Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Grind thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

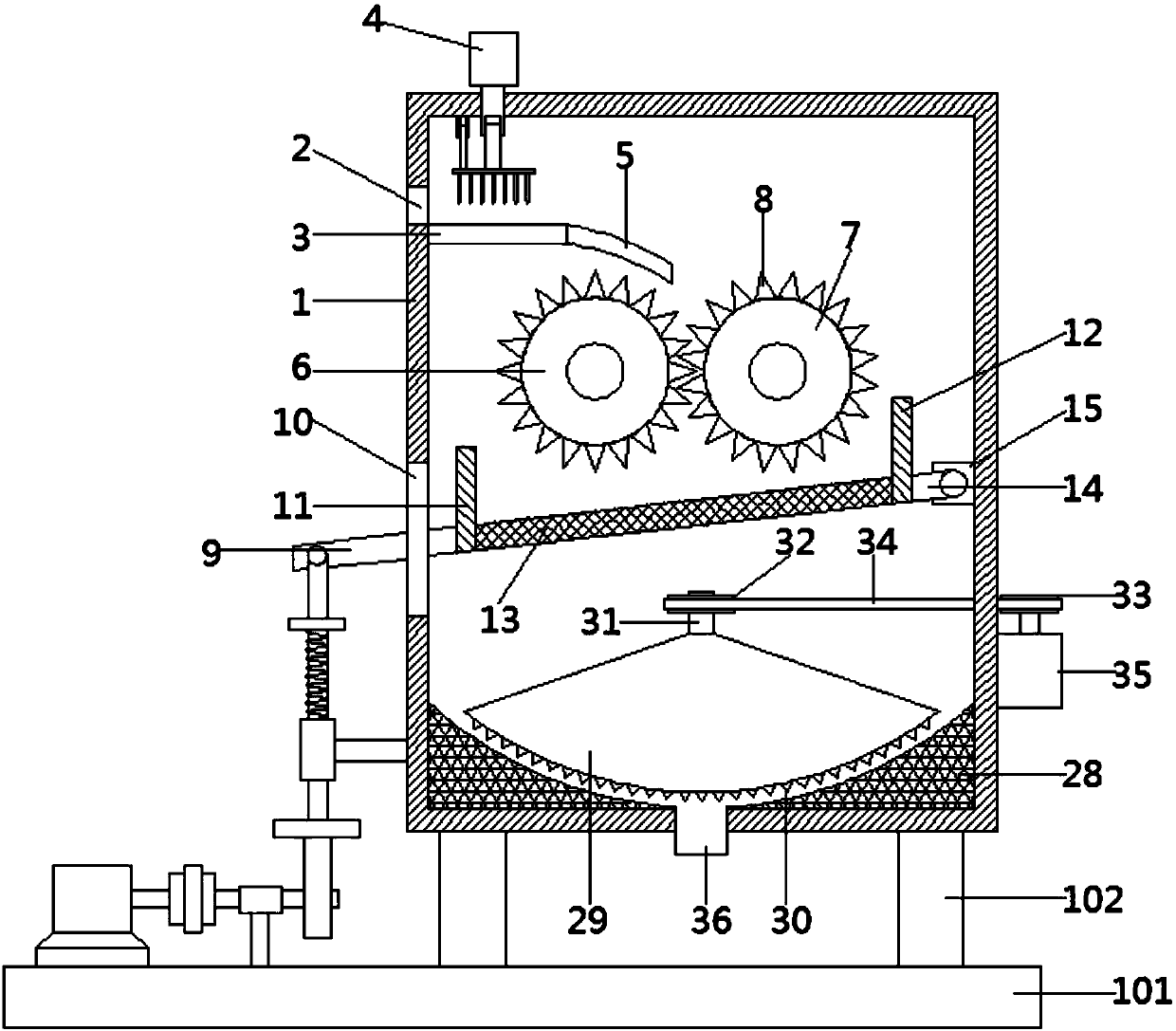

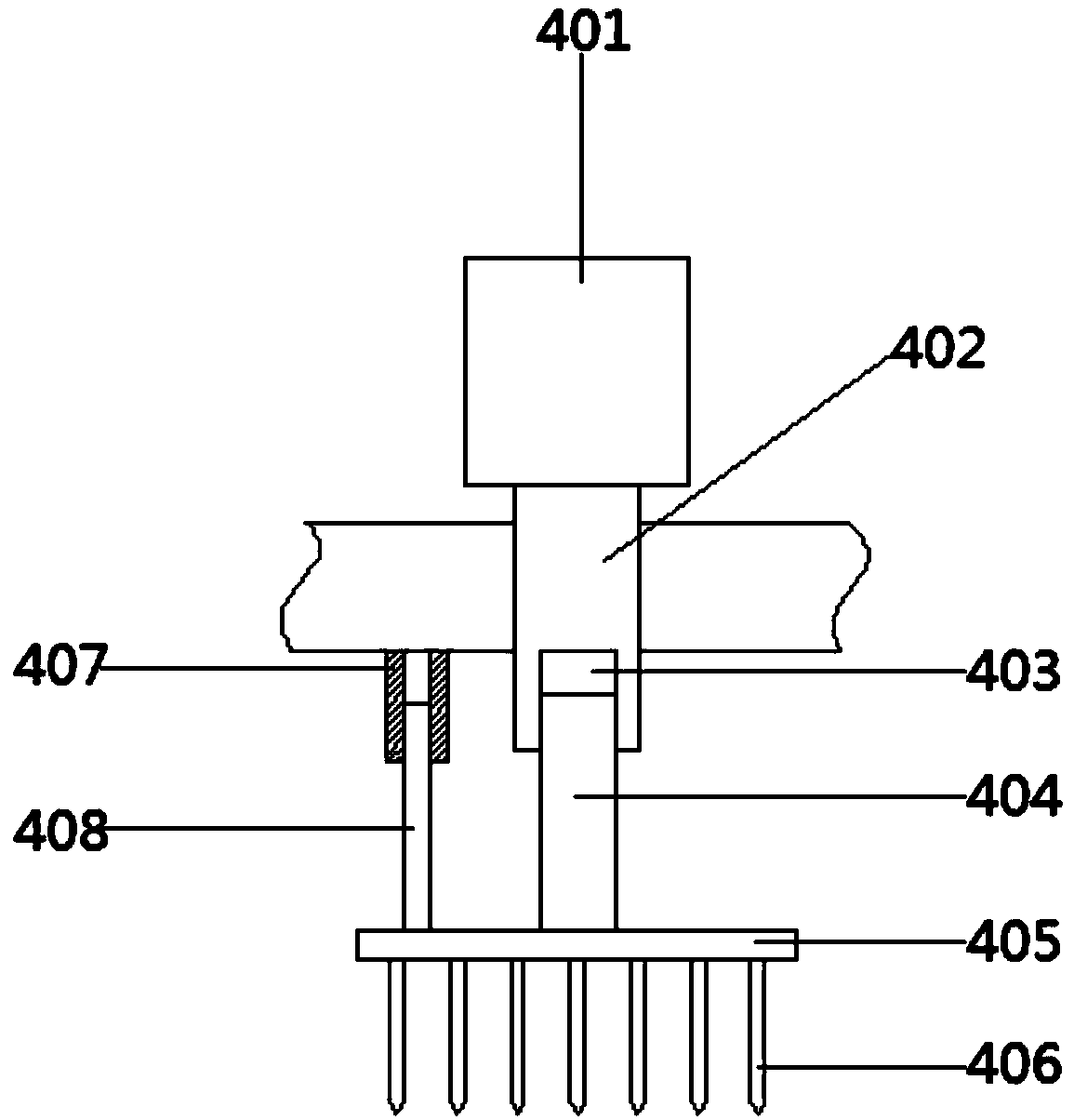

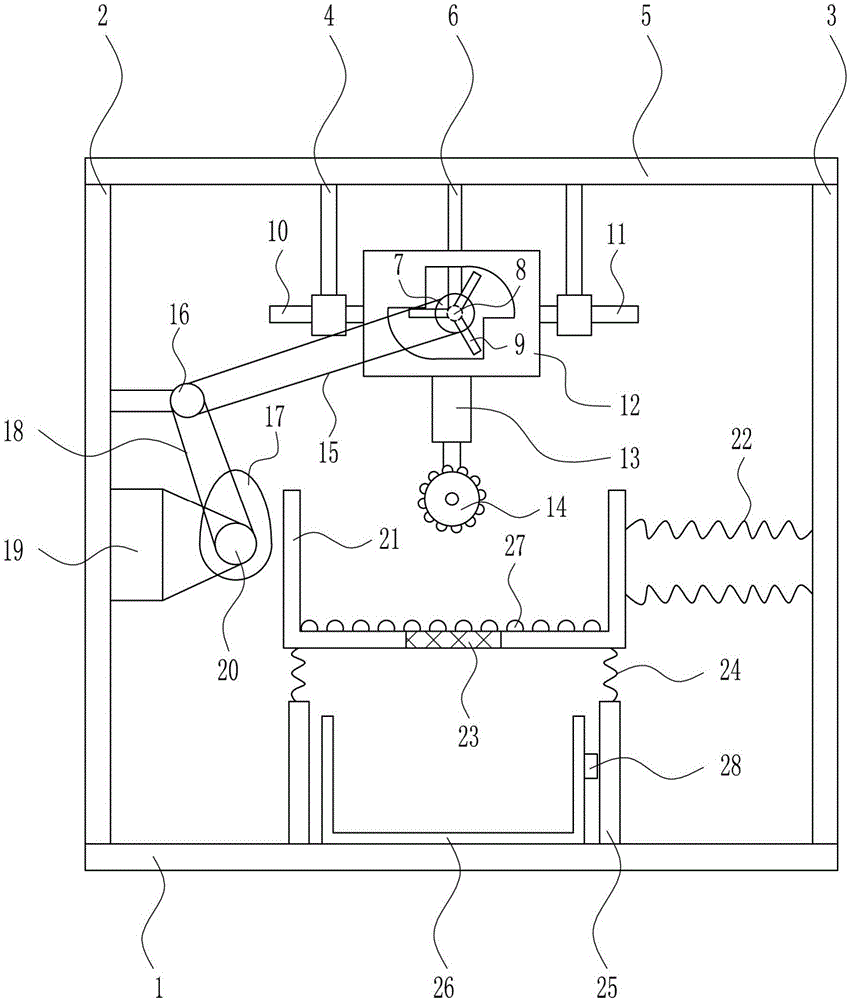

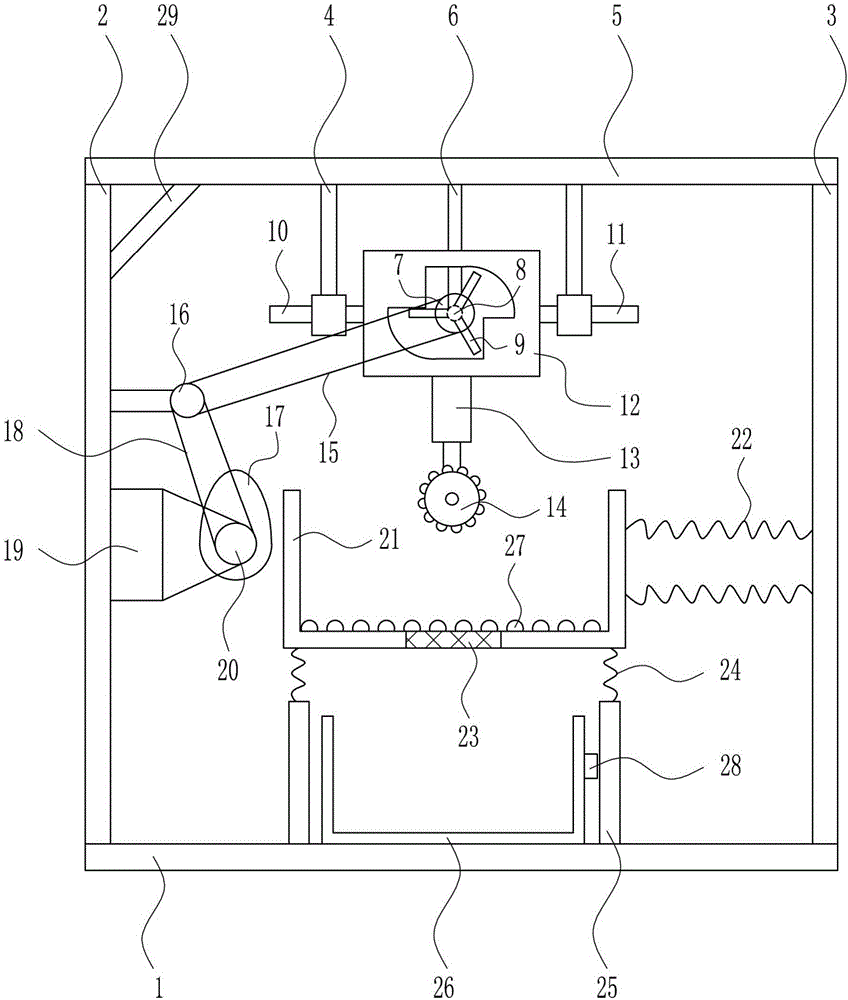

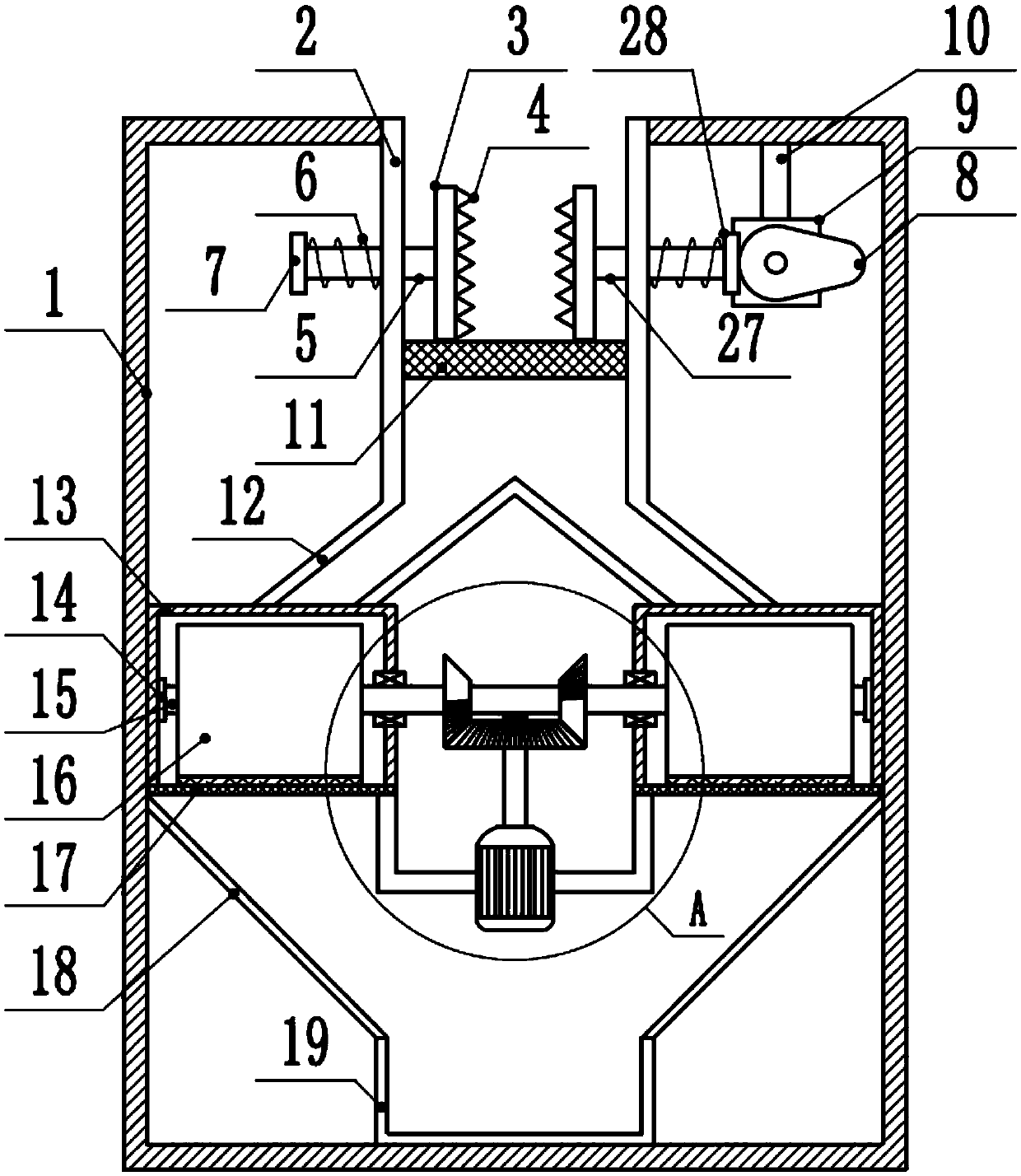

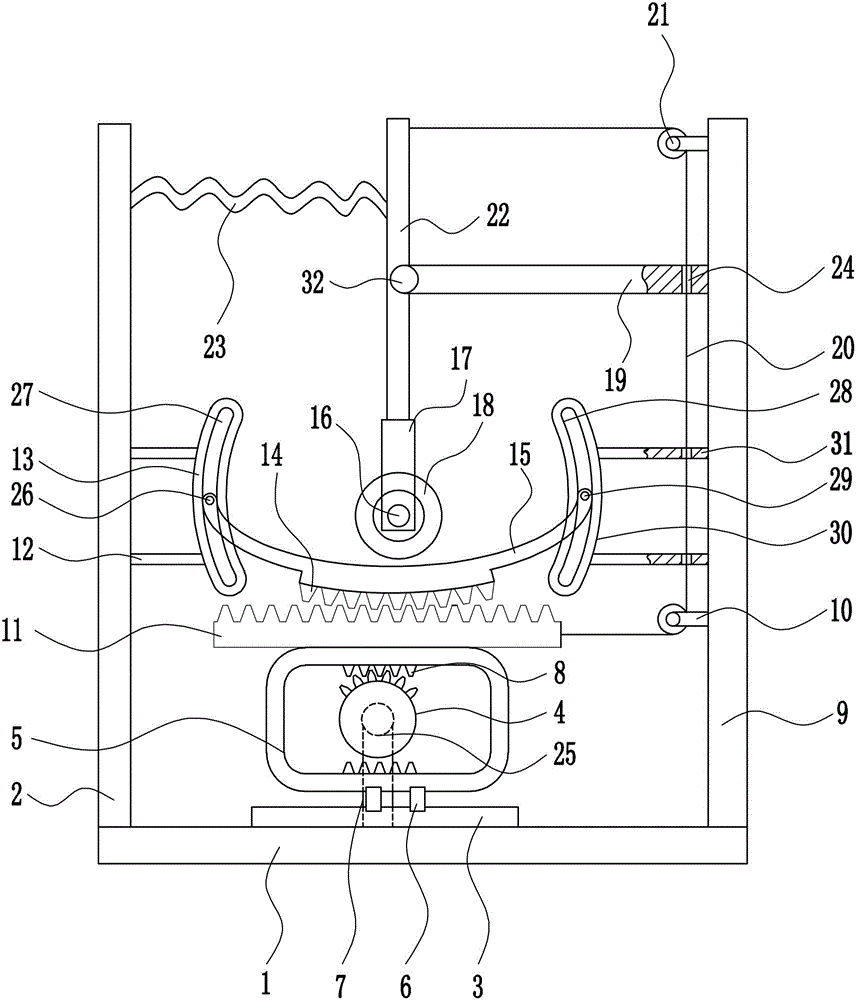

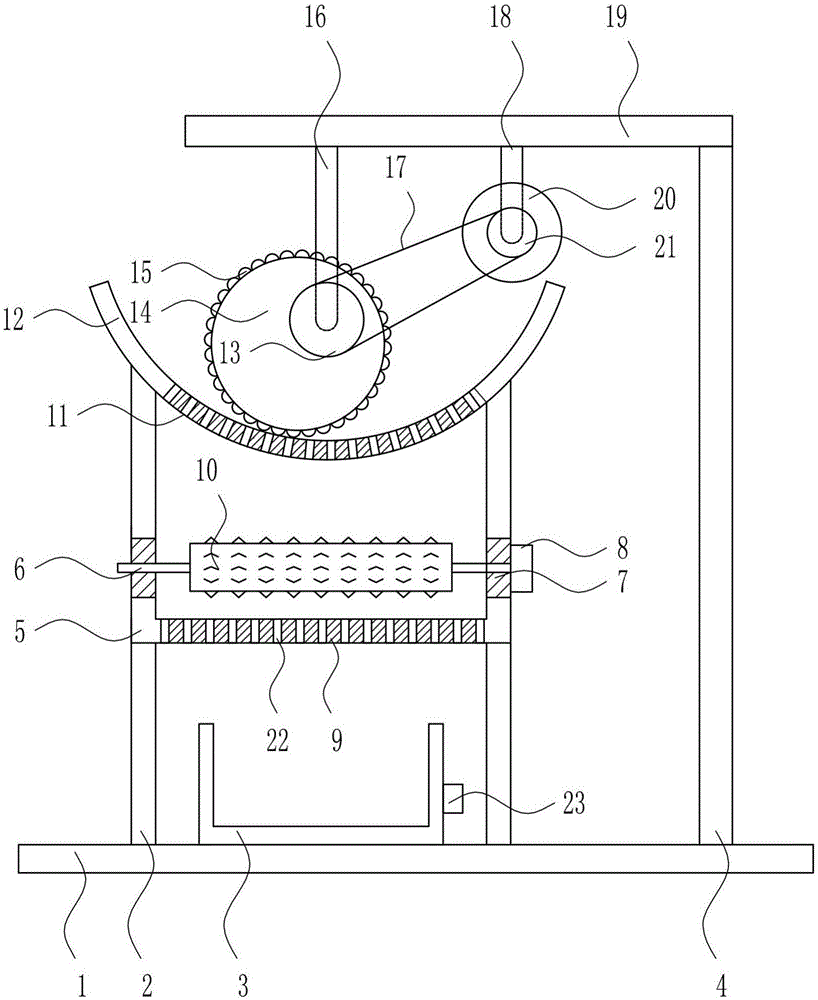

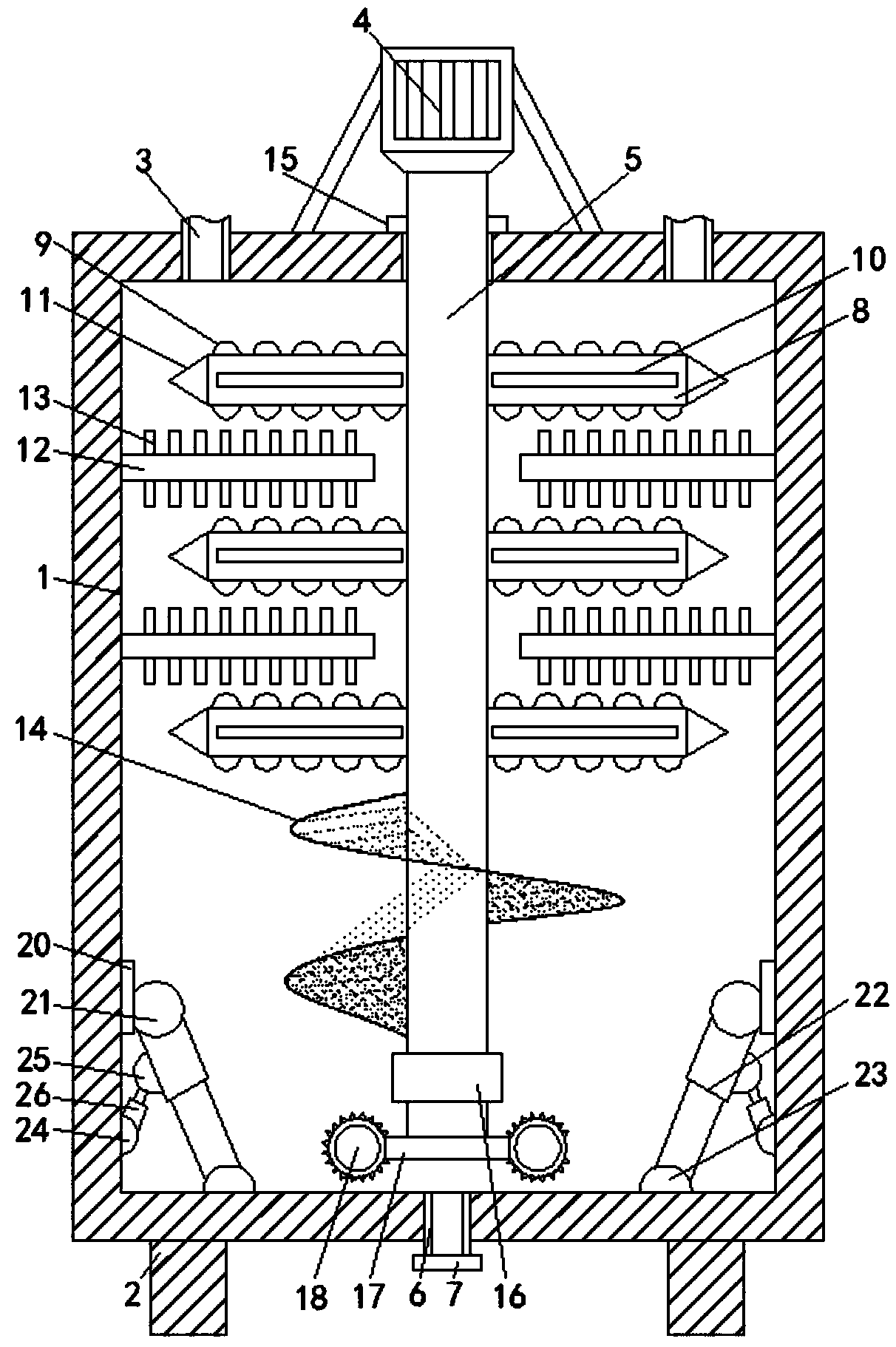

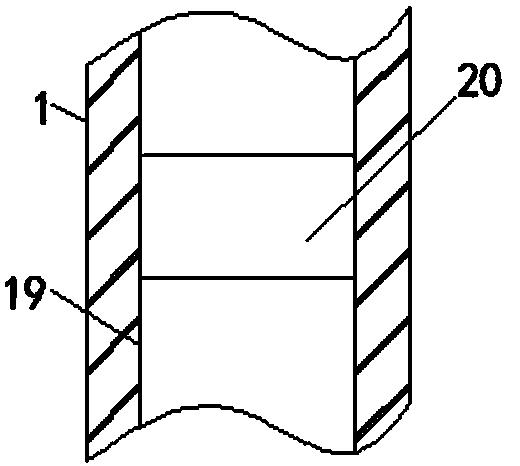

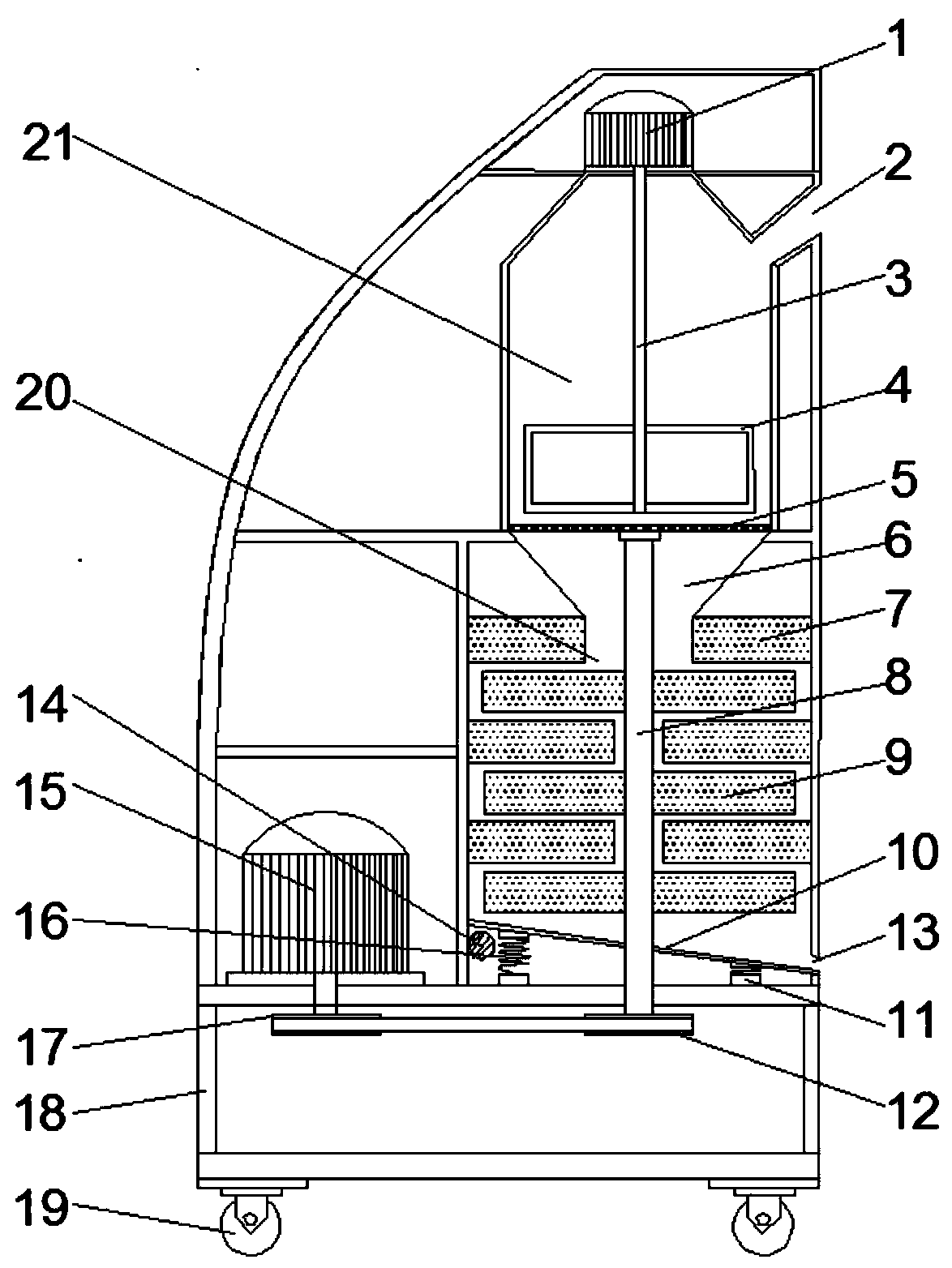

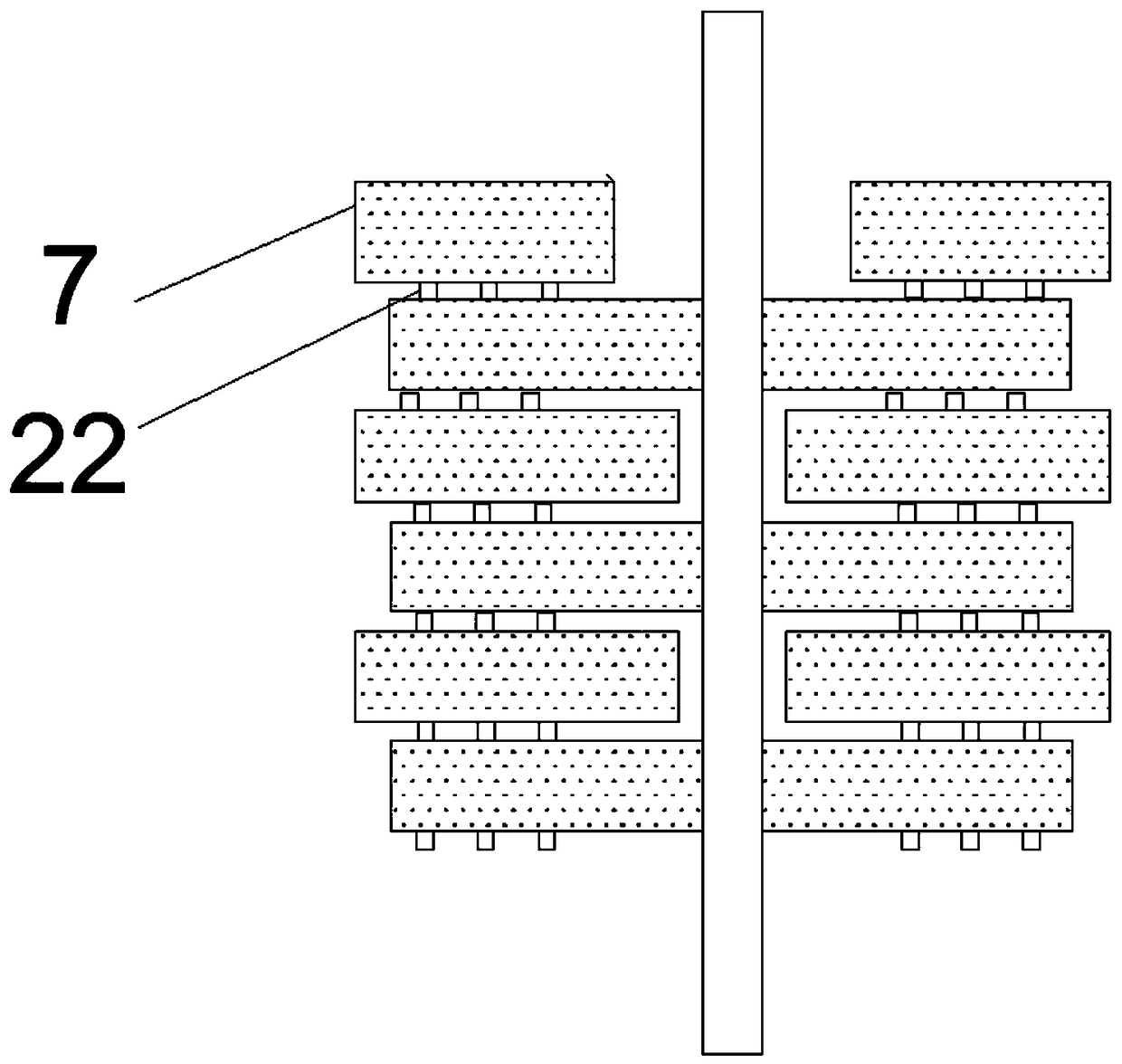

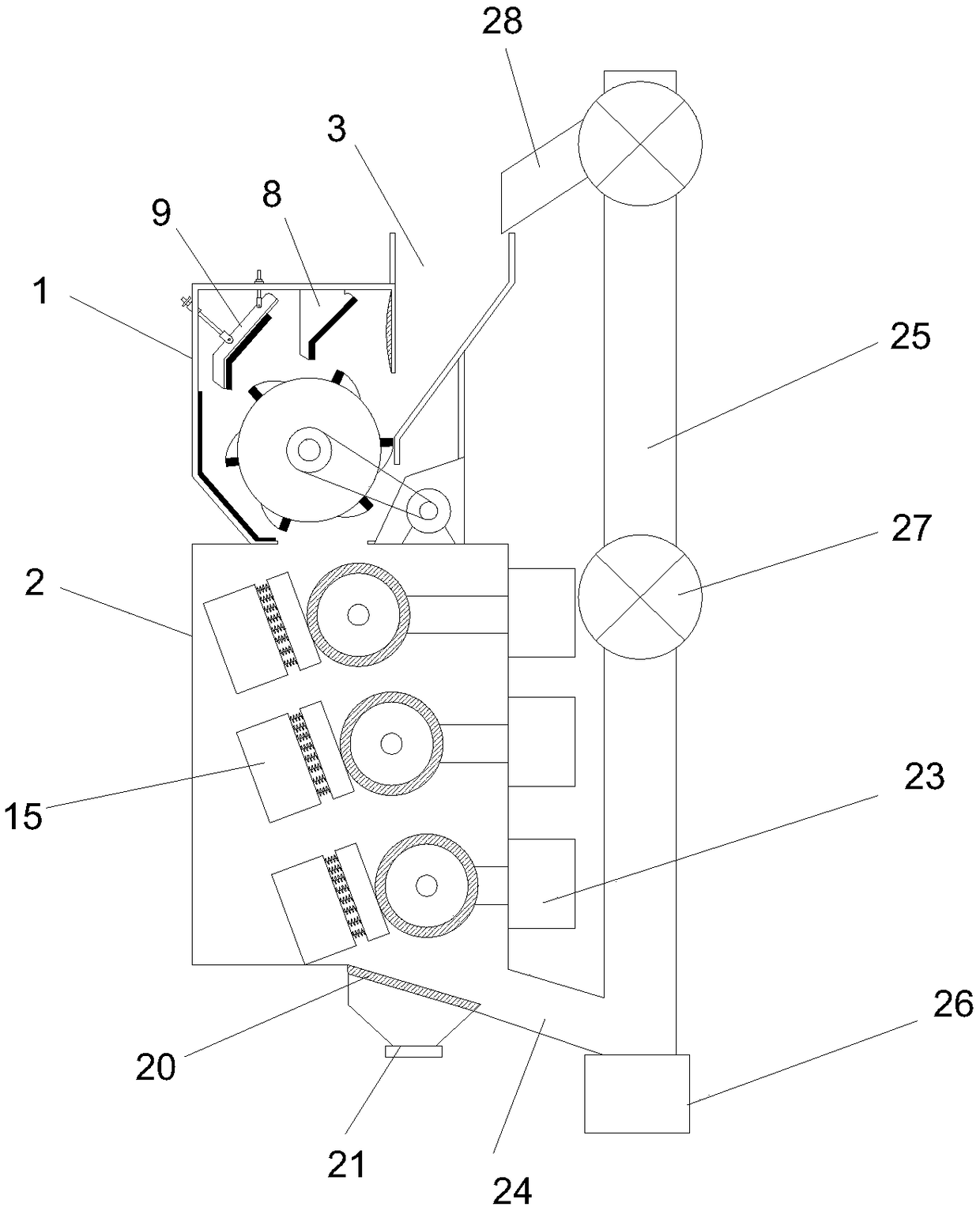

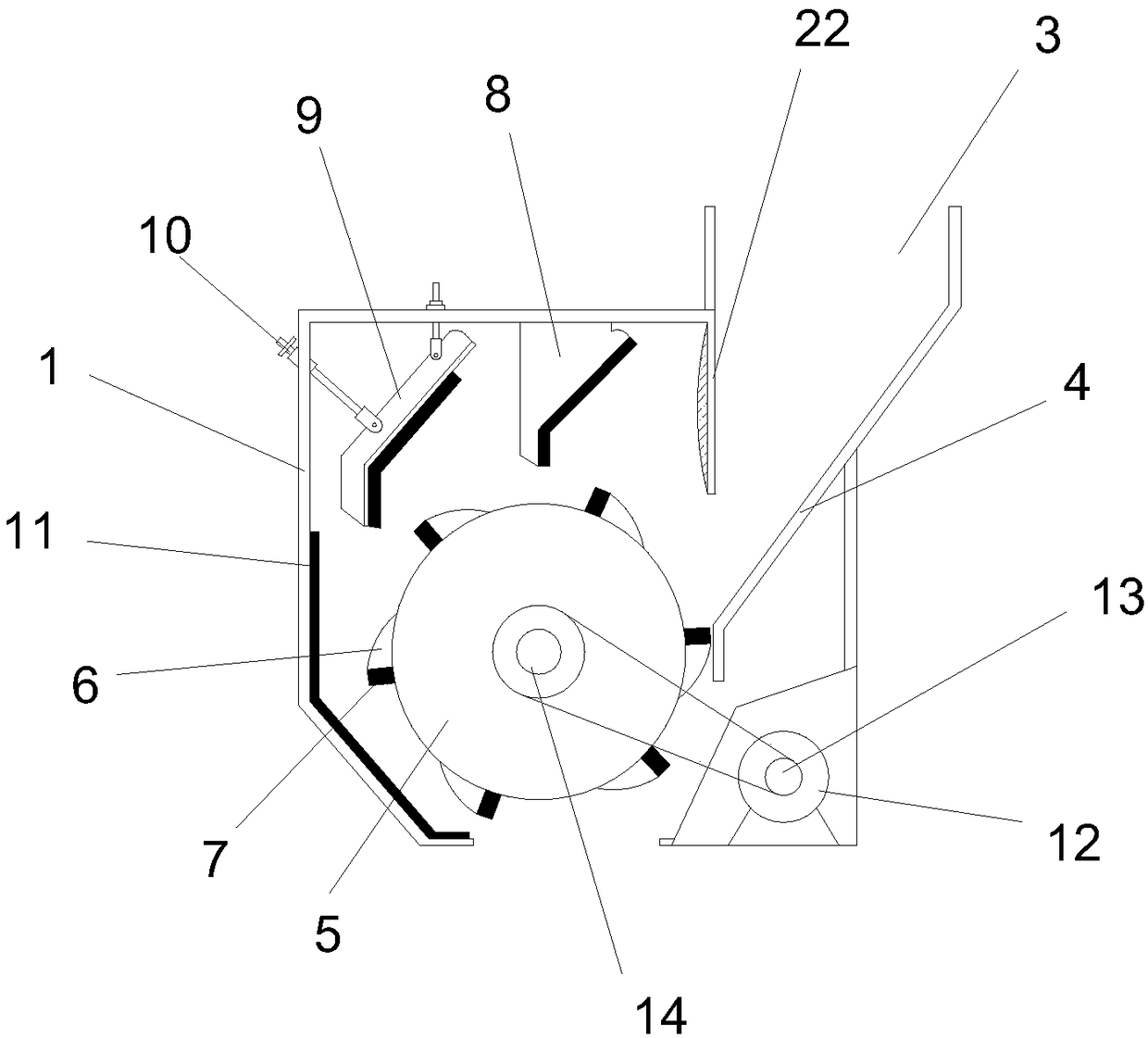

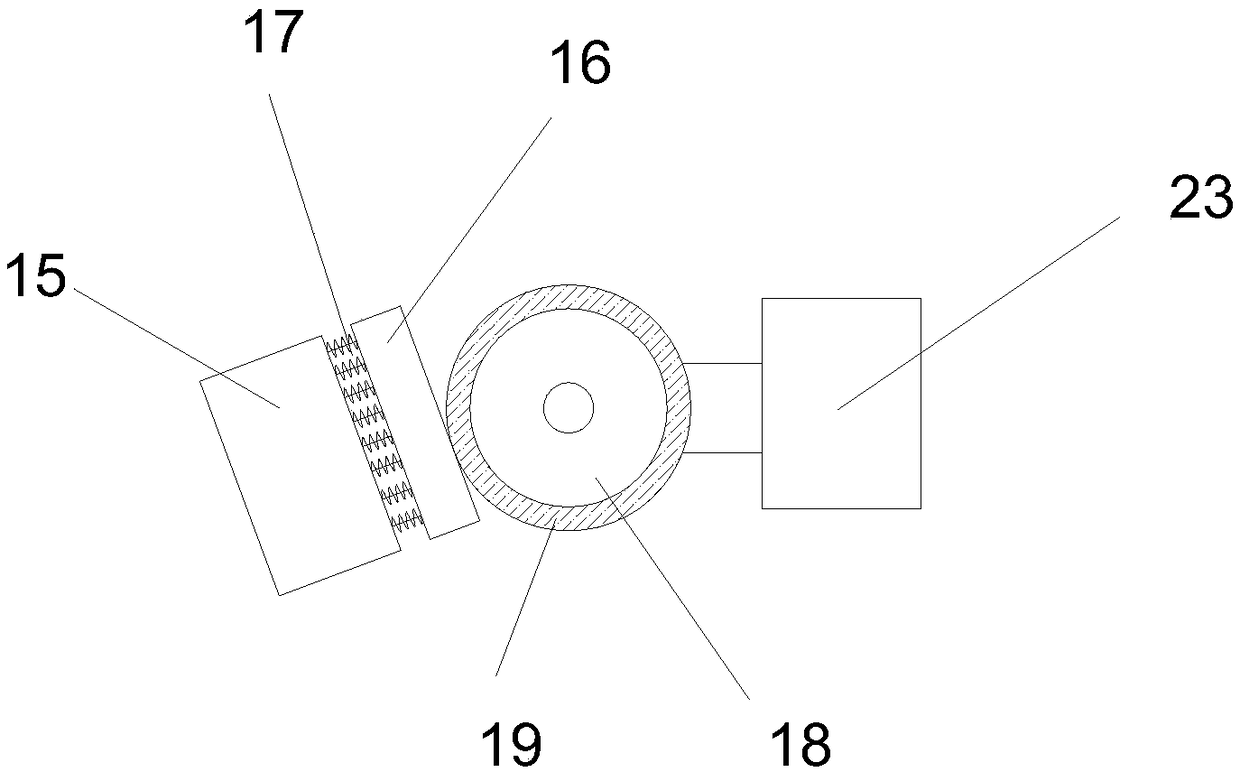

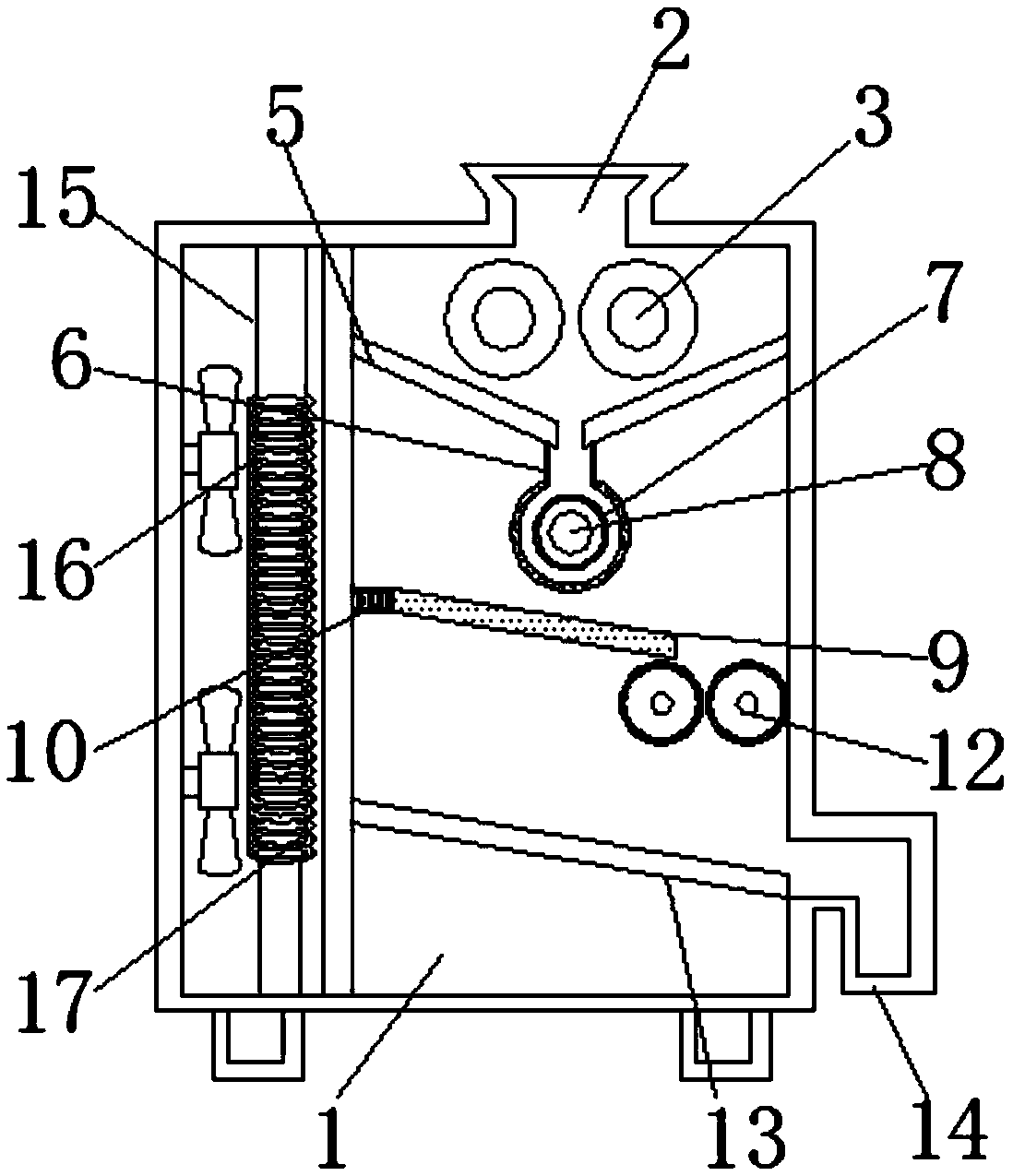

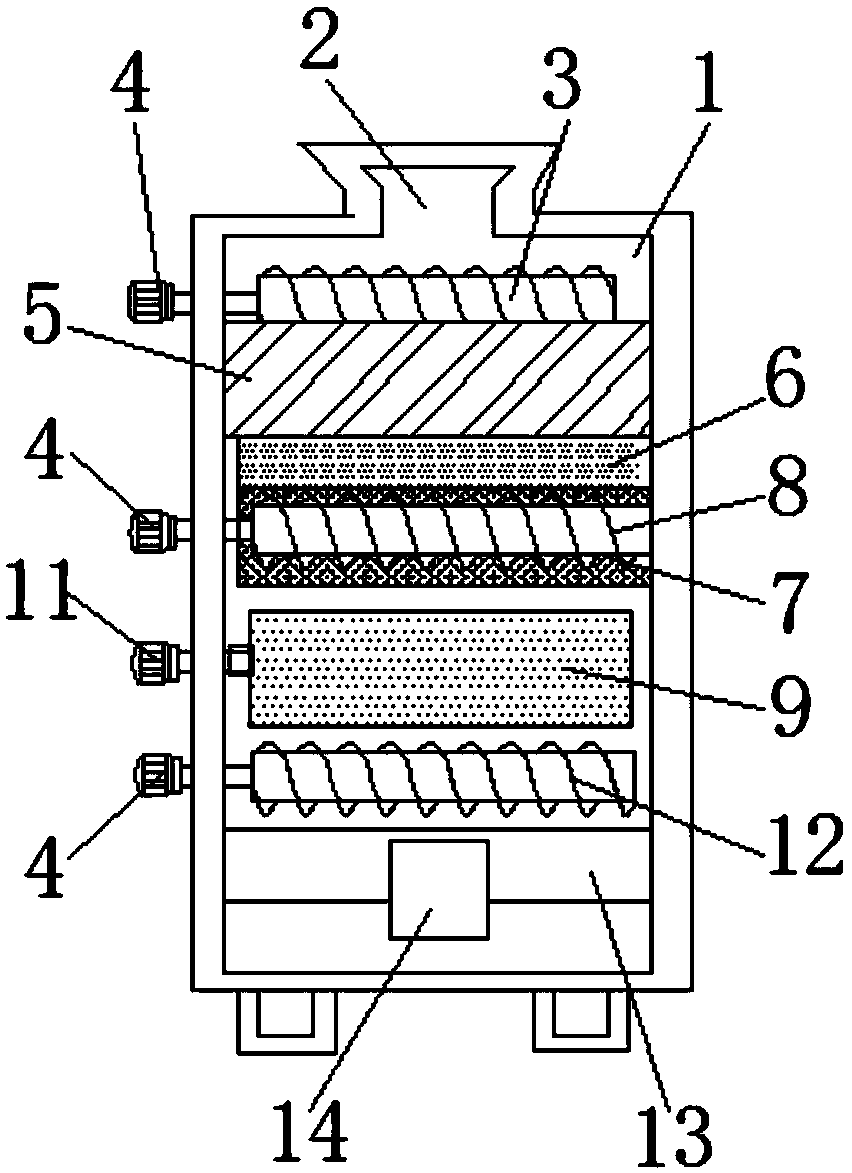

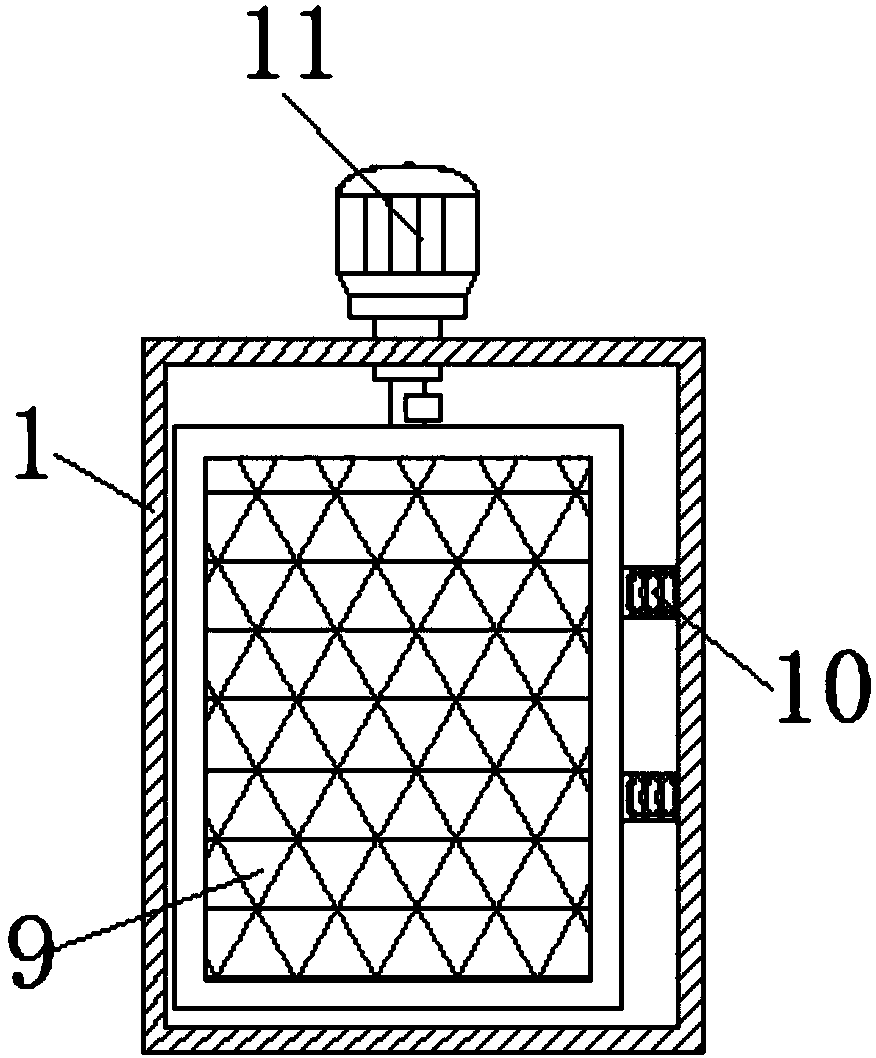

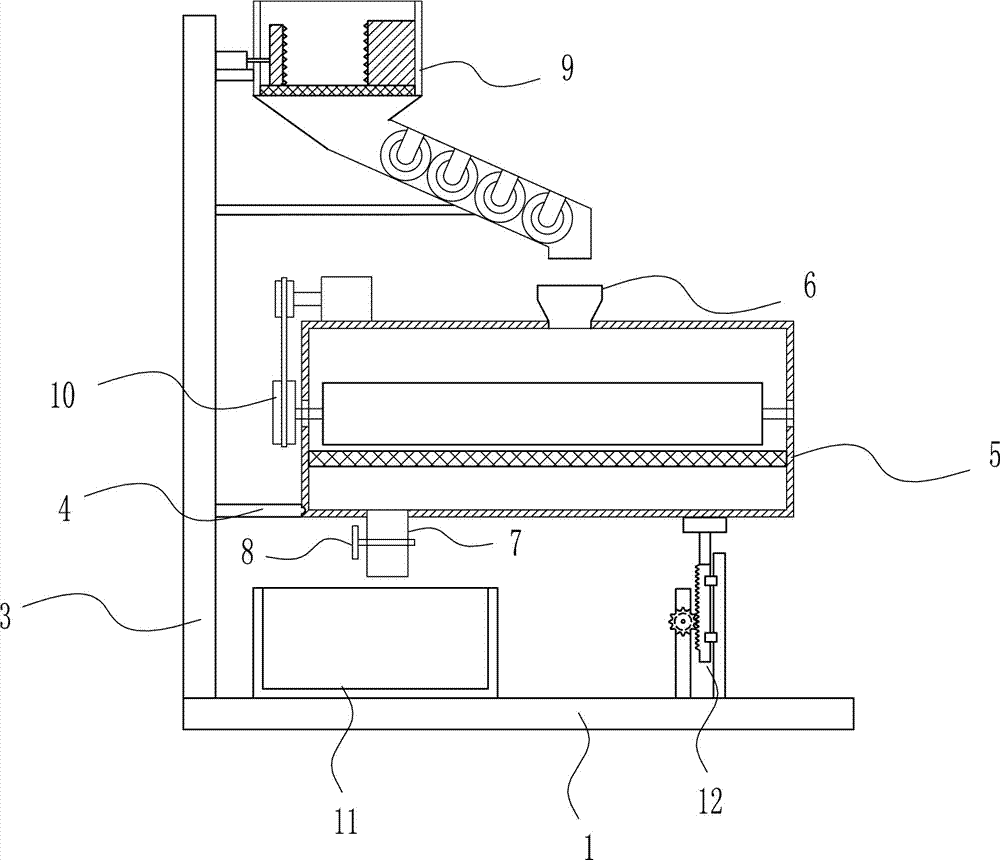

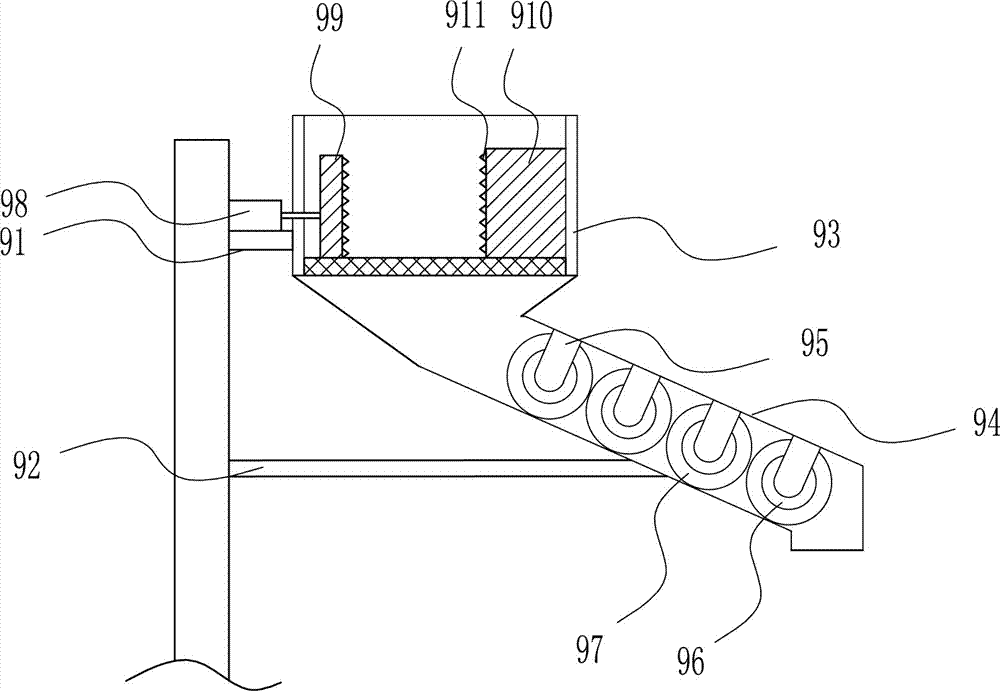

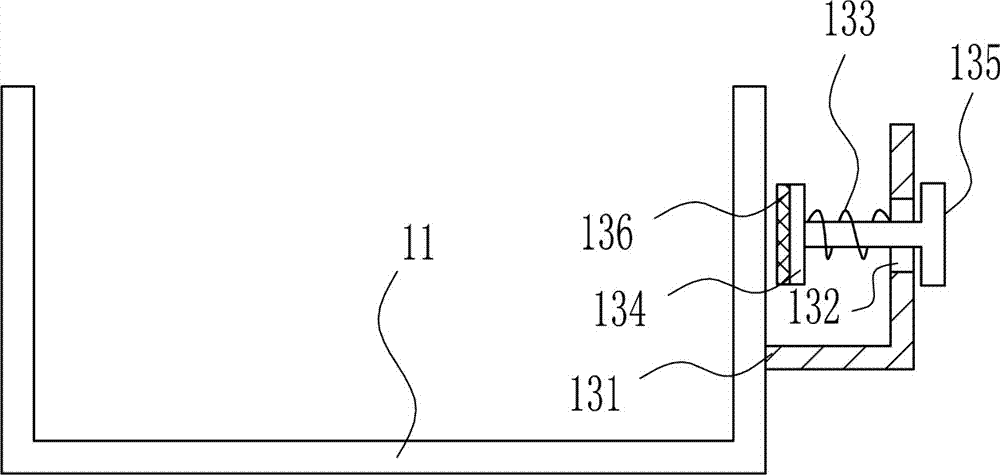

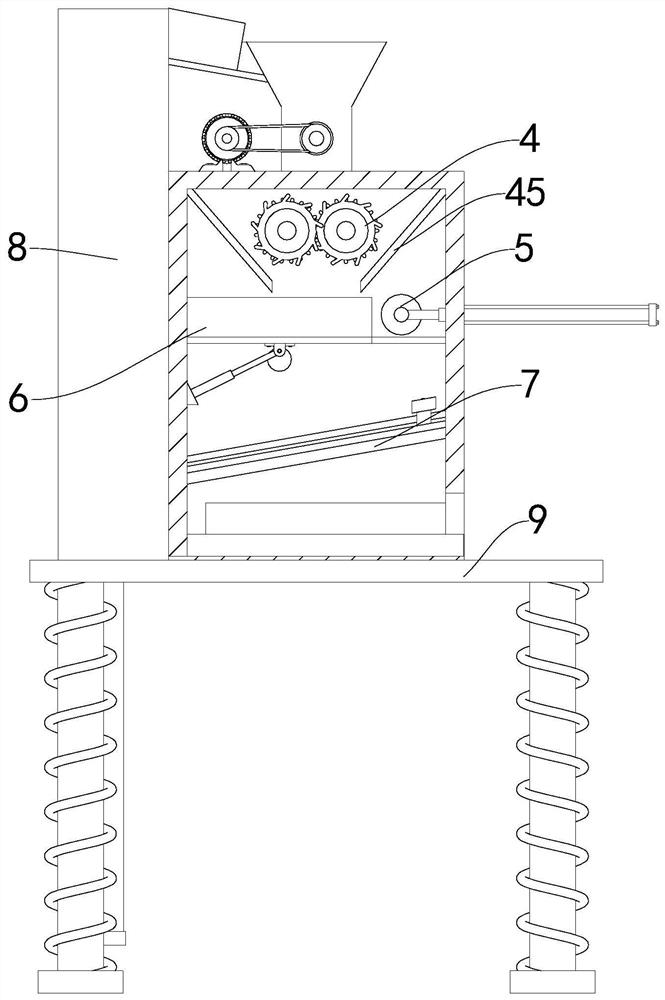

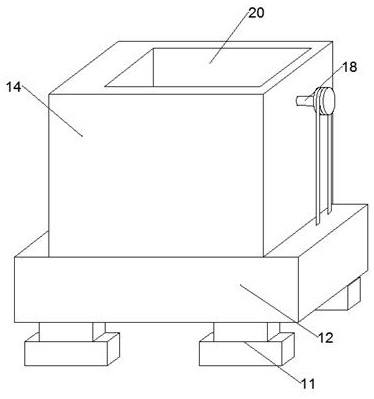

