Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Simple cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

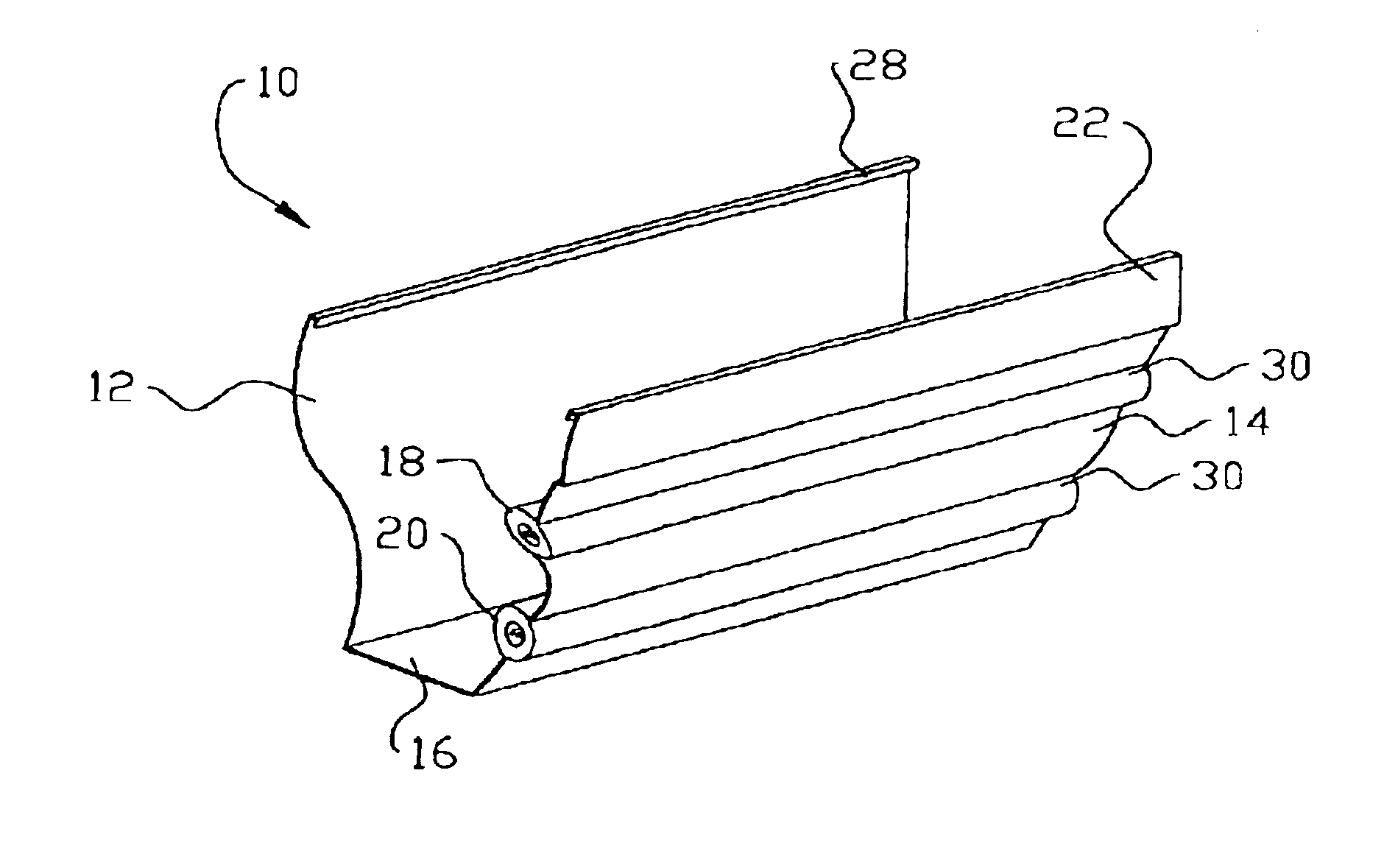

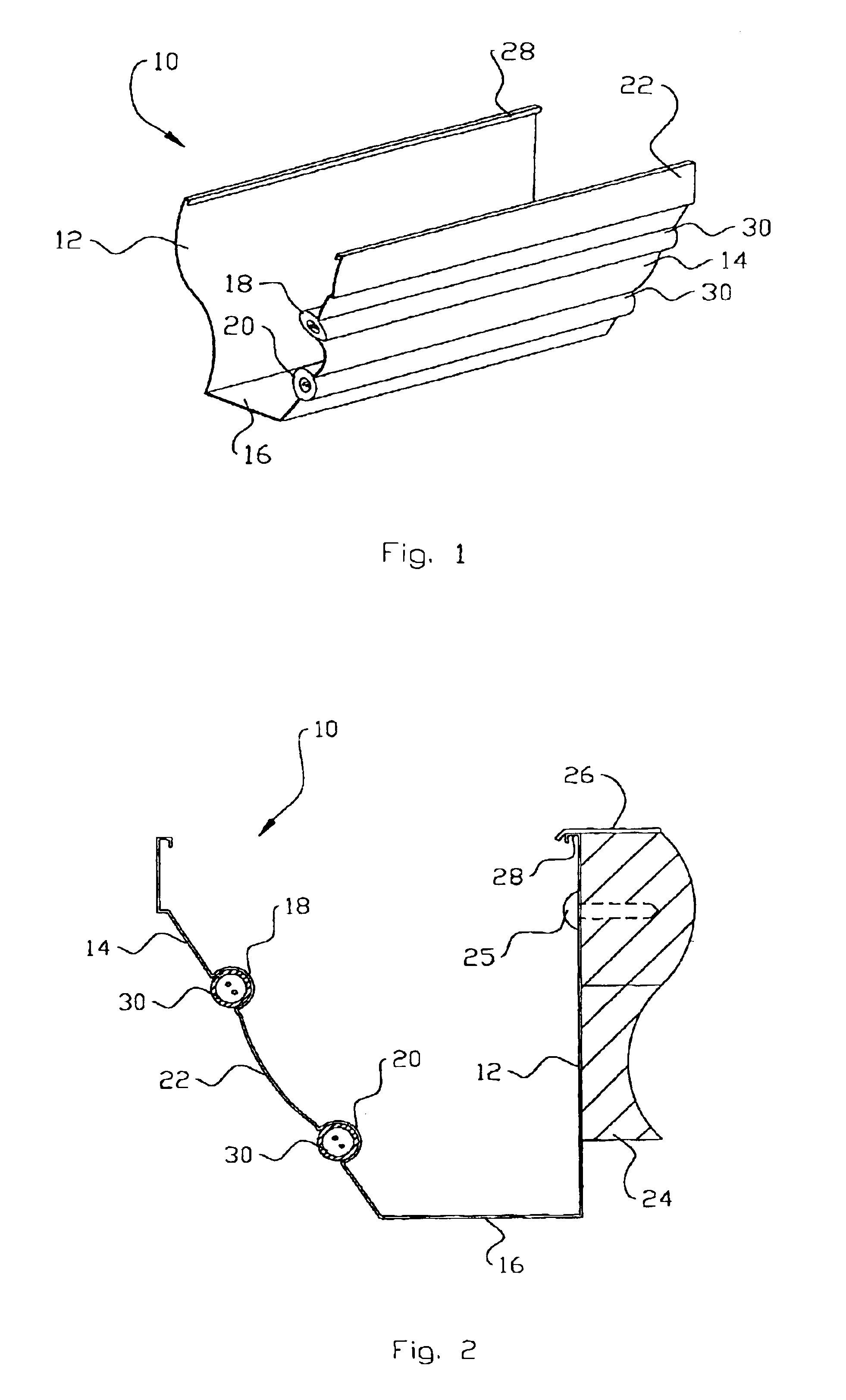

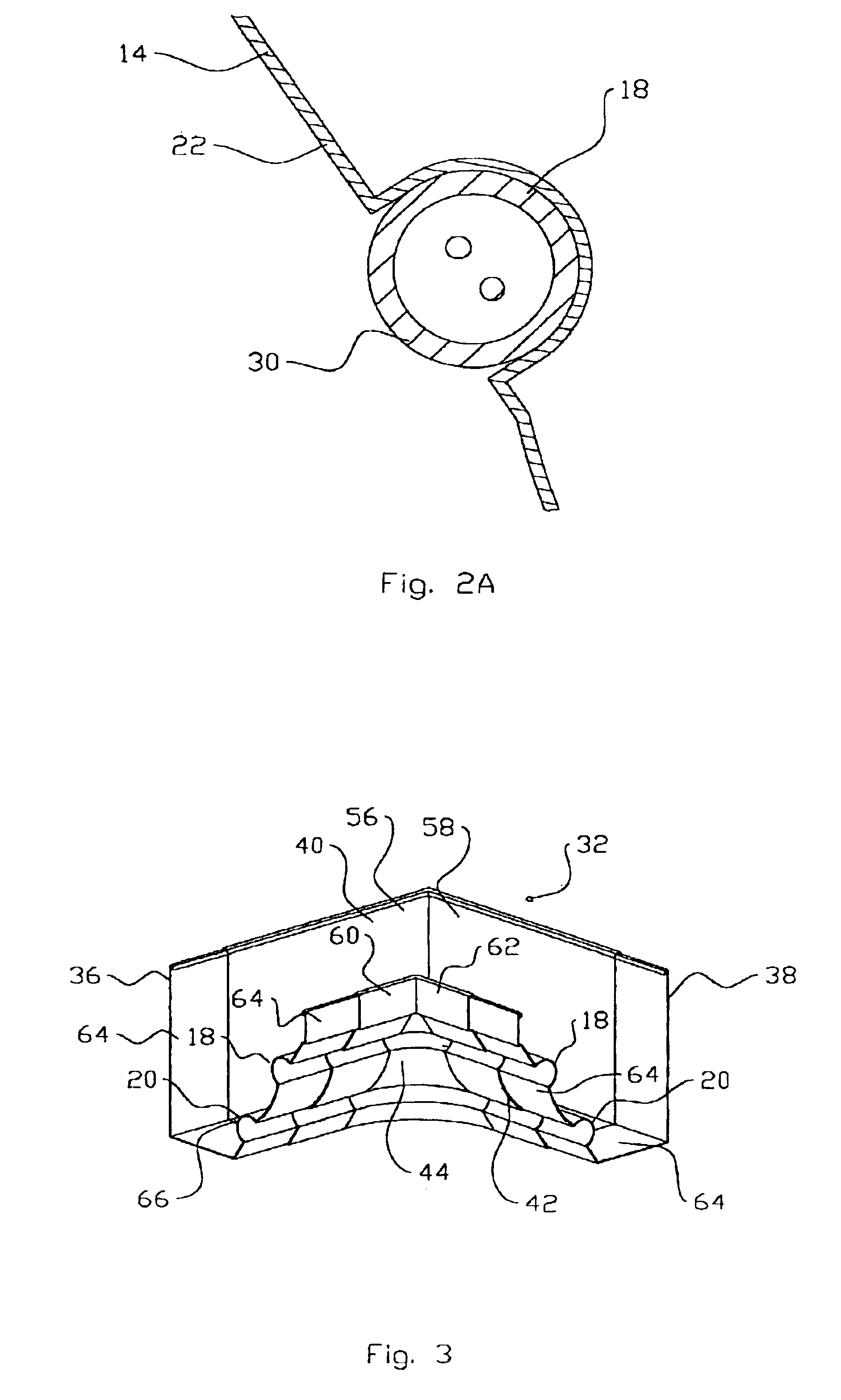

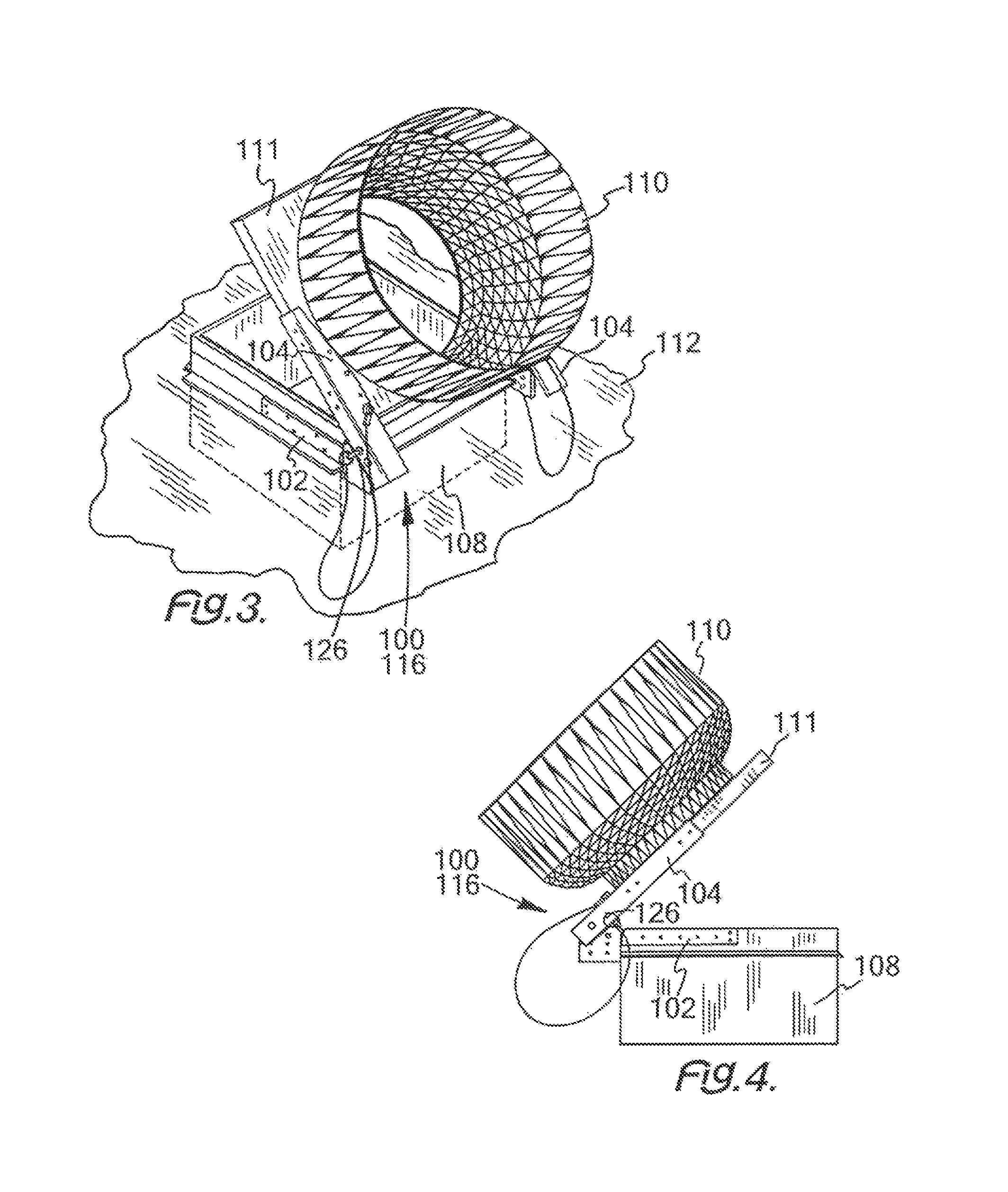

Gutter system with built-in ropelights

InactiveUS6955458B2Easily instalSimple cleaningNon-electric lightingLighting support devicesEngineeringMechanical engineering

A gutter system has decorative ropelights held in a longitudinal groove in the face of the gutter. The groove is adapted to hold a ropelight without using clips or other separate attachment devices. The gutter can also have two or more longitudinal grooves, each holding a ropelight. The system is easy to install on a building and eliminates the need for annual installation and removal of decorative lights.

Owner:NEXT INNOVATION

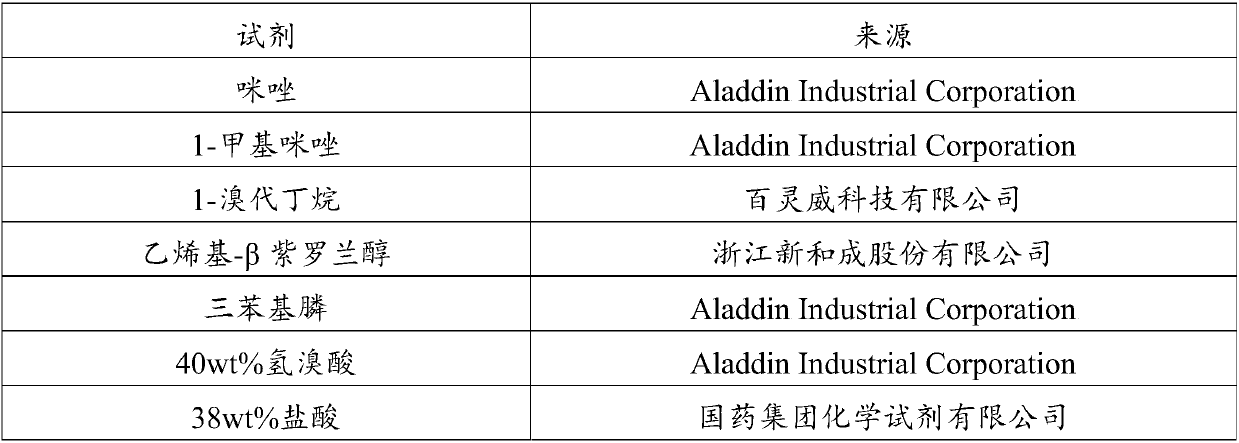

Method for preparing vitamin A acetate

ActiveCN109651150AReduce separation and purification operationsSmooth responseOrganic compound preparationGroup 5/15 element organic compoundsWittig reactionVitamin A Alcohol

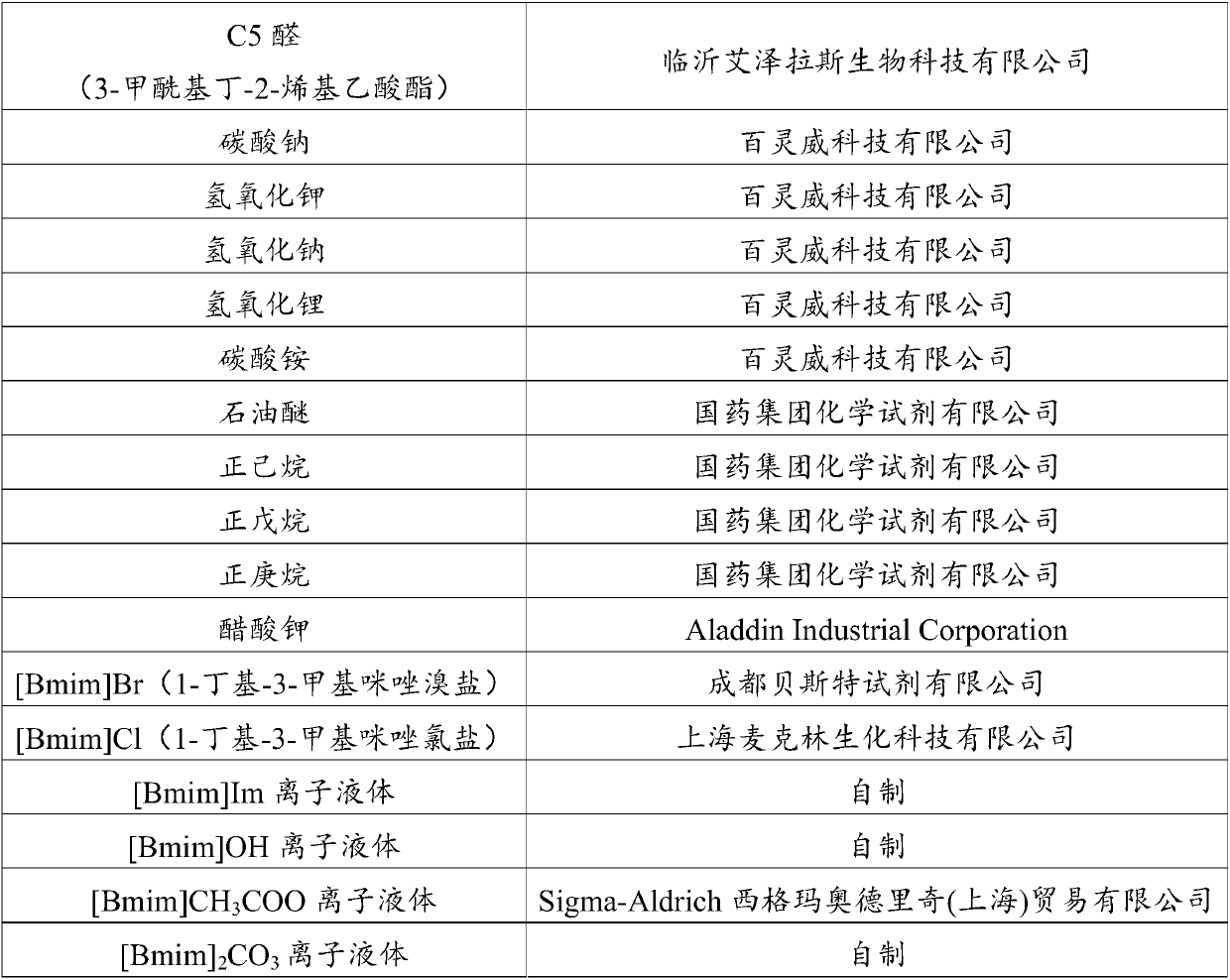

The invention belongs to the technical field of production of vitamin A and its derivatives, in particular to a method for preparing vitamin A acetate. The method comprises the following steps: (1) mixing triphenylphosphine and acid in supercritical CO2, and then contacting the obtained mixture with vinyl-beta-ionol for salt formation to obtain C15 phosphine salt; (2) after adding solvent water, ionic liquid and C5 aldehyde to the finished system of step (1) , CO2 is released for solvent replacement, and the materials are uniformly mixed; (3) adding an extractant to the system after the solvent replacement of step (2), stirring and adding an alkali solution for Wittig reaction to obtain the vitamin A acetate. The method of the invention has mild reaction conditions, safe production and easy control, and the purity and reaction yield of the final product are high.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing lithium hydroxide through electrolysis of salt lake brine

ActiveCN103924258ASimple processEasy to controlElectrolysis componentsLithium hydroxide monohydrateChemistry

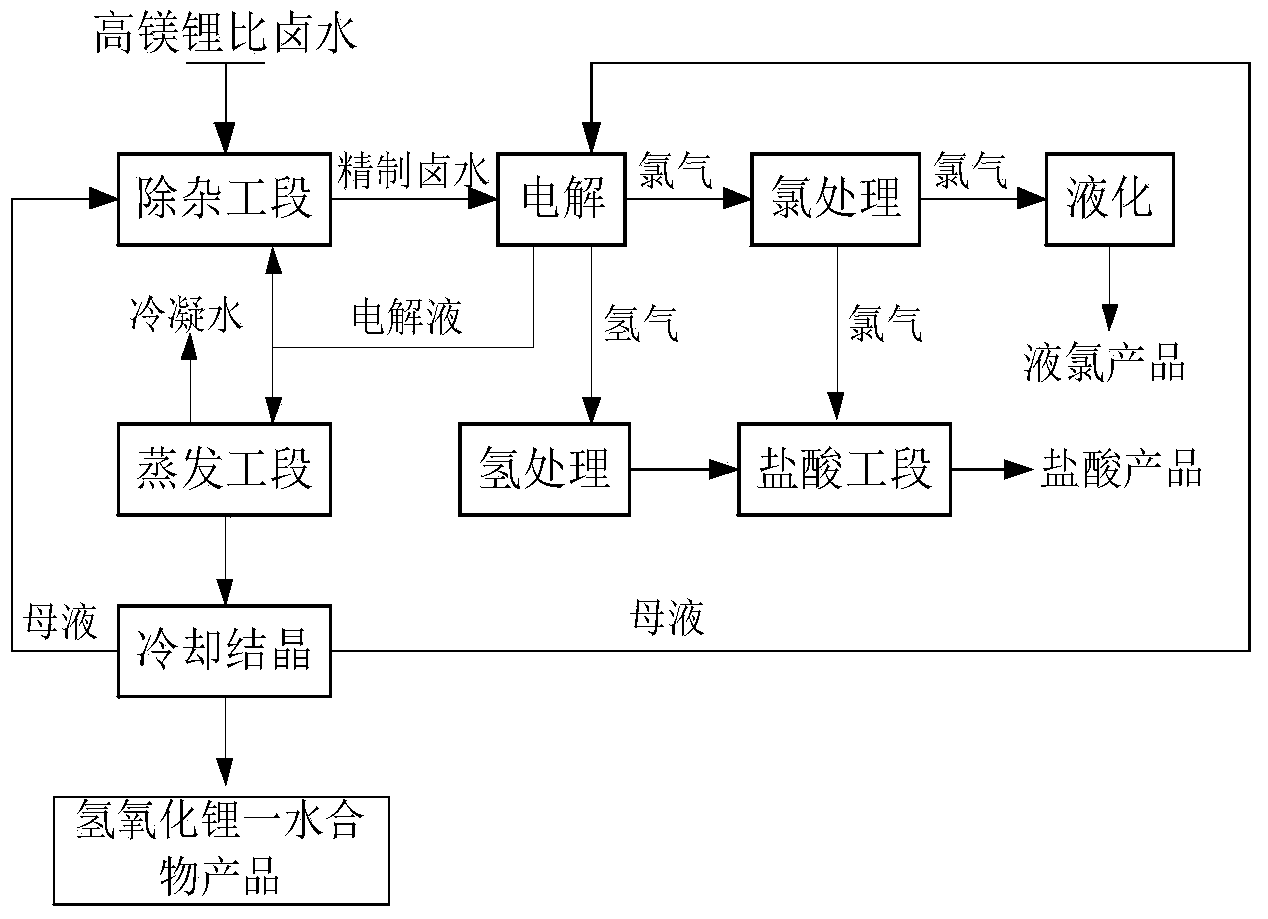

The invention discloses a method for preparing lithium hydroxide through electrolysis of salt lake brine. The method comprises steps of (1) evaporating and concentrating original lithium containing salt lake brine through insolation in a salt pan, so as to obtain the brine with high magnesium-lithium ratio; (2) removing impurities in the brine with high magnesium-lithium ratio so as to obtain refined brine; (3) electrolyzing with the refined brine as anode liquor and lithium hydroxide solution as cathode liquor, and obtaining lithium hydroxide monohydrate solution in a cathode chamber through a cation membrane; (4) evaporating and concentrating, cooling and crystallizing, washing and drying the lithium hydroxide monohydrate solution so as to obtain lithium hydroxide monohydrate. The method can prepare a high-purity product, has low cost and high yield of lithium, is simple and is easy to control.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

