A kind of preparation method of carbon nanotube reinforced aluminum matrix composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of carbon nanotube-reinforced aluminum-based composite materials, can solve problems such as weakening the strengthening effect of reinforcements, and achieve the effects of reducing tube wall defects, small process pollution, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

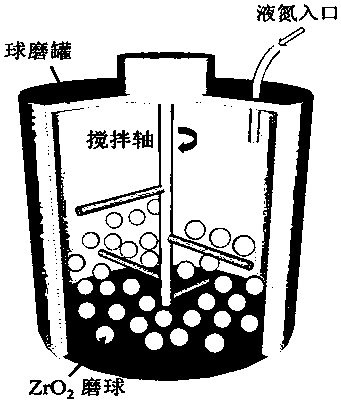

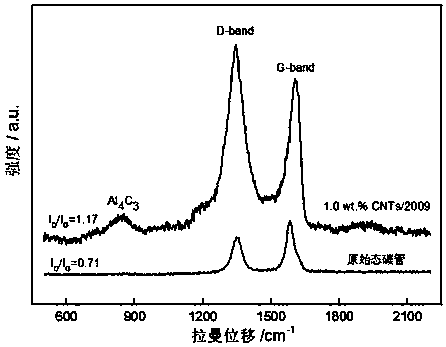

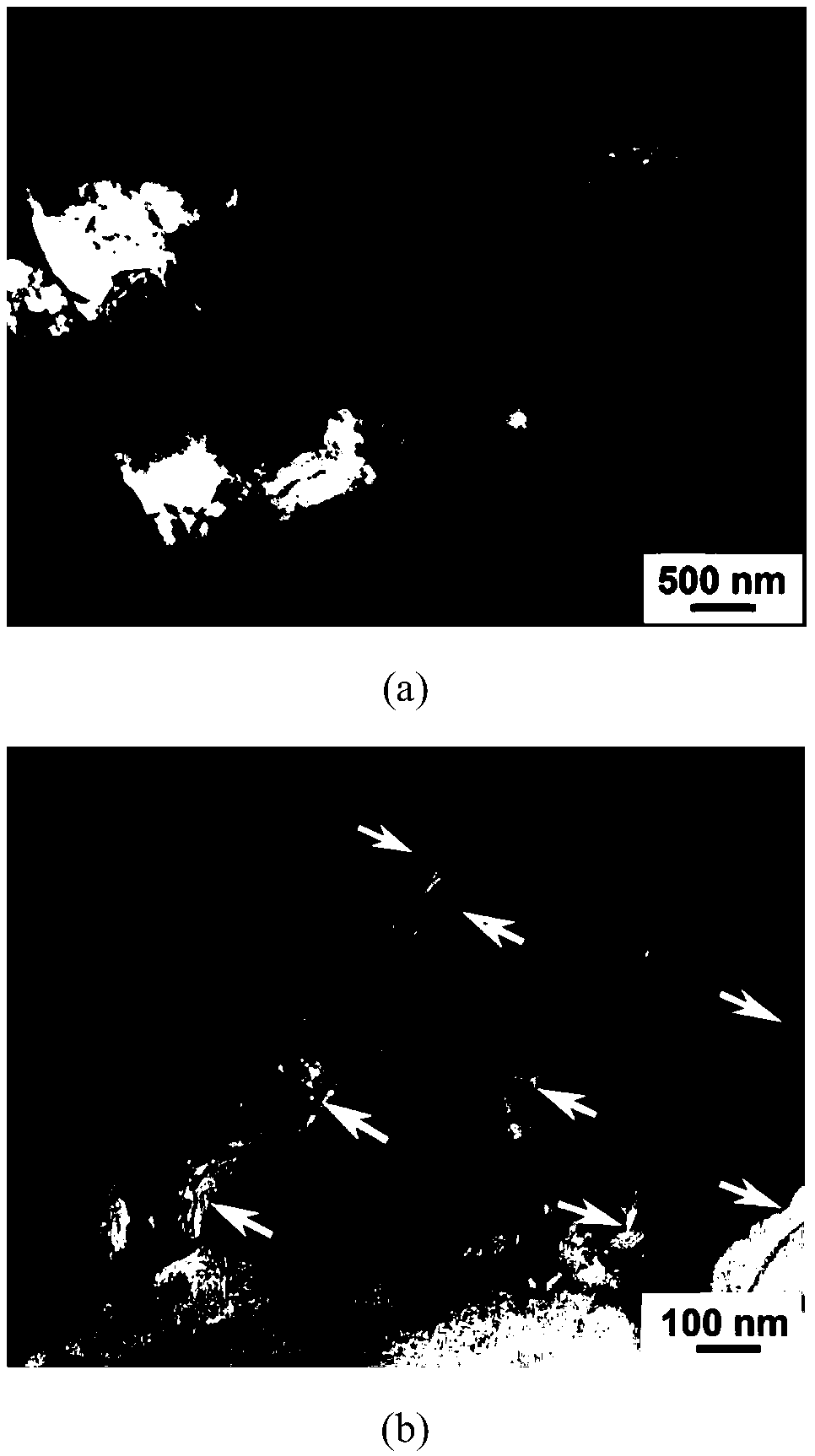

[0024] 2009 aluminum alloy powder is used, the composition is 3.0wt.% Cu, 1.5wt.% Mg, Al balance, the average particle size is 30 μm; the nominal diameter of multi-walled carbon nanotubes is 40-60 nm, and the length is 5-15 μm. Put 1kg of mixed powder of aluminum alloy powder and multi-walled carbon nanotubes and 40Kg of grinding balls into the stirring ball mill, and the material of the grinding balls is ZrO 2 , multi-walled carbon nanotubes accounted for 1.0% of the mass of the mixed powder, the diameters of the grinding balls were 3mm, 5mm, and 8mm, and the corresponding mass ratios were 2:1:1. figure 1 A schematic diagram of a stirring ball mill.

[0025] Pass liquid nitrogen into the ball mill tank, and when the balls and the mixed powder are all immersed in the liquid nitrogen, start ball milling with a rotating speed of 180r / min and a ball milling time of 2h. Pay attention to observe the amount of liquid nitrogen during the ball milling process, so that it can always s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com