Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Short milling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

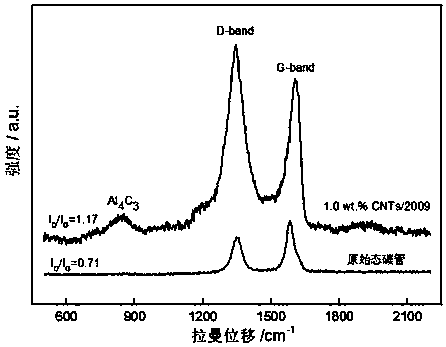

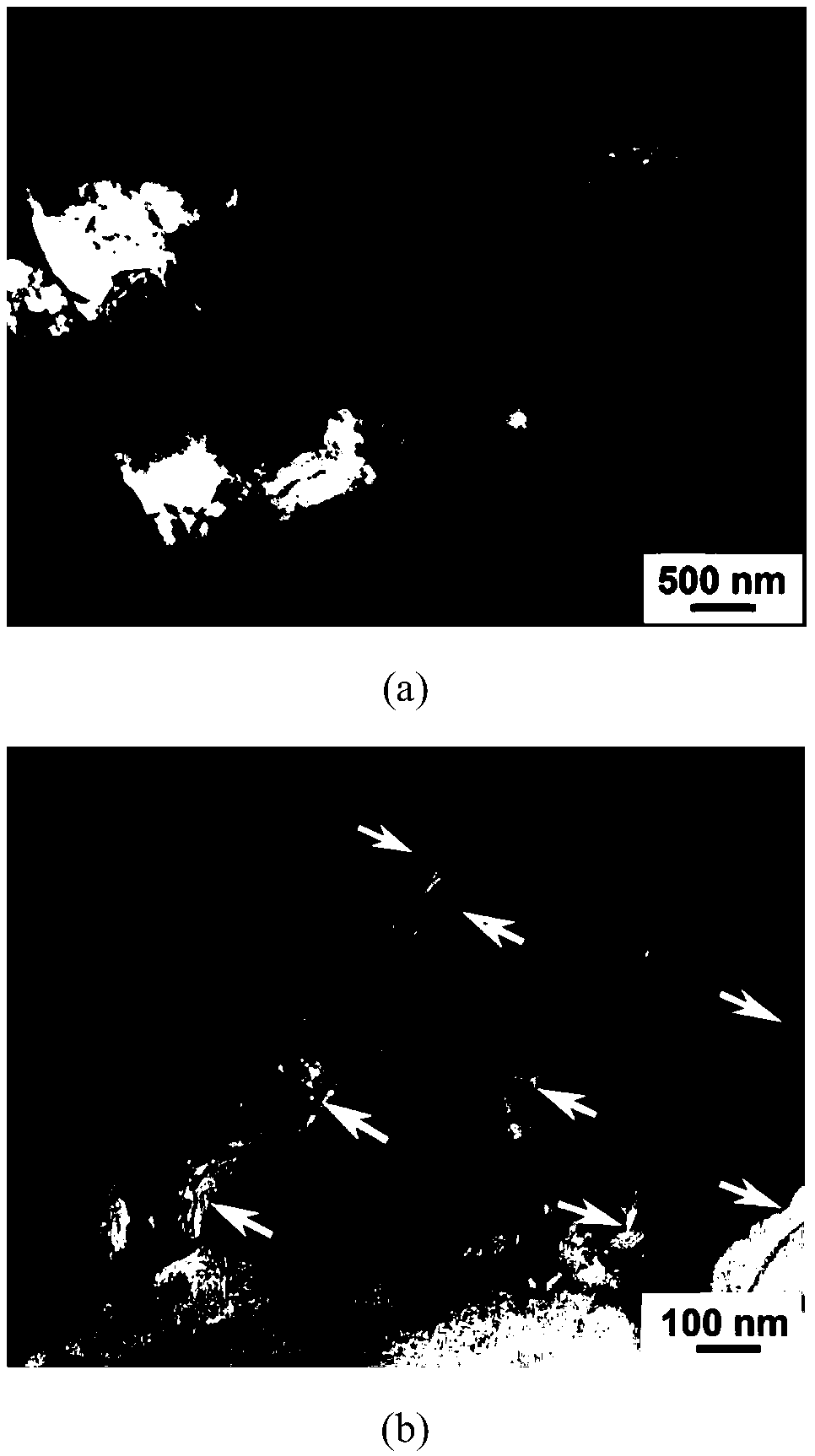

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

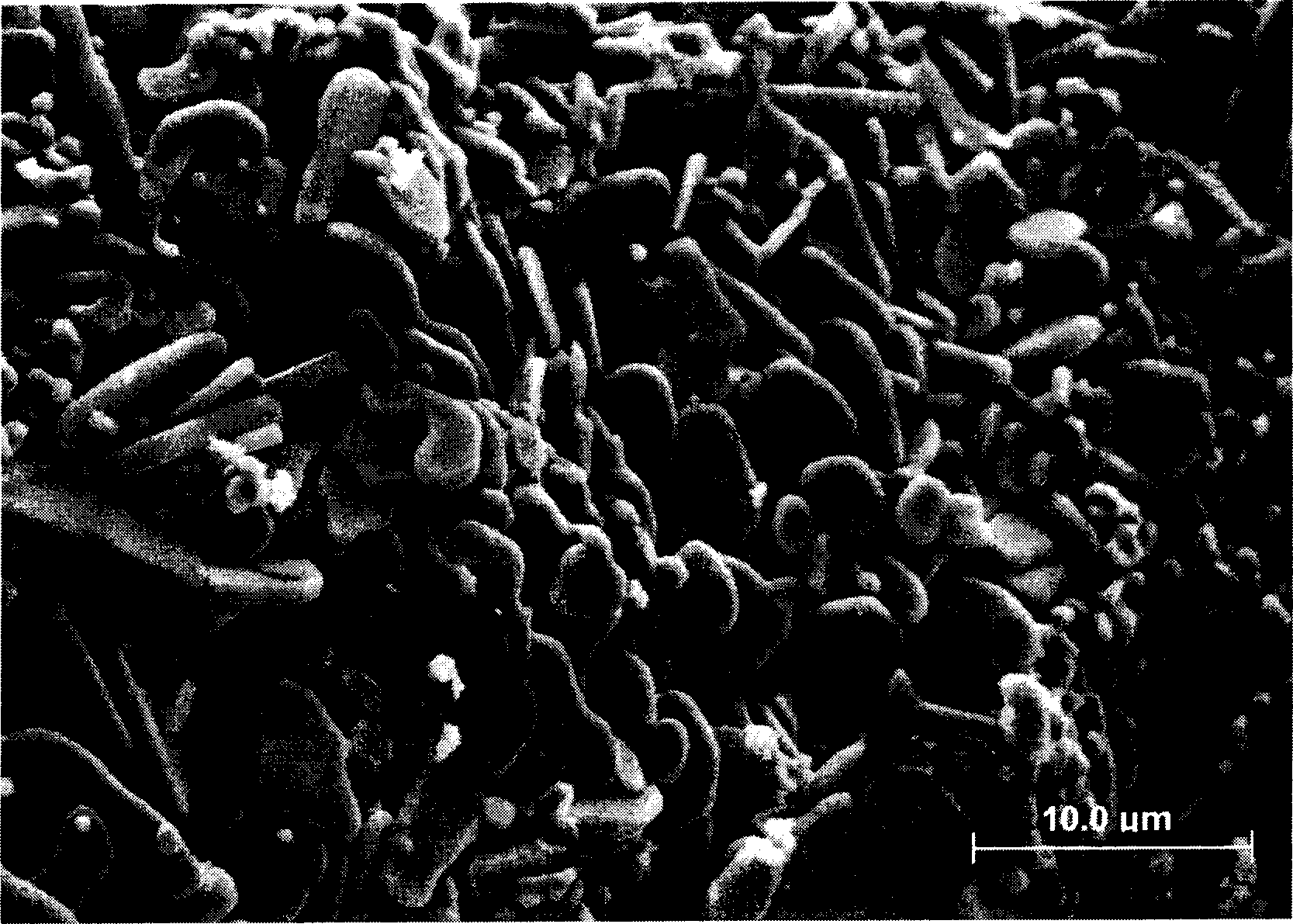

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

Method for preparing nano particle reinforced aluminum matrix composites

The invention discloses a method for preparing nano particle reinforced aluminum matrix composites. The method comprises the steps that firstly, mixed powder of nano ceramic powder and micron-sized aluminum or aluminum alloy powder is used for preparing millimeter-sized composite particles through a dry high-energy ball mill under the protection of vacuum or argon, wherein the volume fraction of nano ceramic particles in the millimeter-sized composite particles is 10-50%; and secondly, the millimeter-sized composite particles are melted directly or added into aluminum or aluminum melt, and supersonic vibration is applied, so that the nano ceramic particles are promoted to be uniformly dispersed in the metal melt, and the nano particle reinforced aluminum matrix composites are prepared. According to the method for preparing the nano particle reinforced aluminum matrix composites, the millimeter-sized composite particles prepared through a dry milling method can be added into the metal melt easily and completely, the problems that the wettability between the nano ceramic particles and matrix metal is poor, and adding of the particles is difficult are solved, and the advantage of low cost of a casting method for preparing metal matrix composites is given to play; the nano particles in the prepared composites are distributed uniformly, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

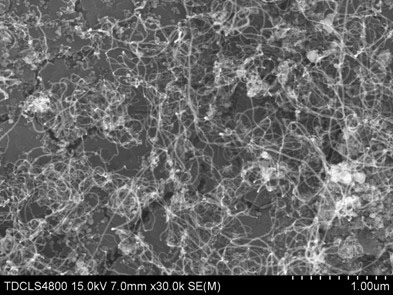

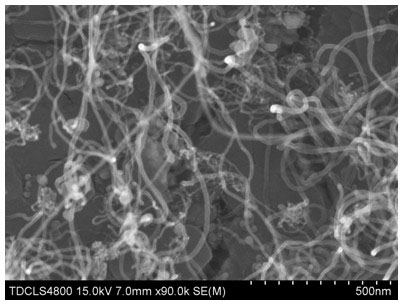

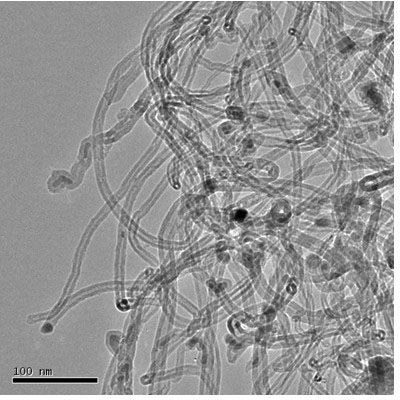

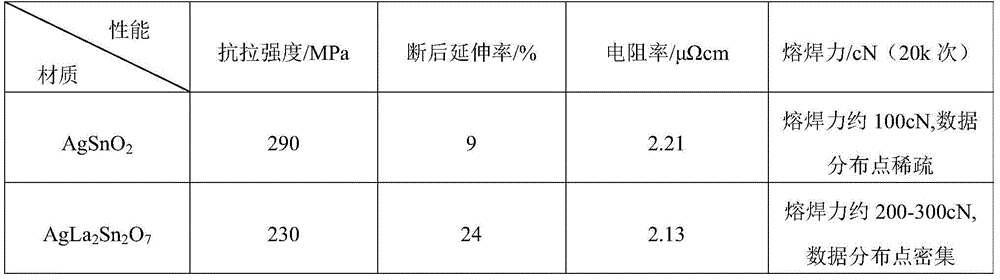

Preparation method of novel Ag-based lanthanum stannate composite electric contact material

The invention relates to preparation of an electric contact material and provides a preparation method of a novel Ag-based lanthanum stannate composite electric contact material. The preparation method comprises carrying out ball-mill mixing on Ag powder and lanthanum stannate nanometer powder to obtain AgLa2Sn2O7 composite powder, carrying out hot pressing sintering treatment to obtain an AgLa2Sn2O7 blank block, and carrying out hot extrusion treatment to obtain an AgLa2Sn2O7 wire rod. The preparation method utilizes a simple AgLa2Sn2O7 composite powder synthesis technology, utilizes a ball milling technology to realize synthesis and has a low cost. Compared with AgSnO2, the AgLa2Sn2O7 wire rod has lower specific resistance, higher elongation percentage after annealing fracture, good tensile strength, excellent mechanical properties and better welding resistance.

Owner:ZHEJIANG UNIV

Method for promoting solid catalyst to depolymerize cellulose

InactiveCN103626633AEasy to recycleAct quicklySugar derivativesOrganic compound preparationCelluloseHigh energy

The invention discloses a method for promoting a solid catalyst to depolymerize cellulose. The method comprises the following steps: placing the cellulose and the solid catalyst into a ball-milling device; performing mixed ball milling on the cellulose and the solid catalyst; and after ball milling is finished, taking out the mixed cellulose and solid catalyst to be used as a reaction substrate and a catalyst for consequent reactions. By the method, the characteristics of ball milling are maintained and the effect between the cellulose and the catalyst is promoted; the method is simple in process, short in ball-milling time, low in energy consumption, quick in consequent reaction and efficient and energy-saving; the catalyst is convenient to recover and easy to industrialize; and the conversion ratio of the cellulose can reach 100 percent. The method provided by the invention does not need inorganic acid, avoids discharge of acid liquid, is an environment-friendly process, and overcomes the defects of discharge of acid liquid, high requirements on equipment, high energy consumption, low yield and low selectivity of target products and the like in the existing production method.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

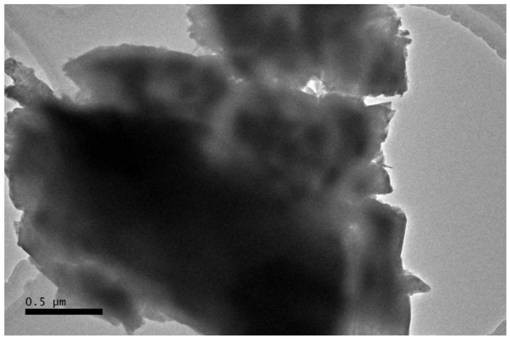

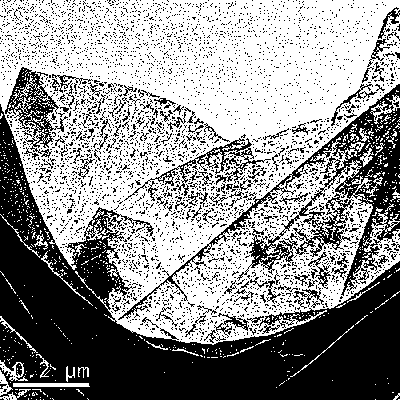

Method for preparing single-layer graphene through mechanical method

InactiveCN107089655AHigh degree of carboxylationIncrease success rateSingle layer grapheneExhaust valveSteel ball

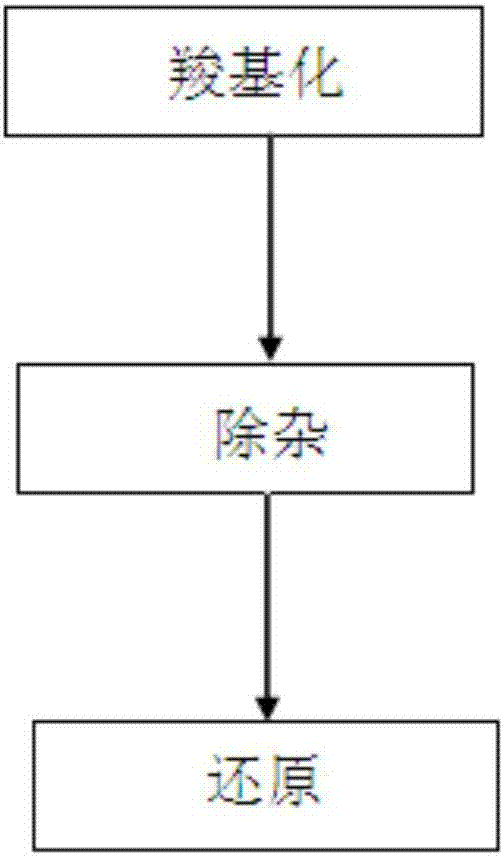

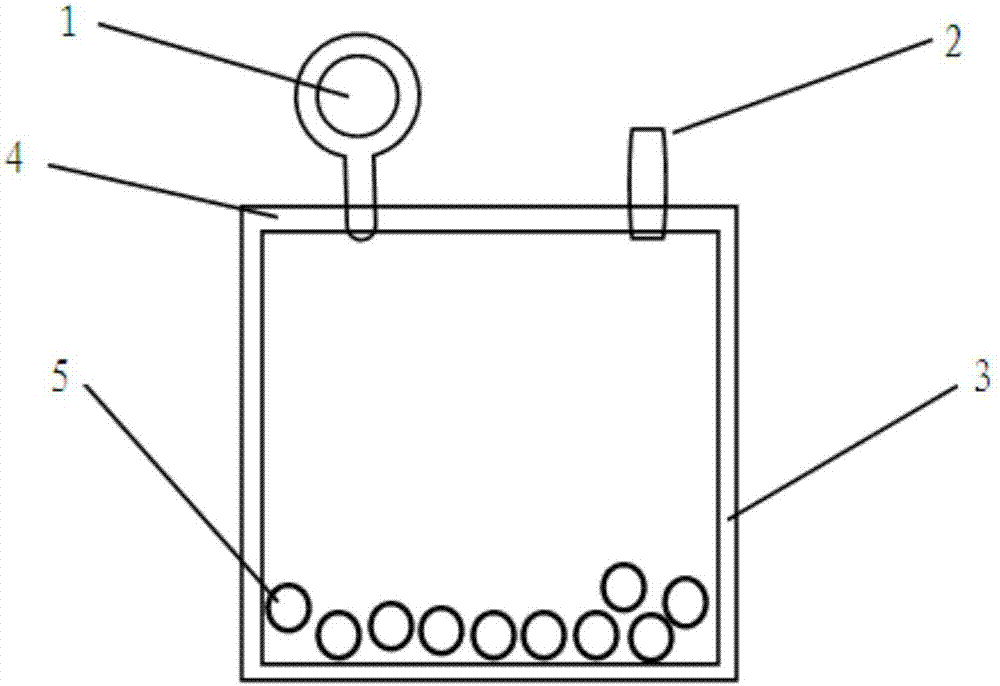

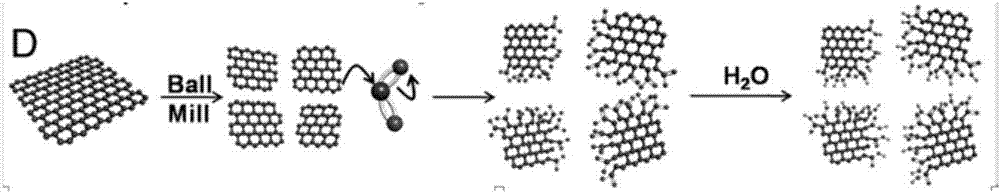

The invention belongs to the technical field of graphene preparation and relates to a method for preparing single-layer graphene through a mechanical method. A specific technological process of the method comprises three steps of a hydroxylation process, a decontaminating process and a reduction process. The edge of natural flake graphite is processed in a carboxylation mode through a ball milling method to obtain initial carboxylation graphene powder, then pure carboxylation graphene powder with small iron content is obtained through the decontaminating process, and high-quality single-layer graphene is obtained through the thermal reduction process. The method avoids any strong oxidant and has high carboxylation degree, short ball milling time and high success rate; the decontaminating process is simple and effective; the reduction process avoids using reducing agents and is environmentally friendly; a main structure of a ball milling tank related to the hydroxylation process comprises a pressure meter, a gas exhaust valve, a tank body, a sealing cover and a stainless steel ball. The method has high preparation success rate, large yield, no pollution and low energy consumption and can achieve large-scale mechanical production through amplifying ball milling equipment.