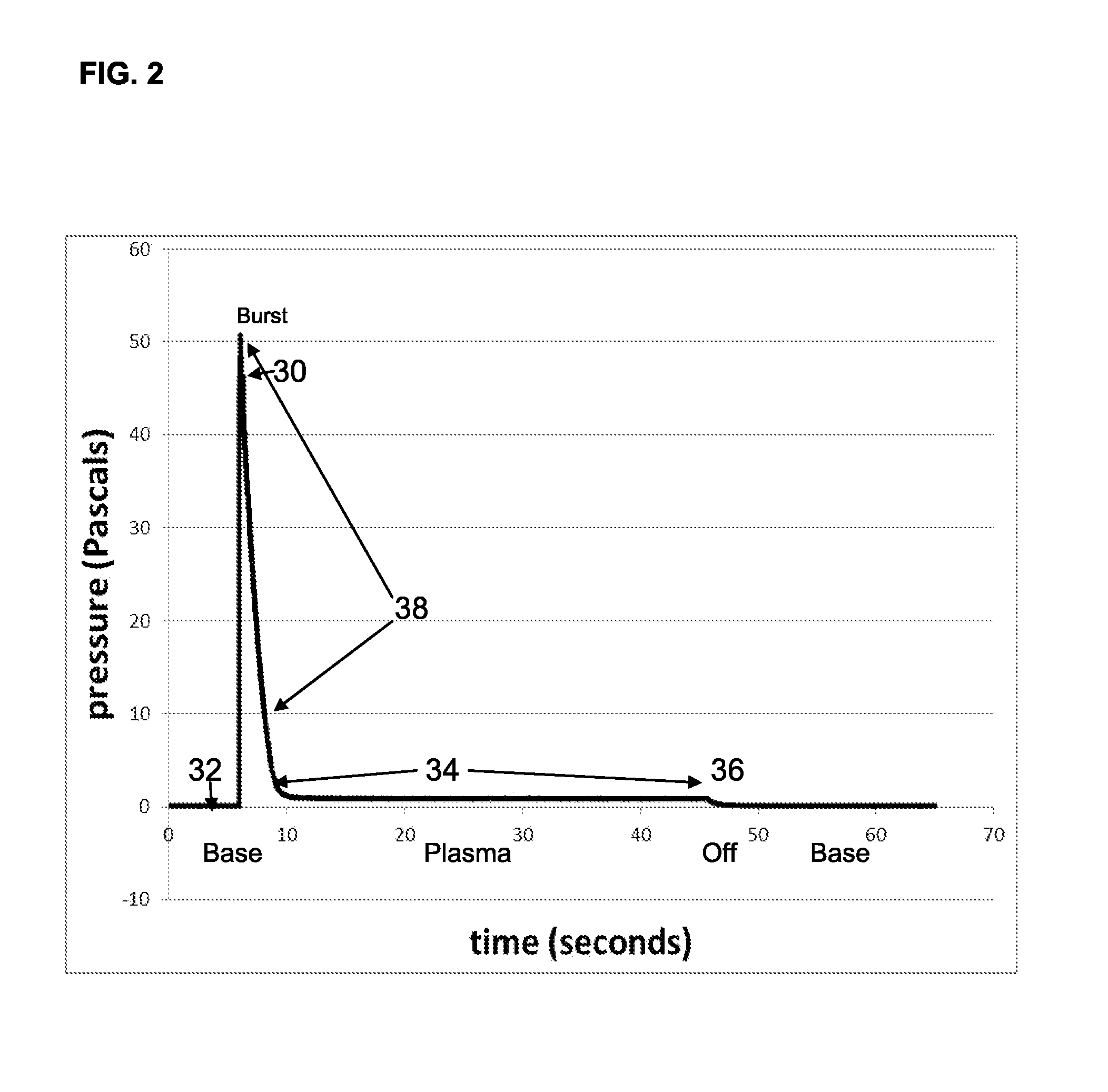

Method and apparatus for plasma ignition in high vacuum chambers

InactiveUS20150097485A1Simple cleaningHigh cleaning rate and rangeElectric discharge tubesElectric arc lampsPlasma treatmentEngineering

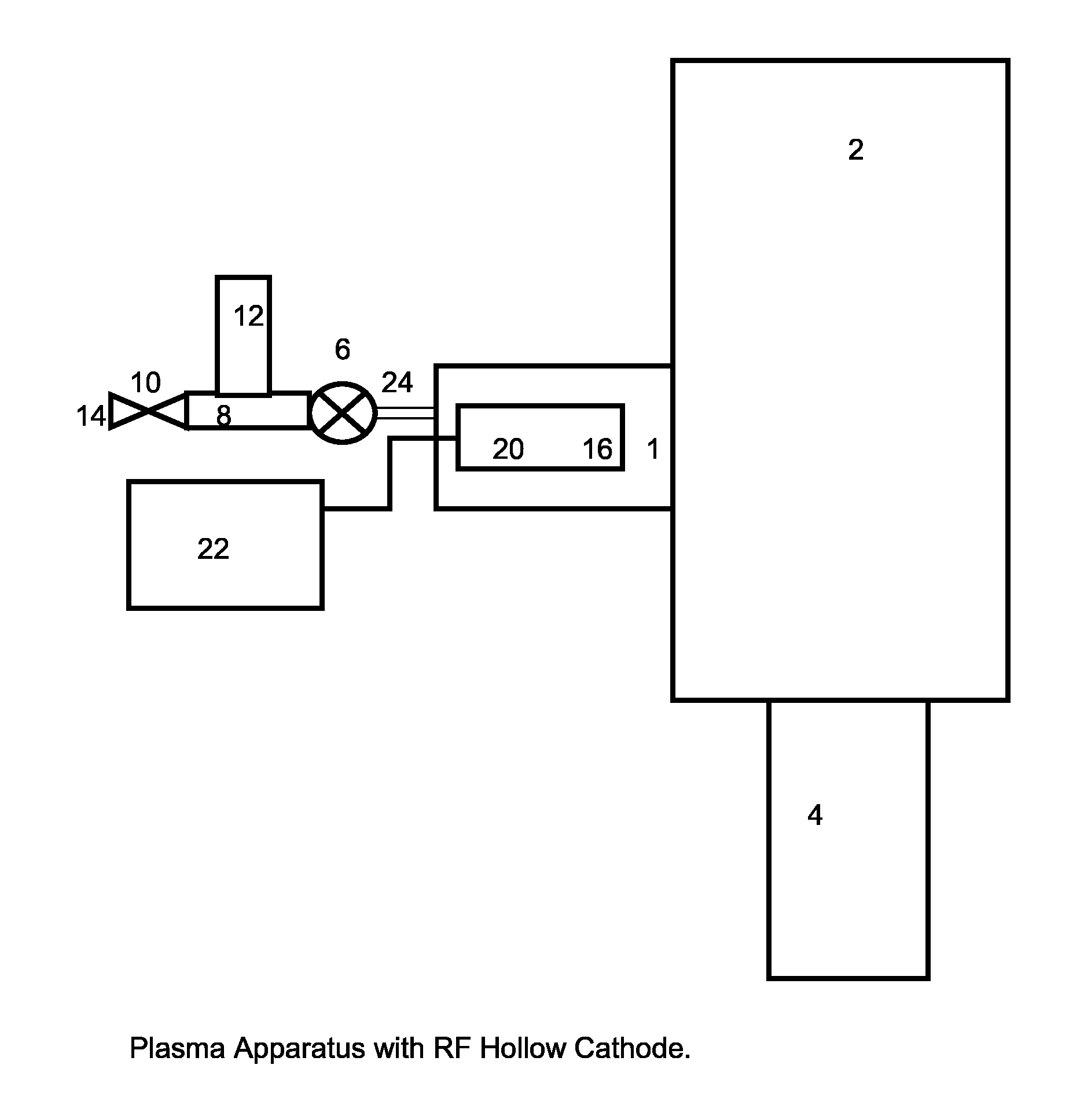

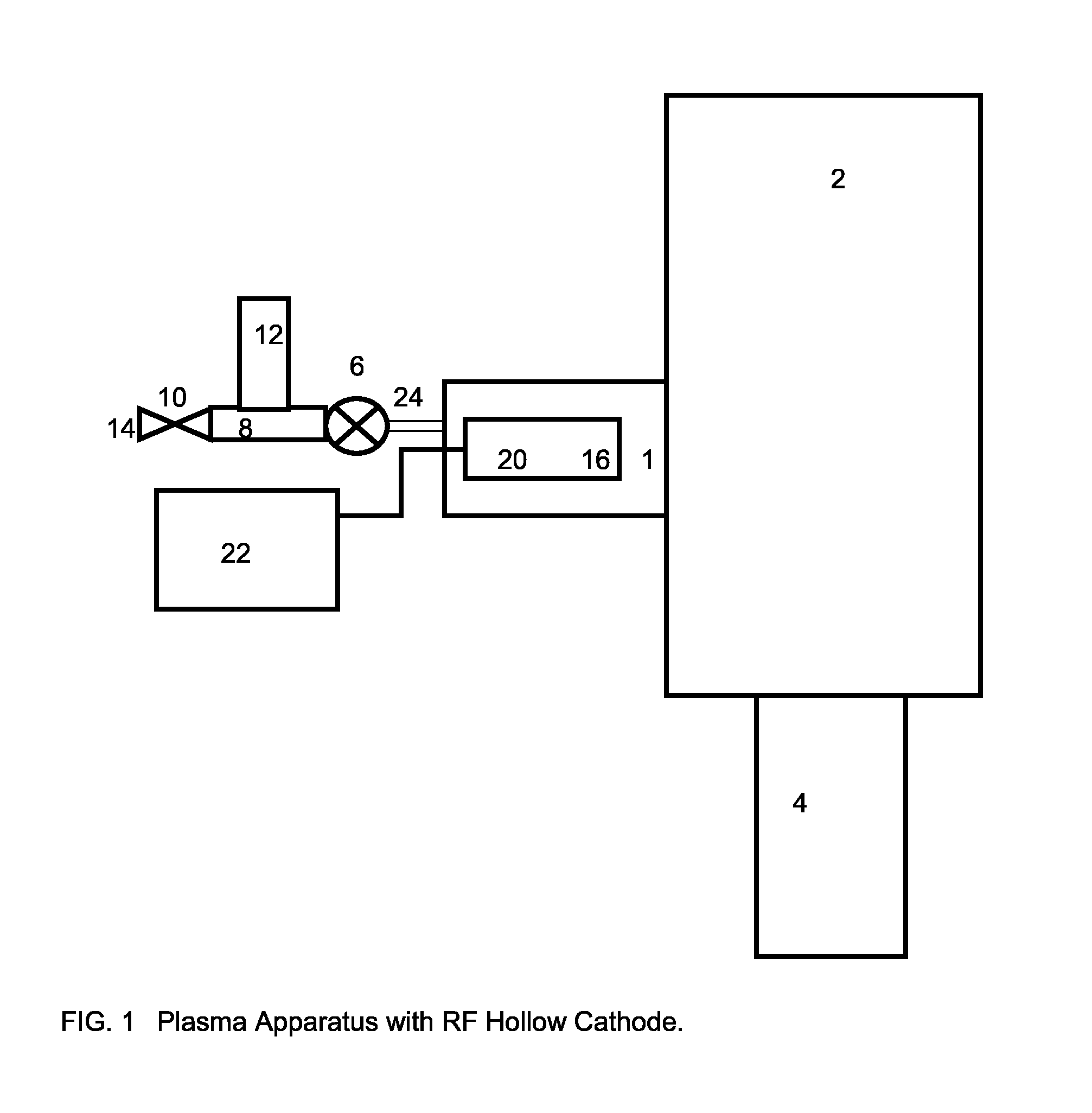

A plasma process method and apparatus for use with a vacuum instrument having a vacuum chamber evacuated by an oil free high vacuum pump to a base pressure below about 1 Pa. A gas buffer chamber in fluid communication with the plasma chamber, the gas buffer chamber having a volume about 1 / 500 to 1 / 2000 of the volume of the vacuum chamber. A valve between the plasma chamber and the gas chamber permits flow between the gas chamber and the plasma chamber, wherein, upon opening the valve, gas is admitted into the plasma chamber and pressure in the plasma chamber rises temporarily to between about 10 and about 200 Pa and plasma ignition can be obtained when the plasma excitation device is energized simultaneously. A flow restriction between the gas source and the gas chamber has a maximum flow rate therethrough of about 25 sccm. (standard cubic centimeters per minute) or less so that pressure in the plasma chamber remains between about 1 and about 7 Pa after plasma ignition to maintain plasma conduction and to avoid overloading or heating of the high vacuum pump.

Owner:XEI SCI

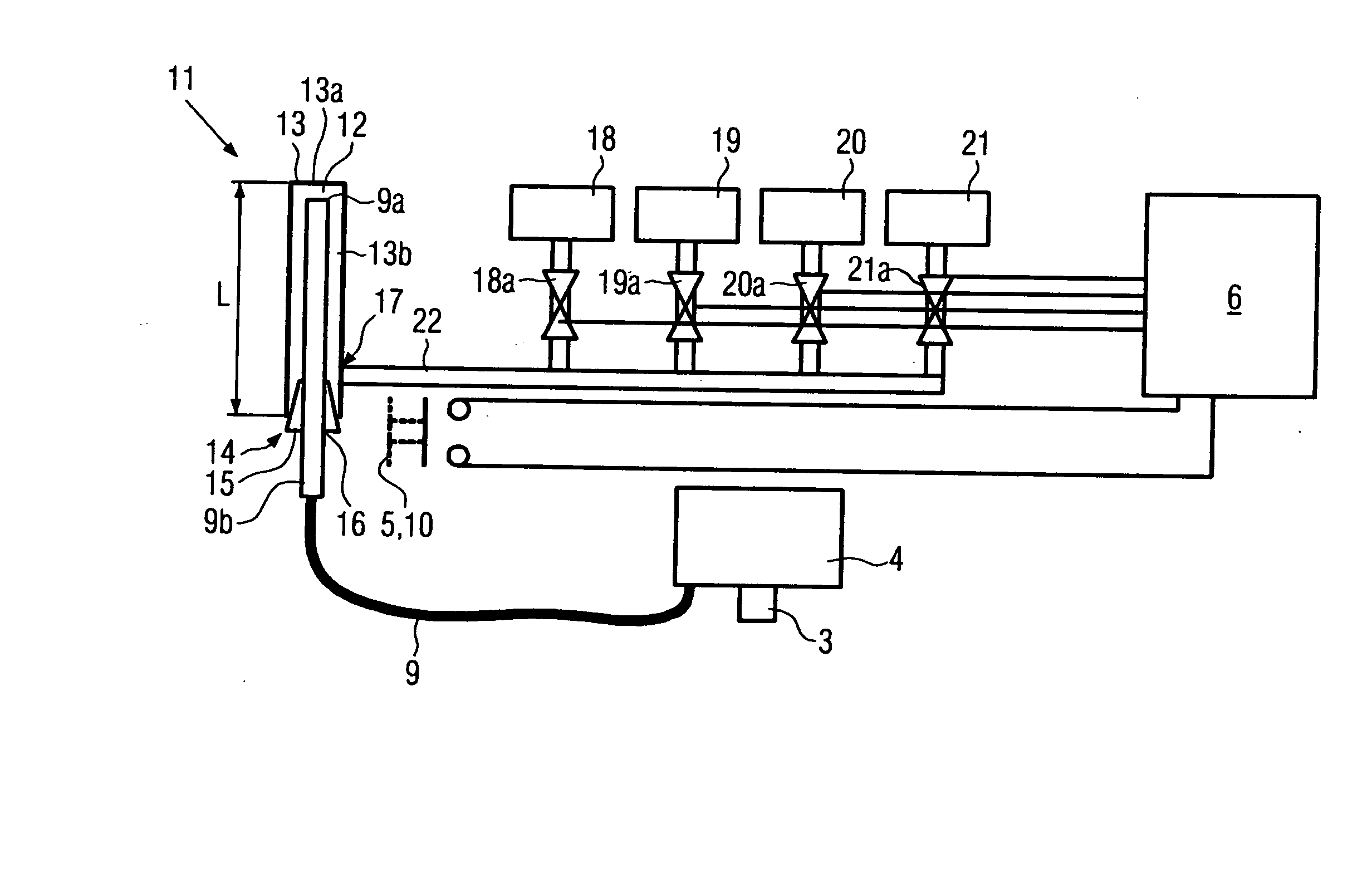

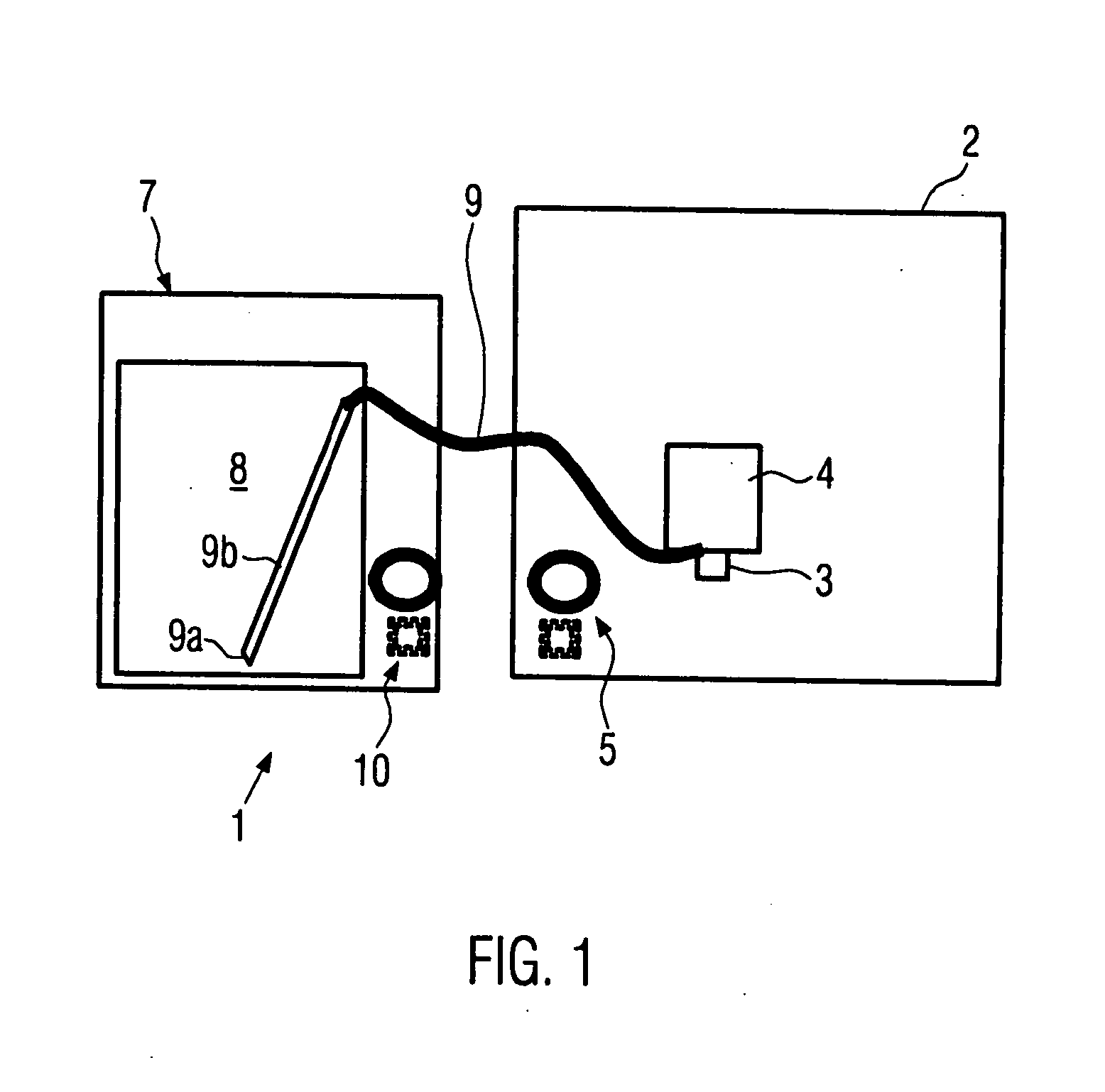

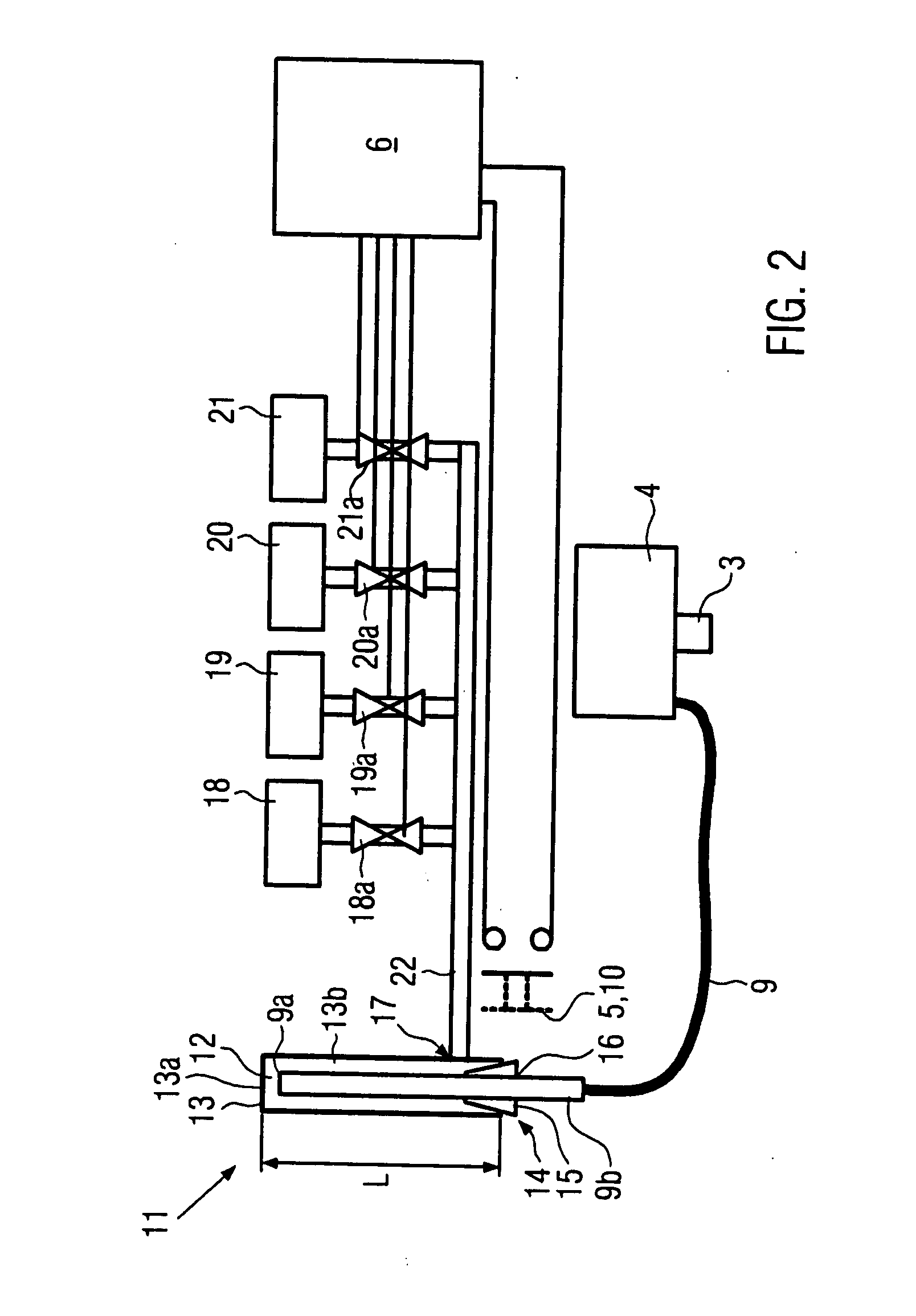

Device for feeding milk

ActiveUS20080053313A1Good removal effectSimple processOpening closed containersBottle/container closureEngineeringCleansing Agents

A device for feeding milk from a storage container (8) to a dispensing device (3), containing a feeding line (9), whose intake end (9a) is detachably connected to the storage container (8), and with a cleaning possibility for at least a portion of the exterior of the feeding line (9). In order to enhance a device of this type such that the cleaning is simplified, a cleaning mechanism (11) be provided for the exterior of the feeding line (9), which comprises a rinsing area (12) for holding the portion of the feeding line (9) that is to be cleaned. The rinsing area (12) contains a hot water intake opening, a steam intake opening, a cleaning agent intake opening, or cold water intake opening (17), and also a connection opening (14) for the detachable introduction of the portion to be cleaned.

