EUV-lithography apparatus having a chamber for cleaning an optical element

a technology of euv lithography and optical elements, which is applied in the field of projection exposure systems, can solve the problems of contamination and/or disruption of the optical surface of the components, the introduction of contaminants into the optical system, and the first and last optical surfaces, etc., to achieve the effect of cleaning the contaminated optical elements regularly and increasing the use tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

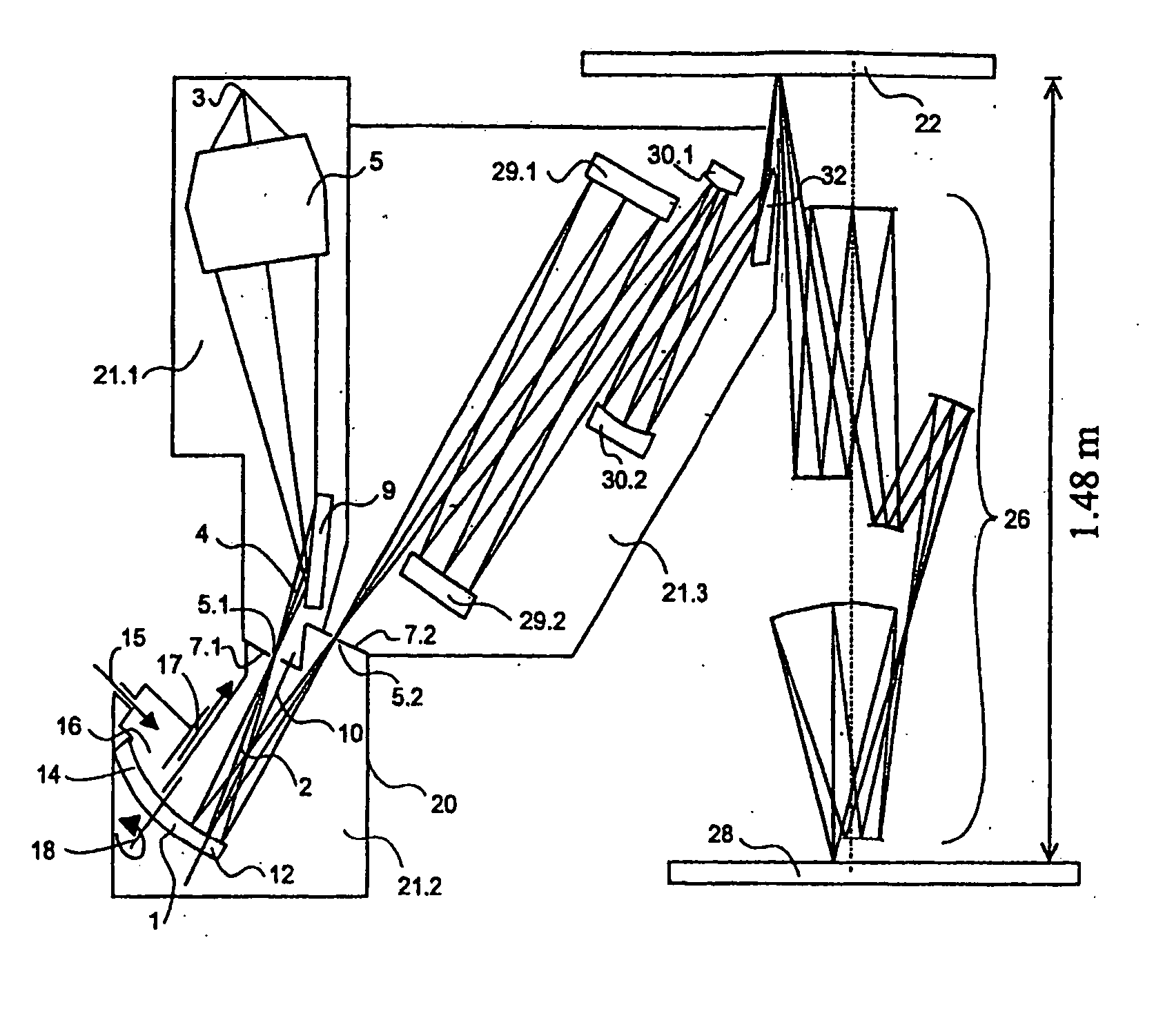

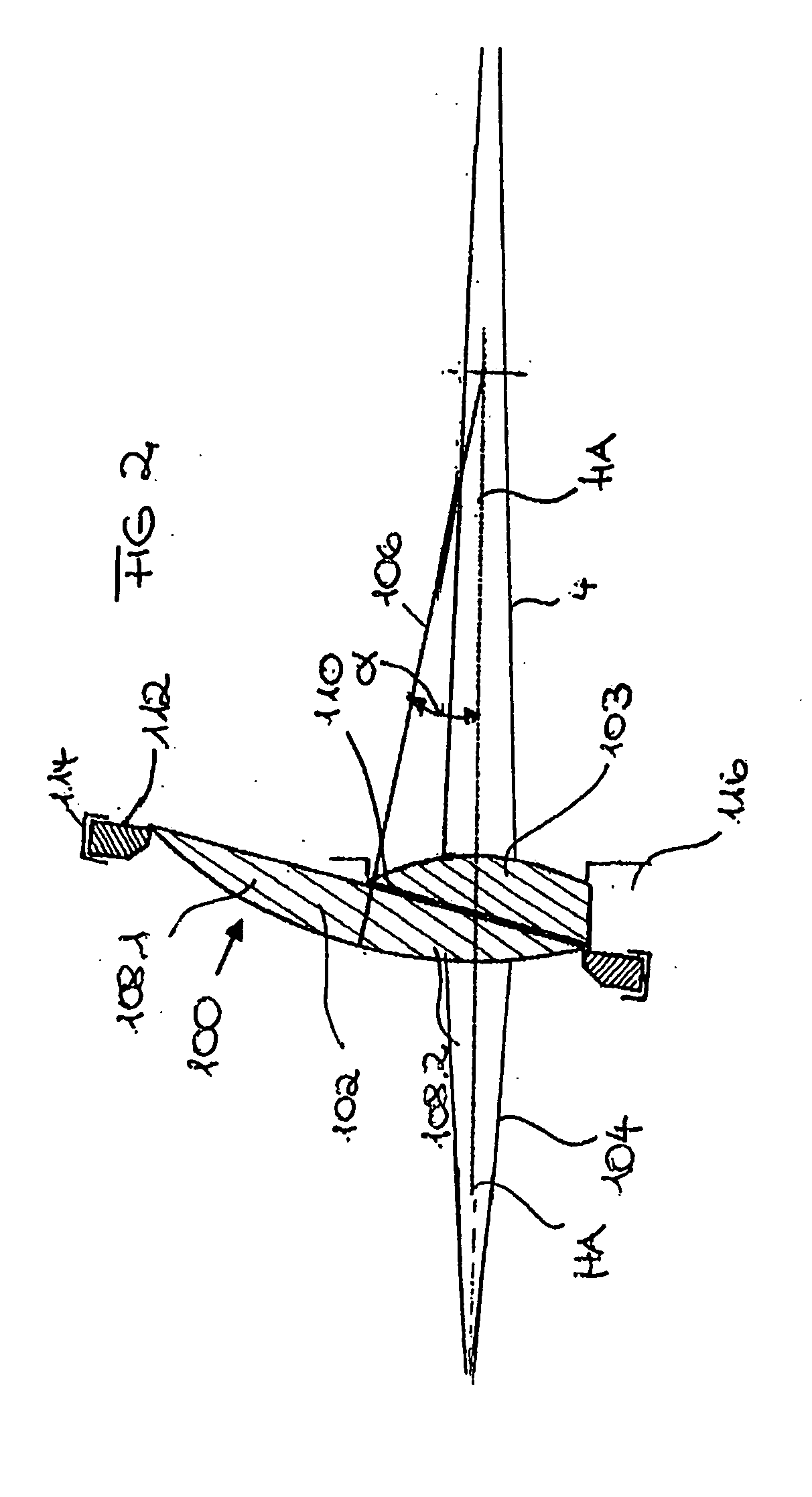

[0031]FIG. 1 shows an EUV projection exposure system with an optical element 1 according to the invention. The optical element 1 is a normal-incidence mirror, onto which rays 2 of a light bundle 4 from light source 3 to field plane 22 impinge at angles α12.

[0032] The dimensions of the optical element 1, here the normal incidence mirror, as can be seen from FIG. 1, are essentially larger than the first used area 12 of the mirror. The second used area 14 of the mirror is transported into a cleaning chamber 16 and is cleaned presently and not used.

[0033] Transport into the cleaning chamber 16 is conducted in the present case by turning around the axis of rotation 18. Other possibilities are also conceivable for transport into the cleaning chamber without departing from the basic concept of the invention. Such possibilities include the lateral transport of planar optical elements or the rolling, e.g., of spherical mirrors or concentric menisci.

[0034] As is clearly seen in FIG. 1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com