Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2385 results about "Barrel Shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

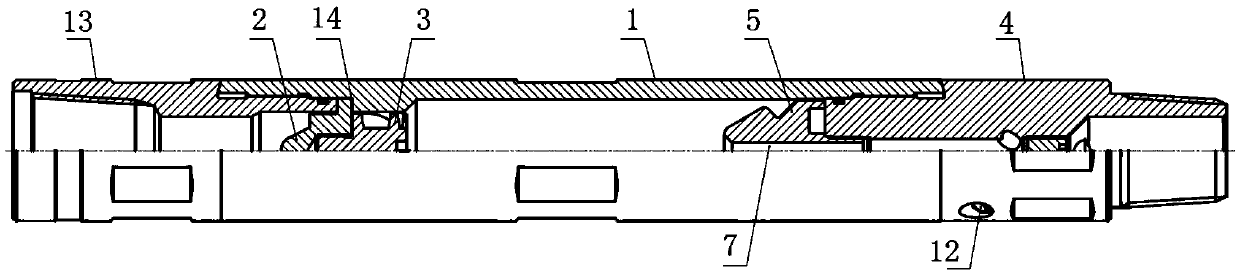

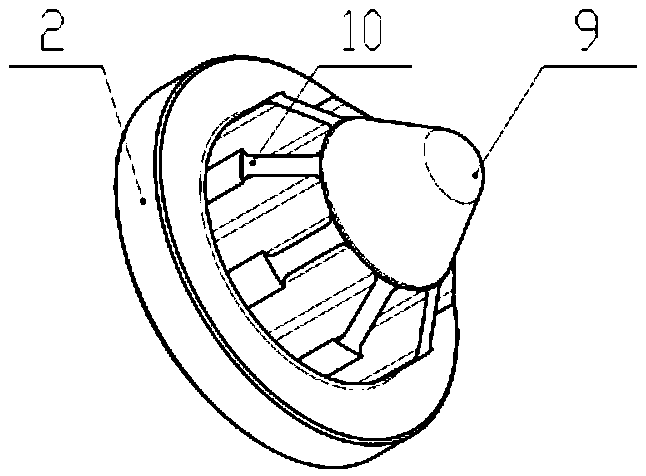

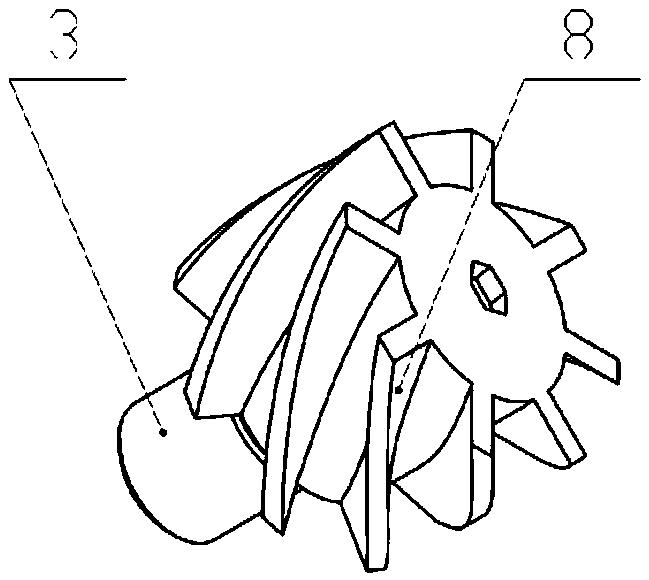

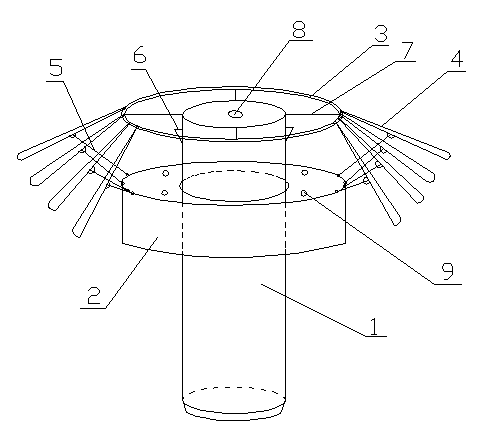

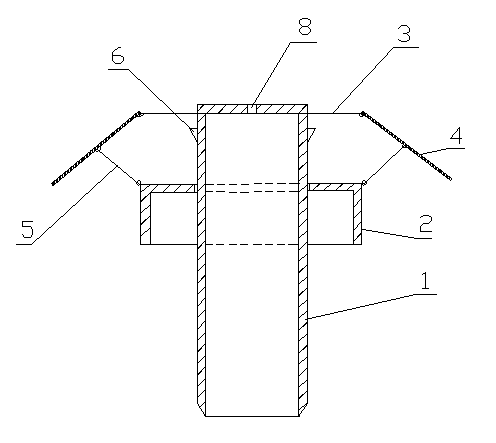

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

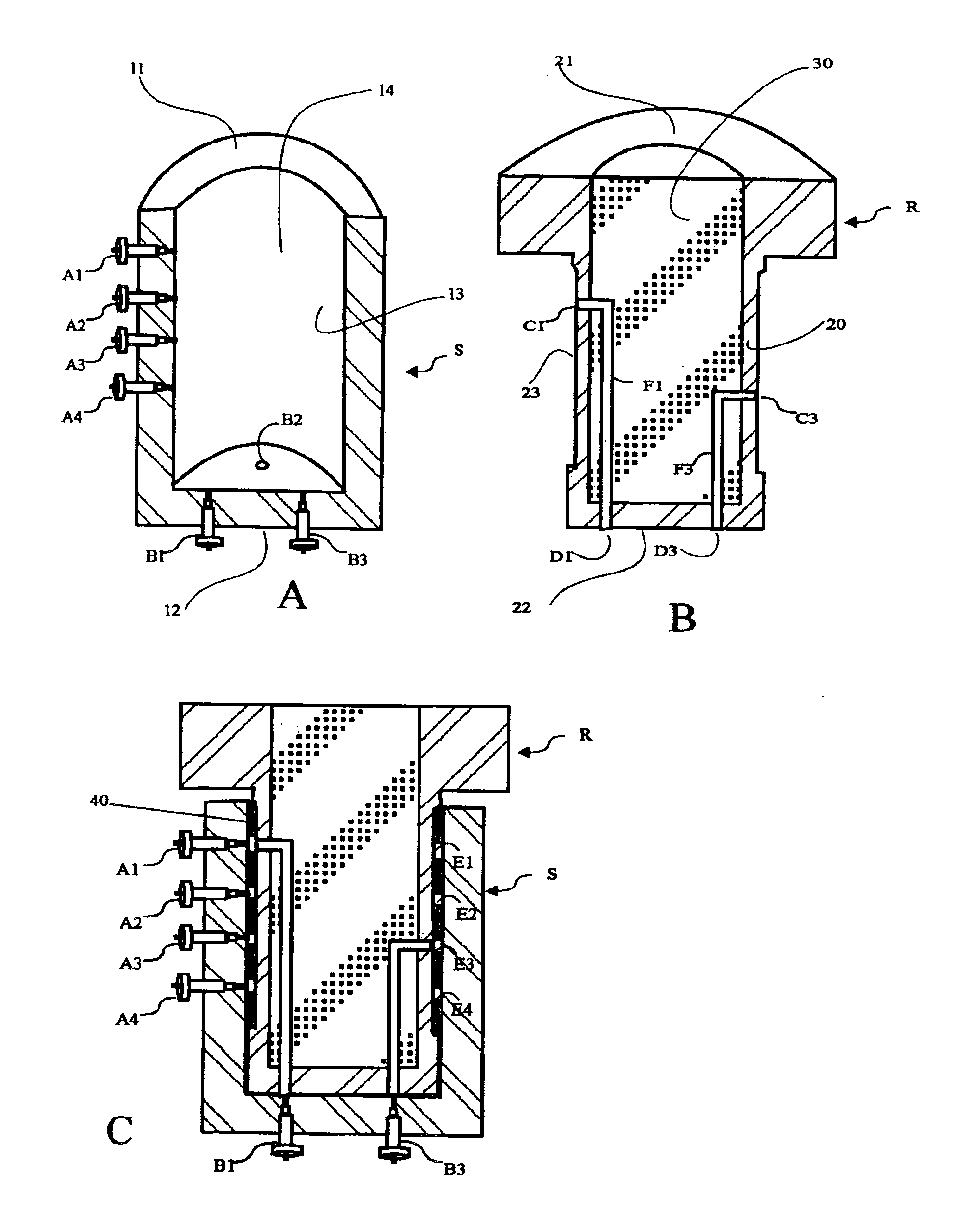

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

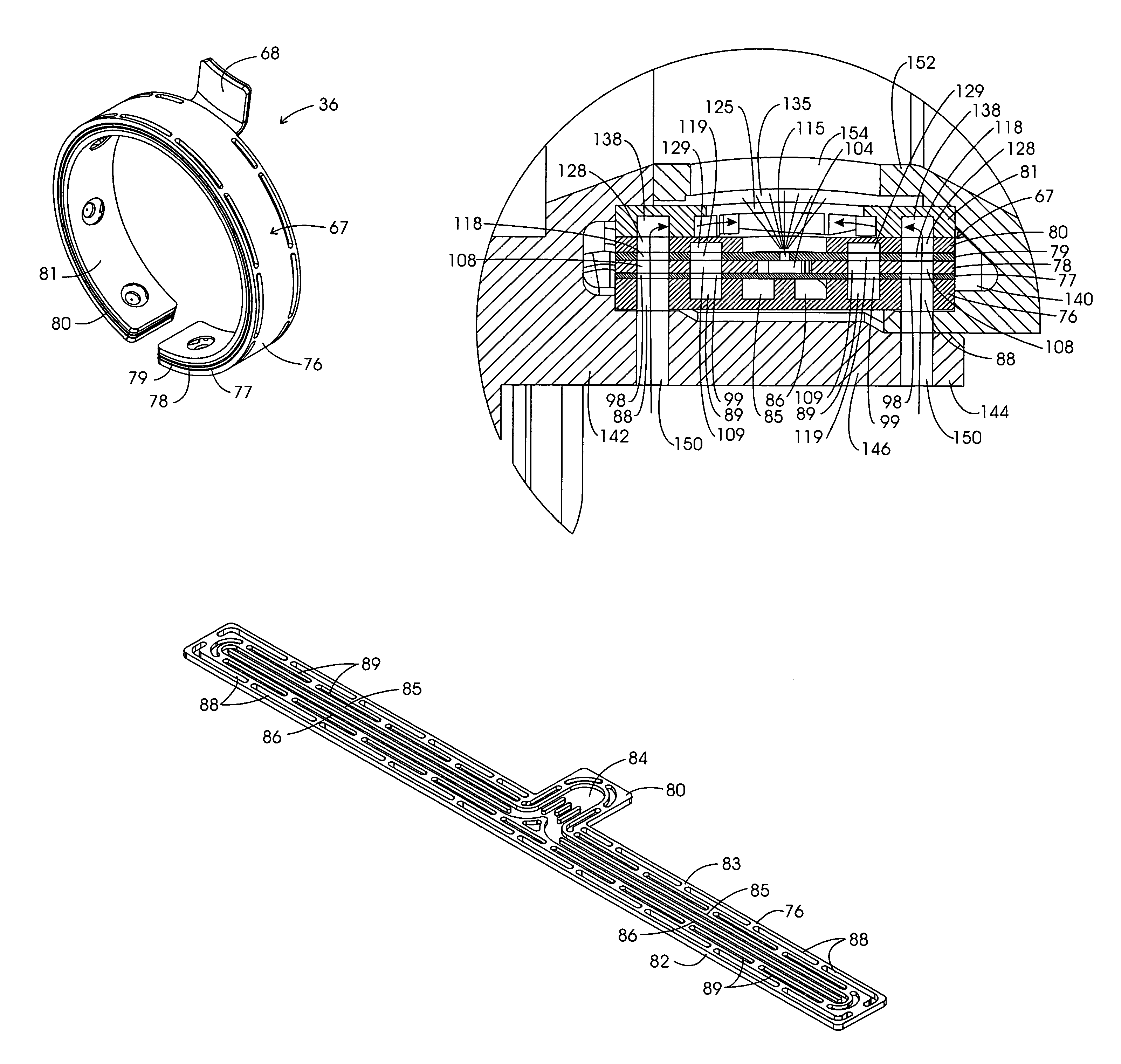

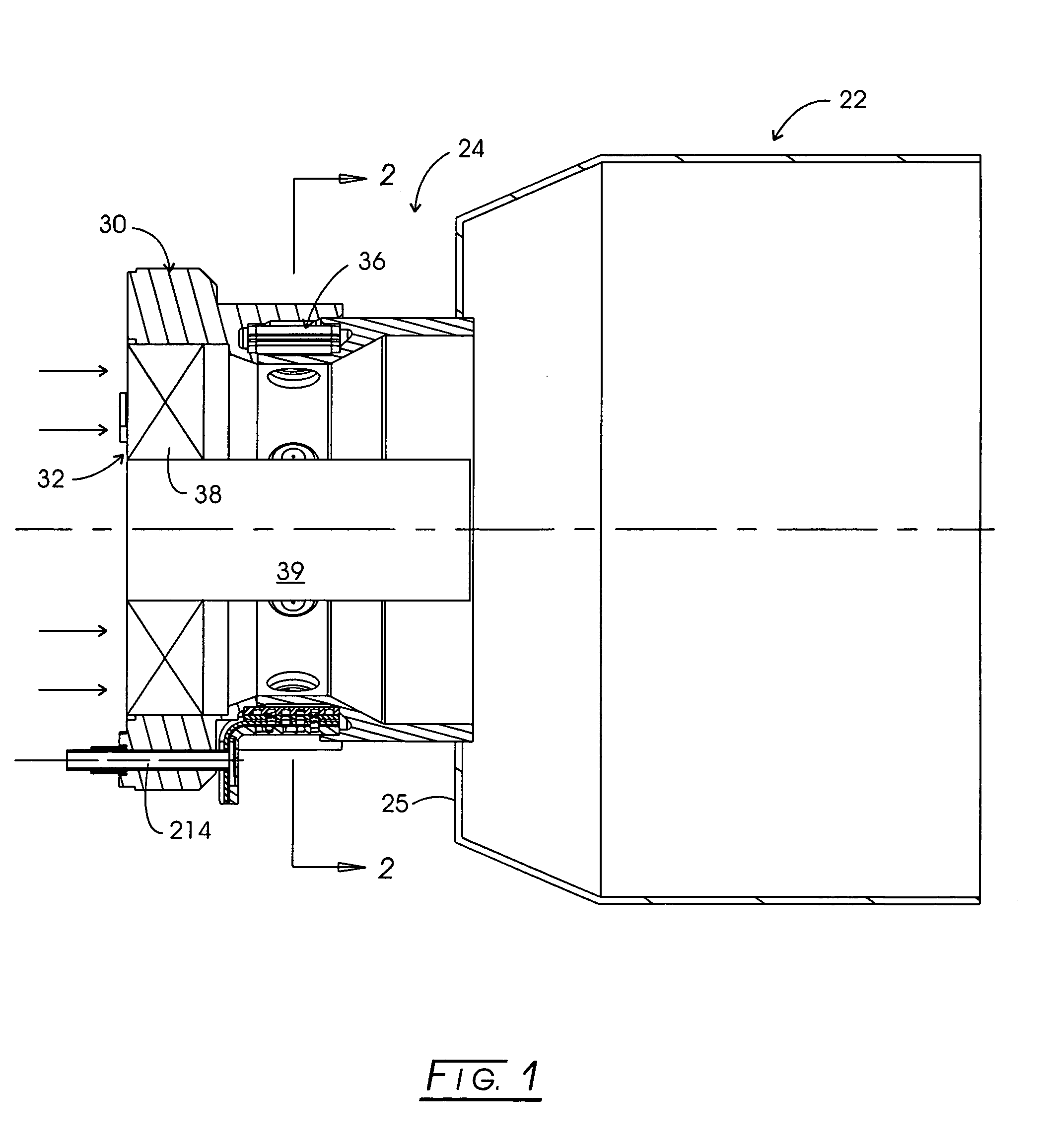

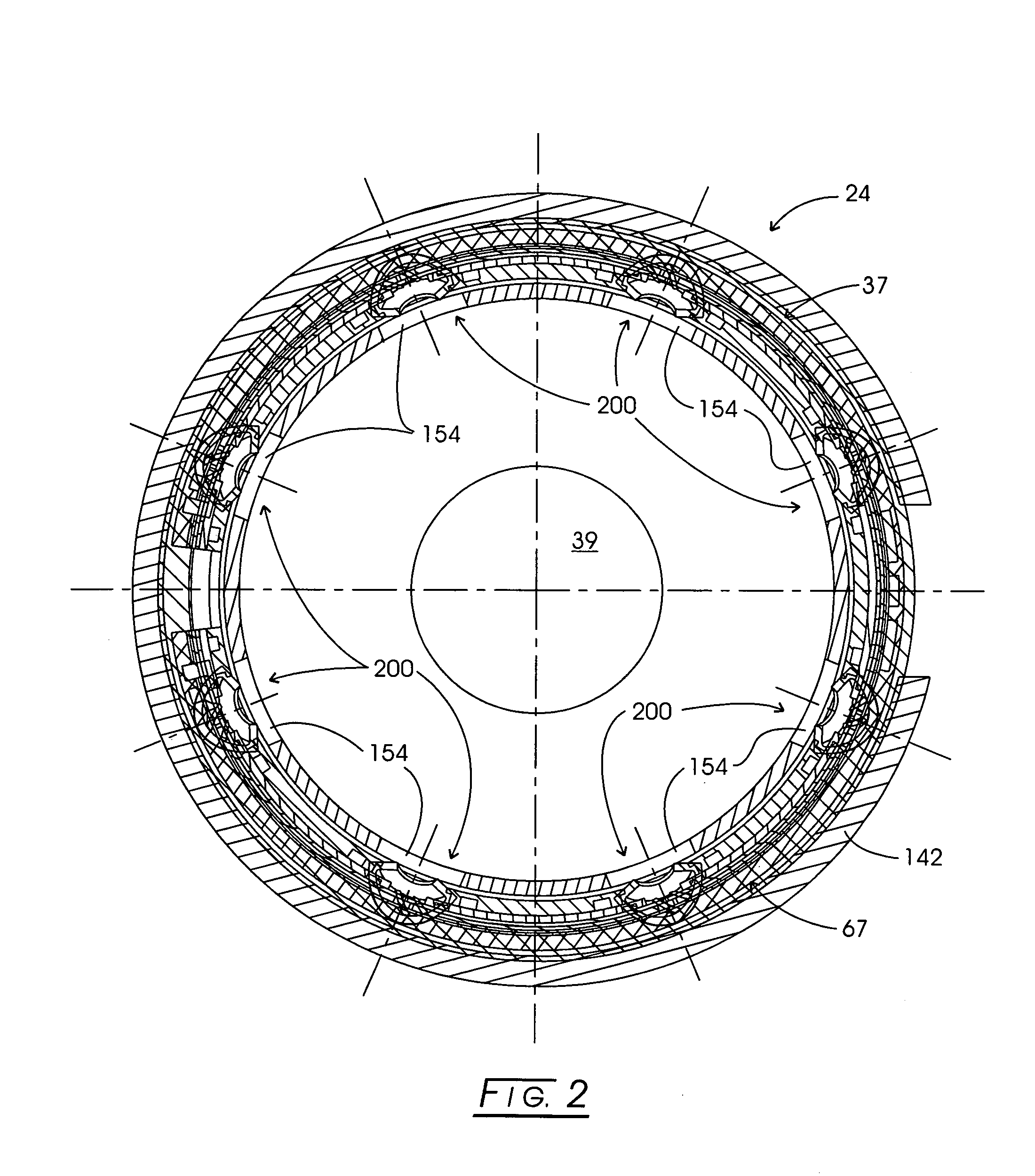

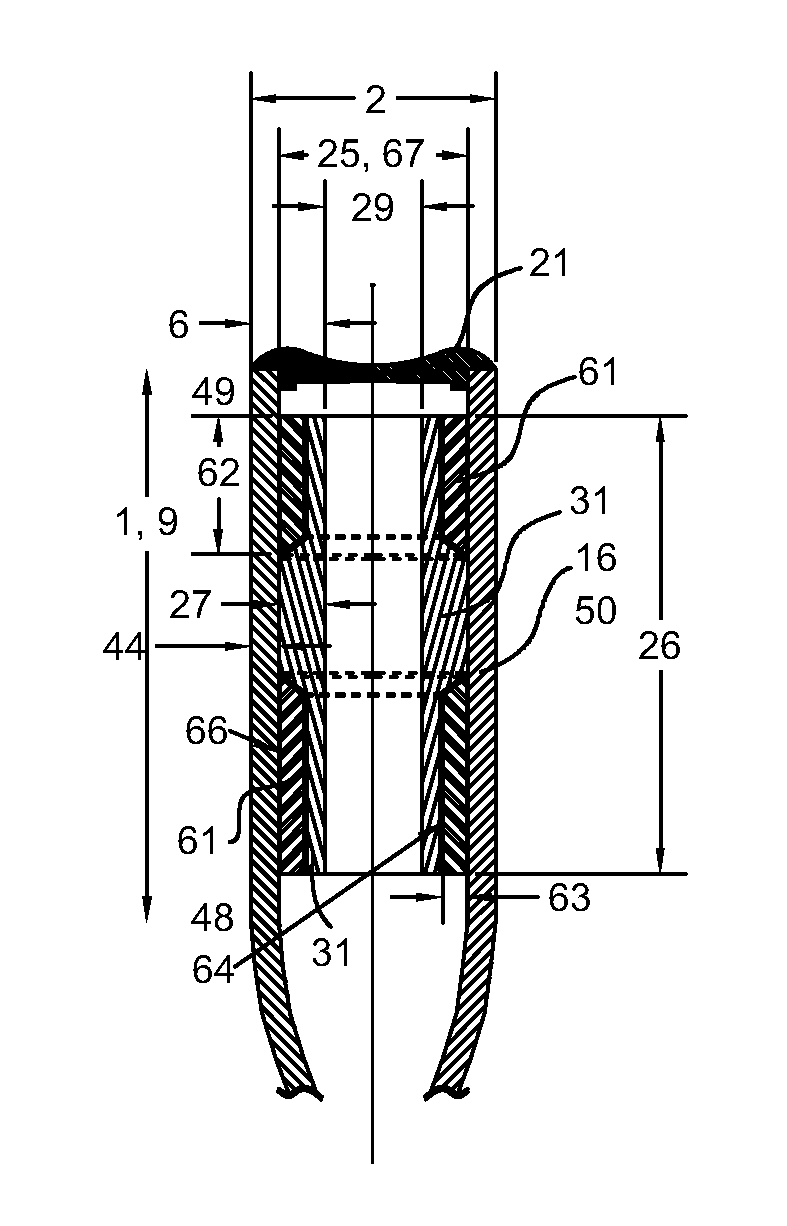

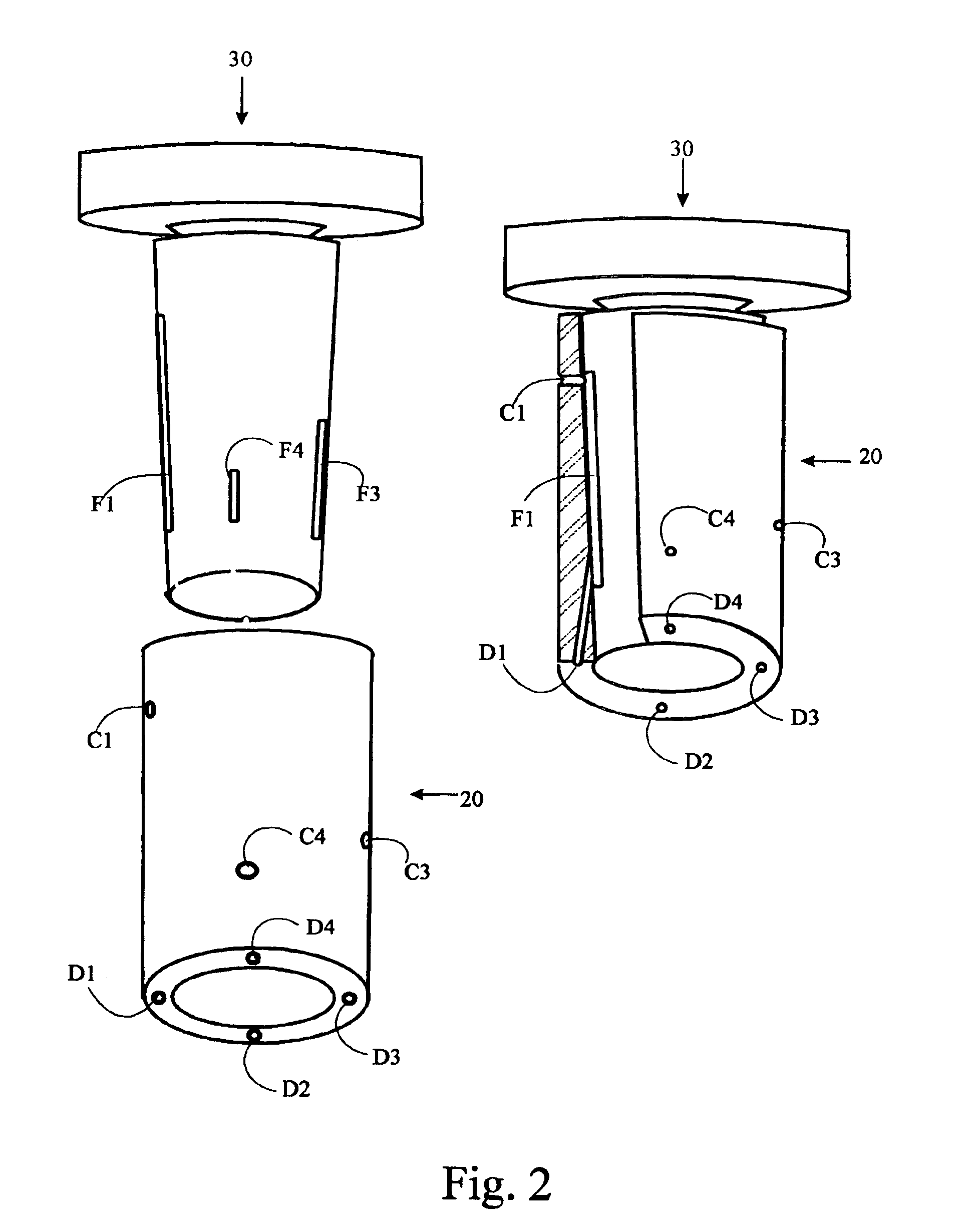

Macrolaminate radial injector

ActiveUS7028483B2Good dispersionAccurately and repeatably manufacturedTurbine/propulsion fuel supply systemsContinuous combustion chamberEngineeringBarrel Shape

An injector assembly includes a barrel-shaped housing and an injector, the injector including a feed ring formed of multiple, etched, T-shaped plates. A plurality of nozzles are arranged in an evenly-spaced array around the injector and direct fluid radially inward into the central annulus of the injector assembly. The injector includes an air inlet port with an internal feed passage fluidly connected to swirl chambers and exit orifices to provide individual sprays of fuel from the