Owner:WMF GRP

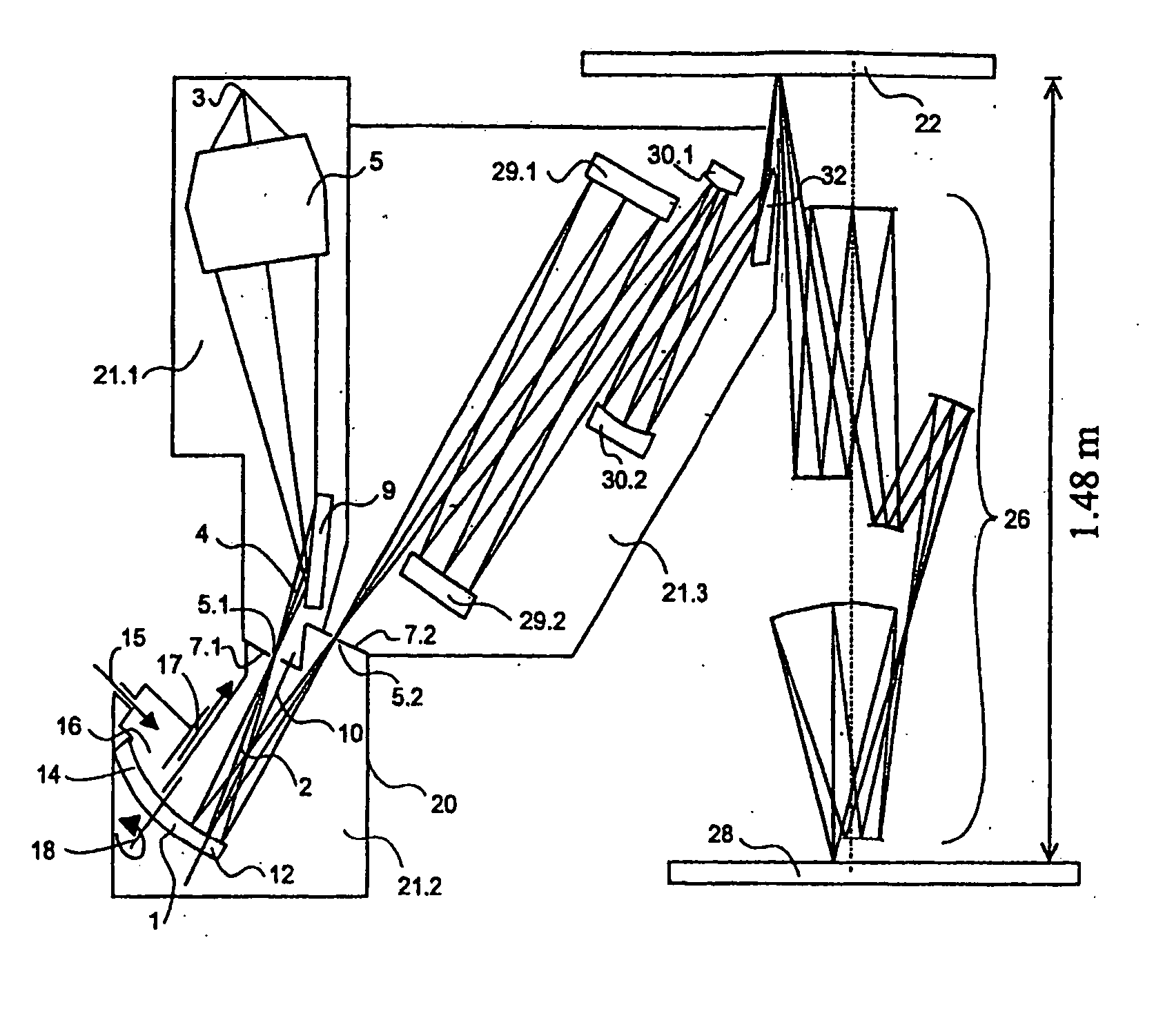

EUV-lithography apparatus having a chamber for cleaning an optical element

InactiveUS20070283591A1Extended use timeClean the contaminated optical elements regularlyDrying solid materials with heatHandling using diffraction/refraction/reflectionLithographic artistLength wave

Owner:CARL ZEISS SMT GMBH

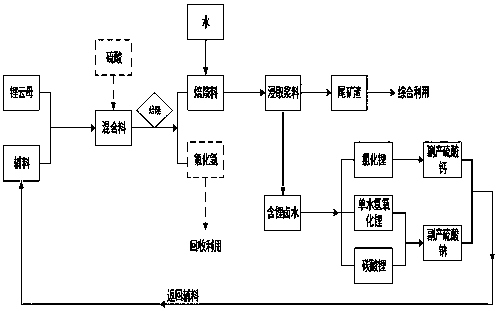

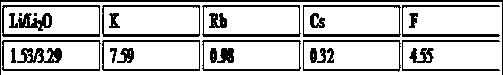

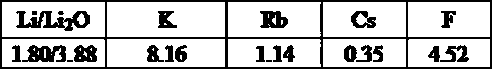

System method for extracting lithium-containing brine from lepidolite and manufacturing lithium salt

ActiveCN111137908AEasy to handleGood choiceAluminium silicatesCalcium/strontium/barium fluoridesLithium chlorideLithium carbonate

The invention discloses a system method for extracting lithium-containing brine from lepidolite and manufacturing lithium salt. The system method comprises the following steps: material mixing, roasting, brine preparation, lithium salt preparation and comprehensive utilization of tailing slag. According to the invention, sulfuric acid double salt and sulfuric acid (selected) are used as auxiliarymaterials to be mixed with the lepidolite for reaction; the system method is applicable to extraction of lithium in high-content and low-content lepidolite; good selectivity is achieved during extraction; the extraction rate of lithium is 95.5%-97.5%; and the extraction rates of K, Rb and Cs are smaller than 30%; the obtained brine is neutral and can be used for directly preparing lithium hydroxide monohydrate, lithium chloride or lithium carbonate, and the total yield of lithium is more than 92%; the process is high in flexibility, can produce single-variety lithium salt, and can jointly produce two or more varieties of lithium salt; and fluorine in the lepidolite can be separated and recovered, so the additional value is increased, and the lithium extraction tailing slag can be comprehensively utilized. The system method provided by the invention has the following advantages: the whole process is short in flow, low in cost and friendly to the environment; and the system method has good economic benefits and social benefits and good industrial application values.

Owner:CHANGSHA YUANPENG CHEM TECH

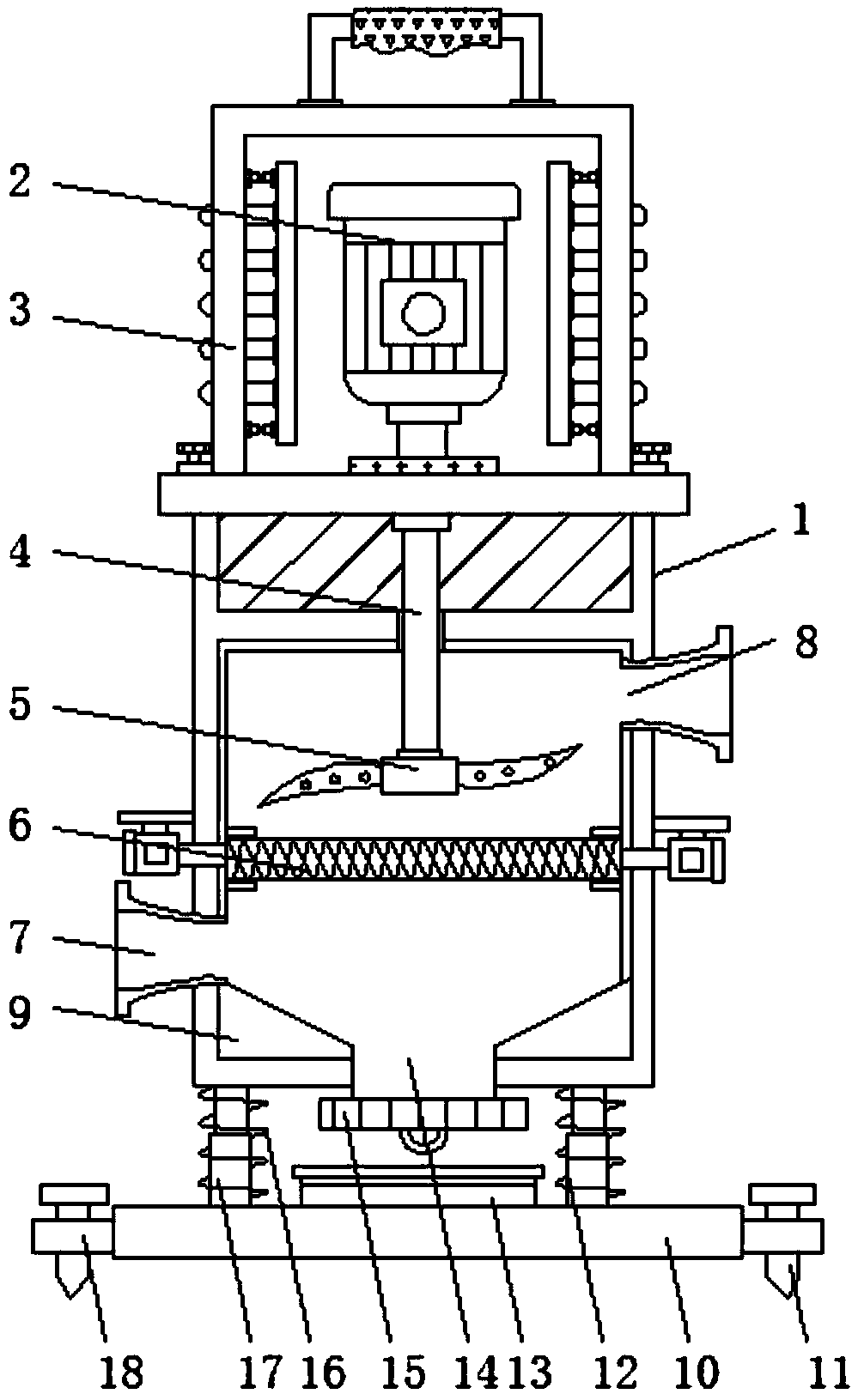

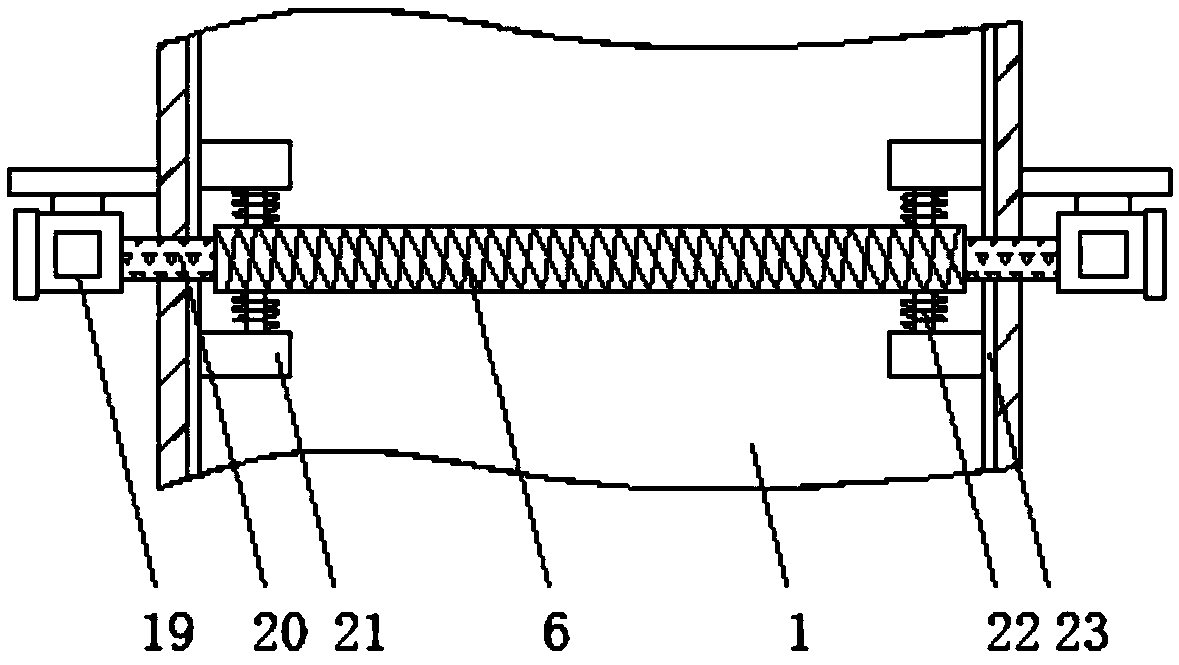

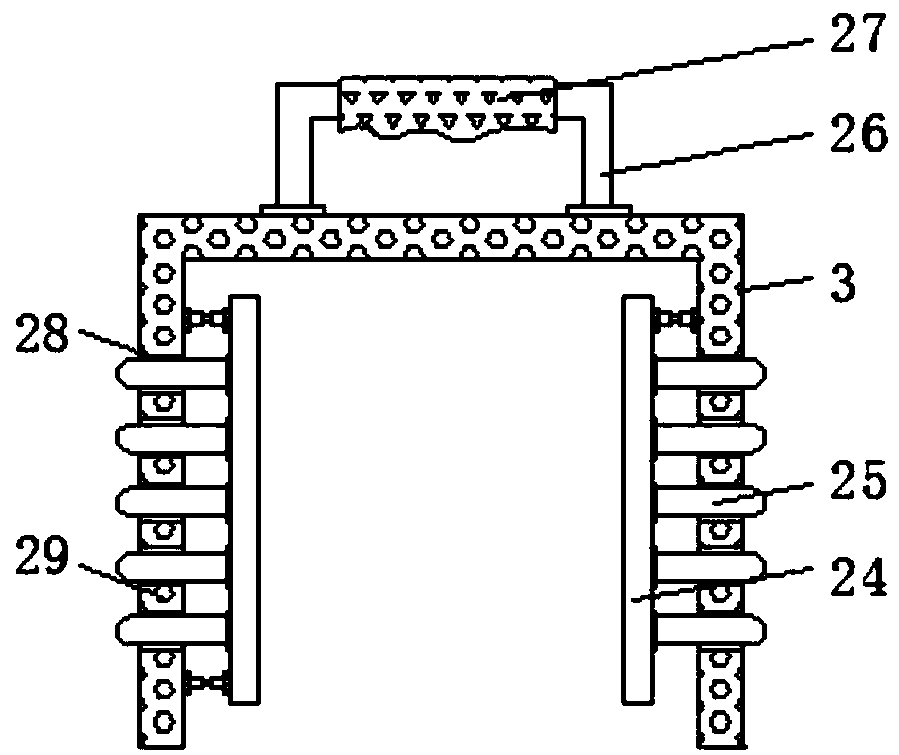

Vertical type sewage pump

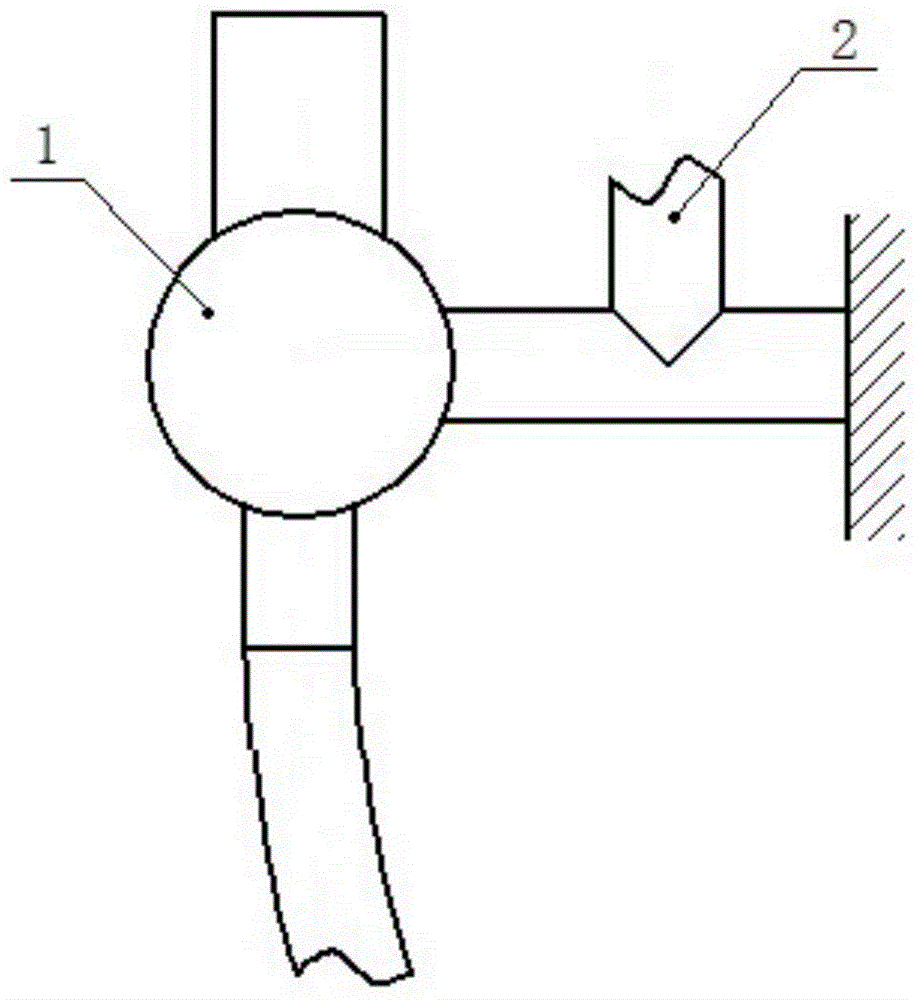

InactiveCN108953159ANoise isolationAvoid temperatureSpecific fluid pumpsPump componentsImpellerCoupling

The invention discloses a vertical type sewage pump. The vertical type sewage pump comprises a pump body and a high-speed motor, wherein a sound insulation cover is arranged at the outer side of the high-speed motor in a covering manner; metal heat absorbing plates are arranged at the two sides of the interior of the sound insulation cover; heat dissipation rods which extend to the exterior of thesound insulation cover are arranged on the metal heat absorbing plates; an output shaft of the high-speed motor is connected to a transmission shaft through a shaft coupling; an impeller is fixed atthe bottom end of the transmission shaft; a water inlet is formed in the bottom end of the outer surface of the pump body; a water outlet is formed in the upper end of the outer surface of the pump body; a filtering net is arranged between the air inlet and the impeller; and vibration motors are arranged on the side walls, located at the two sides of the filtering net, of the pump body, and are connected to the filtering net through a vibration transmission shaft. The vertical type sewage pump is simple in structure and convenient to use, has good sound insulation and noise reduction effects,and can effectively filter out impurities in sewage; and after the vertical type sewage pump is used for a long time, sundries adhered to the filtering net can be shaken off in a vibration manner, andthe removal of impurities on the filtering net is convenient.

Owner:浙江融乐环境科技有限公司

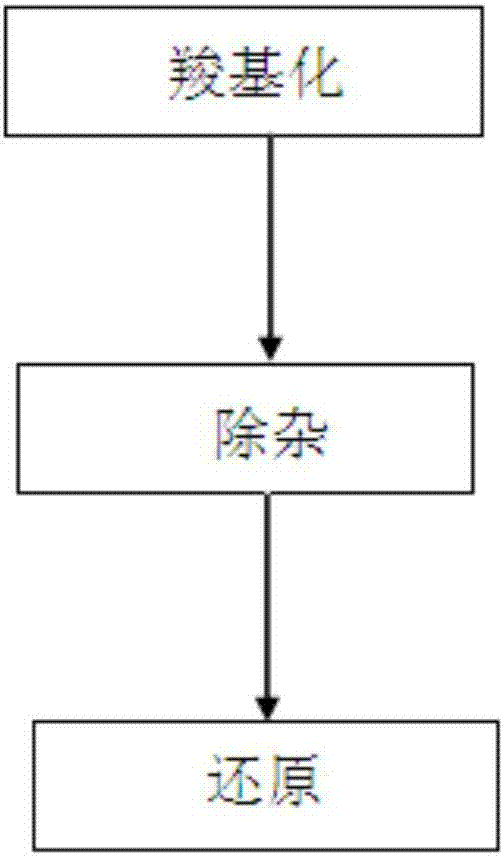

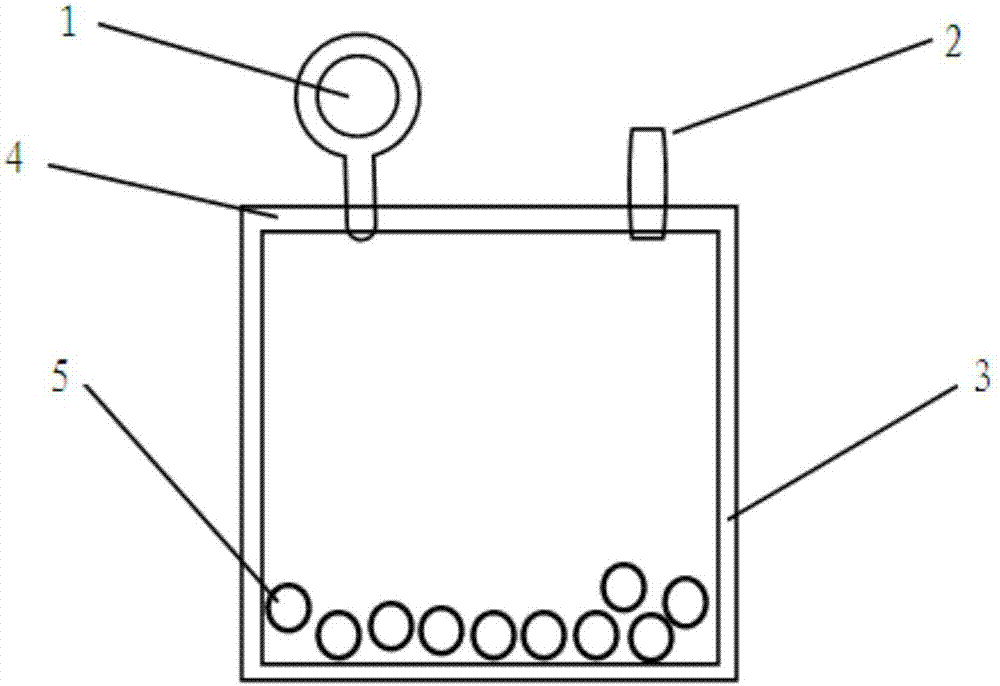

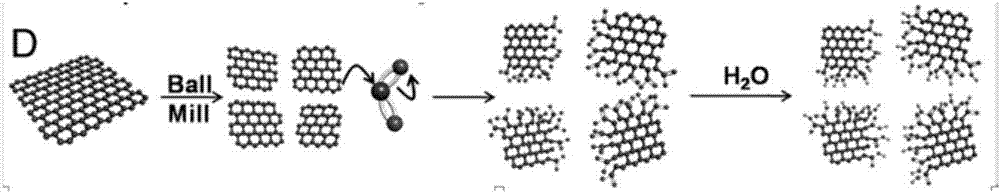

Method for preparing single-layer graphene through mechanical method

InactiveCN107089655AHigh degree of carboxylationIncrease success rateSingle layer grapheneExhaust valveSteel ball

The invention belongs to the technical field of graphene preparation and relates to a method for preparing single-layer graphene through a mechanical method. A specific technological process of the method comprises three steps of a hydroxylation process, a decontaminating process and a reduction process. The edge of natural flake graphite is processed in a carboxylation mode through a ball milling method to obtain initial carboxylation graphene powder, then pure carboxylation graphene powder with small iron content is obtained through the decontaminating process, and high-quality single-layer graphene is obtained through the thermal reduction process. The method avoids any strong oxidant and has high carboxylation degree, short ball milling time and high success rate; the decontaminating process is simple and effective; the reduction process avoids using reducing agents and is environmentally friendly; a main structure of a ball milling tank related to the hydroxylation process comprises a pressure meter, a gas exhaust valve, a tank body, a sealing cover and a stainless steel ball. The method has high preparation success rate, large yield, no pollution and low energy consumption and can achieve large-scale mechanical production through amplifying ball milling equipment.

