Method for preparing single-layer graphene through mechanical method

A single-layer graphene, mechanical method technology, applied in the direction of single-layer graphene, graphene, chemical instruments and methods, etc., can solve the problems of high iron impurity content in products, long ball milling time, low success rate, etc. Short, high success rate, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

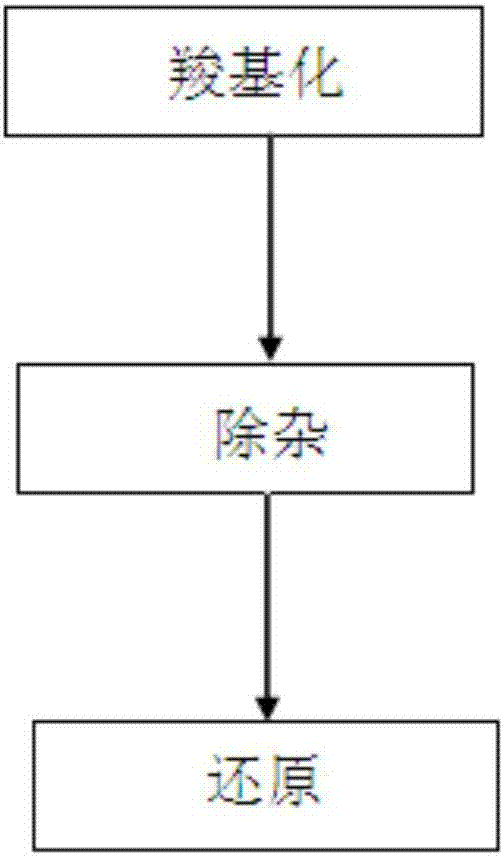

[0024] The specific steps of the method for preparing single-layer graphene by mechanical method involved in the present embodiment are:

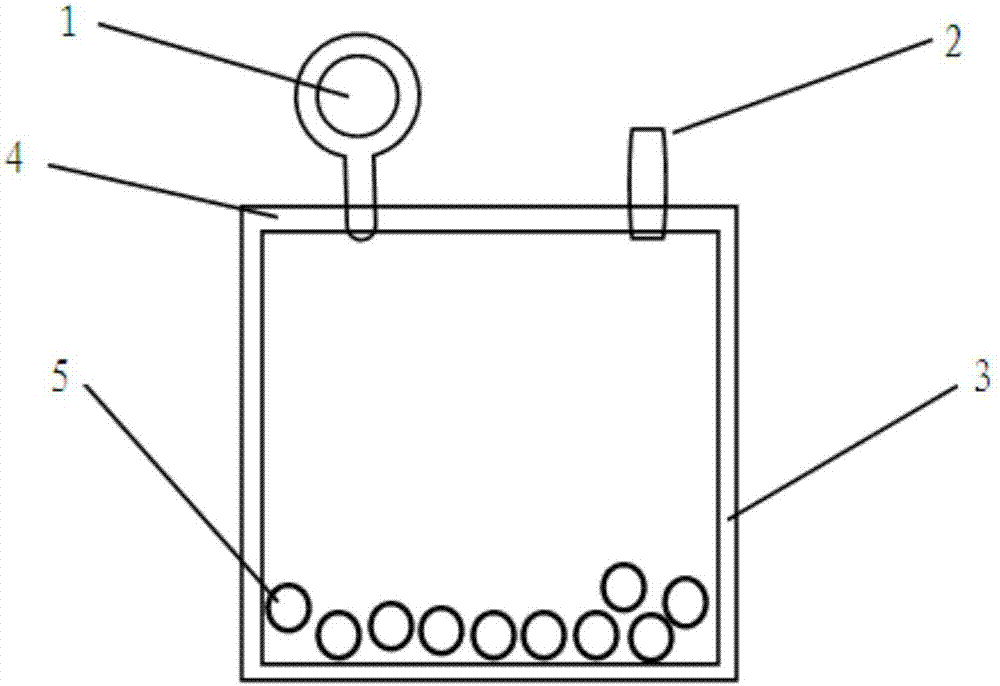

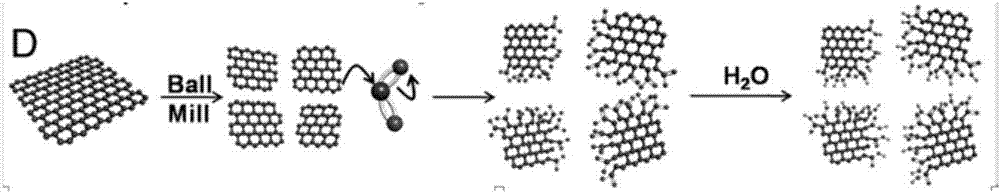

[0025] (1) Carboxylation: Place the natural flake graphite powder in a vacuum drying oven at a temperature controlled at 50°C for 24 hours in a vacuum, take it out after cooling to room temperature, and accurately weigh 5g of the cooled natural flake graphite powder, 105g of dry ice, and 300g in diameter. 5mm stainless steel balls and 250g stainless steel balls with a diameter of 7.5mm are placed together in a sealed ball mill jar and quickly seal the ball mill jar; after the air pressure of the pressure gauge in the ball mill jar is stabilized, adjust the deflation valve to slowly deflate to control the gas Flow 10—20cm 3 / min, 450r / min ball milling for 24h, after the air pressure in the pressure gauge drops to 0, continue ball milling for 6h, open the ball milling tank to expose the natural flake graphite powder to the air to absorb moist...

Embodiment 2

[0030] The specific steps of the method for preparing single-layer graphene by mechanical method involved in the present embodiment are:

[0031] (1) Carboxylation: Place the natural flake graphite powder in a vacuum drying oven at a temperature controlled at 50°C for 24 hours in vacuum, take it out after cooling to room temperature, and accurately weigh 5g of the dried natural flake graphite powder, 105g of dry ice, and 300g in diameter. 5mm stainless steel balls and 250g stainless steel balls with a diameter of 7.5mm are placed together in a sealed ball mill jar and quickly seal the ball mill jar; after the air pressure of the pressure gauge 1 in the ball mill jar is stabilized, adjust the air release valve 2 to deflate slowly, Control gas flow 10-20cm 3 / min, 450r / min ball milling 24h, continue ball milling 6h after the air pressure drops to 0 in pressure gauge 1, open the sealing cover 4 of ball mill jar and make natural flake graphite powder expose in the air to absorb mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com