Owner:QINGDAO UNIV

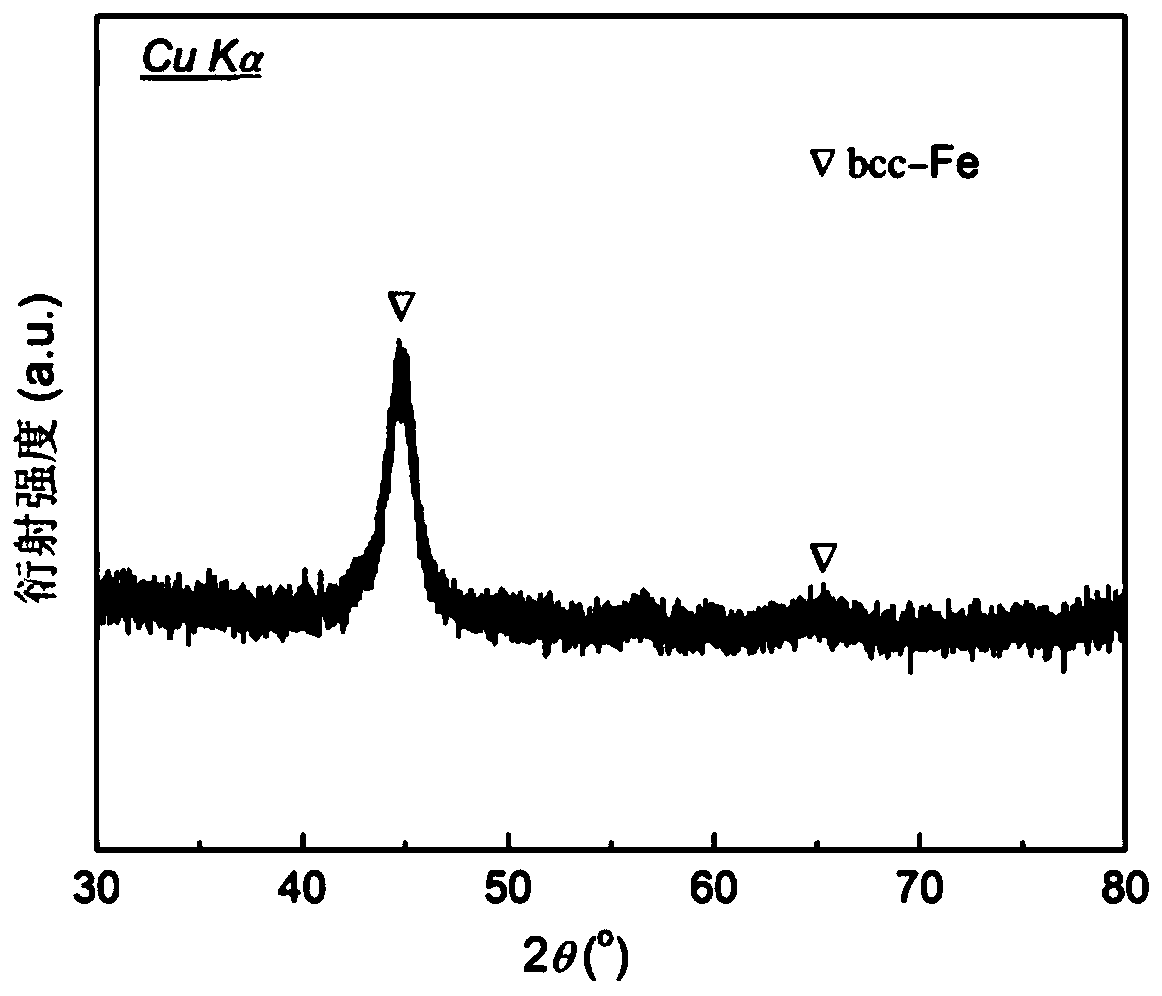

Iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent and preparation method thereof

ActiveCN109732078AHigh strengthImprove permeabilityMagnetic/electric field screeningNanocrystalNanocrystalline alloy

The invention provides an iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent. The component expression of alloy micropowder is FeaSibBcCudMe, wherein M is one or several of Al, Cr, Co, Ni, P and C elements; a, b, c, d and e respectively represent the atomic percent contents of corresponding components; a is not more than 90 and not less than 80; b is notmore than 15 and not less than 1; c is not more than 15 and not less than 3; d is not more than 2.5 and not less than 0; and e is not more than 5 and not less than 0. The invention further provides apreparation method of the iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent; and the preparation method comprises the following steps: (1) preparation ofraw materials for preparing alloy micropowder; and (2) preparation of nanocrystal alloy micropowder: the raw materials for preparing the alloy micropowder with diameters being less than 300 microns are selected to fill in a ball milling tank, inert gas is injected after vacuumizing for protection, and the alloy micropowder is prepared through ball milling. The iron base nanocrystal magnetically soft alloy micropowder electromagnetic wave absorbing agent and the preparation method thereof solve the defects in a traditional electromagnetic wave absorbing agent and a preparation method thereof.

Owner:DALIAN UNIV OF TECH

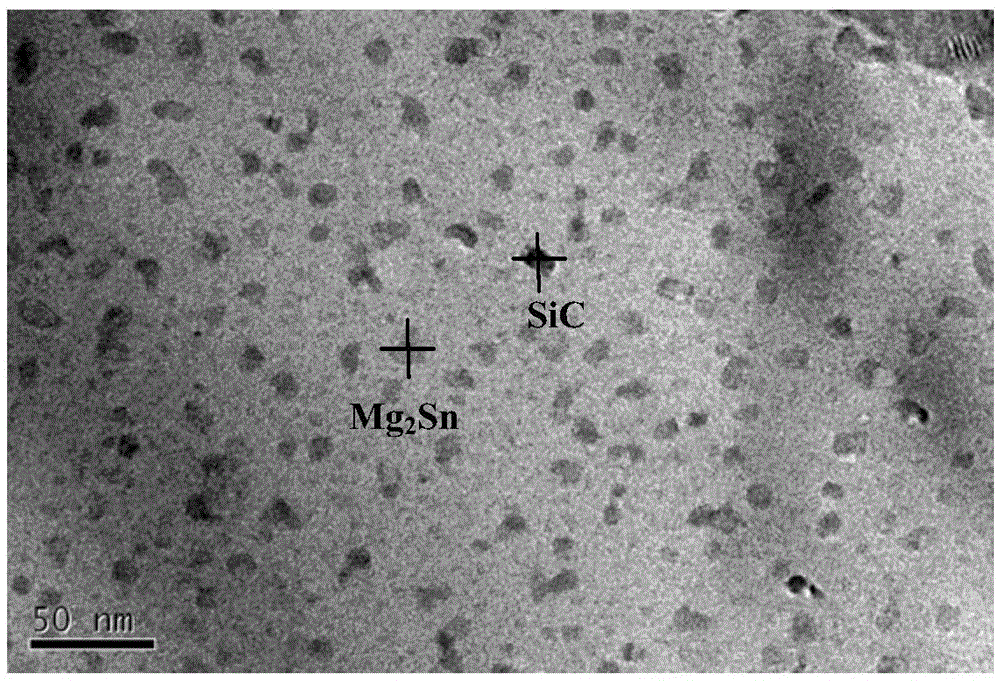

Method for preparing nanometer SiC composite Mg-Si-Sn-based thermoelectric material

ActiveCN105525122AControl contentPrevent oxidationThermoelectric device manufacture/treatmentThermoelectric materialsArgon atmosphere

The invention relates to a method for preparing a nanometer SiC composite Mg-Si-Sn-based thermoelectric material. The method comprises the following steps: first, melting Mg, Si and Sn block materials into cast ingots by using induction melting equipment, then putting the weighed nanometer SiC powder and the crushed cast ingots into a ball milling jar, and carrying out primary ball milling in argon atmosphere by adopting mechanical ball milling equipment; then, putting a graphite mould loading the primary ball-milled powder in a discharge plasma sintering chamber, and sintering into blocks in vacuum atmosphere; crushing the sintered blocks, carrying out secondary ball milling in the argon atmosphere, then sintering in the vacuum atmosphere, and thus obtaining highly-dense Mg2Si1-xSnx / SiCy(x is more than or equal to 0 and less than or equal to 1.0; y is less than or equal to 0.05) blocks. The method has the advantages of being low in cost, wide in range of applicable components, easy to operate and good in reliability, can realize dispersive distribution of nanometer SiC particles in a Mg2Si1-xSnx matrix, and meanwhile can refine the matrix grain size and improve the density and machinability of the materials.

Owner:中国冶金科技成果转化有限公司

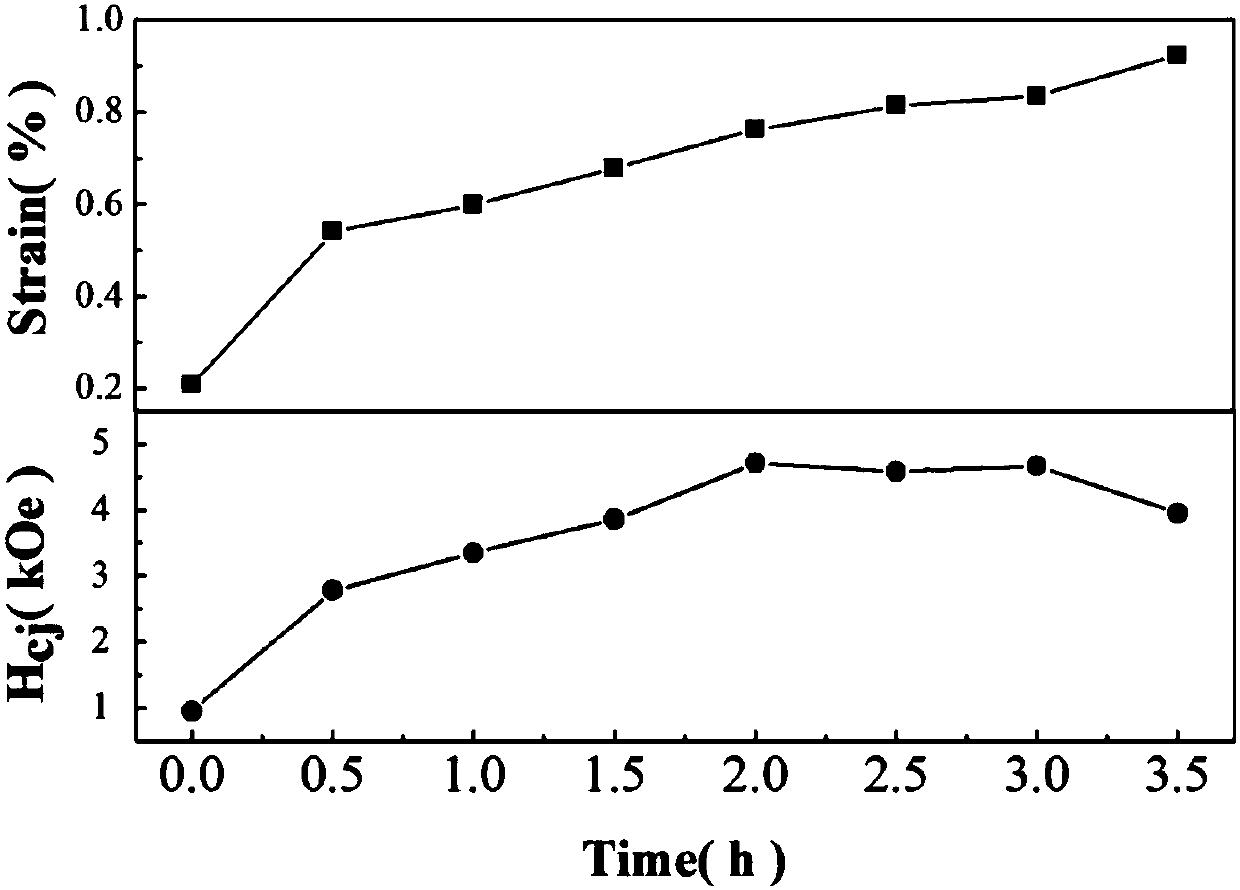

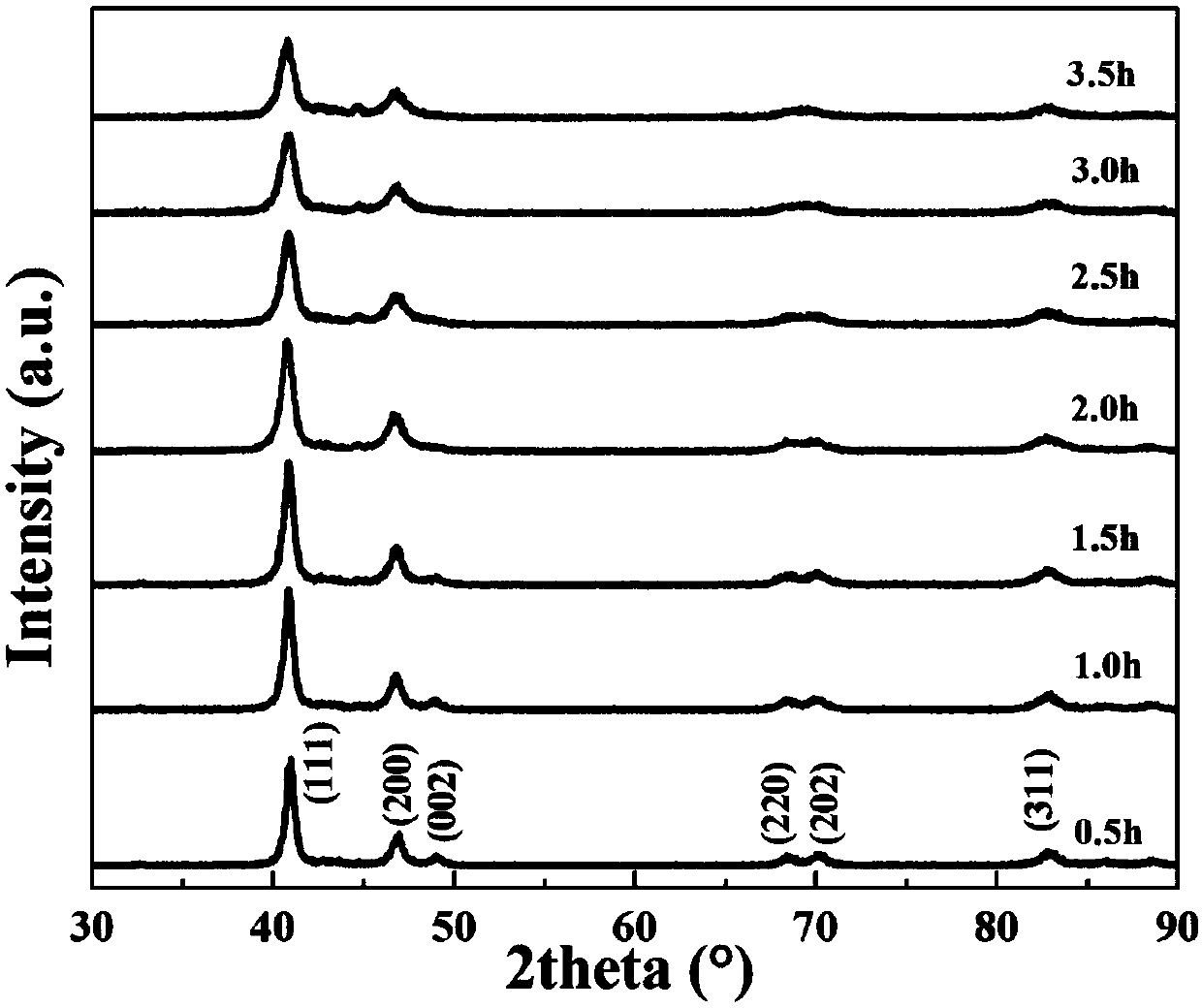

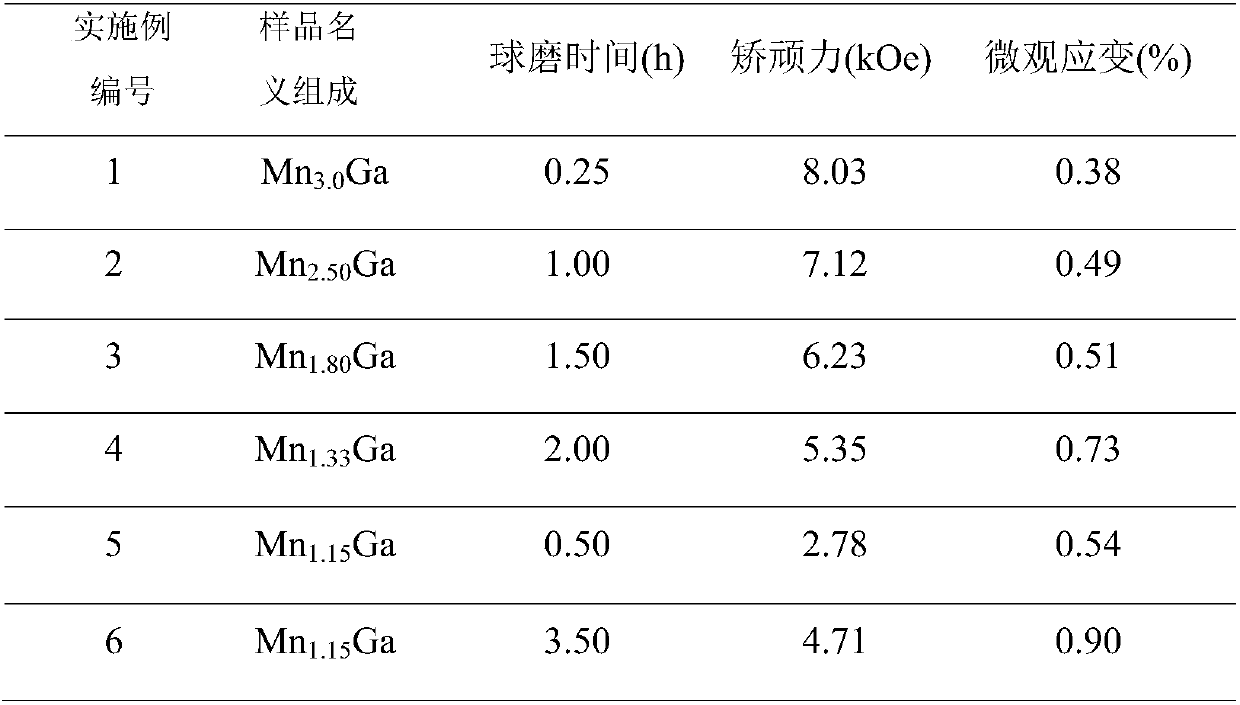

Preparation method of high-coercivity manganese gallium magnetic powder

InactiveCN107622852AShort milling timeImprove coercive forceMagnetic materialsMagnetic powderCoercivity