Owner:QINGDAO UNIV

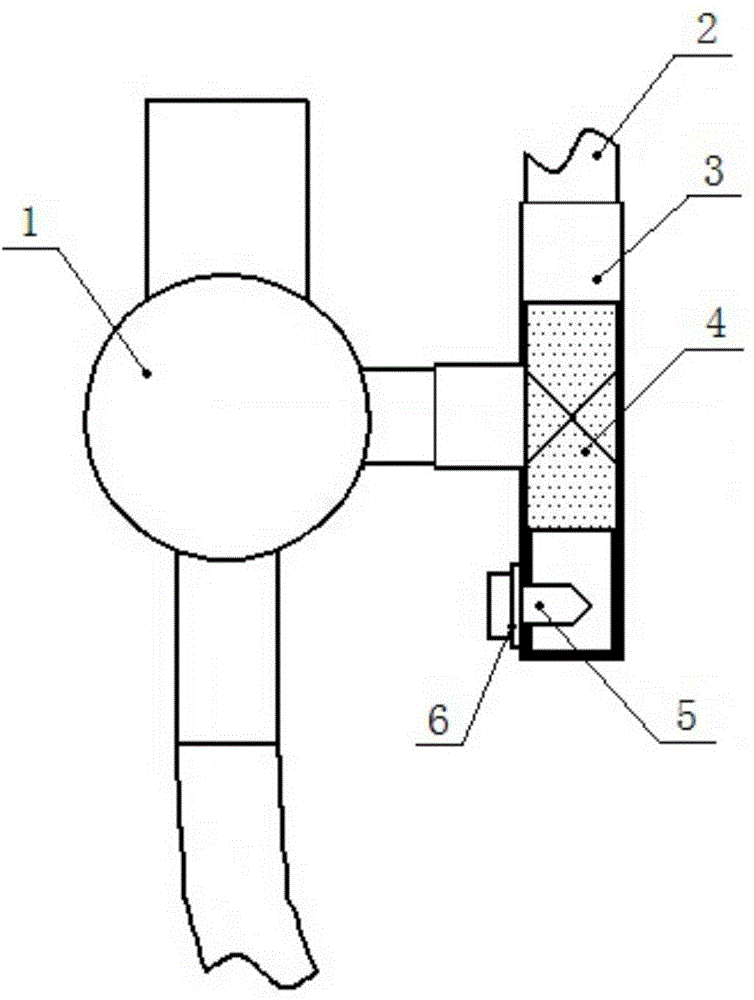

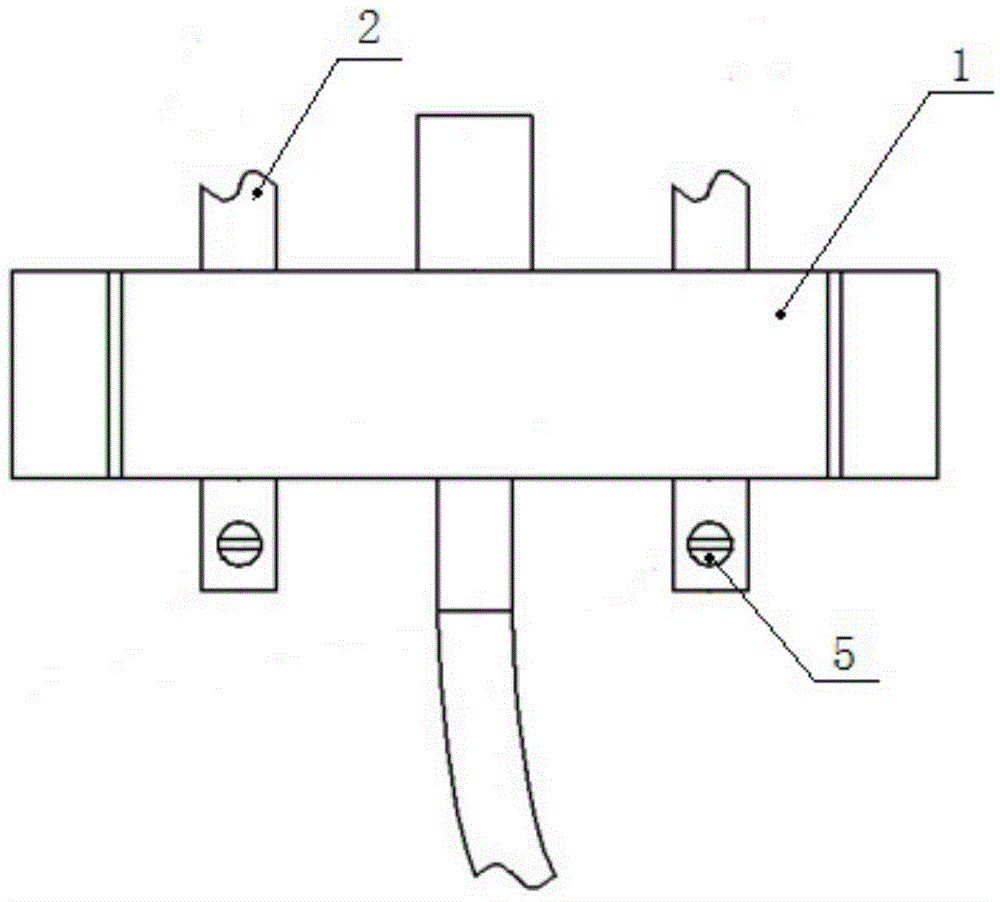

Coal slurry reactant sampling device

ActiveCN1945259ATrue reflection of changeRepresentativeWithdrawing sample devicesBorehole/well accessoriesHydrogenSolvent

The coal slurry reactant sampling device includes one sampling container connected through pipes with valves to the material conveying pipeline; solvent oil pipes with valve; hydrogen pipes; one gas sampling pipe in the upper part of the sampling container; one sampling pipe in the lower part of the sampling container; and one inert gas pipe communicated to the sampling container. The coal slurry reactant sampling device is accurate and reliable in sampling, convenient and safe in operation, and can sampling repeatedly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