nozzles. Integral air swirlers impart a swirling component of motion to the fuel sprays. A venturi configuration is provided by the housing. The nozzles are provided along the venturi configuration, which maintains fluid separation from the walls of the housing downstream from the venturi.

Owner:PARKER INTANGIBLES LLC

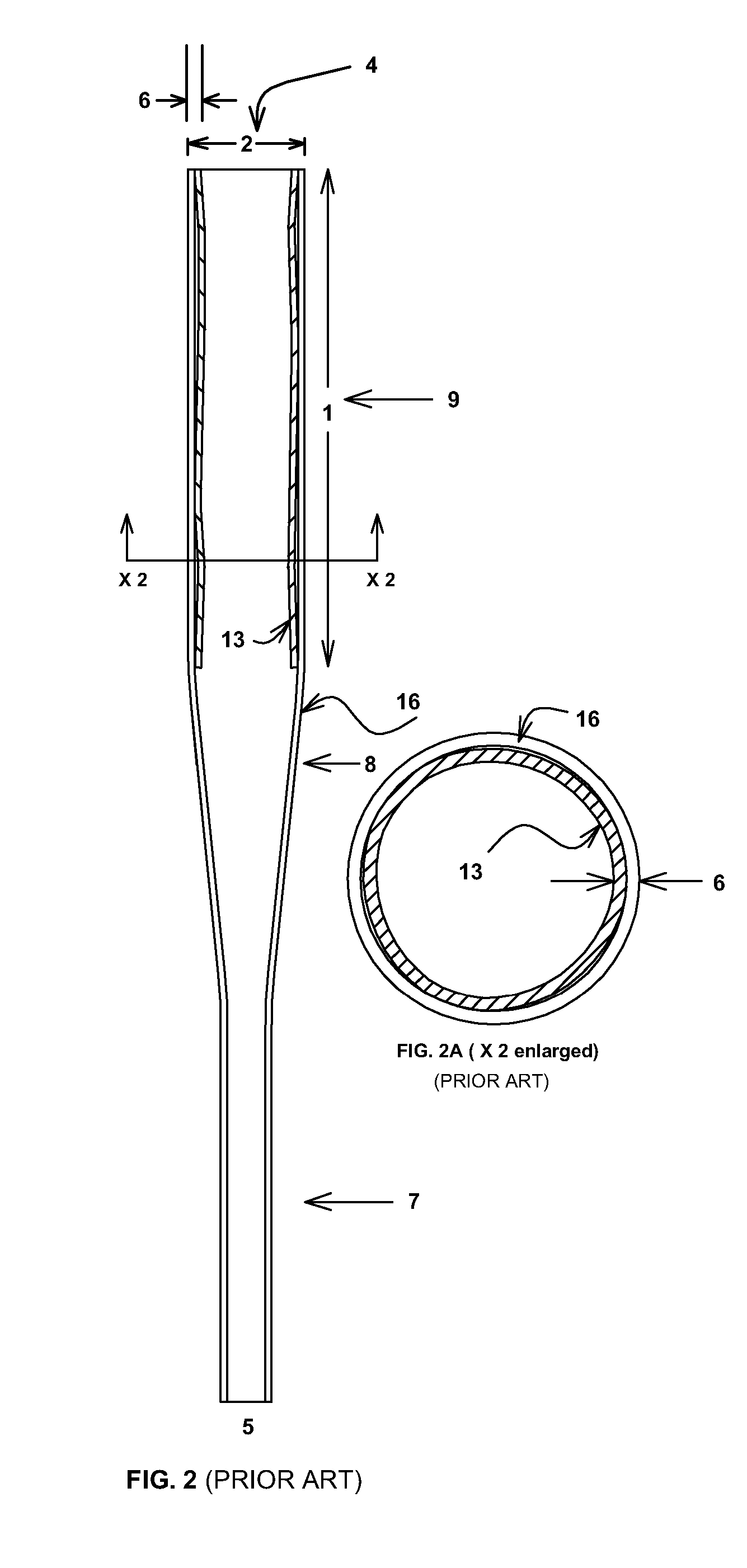

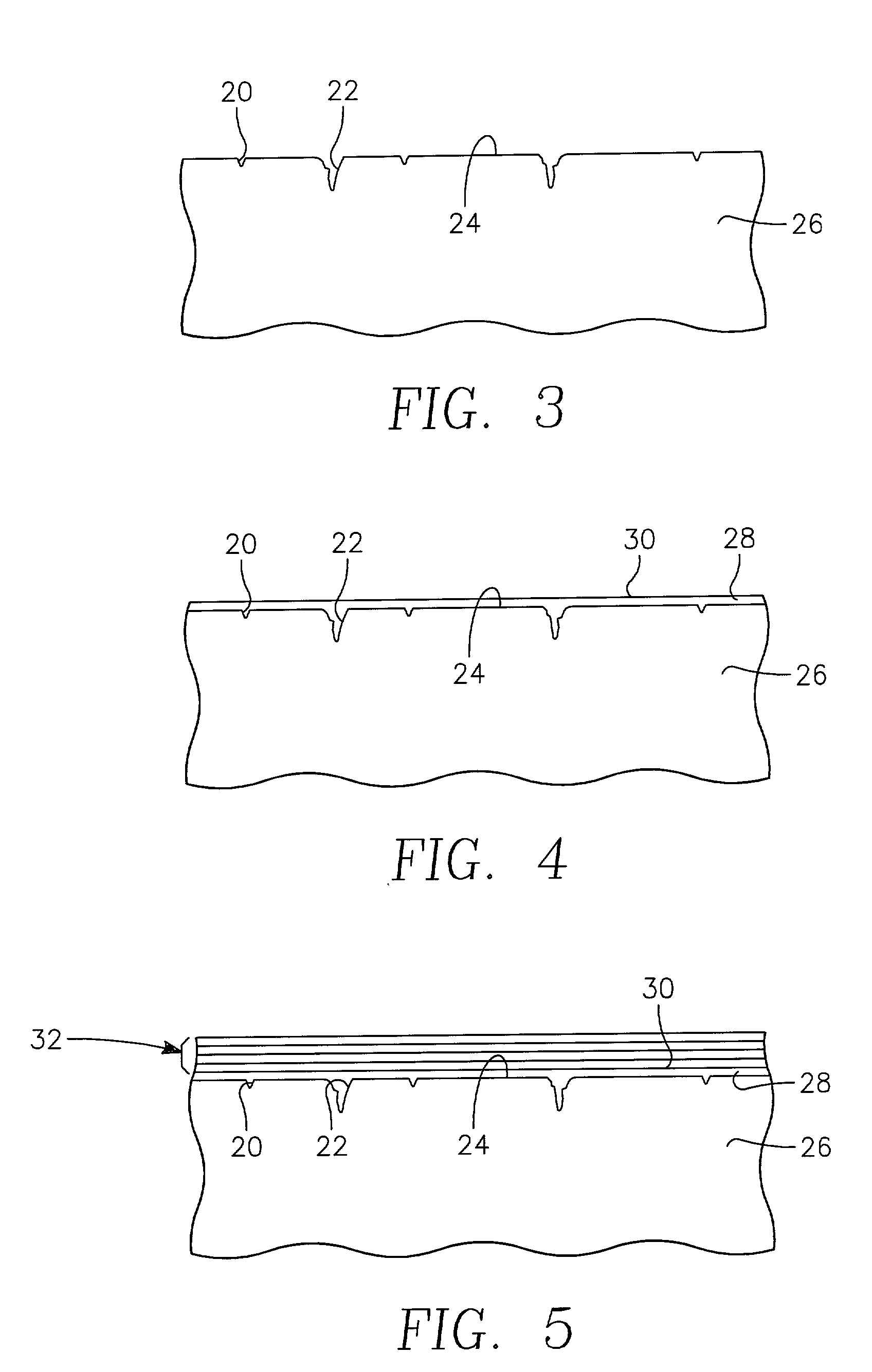

Multi-walled tubular baseball bats with barrel inserts of variable geometry

A multi-walled, tubular baseball bat has a barrel portion with a mid-section wherein the radial stiffness of the overall barrel wall varies along the barrel length to provide an enlarged sweetspot, improved soft feel and performance, plus unique sounds upon impact. The bat has a frame with a barrel portion of consistent diameter. A secondary member, or members, of tubular form extend internally along the barrel. The secondary member provides the required radial stiffness variation by: 1) variations in the thickness of the wall of the secondary member or by, 2) secondary members with unique geometric external surface profiles or by, 3) the presence of functional air cavities, with or without closed ends, between the main bat frame and the secondary member or members or by, 4) the presence of numerous annular secondary members located side by side less than one-half the length of the barrel portion.