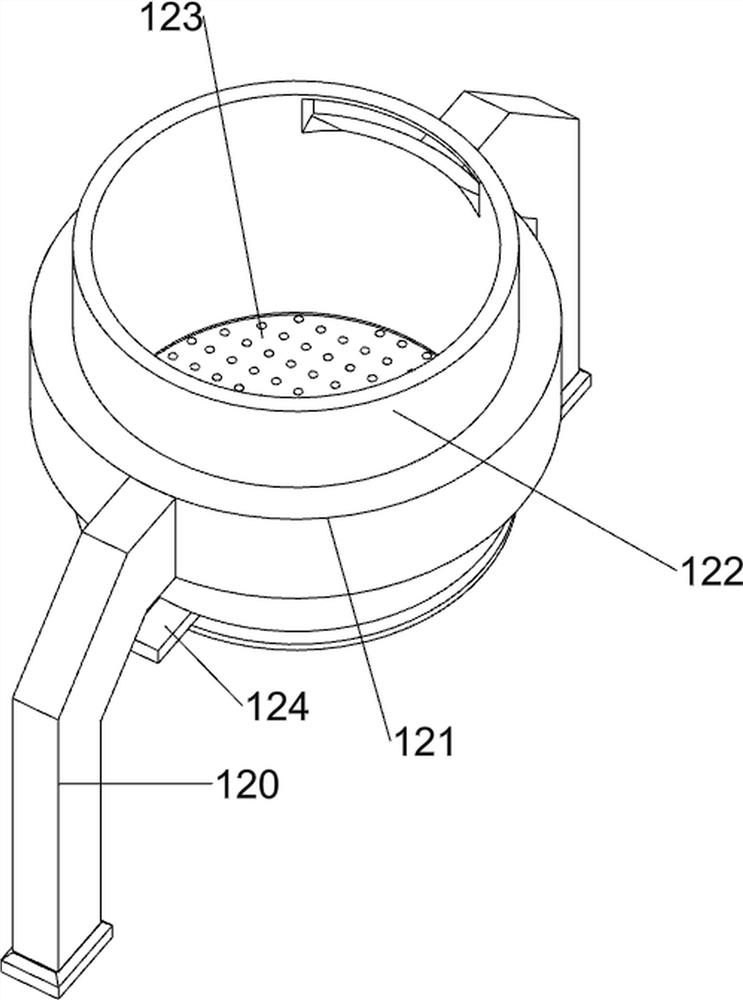

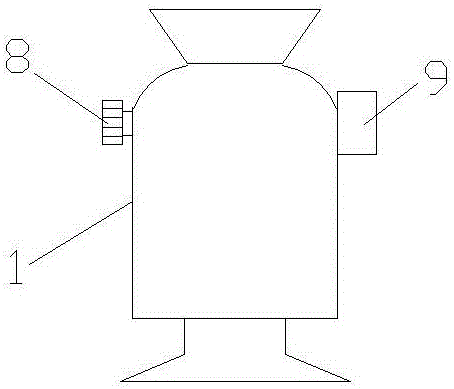

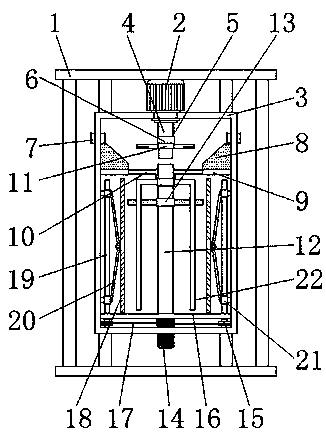

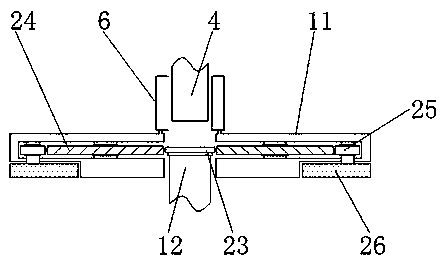

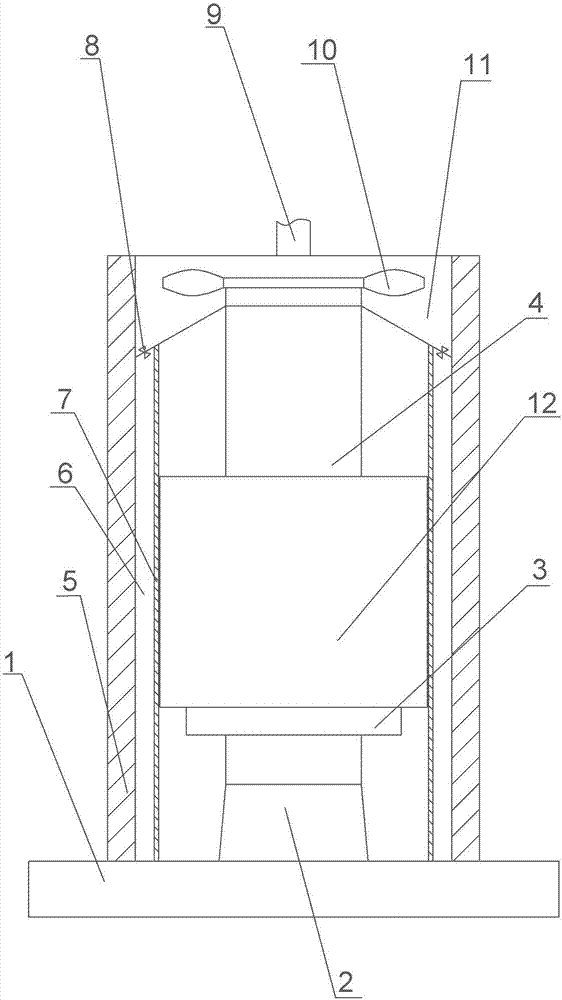

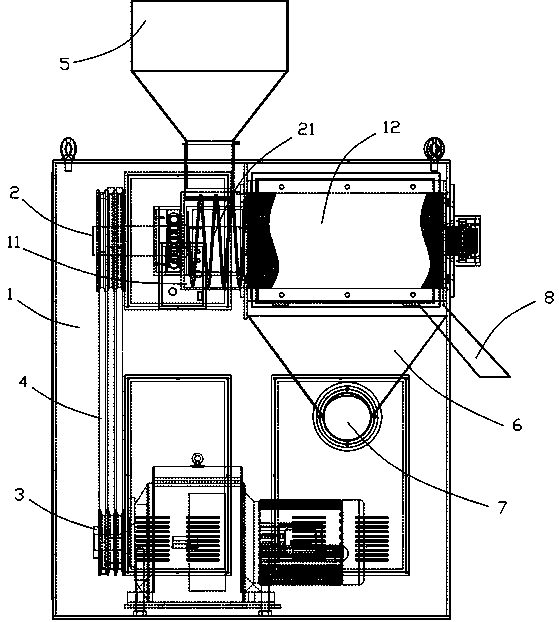

Efficient crushing device for traditional Chinese medicine production

InactiveCN107626418AImprove crushing effect and efficiencyImprove crushing effectSievingScreeningGrindChinese herbology

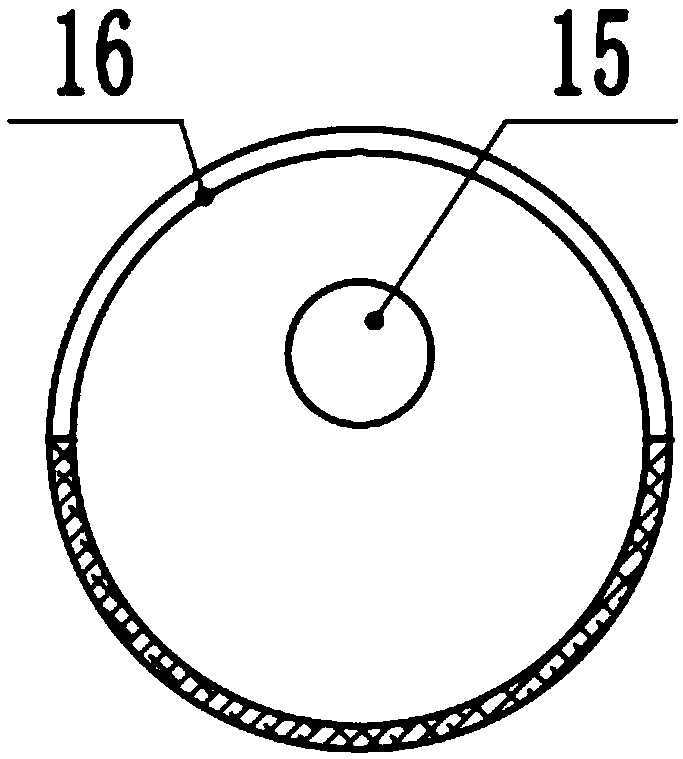

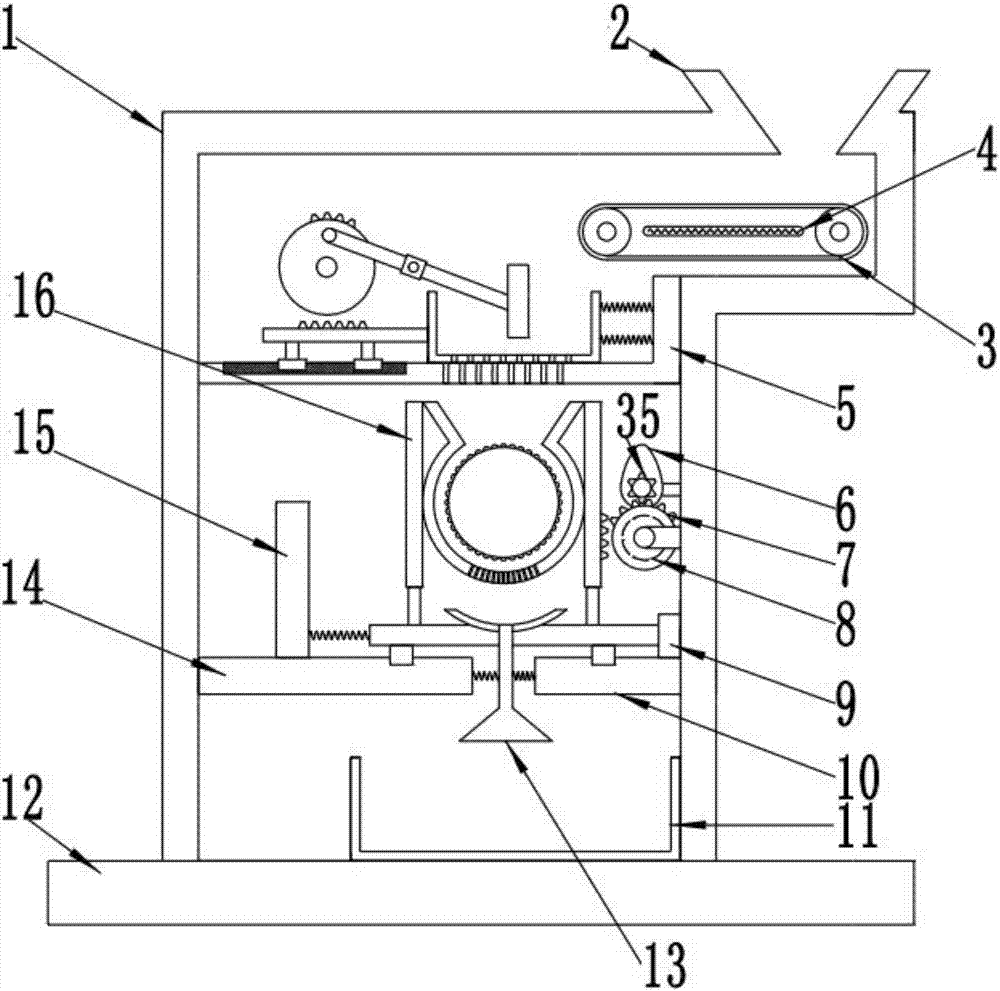

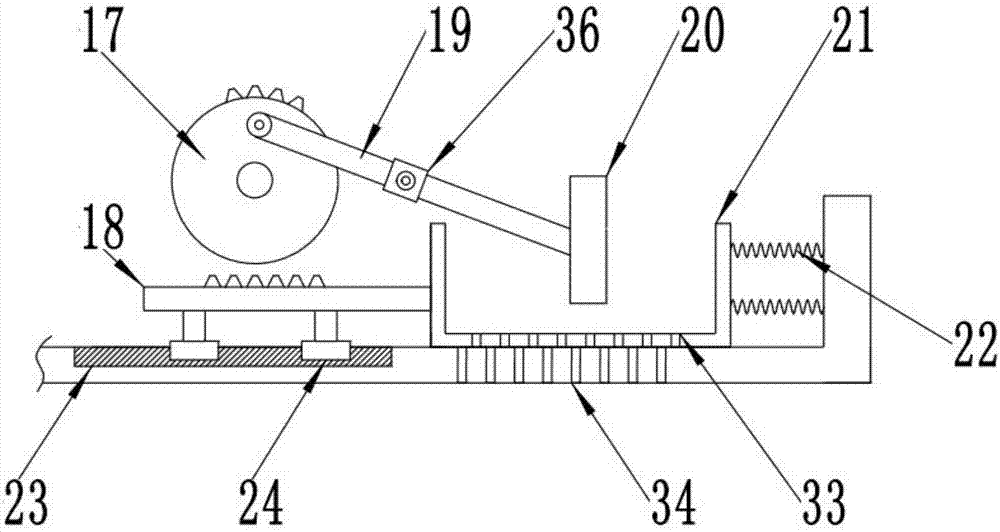

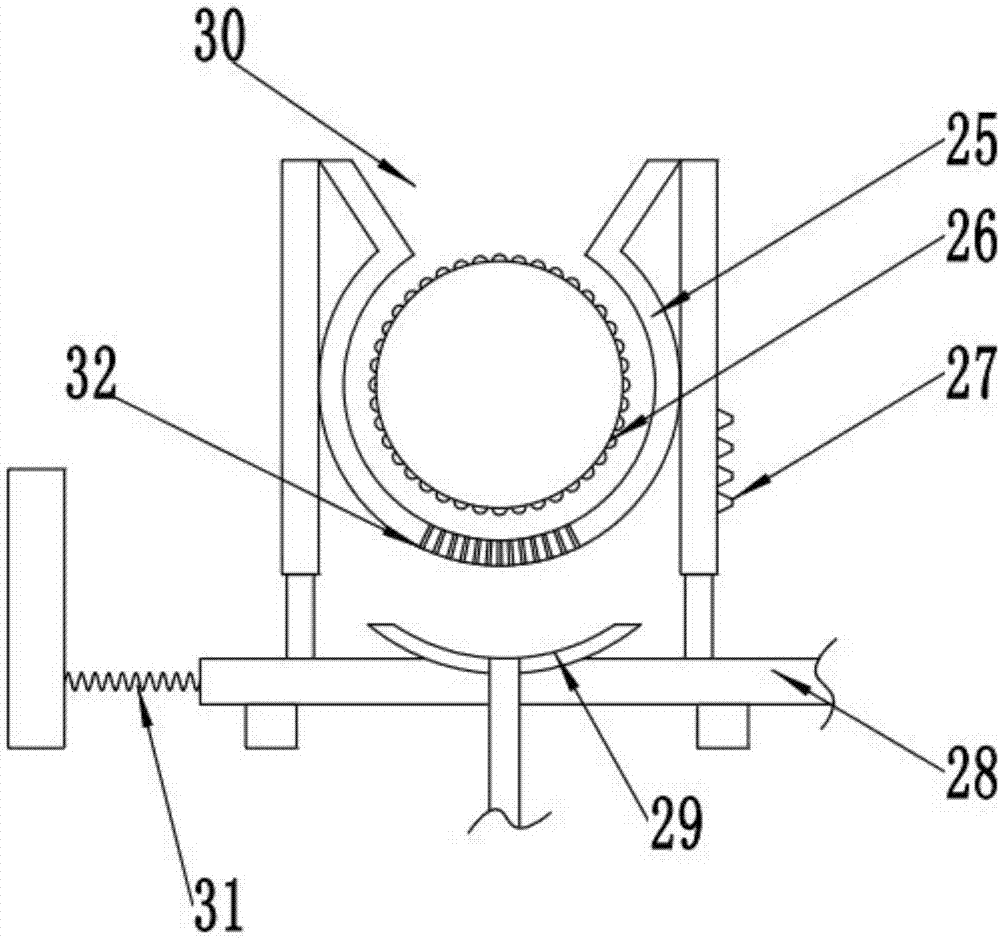

The invention discloses an efficient crushing device for traditional Chinese medicine production. The device comprises a body. A base is arranged in the bottom of the body; the periphery of the bottomof the body is fixed on the base through supporting legs; a feed inlet is formed in the top end of the left side wall of the body; a feeding supporting plate is horizontally arranged at the connection of the inner side of the body and the feed inlet; a pre-cutting device is arranged on one side of a supporting plate; the pre-cutting device comprises a first rotary shaft; the top end of the rotaryshaft penetrates through the body, and the top end of the first rotary shaft is fixedly connected to the output shaft of a first motor. The efficient crushing device for traditional Chinese medicineproduction disclosed by the invention separately pre-cuts the medicinal materials, crushes grinds and the same with crushing teeth through three crushing devices which are arranged up and down, so that the crushing effect of traditional Chinese medicinal materials is ensured, and the quality of the product traditional Chinese medicine is improved; the device fully and uniformly crushes, and is high in work efficiency; a filter screen is arranged to screen the traditional Chinese medicines; in addition, a jittering device is arranged to drive the filter screen to jitter up and down, so that thescreening efficiency is increased effectively.

