Equipment for grinding medicine tablets into powder in biopharmaceutical industry

A technology of biopharmaceuticals and medicines, applied in grain processing, etc., can solve problems such as low grinding efficiency, time-consuming and labor-intensive grinding with mortar and bowl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

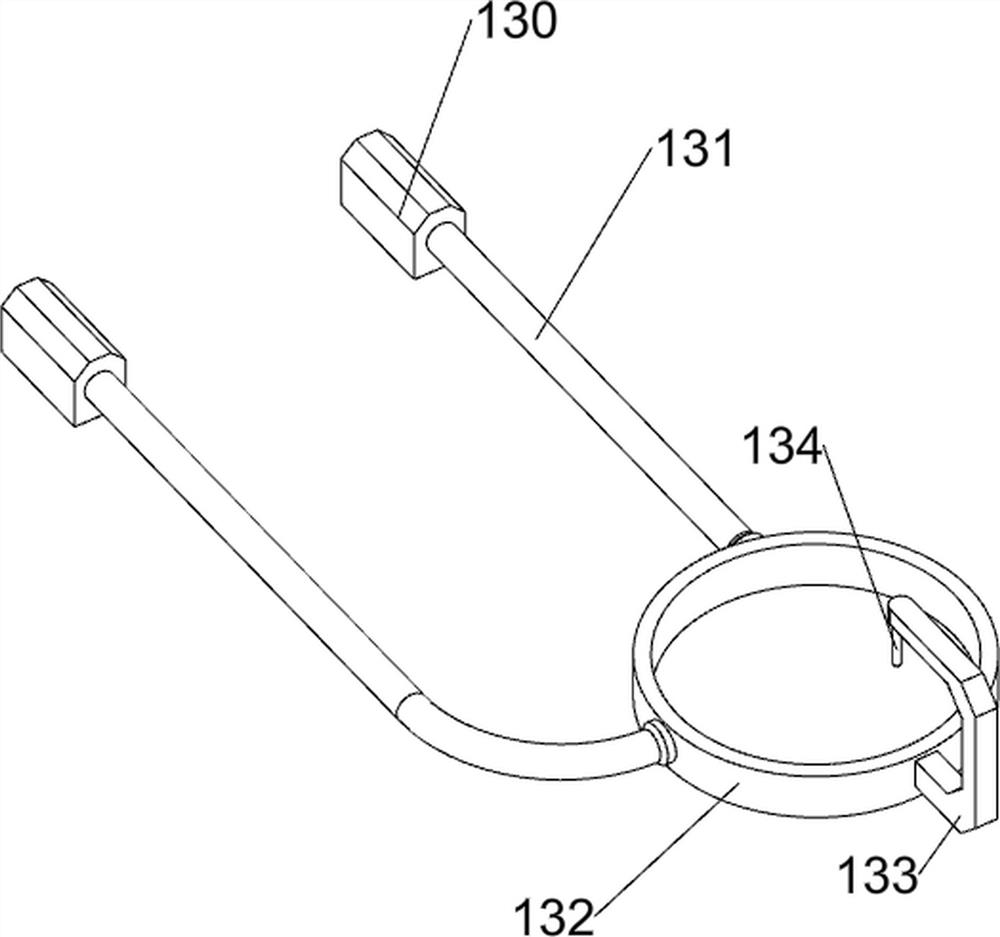

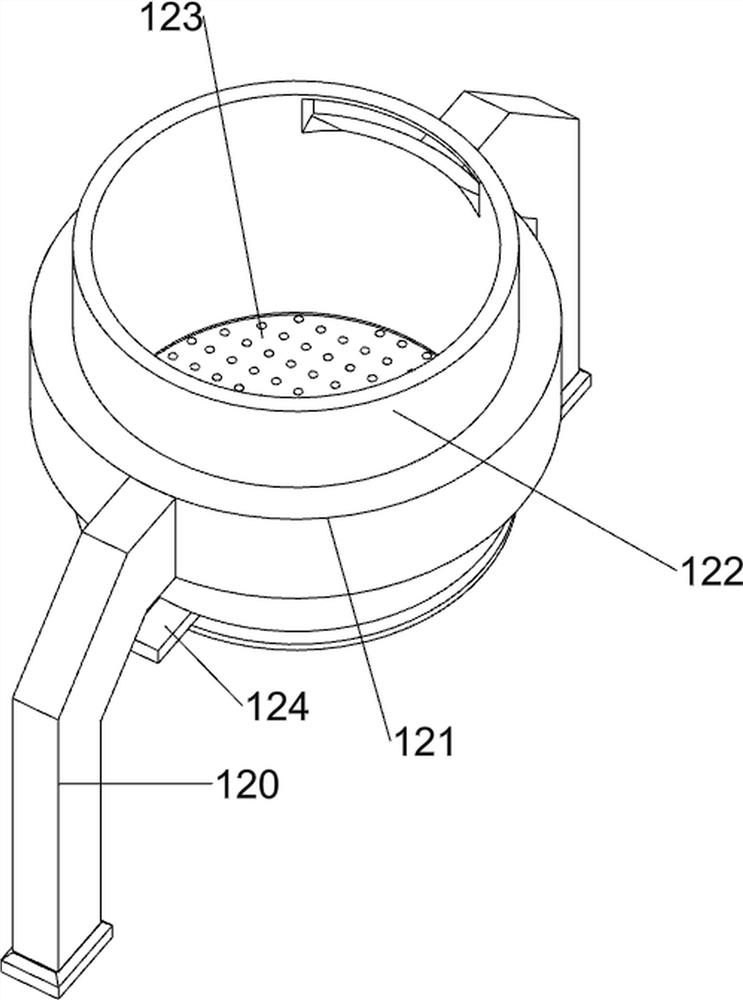

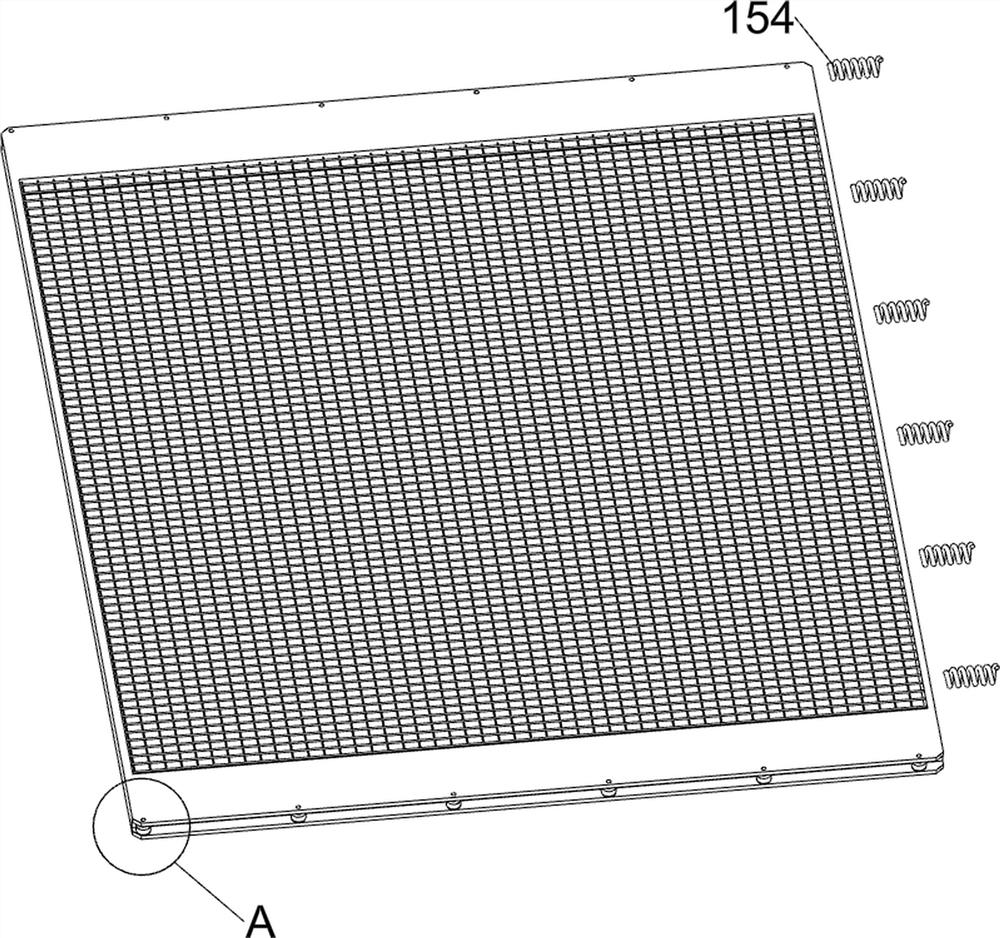

[0070] A device for grinding drug tablets into powder in the biopharmaceutical industry, such as Figure 1-4As shown, it includes a bottom plate 1, a first support frame 2, a first spring 3, a screw sleeve 4, a screw shaft 5, a first connecting plate 6, a connecting ring 7, a connecting shaft 8, a first wedge block 9, a grinding Disk 10, power mechanism 11, charging mechanism 12 and limit mechanism 13, base plate 1 is provided with first support frame 2, and first support frame 2 is provided with screw mandrel cover 4, and screw mandrel cover 4 is internally threadedly connected with The screw shaft 5 is provided with two first connecting plates 6 on the lower side of the screw shaft 5, the first connecting plates 6 are left and right symmetrically arranged, the bottom of the screw shaft 5 is provided with a grinding disc 10, and the lower side of the screw shaft 5 Connected with a connecting ring 7, the front side of the connecting ring 7 is provided with a connecting shaft 8...

Embodiment 2

[0076] On the basis of Example 1, such as Figure 5-9 Shown, also include unloading mechanism 14, unloading mechanism 14 includes the 3rd bracing frame 140, unloading box 141, push plate 142, slide plate 143, the 4th connecting plate 144, the 2nd wedge block 145 and the 2nd spring 146, two third support frames 140 are provided on the left rear side of the bottom plate 1, and a lower material box 141 is arranged between the top of the third support frame 140, and a slide plate 143 is provided on the front side of the lower material box 141, and the inner front side of the lower material box 141 The push plate 142 is slidingly connected, and the left and right sides of the push plate 142 are symmetrically provided with a fourth connecting plate 144, and the fourth connecting plate 144 is slidingly connected with the blanking box 141. A second spring 146 is connected, and a second wedge-shaped block 145 is provided on the outside of the fourth connecting plate 144 , and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com