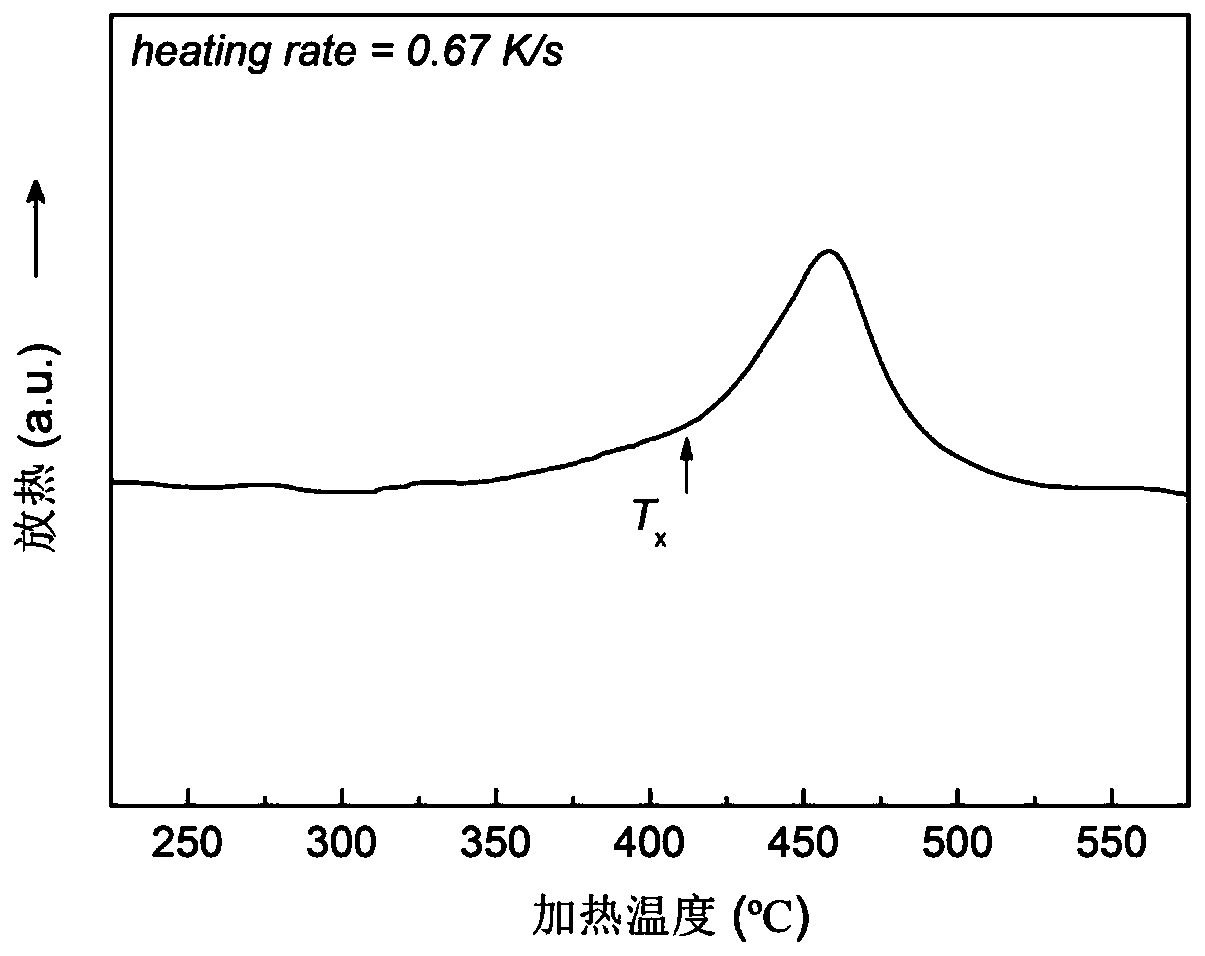

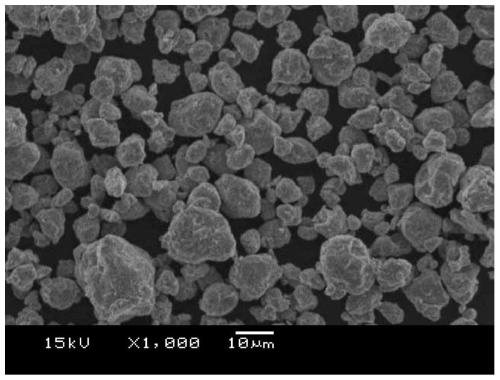

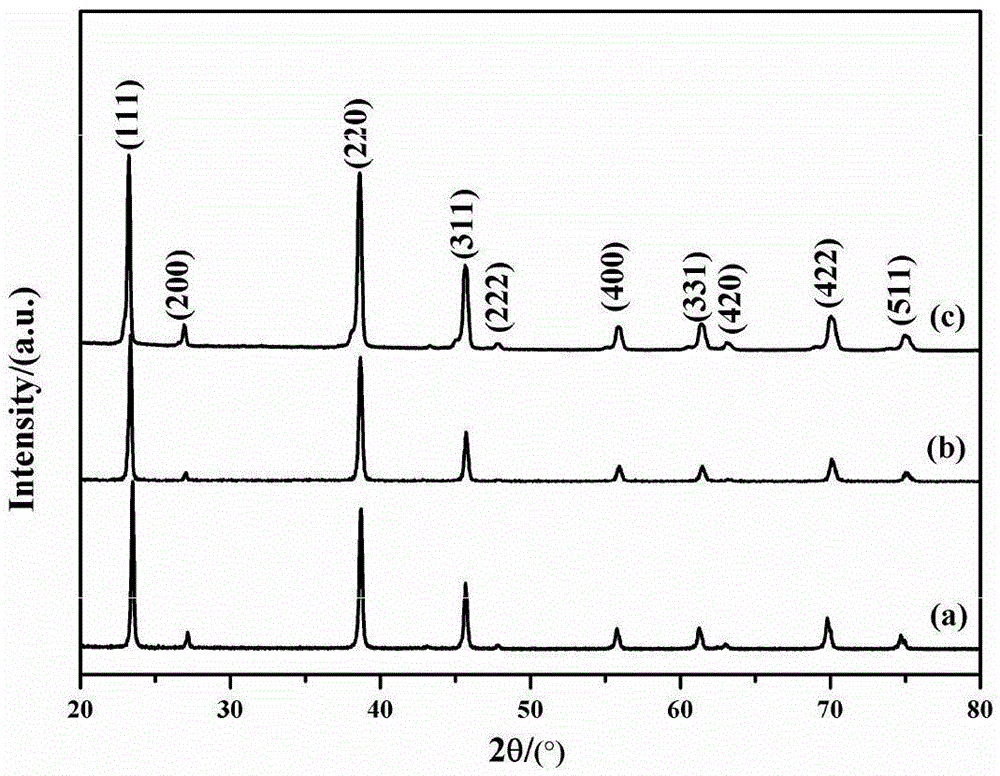

The invention discloses a preparation method of high-coercivity manganese gallium magnetic powder, and belongs to the technical field of a magnetic material. The method for preparing the high-coercivity manganese gallium magnetic powder by a mode of introducing micro strain comprises the steps of obtaining a Mn<x>Ga alloy ingot through a suspension smelting technology firstly; performing annealingat a temperature of 400-650 DEG C for 1-10 days to obtain a tetragonal phase; performing rough crushing and sieving and then putting into a ball mill tank prepared from stainless steel; by adopting gasoline as a medium and by combination with a low-energy ball milling method, performing ball milling for 0-3.5h to obtain the high-coercivity manganese gallium magnetic powder, wherein the micro strain is 0.3-1.0 based on different ingredients and processing technologies. By virtue of rough smashing and by combination with the low-energy ball milling method, the manganese gallium magnetic powderis prepared, so that the problem of phase change caused by overhigh ball milling energy can be avoided; and meanwhile, a phenomenon of induced magnetic anisotropy and high coercivity induced by the stress is observed, so that a new means is provided for magnetic hardening of the manganese gallium permanent magnetic material.

Owner:BEIJING UNIV OF TECH

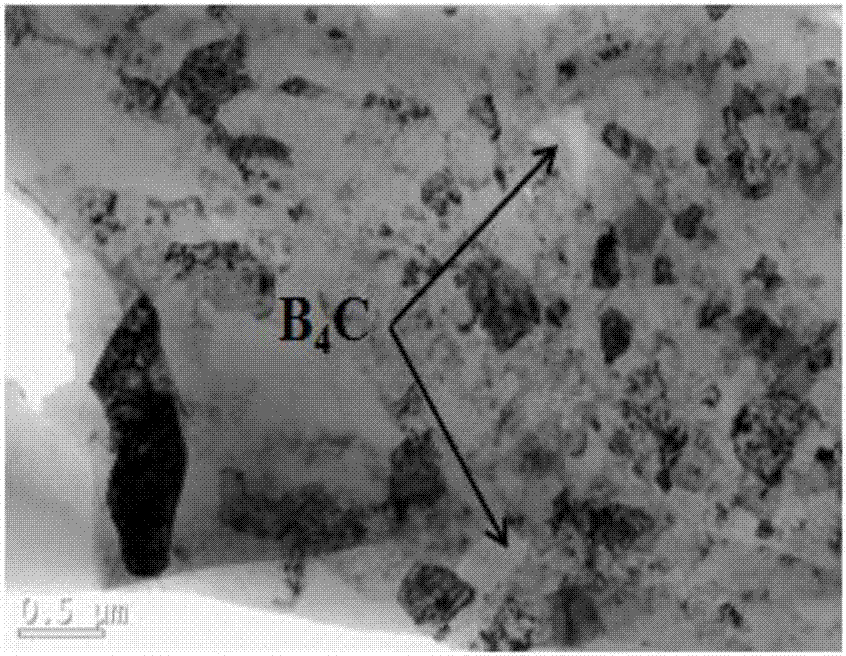

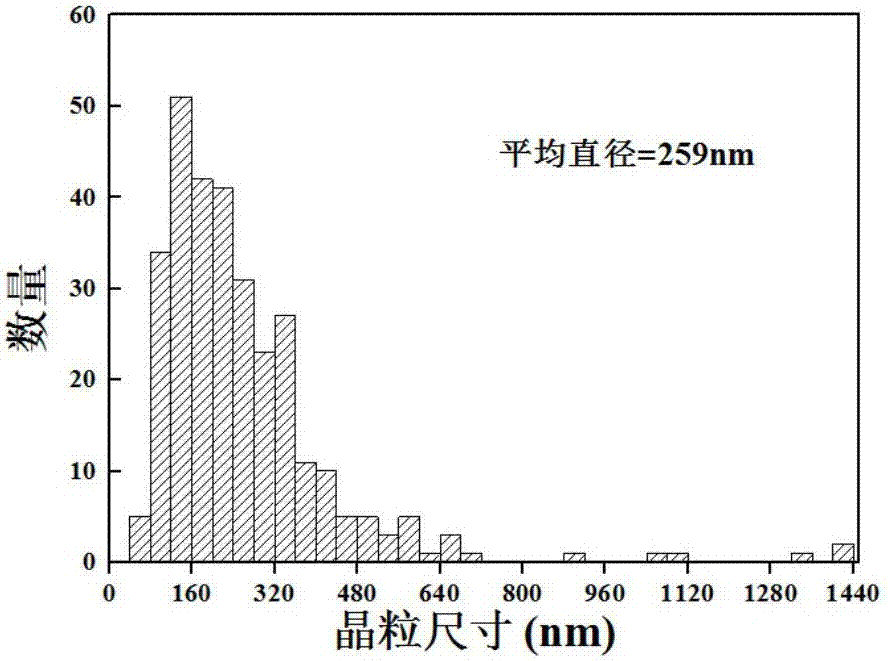

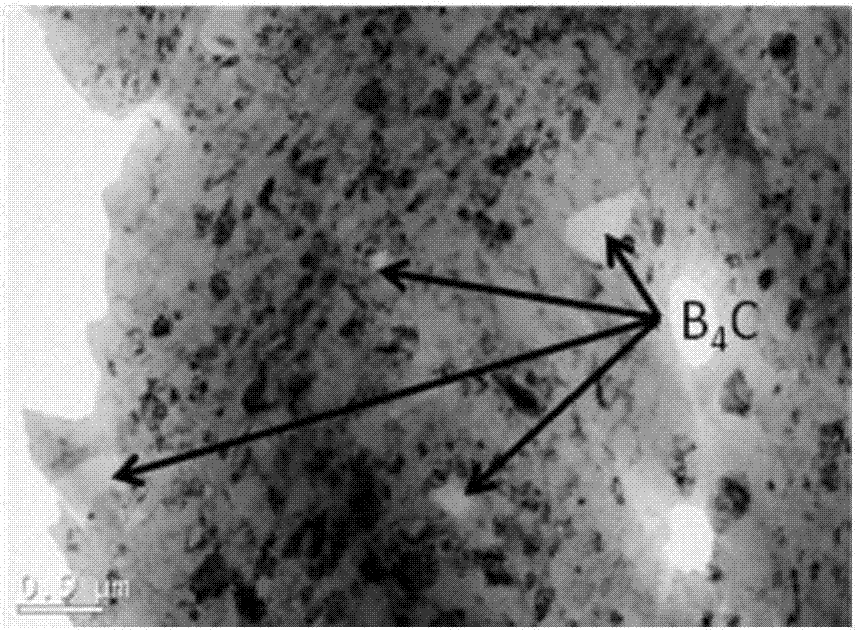

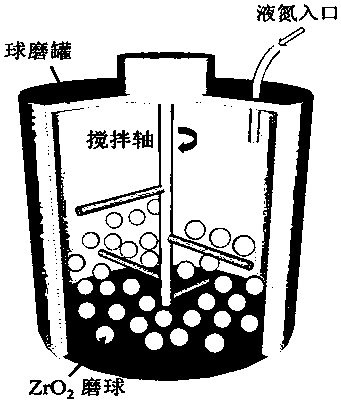

Preparation method for boron carbide particle reinforced nanometer/ultra-fine grain aluminum based composite

The invention relates to a preparation method for a boron carbide particle reinforced nanometer / ultra-fine grain aluminum based composite. According to the method, a low-temperature ball milling method is adopted for preparing nanometer compound powder and plasma activated sintering (PAS) is adopted for realizing the low-temperature compaction of the nanometer compound powder. The preparation method comprises the five steps of mixing raw materials, performing low-temperature ball milling, exhausting, performing discharging plasma activated sintering and perfoming thermal treatment, thereby obtaining the high-compactness nanometer / ultra-fine grain aluminum based composite. The nanometer / ultra-fine grain aluminum based composite prepared according to the invention has the advantages of high compactness, small grain size and excellent mechanical property; the compactness is more than or equal to 90%, the grain size of a substrate is less than 200nm, the hardness reaches up to 242.5HV and the compression yield strength reaches up to 866MPa; the boron carbide particle reinforced nanometer / ultra-fine grain aluminum based composite can be widely applied to the technical fields of aerospace, automobiles and military.

Owner:WUHAN UNIV OF TECH

Preparation method of evaporation material with low refractive index

InactiveCN107285753AUniform compositionSimple and fast operationMaterials preparationRefractive index

The invention discloses a preparation method of an evaporation material with low refractive index. The preparation method comprises the steps of material preparation, material mixing, slurry drying, press forming, sintered body preparation and cleaning and packaging. The preparation method is reasonable in design and convenient to operate, materials are subjected to wet ball-milling in a planet ball mill with water as a mixing medium, shorter ball-milling time is taken, and slurry with uniform and consistent components is obtained. The evaporation material prepared with the preparation method has the advantages as follows: splashing caused by light weight of the electronic gun bombardment evaporation material can be avoided; the density is large, the gas release amount in the coating process is reduced, and thus, the membrane layer quality is improved; the surface is a diffusion reflection plane, the evaporation angels are consistent, the evaporation rate is uniform and stable, and an electronic gun can be focused easily; the surface of the evaporation material is subjected to ultra-cleaning treatment and is clean, dust cannot fall off easily, and sputtering points can be avoided during coating.

Owner:CHANGZHOU PROSRUN PHOTOELECTRIC TECH CO LTD

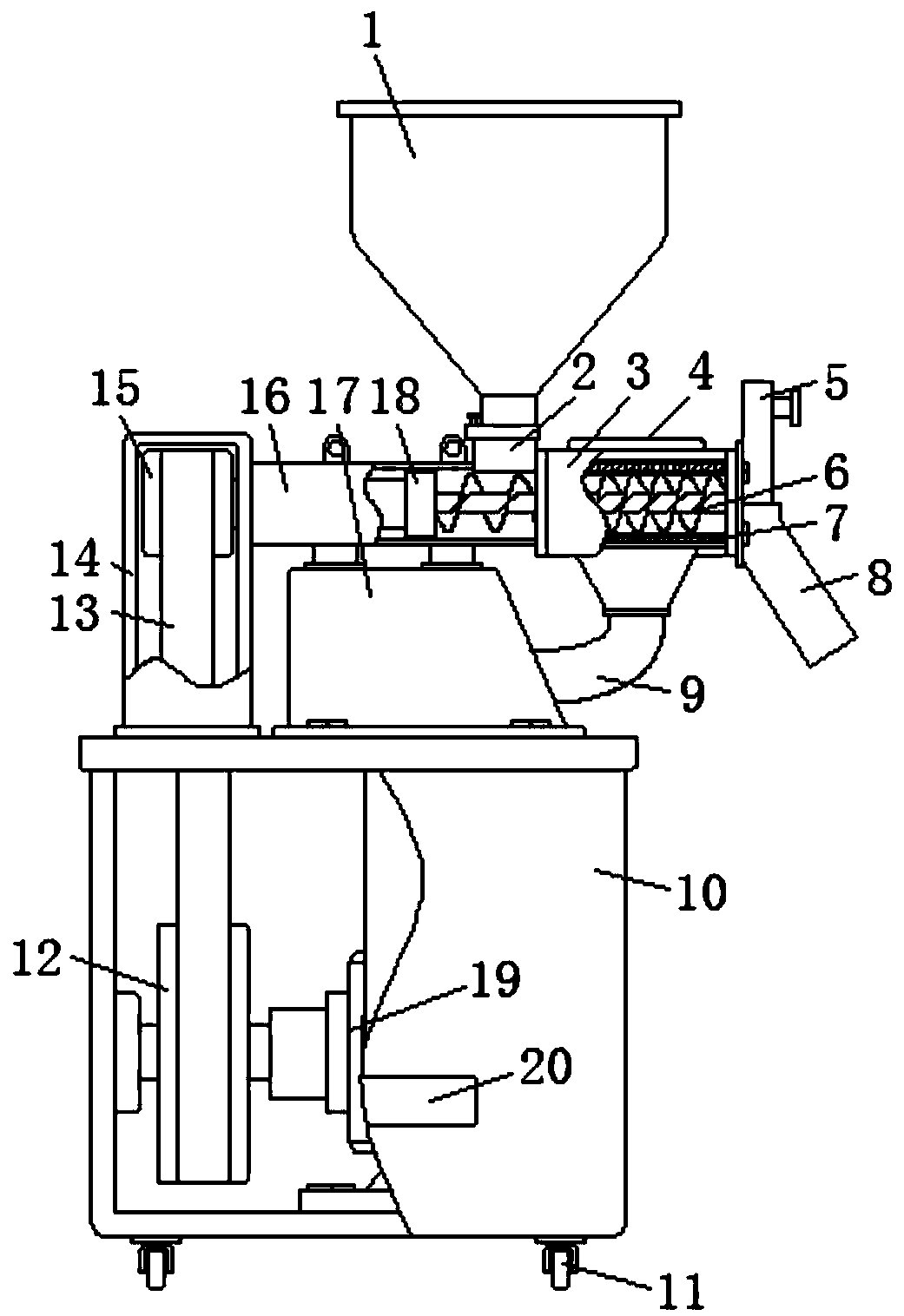

Efficient rice milling machine

The invention discloses an efficient rice milling machine. The machine comprises a case, a fixing base is fixedly connected to the top of the case through bolts, and a conveying pipe is fixedly connected to the top of the fixing base through bolts; a coupler is arranged in the conveying pipe, a spiral rod is fixedly connected to one side of the coupler through a fixing groove, and sliding groovesare formed in the portions, located at the two sides of the fixing groove, of the coupler. According to the efficient rice milling machine, through arrangement of the coupler, the sliding grooves, limit rods, springs and a clamping groove, when the spiral rod is installed, the limit rods and the spiral rod are aligned with the sliding grooves and the fixing groove in the coupler respectively, thenthe spiral rod is pushed, and the spiral rod drives the limit rods to slide in the sliding grooves during movement; meanwhile, by compressing the springs in the grooves through compression of press blocks, when the spiral rod cannot be pushed, the limit rods just reach the corners of the L-shaped sliding grooves, at this moment, the spiral rod is pressed and rotated, and the limit rods enter thehorizontal-movement portions from the corners of the sliding grooves.