Owner:EASTON DIAMOND SPORTS LLC

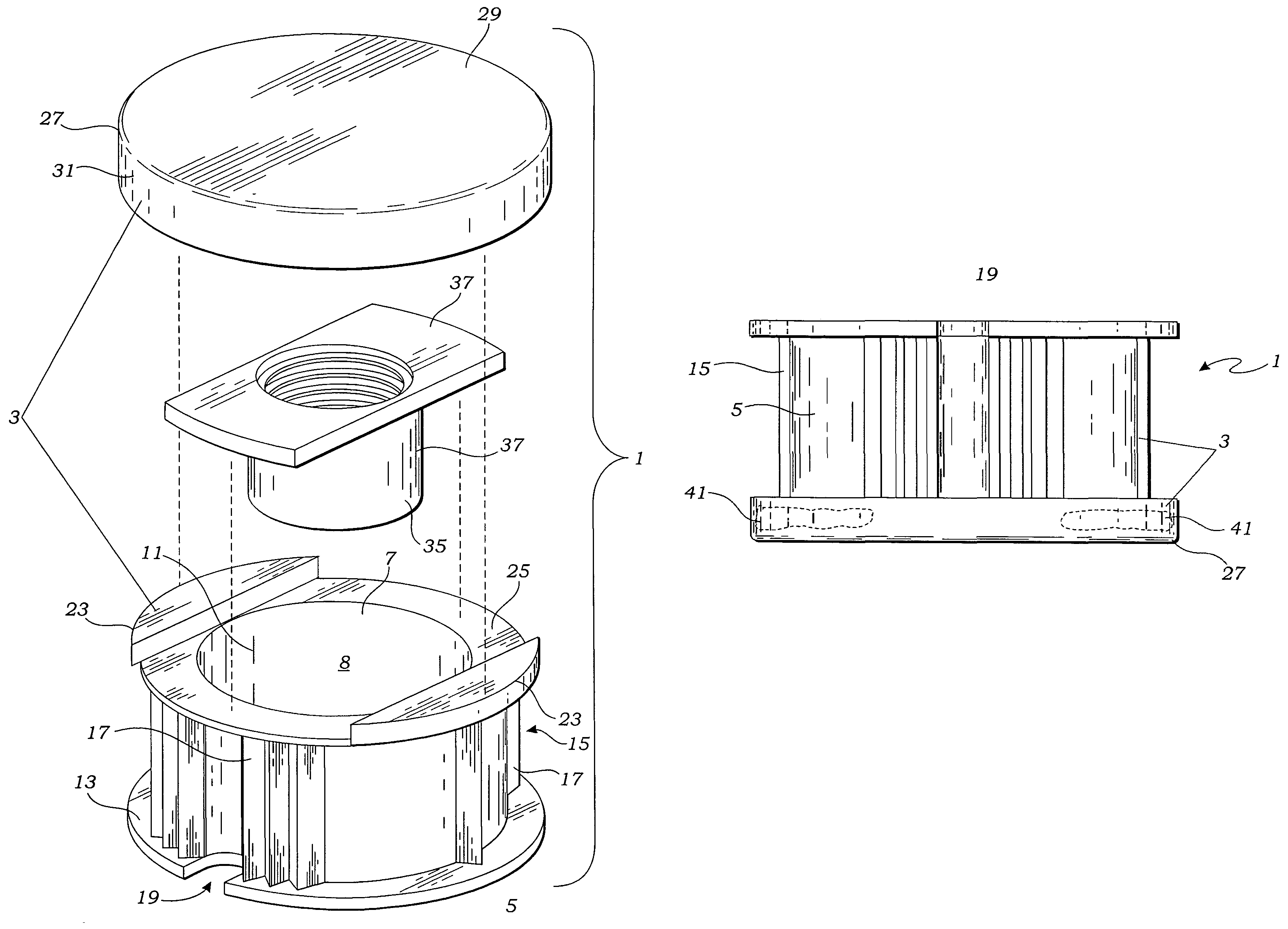

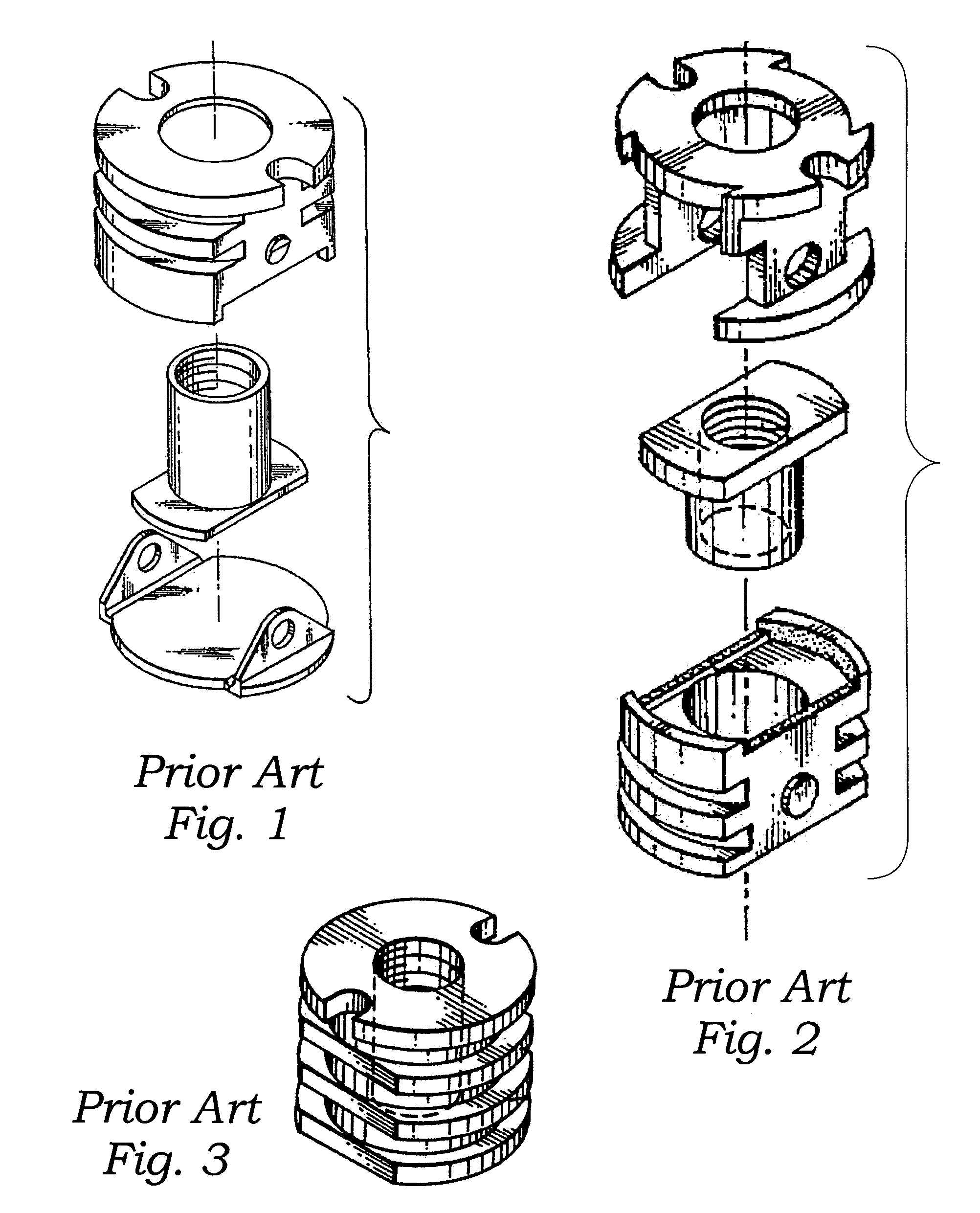

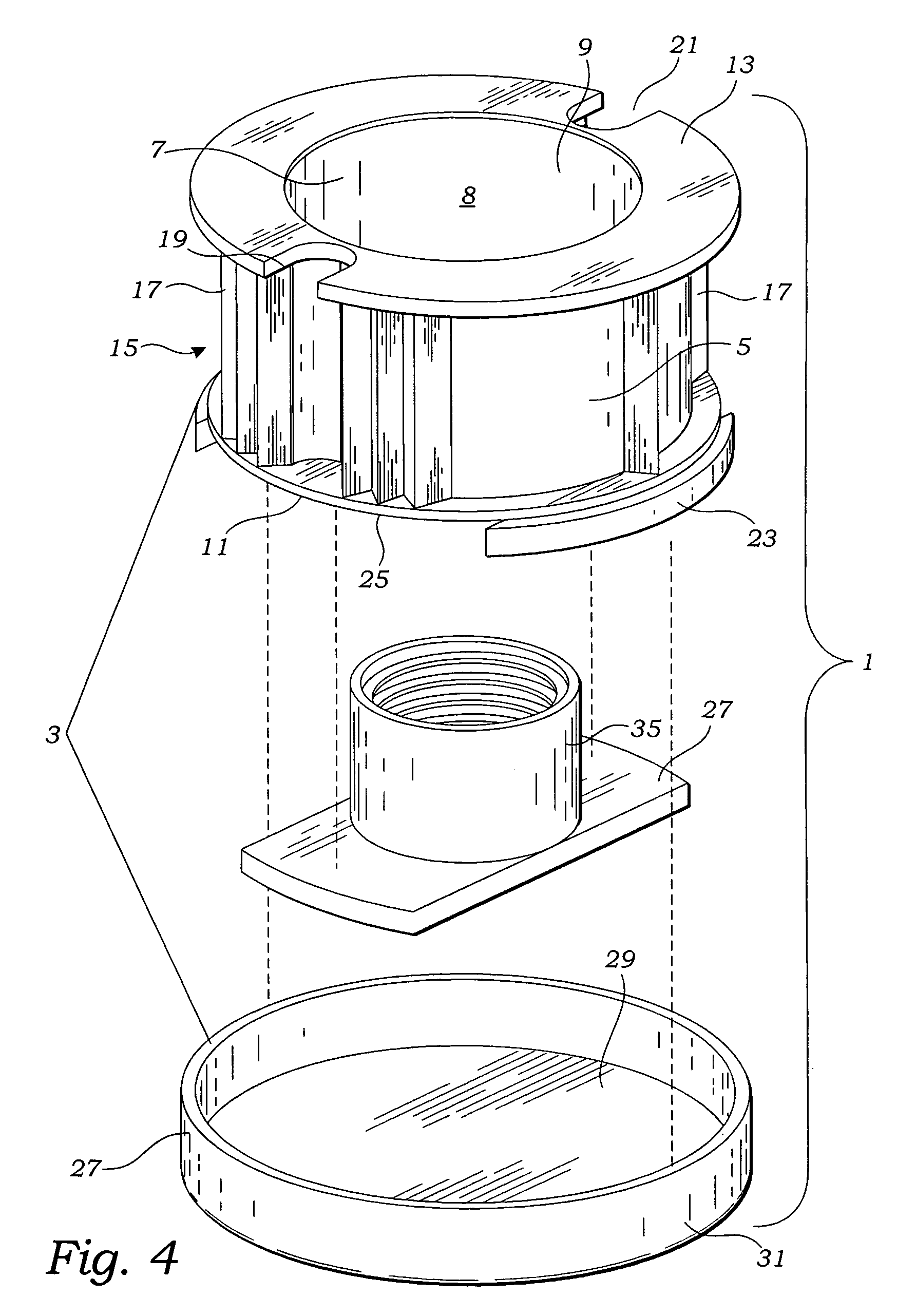

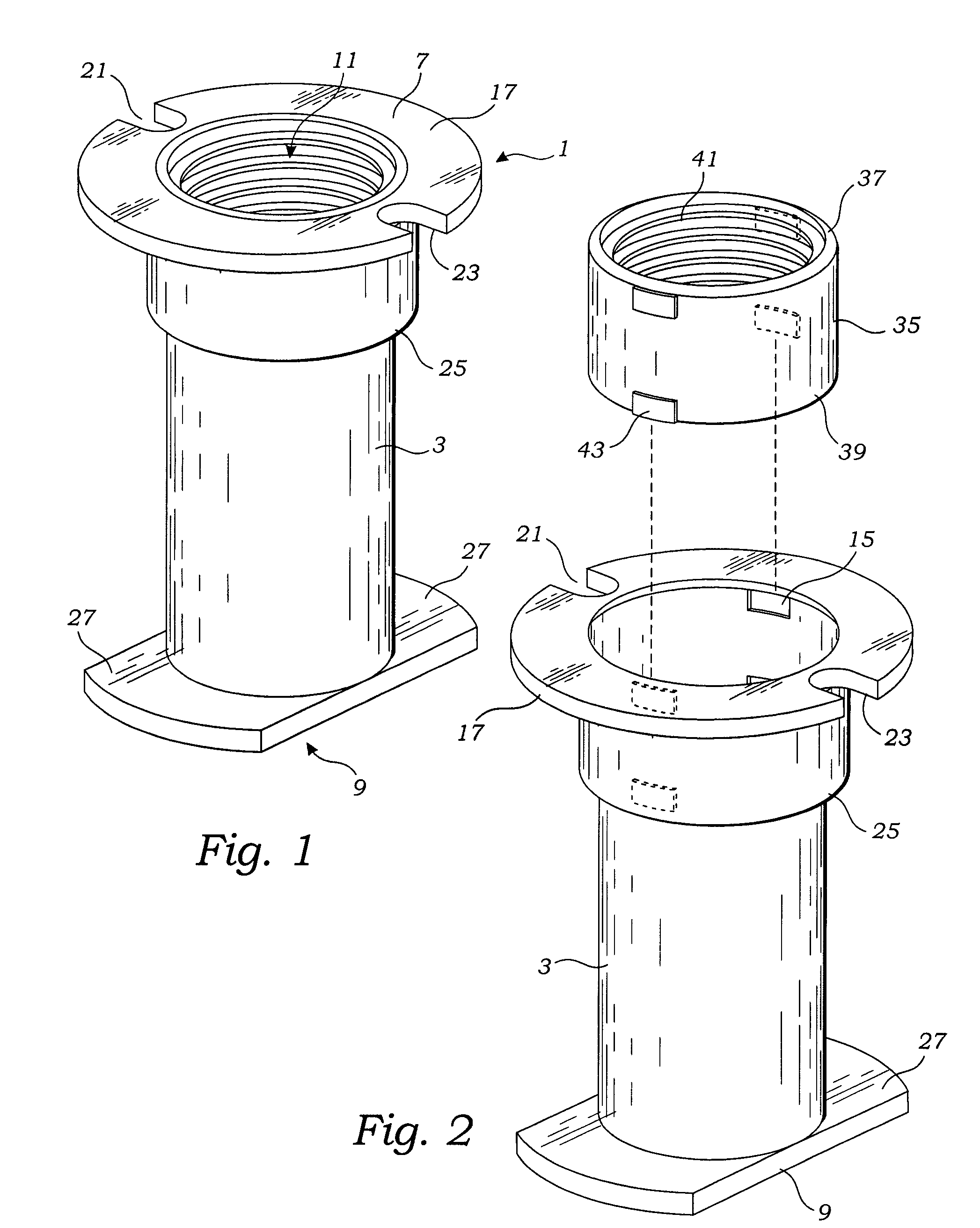

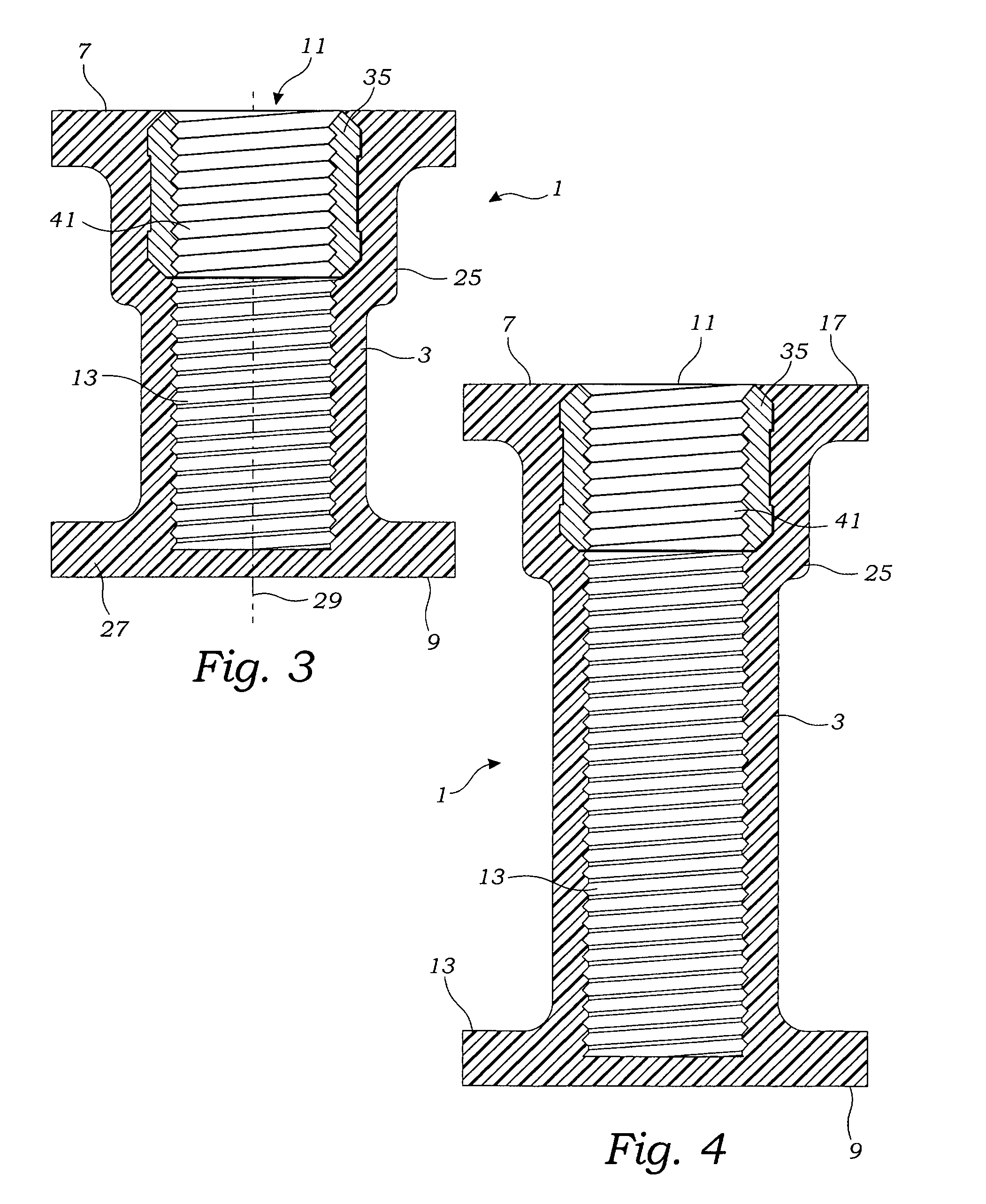

Inset panel fastener

ActiveUS7195436B1Simple engagementPoint of failureRemovable ornamentalMaterial gluingHoneycombAcoustic wave

An inset panel fastener anchors into honeycomb substrates employed in the aircraft industry. The inset panel fastener provides significantly increased load carrying capabilities with a simple inexpensive construction. The inset panel fastener includes a plastic casing and a central floating fastener element. The casing includes a body, disk and cap. The body is generally barrel shaped including a central chamber for holding the fastener element which is preferably a female fastener. The disk radially projects from the top of the body and includes a fill hole and vent hole. Meanwhile, the cap engages and covers the bottom of the barrel shaped body. The cap is affixed in place using a weld, such as a sonic weld.