Owner:单开禹

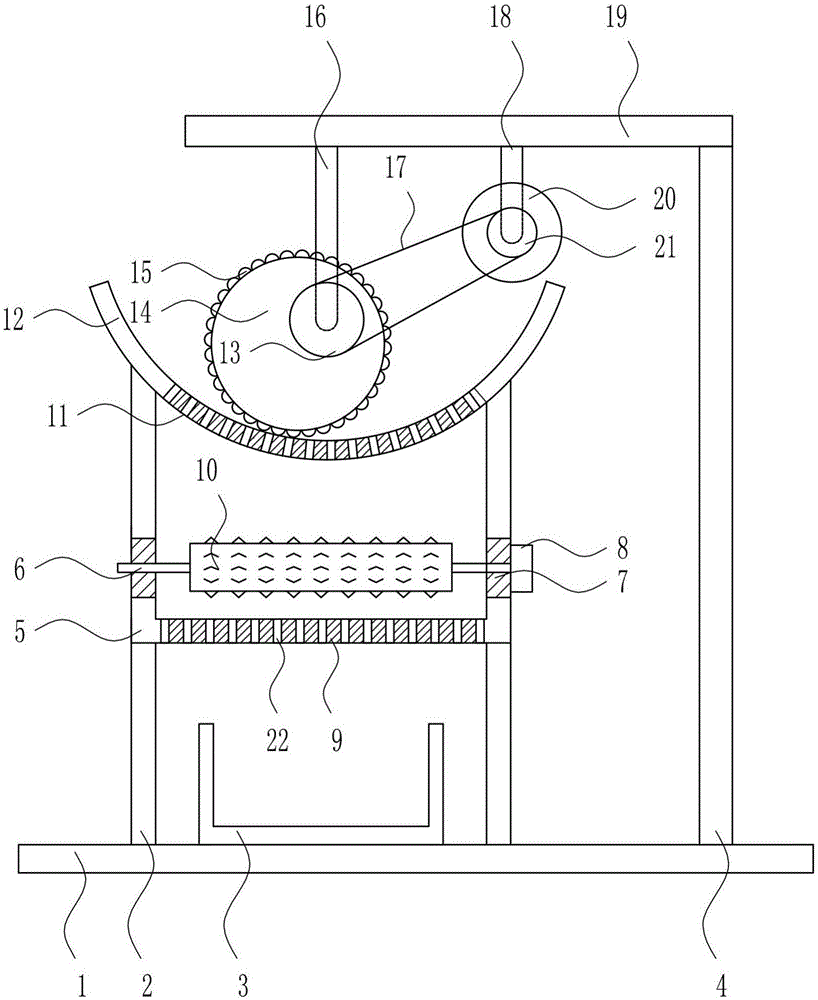

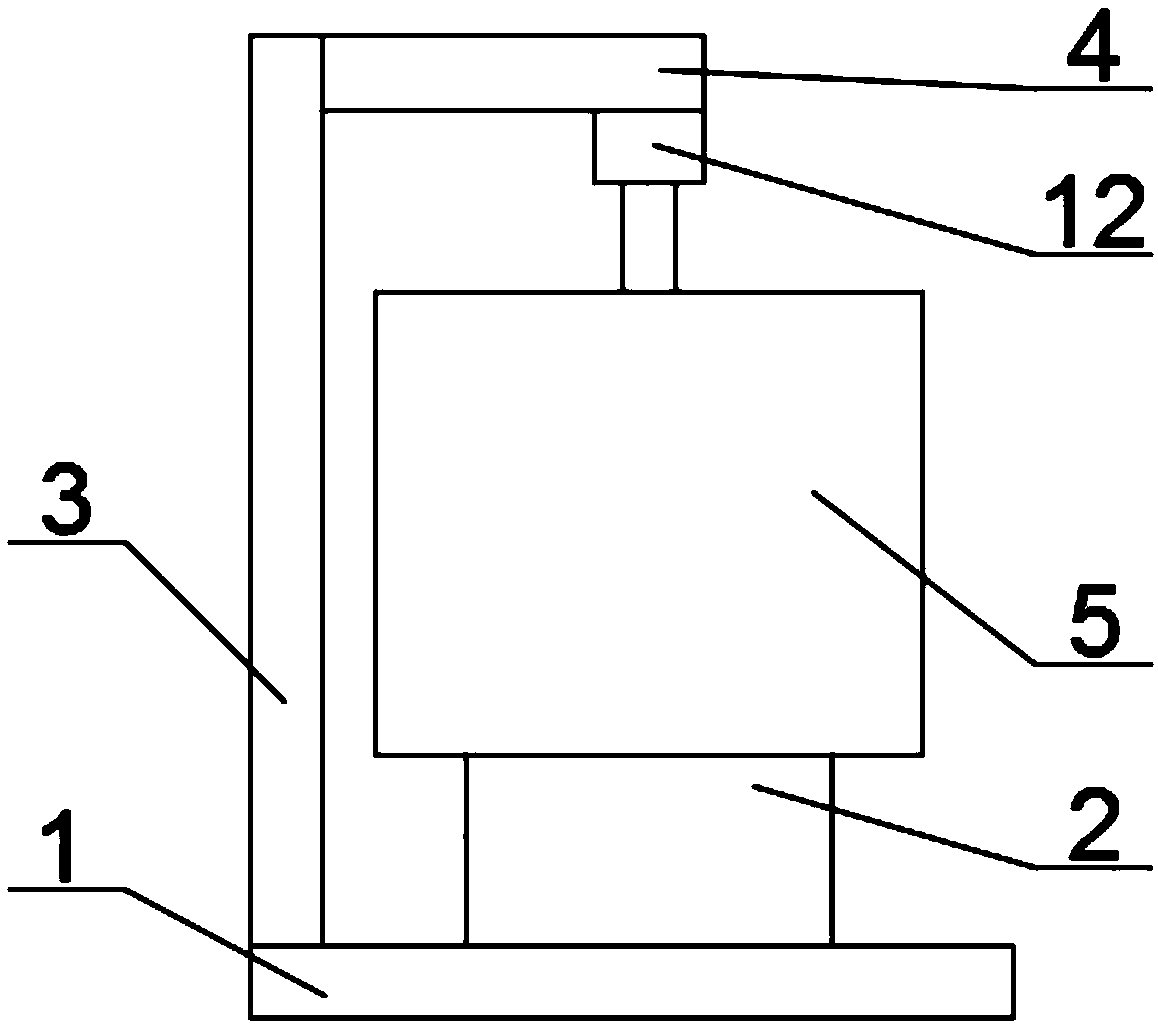

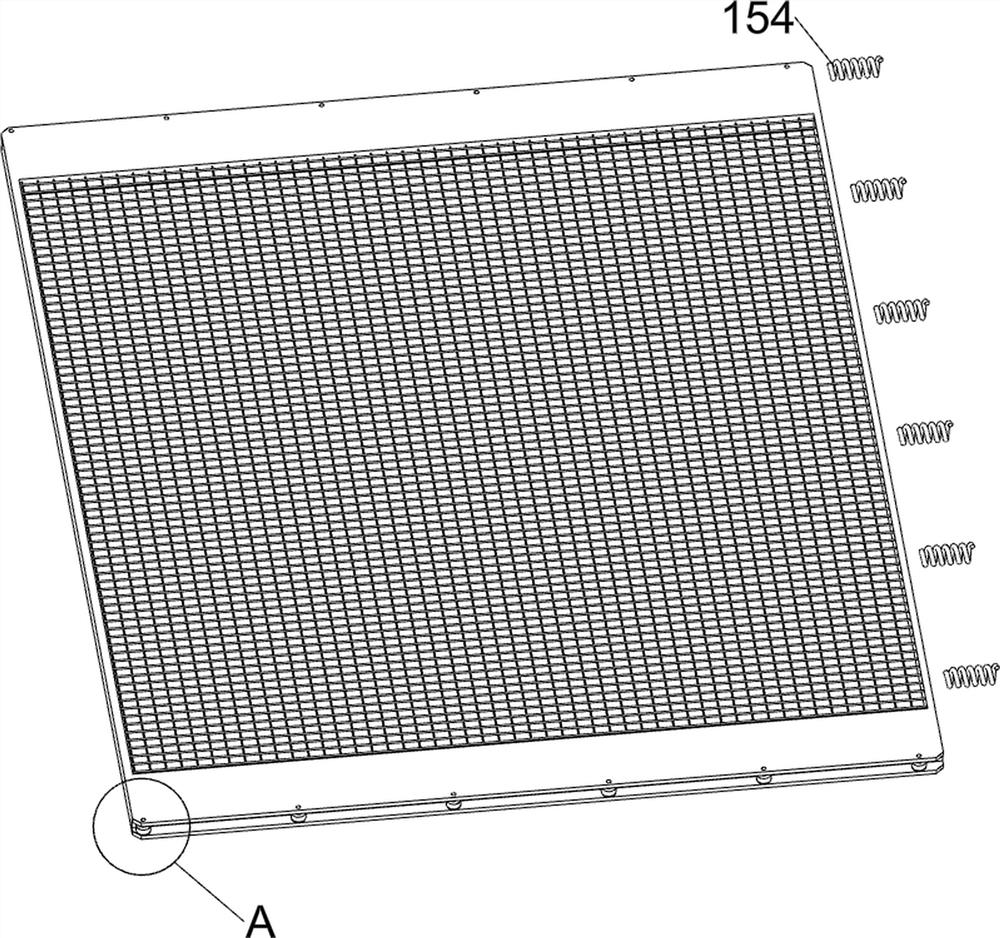

Efficient grinding device for graphite for 3D printing

The invention relates to a grinding device for graphite for 3D printing, in particular to an efficient grinding device for the graphite for 3D printing. The efficient grinding device for the graphite for 3D printing is even, thorough and fast in grinding. The efficient grinding device for the graphite for 3D printing comprises a bottom plate, a left rack, a right rack, guiding sleeves, a top plate, a first supporting rod, a first large belt pulley, a motor, rotating rods, a first guiding rod, a second guiding rod and a movable frame. Two second supporting rods are arranged in symmetry with respect to the center of the top of the bottom plate; a collecting frame is arranged on the top, located between the two second supporting rods, of the bottom plate; a second spring is arranged at the top end of each second supporting rod; a grinding frame is arranged at the top ends of the second springs; and a net plate is arranged in the center of the bottom of the grinding frame. According to the efficient grinding device, the effects of even, thorough and fast grinding are achieved due to the action of a first reinforcing rib and a second reinforcing rib.

Owner:浙江泰嘉光电科技有限公司

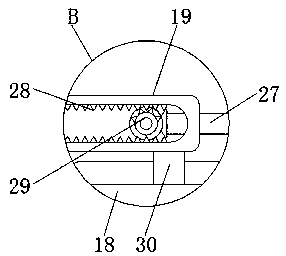

Fine grinding device for producing and processing powder cosmetics

The invention discloses a fine grinding device for producing and processing powder cosmetics and relates to the field of cosmetics. The fine grinding device comprises a device box, wherein a crushingcylinder is fixedly connected with the interior of a middle part of an upper box body of the device box; a first pushing rod and a second pushing rod are in contact connection with the interiors of box bodies on the left side and the right side of the crushing cylinder; the right end of the first pushing rod and the left end of the second pushing rod are respectively fixedly connected with extrusion plates; crushing teeth are respectively fixedly mounted on the surfaces of the extrusion plates; the crushing teeth are in engaged connection with each other; the right end of the second pushing rod is fixedly connected with a second stop block; the outer surface of the right end of the second pushing rod is in contact connection with a spring; the other end of the spring is fixedly connected with the surface of the second stop block; the surface of the right side of the second stop block is in contact connection with a cam; the right rear part of the center of the cam is connected with a first motor. According to the fine grinding device, eccentric grinding rollers are capable of alternately and repeatedly rotating clockwise and counterclockwise so as to grind, so that the raw materials of the cosmetics can be more fully and completely ground; the fine grinding device has better grinding effect and high practicability.