Owner:湖南省好运来机电设备有限公司

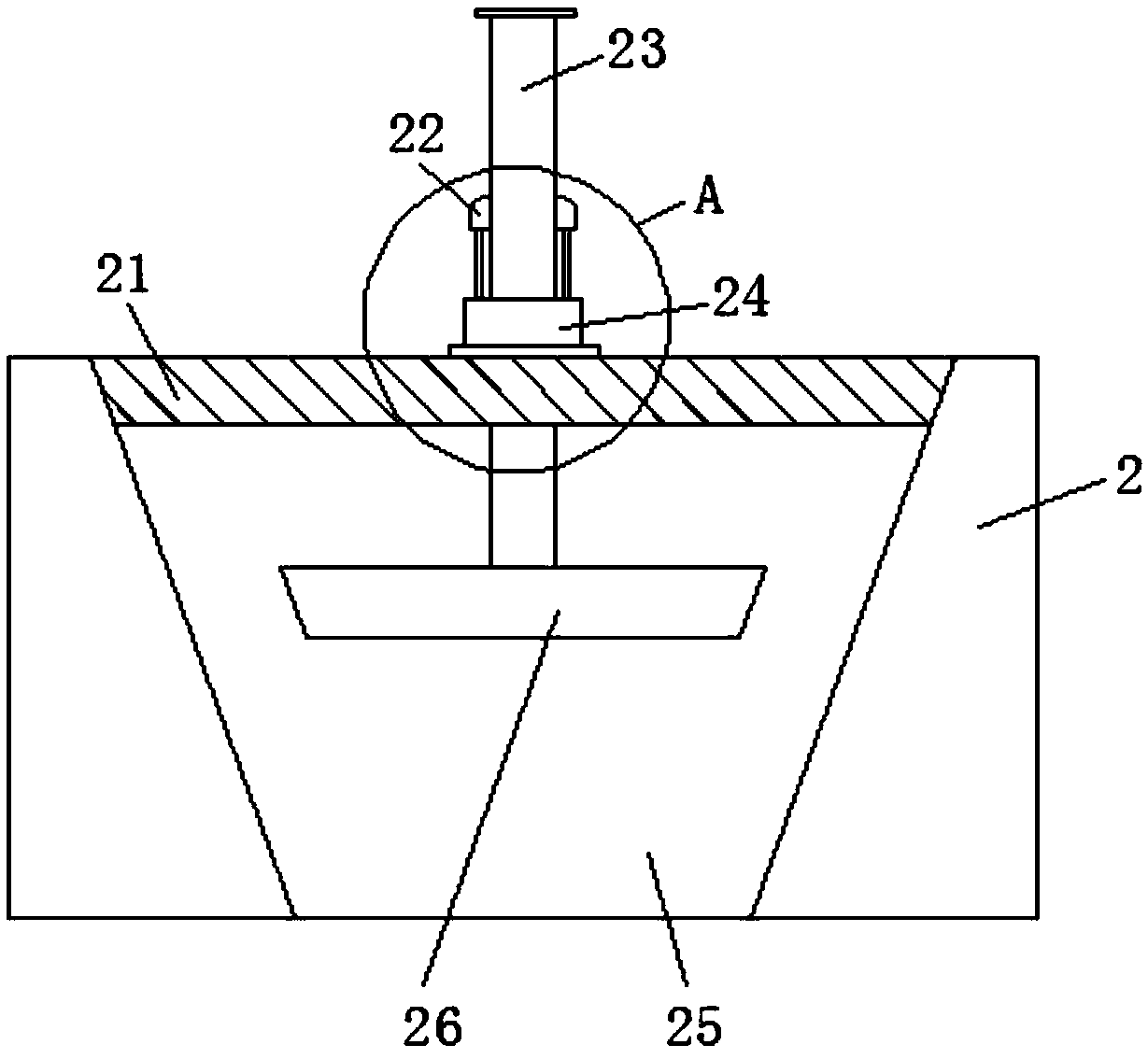

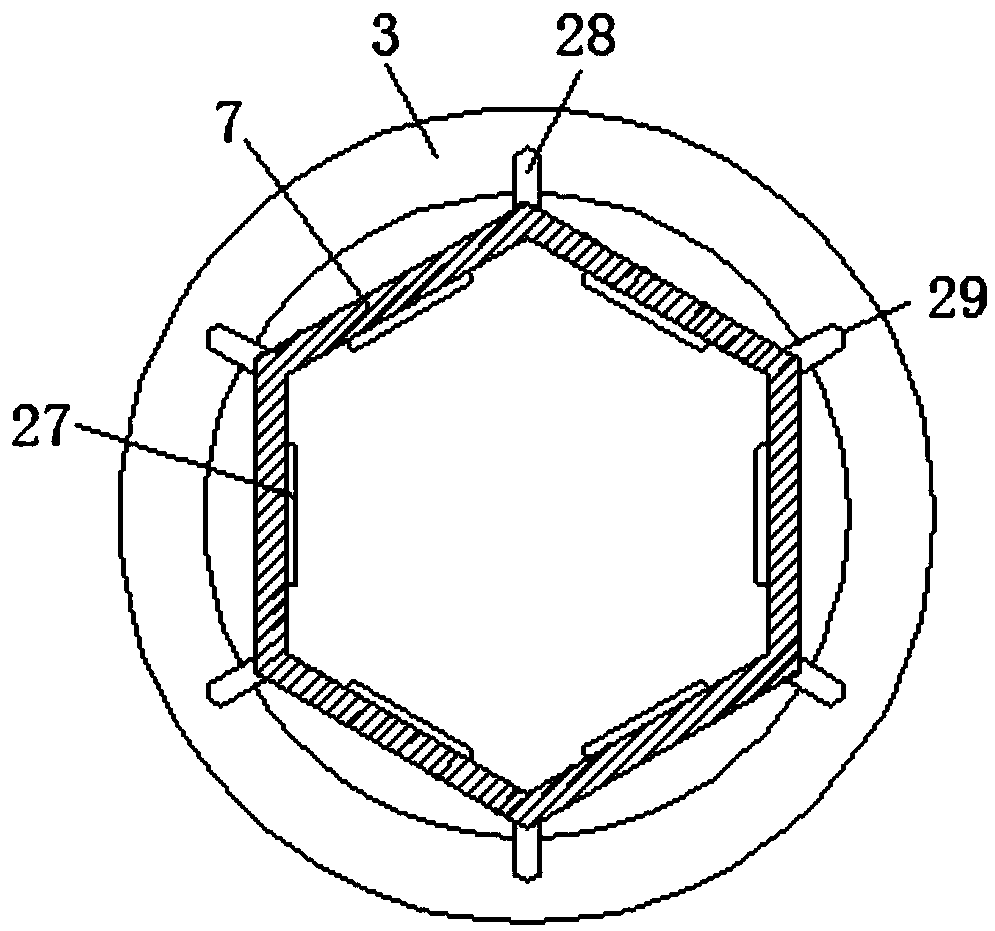

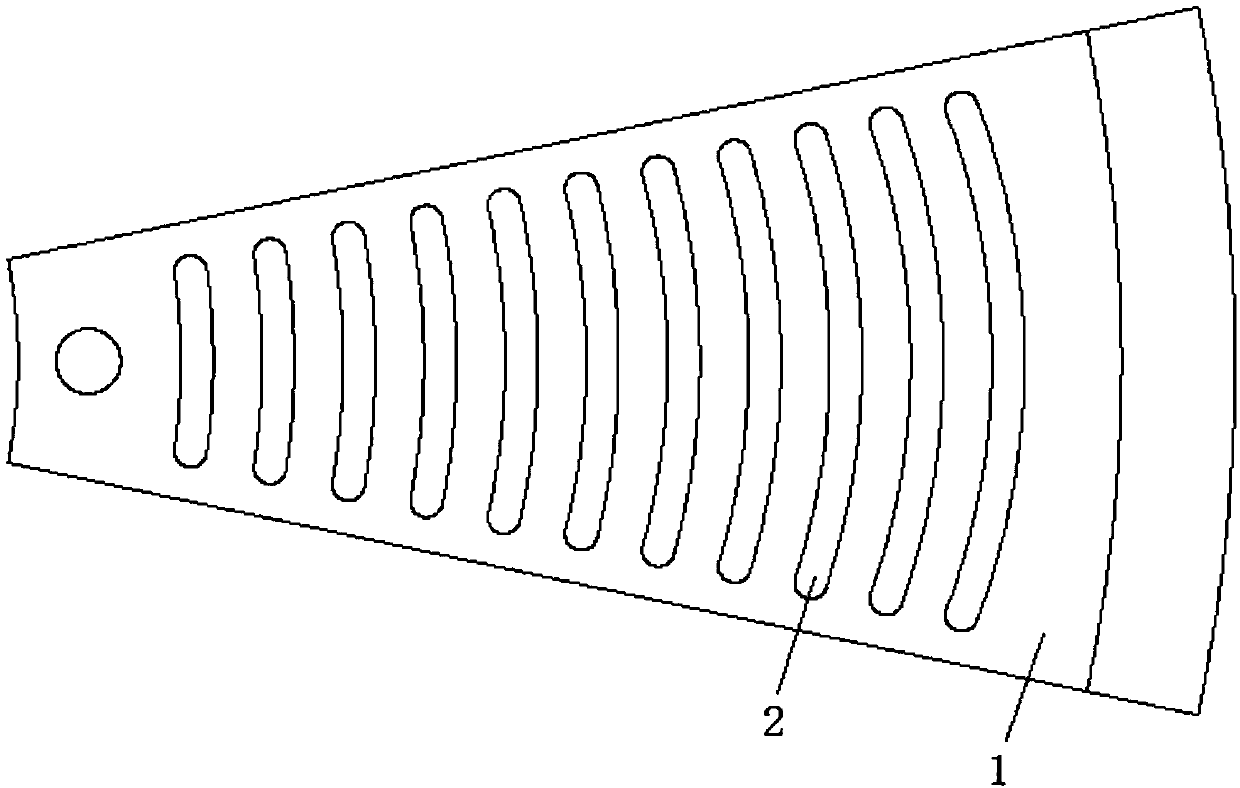

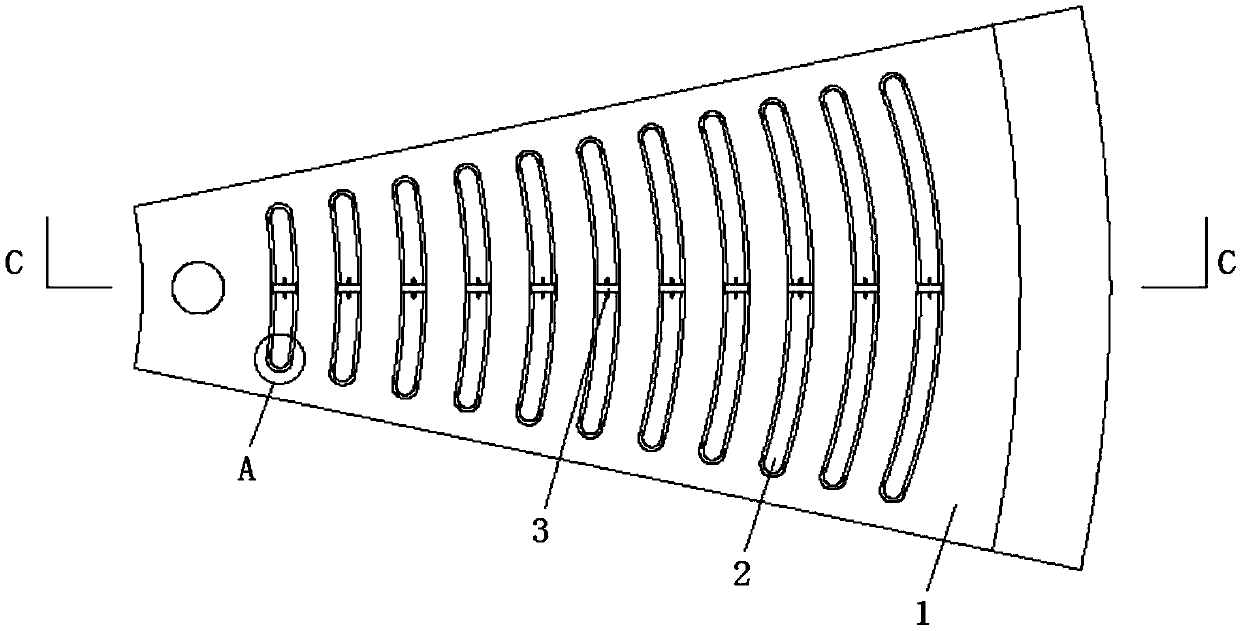

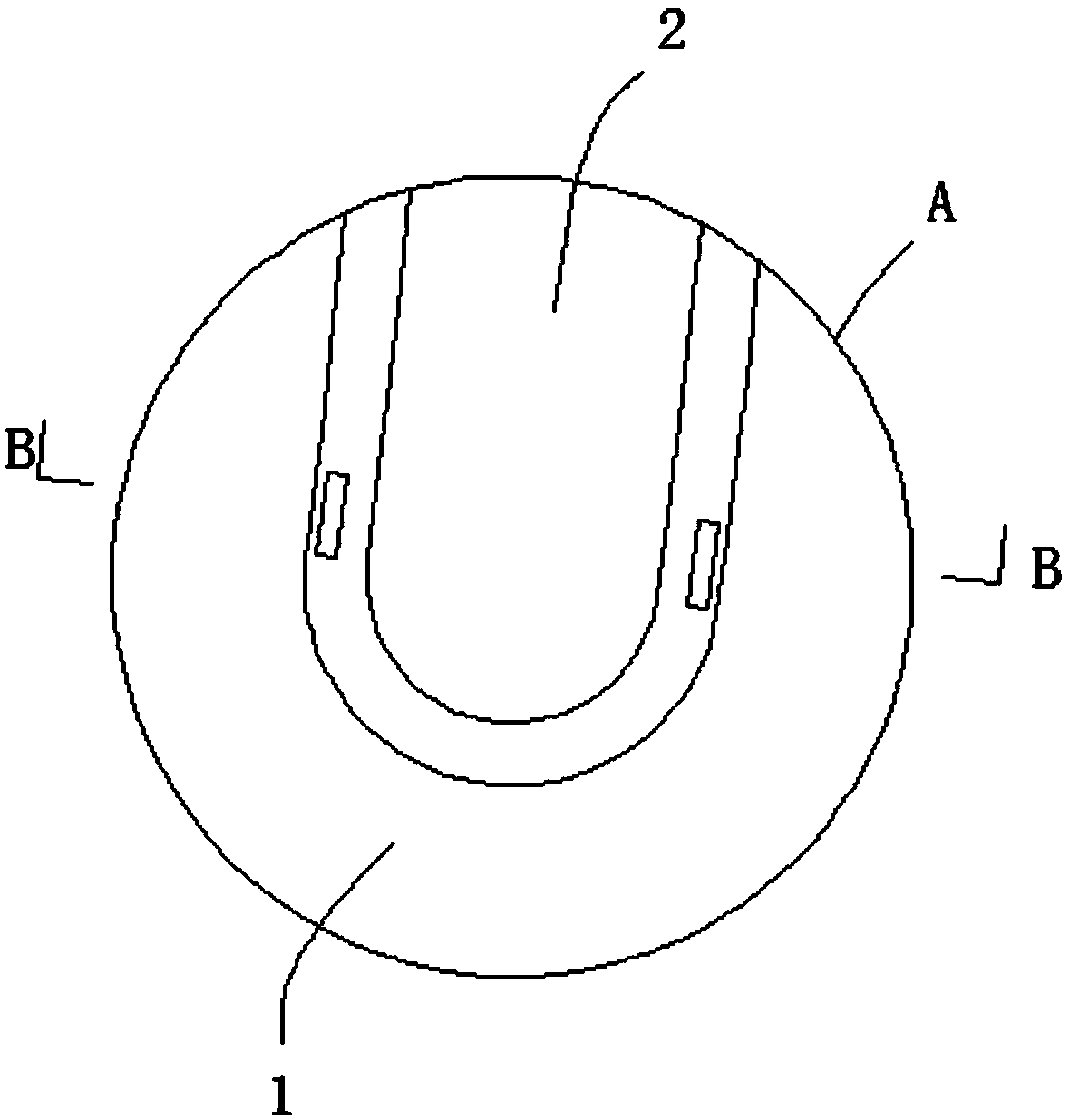

Partition board for ball mill

The invention relates to the technical field of ball mill equipment, and discloses a partition board for a ball mill. The partition board comprises a grate plate; grate seams are formed in the surfaceof the grate plate; cleaning devices are arranged inside the grate seams; and each cleaning device comprises an output-end balancing weight, the output-end balancing weight is glidingly connected with the inner wall of the corresponding grate seam, and a long bolt is arranged on the right side surface of the output-end balancing weight. The grate plate is driven by a barrel to rotate, and the positions and the directions of the grate seams are changed all the time, so that the cleaning devices reciprocate along the grate seams under the action of the gravity of the cleaning devices to clean dirt on the inner walls of the grate seams; by the aid of section triangular scraping strips arranged on the edges of the output-end balancing weights, inlet-end balancing weights and middle balancingweights, the dirt adhering to the inner walls of the grate seams is easier to strip; the dirt adhering to the inner walls of the grate seams is stripped timely and cannot be accumulated layer upon layer on the inner walls of the grate seams, the widths of the grate seams are fixed, material particles after ball milling meet the requirement, the ball milling time is short, and the ball milling production efficiency is high.