Owner:NMC GROUP +1

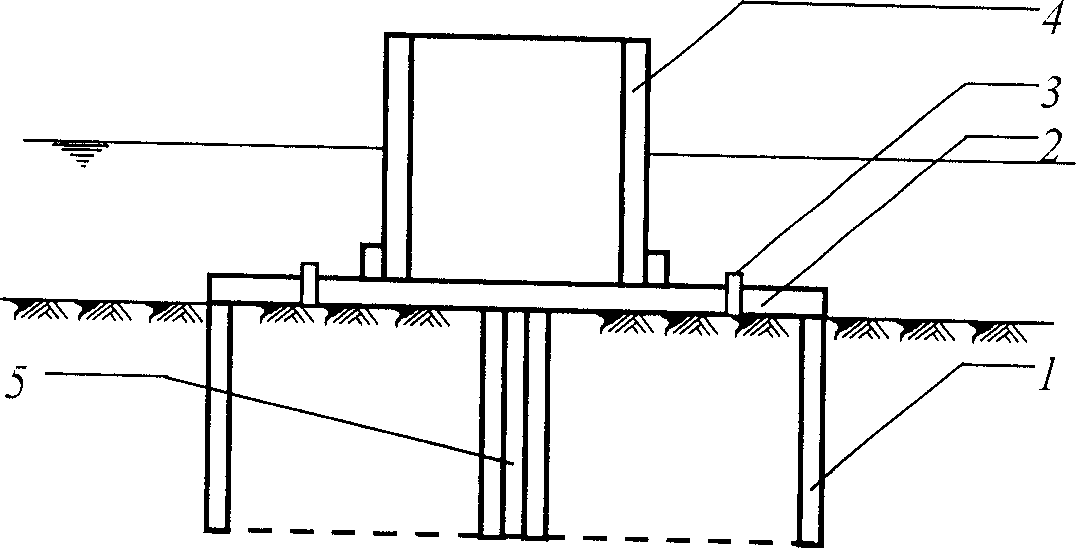

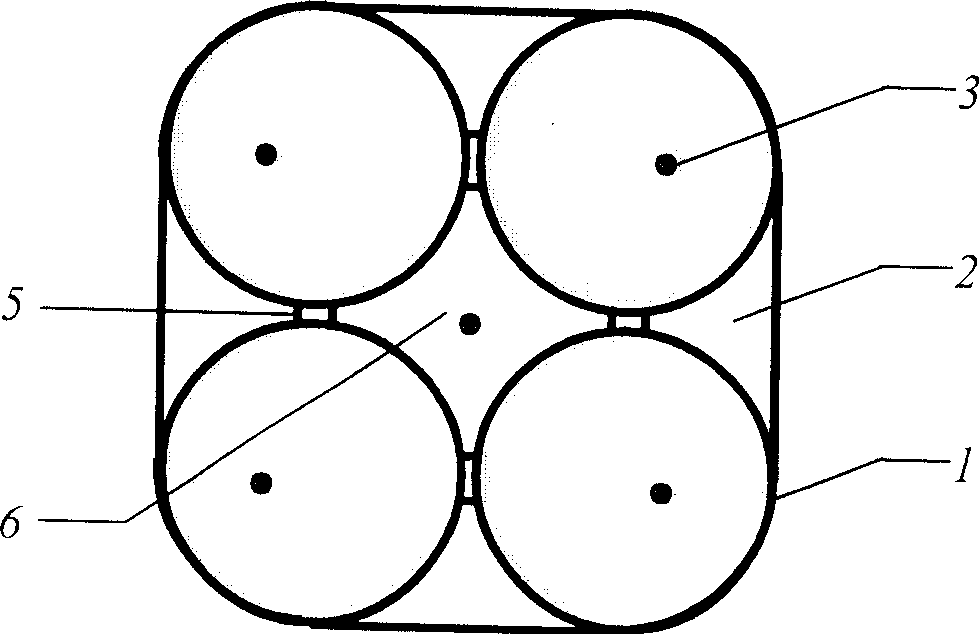

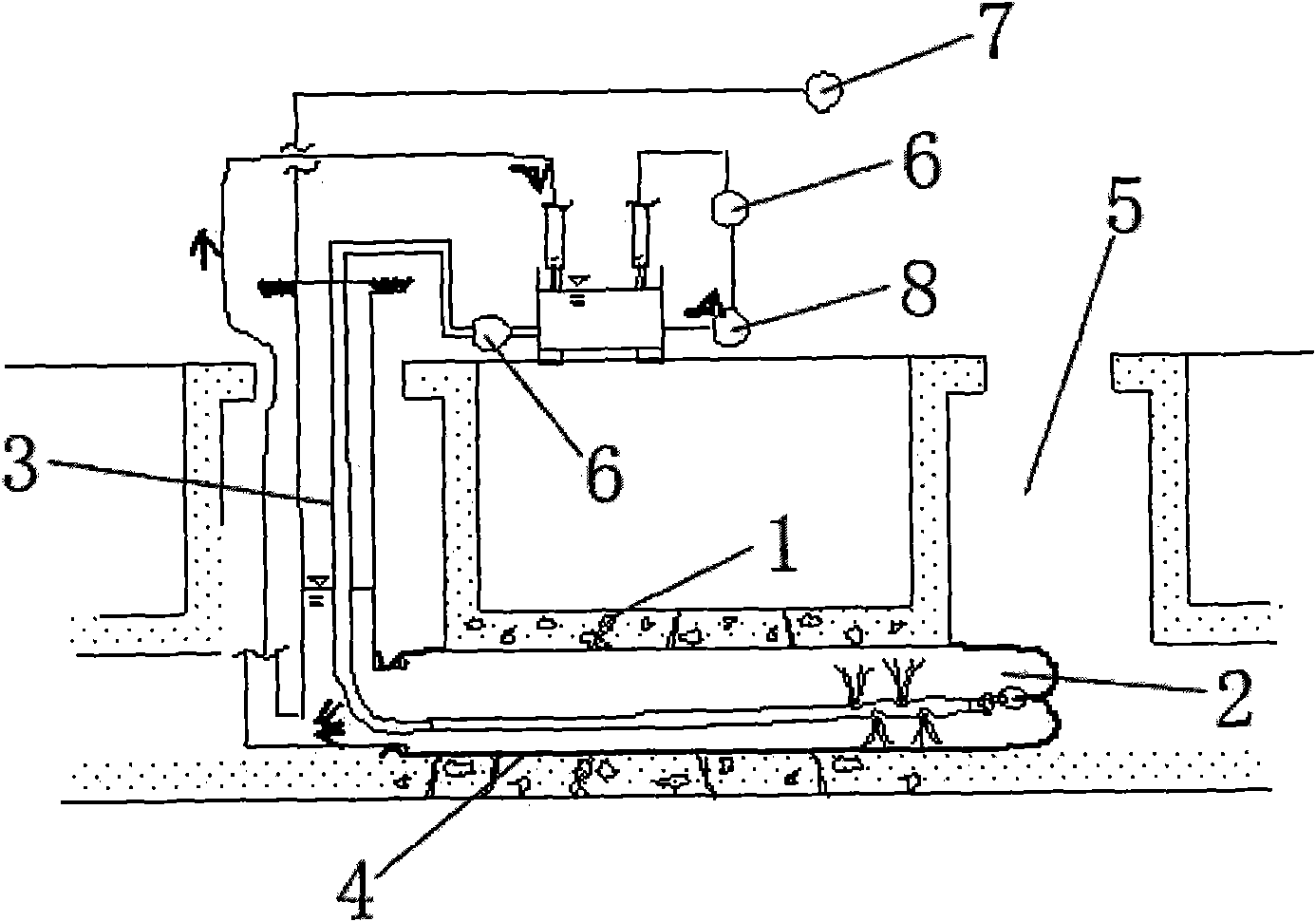

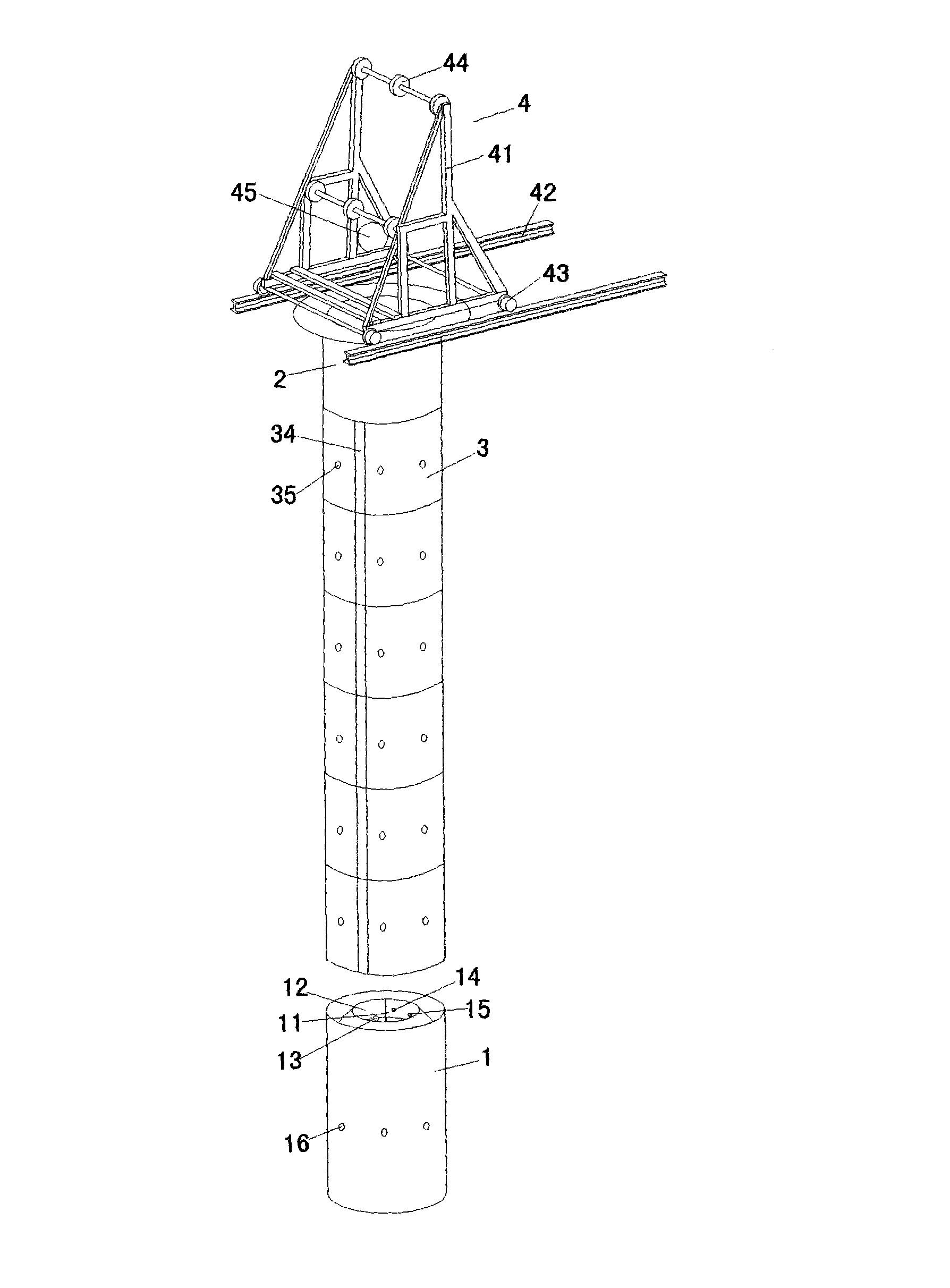

Maritime air float hauling and positioning sinking mounting method for soft-foundation box-cylinder type infrastructure

InactiveCN1730842ALocating sinking equipment is simpleEasy constructionCaissonsEngineeringLightering

The present invention is the marine air floatation hauling and locating and depositing installation process of case and barrel shaped foundation structure for soft soil. The construction process includes inflating the case and barrel shaped foundation structure in water for it to float and hauling to the installation site; locating in the floating state; deflating for deposition via controlling the deflation speed and amount to control the deposition speed and inclination; pumping out air from the structure and applying pressure for further deposition; pumping out water from the structure for further deposition until pumping out all water inside the structure and completing the installation. The said process needs no large hoisting and transportation apparatus, and is simple, controllable and low in cost.

Owner:TIANJIN UNIV

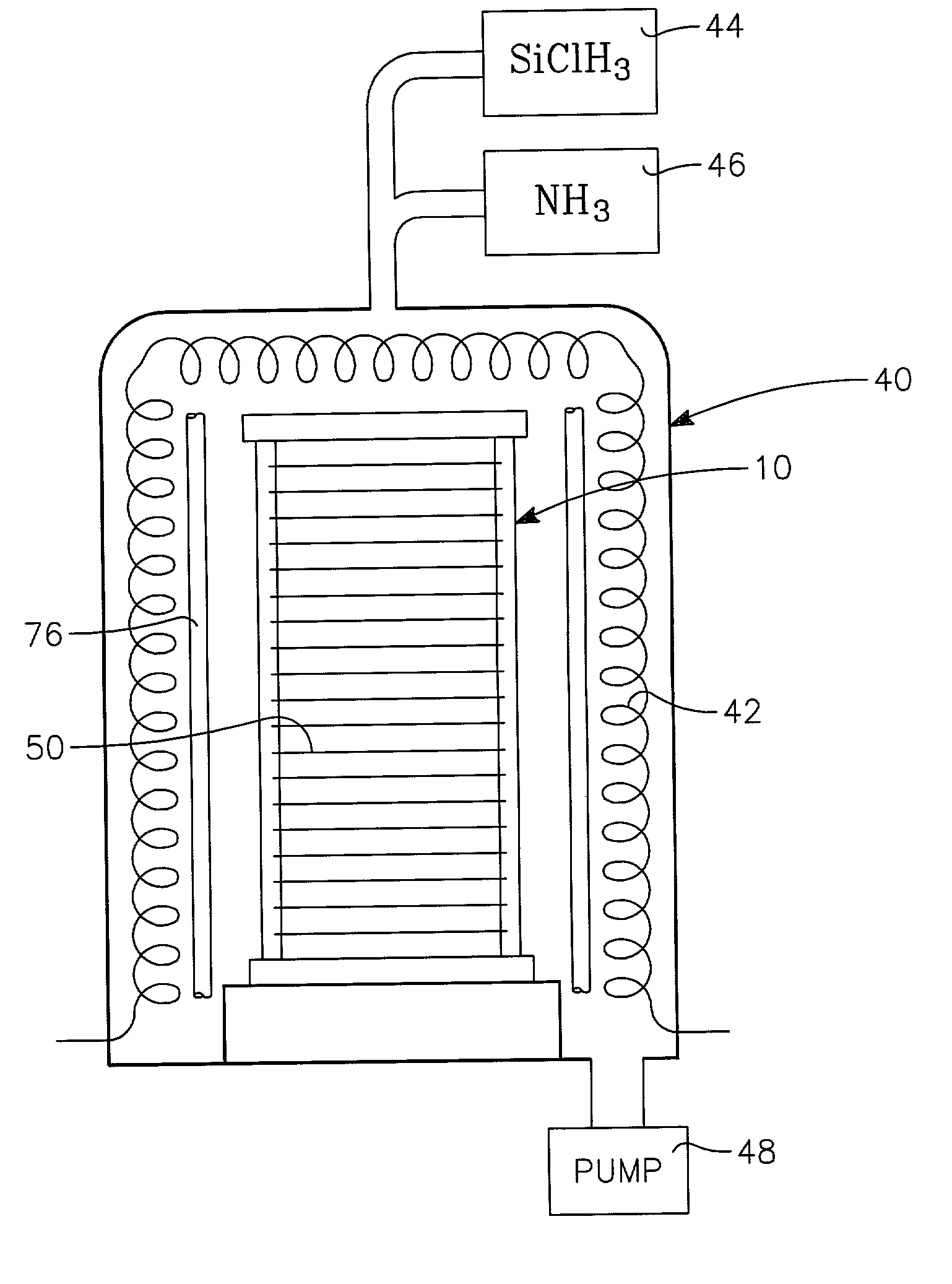

Pre-coated silicon fixtures used in a high temperature process

InactiveUS20020170487A1After-treatment apparatusPolycrystalline material growthGas phaseThermal chemical vapor deposition

A silicon-based wafer support tower particularly useful for batch-mode thermal chemical vapor deposition and other high-temperature processes, especially reflow of silicate glass at above 1200° C. The surfaces of the silicon tower are bead blasted to introduce sub-surface damage, which produces pits and cracks in the surface, which anchor subsequently deposited layer of, for example, silicon nitride, thereby inhibiting peeling of the nitride film. Wafer support portions of the tower are preferably composed of virgin polysilicon. The invention can be applied to other silicon parts in a deposition or other substrate processing reactor, such as tubular sleeves and reactor walls. Tubular silicon members are advantageously formed by extrusion from a silicon melt or by fixing together silicon staves in a barrel shape. The tower parts are preferably pre-coated with silicon nitride or polysilicon prior to chemical vapor deposition of these materials, or with silicon nitride prior to reflow of silica.