Owner:张玉娥

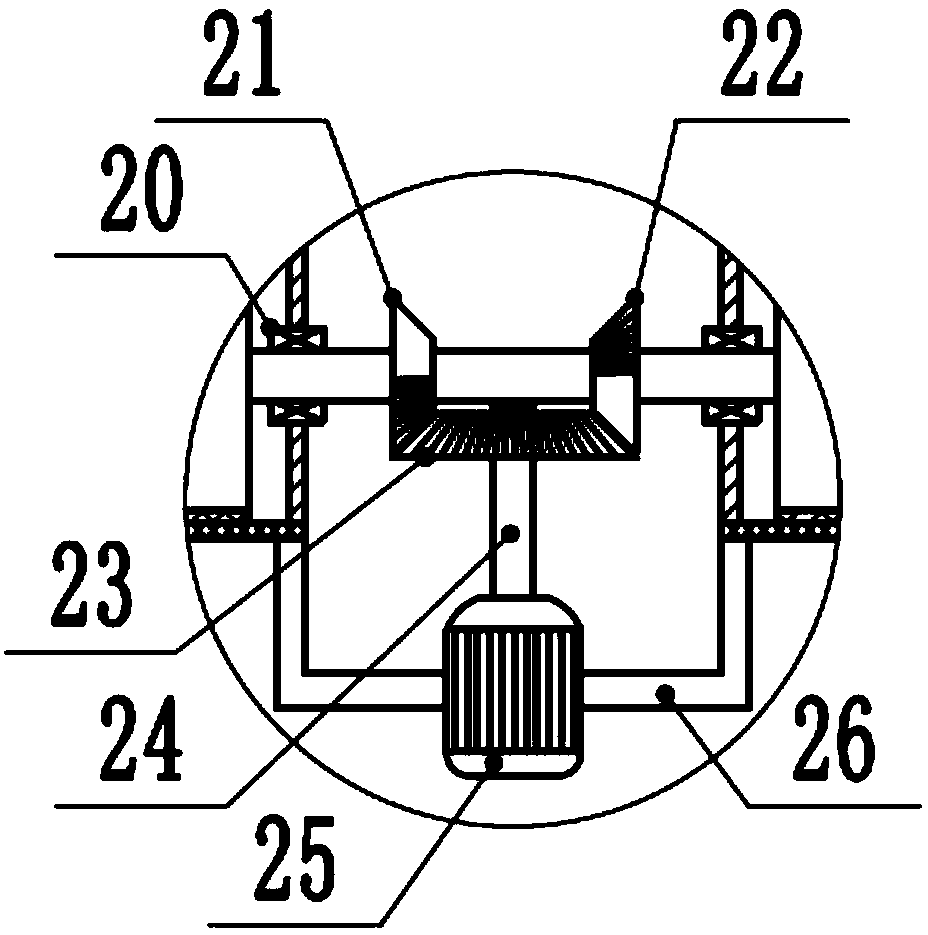

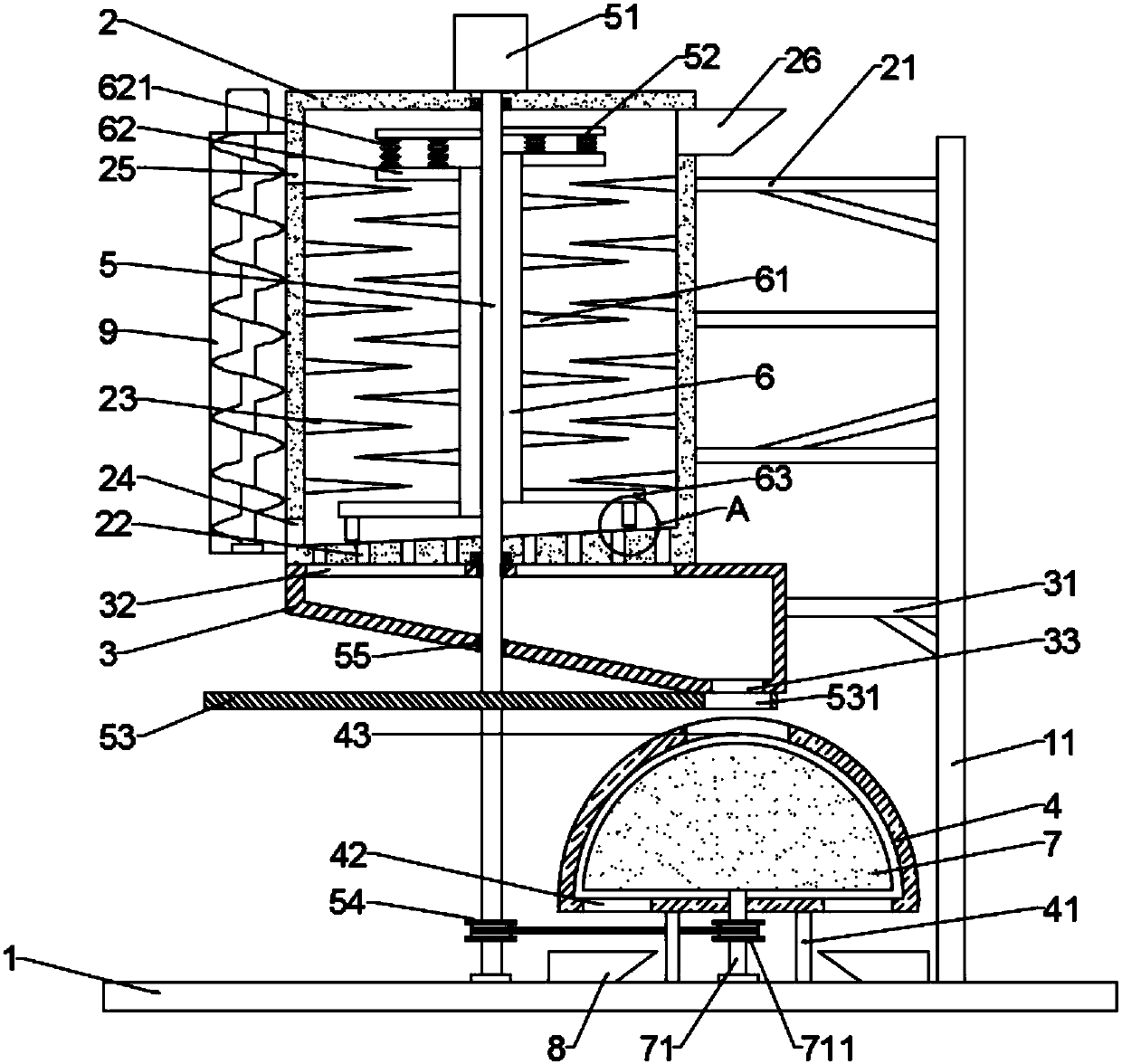

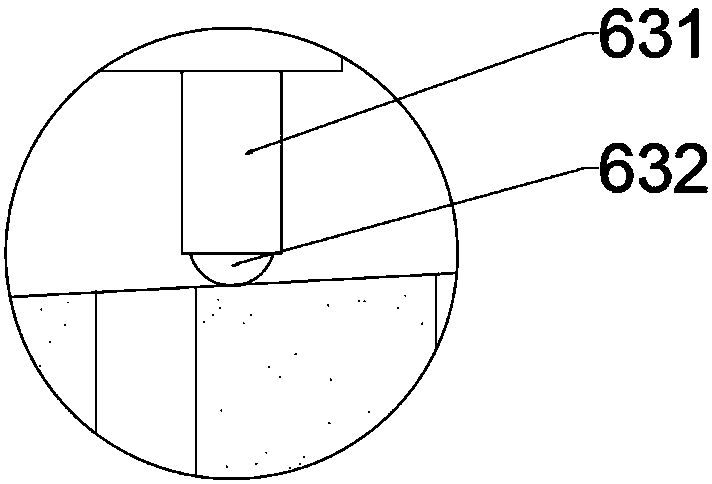

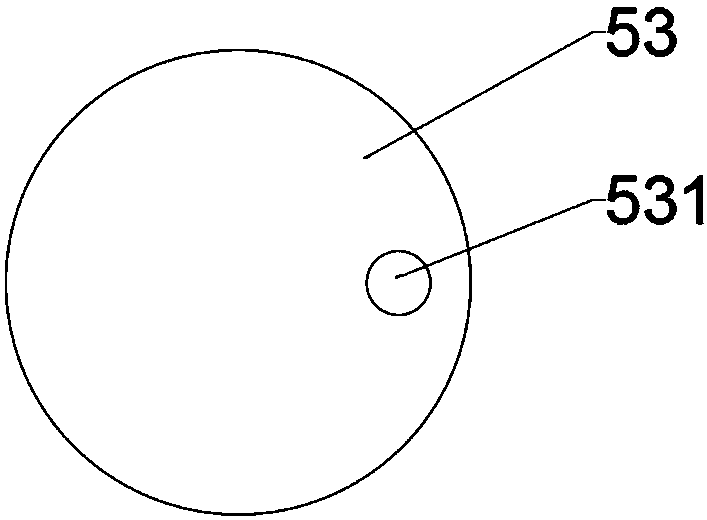

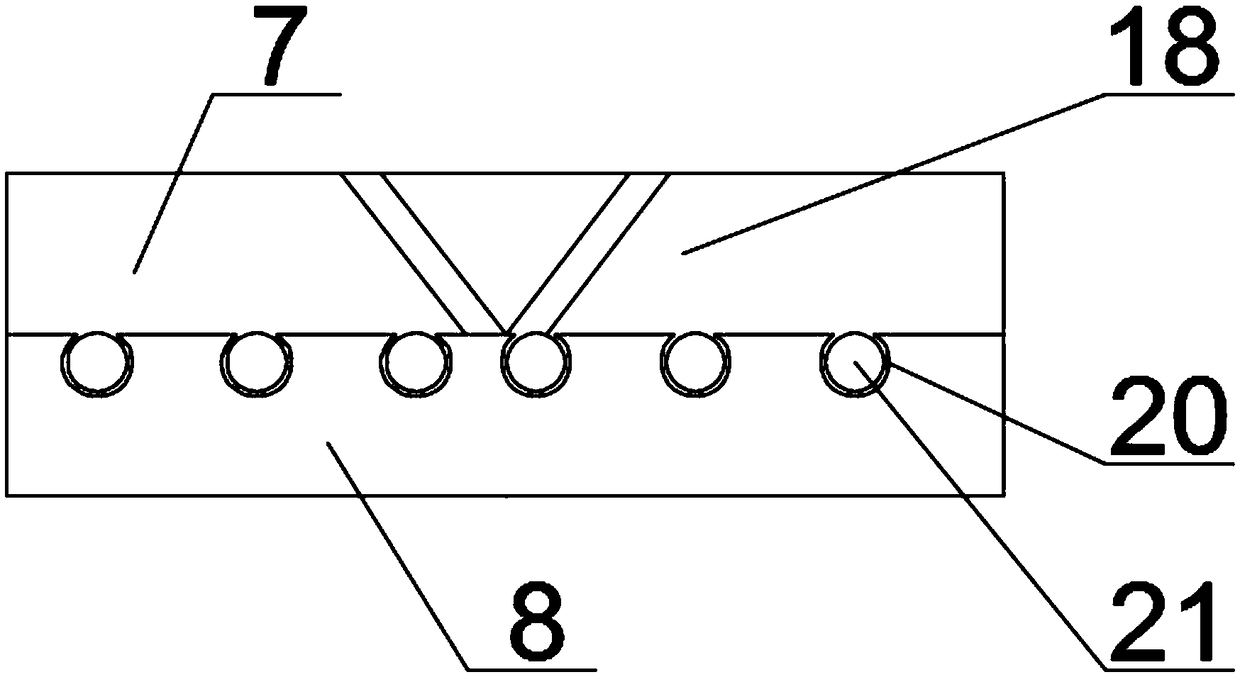

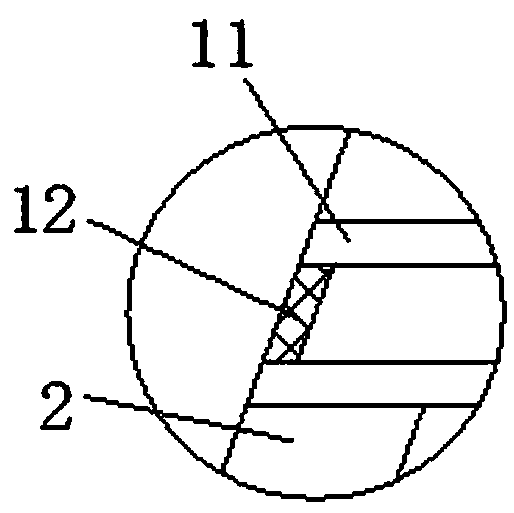

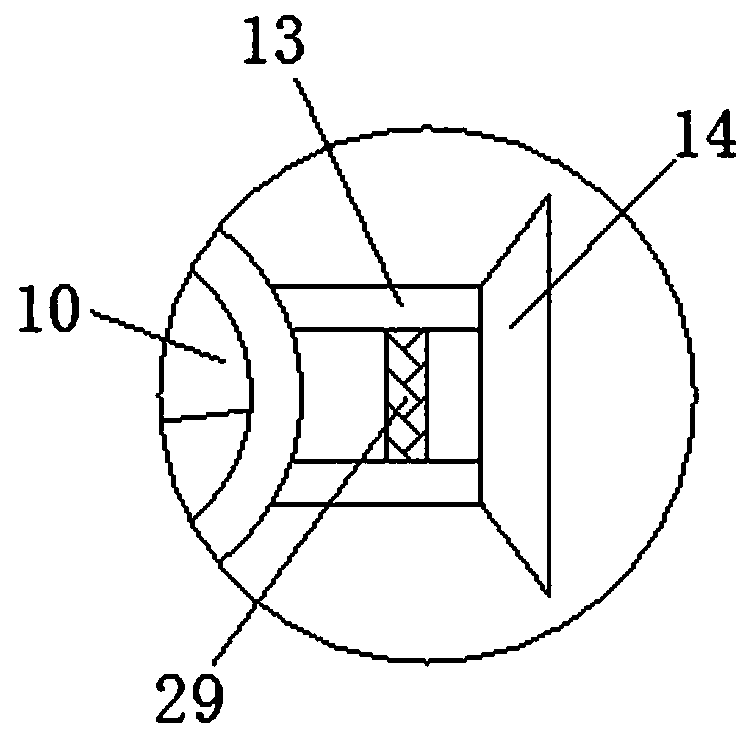

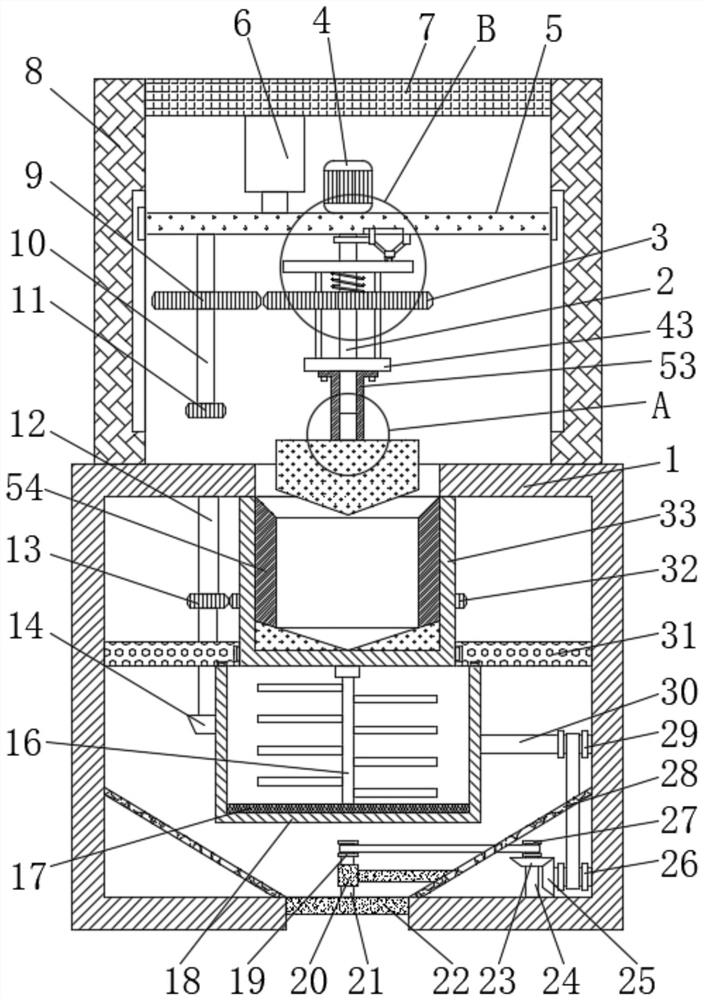

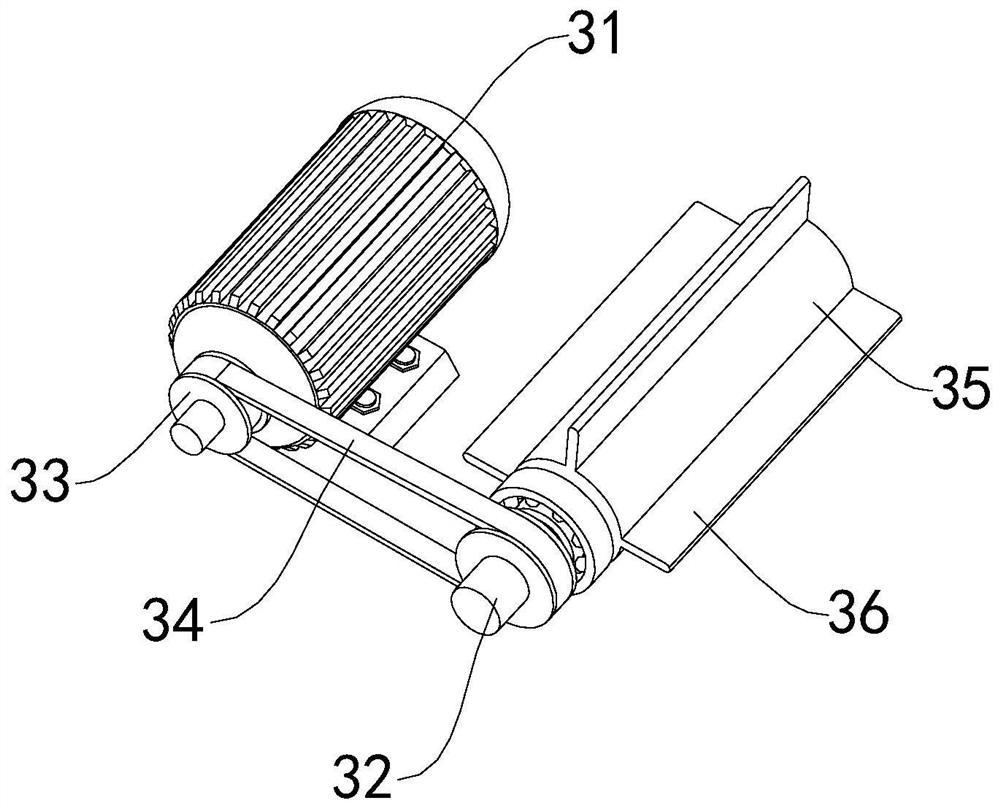

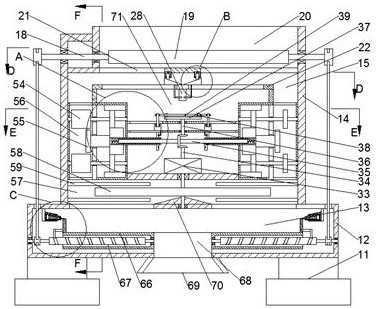

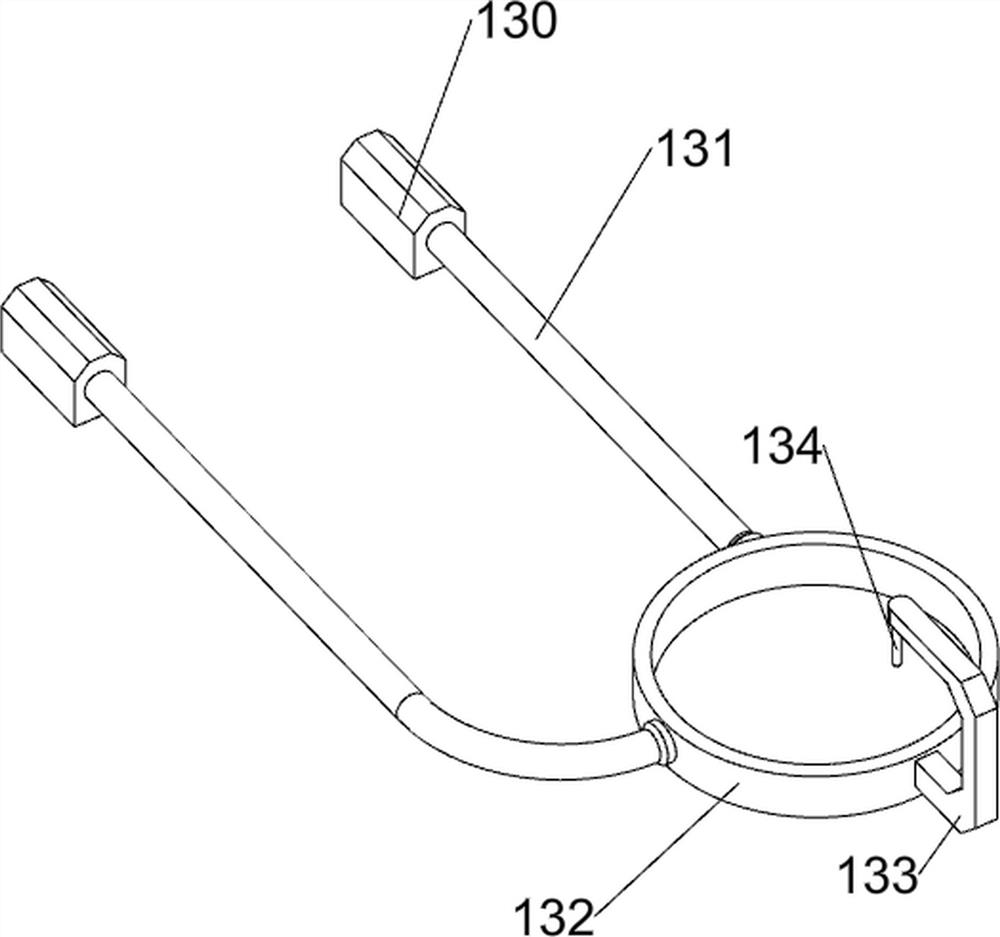

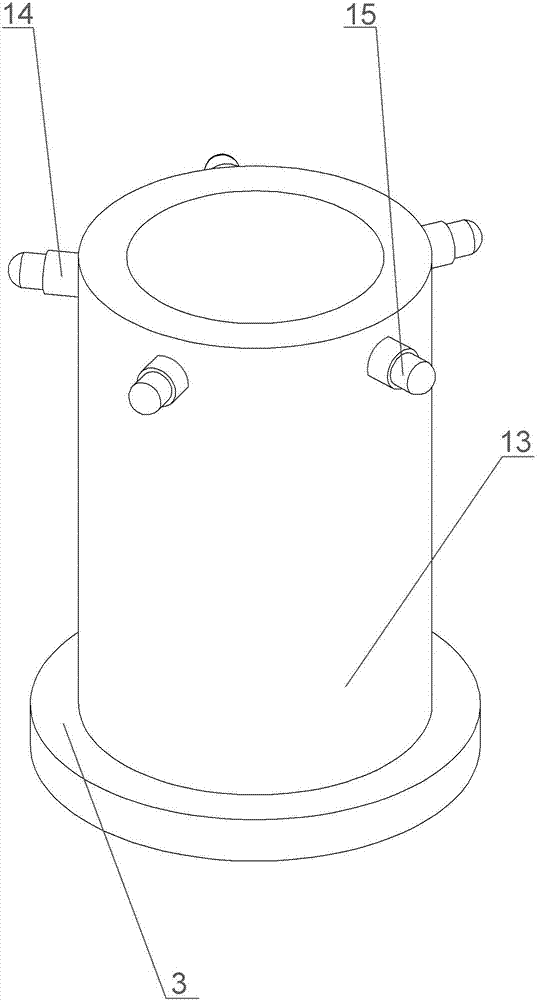

Pulverizing and grinding all-in-one machine for preparing Chinese herbs

ActiveCN107755050ARealize circular crushingGuaranteed uniformityGrain treatmentsDrive shaftMaterial transfer

The invention discloses a pulverizing and grinding all-in-one machine for preparing Chinese herbs. The pulverizing and grinding all-in-one machine comprises a pulverizing box, a material transfer boxand a grinding shell which are arranged on a base from top to bottom as well as a transmission shaft connected with the base in a rotating manner; the transmission shaft is disposed on the center of the pulverizing box, the transmission shaft is connected with a plurality of tool posts in a sliding manner, and the tool posts are provided with movable cutter blades; the material transfer box is fixed on the bottom of the pulverizing box, and the periphery of a shaft body, disposed below the material transfer box, of the transmission shaft is fixedly provided with a rotating baffle plate; the grinding shell is disposed below the right of the material transfer box; a grinding block is arranged in the grinding shell. By integrating a pulverizing step and a grinding step of the Chinese herbs, the working efficiency is increased; moreover, the Chinese herbs can be efficiently and thoroughly pulverized; the ground Chinese herb particles are high in uniformity.

Owner:武汉钧安制药有限公司

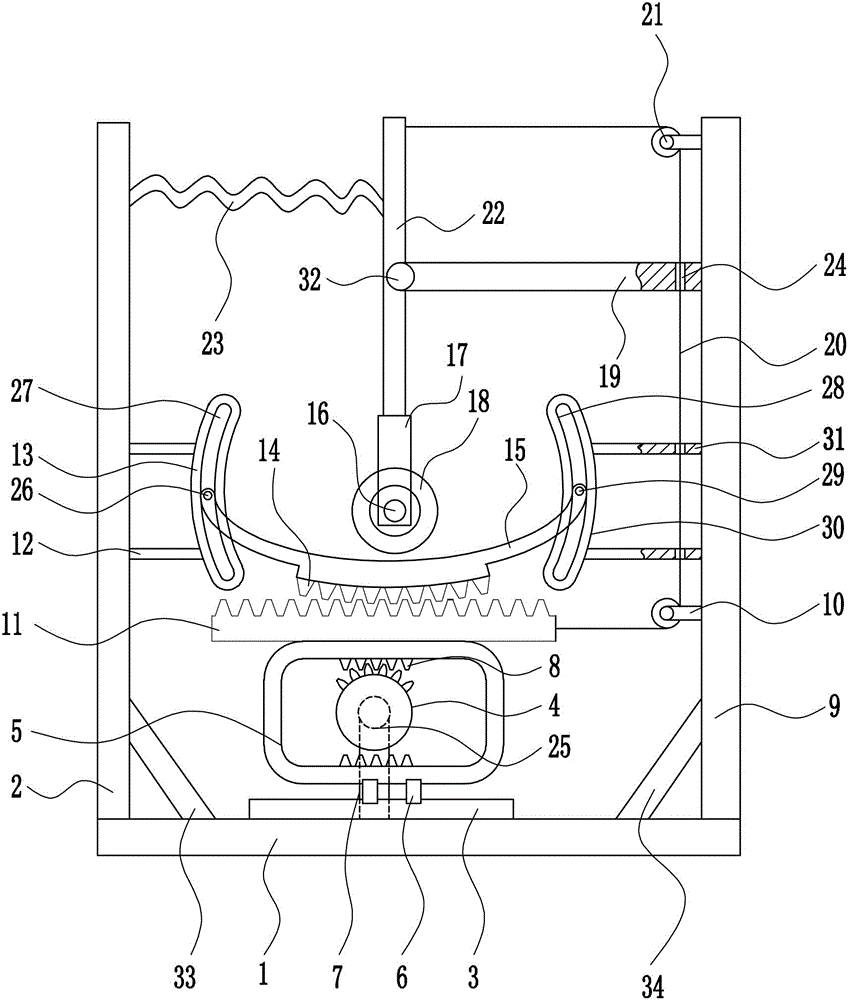

Preparation grinding device of activated carbon for sewage treatment

ActiveCN106552693ASimple structureGrind thoroughlyOther chemical processesGrain treatmentsActivated carbonEngineering

The invention relates to the technical field of sewage treatment and especially relates to a preparation grinding device of activated carbon for sewage treatment. The device has a simple structure, realizes thorough grinding and has small workload. In order to solve the above technical problems, the invention provides the preparation grinding device of activated carbon for sewage treatment. The device comprises a bottom plate, a left frame, a slide rail, a gear, a moving frame, a sliding block, a first support rod, a first rack, a right frame, a first fixed pulley, a second rack and a second support rod. The left end of the top of the bottom plate is welded to the left frame, the middle of the top of the bottom plate is welded to the first support rod, and the top of the first support rod is connected to a rotating motor through bolts. The device has the advantages of simple structure, thorough grinding and small workload, has good grinding effects, improves working efficiency and has high safety.

Owner:广东创晟控股集团有限公司

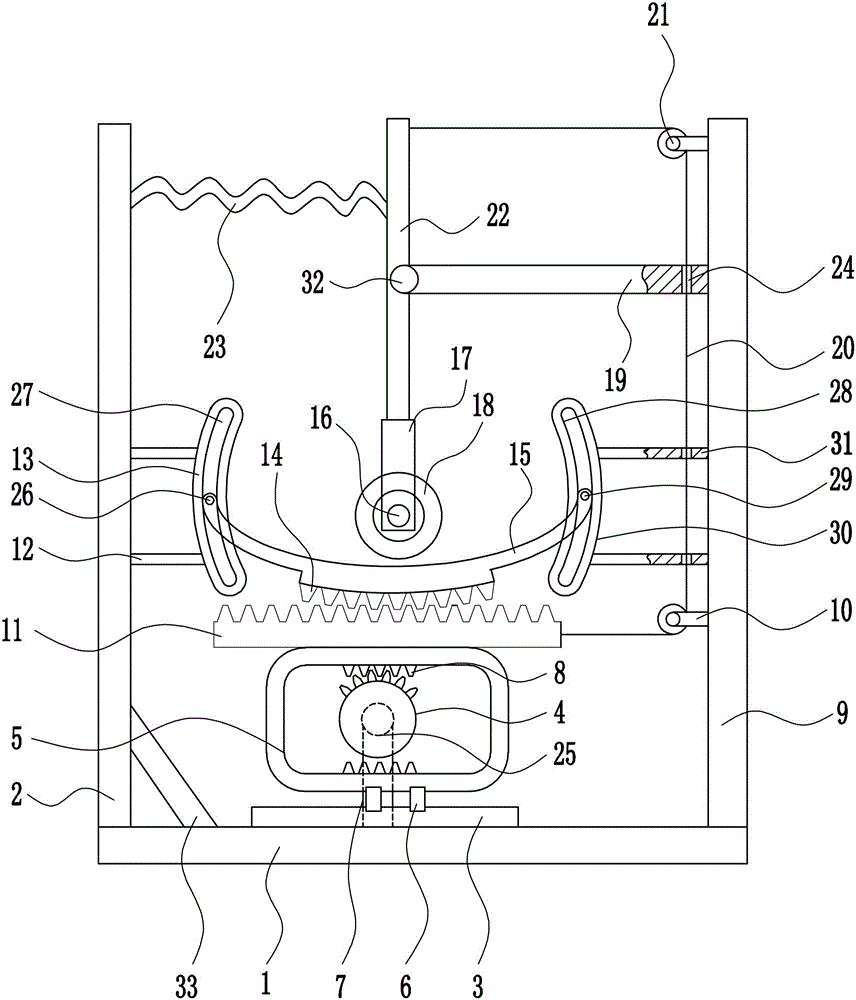

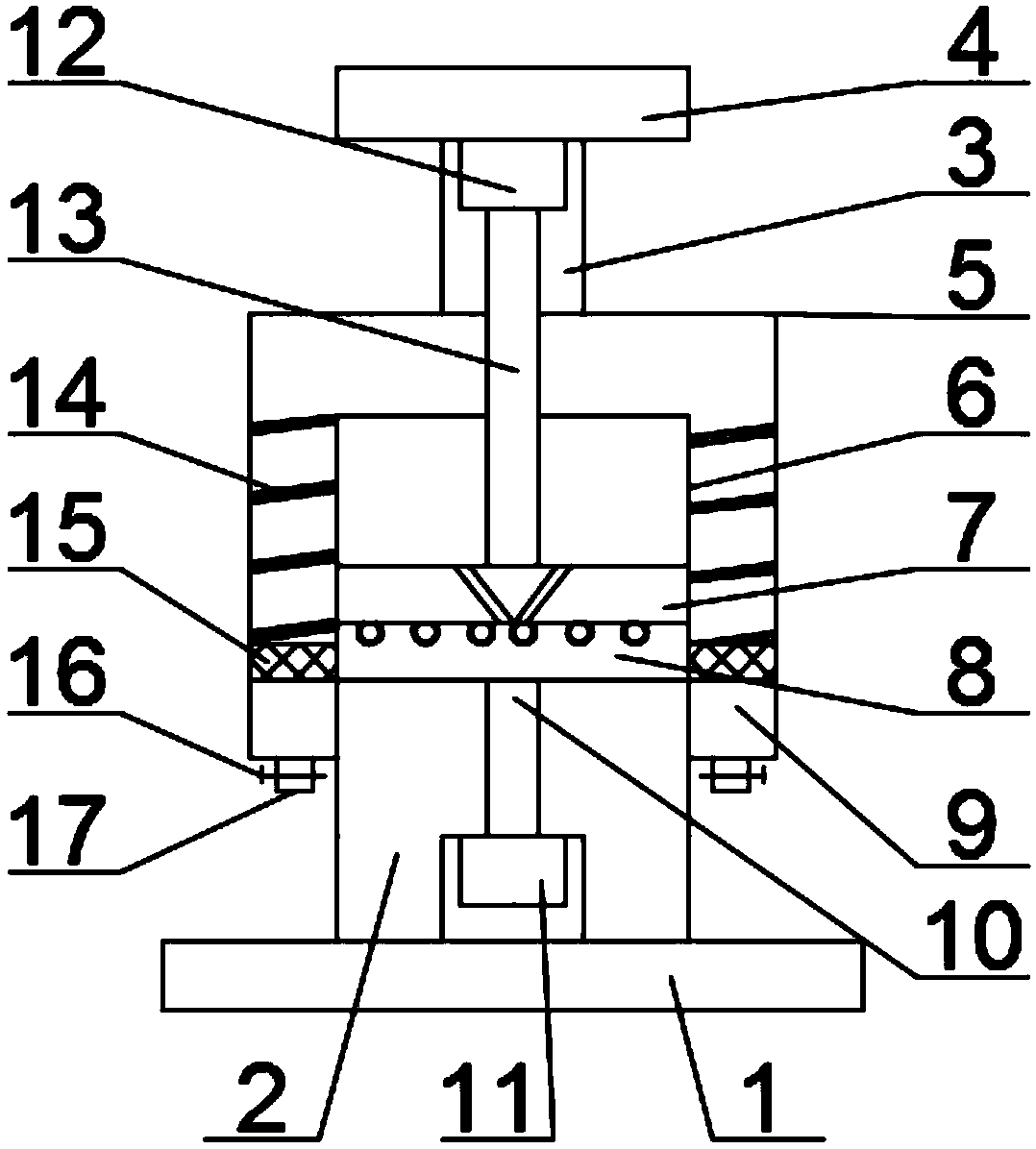

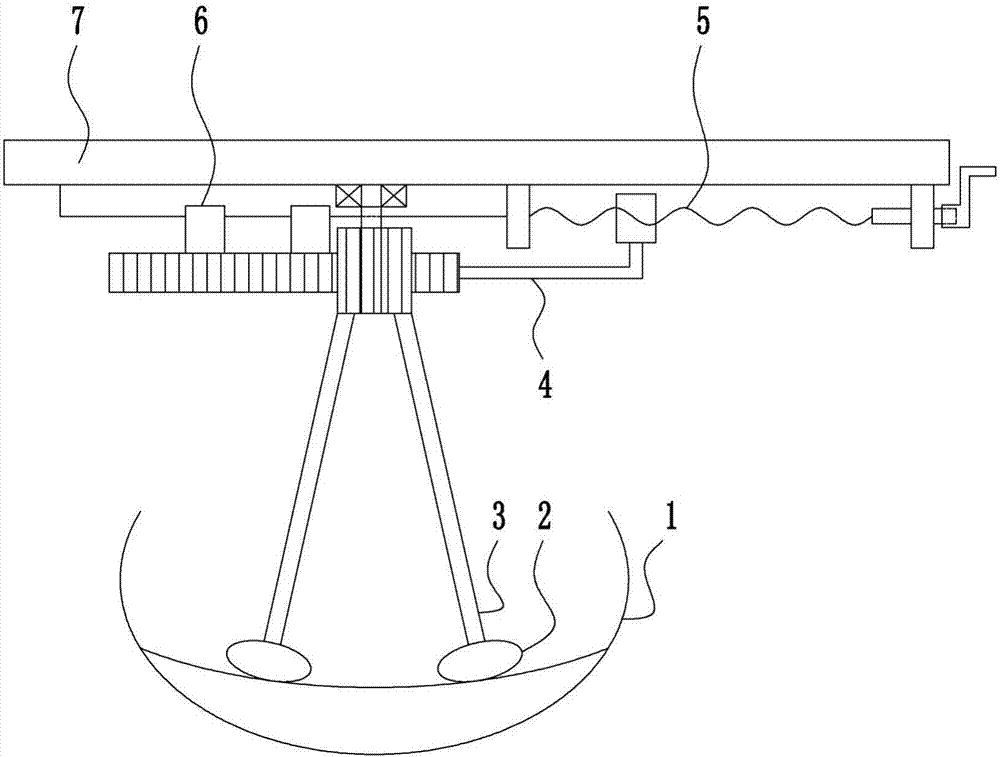

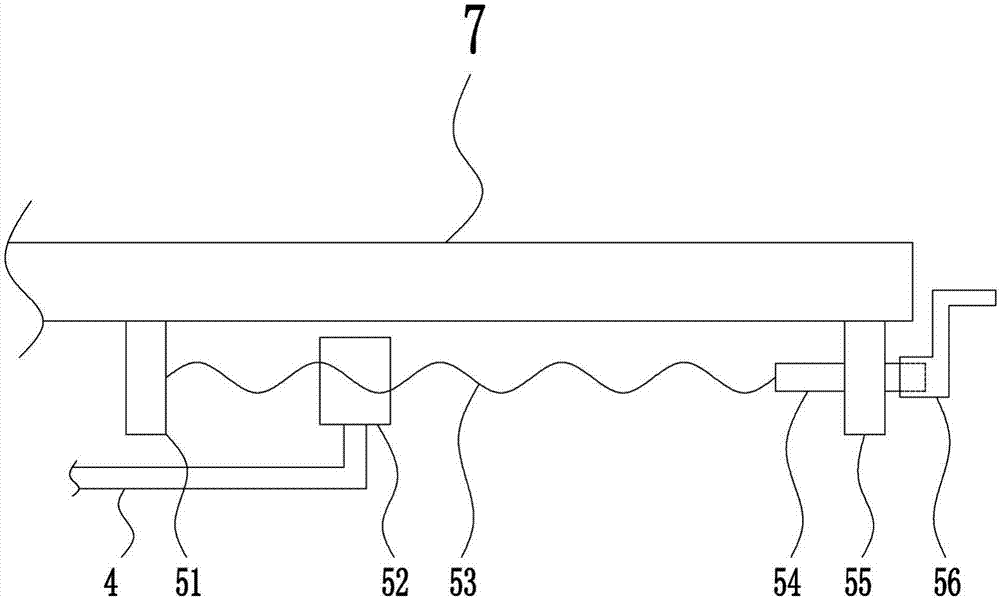

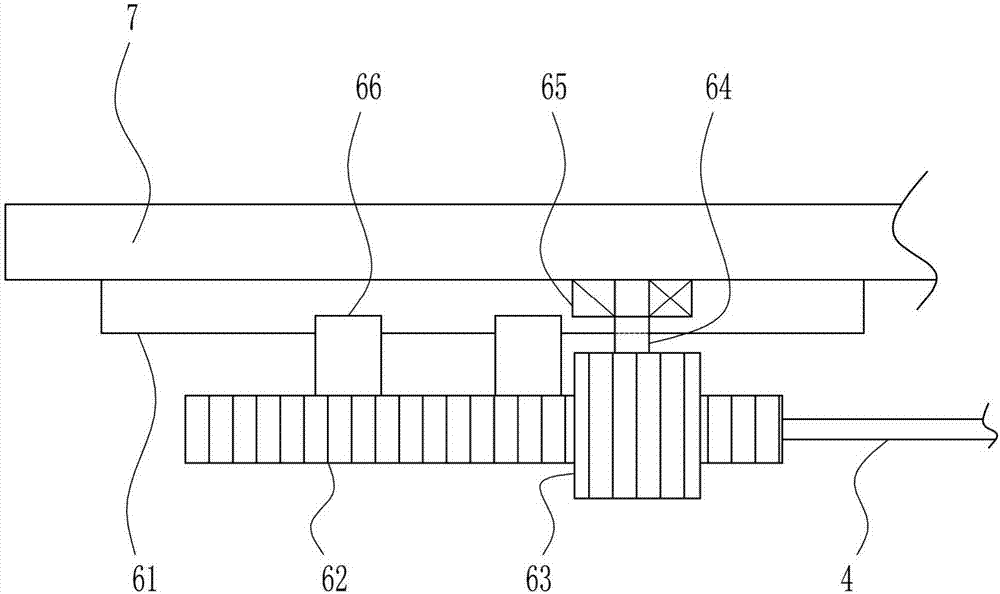

Efficient grinding device of Chinese herbal medicines of traditional Chinese medicine family

InactiveCN106669900ASimple structureEasy to operateGrain treatmentsTraditional medicineChinese herbology

The invention relates to a grinding device of Chinese herbal medicines of a traditional Chinese medicine family, in particular to an efficient grinding device of the Chinese herbal medicines of the traditional Chinese medicine family. The efficient grinding device of the Chinese herbal medicines of the traditional Chinese medicine family is simple in structure, convenient to operate and thorough in grinding. The efficient grinding device of the Chinese herbal medicines of the traditional Chinese medicine family comprises a base plate, a support, a collecting frame, a right frame, a grinding box, a rotary shaft, a bearing seat, a motor II, a sieving net, a grinding tube, an arc-shaped grinding disc, a large belt wheel, an eccentric rotary disc, a grinding gear, a connecting rod I, a flat belt, a connecting rod II, a top plate, a motor I and a small belt wheel; the right frame is installed on the right side of the top of the base plate, the top plate is installed at the top end of the right frame, and the connecting rod I is installed on the left side of the bottom of the top plate; and the connecting rod II is installed on the right side of the bottom of the top plate, and the bottom end of the connecting rod I is connected with the eccentric rotary disc. According to the efficient grinding device of the Chinese herbal medicines of the traditional Chinese medicine family, the effects of being simple in structure, convenient to operate and thorough in grinding are achieved.

Owner:叶诚帆

Coating grinding device

ActiveCN108722560AIncrease grinding timeGrind thoroughlyCocoaGrain treatmentsSpiral bladeElectric machinery

The invention relates to a coating grinding device and belongs to the technical field of coating production. The coating grinding device comprises a base, a support seat, support pillars, a support plate and an outer shell, wherein an inner shell is arranged in the outer shell; a first grinding plate is arranged on the bottom part of the inner shell; a material collecting chamber is arranged on the bottom part of the outer shell and is provided with a discharge hole and a discharge valve; a second grinding plate is arranged on the top part of the support seat and is connected with a first motor through a first rotary shaft; the first grinding plate is connected with a second motor through a second rotary shaft; and a spiral blade is arranged on the outer part of the inner shell. Accordingto the coating grinding device provided by the invention, through arranging a spiral groove and a grinding ball, the grinding time is prolonged, and the thoroughness in grinding is realized; and through arranging the spiral blade, a coating which does not meet the requirement is directly ground again so as to reach to the required grinding level at a time, so that the grinding efficiency is improved.

