport method, and the steps are as follows:

[0043] Place 300g of silicon carbide powder and 10-20g of dopant germanium powder in the growth crucible in the growth furnace; place the dopant at the bottom of the crucible and mix it with the silicon carbide powder, and fix the silicon carbide seed crystal on the top of the crucible on the seed crystal seat. Inject nitrogen gas into the growth atmosphere during the crystal growth process, the flow rate of nitrogen gas is 20 sccm, the growth temperature is 2100-2300° C., and the growth pressure is 50-80 mbar. The growth cycle is 40-60 hours.

[0044] According to the above method, feed materials according to the following proportions to obtain germanium-doped silicon carbide single crystals with different germanium doping concentrations:

[0045] Silicon carbide powder 300g and dopant germanium po...

Embodiment 2

[0046] Silicon carbide powder 300g and dopant germanium powder 15g, germanium doping concentration is 10 18 Atoms / cm 3 , for embodiment 2;

[0047] Silicon carbide powder 300g and dopant germanium powder 10g, germanium doping concentration is 10 17 Atoms / cm 3 , for Example 3.

[0048] Cut, grind and polish the grown crystal ingot to get 10×10mm 2 germanium-doped silicon carbide wafers.

Embodiment 1

[0049] Embodiment 1. A method for forming a germanium-doped silicon carbide ohmic contact, comprising:

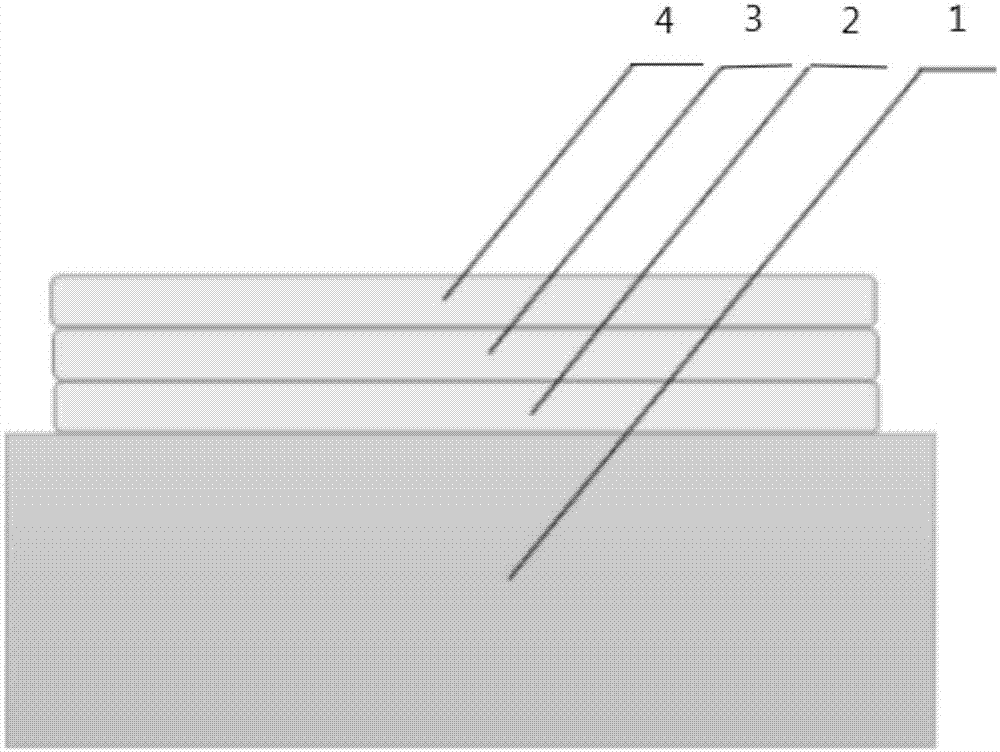

[0050] (1) Provide a germanium doping concentration of 10 19 Atoms / cm 3 Large-scale germanium-doped silicon carbide wafers, prepared by electron beam evaporation 1 × 1mm 2 Titanium-platinum electrodes, in which the thicknesses of Ti, Pt, and Au metal layers are 70nm, 60nm, and 650nm, respectively. A germanium-doped silicon carbide electrode sample was obtained. The schematic diagram of the electrode structure is as figure 1 shown.