Owner:INTEGRATED MATERIALS

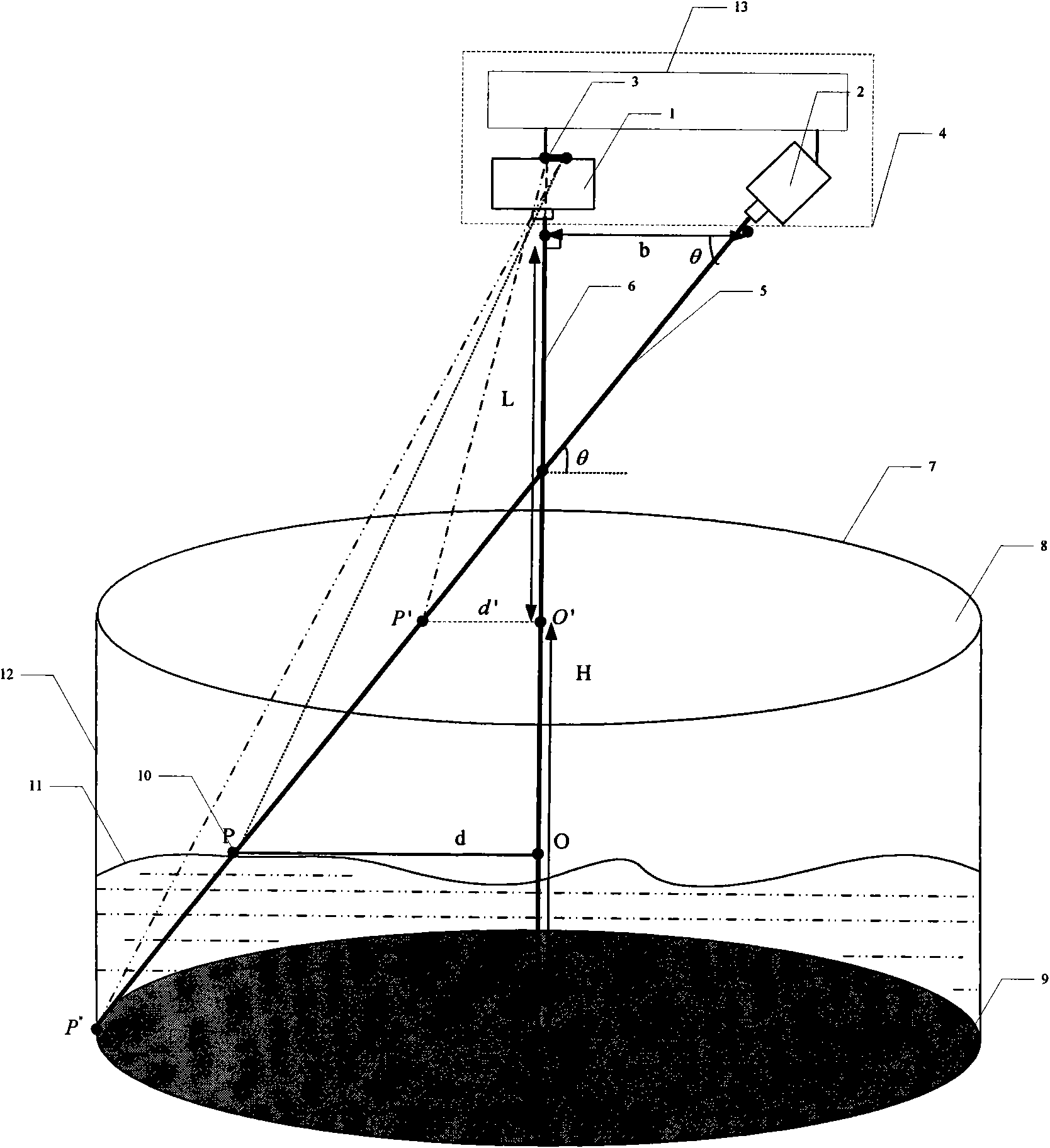

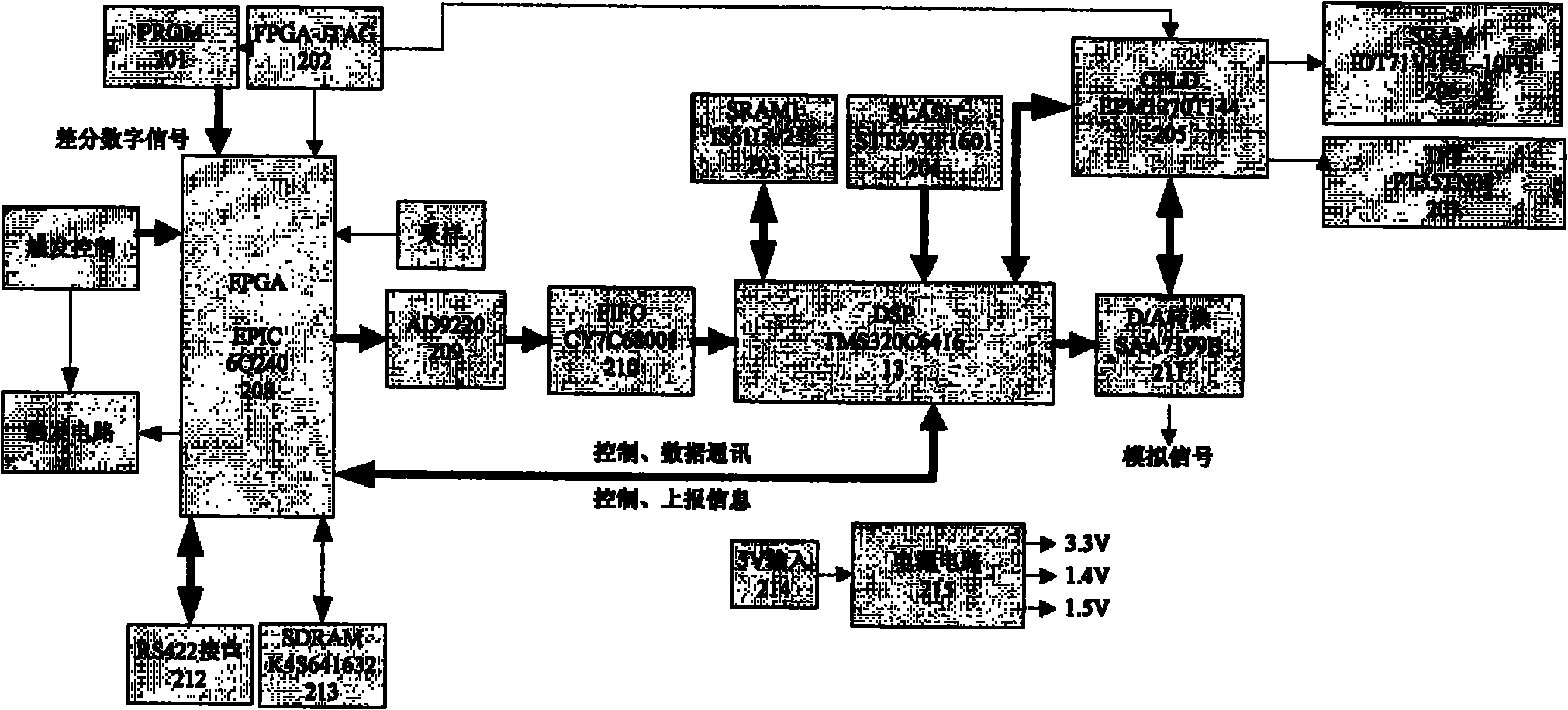

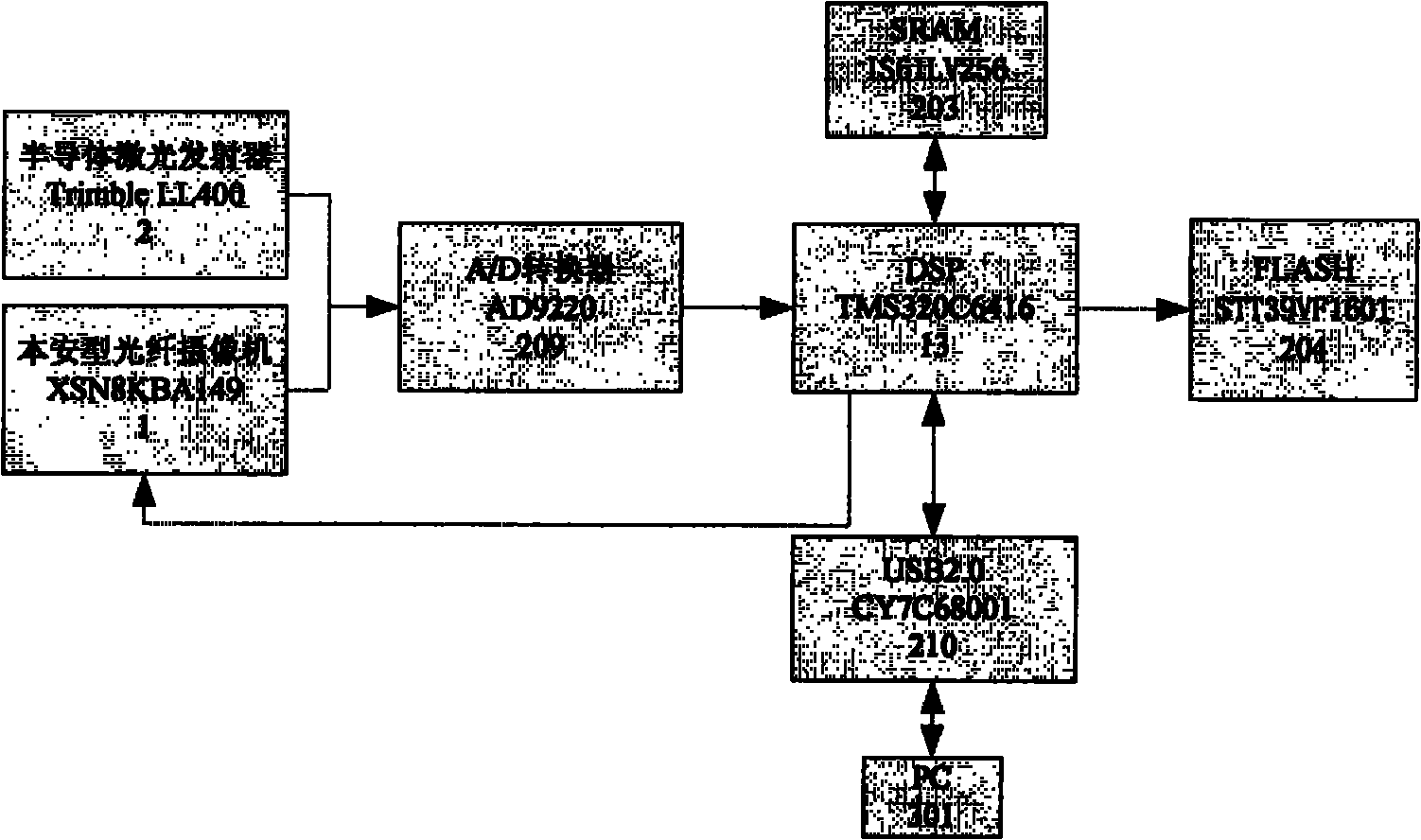

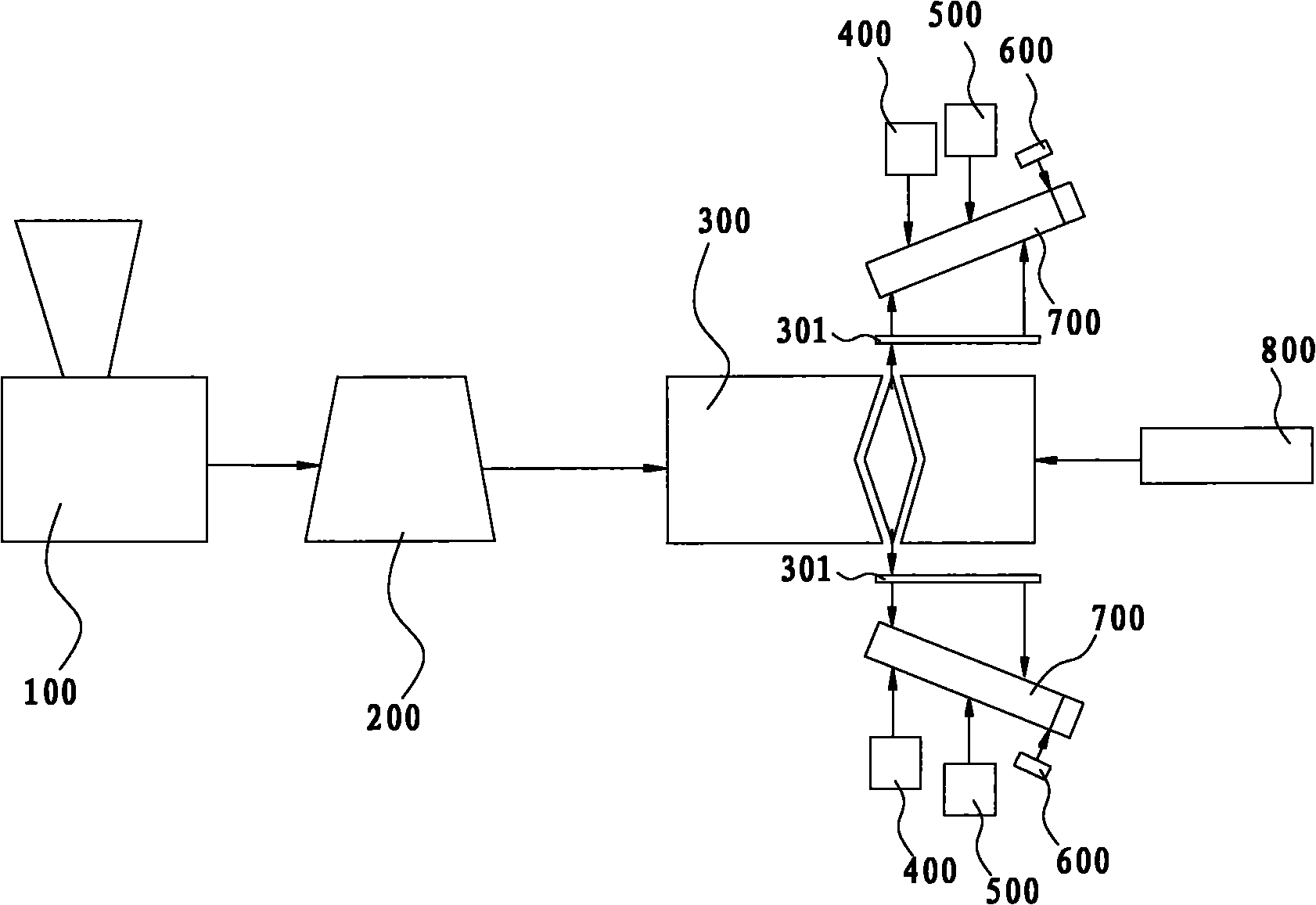

Non-contact photoelectric measurement method and device for bunker coal position

InactiveCN102023045ANo accumulationAccurate measurement dataMachines/enginesLevel indicatorsLaser transmitterMeasurement device

The invention provides a non-contact photoelectric measurement method and device, which obtains the depth value of materials in a bunker on the basis of the number of pixels between a laser facula imaging spot and an image center spot in an image, belonging to the technical field of material position measurement. The invention is especially suitable for measuring the depth of the bunker coal position. In the device of the invention, a digital camera and a laser emitter are fixed on the top of the principal axis of a barrel-shaped bunker, so that the light path of the camera is vertical to the surface of material. The laser emitter is arranged on the position at the angle theta with the horizontal direction so as to ensure that the imaging zone of the laser facula can be projected on the material surface within the field range of the camera. The camera focuses by N-gear segment so as to satisfy the situation that clear images can be shot on all different coal positions of the bunker. DSP (Digital Signal Processor) serves as the inner core of a processor. The number of pixels between the laser facula imaging spot and the image center spot is calculated, and a depth table which is calibrated in advance and corresponds to different pixel number mean values is inquired to finish depth detection. The measurement device is composed of the digital camera, the laser emitter, the image processor and a real-time display module.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

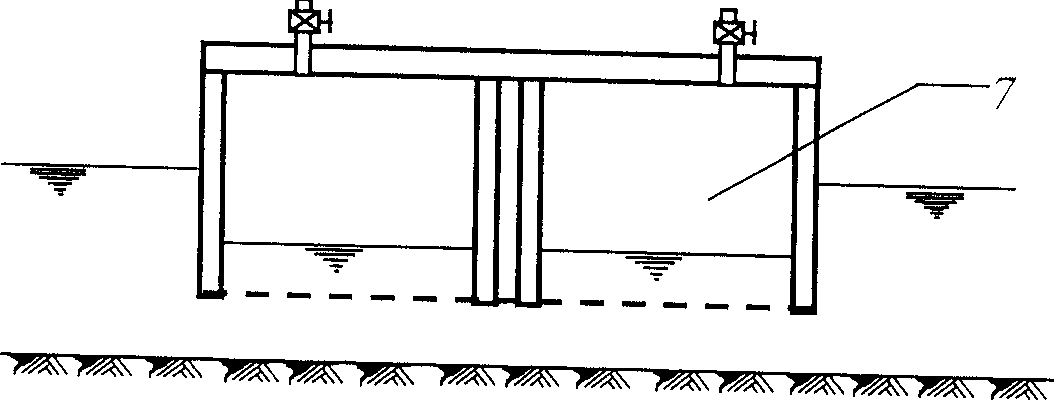

Undersea suction anchor

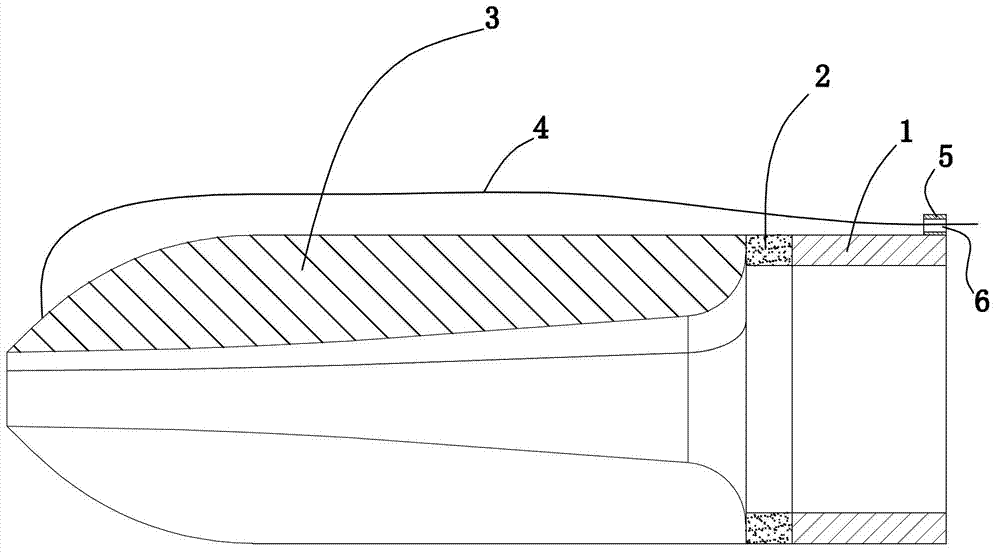

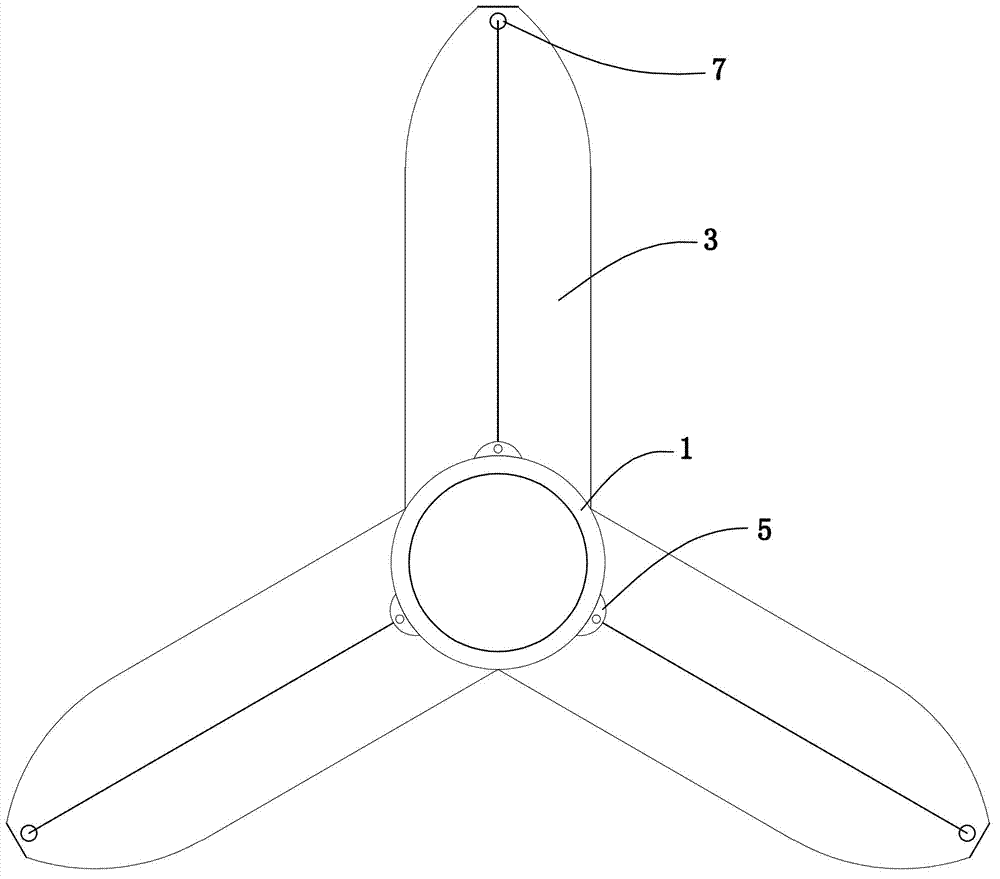

InactiveCN103132521AImprove stabilityImprove pullout resistanceArtificial islandsAnchorsCorrosionSeabed

The invention discloses an undersea suction anchor which comprises a main drum, a top face of the main barrel is sealed, a lower end of the main barrel is opened, and a main barrel drainage hole is arranged on the top face of the main drum. The undersea suction anchor is characterized in that a barrel skirt is movably sleeved on the main drum, the barrel skirt comprises a horizontal top face and a barrel-shaped lateral wall, a barrel skirt drainage hole is formed in the horizontal top face of the barrel skirt, a telescopic hook locating the barrel skirt at the upper portion of the main barrel is arranged on the barrel-shaped lateral wall at the upper portion of the main barrel, an anchor ring concentric with the main barrel is arranged at the upper end of the main barrel, anchor branches are evenly arranged on the anchor ring, one ends of the anchor branches are hinged to the anchor ring, and the other ends of the anchor branches are hinged to the barrel skirt through inclined support rods. The whole vertical section of the suction anchor is in an umbrella shape, in the sinking process of the anchor body, along with landing-on-seabed of the barrel skirt, the anchor branches are driven by the inclined support rods to be gradually opened, and after the main barrel sinking is finished, the anchor branches cling to the surface of the seabed in a horizontal extending mode. The undersea suction anchor can improve the integral stability of the suction anchor, increases pulling resistance and horizontal bearing force, and reinforces wave-corrosion-resistance performance.

Owner:OCEAN UNIV OF CHINA

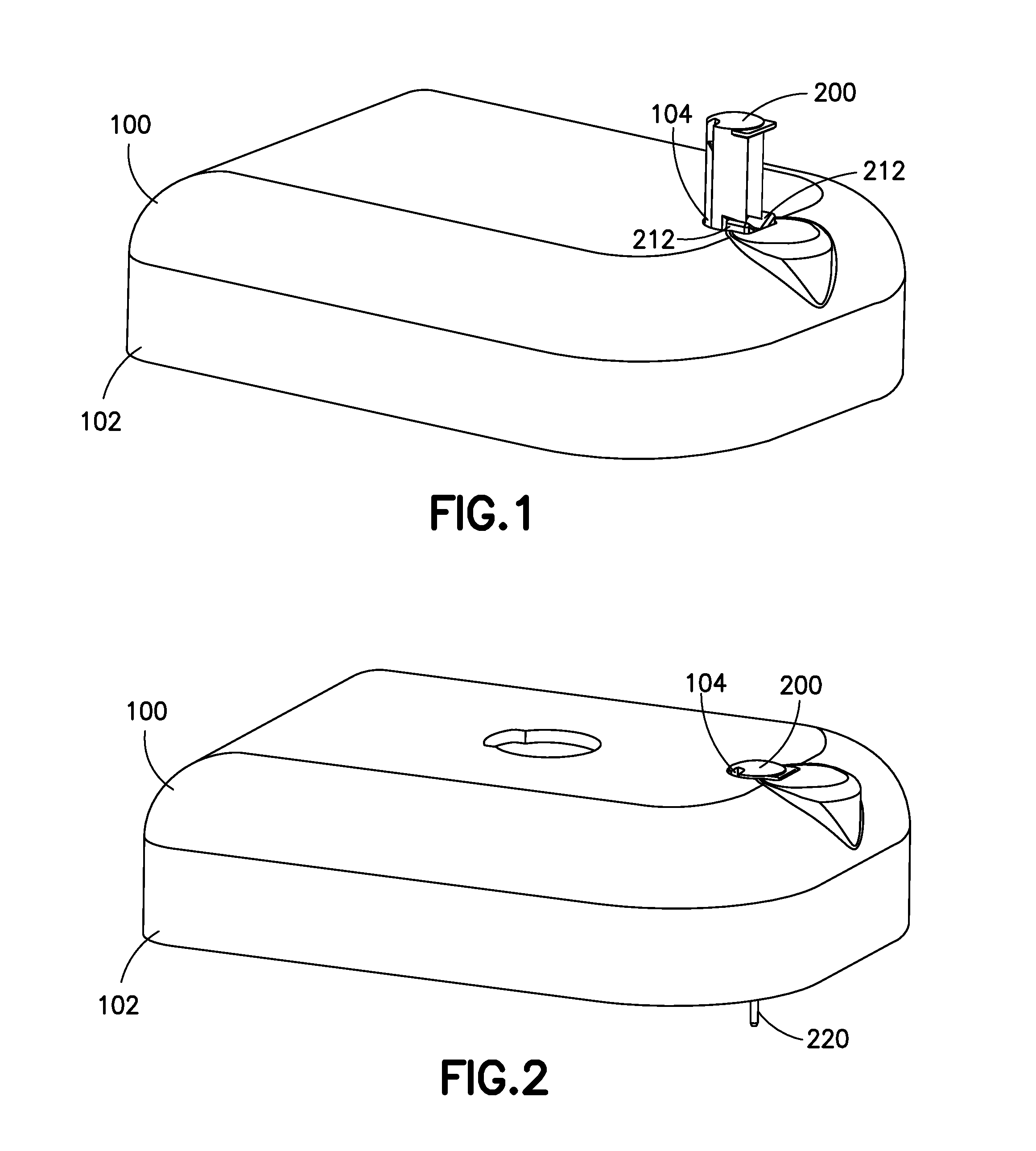

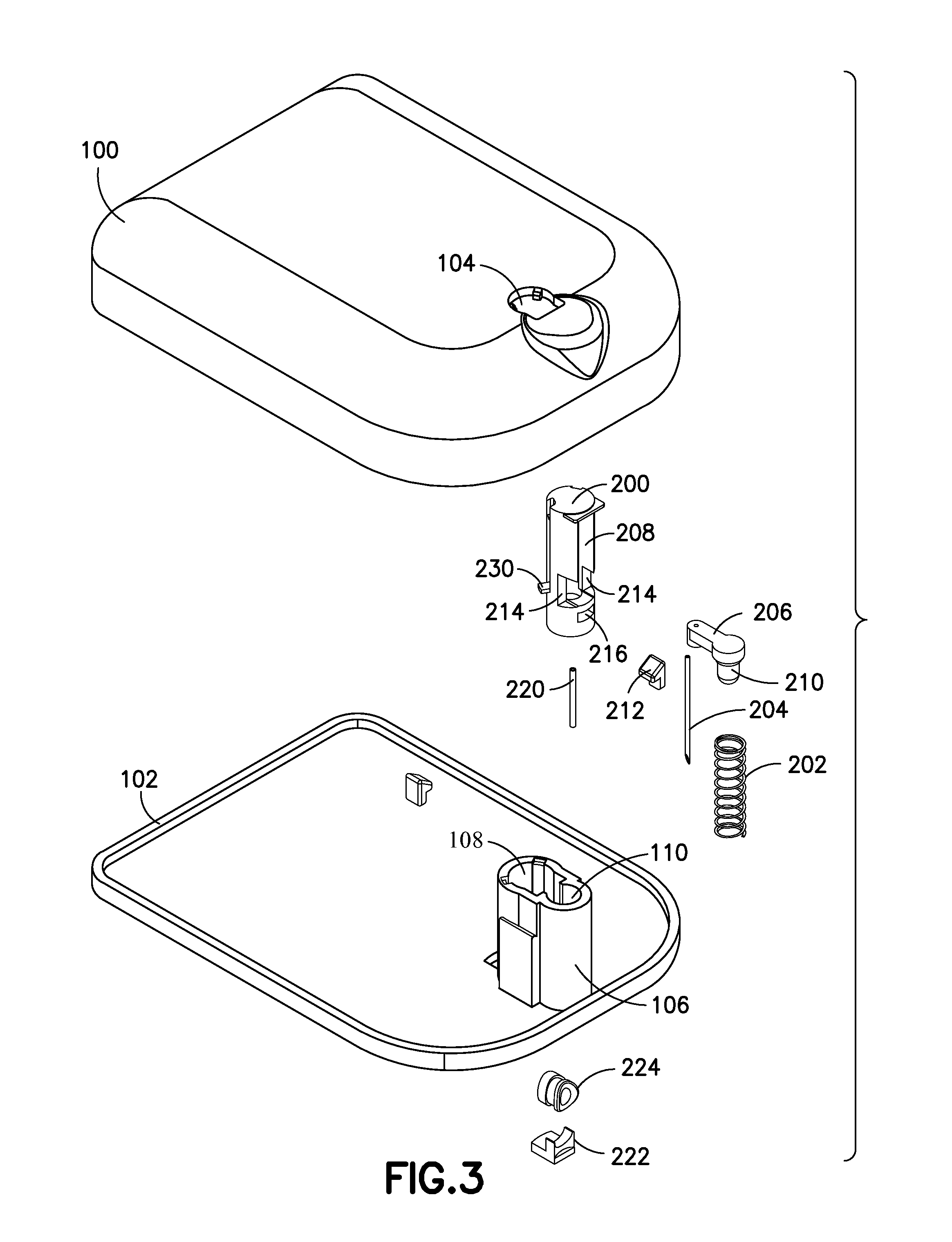

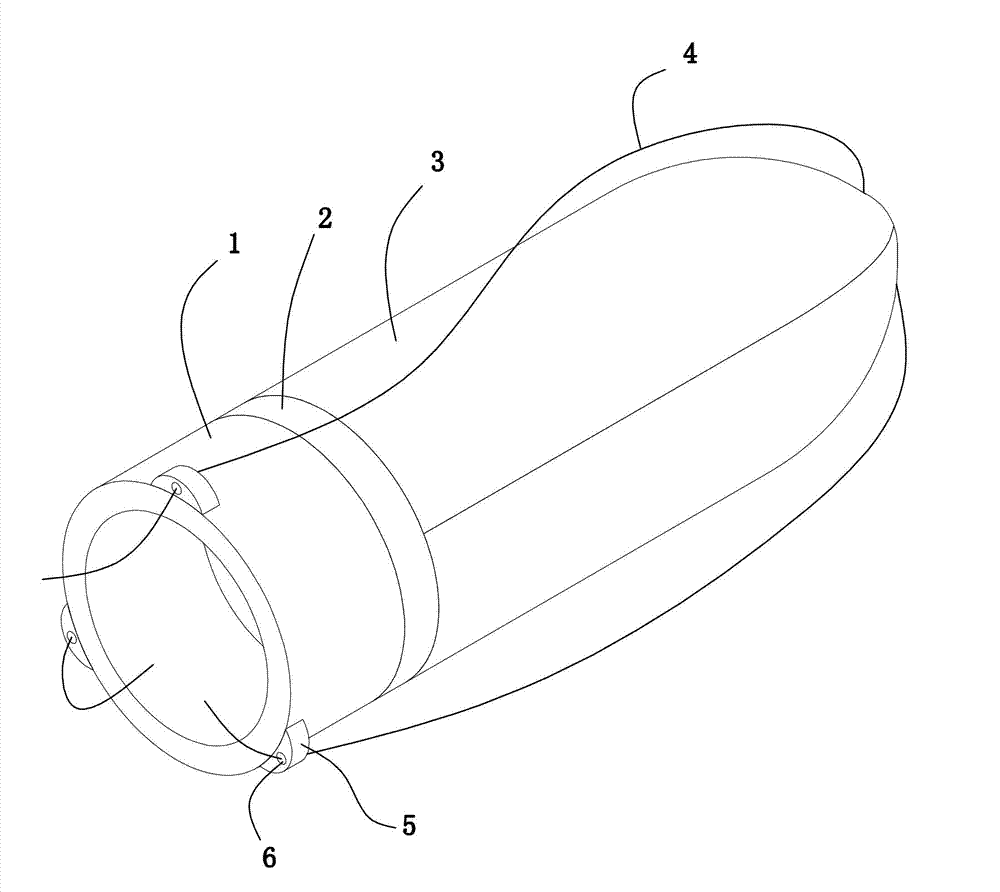

Catheter insertion mechanism for a patch pump

ActiveUS20170021137A1Easy to insertReduce in quantityGuide needlesMedical devicesSkin surfaceManual insertion