Owner:安徽漫画树涂料股份有限公司

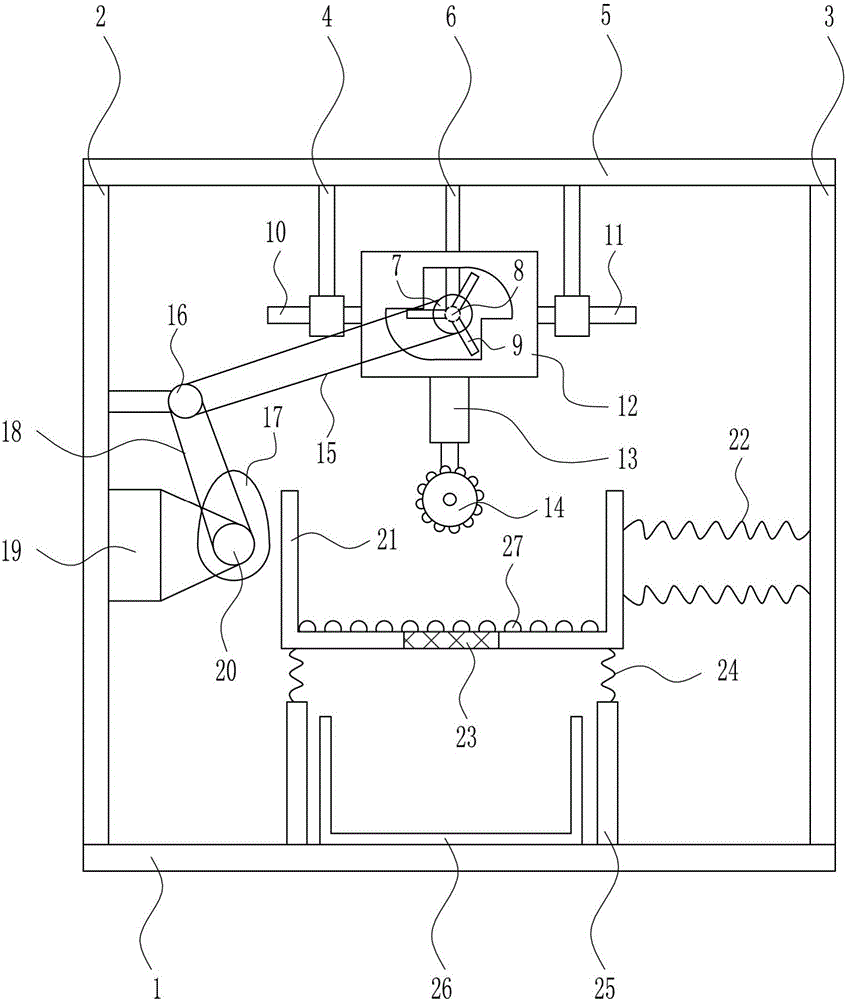

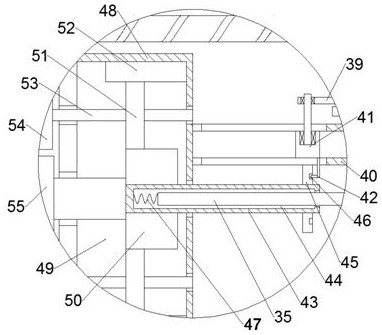

Fine grinding type traditional Chinese medicinal material processing device

ActiveCN107537662AImprove crushing and grinding efficiencyImprove grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a fine grinding type traditional Chinese medicinal material processing device. The fine grinding type traditional Chinese medicinal material processing device comprises a shell, a feeding hole, a bottom plate, a conveyor belt, a crushing mechanism and a grinding mechanism, wherein the shell is arranged at the upper end of the bottom plate; the feeding hole is arranged in the upper end of the shell; the conveyor belt is arranged below the feeding hole; the crushing mechanism is arranged below the left side of the conveyor belt; the crushing mechanism comprises an L-shaped plate, an incomplete gear B, a rack plate, a connecting rod, a crushing hammer, a crushing groove, a first spring, a sliding chute, a slide block, a second blanking hole, a third blanking hole and asleeve; the grinding mechanism is arranged below the crushing mechanism; the grinding mechanism comprises a cam, an incomplete gear A, a rotating motor, a grinding cavity, a grinding roll, a telescopic plate, strip-shaped teeth, a receiving port and a first blanking hole. The fine grinding type traditional Chinese medicinal material processing device has the advantages of simple structure, high grinding efficiency, complete grinding, good grinding effects and high practicability.

Owner:江西杏林白马药业股份有限公司

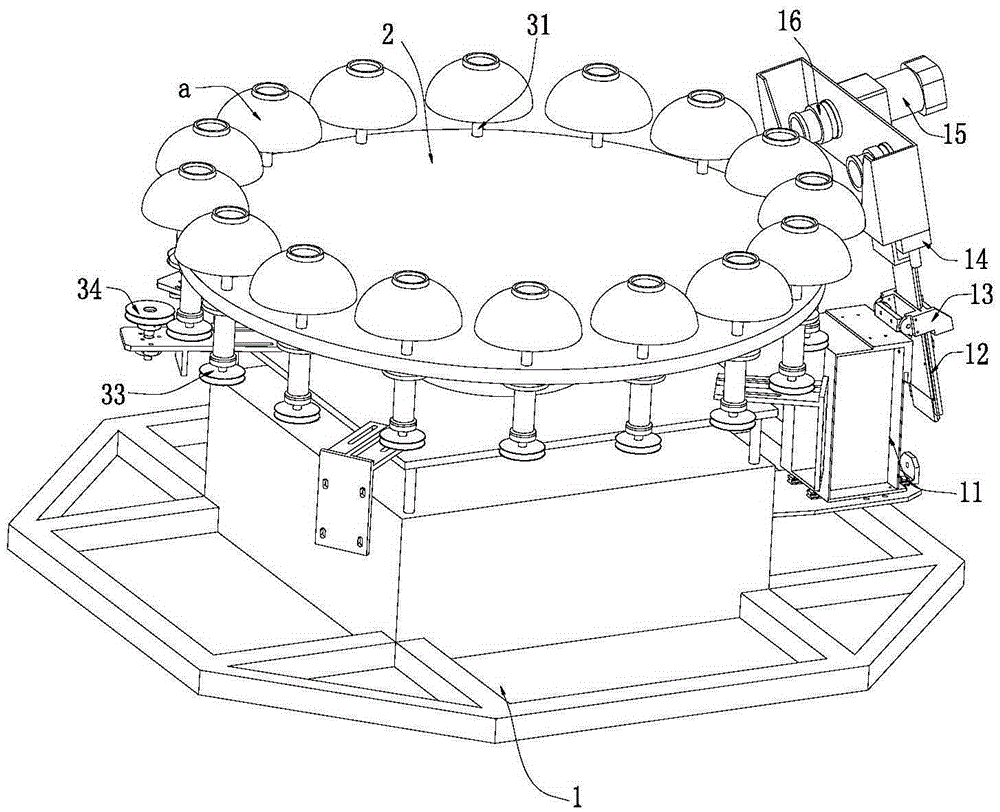

Ceramic edge grinding machine

ActiveCN105364662AGrind thoroughlyEnhance the edge effectEdge grinding machinesGrinding drivesEngineeringMachining

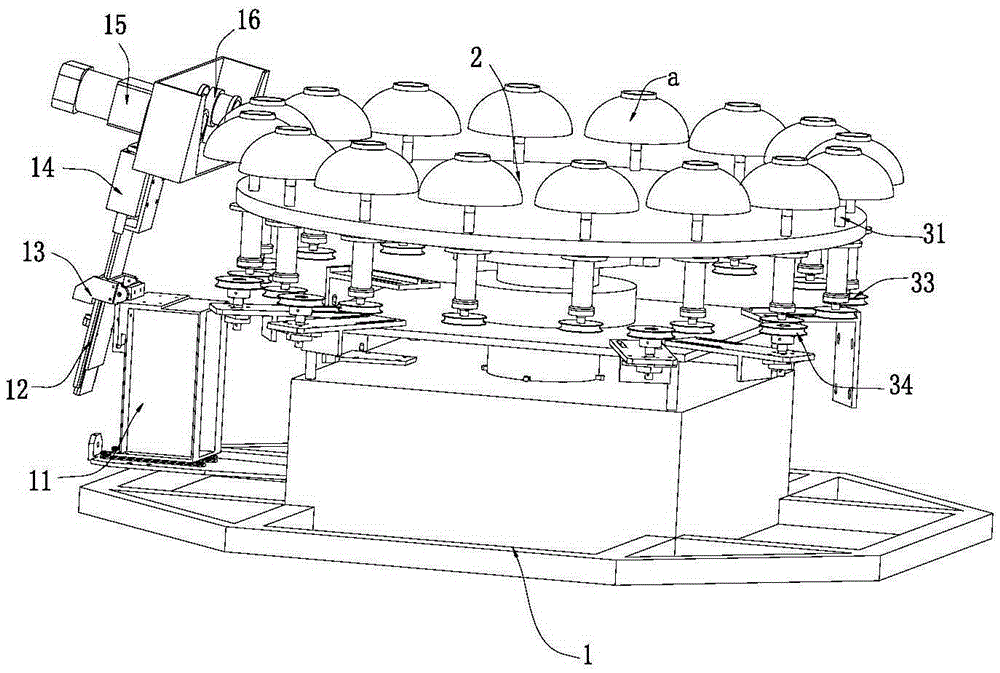

The invention relates to the field of ceramic machining equipment, in particular to a ceramic edge grinding machine. The ceramic edge grinding machine comprises a base, a revolution plate arranged on the base, a plurality of clamping assemblies used for fixing ceramic work-pieces to be ground, and a rotation assembly driving the clamping assemblies and the ceramic work-pieces, to be ground, on the clamping assemblies to rotate. The center of the revolution plate is located on the base and can rotate around the center in the circumferential direction, and the clamping assemblies are arranged along the edge of the revolution plate in the periphery direction; the base is provided with a telescopic air cylinder, the telescopic air cylinder is provided with an edge grinding assembly used for machining the ceramic work-pieces to be ground, and the telescopic air cylinder drives the edge grinding assembly to move back and forth in the axial direction. The ceramic edge grinding machine is novel in structure, and the effect of grinding edges of the ceramic work-pieces is good.

Owner:LONGQUAN JINHONG PORCELAIN

Grinding machine for cosmetic processing

PendingCN107790246ASolve the problem of incomplete grindingThoroughly grindGrain treatmentsPropellerDrive motor

The invention relates to the technical field of cosmetics, and discloses a grinding machine for cosmetic processing. The grinding machine for cosmetic processing comprises a processing box, wherein support frame legs are fixedly connected to the four corners of the bottom of the processing box; material inlet pipes are communicated to the left side and the right side of the top of the processing box; a drive motor is arranged at the top of the processing box; a transmission shaft is fixedly connected to the output shaft of the drive motor; and the bottom end of the transmission shaft penetrates through and extends into the processing box. According to the grinding machine for cosmetic processing, raw materials can be added in the processing box through the material inlet pipes, the drive motor is started, and the transmission shaft is driven to rotate; and stirring sheets are capable of effectively carrying out refining crushing on the raw materials, friction blocks facilitate to increase friction with the raw materials, a cutting knife facilitates to cut the massive raw materials into small blocks, triangular blocks and cutting teeth are capable of better carrying out auxiliary grinding, spiral stirring paddles are capable of carrying out spiral stirring for many times, and crushing balls facilitate to extrude the raw materials into a powder, so that more thorough grinding forthe raw materials is facilitated.

Owner:MYC PACKAGING TECH (SUZHOU) CO LTD

Grain grinding device for agricultural production

The invention discloses a grain grinding device for agricultural production. The grain grinding device for agricultural production comprises a shell, wherein a grinding shell is fixedly connected to the top part of the inner wall of the shell; a grinding motor is fixedly connected to the top part of the shell; a grinding rotary shaft is fixedly connected onto an output shaft of the grinding motor;and the bottom end of the grinding rotary shaft penetrates through the shell and extends into the grinding shell. According to the grain grinding device for agricultural production provided by the invention, through the interaction of the grinding shell, the grinding motor, the grinding rotary shaft, a grinding block, a feeding pipe, a grinding ball, a grinding plate, a fan, a filter screen, a sieve plate, an electric push rod, a rotary shaft and a grinding wheel, in the process of grinding grain, the grinding motor drives the grinding block to rotate, the grinding block drives the grinding ball and the grinding plate to grind the grain, and the fan is matched for blowing grain so as to enable the grain to turn over, so that the grain can be conveniently ground sufficiently; and then thegrain is re-ground through the grinding wheel so as to be sufficiently ground, so that the grain is thoroughly ground, and great convenience is brought for the grinding work of the grain.

Owner:广西永福金穗生态农业发展有限公司

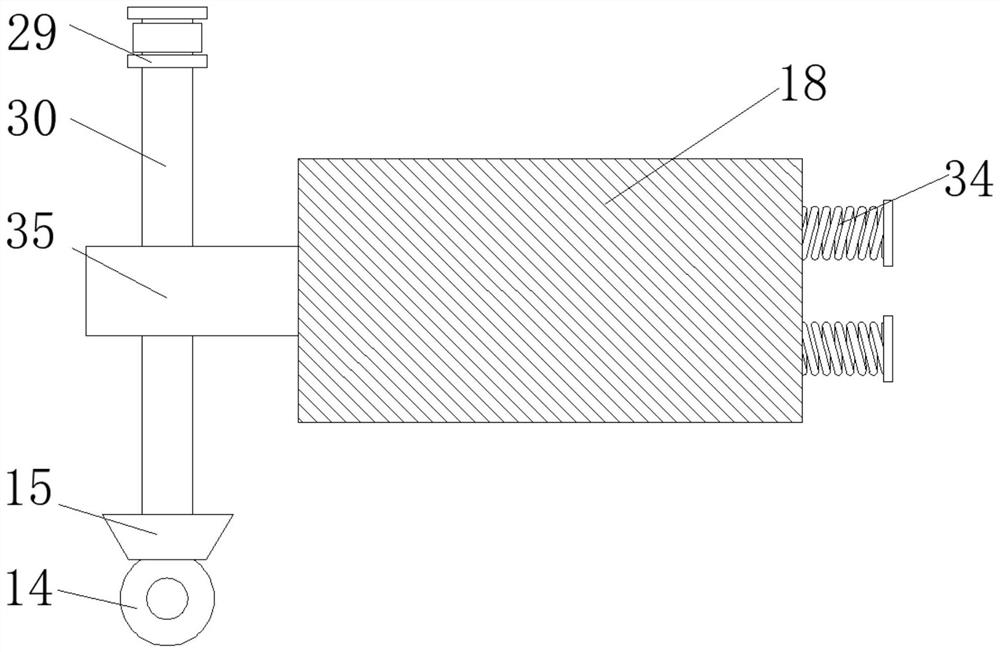

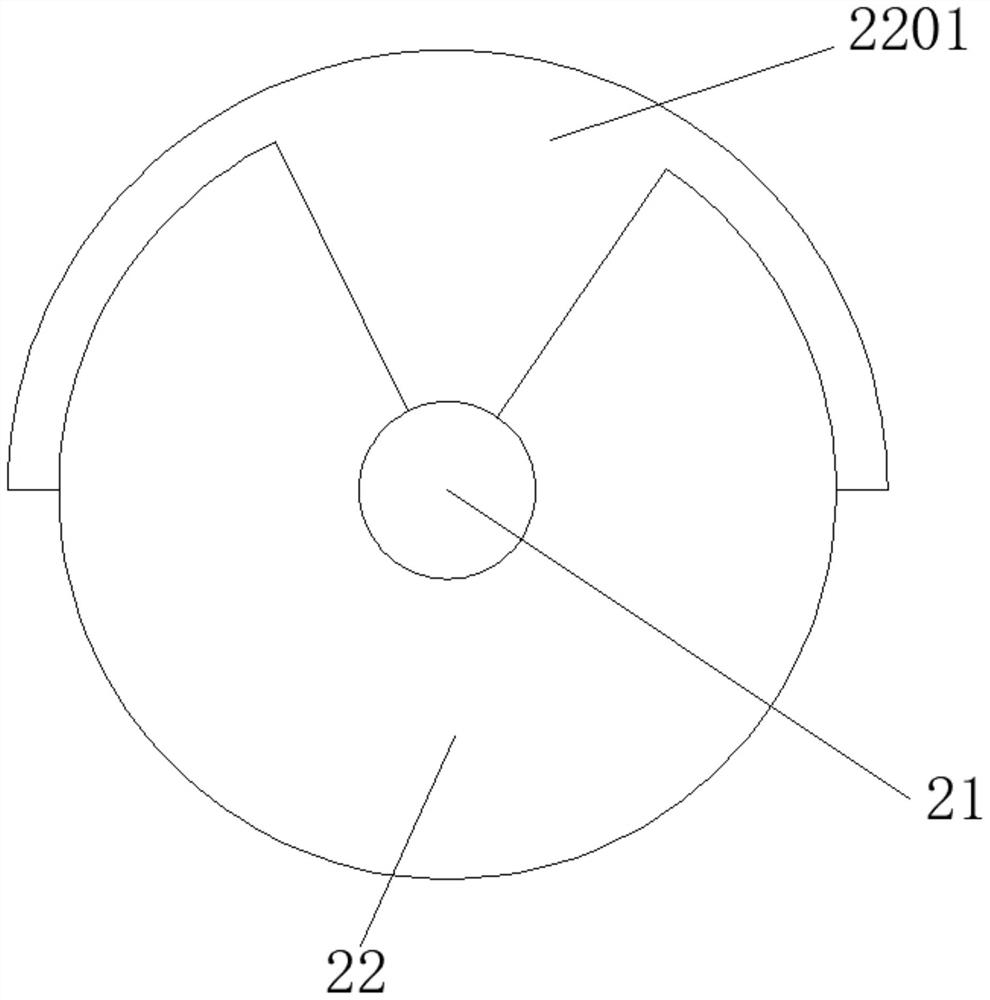

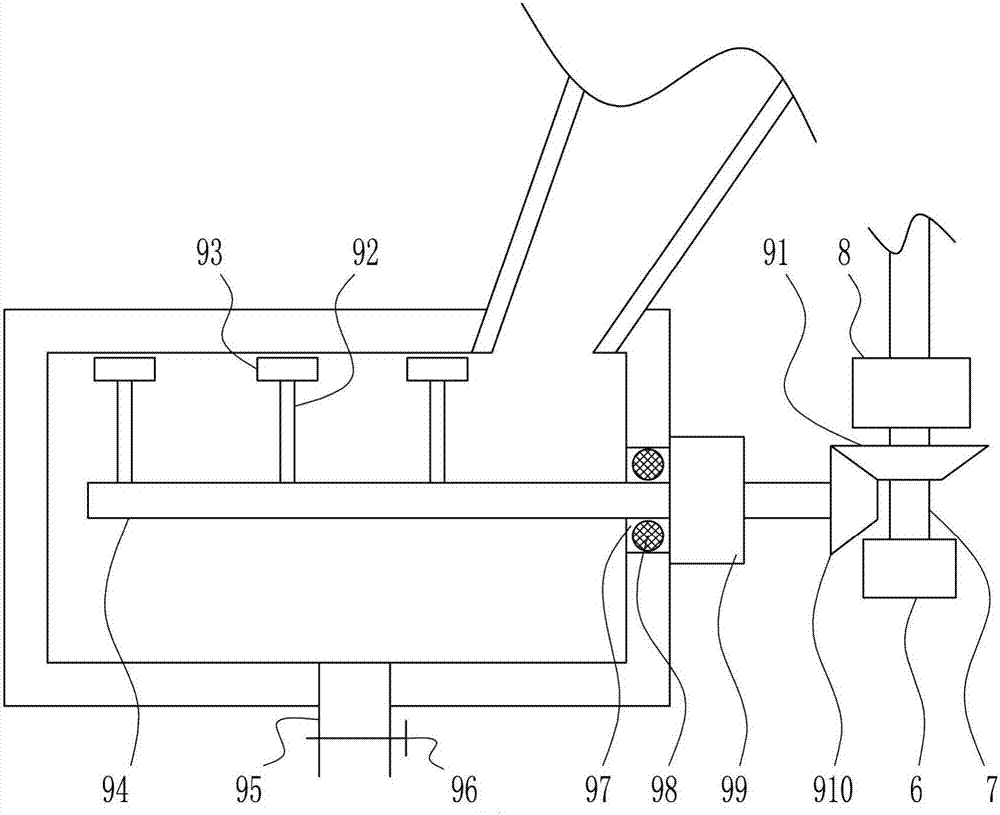

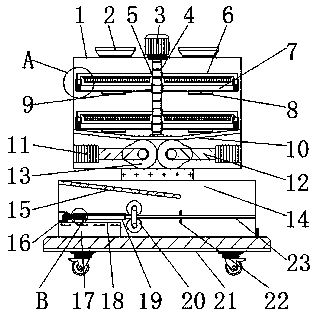

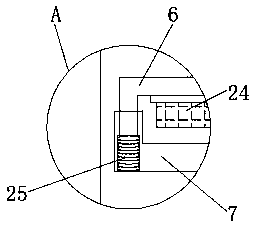

Crushing and grinding device for raw materials of Chinese herbal pieces

PendingCN108714475AScientifically Reasonable CrushingScientific and reasonable structureCocoaGrain treatmentsDrive wheelDrive shaft

The invention discloses a crushing and grinding device for the raw materials of the Chinese herbal pieces. The crushing and grinding device comprises a vehicle body, a crushing chamber, a grinding chamber, a crushing knife, a first transmission shaft, a second rotating shaft, static millstones, rotating millstones, a driving wheel, a driven wheel, a first motor, a second motor, a vibrating motor,a vibrating plate and travelling wheels; the crushing chamber is formed in the upper portion of the vehicle body, the first motor connected with the upper end of the crushing chamber is connected withthe crushing knife through the first transmission shaft in the crushing chamber, and the grinding chamber is formed in the lower portion of the crushing chamber; and the static millstones are arranged in the grinding chamber, the second transmission shaft is fixedly connected with the rotating millstones, the vibrating plate is arranged at the lower portion of the grinding chamber, the lower endof the second transmission shaft is connected with the driven wheel, the second motor is arranged on the right side of the driven wheel, the driving wheel is arranged below the second motor, and the travelling wheels are arranged at the lower portion of a bottom plate of the vehicle body. By means of the crushing and grinding device, the integrated operation of crushing and grinding of the Chineseherbal medicine can be achieved, the crushing and grinding device is simple in structure, low in production cost and short in grinding and crushing time.

Owner:河南豫博药业科技有限公司

Material crushing and fine grinding device

The invention provides a material crushing and fine grinding device. The device comprises a crushing box and a grinding box; a feed port is formed in the right side of the upper surface of the crushing box; a rotating roller is arranged in middle in the crushing box; the outer surface of the rotating roller is fixedly connected with an impact hammer; a first impact plate and a second impact plateare arranged on the upper side in the crushing box; a fixed block is arranged on the left side in the grinding box; the right side of the fixed block is fixedly connected with a grinding plate througha buffer spring; grinding rollers are uniformly and movably connected to the right side in the grinding box; grinding wheels are arranged on the outer surfaces of the grinding rollers; a filter screen is arranged on the lower side in the grinding box; and a discharge port is fixedly connected under the filter screen. The device overcomes the defects in the prior art, and is reasonable in design and compact in structure; through coaction between the impact hammer and the first impact plate, the second impact plate, materials are crushed through continuous collision; and through the effect of movable connection between the grinding wheels and the grinding plate, the materials are finely grinded.

Owner:张琴

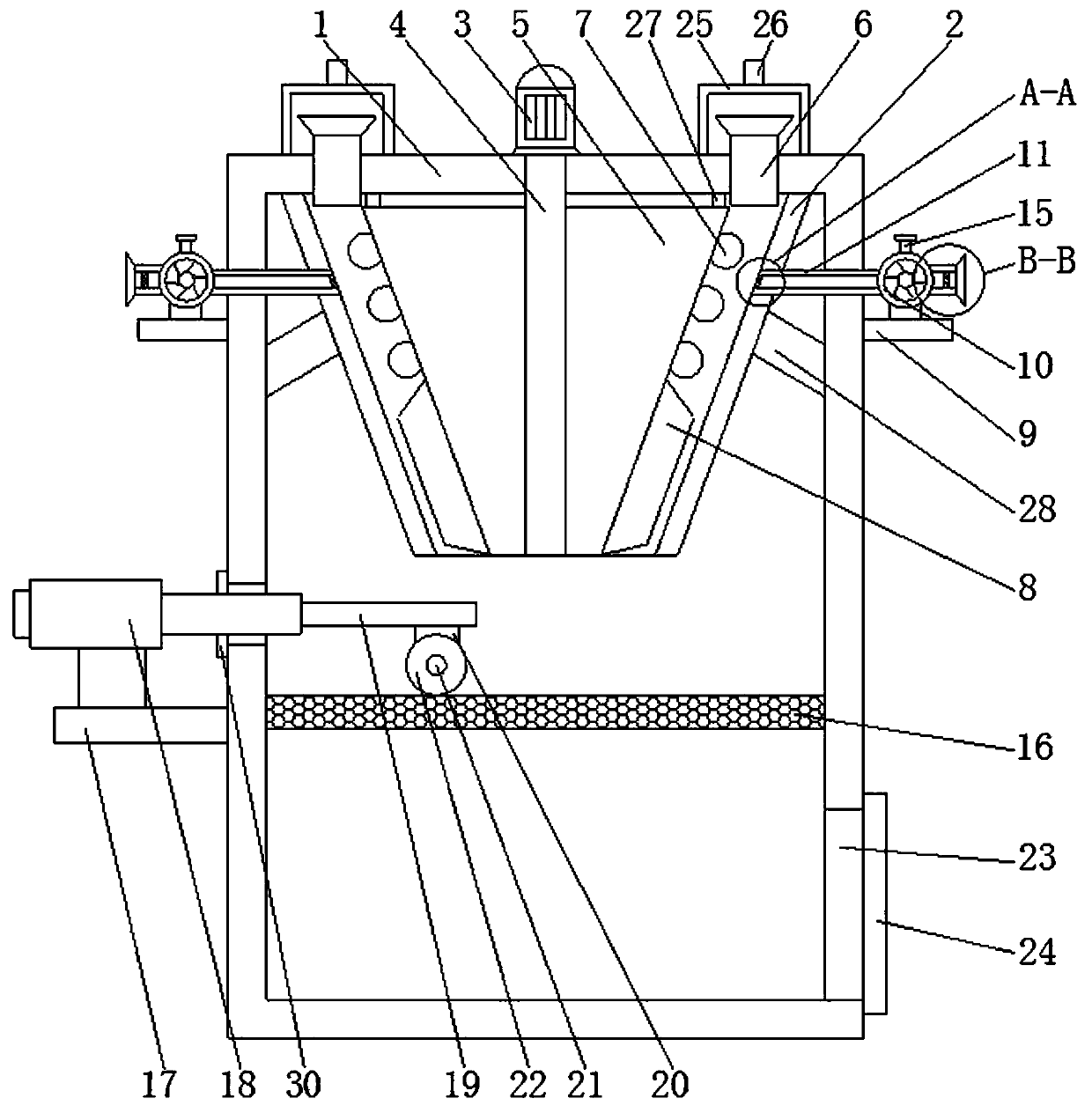

Lifting type water-based coating processing device

InactiveCN113441067AChange angleImprove grinding effectRotary stirring mixersMixer accessoriesElectric machineEngineering

The invention discloses a lifting type water-based coating processing device, relates to the technical field of water-based coating processing, and provides the following scheme for solving the problems of insufficient raw material grinding and the like: the lifting type water-based coating processing device comprises a first box body, a driving motor drives a first rotating shaft to rotate, the first rotating shaft drives a cam to rotate, the cam pushes a moving block to slide in a horizontal chute when rotating, and then the included angle between a first connecting rod and a second connecting rod is changed; the first connecting rod and the second connecting rod push a supporting base to ascend and descend, a buffer wheel on the lower portion of a lifting base pushes a first lifting disc and a second lifting disc to ascend and descend integrally, and then a grinding hammer is driven to rotate in a grinding box in a lifting mode; and raw materials located in the grinding box can fall into the bottom of the grinding box after being ground between the grinding hammer and a grinding cylinder, so that the raw materials passing through the grinding box can be ground, and the grinding effect is greatly improved.

Owner:高雪梅

Grinding device for phosphate processing

InactiveCN110385186AGrind thoroughlyFully groundedDrying gas arrangementsGrain treatmentsPhosphatePulp and paper industry

The invention discloses a grinding device for phosphate processing. The grinding device comprises a box body, a baffle, a filter net, a spring and a third grinding roller, a feed port is formed in thetop of the box body, the baffle is located below a first grinding roller, a screen is fixedly arranged at the bottom of the baffle, a grinding cylinder is arranged on the inner side of the box and isconnected to the baffle through the screen, the filter net is fixed in the box body, a micro vibration motor is connected to one end of the filter net, a discharge plate is fixedly arranged at the bottom of the inner side of the box body, the third grinding roller is located between the filter net and the discharge plate, and an air bellow is arranged on one side of the box body. According to thegrinding device for phosphate processing, three grinding rollers of different specifications are arranged from top to bottom, crystals are ground into powder through the baffle, the filter net and the discharge plate in the box body, and a fan and a resistive heater are arranged at the positions, on one side of the box body, in the air bellow, so that the ground crystals are aired and dried.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

Efficient plastic grinding device for manufacturing of electronic product shell

The invention relates to an efficient plastic grinding device, in particular to an efficient plastic grinding device for manufacturing of an electronic product shell. The efficient plastic grinding device for manufacturing of the electronic product shell aims to achieve the technical effects of being high in work efficiency and achieving complete grinding. The efficient plastic grinding device for manufacturing of the electronic product shell comprises a base plate, a support, a left rack, a first connecting rod, a rolling box, a feeding hopper, a discharging pipe and the like. The left frame is welded to the left side of the top of the base plate. The first connecting rod is welded to the bottom of the right side of the left frame. The right end of the first connecting rod is hinged to the rolling box through a hinged component. A rolling device is connected to the rolling box in a bolted manner. According to the efficient plastic grinding device for manufacturing of the electronic product shell, a breaking device, the rolling device and a pushing device are controlled to work, an electric push rod is controlled to work, and the electric push rod drives a first installation plate to work for primary breaking.