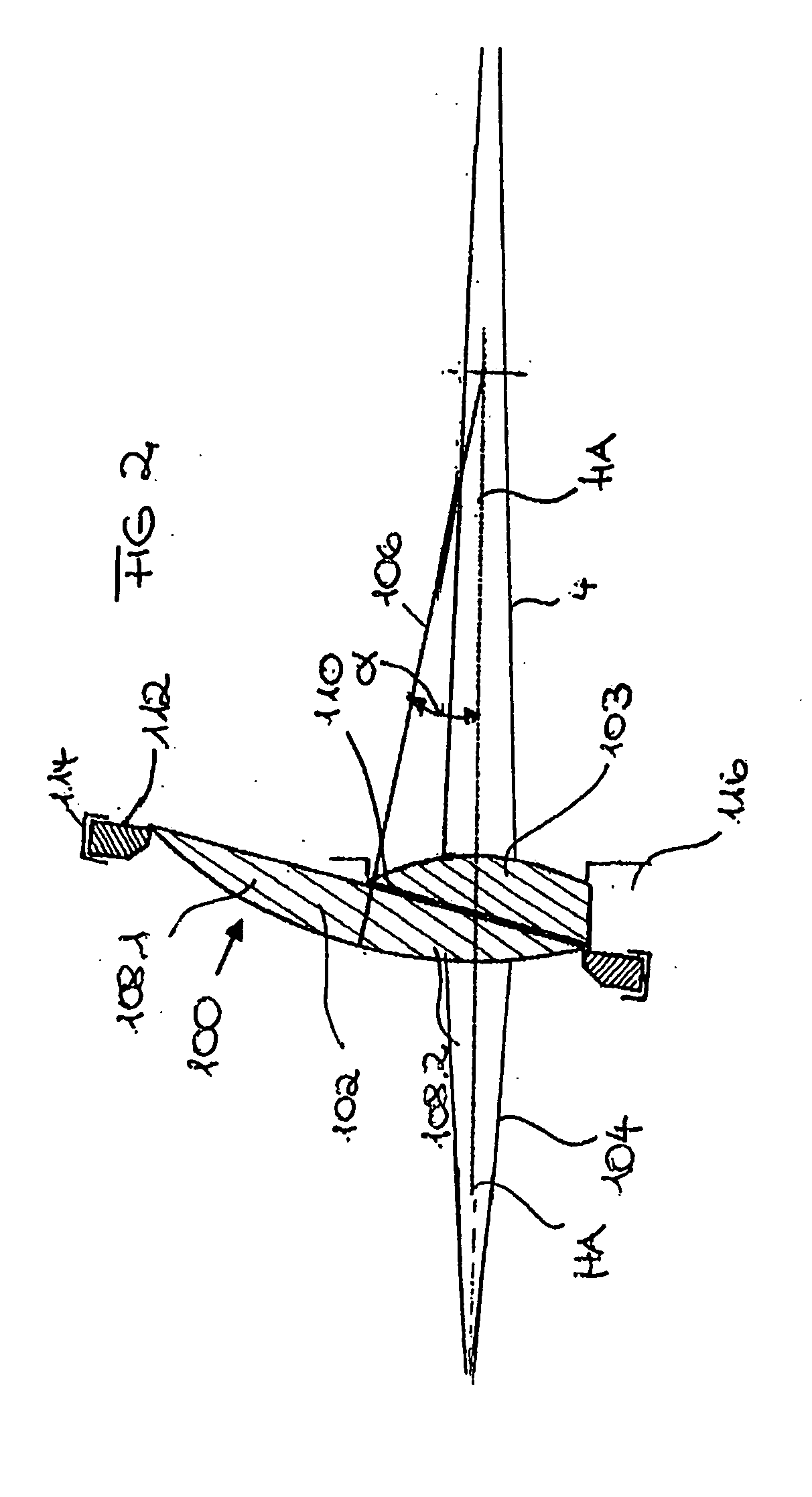

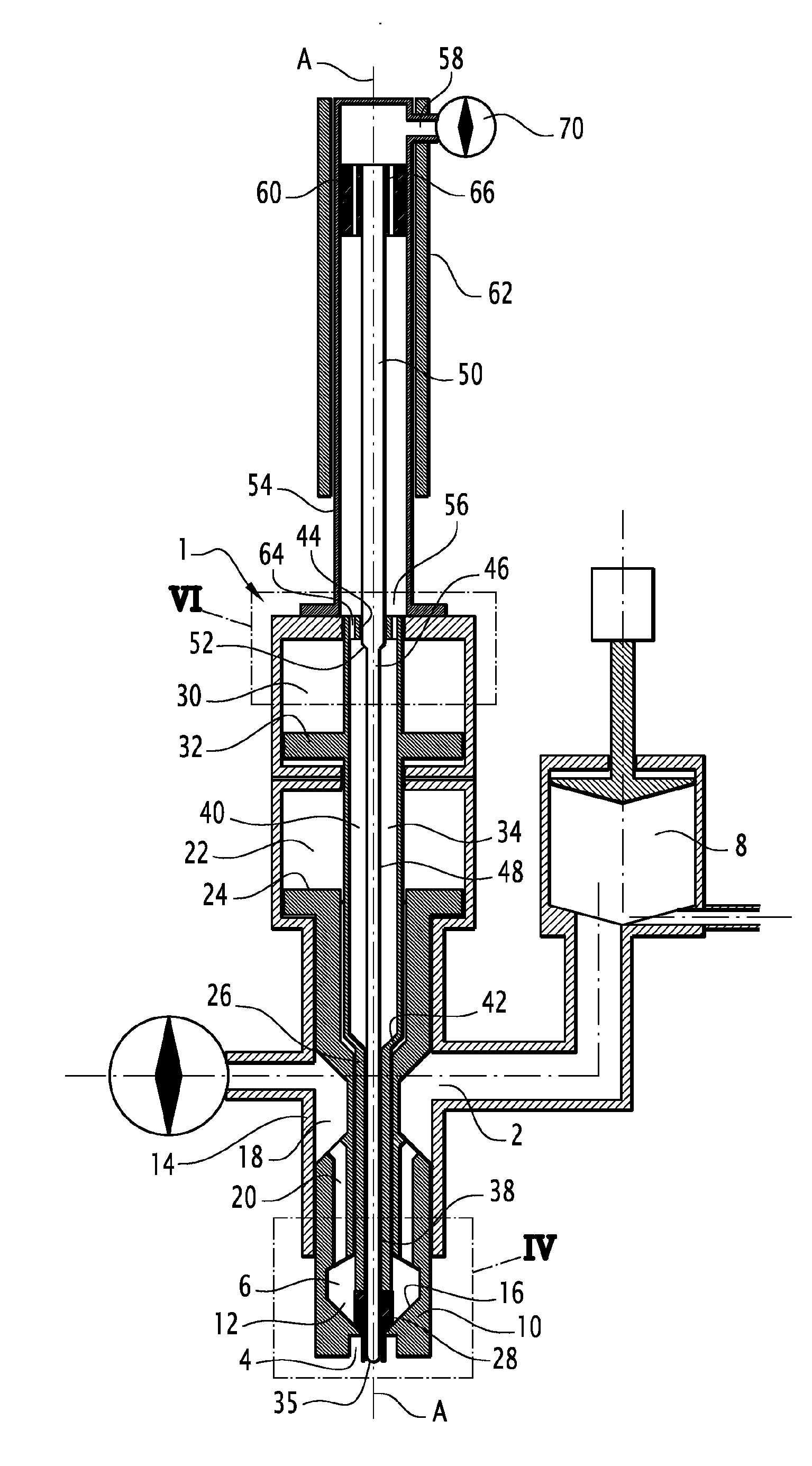

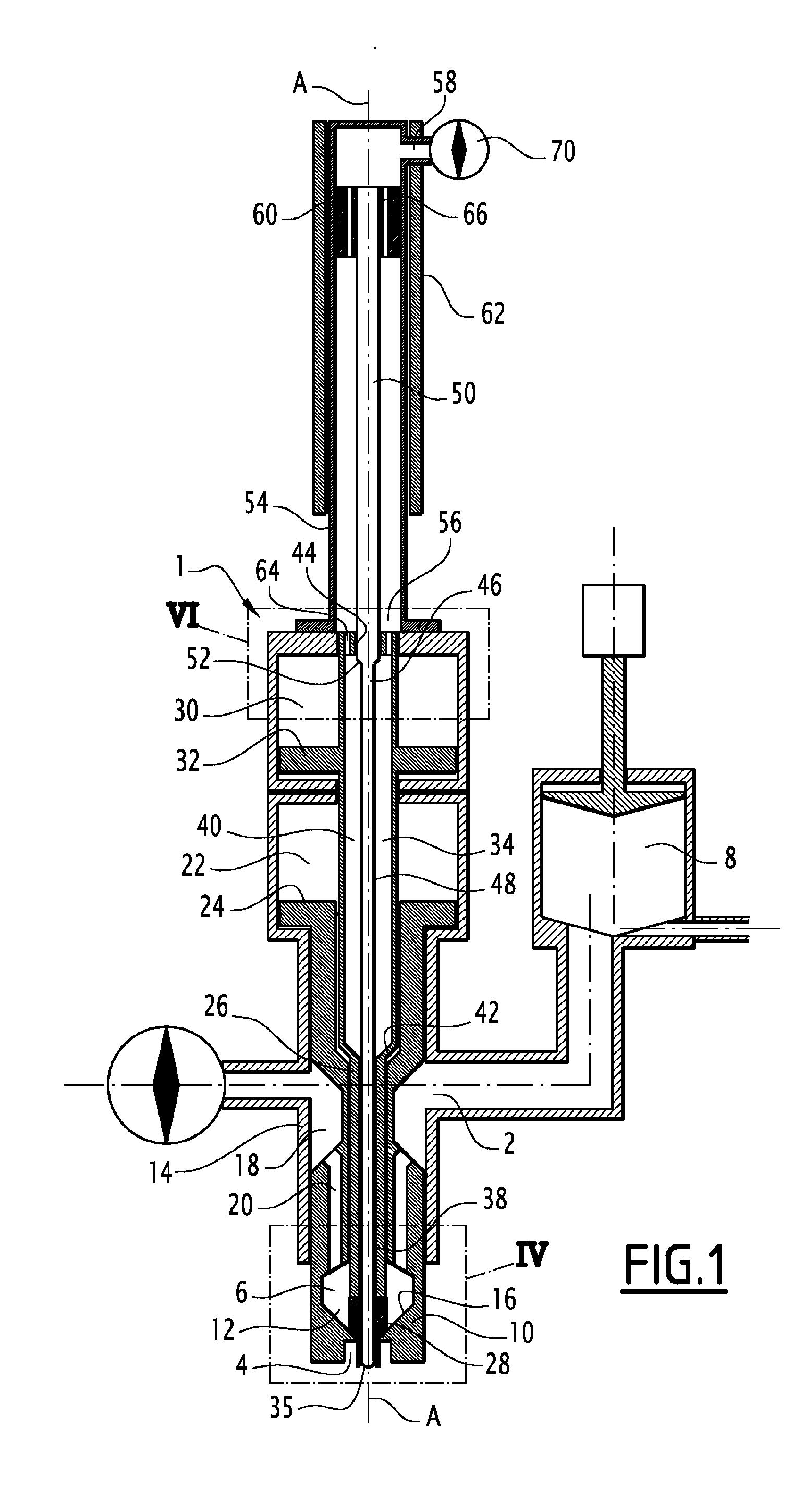

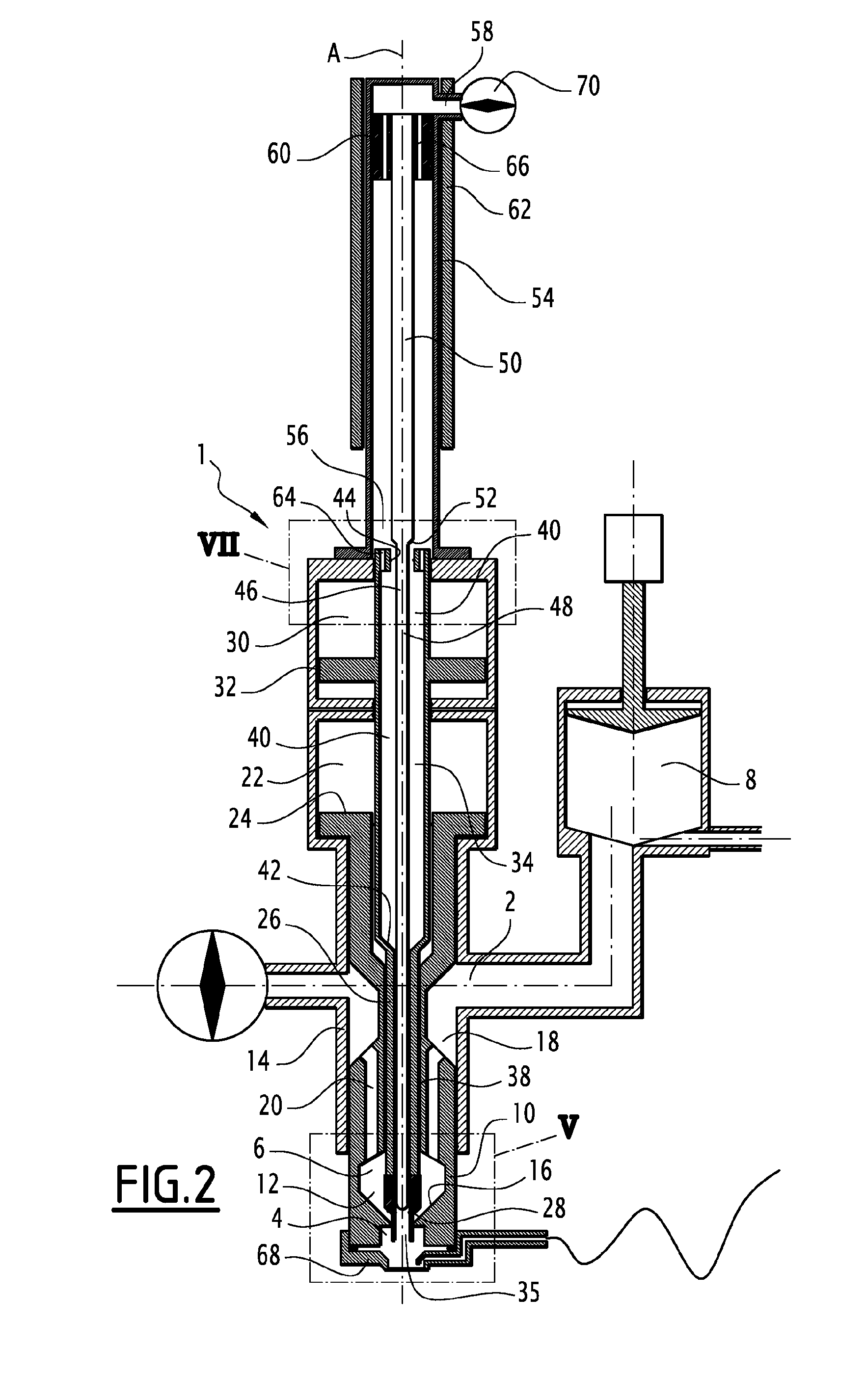

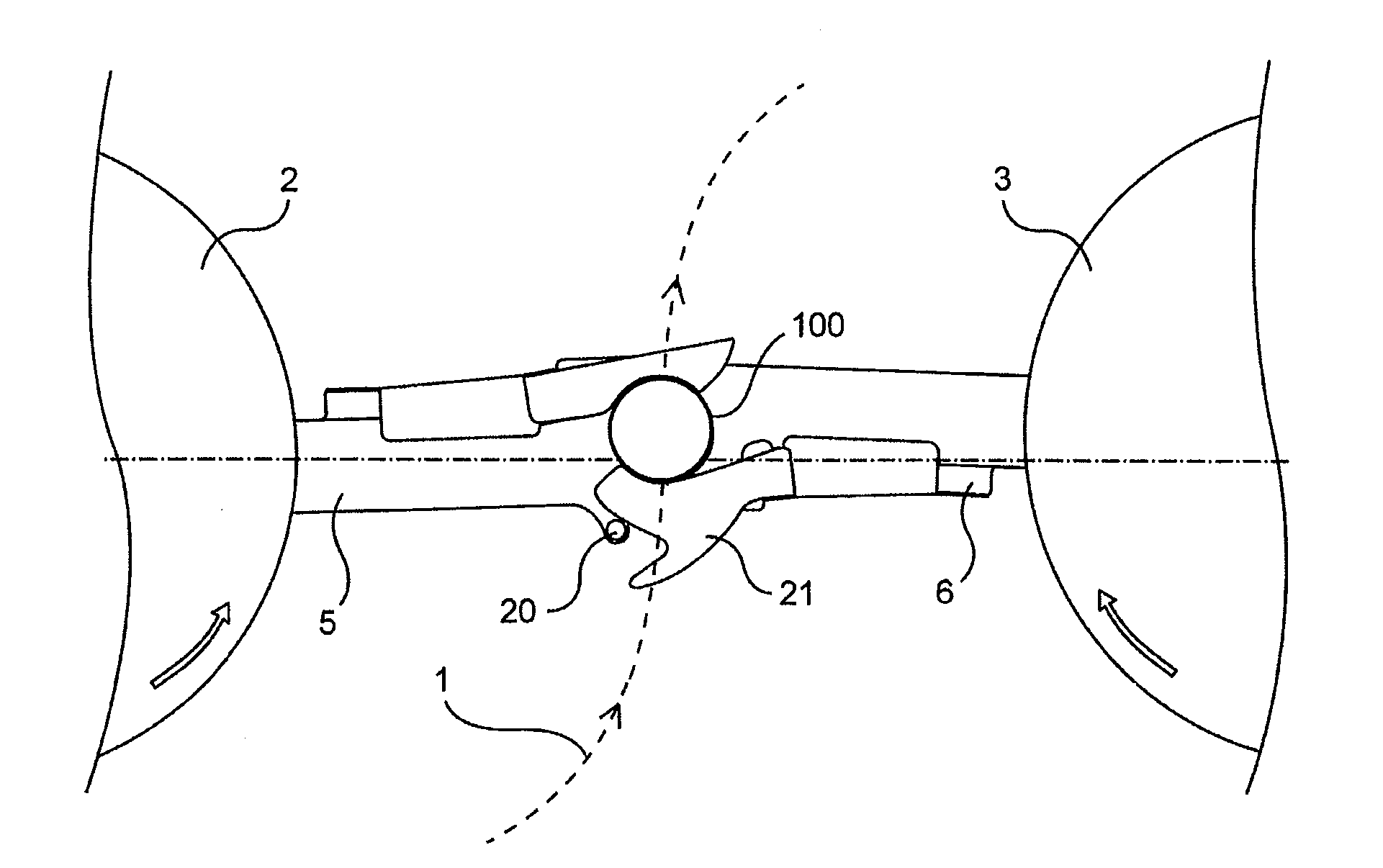

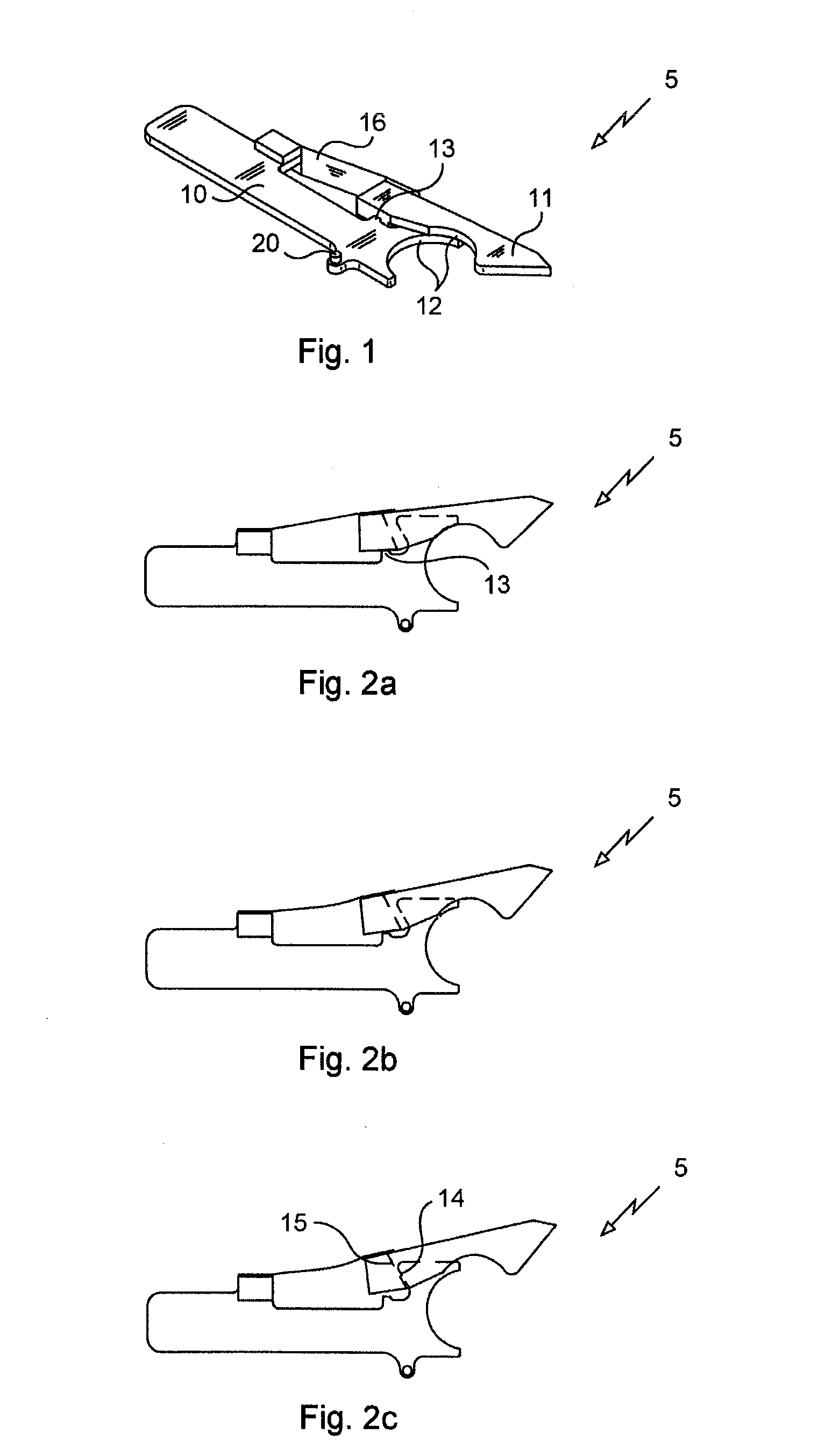

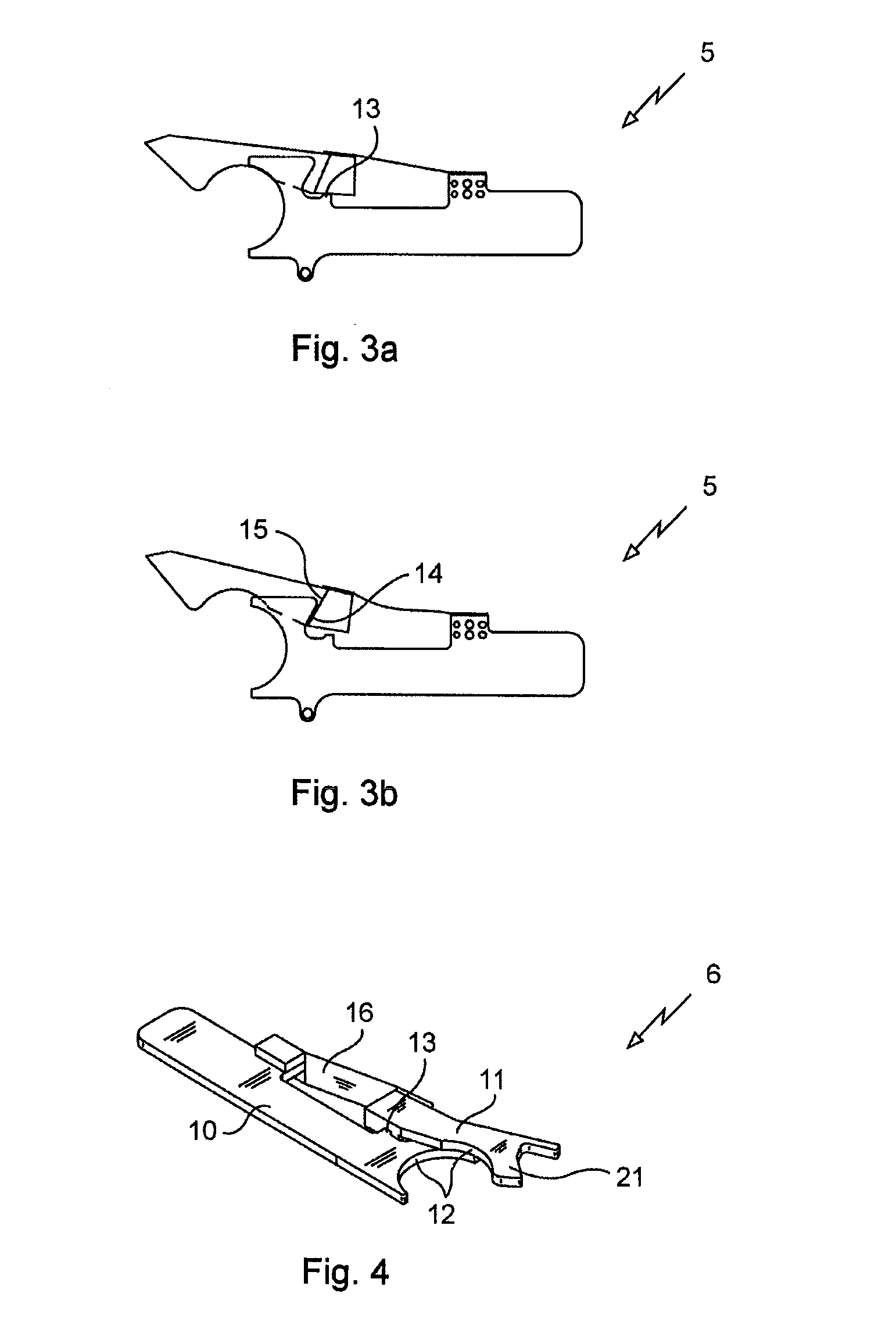

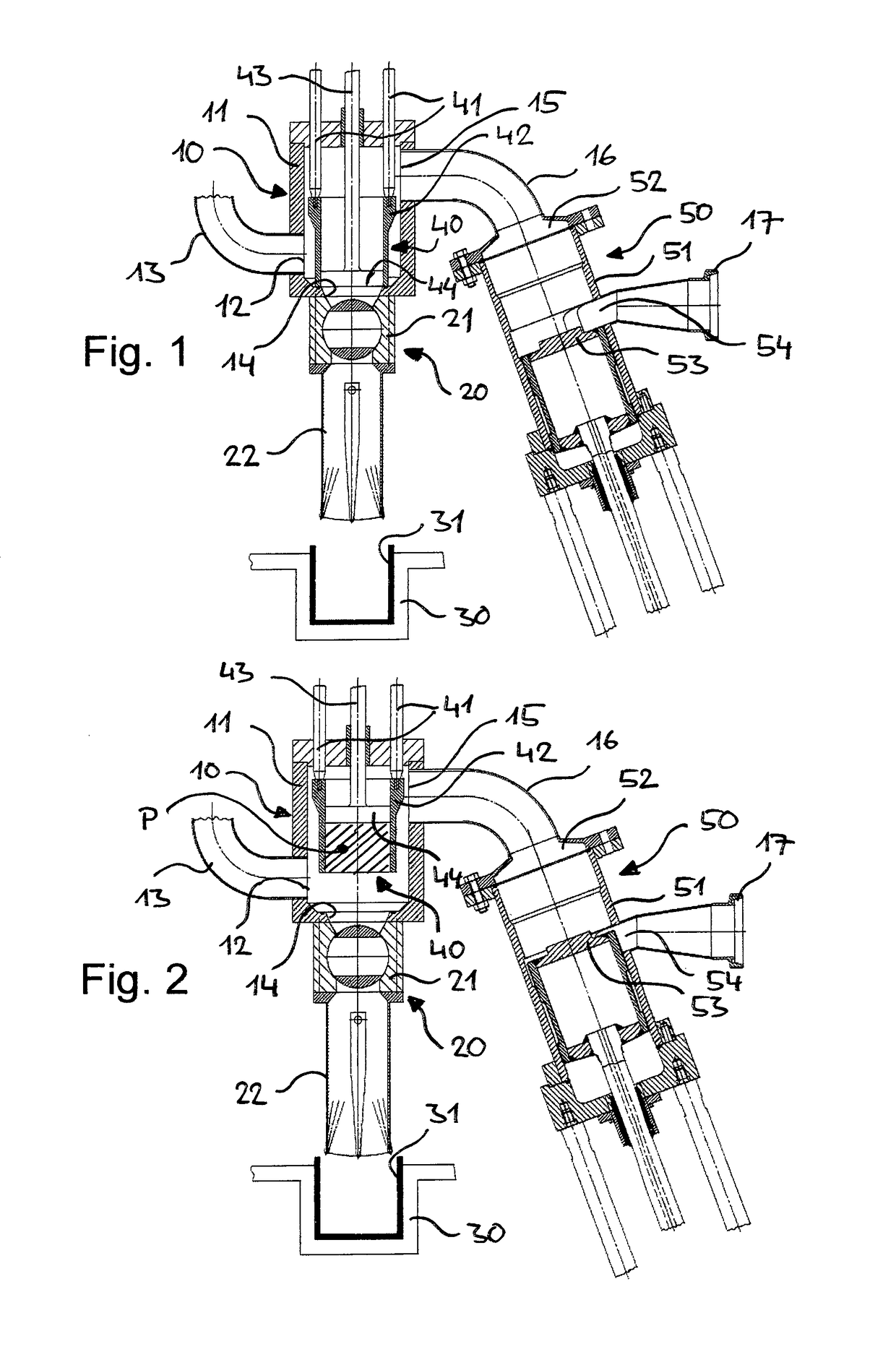

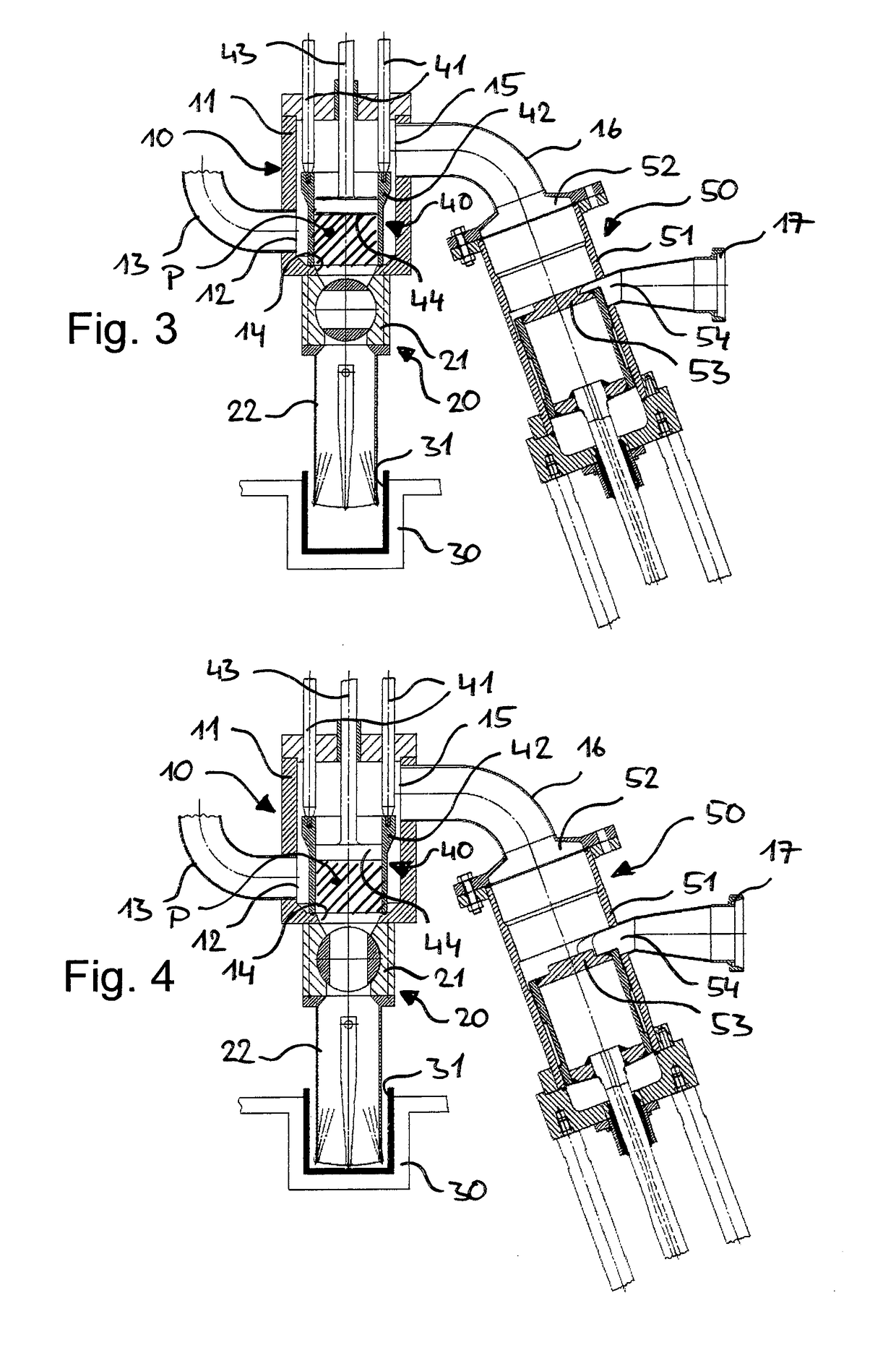

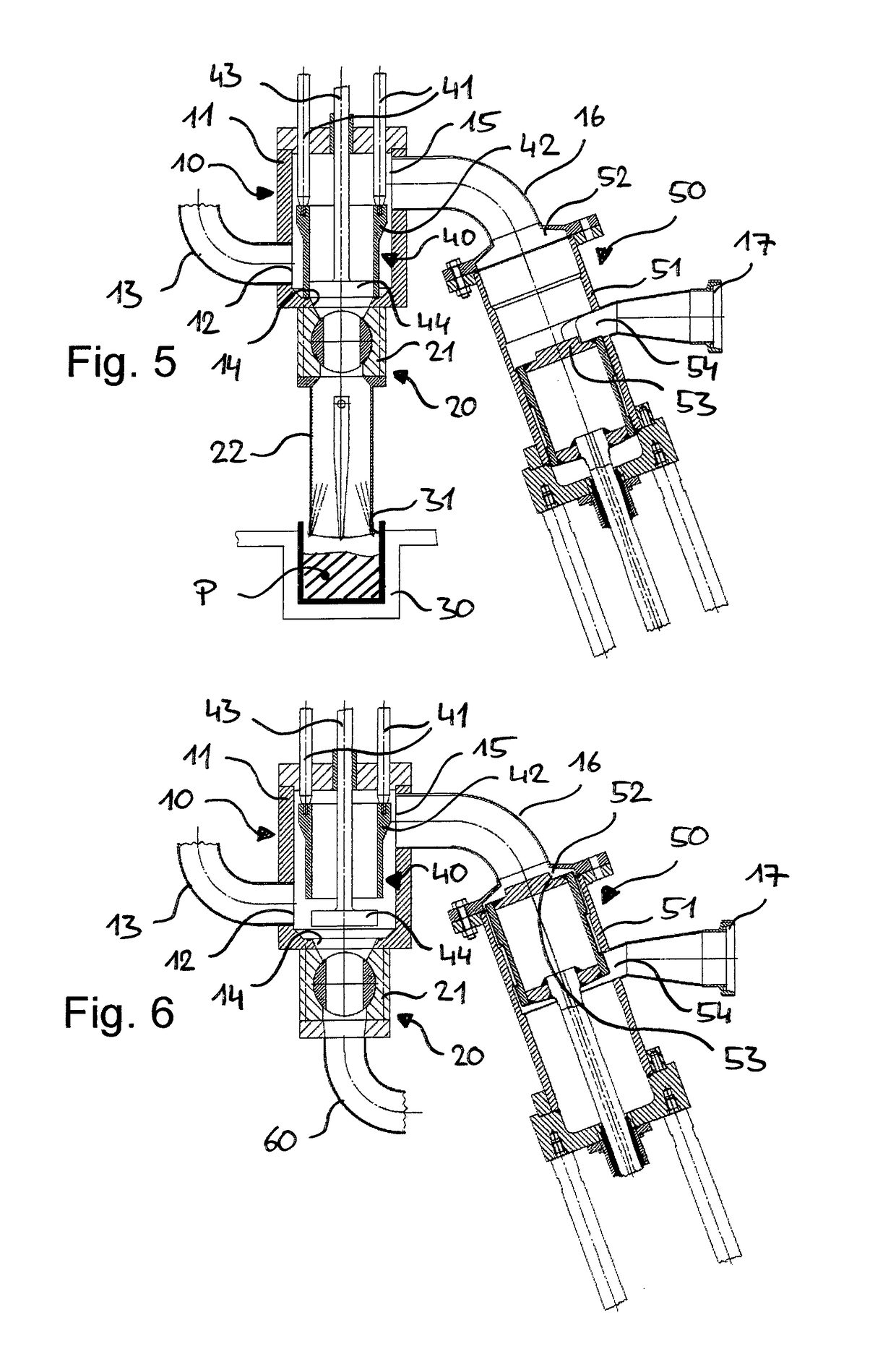

Injection device comprising a central rod movable in a cleaning position

ActiveUS20160107366A1Simple cleaningShort timeHollow article cleaningSpraying apparatusControl rodInjection device

An injection device having an inlet for receiving a fluid, an outlet for injecting the fluid and a chamber therebetween. A hollow control rod is provided in the chamber and includes a duct extending through said control rod. A central rod extends in the duct and is movable between a retracted position and an active position. The central rod and the duct being arranged to prevent fluidic communication between the duct and the chamber when the central rod moves between its retracted and active positions. The central rod and the control rod are further movable relative to each other into a cleaning position, in which the duct is placed in fluidic communication with the chamber.