Manual insertion device has retraction spring (202) and hollow septum configuration (224) implemented using barrel-shaped guides (108, 110) and a guiding boss (210) in insertion device housing (106), and provides a fluid path through alignment of septum openings, side-port openings and catheter openings upon complete catheter insertion. Button (200) causes manual insertion of introducer needle (204) and catheter (220) of a first barrel (108) into a skin surface, and loading of retraction spring (202) disposed in an adjacent second barrel (110). Once introducer needle (204) and catheter (220) are fully inserted, the introducer needle hub (206) is released and automatically retracted by release of the retraction spring (202), leaving the catheter (220) in the user's body. Septums (218, 224) and side-port openings (216, 228) in the button (200) and introducer needle (204) are thus aligned, creating an uninterrupted fluid path between a reservoir or pump and catheter (220).

Owner:BECTON DICKINSON & CO

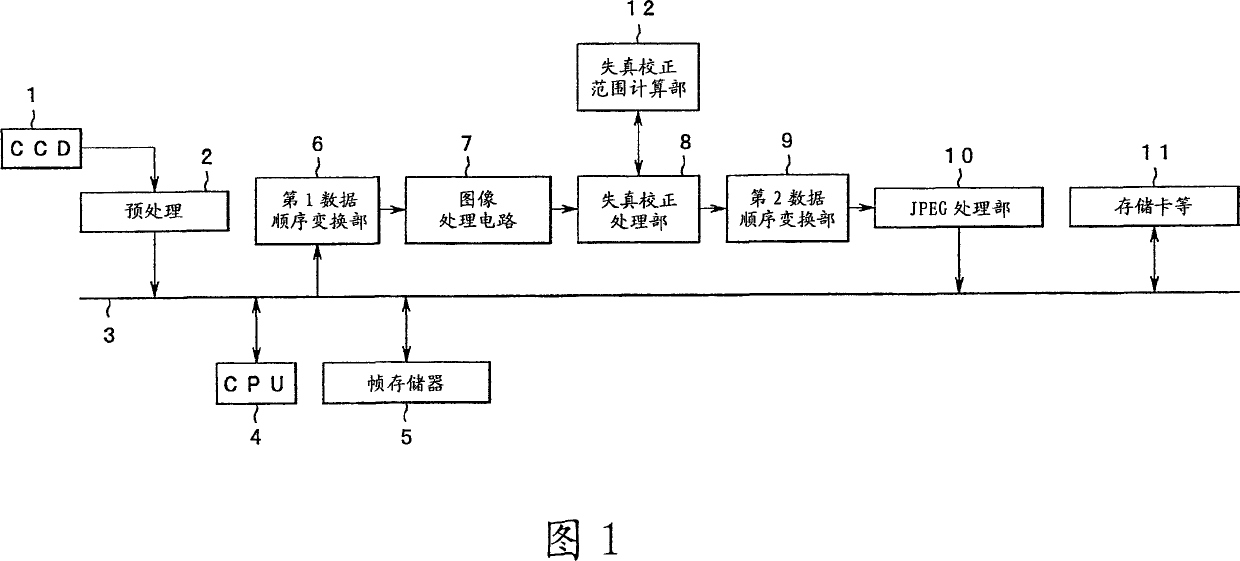

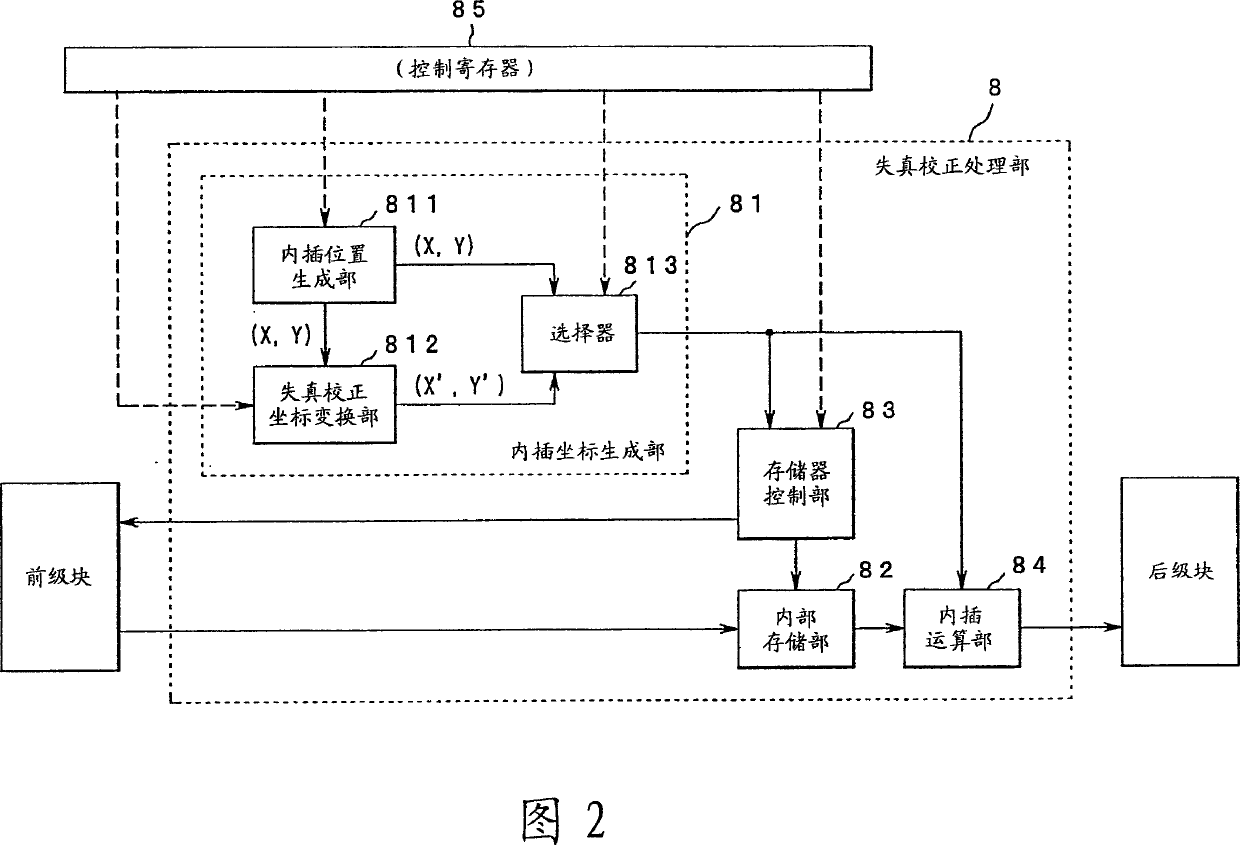

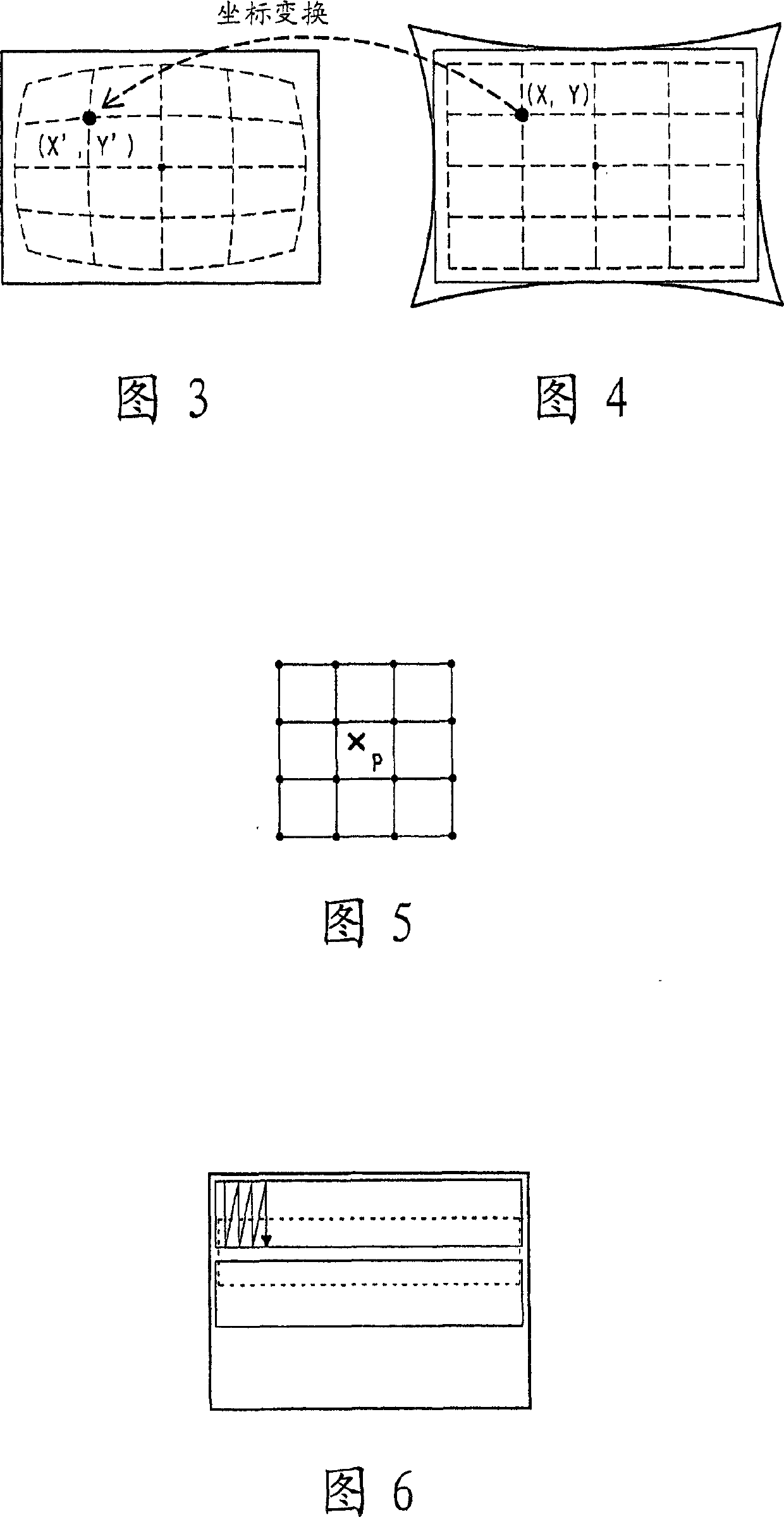

Image processing apparatus, image processing method, and distortion correcting method

The image processor having a distortion correction processing part 8 includes a distortion correction range calculating part 12 for calculating an input image range necessary for the distortion correction processing part 8 to perform distortion correction processing. Thereby, a corrected image(output image) acquired by the distortion correction can be outputted to an image output range neither excessively or insufficiently. Thus, distortion correction processing to effectively use input(photographic) image data being original data can be performed, and effective distortion correction processing can be performed even to bobbin-shaped distortion, barrel-shaped distortion or soldier's helmet-shaped distortion.

Owner:OLYMPUS CORP

Indoor experimental device for simulating interaction of deep water drilling underwater casing string and seabed shallow soft soil

ActiveCN102607872AEasy to useEasy to operateSurface/boundary effectEarth material testingOcean bottomData acquisition

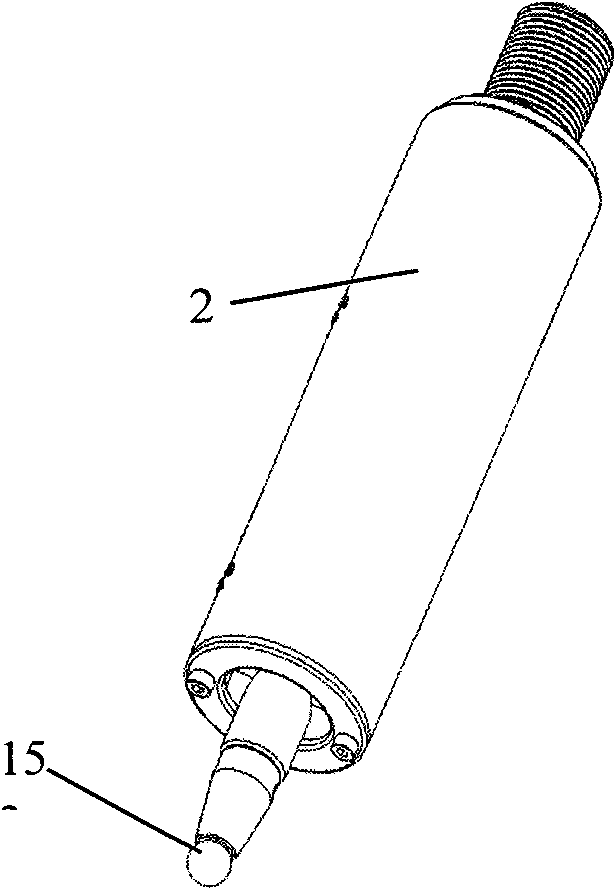

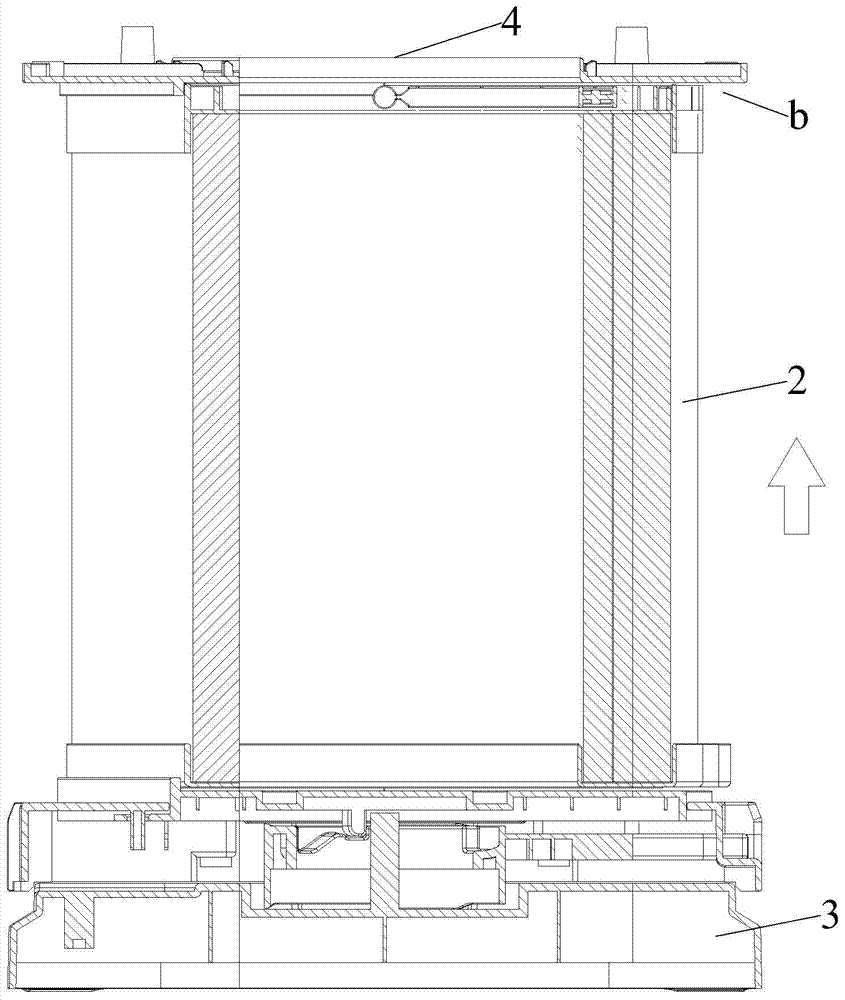

The invention discloses an indoor experimental device for simulating interaction of a deep water drilling underwater casing string and seabed shallow soft soil. The indoor experimental device comprises a hollow barrel-shaped object (1), a bottom clamping device (2), a variable cross-section casing string combination (3) and a data acquisition system (15), wherein the bottom of the hollow barrel-shaped object (1) is provided with the bottom clamping device (2) which is used for clamping and fixing the bottom end of the variable cross-section casing string combination (3) for an experiment; and the data acquisition system (15) is connected with a force sensor (12) of a cyclic loading device (9), an acceleration sensor (10) and a telescopic displacement sensor (11) which are arranged at the top of a casing string, a strain gauge (6) attached on the pipe wall of the variable cross-section casing string combination (3), and a soil pressure meter embedded in the periphery of the variable cross-section casing string combination (3), and is used for acquiring experimental data in real time. According to the indoor experimental device, the indoor experiment research of the interaction mechanism of the underwater casing string and the seabed shallow soft soil under the action of a transverse circulating load under different working conditions of deep water drilling can be completed, an experiment result can provide support for deep water drilling in China, and remarkable economic benefit is brought.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Air bag with high intensity and its manufacturing technique

ActiveCN1666924ALow cost of launchingIncrease elasticitySlipwaysHollow articlesInternal pressureHigh intensity

The invention is a high-intension gas cell and its facture. The gas cell comprises the cell body, the cell head and the air gate mouth. The cell body is composed of the inner sleeving layer and plural layers of curtain cloth. The cell head and the cell body are jointed together to form the conoid shape, the cell head is solidified with the air gate mouth. The facture is to longitudinal arrange the curtain cloth, adhere the two sides and roll them to barrel shape to be the inner sleeve. The demolishing inner pressure of the gas cell is higher than 1.11 MPa, and the cell wall is sealed well. The invention has a wide range of appliance.