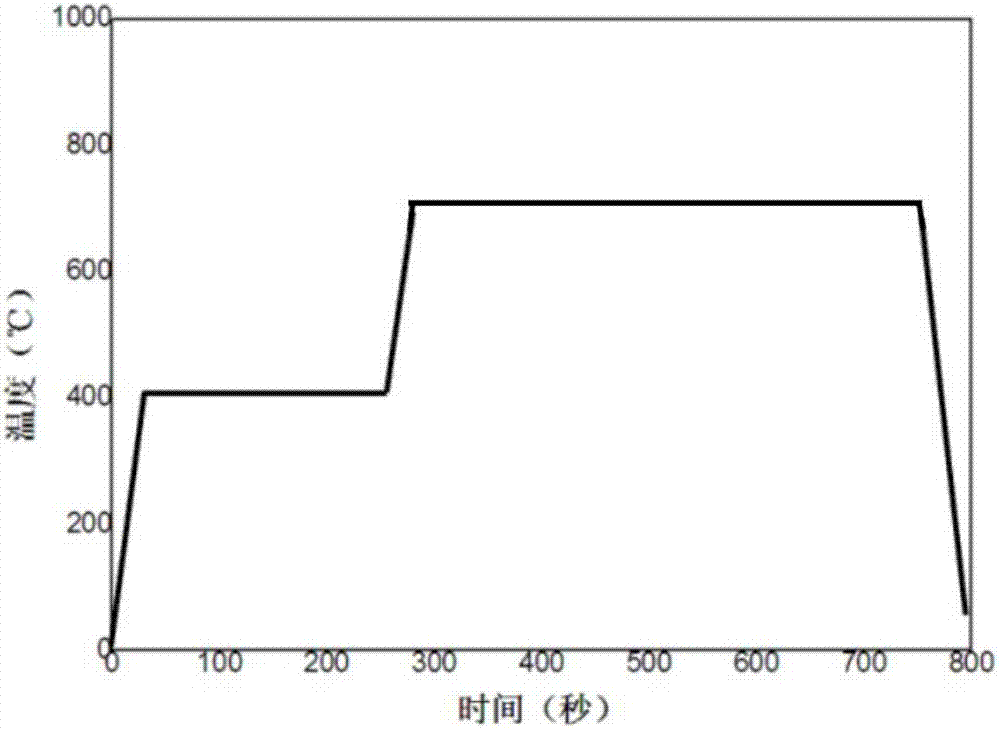

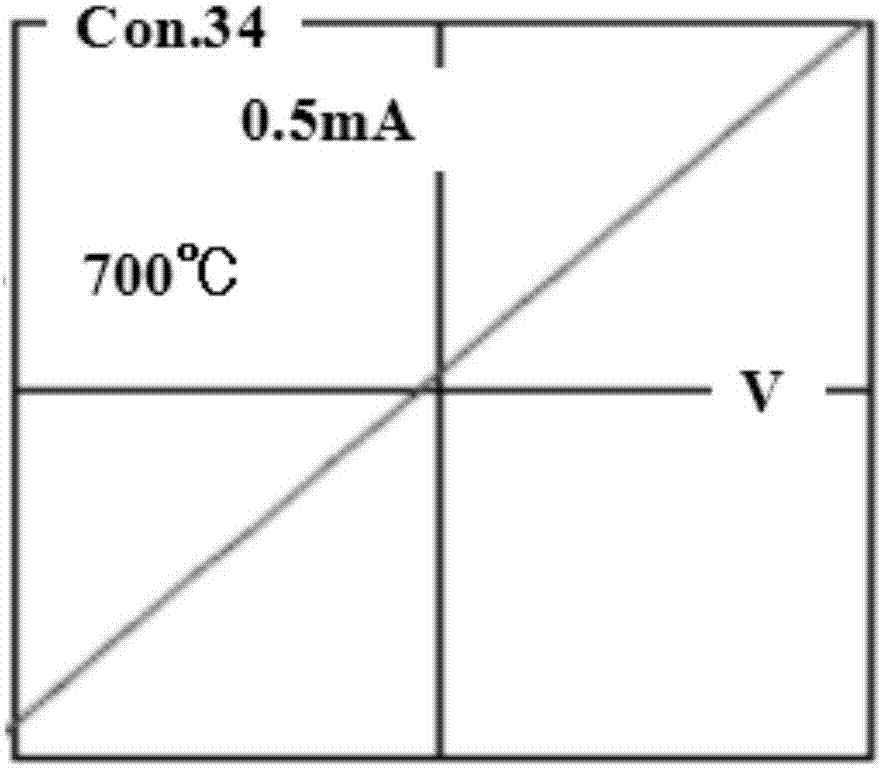

[0051] (2) In the heating stage, the sample is placed in a rapid annealing furnace (RTP) for rapid thermal annealing. The rapid heating stage is divided into two stages. The first stage: the temperature is raised to 400 °C at a heating rate of 16 °C / s. ℃, keep warm for 4 minutes. The second stage: the temperature is raised to 700° C. at a heating rate of 8° C. / second, and the temperature is maintained for 7.5 minutes. The heating surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com