Owner:义乌市鼎莎针织有限公司

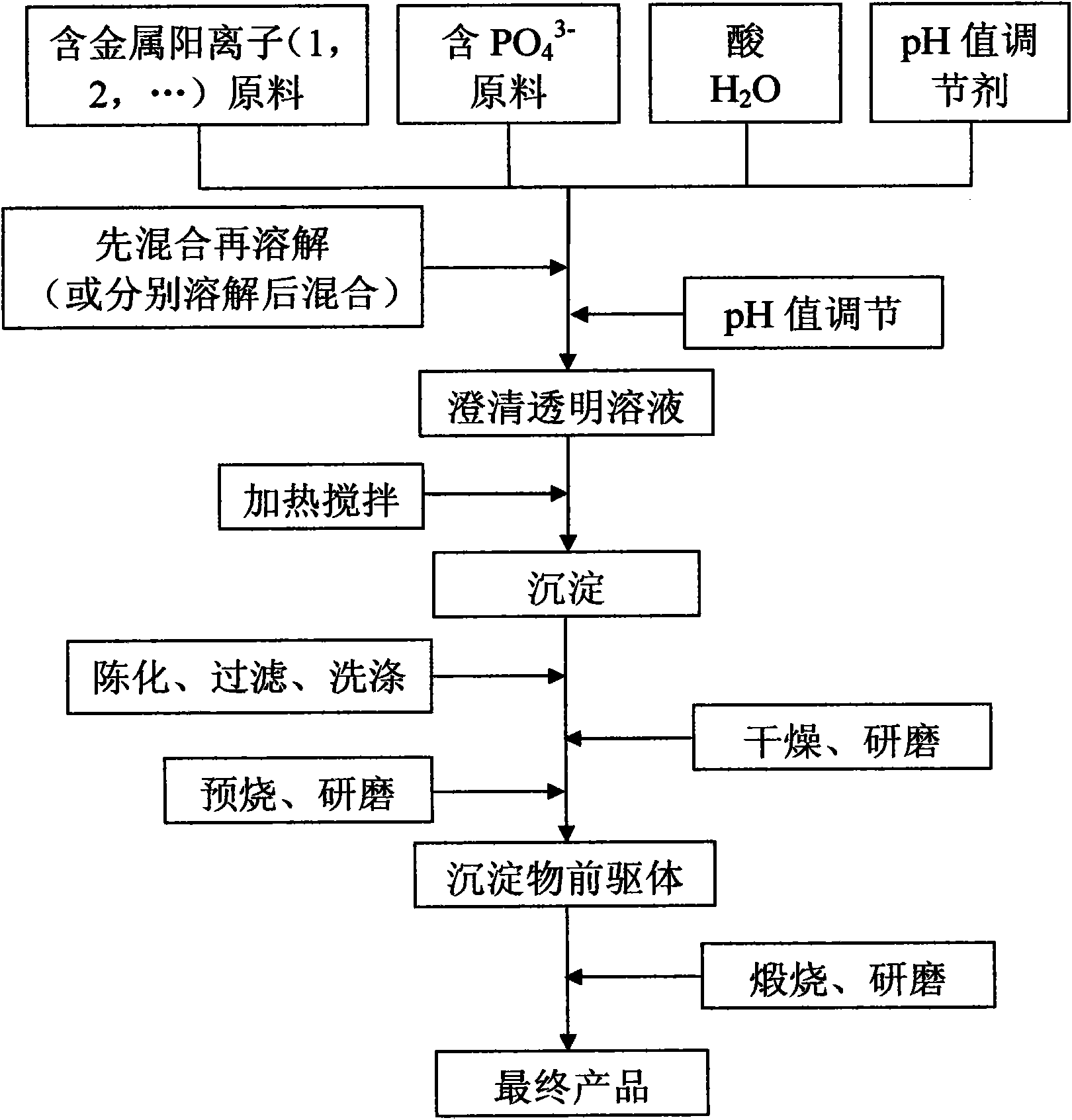

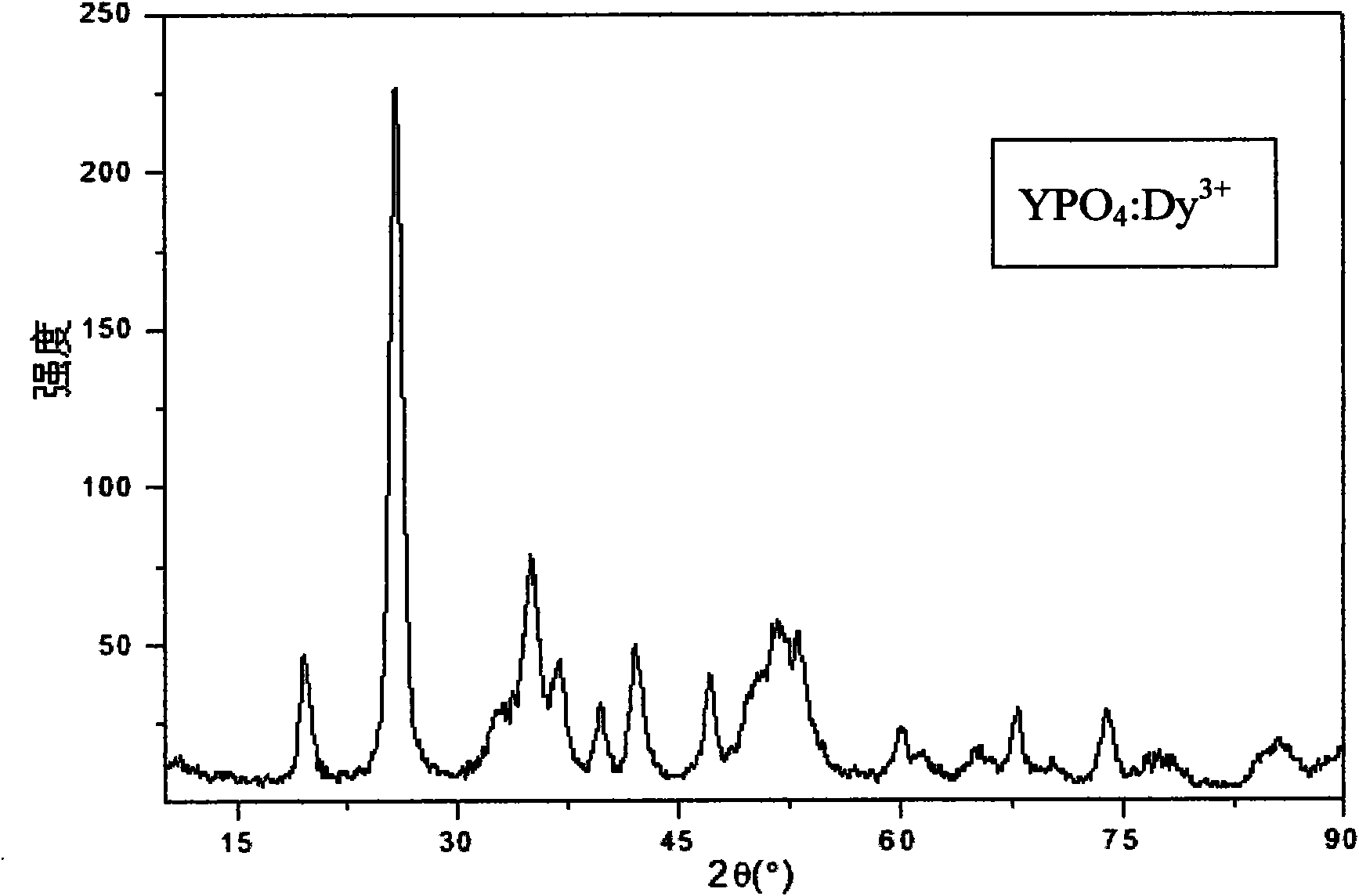

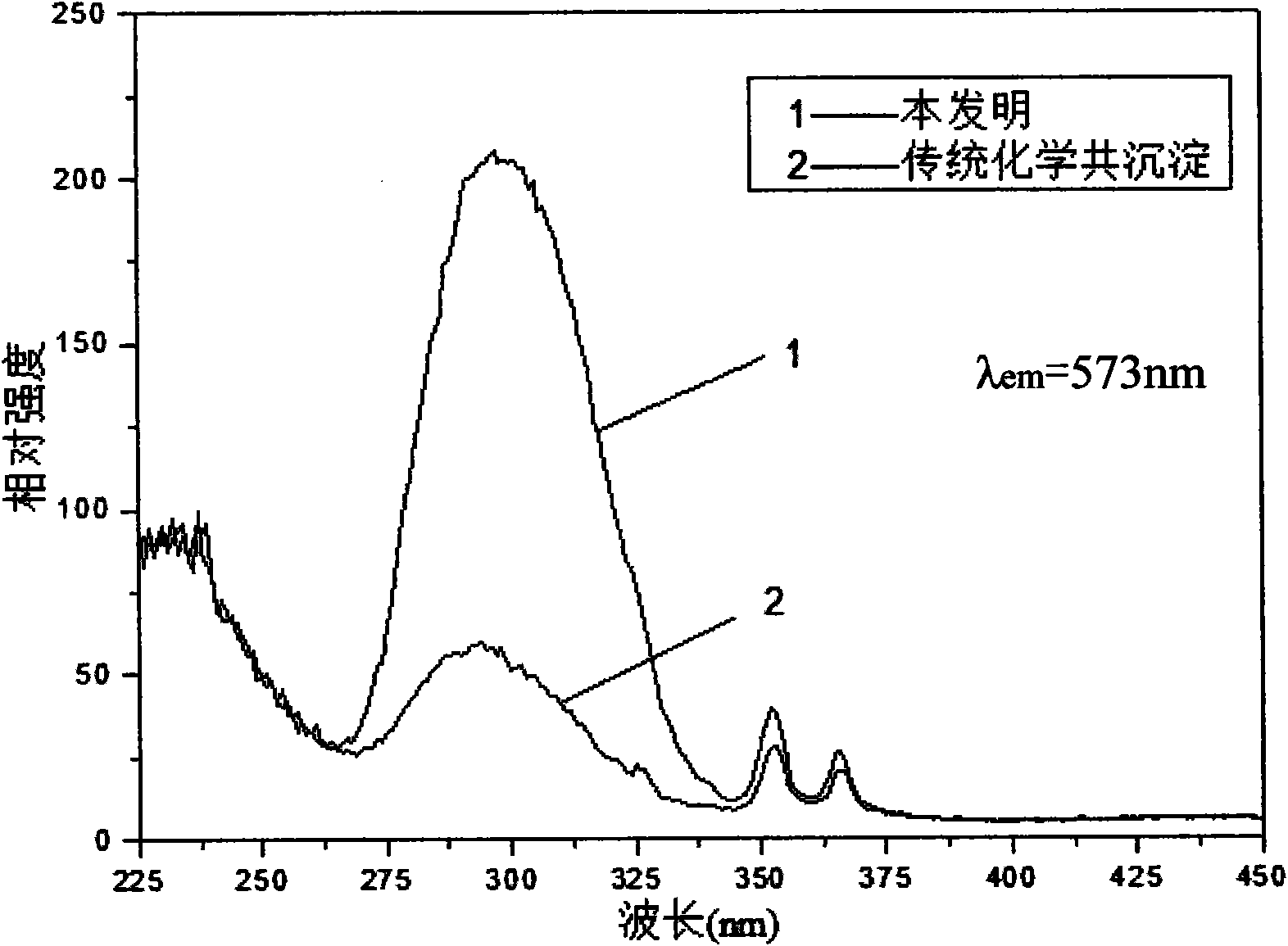

Preparation method of phosphate luminescent material

InactiveCN101982521AUniform size distributionUneven solutionPhosphorus compoundsLuminescent compositionsFluorescencePhosphate

The invention discloses a preparation method of phosphate luminescent material, which is used for preparing monometallic cation phosphate and single-phase polymetallic cation phosphate. In a liquid phase system containing water, the raw materials comprise substance which contains PO4<3-> and can be dissolved into acid or water, and substance which contains corresponding metallic cation, can be dissolved into acid or water and directly reacts with PO4<3-> to generate water-fast phosphate precipitate. The raw materials and the pH value regulator are mixed to be dissolved into acid and water to obtain settled solution. Urea is heated and decomposed to evenly release OH<-> to cause the pH value of the solution to rise, and meanwhile, the phosphate which is not dissolved in the liquid phase system is generated. The final product is obtained by washing, drying, ball milling and high-temperature calcining. The invention has the advantages of simple technology, short flow, easy control, low cost, low calcination temperature, even particle size distribution, good fluorescence performance and the like.

Owner:XIAN UNIV OF TECH

Method for synthesizing tin-titanium carbide at low temperature

InactiveCN1821084AWide variety of sourcesLow priceTin compoundsTitanium compoundsTitanium carbideBall mill

The synthesis process of Ti2SnC powder includes the following steps: ball milling C powder in a ball mill of vacuum degree lower than 1 Pa, rotation speed of 150-300 rpm and with agate balls and material / ball ratio of 10-100 for 4-15 hr to obtain sub-micron or nanometer level superfine C powder; compounding superfine C powder, Ti powder and Sn powder in the molar ratio of 0.7-1 to 2 to 0.8-1.2 and mixing in a mixing machine for 5-10 hr; pressing the mixture at 50-100 MPa pressure the form lumps; and high temperature roasting in a furnace under vacuum or Ar atmosphere in the temperature raising rate of 10-40deg.c / min to 550-850deg.c and maintaining for 5-30 min. The synthesis process has short synthesis period, low temperature, wide temperature range and low cost, and is suitable for industrial production.

Owner:BEIJING JIAOTONG UNIV

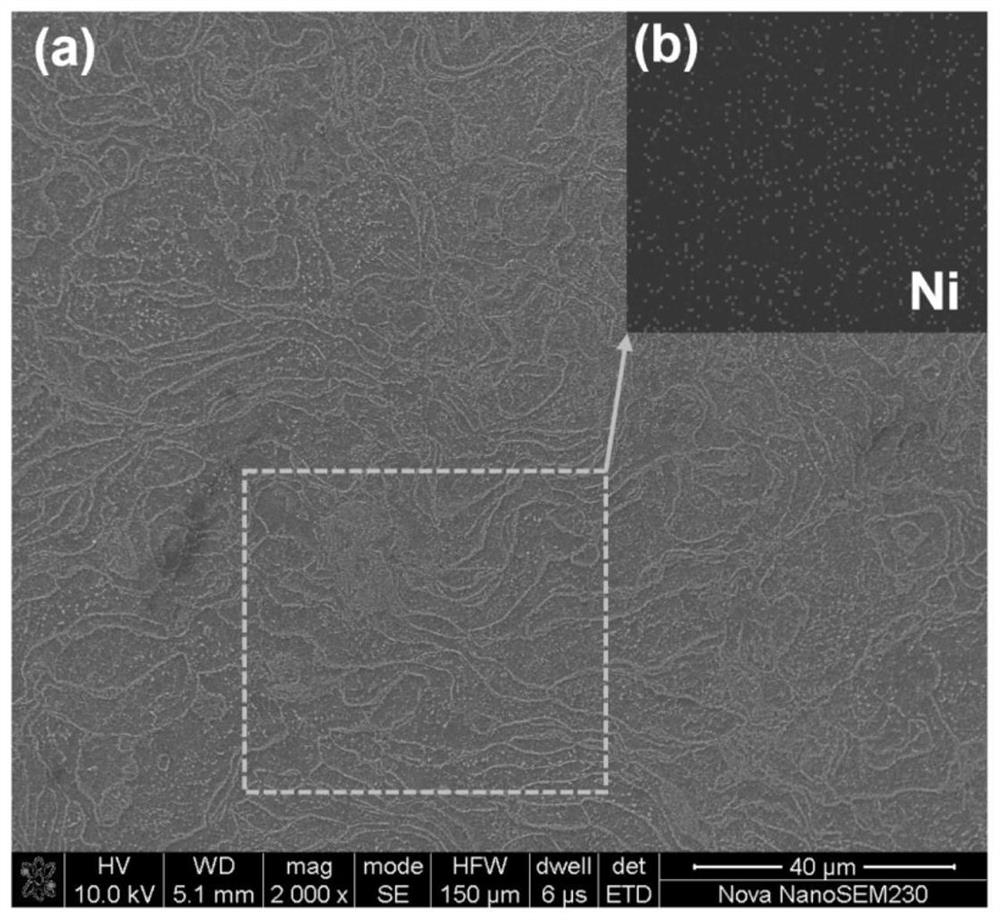

Method for improving comprehensive performance of carbon nanomaterial reinforced nickel-based superalloy

InactiveCN112008087AEliminate agglomerationEvenly dispersedMaterial nanotechnologyAdditive manufacturing apparatusOxidation resistantSuperalloy

The invention provides a method for improving the comprehensive performance of a carbon nanomaterial reinforced nickel-based superalloy, and belongs to the field of powder metallurgy and superalloy. Aiming at the problem that the high-temperature oxidation resistance of the carbon nanomaterial reinforced nickel-based superalloy is reduced, the surface of a carbon nanomaterial is coated with a compact Ni layer for the first time, so that the problems of poor mechanical property and high-temperature oxidation resistance caused by easy agglomeration of the carbon nanomaterial, poor bonding with amatrix interface and the like are solved. Through a specific ball milling process, mixed powder with uniformly dispersed carbon nanomaterials is obtained, and further uniform dispersion of the carbonnanomaterials is realized. A carbon nanomaterial reinforced Rene104 nickel-based composite material is prepared through spark plasma sintering (SPS), hot isostatic pressing, hot pressing, hot extrusion or hot forging, or 3D printing and other powder forming methods, so that the prepared material is excellent in mechanical property and excellent in high-temperature oxidation resistance, and the problem that the carbon nanomaterial reinforced metal-based composite material cannot be used as a high-temperature structural material is effectively solved.

Owner:CENT SOUTH UNIV

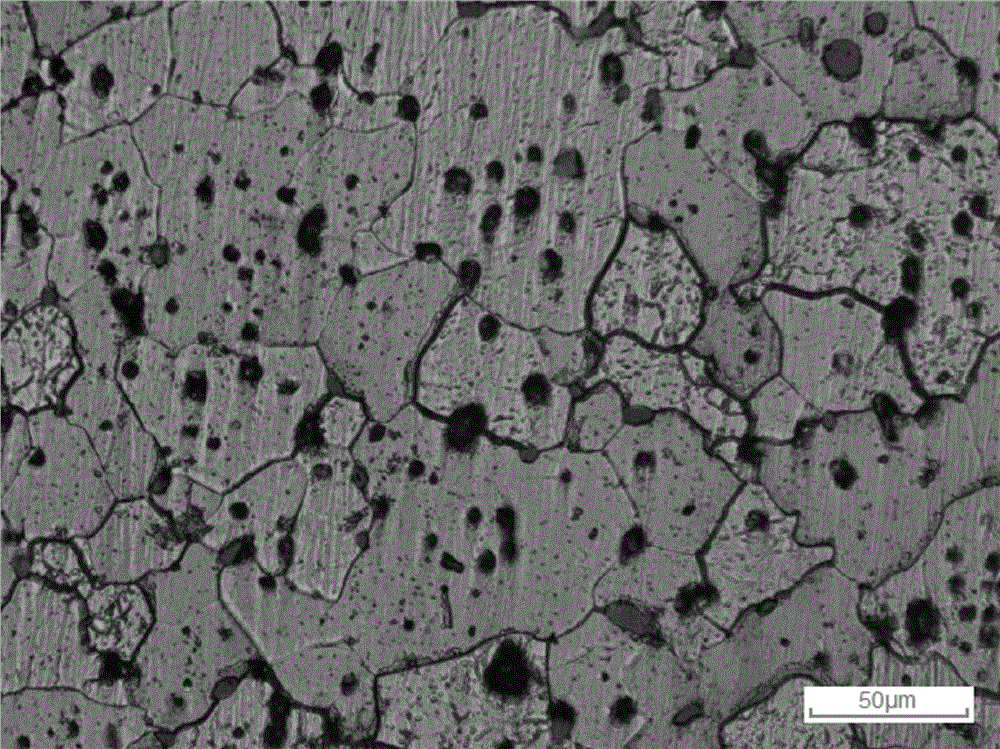

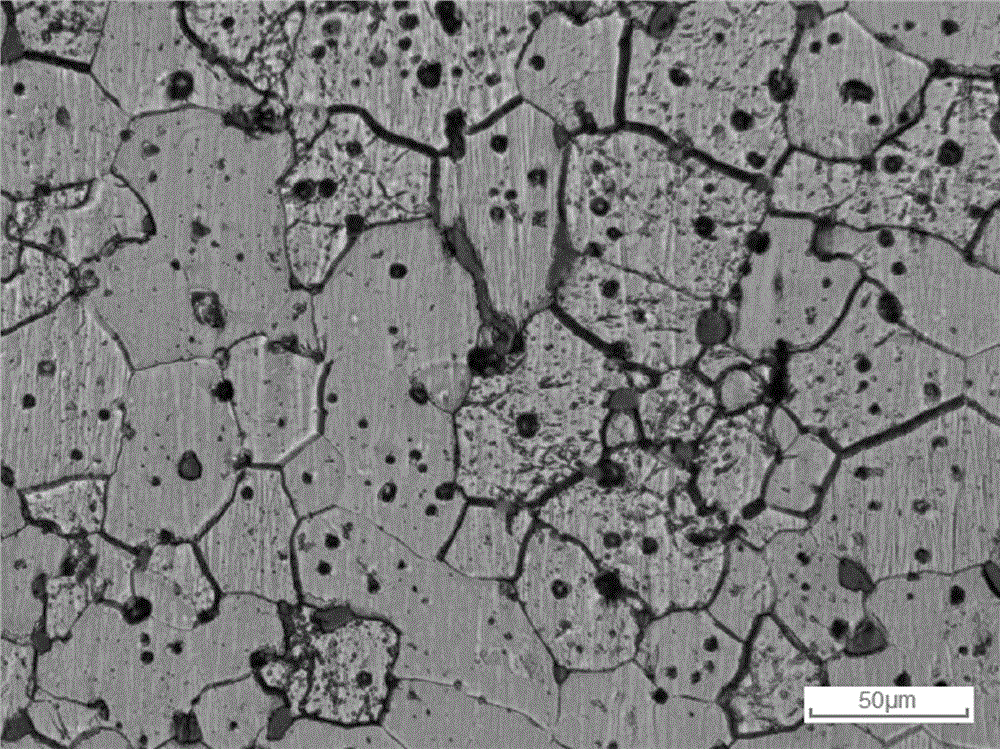

Preparation technology of molybdenum-niobium alloy sputtering target material

ActiveCN105887027ALower surface energyAvoid sticky ballsTransportation and packagingMetal-working apparatusEthyl stearatePolyvinyl alcohol

The invention belongs to the technical field of metallurgy materials, and particularly relates to a preparation technology of a molybdenum-niobium alloy sputtering target material. The preparation technology comprises the steps of milling, molding, vacuum sintering, machining, and the like, wherein the milling process comprises the steps of putting molybdenum powder and columbium powder into a ball mill according to the principle that the ratio of molybdenum powder to columbium powder is (6 to 10) to 1; then, adding a process control agent and zirconia grinding balls; carrying out ball milling under argon protection; sieving; and separating to obtain molybdenum-niobium alloy composite powder; weights of the process control agent and the zirconia grinding balls are respectively (0.01 to 0.05) times and (5 to 20) times the total weight of molybdenum powder and columbium powder; and the process control agent is one or more of zinc stearate, palmitic acid, ethyl stearate, polyvinyl alcohol and stearic acid. According to the preparation technology, the obtained molybdenum-niobium alloy sputtering target material is a single phase structure, the structure is uniform and free of holes, the average grain size is 40 to 65 [mu]m, the density is 9.85 g / cm<3> or above, the performance is excellent, and the molybdenum-niobium alloy sputtering target material can be widely applied to the fields such as flat displays.