Owner:JINAN CHANGLIN AIR BAG CONTAINER FACTORY

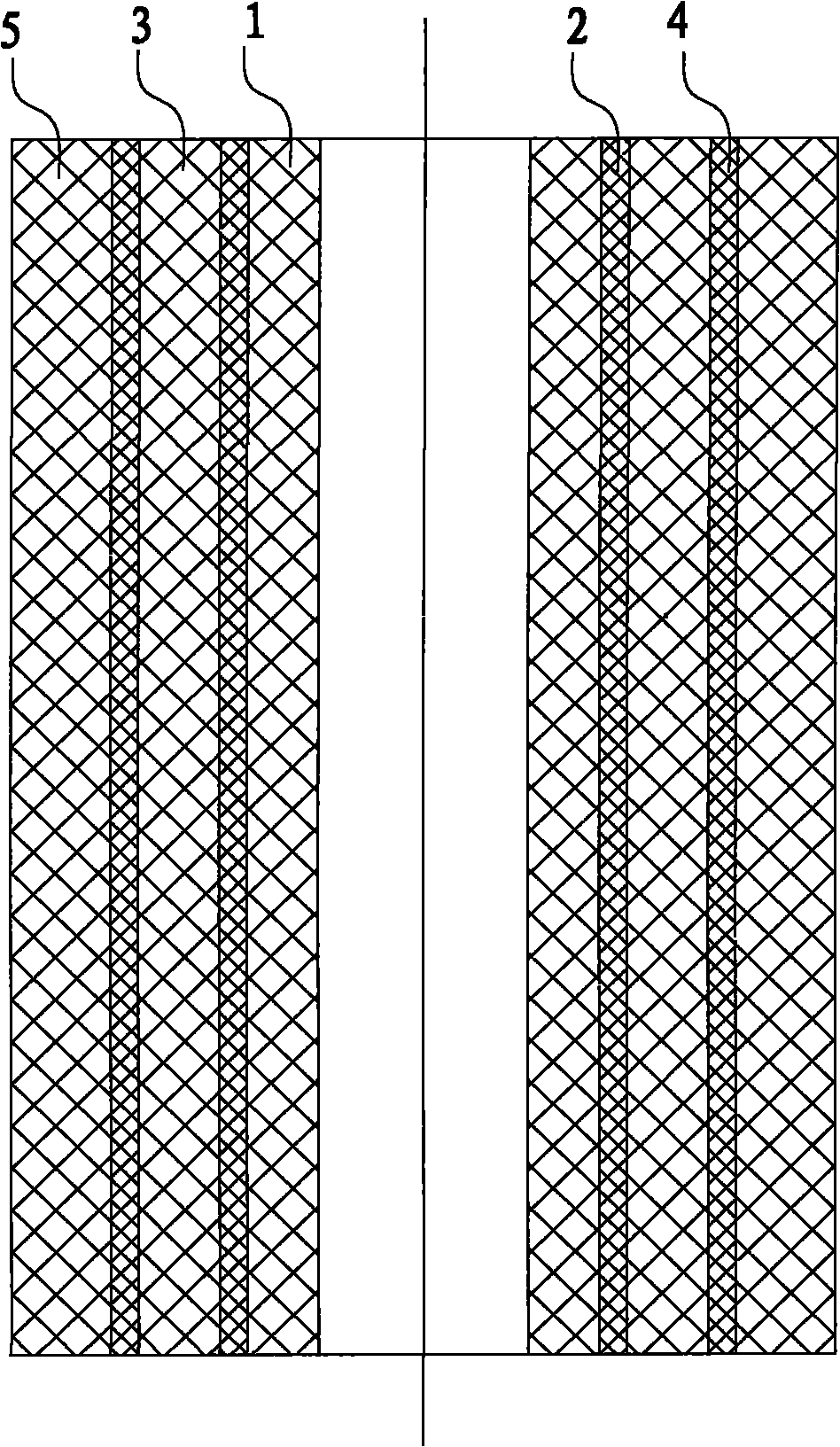

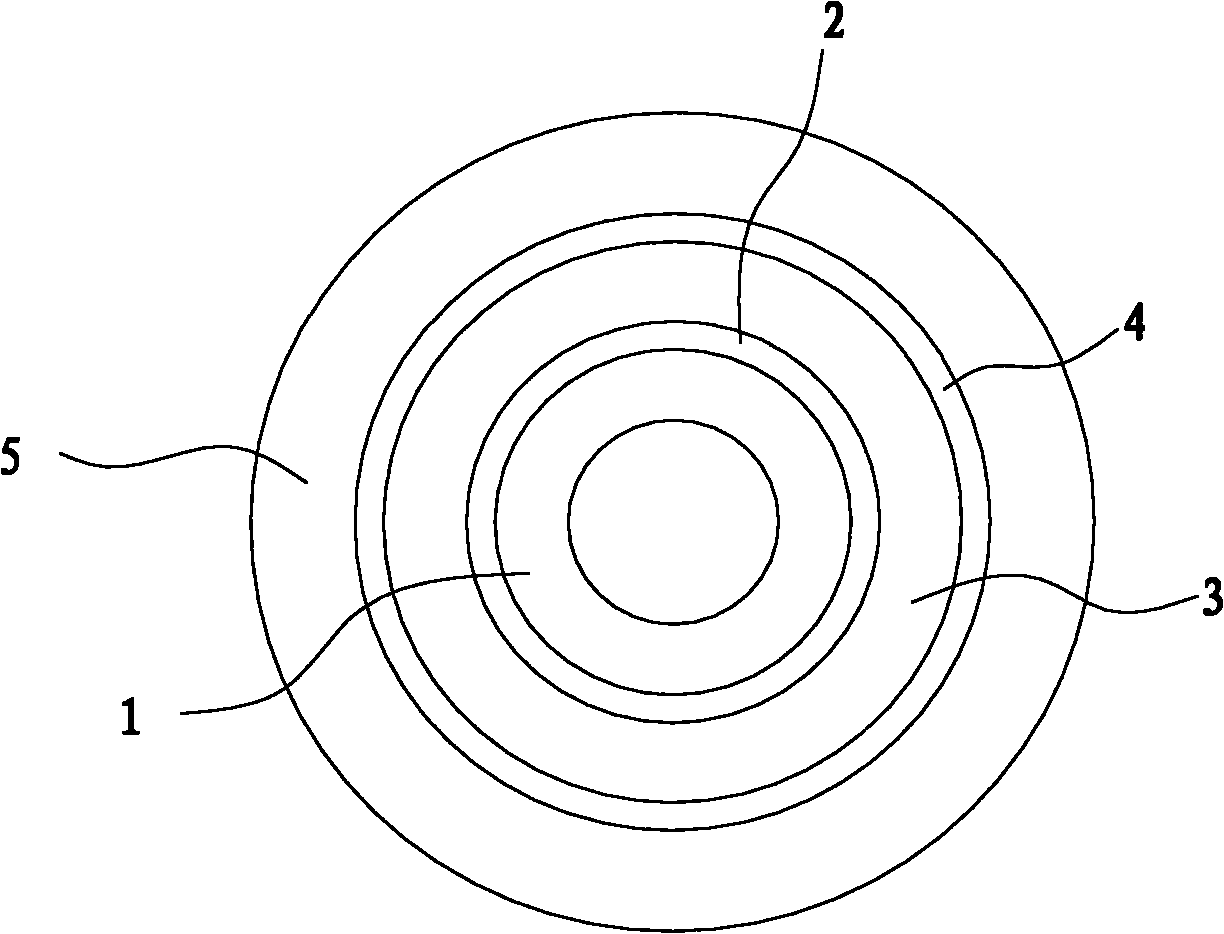

Filter core and manufacturing method thereof

InactiveCN101829452AImprove stiffnessHigh hardnessDispersed particle filtrationMembrane filtersHigh stiffnessCarrying capacity

The invention discloses a filter core. The filter core is barrel-shaped and sequentially comprises an inner fine-filtering fiber layer, an adsorptive fiber layer, a middle fine-filtering fiber layer, a skeleton fiber layer and an outer coarse-filtering fiber layer from inside to outside in the radial direction, wherein the filtering pore diameters of the inner fine-filtering fiber layer, the middle fine-filtering fiber layer and the outer coarse-filtering fiber layer are gradually increased from inside to outside in the radial direction. The filter core of the invention has the advantages of wide application range, high filtering precision, large pollutant carrying capacity, high stiffness and long service cycle, thereby being a non-metal low-carbon filter core which can be reclaimed for cyclic utilization. The invention also discloses a manufacturing method of the filter core.

Owner:BEIJING SZYN TECH

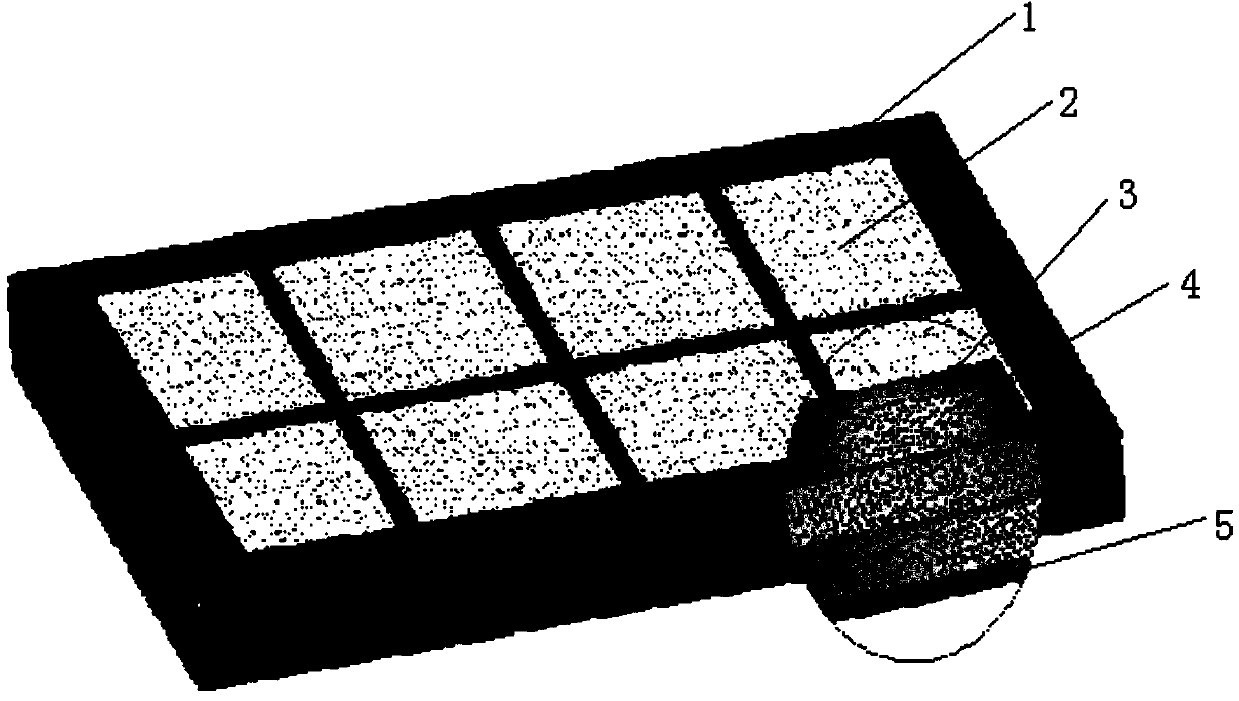

Preparation method of activated carbon fiber net of air purifier

ActiveCN103736467AEvenly distributedReduce usageOther chemical processesSynthetic resin layered productsMolten stateFiltration

The invention relates to the technical field of auxiliary parts of an air purifier, and particularly relates to an activated carbon fiber net of an air purifier and a preparation method of the activated carbon fiber net. The activated carbon fiber net comprises a filter core and a filter frame, wherein the filter core is in a barrel shape or a plate shape; the filter core is adhered to the filter frame; the filter core comprises an upper nonwoven fabric layer, at least two layers of activated carbon filter layers and a lower nonwoven fabric layer; the upper nonwoven fabric layer, at least one layer of activated carbon filter layer and the lower nonwoven fabric layer are orderly laminated; the activated carbon fiber layer comprises a polymer support net and a mixing layer composed of an adhesive fiber in a molten state and activated carbon; the polymer support net is adhered to the mixing layer; the dosage of the adhesive is low; a microcellular structure at the surface of the activated carbon is hardly affected; the adsorptive property is not affected; the activated carbon is evenly distributed in the overall filter net, is fully contacted with air during use; the filter resistance is uniform; a drift phenomenon does not exist; the adsorption and filtration efficiency is high.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

Inset panel fastener

An inset panel fastener is provided primarily for honeycomb substrates, such as those employed in the aircraft industry. The inset panel fastener includes a plastic body portion and a metal female threaded nut positioned within the body. The body includes a cylindrical barrel shape having a top and a bottom. A bore extends through the body from the top to form an opening for receipt of a male fastener. The metal nut has locking threads and is positioned in body's bore at the body's top proximal extremity. The body further includes non-locking plastic female threads integrally formed into said body's bore. The plastic female threads have the same diameter as the metal threads and are immediately adjacent to the metal threads so as to form continuous threads for permitting receipt of a male threaded fastener. The metal female threads are locking threads to provide a locking action for locking a male fastener to the inset panel fastener. Meanwhile, the plastic female threads provide primary load bearing capabilities for the inset panel fastener.

Owner:NMC GROUP +1

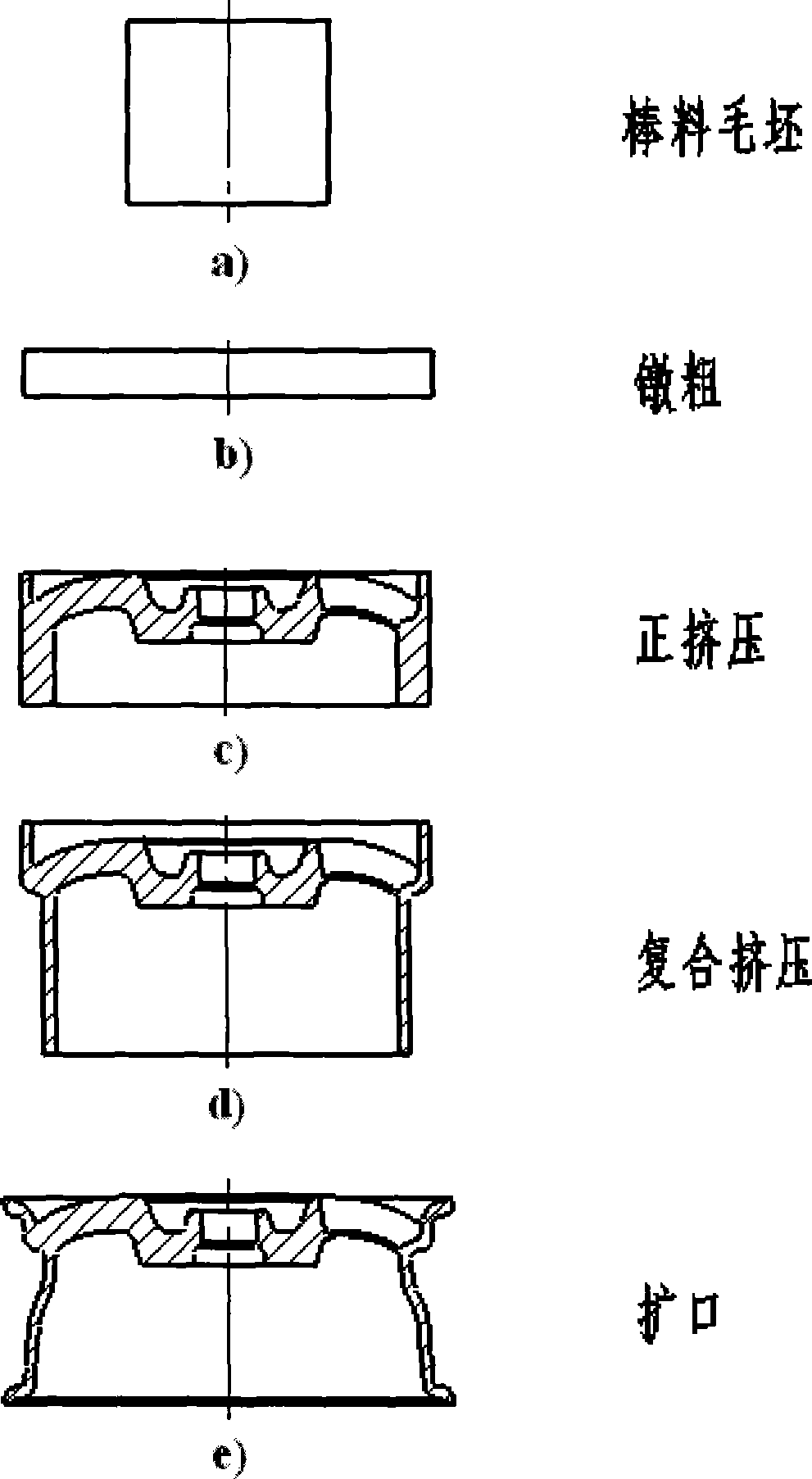

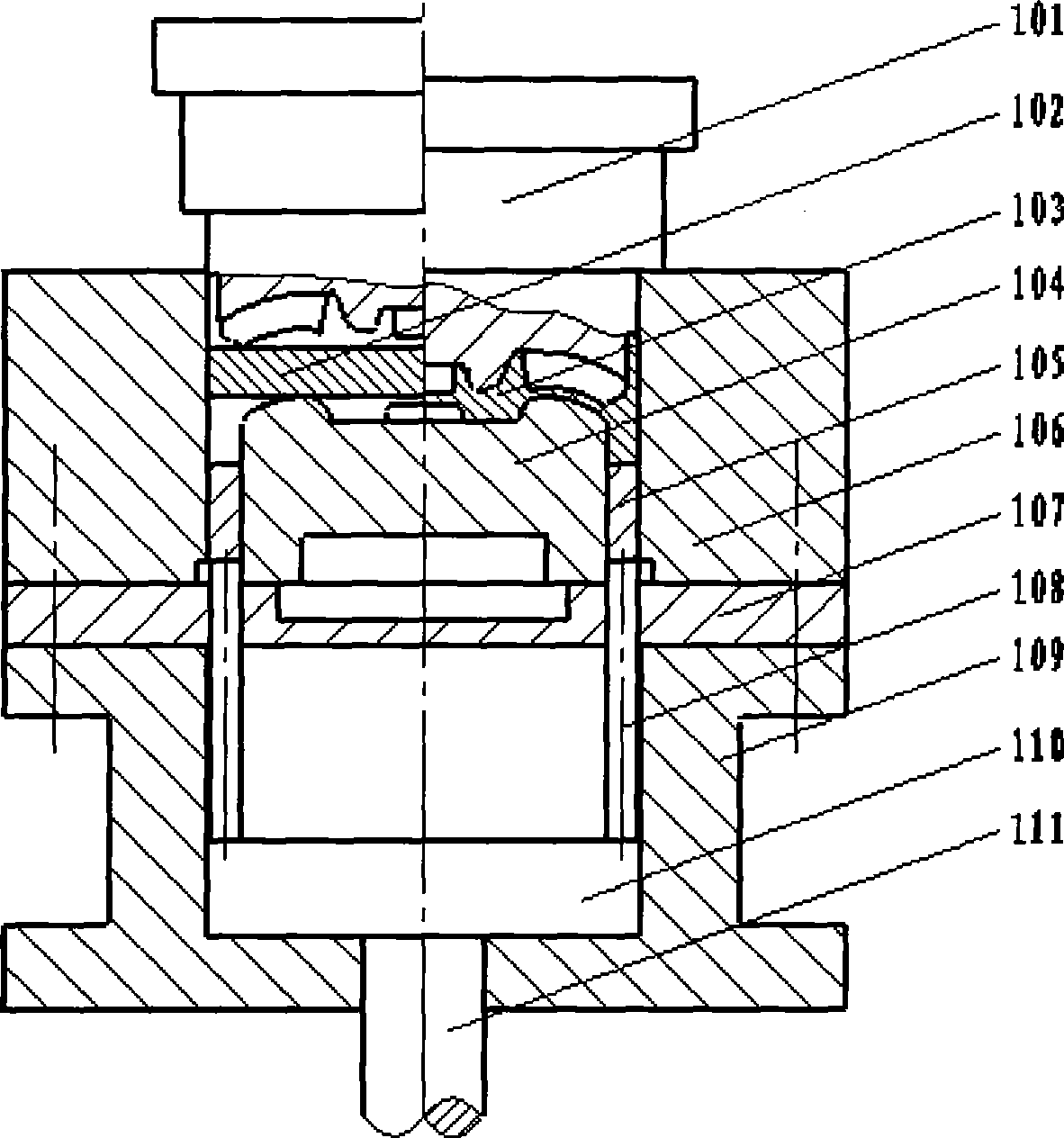

Press forming method of automobile hub and matched forming mold thereof

The invention relates to an extrusion forming method for a wheel hub of an automobile, and an extrusion piece for the wheel hub is formed by adopting work division procedures isothermally. The method comprises the following steps: a biscuit which has the same outside dimension as the outside dimension of the wheel hub to be formed is taken, and is subjected to processing and forming through forward extrusion, combined extrusion and a flaring procedure in sequence, wherein the forward extrusion forms a wheel arm and enables the rest metal to be gathered evenly in the peripheral positions of the wheel arm preliminarily; the combined extrusion pre-forms a barrel-shaped wheel rim and the upper and the lower wheel flanges of the wheel rim; and the flaring process enables the wheel rim to be formed. The invention further relates to three sets of moulds, which include a forward extrusion and forming mould, a combined extrusion and forming mould and a wheel rim flaring mould. The technical proposal of the invention can reduce the forming force, save the investment of the equipment and the mould, lower the production cost, and improve the quality of forming products.