Owner:DISCMA

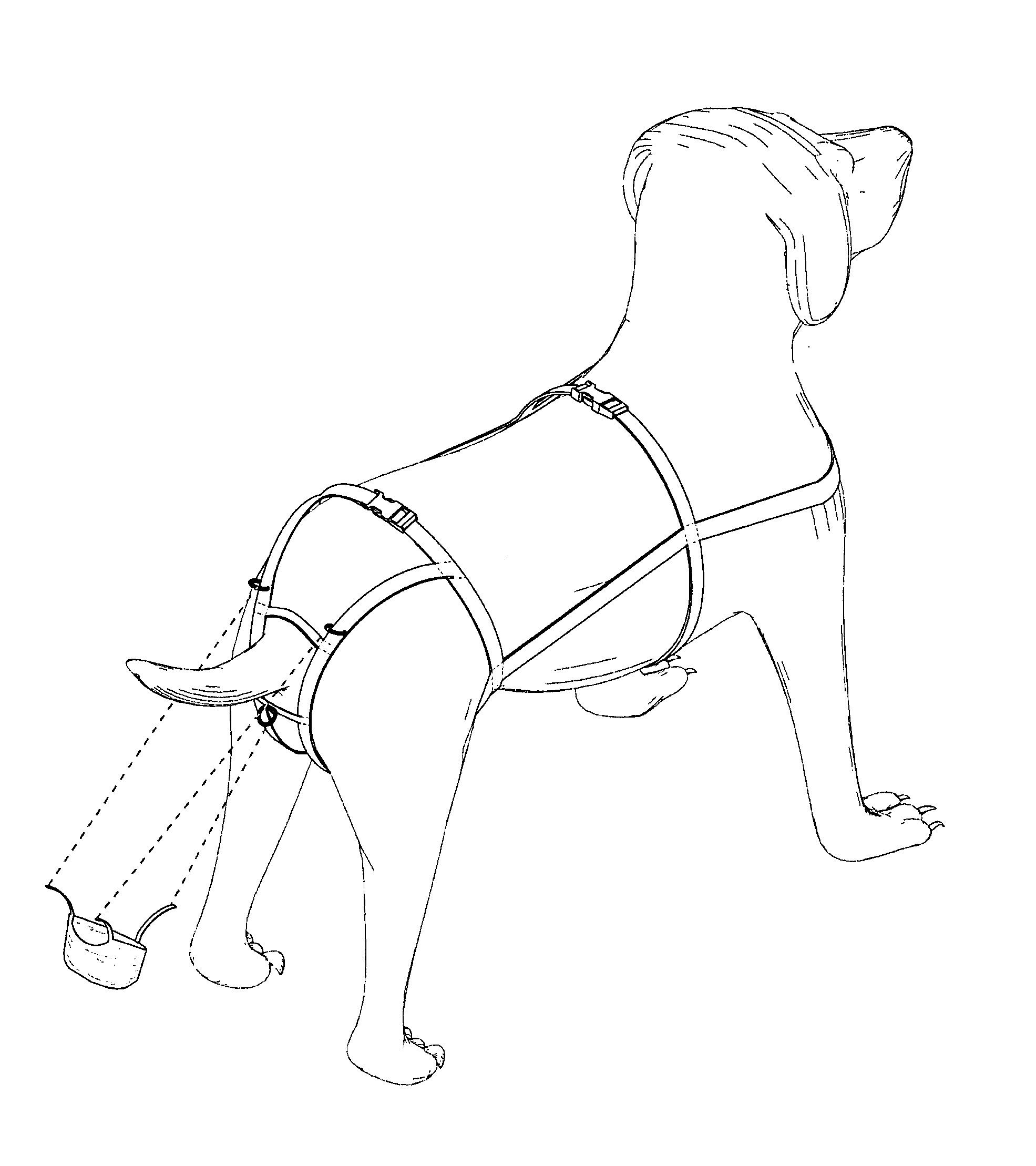

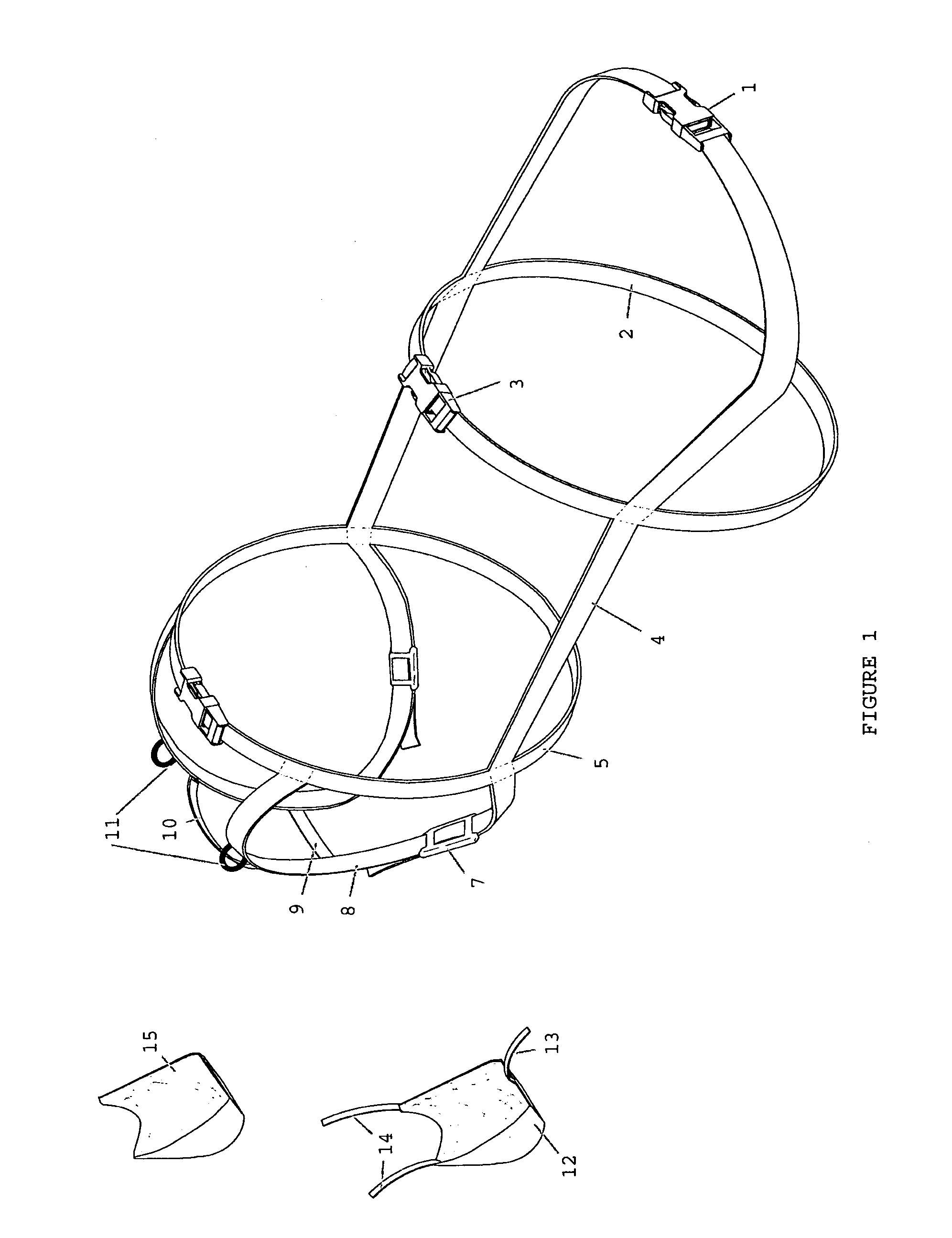

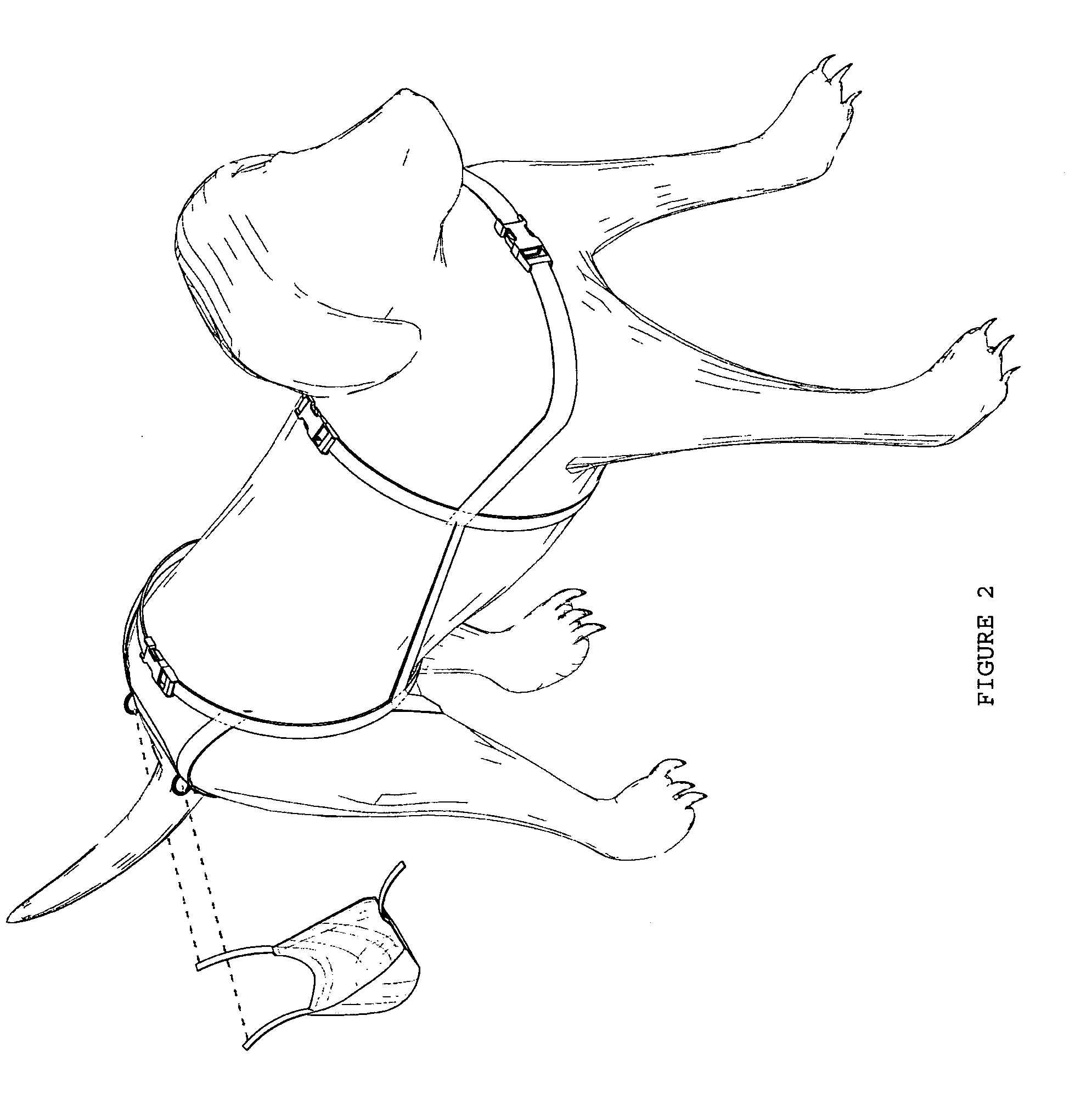

Doggie's bathroom bag

A removable water resistant cloth bag that can be used with or without a disposable bag directly on the animal's body by a harness that can be worn to catch urine, feces or both forms of waste. There may be a back strap that may connect to a dog's collar, two side straps that connect around the dog's chest, and straps connects to the side straps over the dogs shoulders behind the head, two nylon straps or bra straps that wraps and adjust to fit around the dog's hind legs, all the straps may utilize hook, loop fasteners, side release snaps, the bottom section may be where the bag can be attached; the top section the dog's tail may be inserted, the bag may then be positioned to catch urine, lined with an absorbent lining, or to collect feces, a longer bag may catch all waste at the same time.

Owner:WALLS LINDA FAY

Method and system for extracting vanadium from stone coal by compound alkali leaching

ActiveCN107299223ALow equipment requirementsImprove leaching rateProcess efficiency improvementCarbonationSodium carbonate

The invention relates to a method and a system for extracting vanadium from stone coal by compound alkali leaching, and particularly provides a method and a system for extracting vanadium from the stone coal. The method comprises the steps of A, roasting stone coal powder to obtain a stone coal roasting residue, B, leaching the stone coal roasting residue by a compound alkali leaching agent, and performing solid-liquid separation to obtain a leaching solution and a leaching residue, C, washing the leaching residue by water, and performing solid-liquid separation to obtain a washing solution and a washing residue, D, supplementing compound alkali to the washing solution and the partial leaching solution, and returning to Step B as the compound alkali leaching agent, E, adding a calcium compound to the rest leaching solution for a reaction, and performing solid-liquid separation to obtain an impurity removal solution, and F, supplying carbon dioxide to the impurity removal solution, performing carbonation, separating out sodium carbonate, and performing solid-liquid separation to obtain sodium carbonate and a rich-vanadium solution.

Owner:HUNAN LONGE GALLOP TECH CO LTD

Preparation method for iron sodium ethylene diamine tetraacetate

ActiveCN105294469APrecipitation particles are largeHigh reactivityOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineAcetic acid

The invention discloses a preparation method for iron sodium ethylene diamine tetraacetate. The preparation method comprises the following steps: (1) weighing a predetermined amount of ferrous sulfate heptahydrate, adding ferrous sulfate heptahydrate into deionized water, weighing a predetermined amount of bicarbonate, carbonate or a mixture of bicarbonate and carbonate, adding the weighed bicarbonate, carbonate or mixture into a ferrous sulphate solution, carrying out a reaction so as to obtain large-grain ferrous hydroxide precipitate and introducing air to completely oxidize ferrous hydroxide into reddish brown iron hydroxide powder for subsequent usage; (2) weighing a predetermined amount of ethylene diamine tetraacetic acid and sodium hydroxide and adding ethylene diamine tetraacetic acid and sodium hydroxide into deionized water; and (3) addin gthe iron hydroxide powder into the solution obtained in the step (2) under stirring according to a predetermined mol ratio, adjusting a pH value to 4.5 to 6.0, heating the solution to 60 to 80 DEG C, carrying out stirring reaction for 30 to 50 min and subjecting the solution to filtering and crystallization so as to obtain finished iron sodium ethylene diamine tetraacetate. The method provided by the invention prepares iron hydroxide through on-site oxidation of ferrous hydroxide, and the prepared iron hydroxide has high reaction activity, needs short time for subsequent chelation reaction and enables product yield to be high and production efficiency to be greatly improved.

Owner:上海永通生态工程股份有限公司

Method for preparing battery grade lithium hydroxide monohydrate

InactiveCN110422863ARich sourcesWith resource recyclingLithium oxides/hydroxidesElectrolysisLithium carbonate

The invention provides a method for preparing battery grade lithium hydroxide monohydrate. The method utilizes crude lithium carbonate as a raw material, and includes the following steps: acid dissolution, preliminary impurity removal, deep impurity removal, evaporation concentration, preparation of lithium hydroxide by ion-exchange membrane electrolysis, evaporation crystallization, and recrystallization. The method is rich in source of raw material and has the advantages of recycling and utilizing resources, and being less in type of contained impurities and easy to remove; chlorine gas polluting the environment is not produced and product sulfuric acid can be reused to dissolve, and consumption of raw materials is reduced; and the pH of an anolyte is controlled by controlling a circulation anolyte to increase the efficiency of current.

Owner:JIANGXI RUIDA NEW ENERGY TECH CO LTD

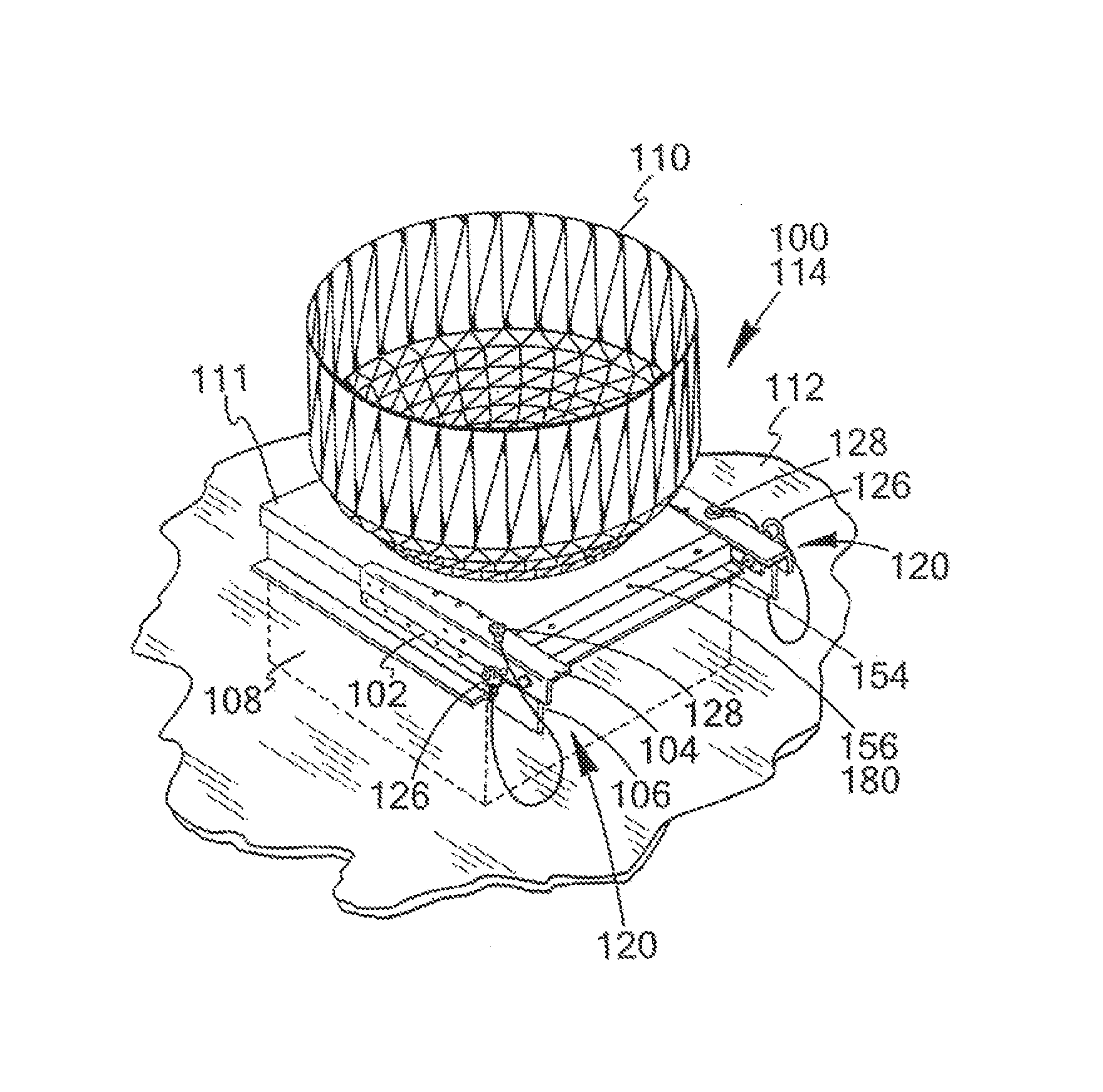

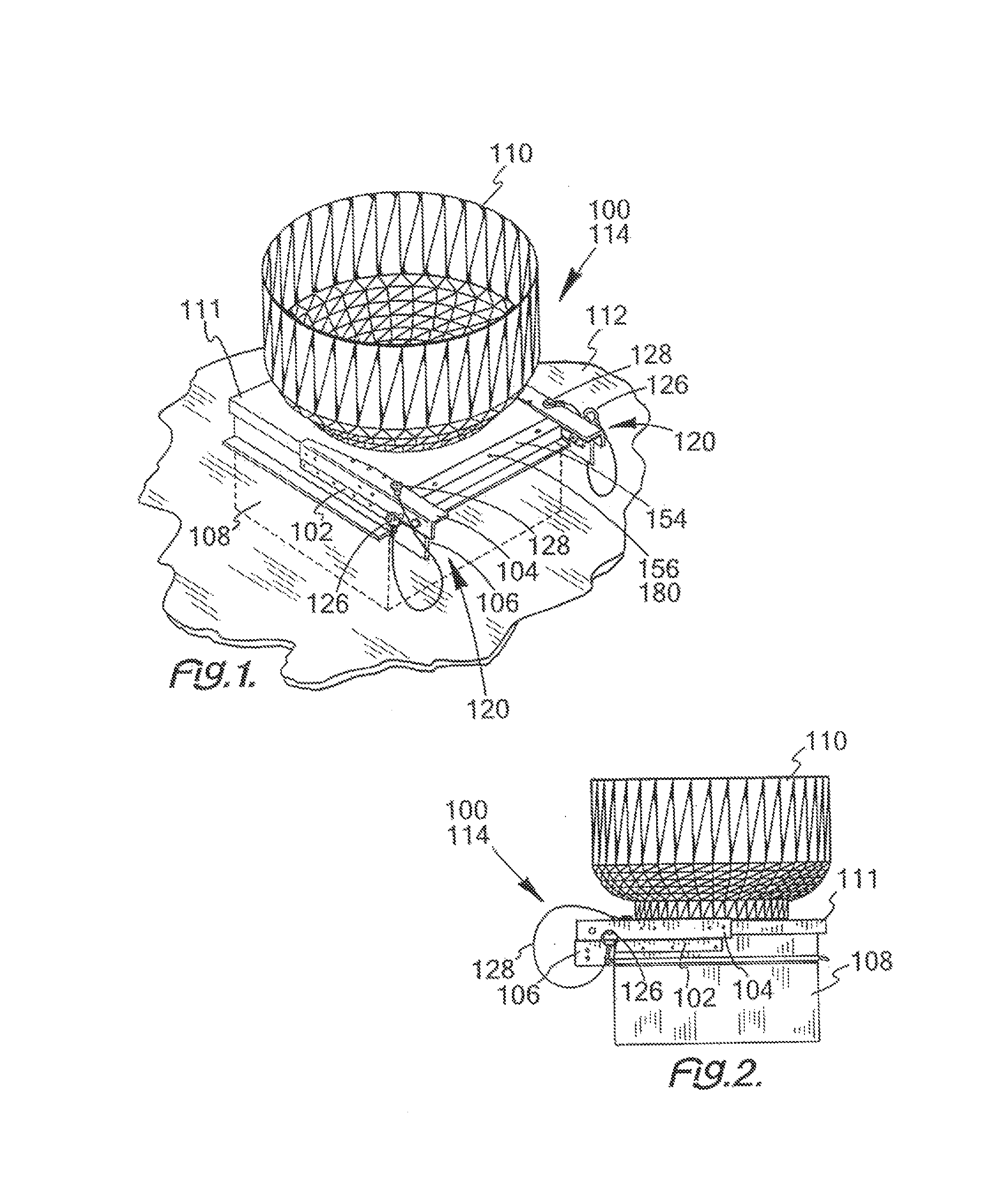

Hinge assembly for supporting a fan on a roof

ActiveUS9435556B1Easy procedureEasy to cleanPump componentsSpace heating and ventilation detailsEngineeringMechanical engineering

A hinge assembly or a flexible hinge assembly adjusts to fit a vent on a wall or a roof in order to hold a fan thereon, which fan is especially suitable for a restaurant roof or wall. The hinge assembly attaches to a roof or wall vent to hold the fan in a proper position, yet permits the fan to be easily moved for cleaning of vent and the fan.

Owner:OMNI CONTAINMENT SYST

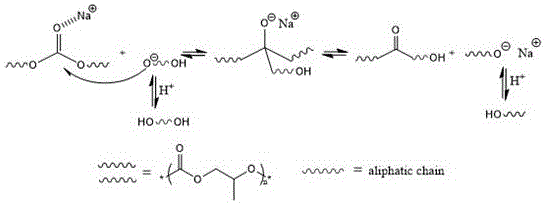

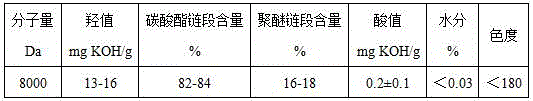

Aliphatic polycarbonate dibasic alcohol and preparation method thereof

The invention relates to the technical field of polymer materials, and discloses an aliphatic polycarbonate dibasic alcohol and a preparation method thereof. The preparation method of the aliphatic polycarbonate dibasic alcohol comprises the following steps: carrying out ester exchange reaction on polymethylethylene carbonate and an aliphatic dibasic alcohol under the condition of a catalyst, and removing impurities, wherein the molecular weight of the polymethylethylene carbonate is greater than 10000Da. The molar weight of the aliphatic dibasic alcohol accounts for 15-100% of that of the polymethylethylene carbonate. The catalyst accounts for 0.01-5% of the molar weight of the polymethylethylene carbonate. The ester exchange reaction is performed by heating to 80-180 DEG C in an inert gas atmosphere and refluxing for 1-30 hours. The invention provides a method for preparing low-molecular-weight aliphatic polycarbonate dibasic alcohol from high-molecular-weight polycarbonate, and widens the applicability of the high-molecular-weight polycarbonate. The molecular weight of the aliphatic polycarbonate dibasic alcohol and the hydroxy functional group degree can be adjusted according to needs, and the primary product of the aliphatic polycarbonate dibasic alcohol is easy for impurity removal.

Owner:SUN YAT SEN UNIV

Method for producing nadroparin calcium from heparin sodium crude product

The invention discloses a method for producing nadroparin calcium from a heparin sodium crude product. The method comprises the following steps: dissolving the raw material crude product heparin sodium in water, precipitating by centrifugation and secondary salting-out to remove impurities in the heparin sodium crude product, carrying out nitrous degradation and reduction to obtain low-molecular heparin containing free sulfates, adding barium chloride to remove the free sulfates generated by degradation, and using an anion exchange resin and adjusting to appropriate parameters to carry out calcium conversion and final impurity removal; and finally, carrying out oxidation decolorization, sterile filtration and dehydration to obtain the nadroparin calcium raw material. By using the crude product heparin sodium as the raw material, the production cost is lowered; the technical steps are simplified to enhance the yield of the nadroparin calcium and reduce the titer loss of the nadroparin calcium; and the method can ensure the safety of the product, and is convenient for industrialized mass production.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