Owner:徐州聚西廷新型材料科技有限公司

Dye grinding device for leather dyeing

The invention relates to a dye grinding device, in particular to a dye grinding device for leather dyeing. According to the technical problem to be solved, the dye grinding device for leather dyeing is provided. In order to solve the technical problem, the dye grinding device for leather dyeing is provided, and comprises a support, a first bearing pedestal, a first rotating shaft, a first small belt pulley, a first flat belt, a second bearing pedestal, a second rotating shaft, a second small belt pulley, a box body and the like. A grinding body is arranged in the middle of the right side wall of the interior of the support, first penetrating holes are formed in the middle of the top and the middle of the bottom of the grinding body, and first sealing rings are arranged in the first penetrating holes. A grinding box is arranged inside the grinding body, and a first rubber guide sleeve is arranged in the middle of the top of the grinding box. The dye grinding device for leather dyeing achieves the effects that dye grinding operation is more sufficient and more thorough, and ground dye is fine and smooth, the dye coloring efficiency is improved, the phenomenon that due to the fact that dye is coarse, leather is damaged is avoided, the dye recovery efficiency is high, and the grinding efficiency is high.

Owner:湖州东方皮革有限公司

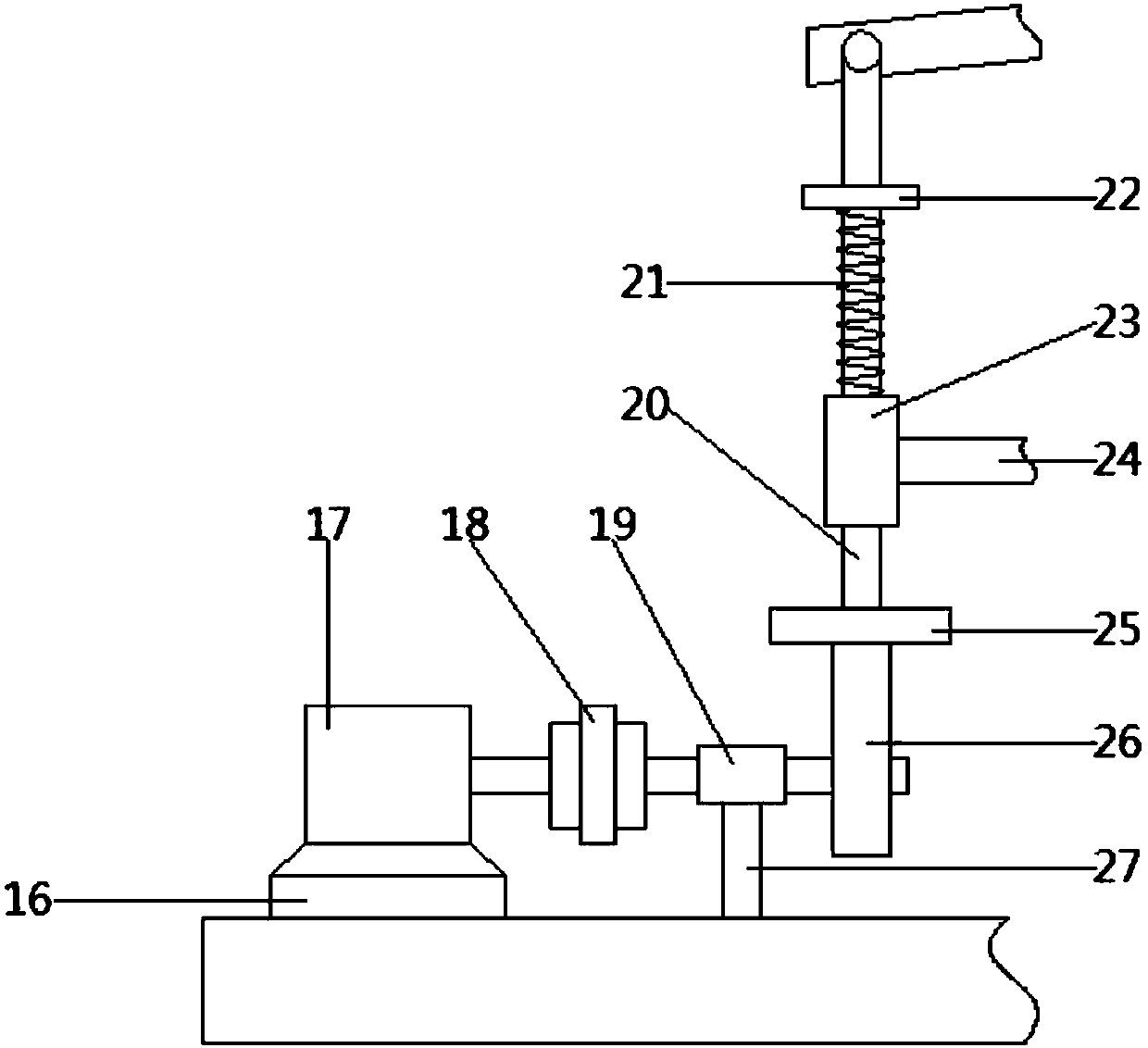

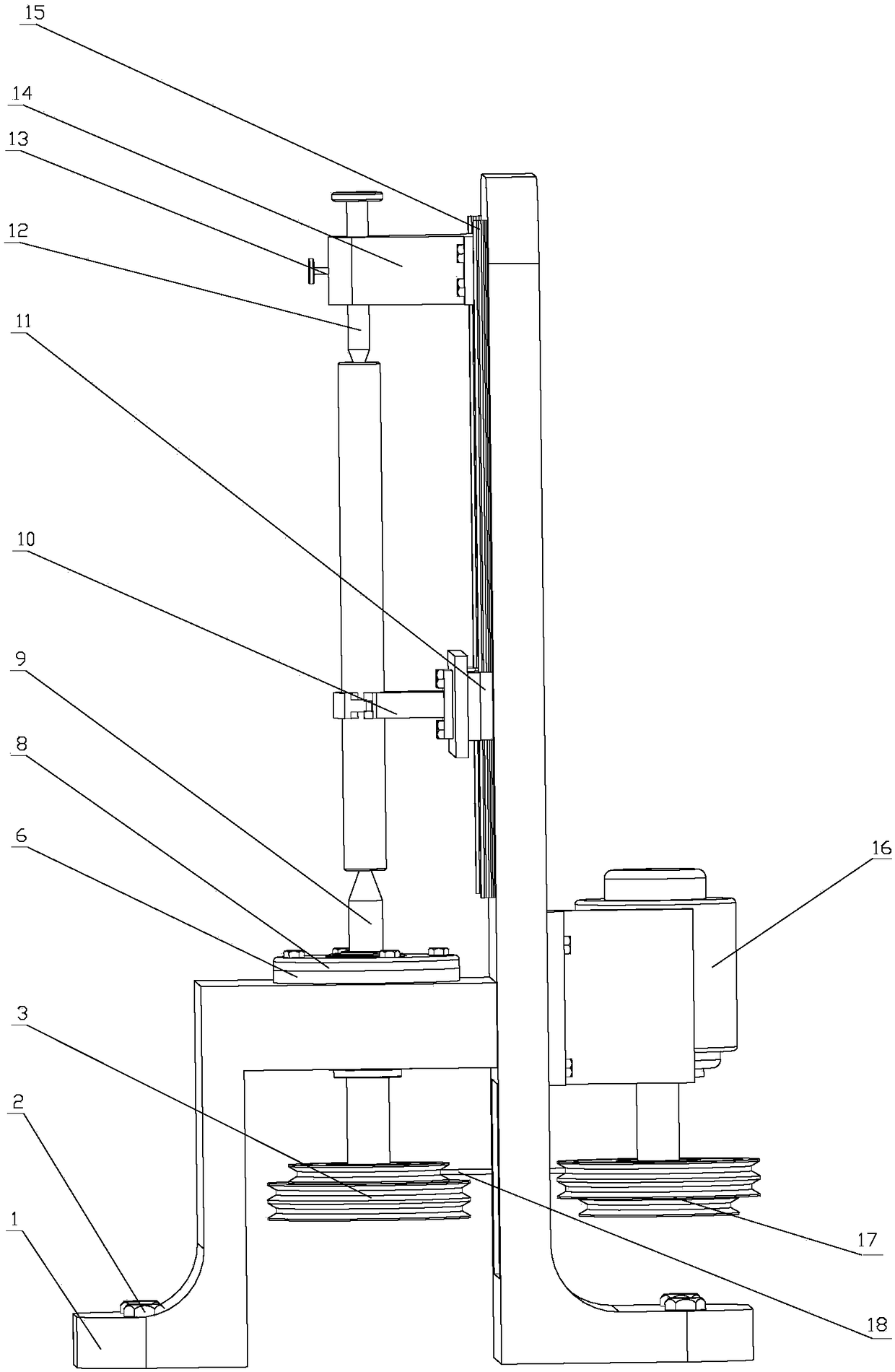

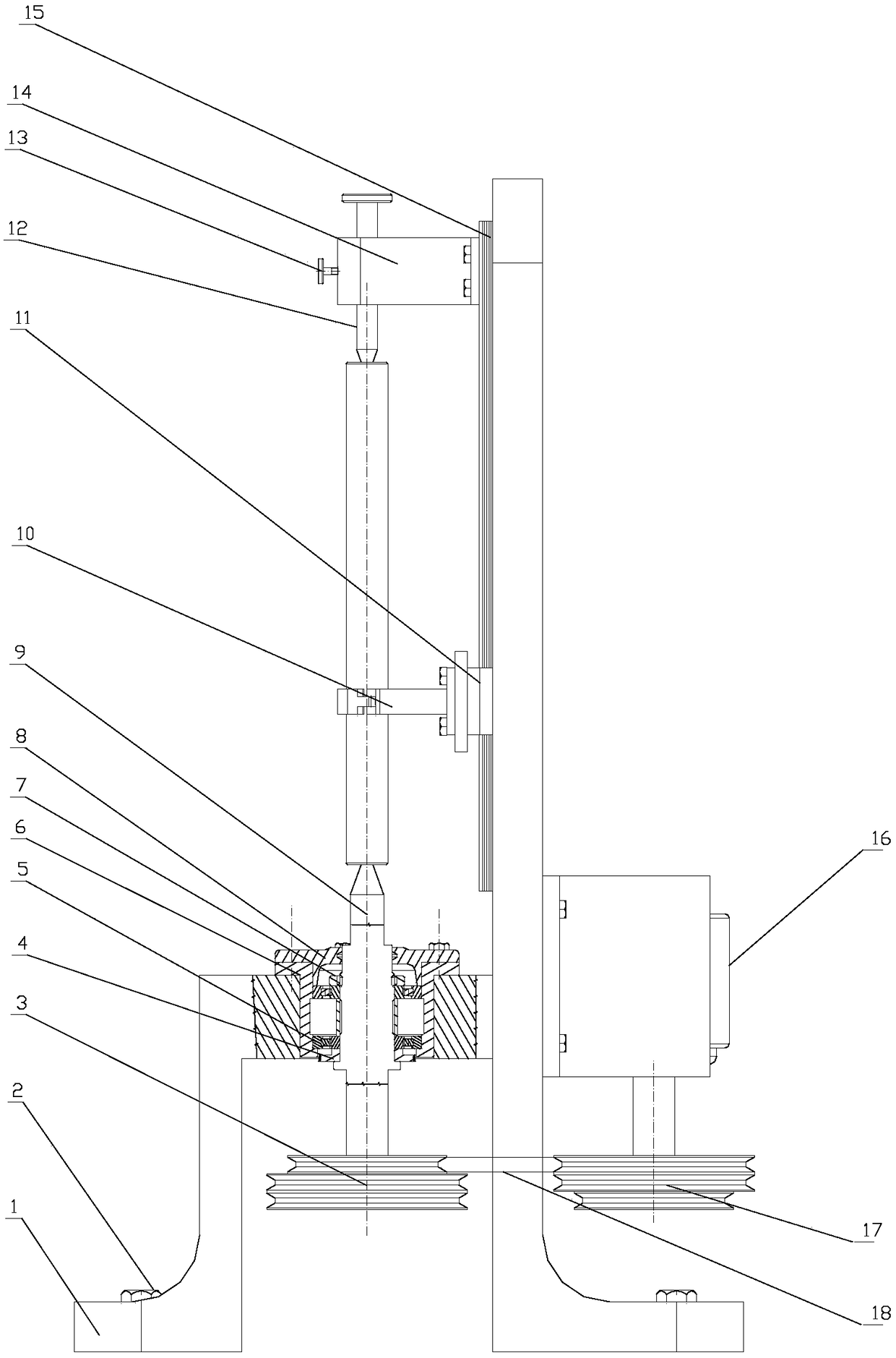

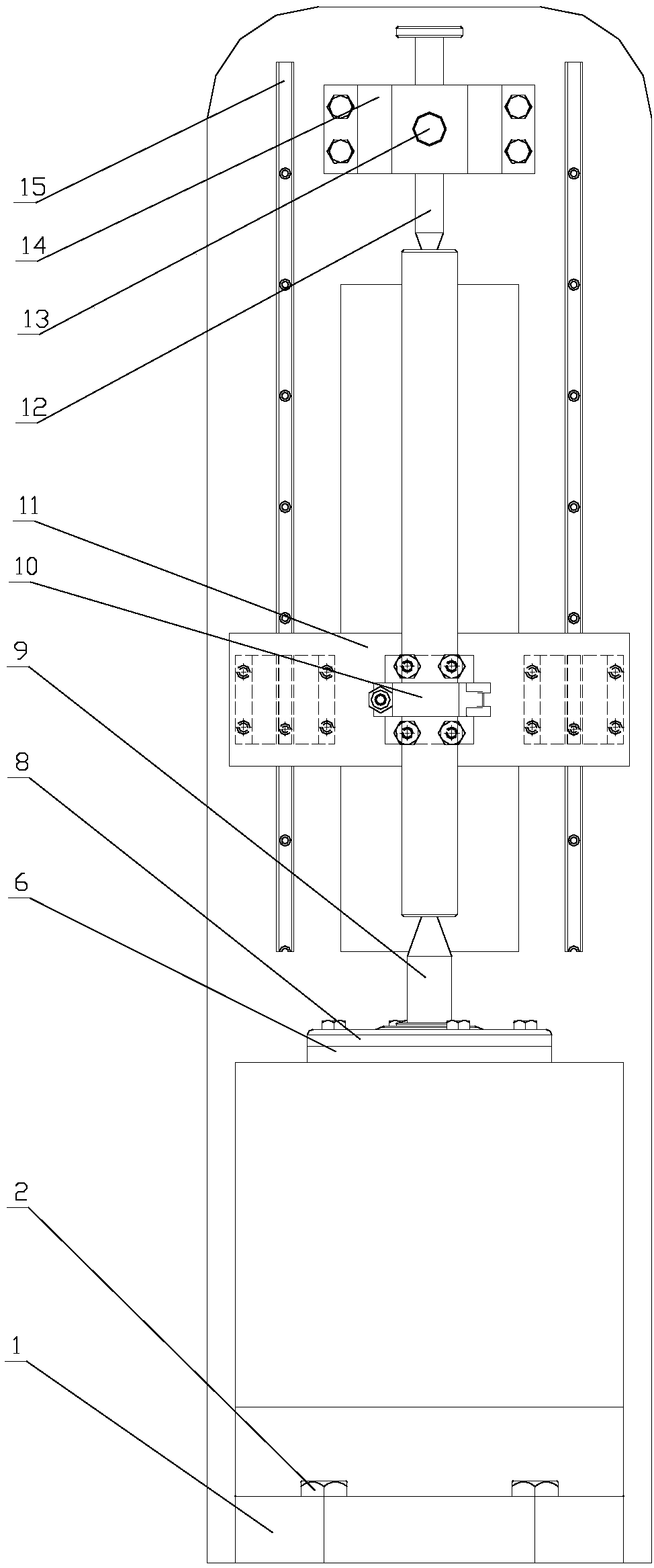

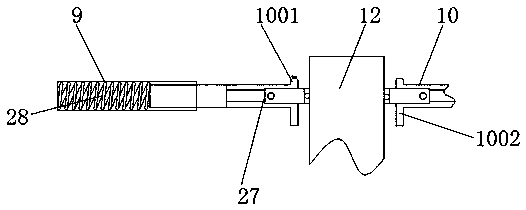

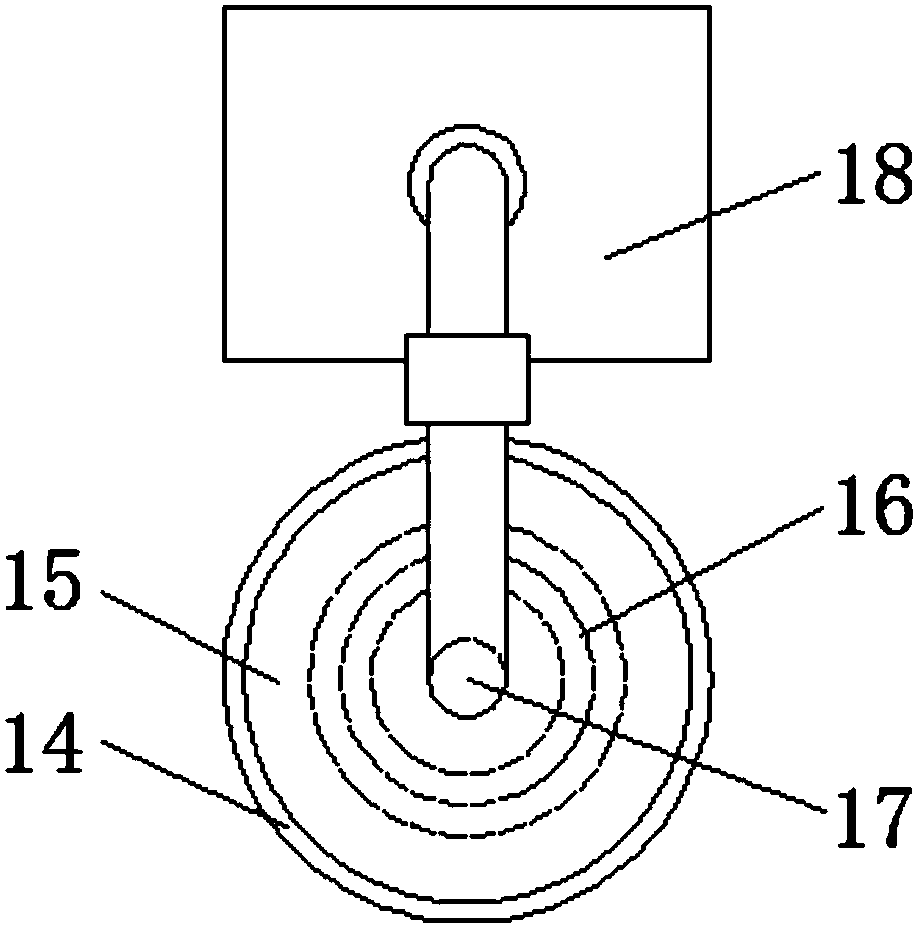

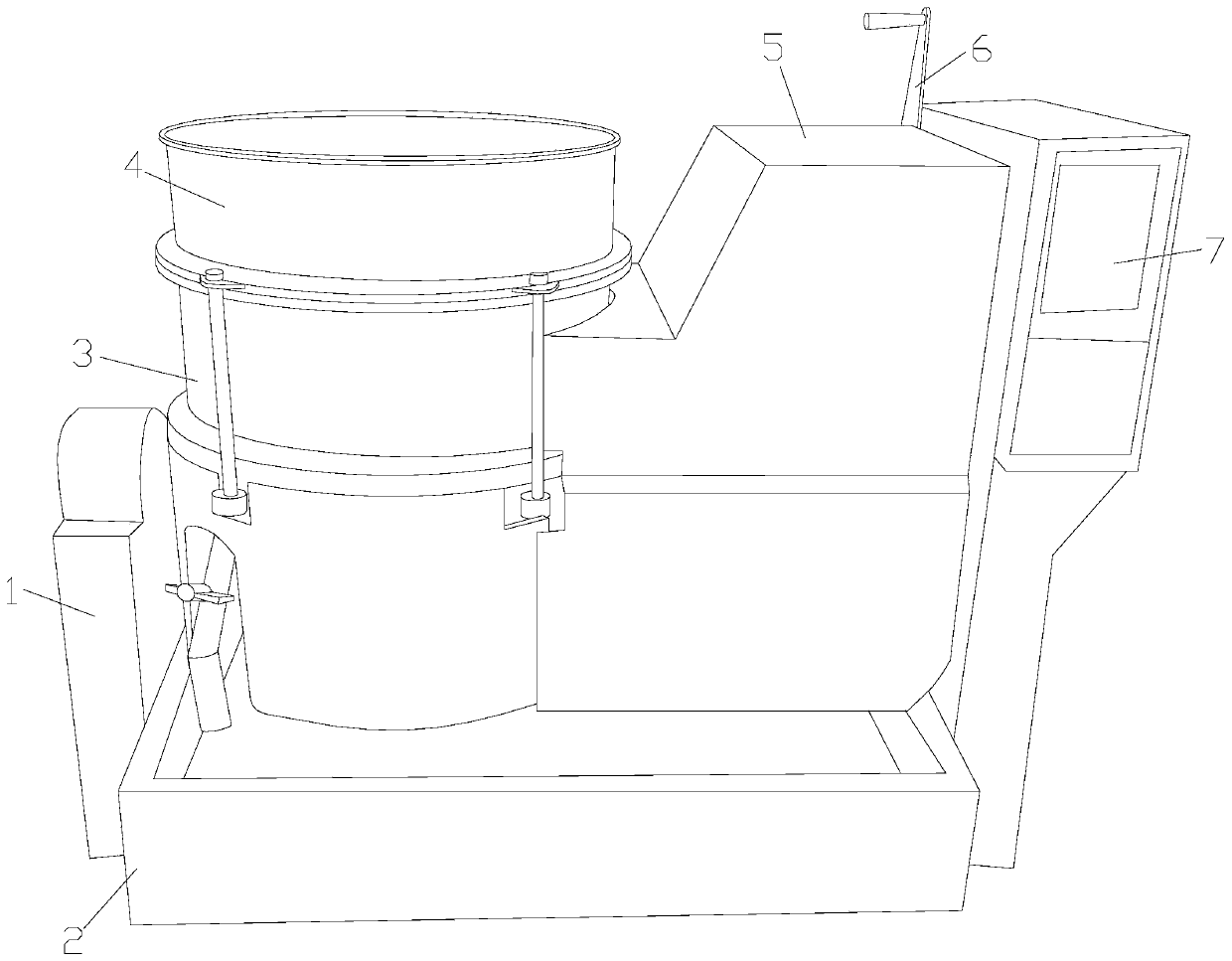

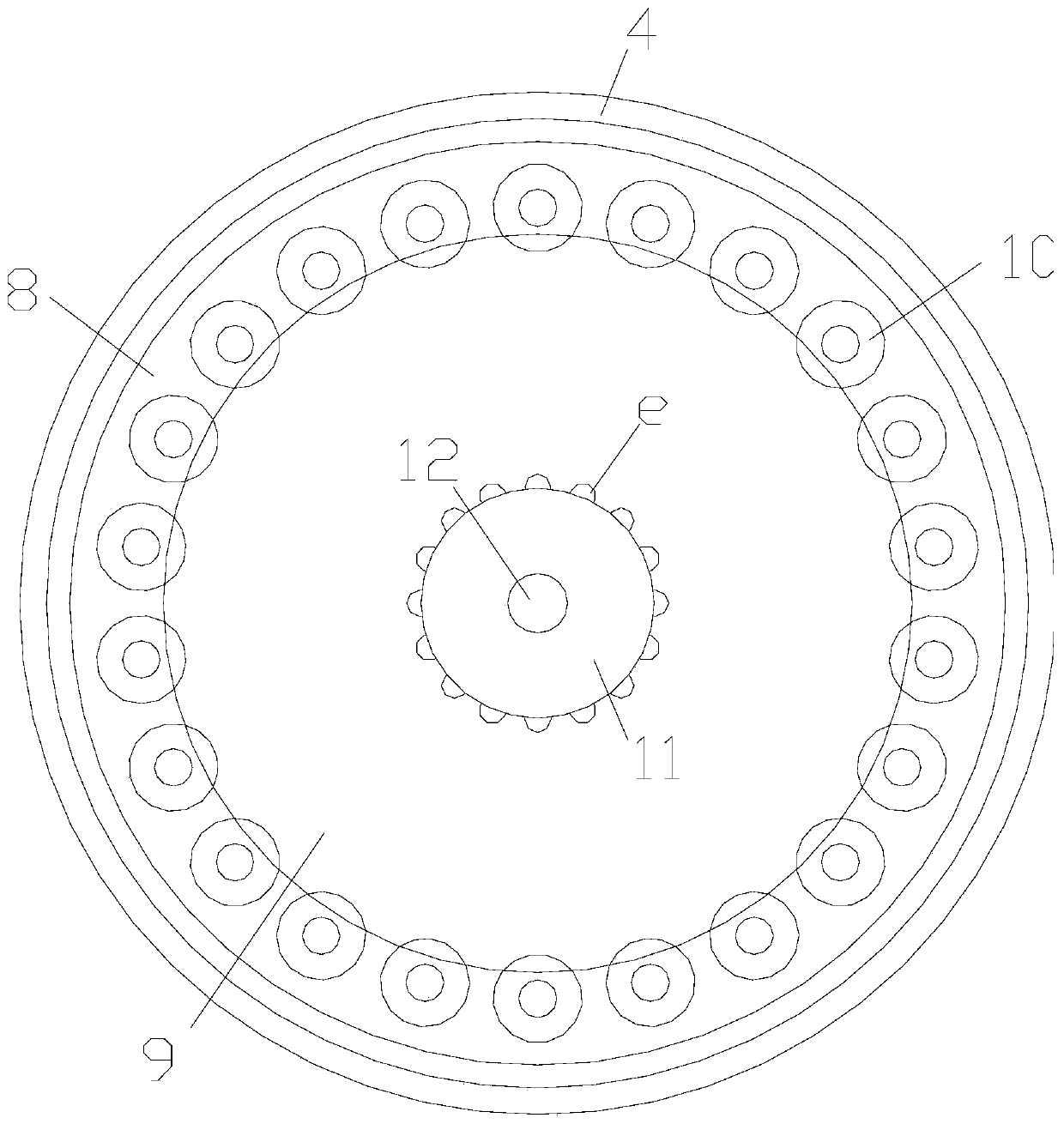

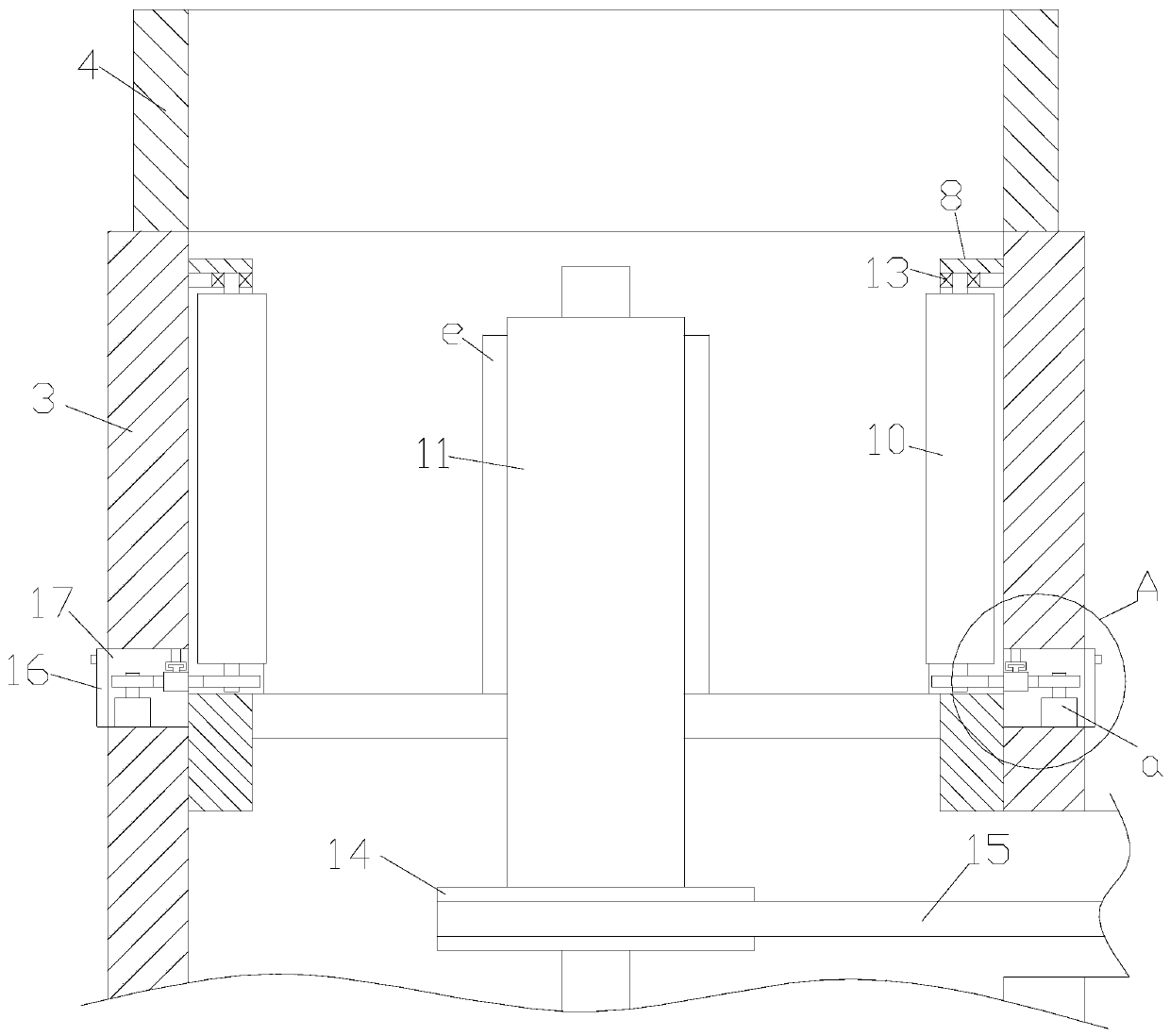

Rotary Shaft Double-head Central Hole Vertical Grinder

PendingCN108115477ASimple structureReduce manufacturing costGrinding carriagesRevolution surface grinding machinesEngineeringMachining process