Owner:洛阳丰联科绑定技术有限公司

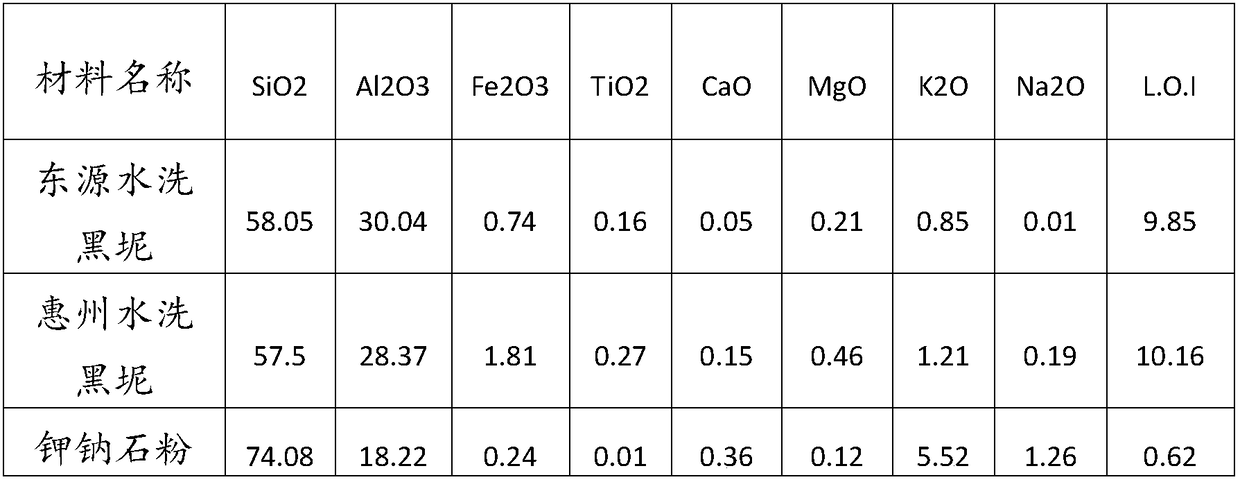

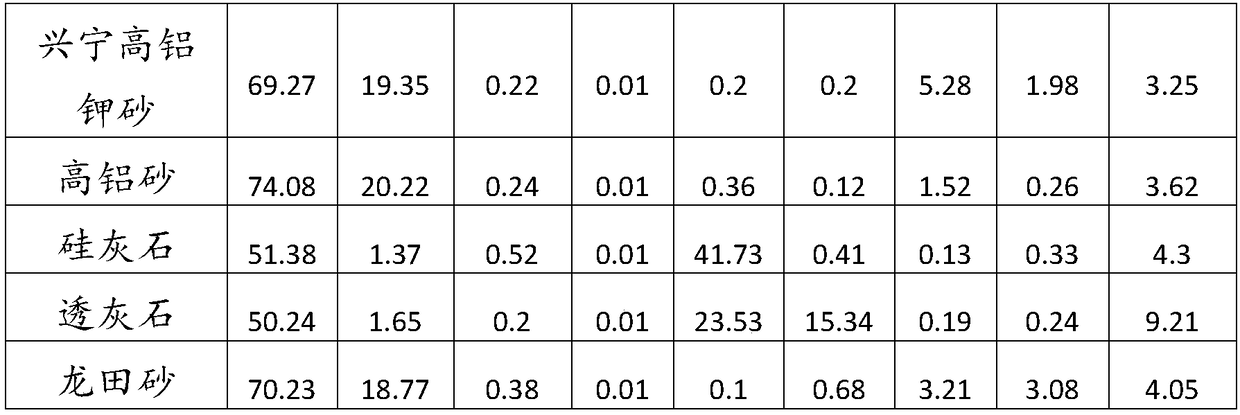

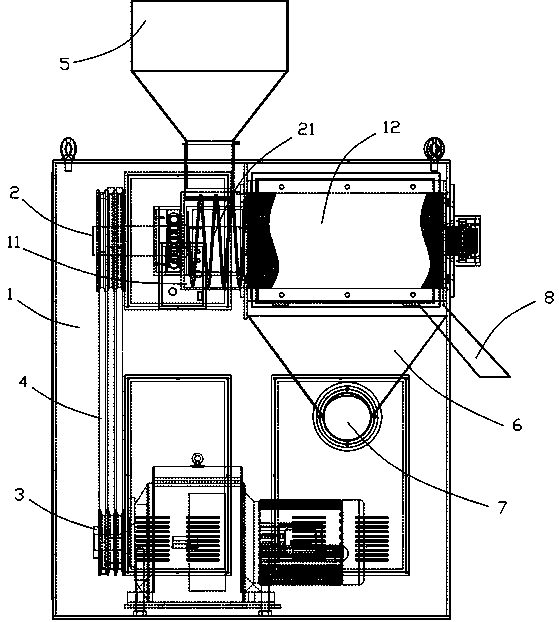

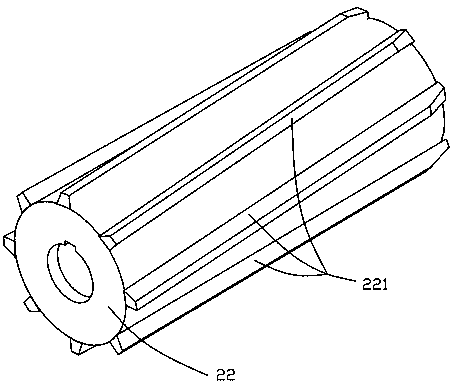

Preparation method of washed-black clay glazed brick green body

The invention provides a preparation method of a washed-black clay glazed brick green body. Local resourceful raw mineral materials of Guangdong washed-black clay, potassium-sodium stone powder, Xingning high-aluminium high-potassium sand, high-aluminium sand, wollastonite, burnt lime and Longtian sand are used, by adjusting the raw material composition proportion, the soft raw material washed-black clay and the hard raw materials are subjected to ball-milling separately, after spray drying, hydrocyclone reaction is conducted, then a polyvinyl alcohol solution is added in an atomizing and spraying mode, compression moulding and drying are conducted to prepare a brick green body, and finally, a biscuit is obtained through sintering. According to the method, ball-milling time is short, the efficiency is high, the washed-black clay is good in dispersibility and small in grain size, even mixing can be achieved by the washed-black clay and the hard raw materials, compared with a traditionalball-milling mixing working procedure, the method has the advantages that the usage of the additive polyvinyl alcohol solution can be reduced, and meanwhile, the glazed brick green body with high drying strength and rupture strength can be obtained.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Camellia oleifera seed sheller thorough in milling

PendingCN108783480AGrinding and shelling thoroughlyGrind thoroughlyFatty-oils/fats productionHuskingCamellia oleiferaEngineering

The invention relates to the technical field of shelling equipment, and discloses a camellia oleifera seed sheller thorough in milling. The camellia oleifera seed sheller comprises a machine frame, arotating shaft arranged in the machine frame and a driving device for controlling the rotating shaft to rotate, wherein a spiral transmission structure is arranged on the periphery of the first end part of the rotating shaft, and is used for transmitting camellia oleifera seeds to a milling position; a sleeve which is fixed to the machine frame is arranged on the periphery of the spiral transmission structure; a roller is arranged on the periphery of the second end part of the rotating shaft, and rotates along with the rotating shaft; a plurality of ribs which extend in the length direction ofthe roller are arranged on the periphery of the roller; a spacing is generated between every two adjacent ribs; a sieving cylinder is fixedly arranged in the length region of the roller, on the machine frame; the roller penetrates in the sieving cylinder and is coaxial with the sieving cylinder; a gap is formed between the free end away from the roller, of each rib, and the sieving cylinder; thefirst end part and the second end part of the rotating shaft are connected; and the sleeve is connected with the end part of the sieving cylinder, or a gap is formed between the sleeve and the end part of the sieving cylinder. The camellia oleifera seeds are slowly transmitted to the roller through the spiral transmission structure for milling, the quantity of milled camellia oleifera seeds in unit time is relatively low, and the shelling of the camellia oleifera seeds is thorough.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

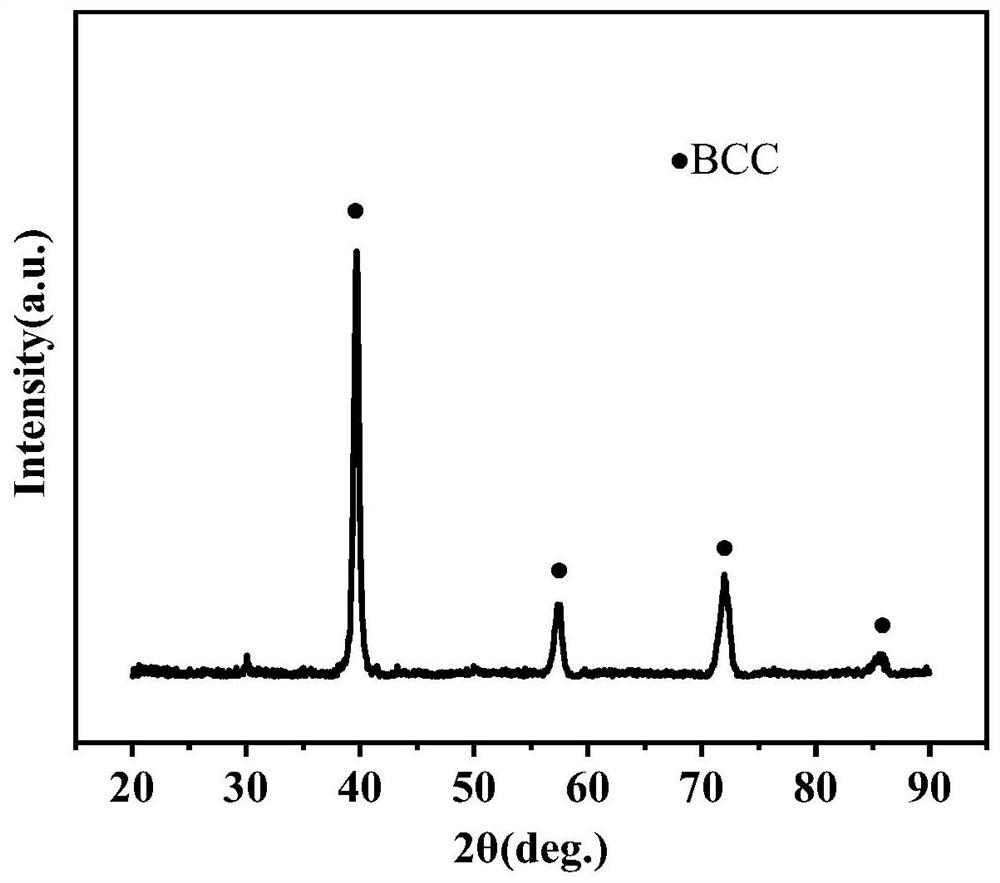

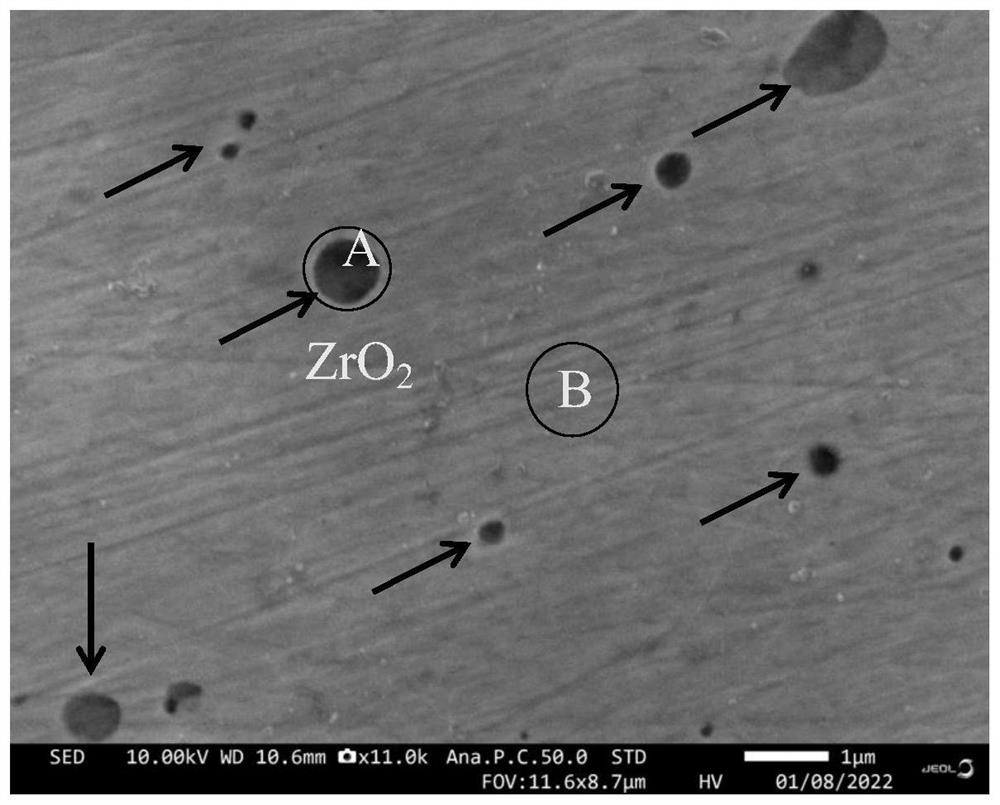

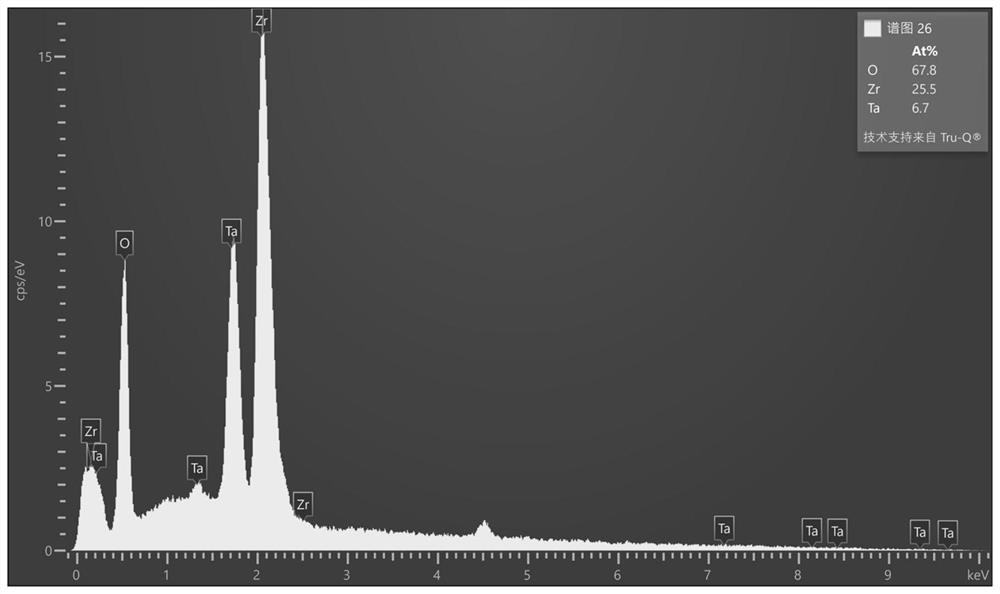

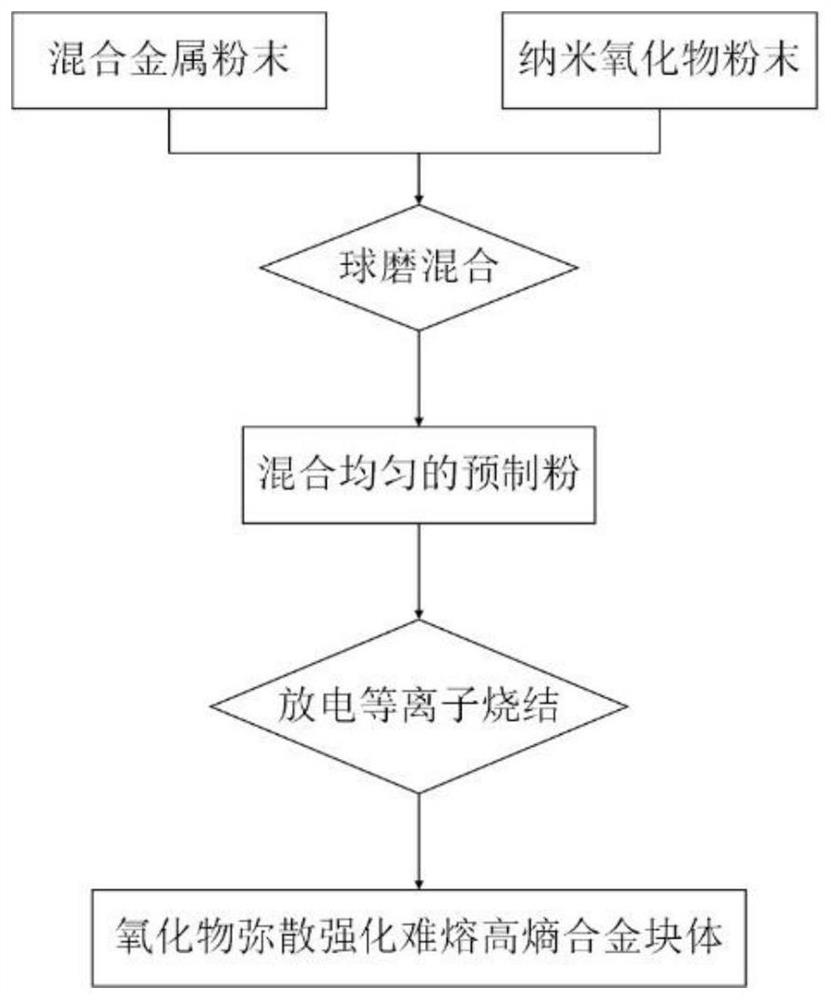

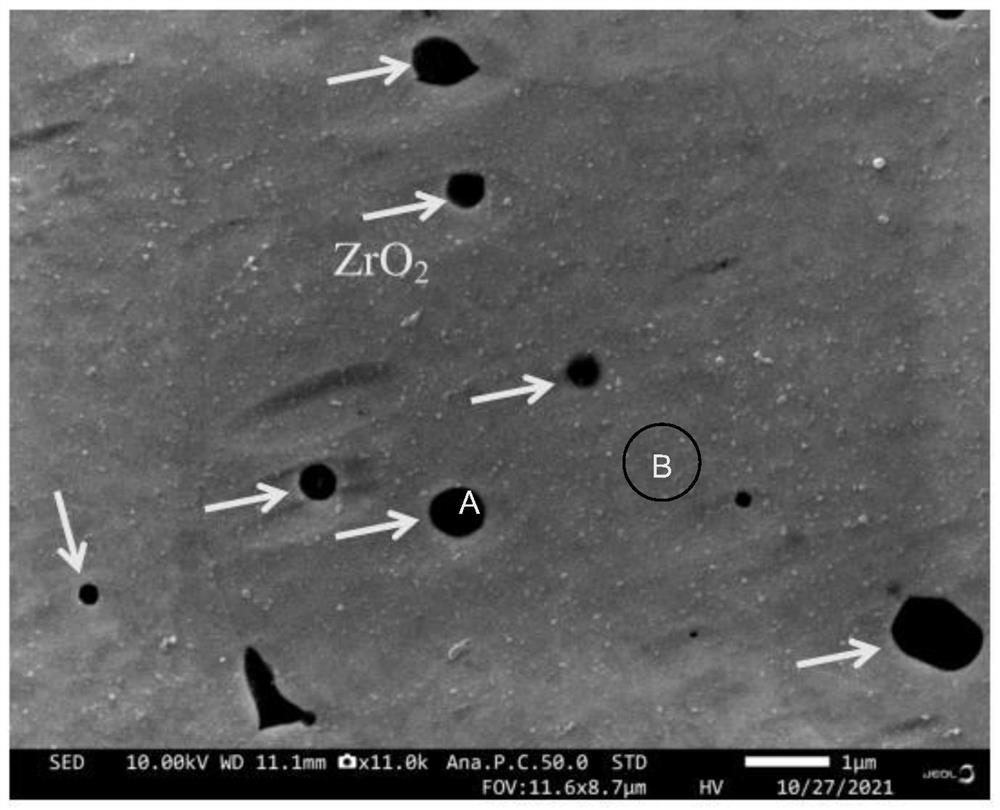

Preparation method of nano zirconium dioxide reinforced NbMoTaW refractory high-entropy alloy