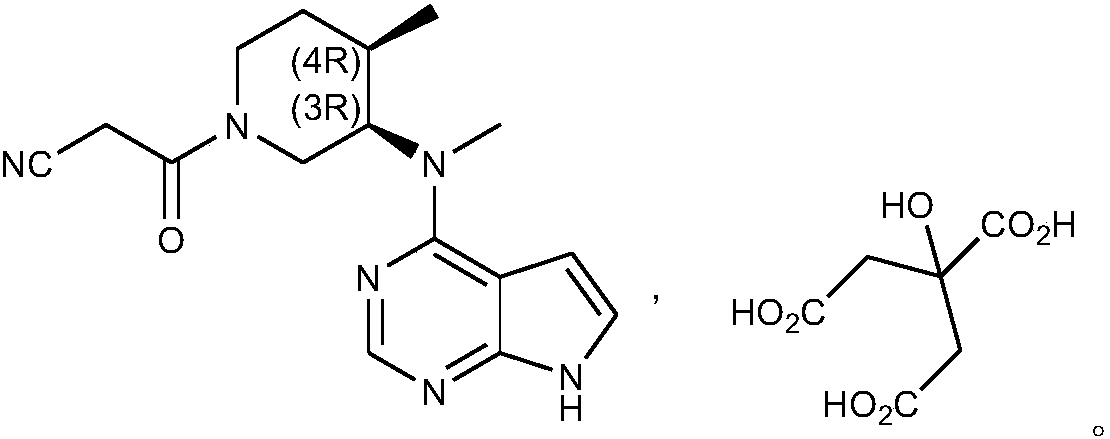

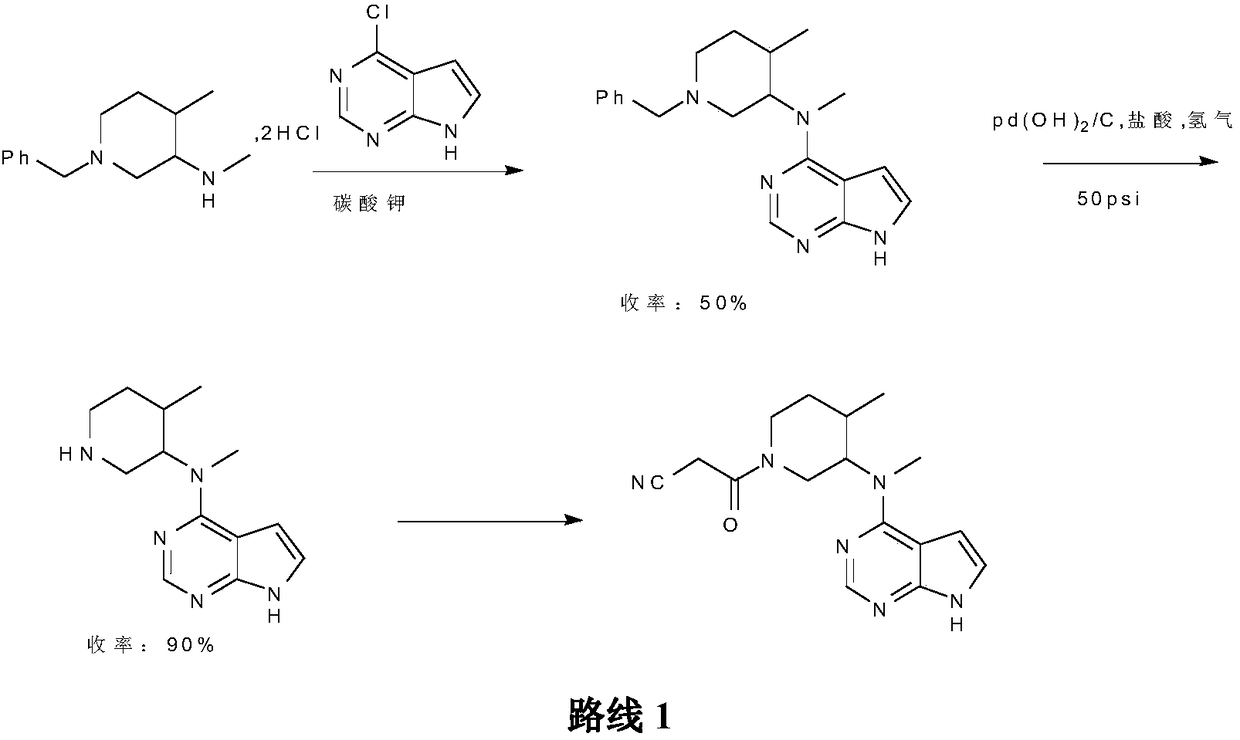

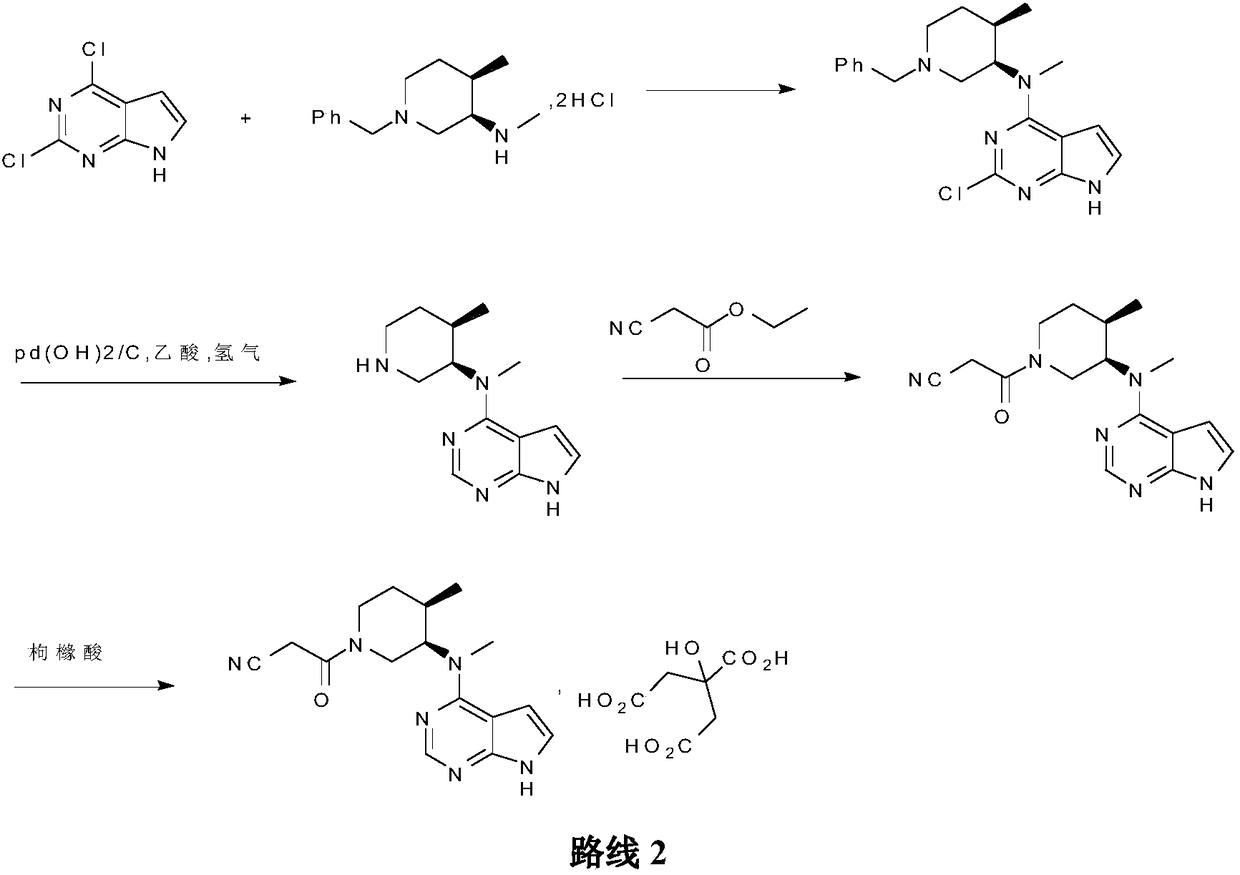

Preparation method of tofacitinib citrate

ActiveCN108276414AThorough responseHigh purityOrganic chemistry methodsCarboxylic acid salt preparationSolventEthyl fumarate

The invention discloses a preparation method of tofacitinib citrate. The preparation method comprises the following steps: stirring an organic solvent, a compound 3, 5 percent wet palladium on carbonand acetic acid until a mixture is suspended; conveying the mixture into a micro-reactor from a channel A; meanwhile, conveying alkylsilane into the micro-reactor from a channel B; controlling the temperature of the micro-reactor to 20 to 30 DEG C and carrying out reaction; carrying out post-treatment to obtain a compound 2; after uniformly mixing an alcohol type solvent, the compound 2, ethyl cyanoacetate and DBU (1,8-Diazabicyclo [5,4,0]undec-7-ene), conveying a mixture into the micro-reactor from the channel A; dissolving citric acid into a mixed solution of water and the alcohol type solvent, conveying a mixture into the micro-reactor from the channel B; controlling the temperature in the micro-reactor to 70 to 80 DEG C and carrying out reaction; cooling and crystallizing to obtain thetofacitinib citrate. The method provided by the invention has the advantages of controllable reaction condition and simplicity in operation; dangers caused by the fact that flammable and explosive gas is used are avoided and the safety is higher; reaction can be finished instantly and the reaction time is greatly shortened; debenzylation reaction and acylation reaction are complete and post-treatment is simple; the preparation method is suitable for industrial large-scale production. A formula is shown in the description.

Owner:山东安信制药有限公司

Container Holder Device Including a Leaf Spring, and a Container Treatment Installation Including Such a Device

A device for holding a container comprising a stationary jaw and a movable jaw mounted on the stationary jaw to be movable between a closed position for holding the container and an open position for releasing the container. A resilient element connecting the two jaws together to urge the movable jaw towards the closed position. The resilient element is a leaf spring having an end portion secured to the stationary jaw and an end portion secured to the movable jaw in order to carry the movable jaw. A container treatment installation is also provided including at least one such holder device.

Owner:SERAC GROUP

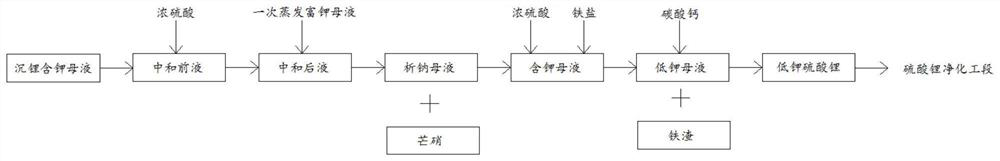

Potassium removal process of production system for lithium extraction from ore

ActiveCN113387374AAvoid pollutionEasy to operateIron compoundsProcess efficiency improvementPhysical chemistryPotassium

The invention discloses a potassium removal process of a production system for lithium extraction from ore, belonging to the field of wet metallurgy. The invention particularly relates to the field of lithium salt production, and aims to solve the problems of long potassium removal process flow and high potassium removal operation difficulty in conventional removal of potassium in lepidolite. The potassium removal process comprises the following steps: conducting neutralization and nitrate removal through evaporation to generate potassium-rich sodium precipitation mother liquor; adding ferric salt into the potassium-rich sodium precipitation mother liquor with an adjusted pH value to obtain potassium-containing mother liquor; heating the potassium-containing mother liquor to 95 DEG C, and conducting stirring, reacting and crystallizing for 1-3 hours to obtain a suspension; and settling the suspension, carrying out solid-liquid separation, adjusting the pH value of a supernatant to 5-7 by using calcium carbonate, and removing iron. The process is short in process flow, convenient to control, simple in subsequent impurity removal, compatible with a sulfuric-acid-method lithium extraction process, simple in design and easy to implement.

Owner:四川能投鼎盛锂业有限公司

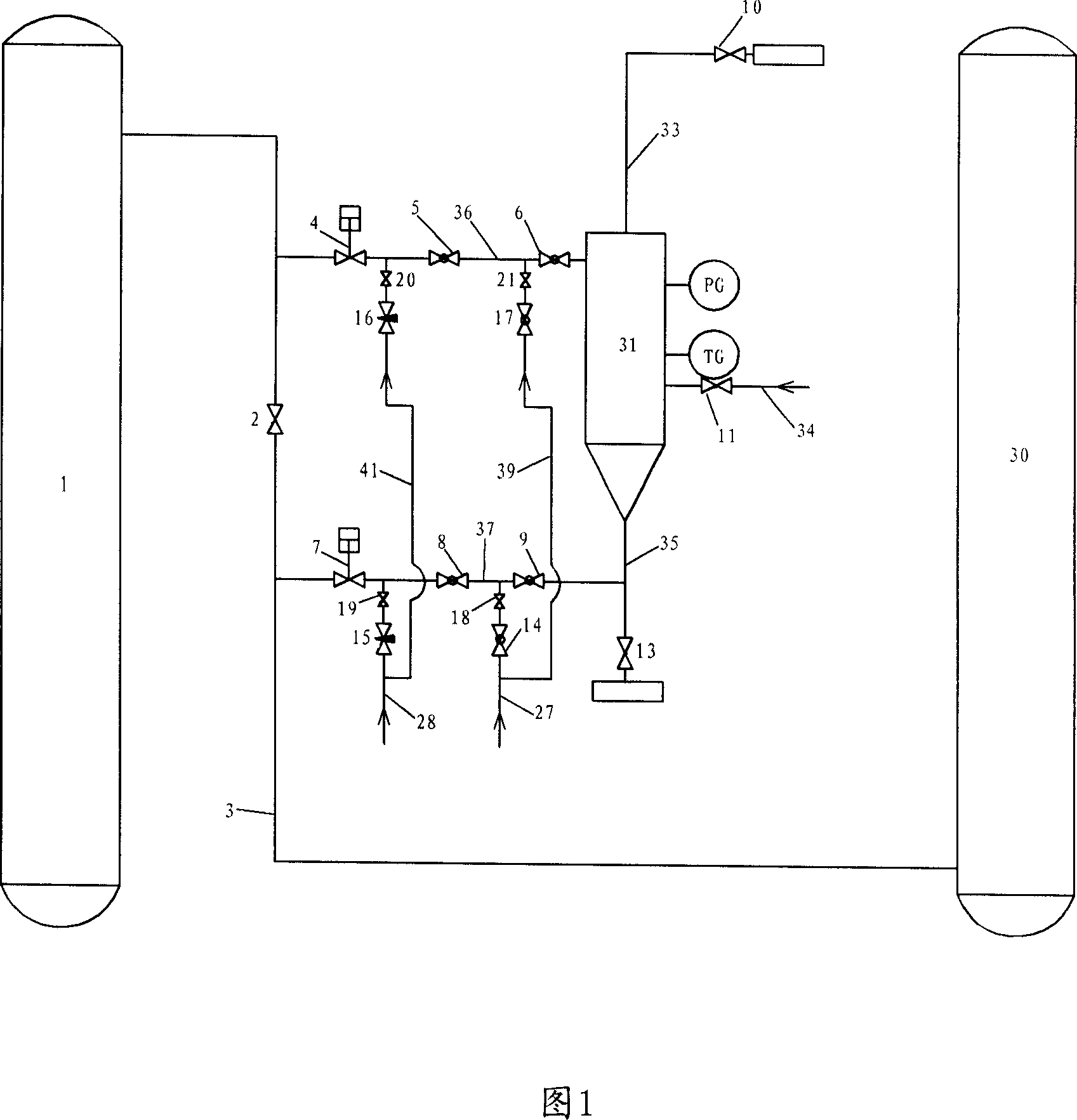

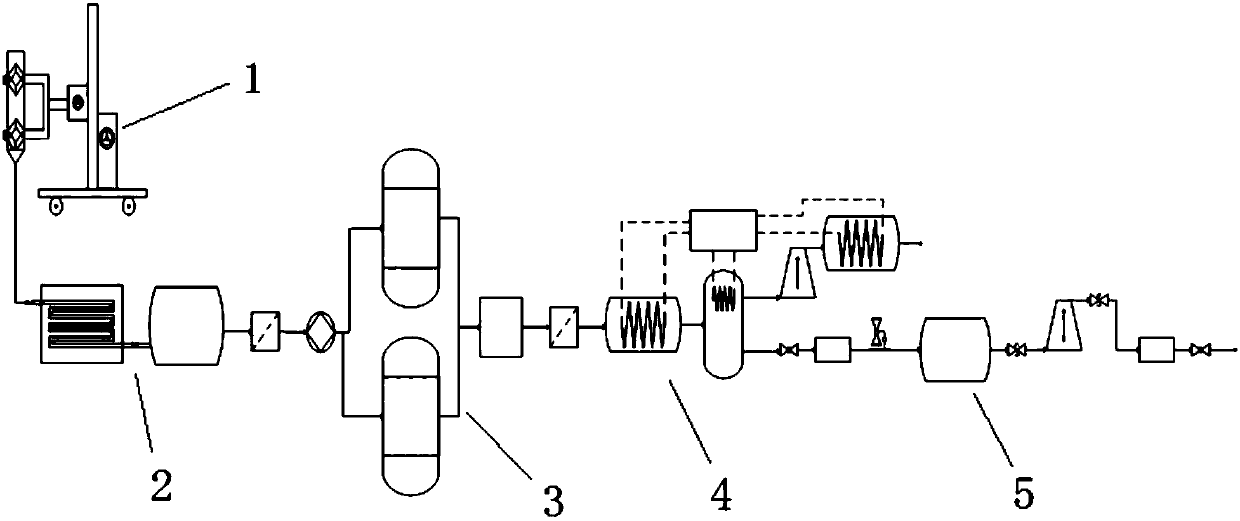

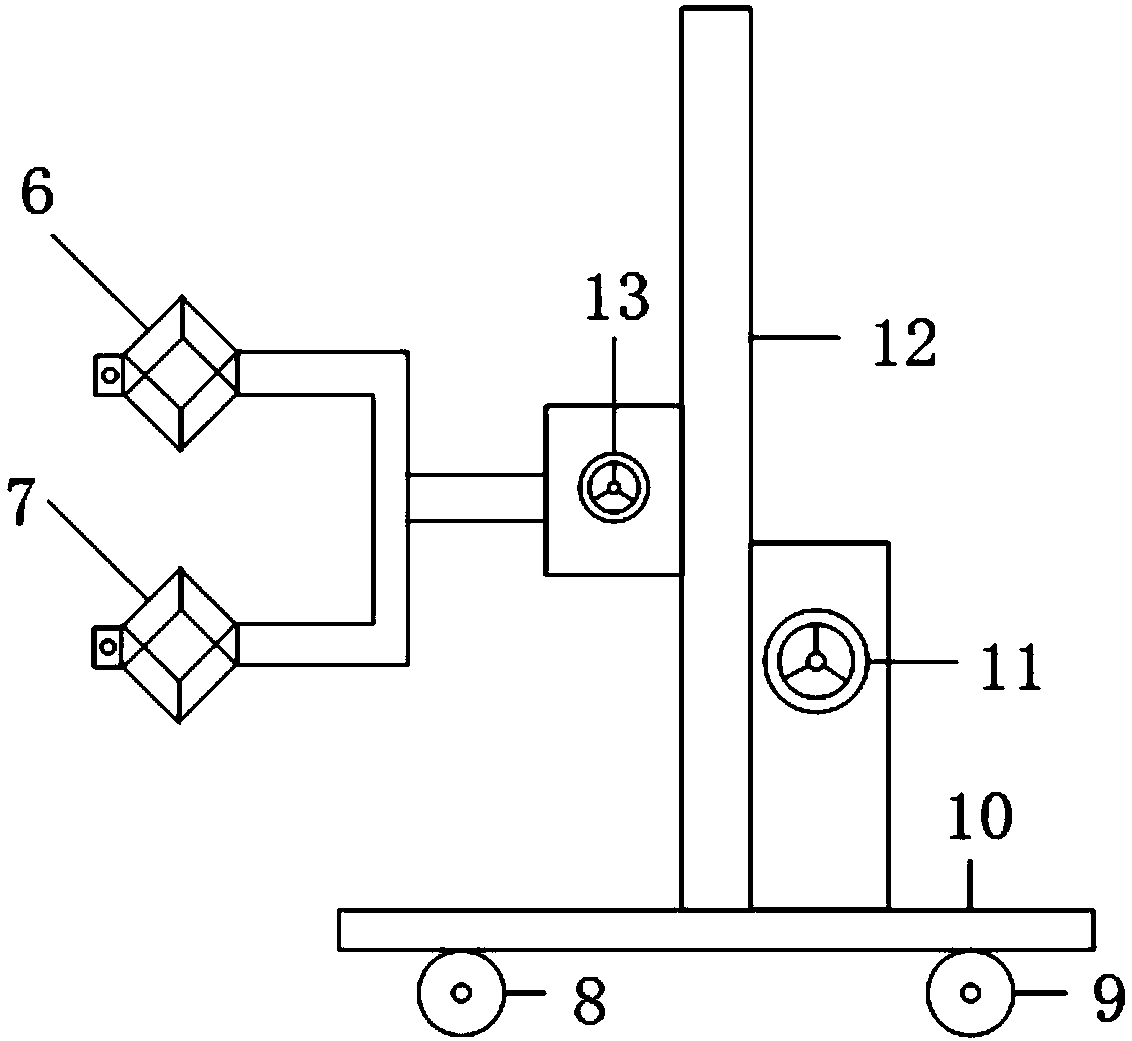

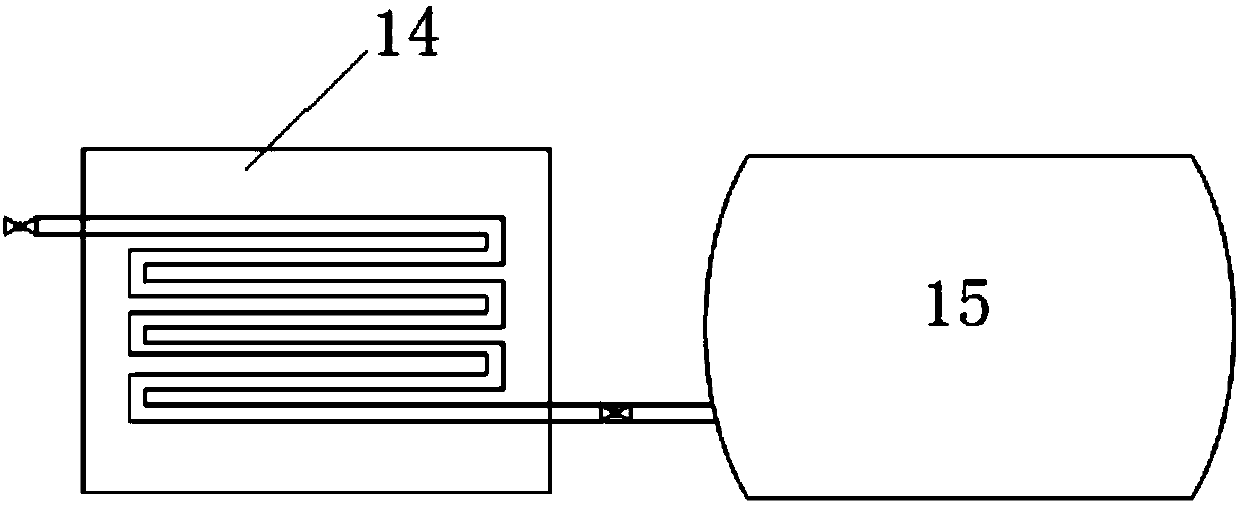

Separation system and separation method for sulfur hexafluoride and carbon tetrafluoride

PendingCN107715493ASolve the problem of no flowFacilitate the process of primary purification by adsorption treatmentProductsGas treatmentSulfur hexafluorideProcess engineering

The invention discloses a separation system and a separation method for sulfur hexafluoride and carbon tetrafluoride. The separation system comprises a reversing unit, a buffering unit, a treatment unit and a cryogenic separation unit, wherein the reversing unit is a reversing device, and is used for clamping a steel bottle and rotating the steel bottle to reverse the steel bottle such that a liquefied mixture in the steel bottle can flow out successfully; the buffering unit comprises an evaporator and a first buffering tank; an inlet of the evaporator is connected with an outlet of the steelbottle; an outlet of the evaporator is connected with an inlet of the first buffering tank; the treatment unit comprises an adsorption tower; an inlet of the adsorption tower is connected with an outlet of the first buffering tank to adsorb and remove impurities from the mixture; the cryogenic separation unit comprises a heat exchanger and a low temperature rectifying tower; an outlet of the adsorption tower is connected with a hot medium inlet of the heat exchanger; a cold medium outlet of the heat exchanger is connected with an inlet of the low temperature rectifying tower.

Owner:ELECTRIC POWER RES INST OF EAST INNER MONGOLIA ELECTRIC POWER +3

Direct-seeding seed production method for two-line system hybrid rice

InactiveCN105746333AImprove lodging resistanceIncrease productionPlant genotype modificationRice cultivationHybrid seedEcology

The invention discloses a direct-seeding seed production method for two-line system hybrid rice. The method comprises the steps of seeding, field management, purity assurance and harvesting storage, wherein the seeding step comprises the following sub-steps: selecting Huanghuazhan as a male parent, examining and approving a sterile line in promotion mix as a female parent; taking a large-area Huanghuazhan planting area as a seed production field before use; fixing the sowing time according to the sowing date of the male and female parents, and ensuring flower synchronization of the male and female parent; ensuring that the sowing plot width of the male parent is equal to the harvesting width of a harvester, the sowing plot width of the female parent is 1-2 times that of the harvesting width of the harvester, and the spacing between the male parent and the female parent is 40-60cm, so that the male and female parents are conveniently and respectively harvested with machine; and manually transplanting a line of male parents at the seedling age of 22-25 days of the male parent, wherein 2-3 rice seedlings are planted in each stump, the row spacing is 25-40cm, and the spacing between the male parent transplanting line and the direct seeding male parent is 20-30cm. According to the method disclosed by the invention, the problems that the female parent is susceptible to lodging, the seed production yield is low, the weeding difficulty is high, the purity of hybrid seeds is low, the production efficiency is low and the cost is high are solved.

Owner:HUNAN RICE RES INST

Special grinding ball of titanium dioxide and preparation method thereof

The invention discloses a special grinding ball of titanium dioxide for grinding in titanium dioxide industry and a preparation method thereof. The raw materials of the grinding ball comprise the following components by weight percent: 3.40%-3.80% of C, 2.30%-2.60% of Si, 0.60%-1.00% of Mn, 0-0.035% of S, 0-0.35% of P, 0-0.03% of nanometer alloy modifier, 0.01%-0.03% of rare earth magnesium and the balance of steel scrap (Fe). The preparation method of the special grinding ball is based on the alloy cast ball casting technology and comprises the steps of changing chemical compositions and adjusting heat treatment technology. The special grinding ball of titanium dioxide prepared by the formulation and preparation method of the invention has extremely low chromium alloy content, high hardness and low wear and out-of-roundness, and titanium dioxide grinded by the grinding ball has high purity, good whiteness and high quality.

Owner:广东翔龙建材有限公司

Method for preparing vanadium-nitrogen alloy through stone coal vanadium extraction vanadium-rich liquid

The invention relates to a method for preparing vanadium-nitrogen alloy through stone coal vanadium extraction vanadium-rich liquid. According to the technical scheme, a carbonaceous reducing agent is added into the vanadium-rich liquid, stirring and drying are conducted, and a precursor is obtained; the vanadium-rich liquid is an intermediate product of stone coal vanadium extraction; the molar weight of the carbonaceous reducing agent is 1.5-4 times the total molar weight of positive ions in the vanadium-rich liquid, the precursor is mechanically pressed into a block shape, at the ordinary pressure and a nitrogen atmosphere, the blocky precursor is subjected to heat preservation for 1-5 h under the condition of 1000-1400 DEG C, then cooled with a furnace and levigated, and a second intermediate product is obtained; a hydrochloric acid solution is added into the second intermediate product, stirring and solid-liquid separation are conducted, and solid slag is obtained; the molar weight of HCl in the hydrochloric acid solution is 3-5 times the total molar weight of positive ions except vanadium positive ions in the vanadium-rich liquid; and the solid slag is dried and briquetted, and the vanadium-nitrogen alloy is obtained. The method has the characteristics that the stone coal vanadium extraction vanadium-rich liquid is used as a vanadium source, the production cost is low, the raw material consumption is low, and the reaction time is short.