The invention discloses a rotary shaft double-head central hole vertical grinder, and aims to provide a vertical grinding device which has the advantages of simple structure, convenient operation andhigh efficiency, and can be adjusted according to the size and the length of different shafts. The invention will be realized according to the following technical scheme: an active center (9) is formed on the connecting shaft of the belt wheel (3), the active center is vertically upwards through a rolling bearing assembled by the pi-shaped base (1) platform and its bushing end cover (8), bearing the center hole of one end of shaft workpiece, the shaft-like workpiece is connected to a clamping device (10) on the slide rail (15) of the upright post by sliding method, and the central hole at theother end is coaxial with the tail seat rotary tip (12) of the tail seat bracket (14) above the upright post plate. The invention solves the problem that the traditional manual grinding mode has incomplete grinding and uneven grinding quality on the central hole oxide layer at two ends of the shaft and that it is difficult to guarantee the grinding quality of the central hole, large center jumpingand large error, and is easy to cause the problem of super-difference or rejection of the shaft parts.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Fine grinding device for preparation of conductive silver adhesives

The invention relates to a grinding device, in particular to a fine grinding device for preparing conductive silver glue. The technical problem to be solved by the present invention is to provide a fine grinding device for the preparation of conductive silver glue. In order to solve the above technical problems, the present invention provides such a fine grinding device for the preparation of conductive silver glue, which includes a grinding tank, a grinding roller, a swing rod, a push rod, a moving device, etc.; the bottom of the top plate is provided with a moving device and a swinging device , the moving device is set on the right side of the swinging device, a push rod is connected between the moving device and the swinging device, a grinding tank is set under the top plate, a swinging rod is symmetrically connected to the swinging device, and a grinding roller is connected to the end of the swinging rod . The invention achieves thorough grinding of the raw materials for the preparation of the conductive silver glue, high grinding efficiency, sufficient and fine grinding, full utilization of the raw materials, and prevention of the adhesion of the raw materials for the preparation of the conductive silver glue to the inner wall of the grinding tank.

Owner:谢航洋

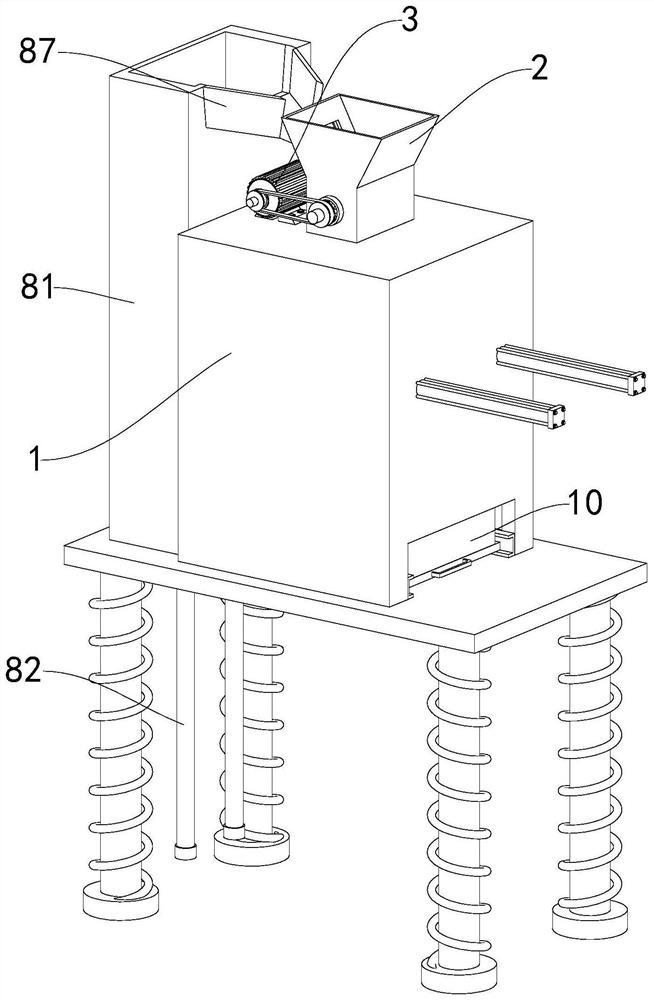

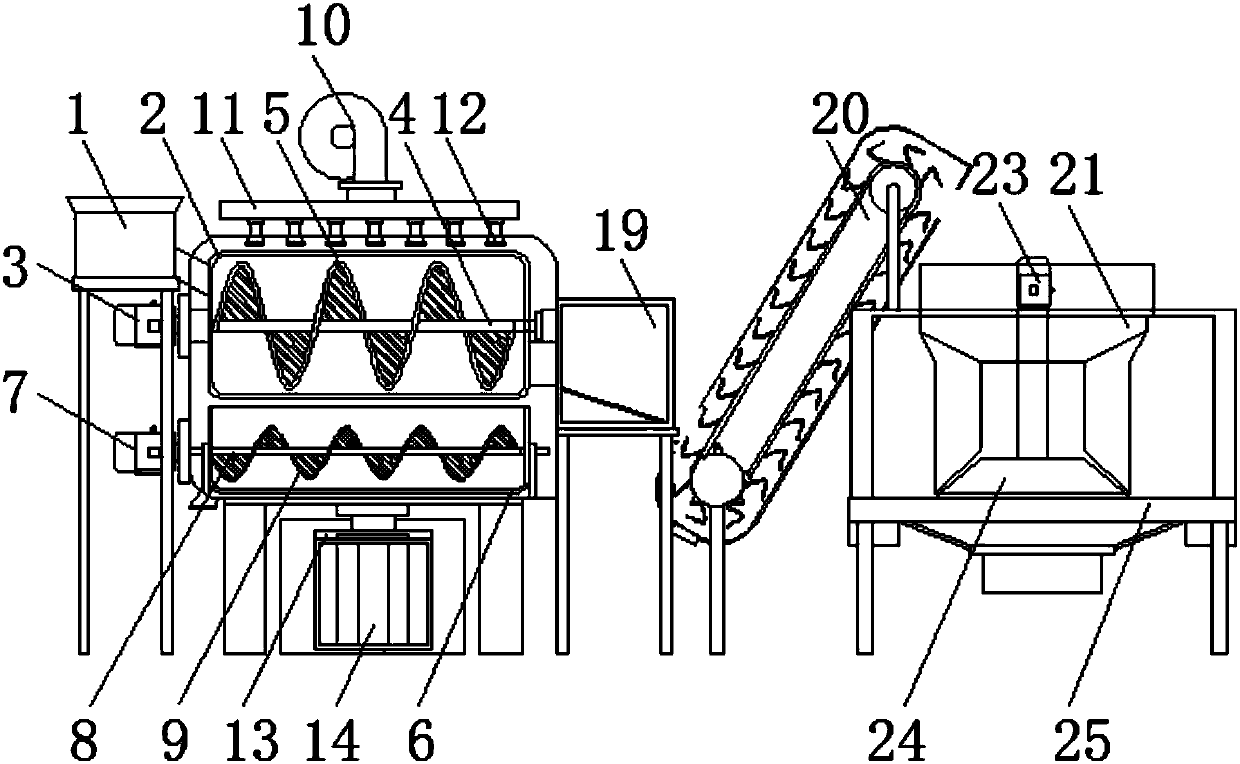

Corn crushing and grinding device

InactiveCN112517184ASolve the blockageEasy to GrindGrain treatmentsGrindingManufacturing engineering

The invention relates to the technical field of corn grinding, and discloses a corn crushing and grinding device. The device comprises a shell, a feeding hopper, a quantifying assembly, a crushing assembly, a grinding assembly, an opening and closing assembly, a screening assembly, a conveying assembly, a workbench and a loading box, wherein the shell is arranged at the top end of the workbench, the feeding hopper is arranged at the top end of the shell, the quantifying assembly is arranged at the top end of the shell, the crushing assembly is arranged inside the shell, the grinding assembly is arranged in the shell, the opening and closing assembly is arranged below the crushing assembly and located beside the grinding assembly, the screening assembly is arranged below the opening and closing assembly, the conveying assembly is arranged at the top end of the workbench, the workbench is arranged at the lower end of the shell and the loading box is arranged in the shell. By means of thedevice, the situation that the corn processing efficiency is affected due to the fact that a feeding port is prone to being blocked when too much corn is poured into during feeding, and the corn grinding quality is affected due to the fact that existing equipment does not grind corn thoroughly during corn grinding is avoided.

Owner:杜永波

Crushing and grinding device facilitating complete discharging for traditional Chinese medicinal materials

The invention discloses a crushing and grinding device facilitating complete discharging for traditional Chinese medicinal materials. The crushing and grinding device comprises a crushing main body, aguiding plate, a second motor, pressing plates, a slider and pairs of crushing scissors, wherein a feed opening is fixedly mounted at the top end of the crushing main body; a first motor is arrangedin the middle of the feed opening; a sliding block is fixedly mounted above the slider; a gear groove is formed inside the sliding block; a steering gear set is arranged in the middle of the gear groove; a rotating shaft is connected to the right side of the steering gear set; the upper part of each pair of crushing scissors is connected to fixed pulleys through pull wires; and upper parts of observation cover plates are connected to the crushing main body and a discharge cavity through hinges respectively. According to the crushing and grinding device facilitating complete discharging for thetraditional Chinese medicinal materials, the spatial transitivity is reduced, and the preheating time is shortened. Not only can the traditional Chinese medicinal materials on heating base plates bewell heated and dried directly, but also extrusion can be well performed under the action of the pressing plate after finish of drying.

Owner:GUANGZHOU WANGLAOJI PHARM CO LTD

Macromolecular water-based paint grinding device

ActiveCN113368947AImprove efficiencyGuaranteed grinding efficiencyGrain treatmentsReciprocating motionProcess engineering

The invention discloses a macromolecular water-based paint grinding device which comprises a base. A collecting base plate is arranged on the base, a machine body shell is arranged on the collecting base plate, a machine body cavity with an upward opening is formed in the machine body shell, and a mashing mechanism is arranged on the machine body shell. According to the macromolecular water-based paint grinding device, a mashing roller is used for grinding raw materials for the first time, then the mashed raw materials are divided into two parts, mashed chippings are smashed again through a planetary gear structure and a reciprocating motion structure, the smashing efficiency is extremely high, then the fully-smashed materials are ground for the third time, and the raw materials to be treated are ground for the third time, so that the grinding efficiency is greatly guaranteed, grinding is more thorough, the product quality is improved, and waste caused by unqualified raw materials is prevented.

Owner:广东升百年新材料科技有限公司

Equipment for grinding medicine tablets into powder in biopharmaceutical industry

PendingCN113231169AGrind thoroughlyFully exert the medicinal propertiesGrain treatmentsBiopharmaceutical industryManufacturing engineering

The invention relates to powder forming equipment, in particular to equipment for grinding medicine tablets into powder in the biopharmaceutical industry. The technical problem of the invention is to provide the equipment for grinding the medicine tablets into powder in the biopharmaceutical industry, and the equipment is time-saving and labor-saving and can improve the grinding efficiency. The equipment for grinding medicine tablets into powder in the biopharmaceutical industry comprises a bottom plate, a first supporting frame, a lead screw sleeve, a lead screw shaft, first connecting plates, a grinding disc and a connecting ring, and the first supporting frame is arranged on the bottom plate. The lead screw sleeve is arranged on the first supporting frame. The lead screw shaft is in threaded connection with the lead screw sleeve. The two first connecting plates are arranged on one side of the lead screw shaft, and the first connecting plates are symmetrically arranged. The grinding disc is arranged on the lead screw shaft. One side of the lead screw shaft is rotationally connected with the connecting ring. Through the arrangement of a limiting mechanism, the situation that a second bevel gear moves downwards and is separated from a first bevel gear, and then the equipment cannot continue to operate is avoided.

Owner:万一

Sesame oil production process

InactiveCN106811287AAffect qualityPerfect protein denaturationFatty-oils/fats productionEdible oils/fatsProcess engineeringSesame Oils

The invention discloses a sesame oil production process which comprises the following specific steps: 1, selecting semen sesami nigrum as a raw material, and removing impurities and premature seeds in the raw material; 2, bleaching the selected raw material in a bleacher; 3, stir-frying the raw material of which the moisture content reaches the standard in a sesame frying machine, and matching with a power stirrer; 4, taking out the sesames out of the sesame frying machine, and performing heat dissipation treatment on the raw material by using a smoking machine; 5, screening the cooled sesames, and removing sesame skin, oil powder and the like dropping while frying; 6, grinding the sesames in a carborundum grinder pulping machine so as to obtain paste; and 7, mixing the pulp, taking the oil, adding the ground sesame paste into a pulp mixing pot, and filling water into the sesame paste so as to enable the sesame oil to suspend on the surface, wherein the water adding amount is 81-84% of the weight of the sesame paste. According to the process disclosed by the invention, the system is perfect, the oil contained in the sesames can be extracted to the greatest degree, and the processing efficiency is high.

Owner:安徽达园粮油有限公司

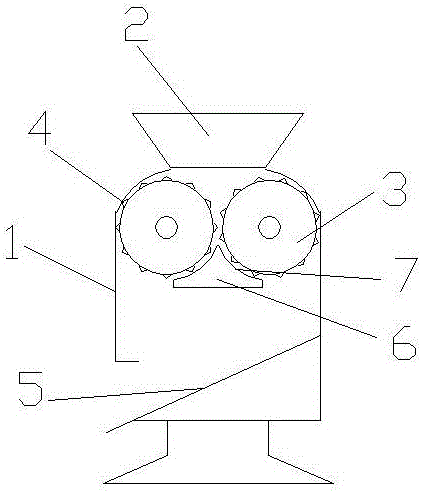

Sweet potato flour mill

InactiveCN106732926AImprove efficiency and effectivenessImprove efficiencyGrain treatmentsEngineering

A sweet potato flour mill comprises a mill shell. The upper end of the mill shell communicates with a feeding inlet, and two thorn rollers are adjacently and movably connected in the mill shell side by side in a penetrating mode. The two thorn rollers are both connected with a driving device, and a discharging plate is connected below the two thorn rollers. According to the sweet potato flour mill, the two thorn rollers are used for grinding sweet potatoes mutually to replace grinding between the thorn rollers and the mill shell, the two thorn rollers simultaneously drive the sweet potatoes to be mutually extruded, protrusions on the surfaces of the two thorn rollers jointly grind the sweet potatoes, and meanwhile, sweet potato mash on the surfaces of the thorn rollers are also mutually removed, so that the sweet potatoes are ground more quickly and thoroughly, potato mash is prevented from adhering to the thorn rollers, and continuous working efficiency of the mill is ensured.

Owner:WENZHOU PUHONG AGRI SCI & TECH CO LTD

Deodorant fly eradication agent production device, use method and prepared deodorant fly eradication agent

ActiveCN109876893AAvoid wastingGrinding and mixing work smoothlyMixer accessoriesCocoaDeodorantAgricultural engineering

The invention discloses a deodorant fly eradication agent production device, a use method of the device and a prepared deodorant fly eradication agent prepared by the device. The device comprises an outer supporting rod, a first motor, a single-rotation reciprocating screw rod, a second rotating sleeve, a second motor, an automatic telescopic rod, a reset spring and a blockage block. During use ofthe deodorant fly eradication agent production device, raw materials required to be mixed can be ground well and thoroughly in the initial period of discharging, meanwhile, the subsequent mixing workof the whole device is performed very thoroughly, the raw materials can be discharged to the maximum extend, thus waste of the raw materials is avoided, and the subsequent grinding and mixing work can be performed smoothly. The deodorant fly eradication agent ground and mixed by the device is better in mixing effect, and the mixing ratio control is more accurate.

Owner:湖南万惠生物科技有限公司

Tool for machining automobile sleeve

PendingCN107030592AEasy to GrindGrind thoroughlyLapping machinesGrinding/polishing safety devicesScrew threadBarrel Shape

The invention belongs to the field of manufacturing of automobile accessories, and specifically discloses a tool for machining an automobile sleeve. The tool for machining the automobile sleeve comprises a grinding barrel body, a base, an air feeding pipe, and a connector for fixing the automobile sleeve, wherein an air feeding section which communicates with the air feeding pipe is arranged at the upper part of the grinding barrel body; a grinding part consisting of an air bag and a grinding layer is arranged on the inner wall of the grinding barrel body; the grinding layer is arranged on the outer wall of the air bag; the air feeding section communicates with the air bag, and an one-way valve is arranged at a part where the air feeding section communicates with the air bag; the base is detachably connected with the grinding barrel body; a screw is rotatably connected to the upper end of the base and is vertical to the upper end surface of the base; blades are detachably connected to the upper end of the screw and are positioned in the air feeding section, and moreover the blades can be rotated while air is fed through the air feeding pipe; the connector is in a barrel shape, and threads are formed in the inner wall of the connector; the connector is in thread connection with the screw. With the adoption of the tool, the automobile sleeve can be conveniently and quickly grinded completely.

Owner:遵义顺峰汽车零部件制造有限公司

Marine product dewatering and grinding integration device with filtering function

The invention discloses a marine product dewatering and grinding integration device with a filtering function. The device comprises a first feed box, a second filter box, a hot air generating device,a water guide pipe, a water storage box, a second feed box, a grinding barrel, guide strips and a screening tray, wherein a first filter box is connected with the right side of the first feed box andis internally provided with a first rotating shaft and a first mixing blade; the first rotating shaft is connected with a first motor; the second filter box is arranged at the lower side of the firstfilter box and is internally provided with a second rotating shaft and a second mixing blade; the second rotating shaft is connected with a second motor; an air distributing plate is connected with the lower side of the hot air generating device, and air spray nozzles are arranged at the lower side of the air distributing plate; the filter boxes are connected with the lower side of the water guidepipe. The marine product dewatering and grinding integration device with the filtering function is provided with the first filter box and the second filter box, thus being capable of screening and separating out marine products with different quality and sizes, and further enabling the marine products to be dried in a separated way.

Owner:张巧芳

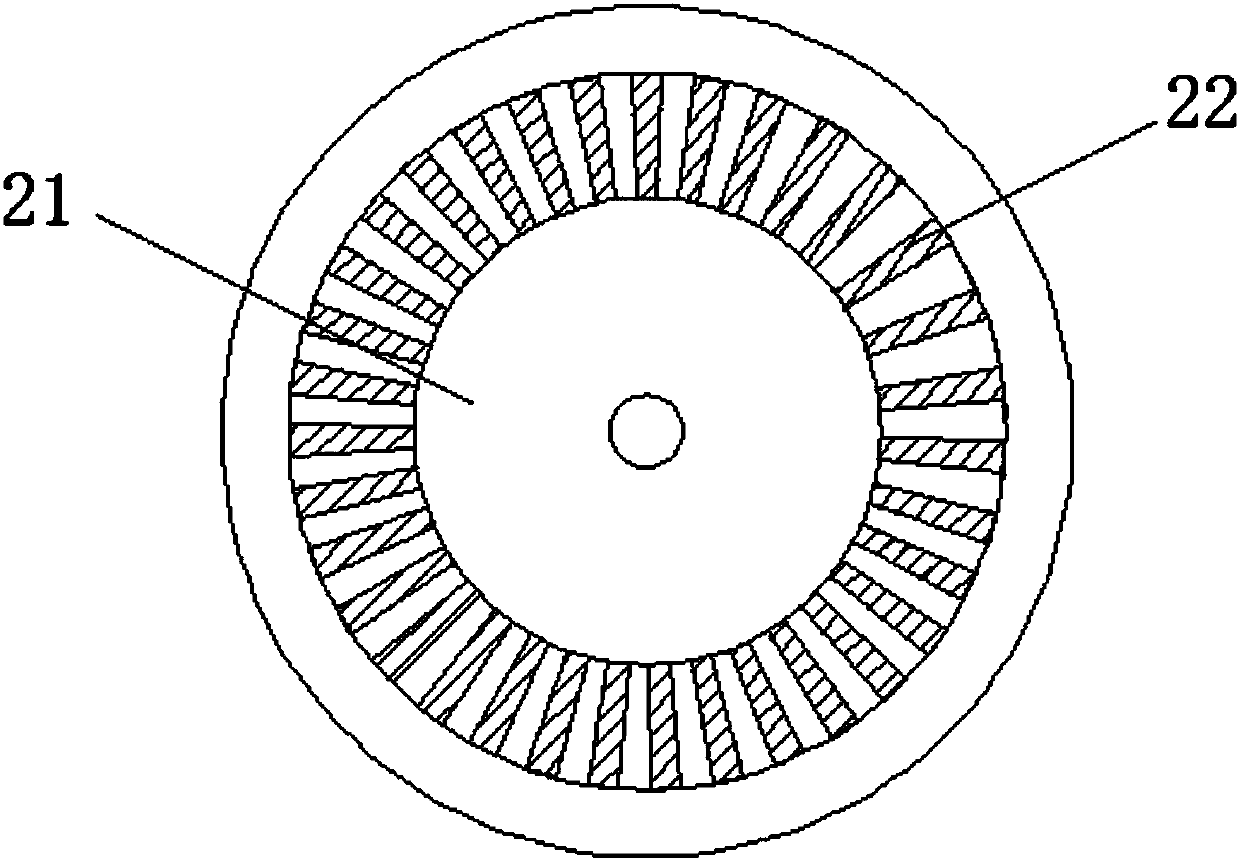

Raw material grinding equipment for chemical machinery

InactiveCN111330688AGrind thoroughlyPrevent insufficient grindingGrain treatmentsElectric machineryEngineering

The present invention discloses raw material grinding equipment for chemical machinery. The equipment structurally comprises a rack, a water containing groove, a grinding cylinder, a top ring, a machine body, a rocker rod and a control panel, wherein the bottom of the rack is provided with the water containing groove; the machine body is movably installed on the rack and located above the water containing groove; the grinding cylinder is connected with the left side of the machine body; the top ring is installed above the grinding cylinder through four groups of bolt rods; the rocker rod is installed on the back end of the right side of the top of the machine body; and a column on the right side of the machine body is provided with the control panel. The equipment has the beneficial effects that a ring sleeve in the grinding cylinder is internally provided with twenty-two groups of grinding rollers, the bottoms of the grinding rollers are provided with rotating rings, an external motordrives the rotating rings to rotate, and inner gear rings on the inner sides of the rotating rings can enable the twenty-two groups of grinding rollers to rotate for grinding ceramic raw materials attached to the edge of the groove, thereby preventing the phenomena of insufficient grinding.

Owner:张忠余

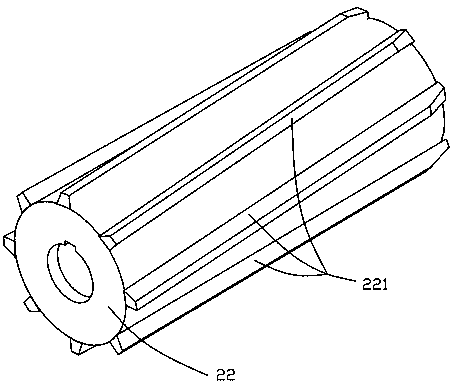

Camellia oleifera seed sheller thorough in milling

PendingCN108783480AGrinding and shelling thoroughlyGrind thoroughlyFatty-oils/fats productionHuskingCamellia oleiferaEngineering

The invention relates to the technical field of shelling equipment, and discloses a camellia oleifera seed sheller thorough in milling. The camellia oleifera seed sheller comprises a machine frame, arotating shaft arranged in the machine frame and a driving device for controlling the rotating shaft to rotate, wherein a spiral transmission structure is arranged on the periphery of the first end part of the rotating shaft, and is used for transmitting camellia oleifera seeds to a milling position; a sleeve which is fixed to the machine frame is arranged on the periphery of the spiral transmission structure; a roller is arranged on the periphery of the second end part of the rotating shaft, and rotates along with the rotating shaft; a plurality of ribs which extend in the length direction ofthe roller are arranged on the periphery of the roller; a spacing is generated between every two adjacent ribs; a sieving cylinder is fixedly arranged in the length region of the roller, on the machine frame; the roller penetrates in the sieving cylinder and is coaxial with the sieving cylinder; a gap is formed between the free end away from the roller, of each rib, and the sieving cylinder; thefirst end part and the second end part of the rotating shaft are connected; and the sleeve is connected with the end part of the sieving cylinder, or a gap is formed between the sleeve and the end part of the sieving cylinder. The camellia oleifera seeds are slowly transmitted to the roller through the spiral transmission structure for milling, the quantity of milled camellia oleifera seeds in unit time is relatively low, and the shelling of the camellia oleifera seeds is thorough.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com