ActiveCN114774727ALow industrial application valueHigh industrial application valueHigh entropy alloysNanoparticle

The invention relates to a preparation method of a nano zirconium dioxide reinforced NbMoTaW refractory high-entropy alloy, which comprises the following steps of: ball-milling and mixing metal powder formed by mixing Nb powder, Mo powder, Ta powder and W powder with equal molar ratio or nearly equal molar ratio and nano ZrO2 particles in a high-energy ball mill to obtain mixed powder; and the obtained mixed powder is placed in a graphite mold, pressure sintering is conducted in a high vacuum state through a spark plasma sintering method, and the high-strength ZrO2 reinforced NbMoTaW refractory high-entropy alloy is obtained. According to the method, the technological process is simple, the cost is low, the efficiency is high, the ZrO2 enhanced NbMoTaW refractory high-entropy alloy which is uniform in structure, fine in crystal grain and high in strength and plasticity and has nano ZrO2 dispersed distribution is obtained, compared with the prior art, the room-temperature plasticity of the NbMoTaW refractory high-entropy alloy is greatly improved, and the alloy has the advantages of being high in strength and plasticity. The defects of composition segregation, long mechanical alloying test period and low powder yield caused by an existing casting method preparation process are effectively overcome.

Owner:HENAN UNIV OF SCI & TECH

Hole-filling printing paste for HTCC and preparation method of hole-filling printing paste

PendingCN113130111AResolve offsetUniform fluiditySemiconductor/solid-state device detailsSolid-state devicesSilicon oxideSlurry

The invention belongs to the technical field of semiconductor manufacturing, and particularly relates to hole-filling printing paste for HTCC and a preparation method of the hole-filling printing paste. The pore-filling printing paste is composed of the following raw materials in parts by weight: 75-85 parts of metal powder, 9-12 parts of an inorganic additive and 8-10 parts of an organic carrier, the metal powder is tungsten powder or mixed powder composed of tungsten powder and molybdenum powder, and the inorganic additive is composed of aluminum oxide and silicon dioxide according to the weight part ratio of (7-10): (1-3). The organic carrier is composed of a solvent, a slurry auxiliary agent and a binder according to a weight part ratio of (6-10): (0.03-0.06): (0.5-2). Through selection of the types and proportions of the raw materials, good flatness after slurry hole filling and sintering is realized, downstream processing procedures are not affected, and the yield is high.

Owner:瓷金科技(河南)有限公司

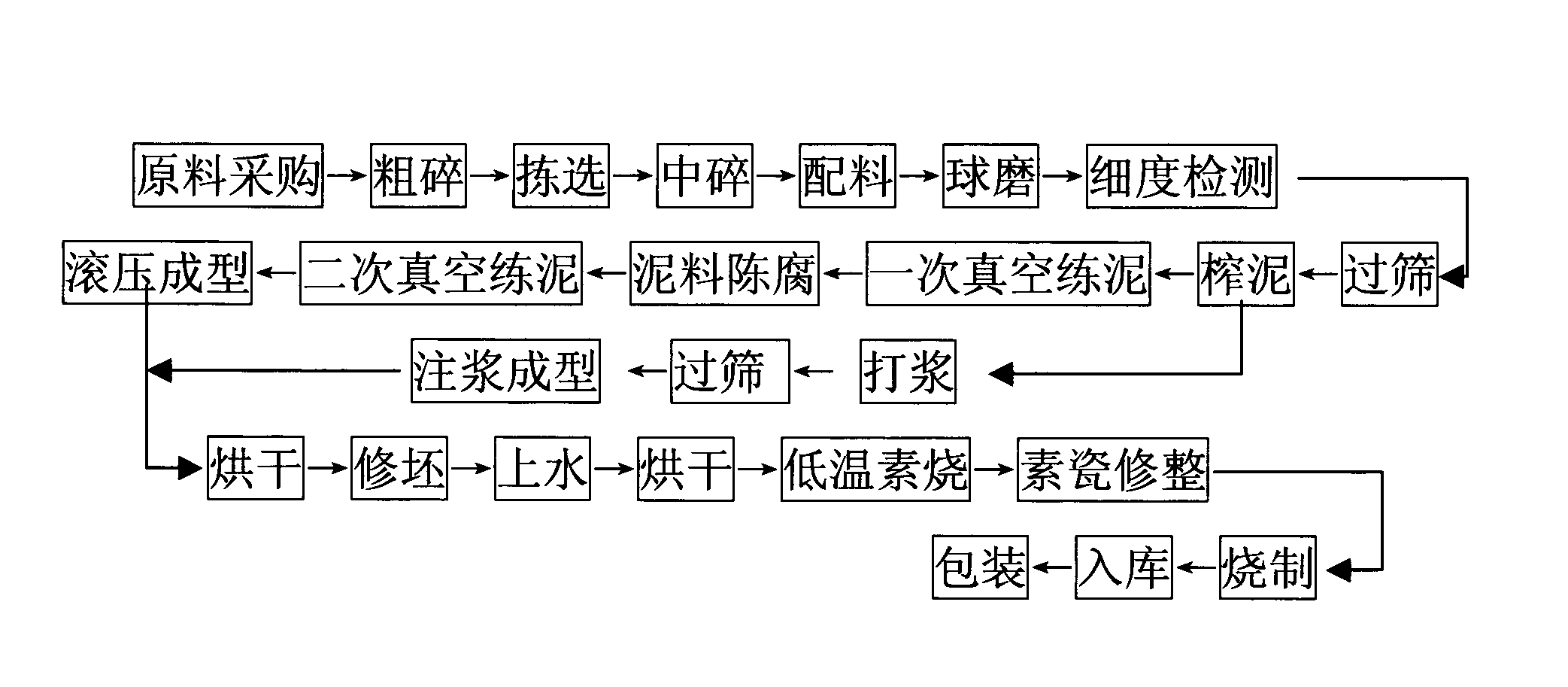

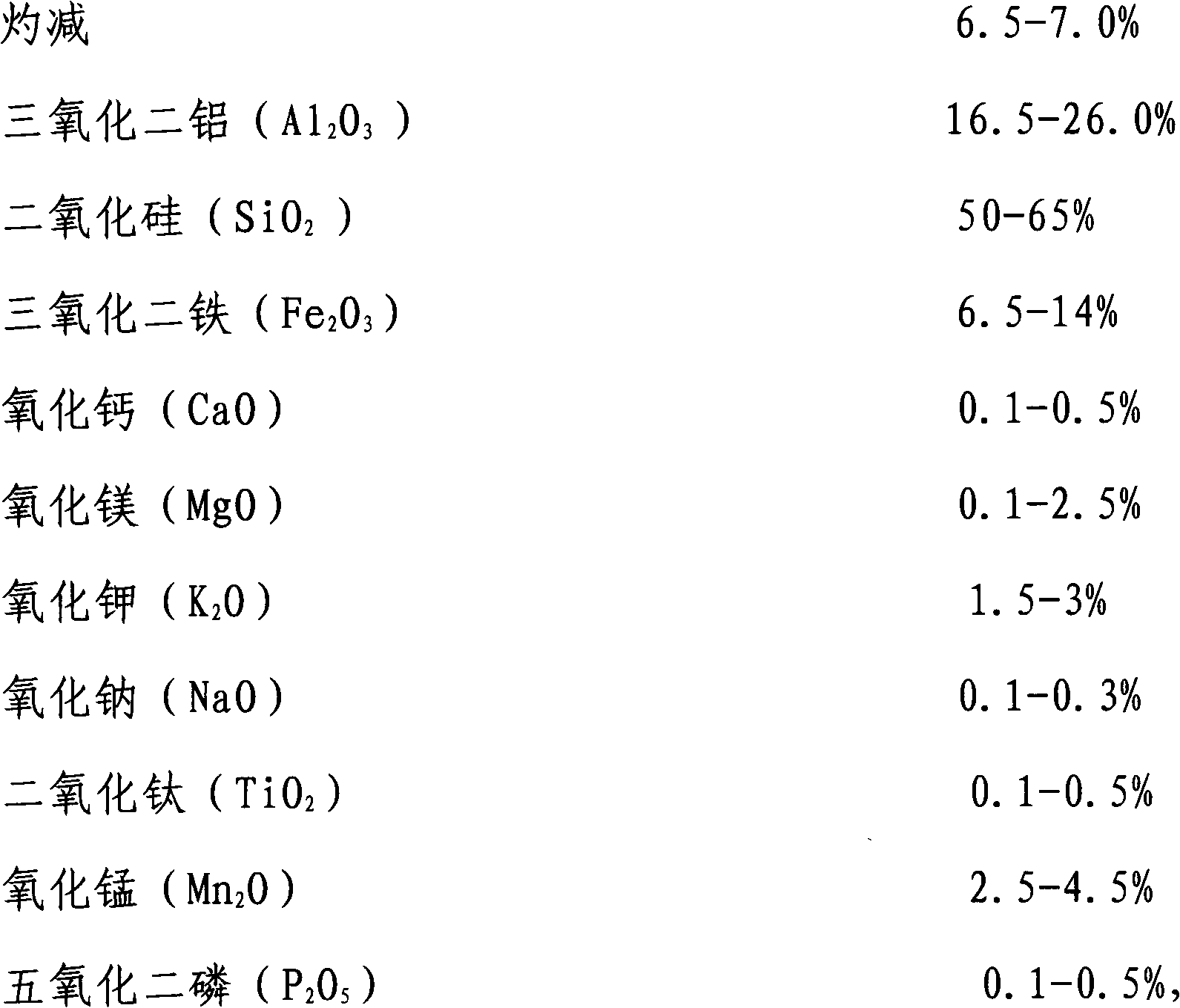

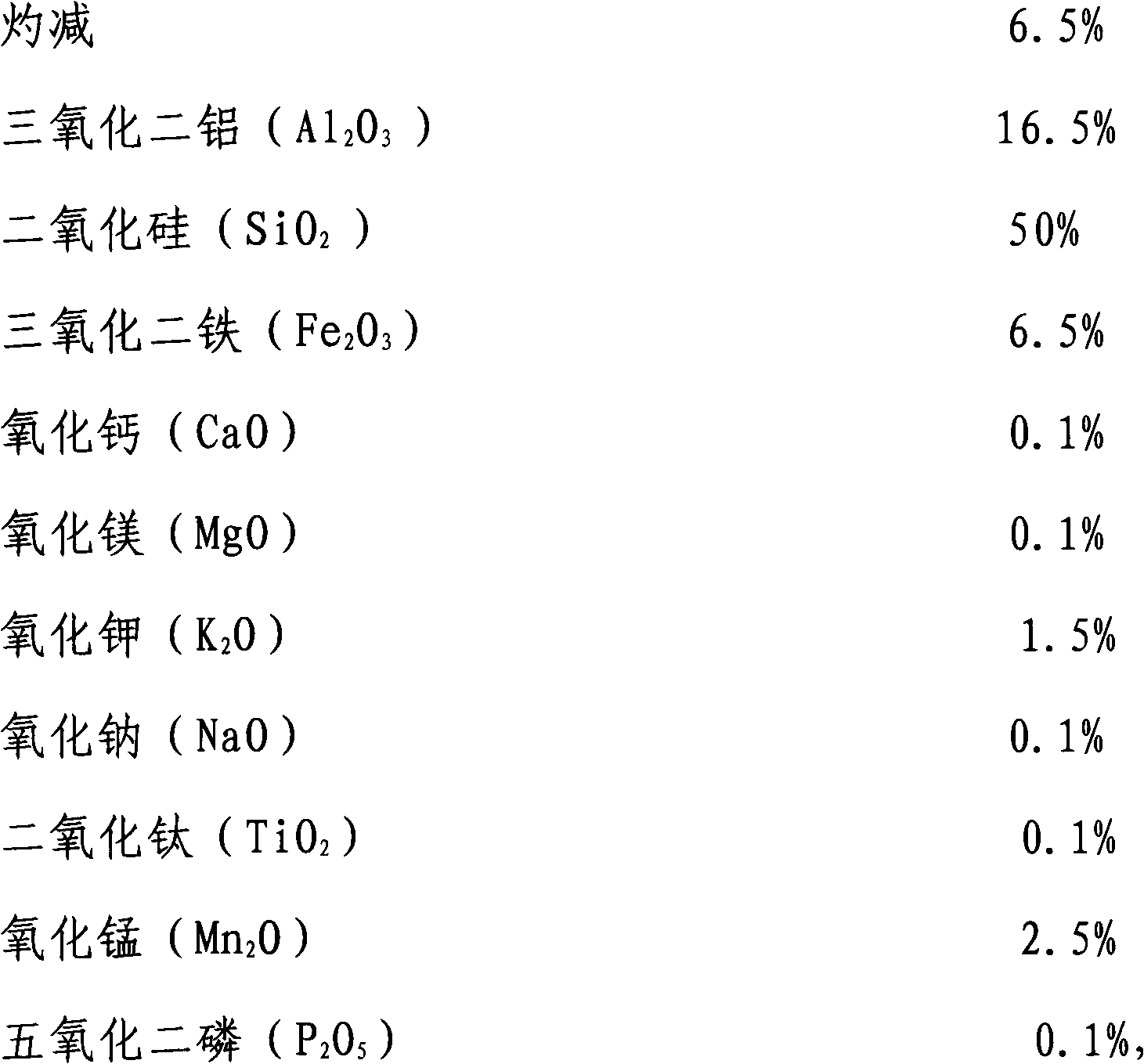

Iron-manganese heat resistant cooker and production technology thereof

The invention belongs to the technical field of ceramic materials, and provides a novel iron-manganese heat resistant cooker and a production technology thereof. A low expansion coefficient raw material such as spodumene is not required in the formula of the product; the heat conductivity coefficient of the ceramic ware is greatly improved by improving the heat conductivity coefficient and the thermal shock resistance of ceramic; the sintering temperature is low, and the maturing temperature is wide in range and is 1,160 to 1,230 DEG C; the product is high in superior quality, can be quickly sintered, can tolerate the heat exchange of 500 to 20 DEG C without cracking, has the advantages of low energy consumption, high heat conductivity, high impact strength, thermal shock resistance and the like, and can be used for directly steaming, boiling, stewing and stir-frying food over a heat source; and the cooker keeps the cooking flavor of the conventional ceramic ware, does not decompose nutritional components in the food, and is an ideal multifunctional cooking ware for modern families, hotels and restaurants.

Owner:邱东烽

A kind of preparation method of carbon nanotube reinforced aluminum matrix composite material

The invention provides a preparation method for a carbon nano tube reinforced aluminum matrix composite material. The preparation method comprises the following steps that firstly, composite powder with carbon nano tubes evenly dispersed is obtained by adopting low-temperature ball milling; and then a composite blank is obtained after the powder is solidified by sleeve installing, air removing and hot isostatic pressing; and further, a bar material, or a sectional material or a forge piece product is formed by normal hot working methods such as squeezing and forging and pressing; and finally, heat treatment is conducted. According to the preparation method, the carbon nano tubes have good dispersity in an aluminum alloy matrix, the damage degree of reinforced bodies of the carbon nano tubes is small, the formed composite material has even microstructures and good interface bonding; and meanwhile, the composite material has high strength and plasticity, and is expected to be applied to the fields, such as aerospace and cars, which have strong needs for light-weight high-strength structural materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

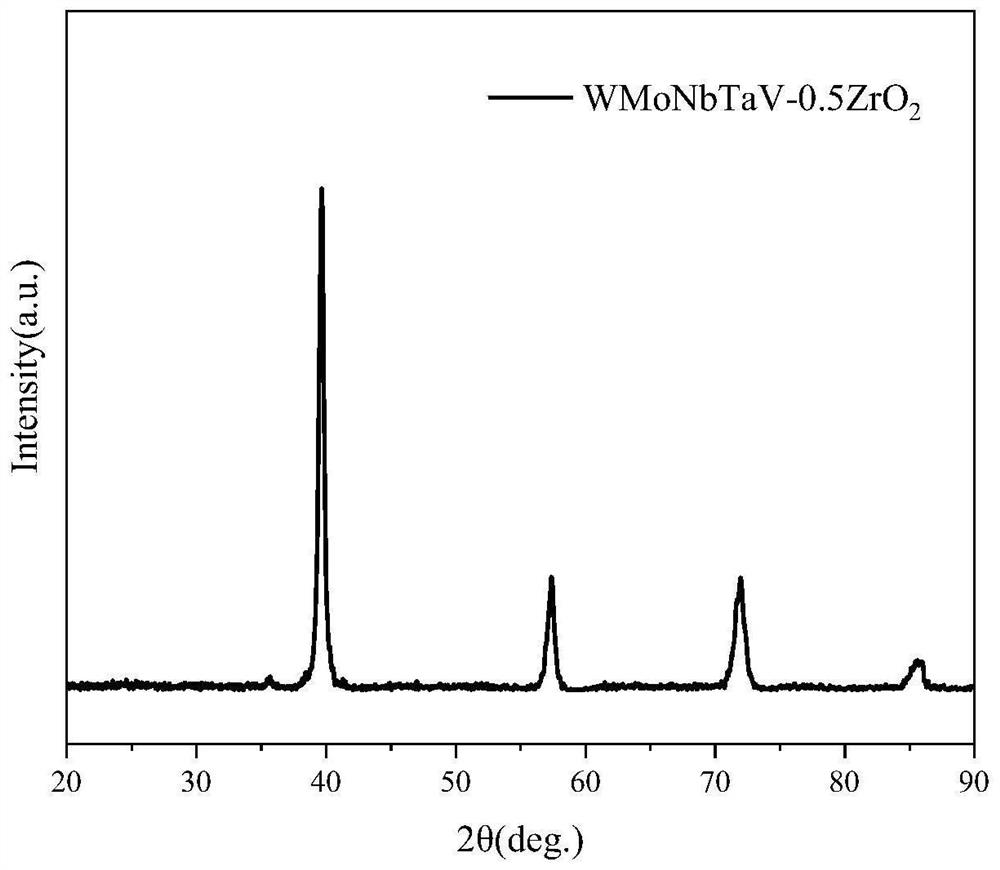

Preparation method of ceramic particle reinforced refractory high-entropy alloy

PendingCN114799155AHigh strengthImprove plasticityTransportation and packagingMetal-working apparatusHigh entropy alloysNanoparticle

The invention relates to a preparation method of a ceramic particle reinforced refractory high-entropy alloy, which comprises the following steps of: ball-milling and mixing metal powder formed by mixing W powder, Mo powder, Nb powder, Ta powder and V powder with equal molar ratio or nearly equal molar ratio and nano ZrO2 particles in a high-energy ball mill to obtain mixed powder; and the obtained mixed powder is placed in a graphite mold, pressure sintering is conducted in a high-vacuum state through a spark plasma sintering method, and the nano ZrO2 reinforced WMoNbTaV refractory high-entropy alloy is obtained. The method is simple in technological process, low in cost and high in efficiency, the nano ZrO2 particles are introduced into the WMoNbTaV matrix, the strength and plasticity of the WMoNbTaV refractory high-entropy alloy are improved, compared with the prior art, the room-temperature plasticity of the WMoNbTaV refractory high-entropy alloy is greatly improved, and the problems that component segregation and long mechanical alloying test period caused by an existing casting method preparation technology are effectively solved, and the mechanical alloying performance of the WMoNbTaV refractory high-entropy alloy is greatly improved are solved. And the powder yield is low.