Owner:WUHAN UNIV OF SCI & TECH

A kind of preparation method of sodium iron edetate

ActiveCN105294469BPrecipitation particles are largeHigh reactivityOrganic compound preparationAmino-carboxyl compound preparationFerric hydroxideEthylenediamine

The invention discloses a preparation method of sodium ferric EDTA, comprising the following steps: (1) weighing a predetermined amount of ferrous sulfate heptahydrate and adding it to deionized water; weighing a predetermined amount of bicarbonate, carbonic acid The mixture of salt or bicarbonate and carbonate is added in the ferrous sulfate solution, and the reaction obtains large particle ferrous hydroxide precipitation; Bubbling air is fully oxidized to ferrous hydroxide powder for subsequent use; ( 2) Weigh a predetermined amount of EDTA and sodium hydroxide, add deionized water; (3) according to a predetermined molar ratio, add ferric hydroxide to the solution obtained in the step (2) under agitation powder, adjust the pH to 4.5-6.0, heat to 60 ℃-80 ℃, stir and react for 30min-50min, the solution is filtered and crystallized to obtain the finished product of sodium iron ethylenediaminetetraacetate. The ferric hydroxide prepared by the on-site oxidation of ferrous hydroxide in the method of the invention has high reaction activity, short subsequent chelation reaction time, high product yield and greatly improved production efficiency.

Owner:上海永通生态工程股份有限公司

Method for packaging liquid or pasty products and packaging machine suitable for this purpose

ActiveUS10189590B2Highly sensitive pastyEasy to cleanContracting/expanding measuring chambersMovable measuring chambersDowntimeEngineering

A method for the portioned packaging of liquid or pasty products using a packaging machine. The product is fed via an inlet to a metering chamber, being metered in the metering chamber by a metering member to form a product portion, and the product portion being fed via a metering outlet to a package. In order to avoid impairments of products which are sensitive to crystallizing out in the inoperative state, the metering chamber is operated in continuous flow in at least one operating state of the packaging machine from the following group: downtimes of the packaging machine, start-up of the packaging machine and operation of the packaging machine, by the product—whether entirely or in a partial flow—being removed entirely or partially from the metering chamber past the metering member via an outlet provided in addition to the metering outlet and being recirculated.

Owner:BENHIL GMBH

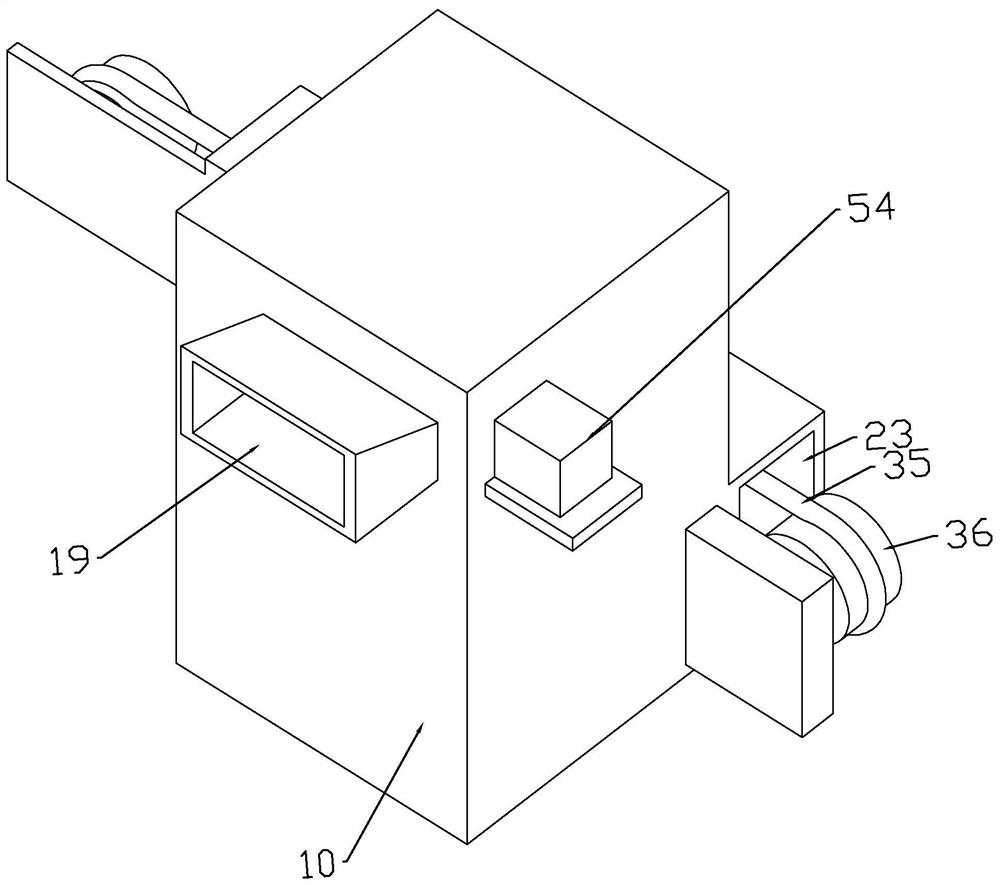

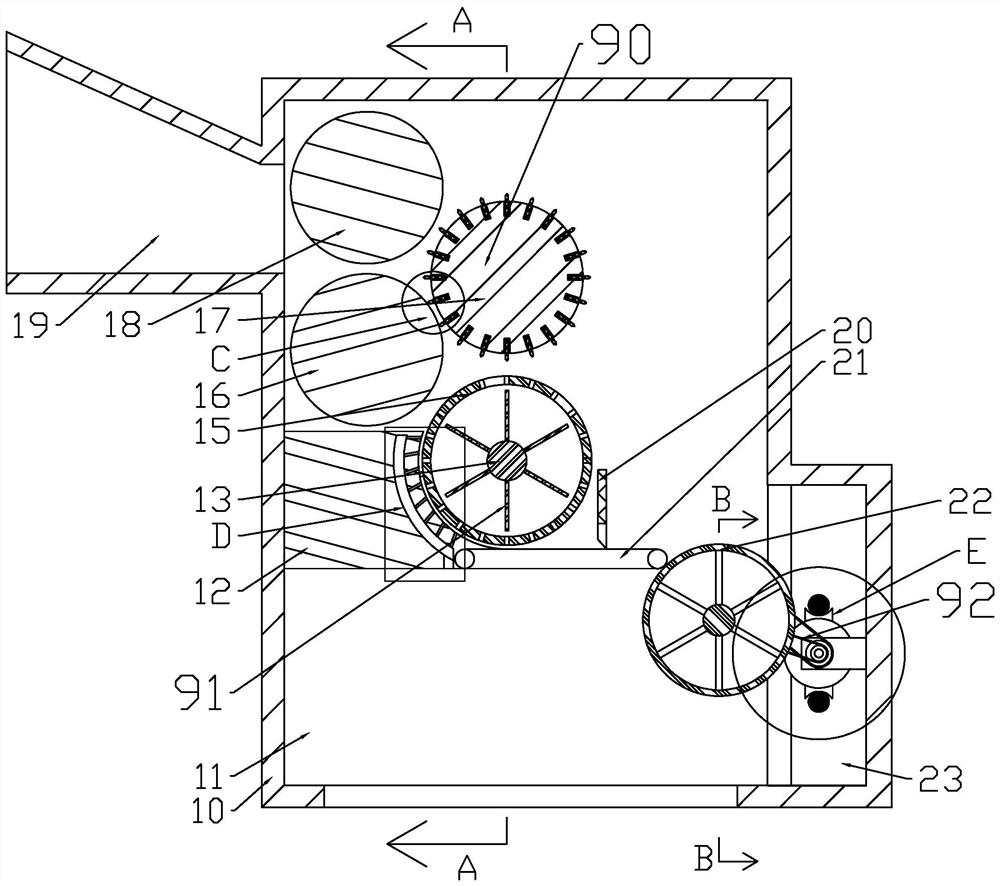

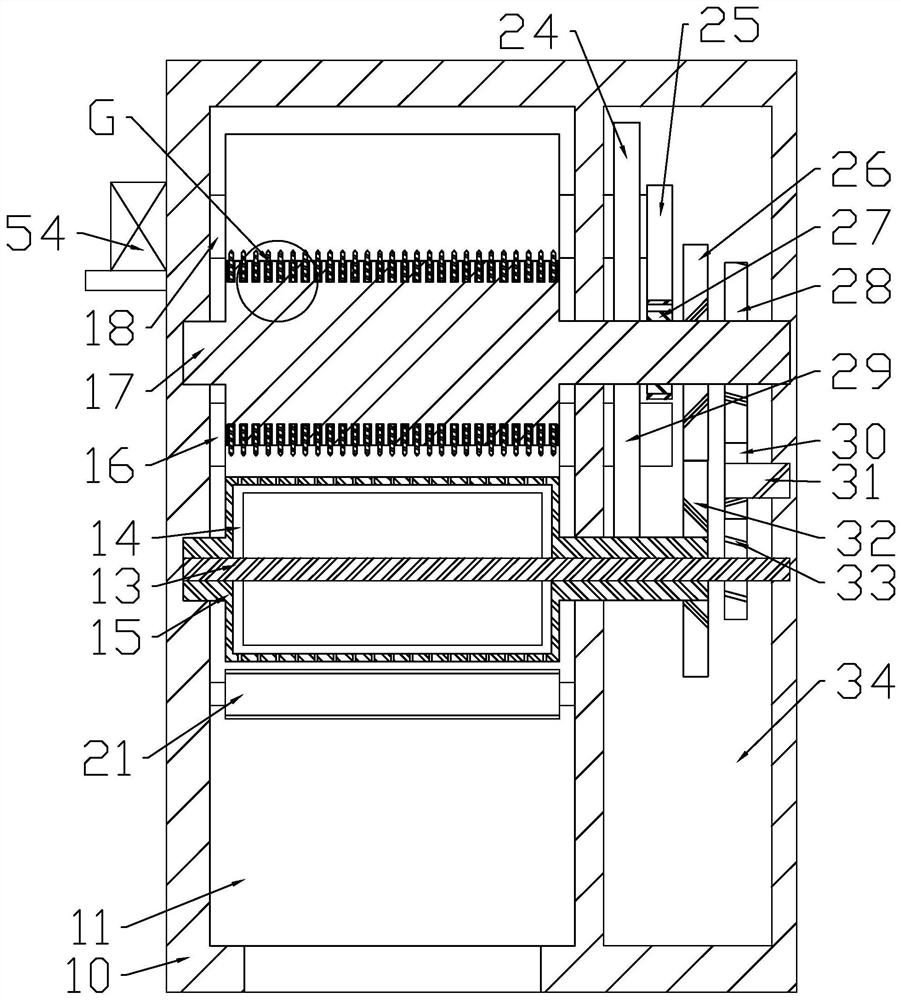

Jute fiber extraction process

ActiveCN113564725AEasy to remove impuritiesShorten drying timeMechanical fibre separationHemp fiberEngineering

The invention belongs to the field of fiber extraction, and particularly relates to a jute fiber extraction process. The jute fiber extraction process by a jute fiber extraction method also particularly relates to a jute fiber extraction device. The jute fiber extraction device comprises a shell; a working space is formed in the shell; a feeding port is formed in one side of the shell; a through conveying space is formed in the side, away from the feeding port, of the shell; a fiber extraction mechanism is arranged at the position, close to the feeding port, in the working space; an impurity removal and cleaning mechanism is arranged at the position, close to the conveying space, in the working space; a water removal mechanism is arranged in the working space and located between the fiber extraction mechanism and the impurity removal and cleaning mechanism; and a power cavity is formed in the side, perpendicular to a through opening of the conveying space, of the shell. Air generated by rotation of a first fan is blown out through air holes, and water on jute fibers is blown into a drainage cavity to be drained, so that the water in the jute fibers can be effectively removed, impurity removal is easier, and the airing time can be shortened.

Owner:武汉清华服装有限公司

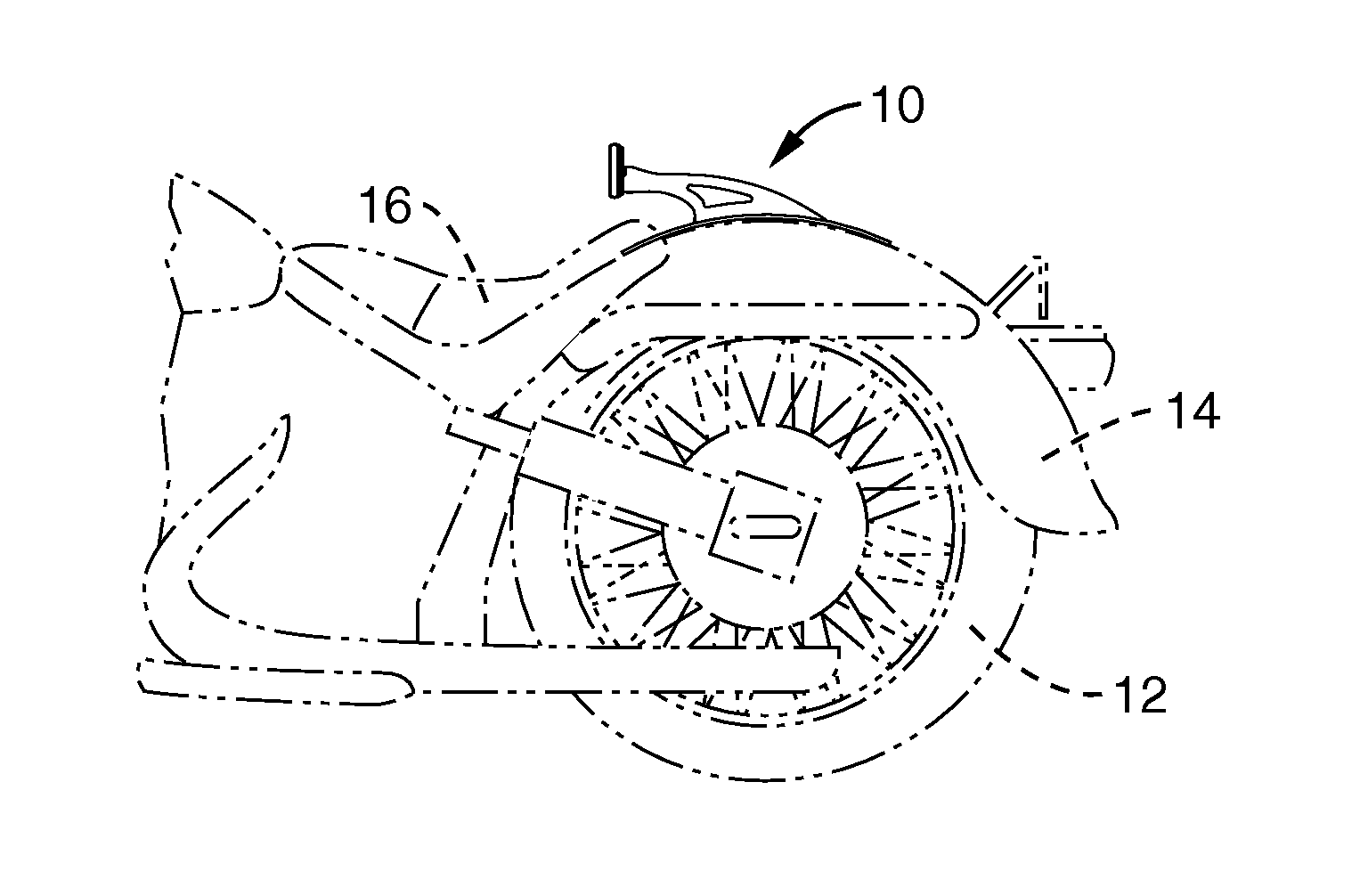

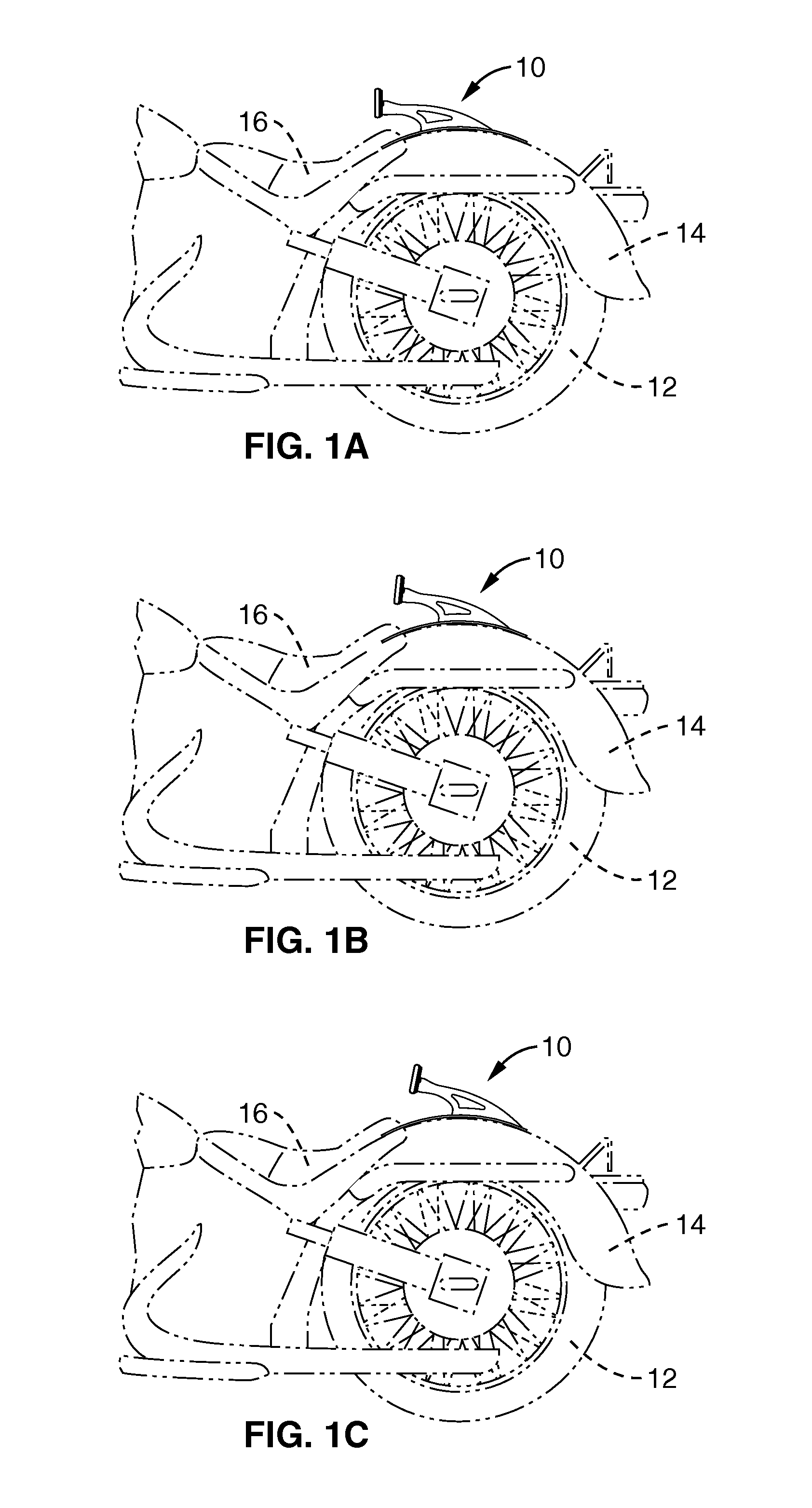

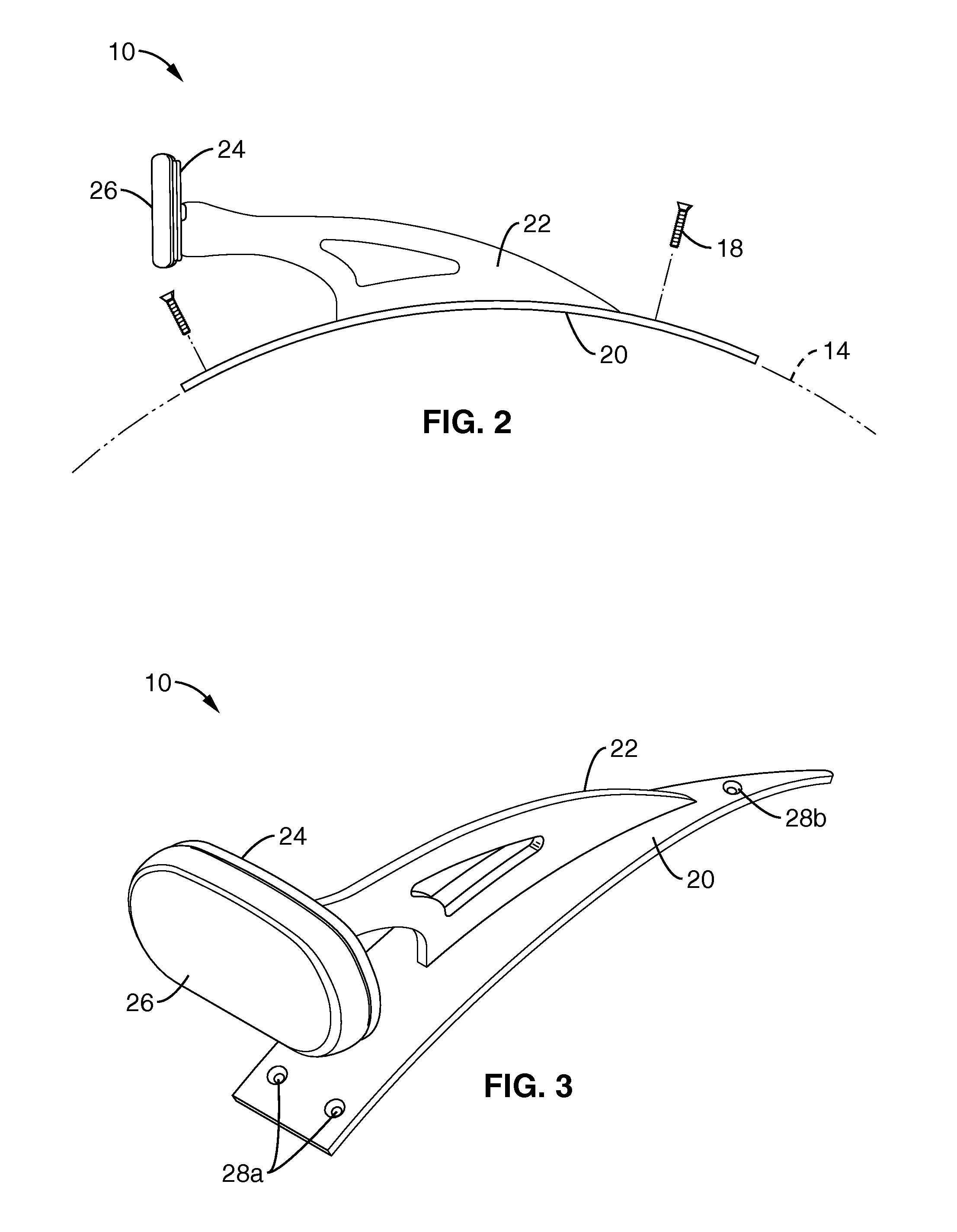

Adjustable motorcycle-mounted back support

An adjustable back support assembly with a cushioning pad for use with a motorcycle is disclosed. The angle of support is adjustable, and the back support and cushioning pad of varying sizes may be used with the assembly. The assembly is attached to the motorcycle using stock holes present in the rear fender and requires little or no disassembly of the motorcycle to install. The assembly is shaped to complement the styling of the motorcycle and is removable without damaging the paint or finish.

Owner:INGLISH HOWARD

Water scale removing device for water mixing valve

InactiveCN104455913ASolve the problem that the sealing is damaged and the sensitivity becomes invalidSolve the problem of sensitivity failurePipe elementsArchitectural engineeringWater pipe

The invention discloses a water scale removing device for a water mixing valve. The water scale removing device comprises the water mixing valve and water inlet pipes, and the water scale removing device is arranged on the parts, in front of the water mixing valve, of the water inlet pipes. The water scale removing device comprises a shell and a cylindrical filter screen, the shell is of a three-cavity T-shaped pipe structure, the long pipe is a vertical pipe, the short pipe is a horizontal pipe, a step table is arranged at the lower end of the inner wall of the vertical pipe, an end opening of the lower end of the inner wall of the vertical pipe is sealed, a discharging port is formed in the position, close to the bottom, of the lower end of the vertical pipe, and the discharging port is sealed through a screw and a sealing ring. The two ends of the tubular filter screen are through, the outer diameter of the tubular filter screen is matched with the diameter of the inner wall of the water inlet pipe, the tubular filter screen is arranged in the vertical pipe, the upper end of the tubular filter screen is higher than the top of the inner wall of the horizontal pipe, and the other two end openings of the shell are connected with the water inlet pipes. The water scale removing device is additionally provided with a filter device, a user can remove dirt regularly, the problem that water scale and other impurities enter a valve element of the water mixing valve, the sealing performance of the valve element is damaged, and the sensitivity of the valve element becomes invalid is solved, and the water scale removing device has the advantage that cleaning is convenient and fast.

Owner:SHANDONG LINUO PARADIGMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com