Owner:HENAN UNIV OF SCI & TECH

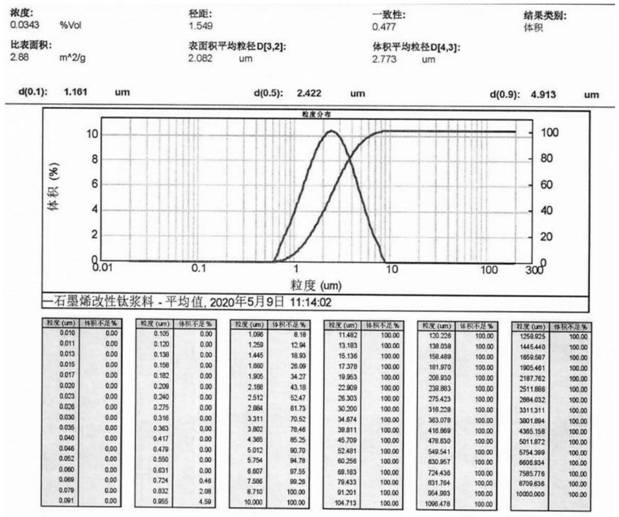

Graphene modified silicon-titanium nano polymer slurry as well as preparation method and application thereof

ActiveCN113416469AHigh degree of graftingImprove compactnessAnti-corrosive paintsEpoxy resin coatingsCrack resistanceSlurry

The invention belongs to the technical field of coatings, and particularly relates to graphene modified silicon-titanium nano polymer slurry as well as a preparation method and application thereof. The graphene modified silicon-titanium nano polymer slurry provided by the invention is added into a polymer coating, and the medium permeability resistance of a formed coating layer is greatly improved through the superstrong gas and liquid permeability resistance of graphene and a silicon-titanium graphene network structure; due to the corrosion resistance of graphene, titanium and silicon nanoparticles, the coating layer is endowed with super-strong stability, is not easy to react with various media such as acid, alkali and salt, is not easy to consume to form pores and is not easy to react with corrosive media to generate soluble salt or cathode loose and expanded products, and the components and the structure of the coating layer are stable for a long time and are not damaged; and the silicon-titanium graphene network structure can improve the adhesive force, hardness, toughness, wear resistance, crack resistance and other comprehensive corrosion resistance of the coating layer.

Owner:CHANGSHA TIANYUAN EMPIRE MATERIALS TECH CO LTD

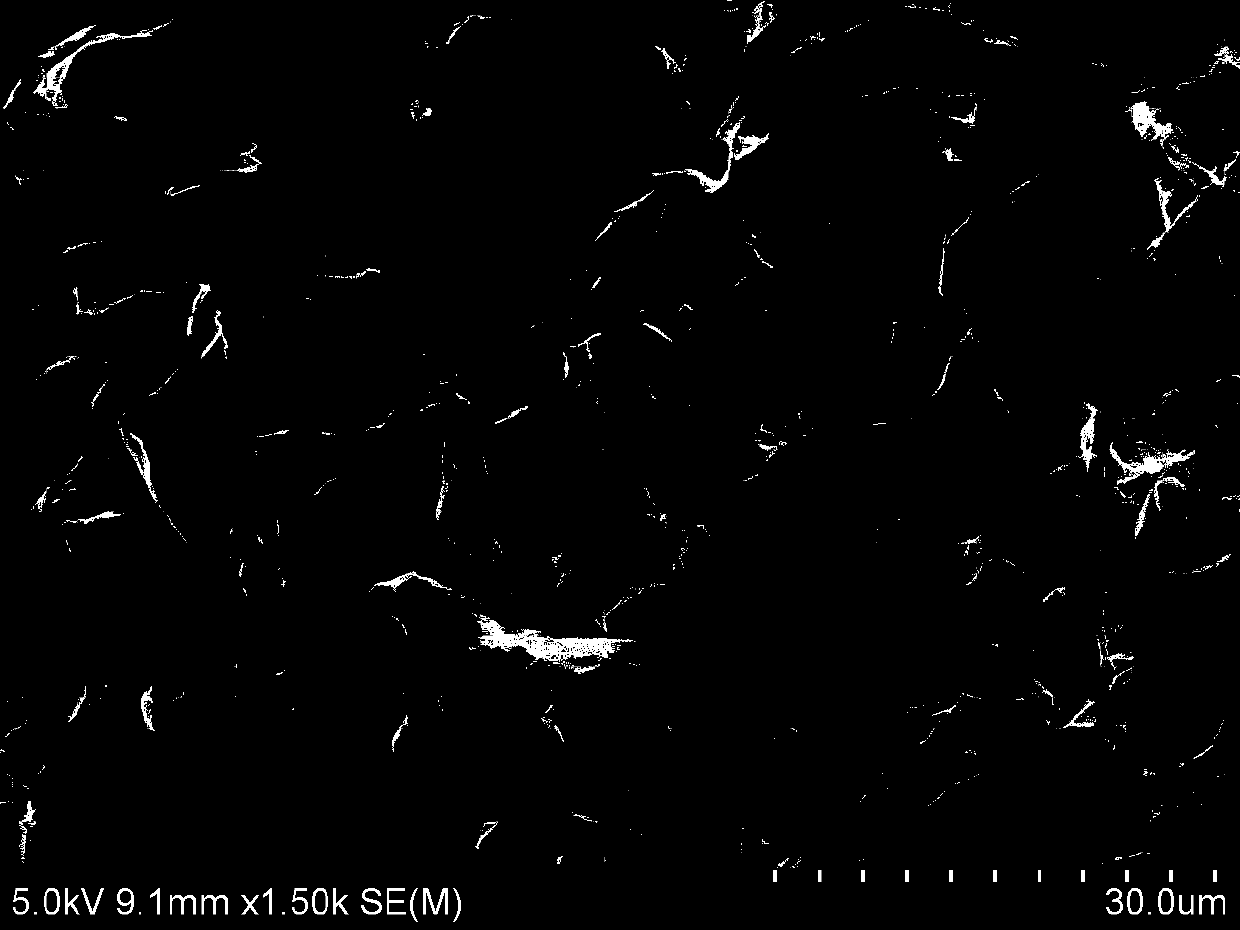

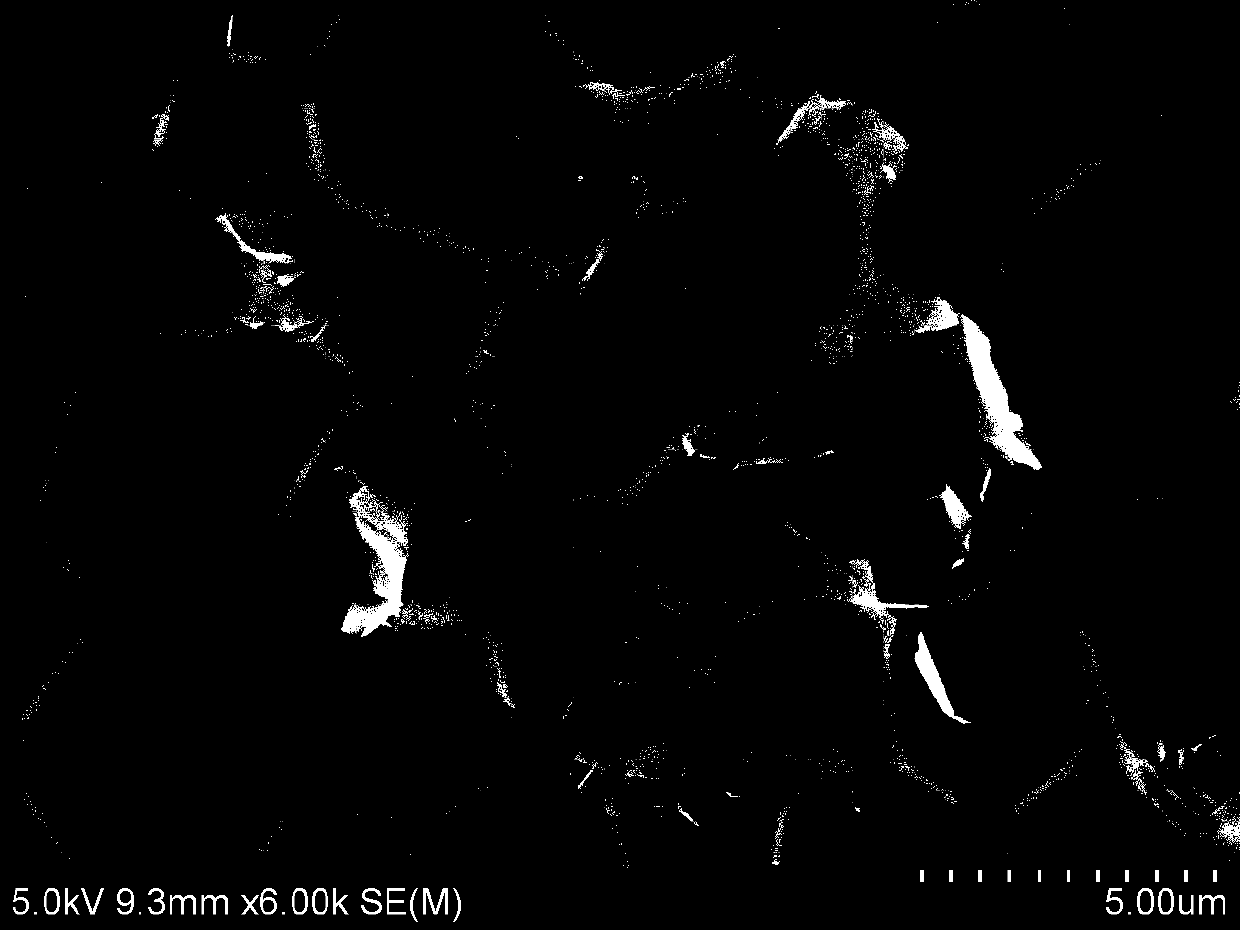

Method for preparing high-quality large-size graphene on large scale

The invention discloses a method for preparing high-quality large-size graphene on a large scale, and belongs to the technical field of novel materials. The method comprises the steps of carrying outball-milling on original graphite powder for a short time to damage edge structures of graphite; and then carrying out oxidative intercalation stripping at the low temperature to obtain the graphene.The method is simple and practicable, and the yield nearly reaches 100%; and meanwhile, a solvent during ball-milling and a subsequent intercalation agent are perchloric acid solutions, so that the solvent and the subsequent intercalation agent can be reused, and the cost is saved; and water washing and waste liquid discharging processes are not involved, and waste of water resources and pollutionof waste liquid to the environment are avoided.

Owner:YANSHAN UNIV

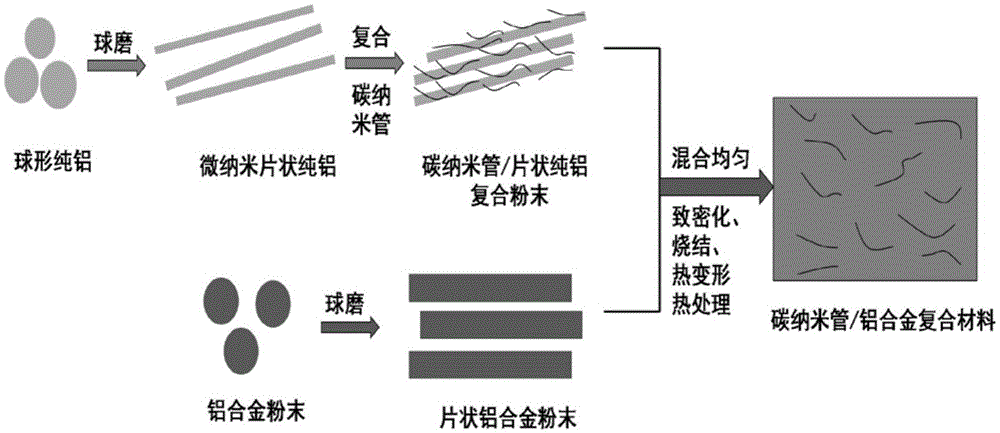

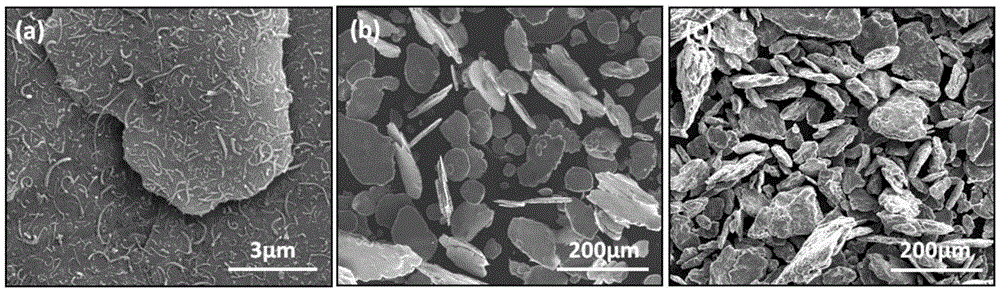

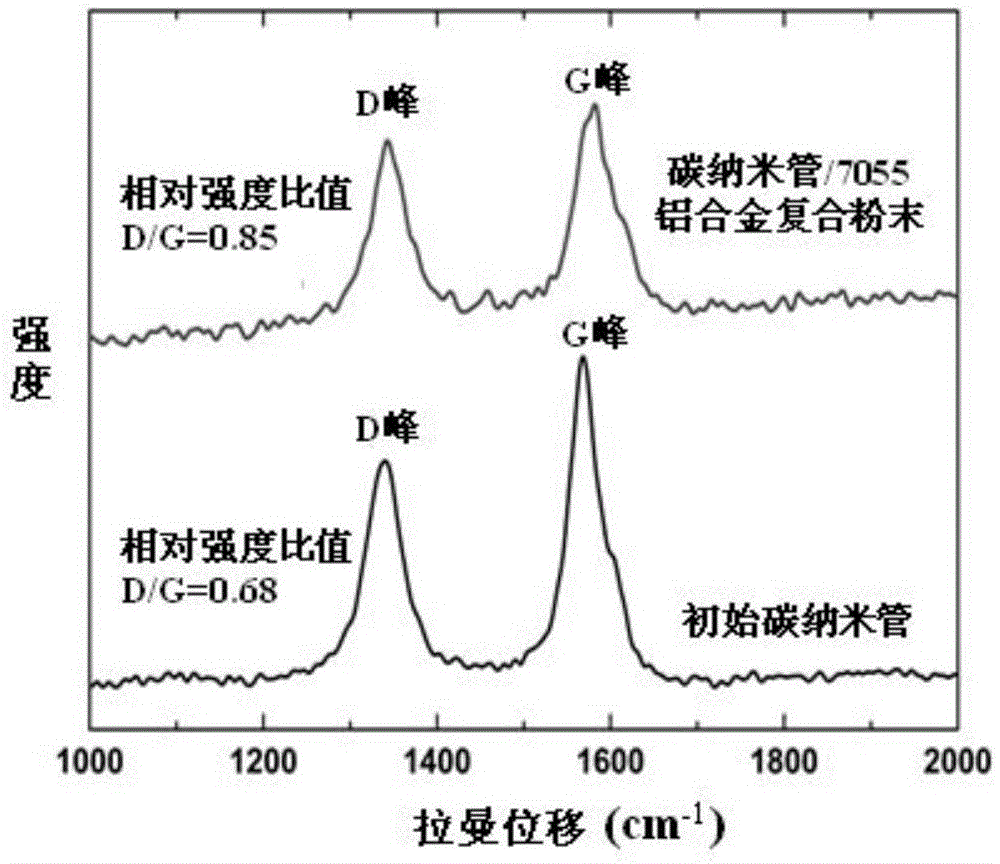

A powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminium alloy composite material. According to the powder metallurgy preparation method, slurry mixing method or in-suit growth method is adopted for pre-preparation of carbon nanotube / pure aluminium flaky composite powder; the carbon nanotube / pure aluminium flaky composite powder is mixed with aluminium alloy powder according to a certain ratio; an obtained mixture is subjected to densifying, sintering, thermal deformation processing and heat treatment so as to obtain the carbon nanotube reinforced aluminium alloy composite material. The powder metallurgy preparation method is capable of solving problems that dispersion of carbon nanotube in aluminium alloy powder is difficult to realize, and hydrolysis is easily caused, so that it is beneficial for preparation of the carbon nanotube / aluminium alloy composite material with high strength, high modulus, and high plasticity.

Owner:SHANGHAI JIAOTONG UNIV

A method for preparing nanoparticle-reinforced aluminum matrix composites

The invention discloses a method for preparing nano ceramic particles reinforced aluminum matrix composite material. Firstly, the mixed powder of nano-ceramic powder and micron-sized aluminum or aluminum alloy powder is prepared by dry-type high-energy ball milling under vacuum or argon protection to prepare millimeter-sized composite particles with a volume fraction of nano-ceramic particles of 10-50%. Then the millimeter-scale composite particles are directly melted or added to the aluminum or aluminum alloy melt, and ultrasonic vibration is applied to promote the uniform dispersion of the nano-ceramic particles in the metal melt, and the nano-ceramic particle-reinforced aluminum matrix composite material is prepared. The millimeter-scale composite particles prepared by the dry grinding method in the present invention can be easily and completely added to the metal melt, which solves the problem of poor wettability between the nano-ceramic particles and the base metal and difficulty in adding them. The low-cost advantage of composite materials. The nano particles are evenly distributed in the prepared composite material, and the material performance is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com