Owner:HENAN UNIV OF SCI & TECH

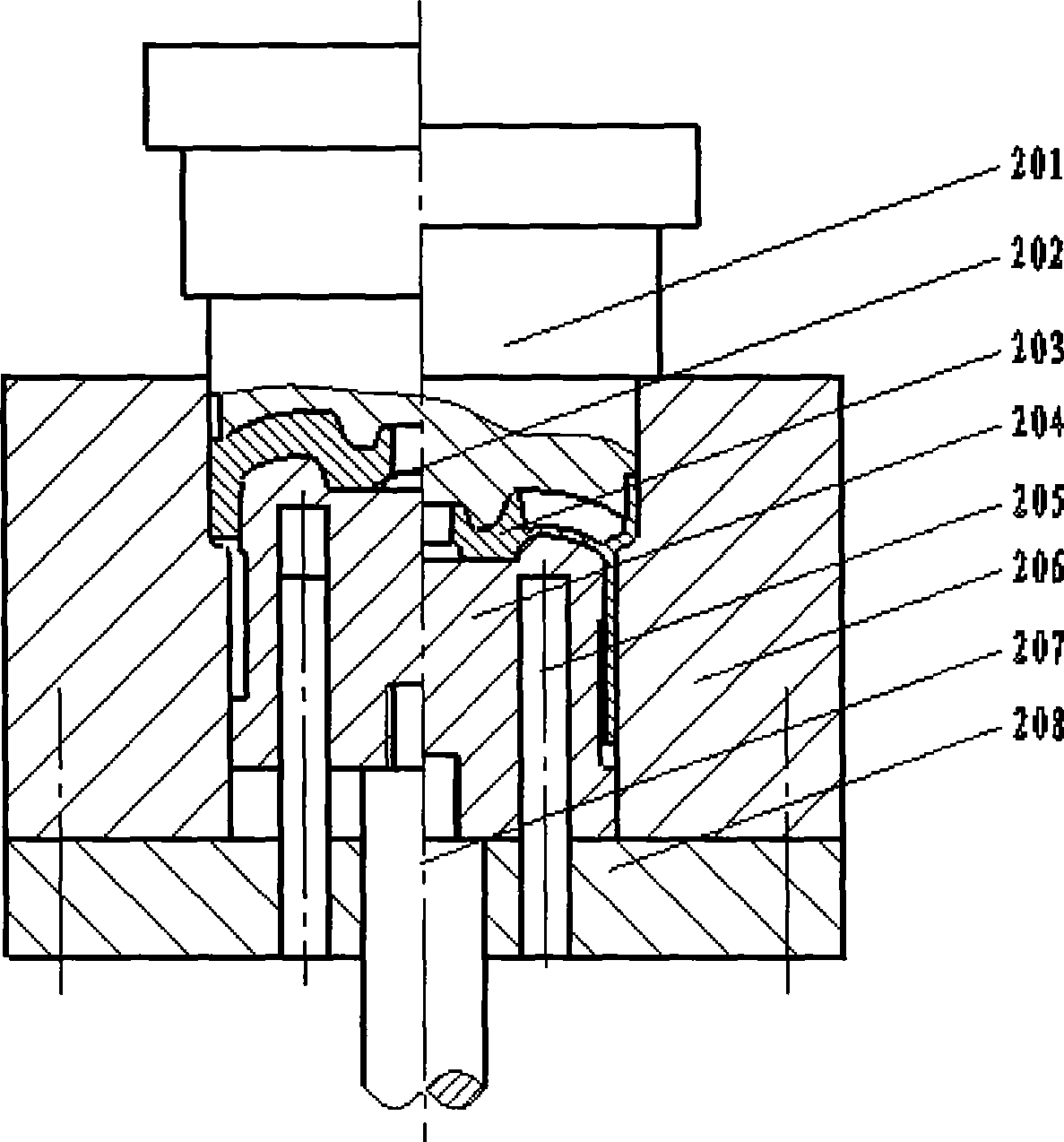

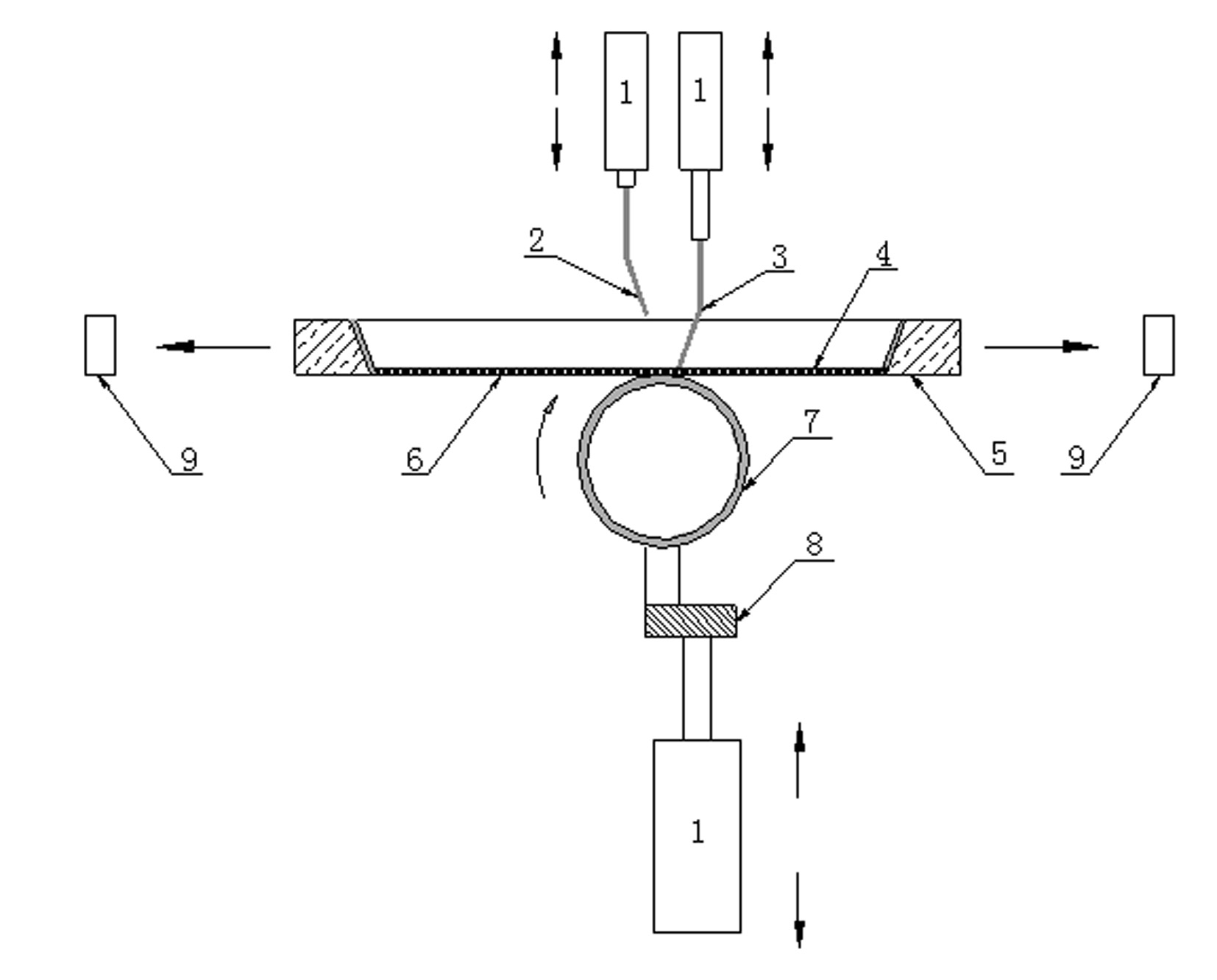

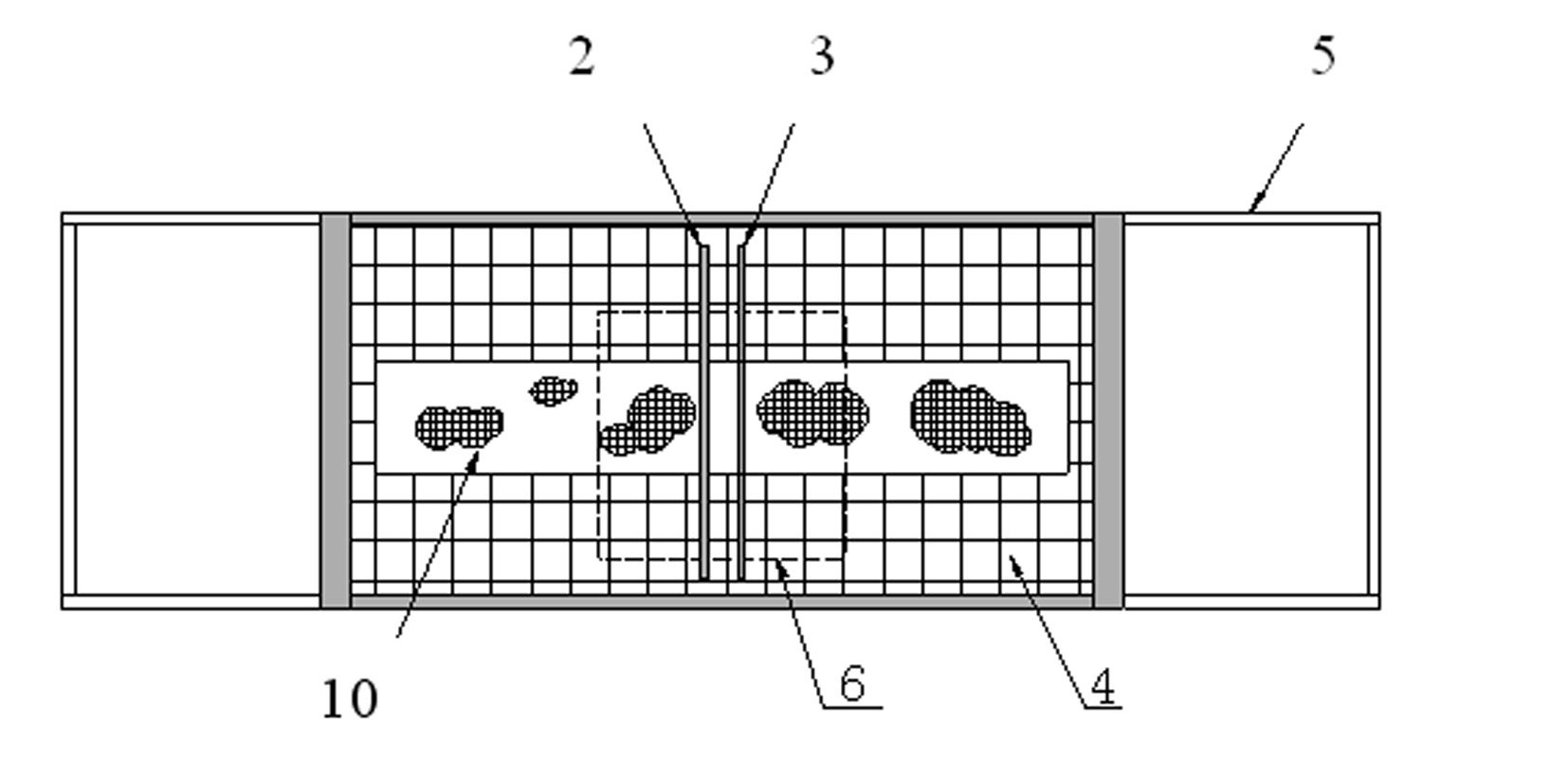

Method and device for ceramic curved surface screen printing

InactiveCN101961946AEasy to printHigh precisionScreen printersOther printing apparatusScreen printingCeramic

Owner:江苏玉泉机械制造有限公司 +1

Flow-diverting rotary valves of multiple paths

InactiveUS6904936B2Increase fluid pressureMinimized volumeMultiple way valvesThin material handlingRotary valveEngineering

The present invention describes a rotary valve for simultaneously diverting a plurality of liquid streams among a plurality of liquid receivers in a sequential and cyclic manner. Said rotary valve comprises: (1) a stator of barrel shape having a circular cavity, a bottom, a lateral structure, a group of first ports being spaced longitudinally along the lateral structure, and a group of second ports being evenly spaced apart on the bottom around the axis of the stator at the same distance from said axis, the number of the second ports being n multiple of that of the first ports wherein n is an integer of 1 or larger; (2) a rotor constructed by a hollow shaft section and a core section within said hollow shaft section, said hollow shaft section having a lateral structure accommodating a plurality of top openings that are longitudinally spaced apart and a bottom end accommodating a plurality of bottom openings that are evenly spaced apart around the axis of the hollow shaft at the same distance from said axis as the distance of the second ports from the axis of the stator, said core structure accommodating a plurality of flow passages that connect the top openings to the corresponding bottom openings; (3) the rotor being assembled in the circular cavity of the stator and a plurality of ring structures being sandwiched in-between the lateral exterior surface of the hollow shaft section of the rotor and the interior surface of said circular cavity and being longitudinally spaced apart, two adjacent ring structures forming one circular groove that is in fluid communication with a corresponding first port of the stator and a corresponding top opening of the rotor, the rotor being rotatable about the axis of said circular cavity, the junction between the exterior surface of the bottom end of the rotor and the interior surface of the bottom of the circular cavity of the stator forming a leak-proof contact with an exception of the bottom openings of the rotor which are in fluid communication with the corresponding second ports of the stator when a stepwise rotation of the rotor is properly indexed, each flow passage constantly being fluidly communicated with a corresponding first port, a top opening, and a bottom opening to form a constant flow path that contains the same fluid regardless of rotation, each second port of the stator receiving a different fluid when the second port is switched away from the currently engaged bottom opening to the adjacent bottom opening by a stepwise rotation, simultaneous diversion of multiple fluids being thus realized.

Owner:ARCHIDEX

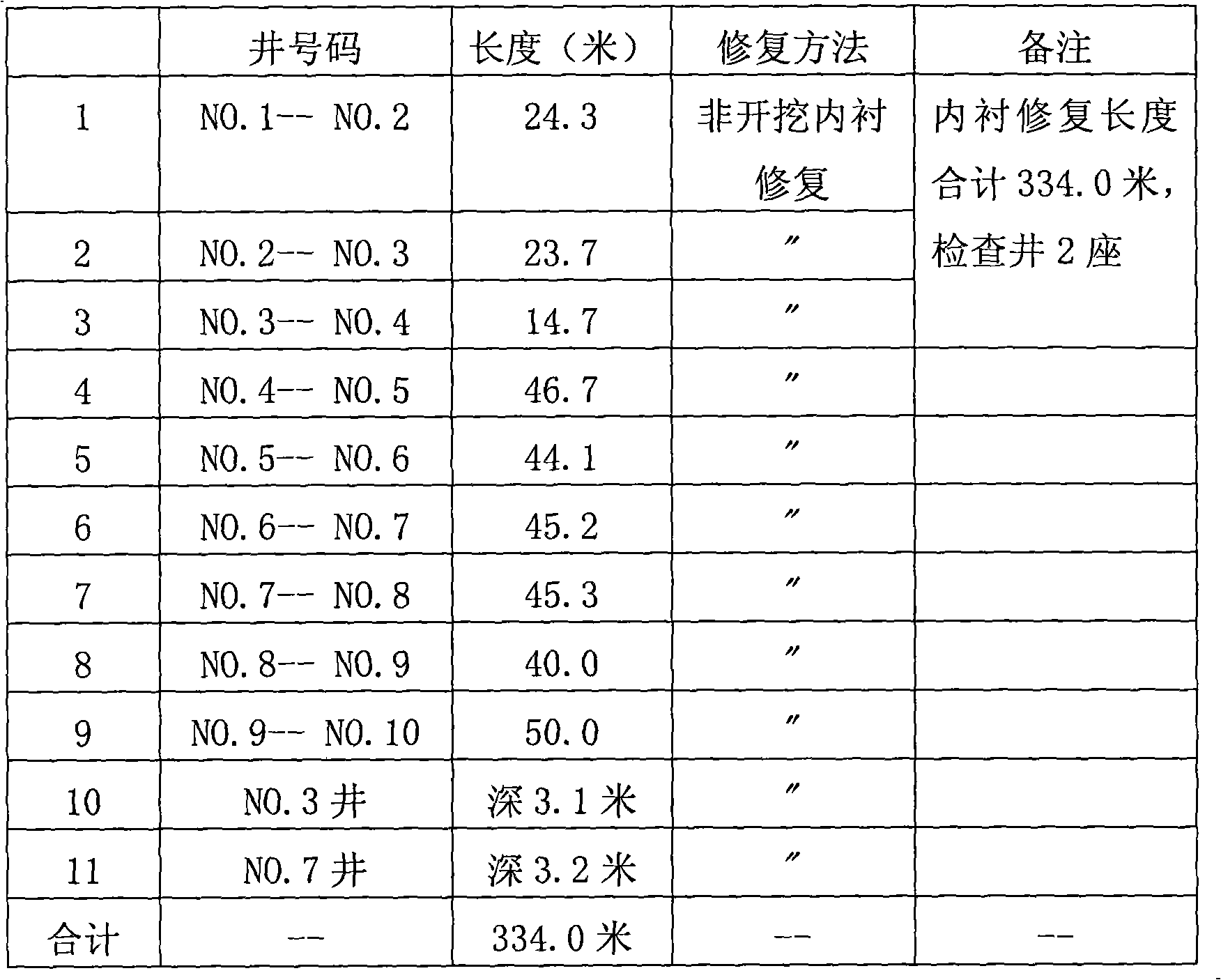

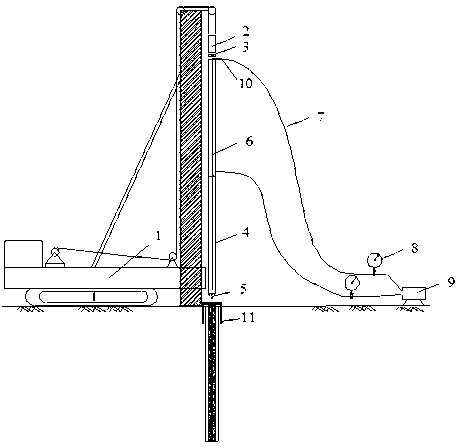

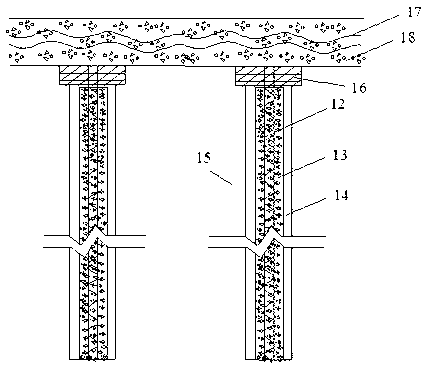

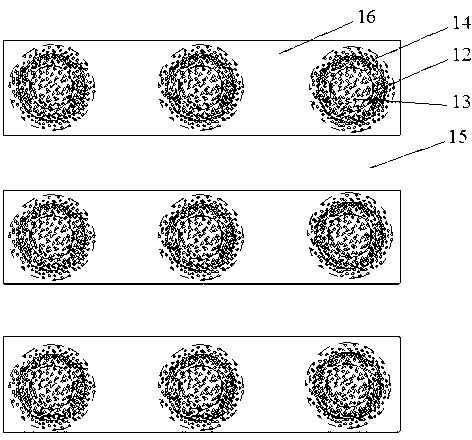

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

High polymer material slurry filled discrete material pile composite foundation and construction method thereof

The invention discloses a high polymer material slurry filled discrete material pile composite foundation and a construction method thereof. A discrete material pile is filled in a soft soil foundation through a vibrating immersed pipe, a rigid injection pipe is embedded in advance in the middle of the discrete material pile, a barrel-shaped cover plate is embedded on the top of the discrete material pile, and high polymer material slurry is sprayed to the discrete material pile at high pressure through a slurry injection system. The high polymer material slurry is filled in the clearance of the discrete material pile and splits to permeate into pile soil, so that the discrete material pile body is engaged and contacted with the soil around the discrete material pile, and the friction coefficient of the pile-soil contact surface is effectively increased. Bar pile caps are poured on the top which is formed by a high polymer material slurry filled discrete material pile body, a high polymer material slurry filled soil body and the pile soil. A high polymer material is insoluble and has certain expansibility. In the process of spraying at high pressure, water in a part of the soil body is discharged through a passage of the discrete material pile. The high polymer material slurry filled discrete material pile composite foundation has the advantages of simple construction process, strong operability, convenience in quality control, good engagement effect of the pile-soil contact surface, obvious economic benefit and significant effect for reinforcing the soft soil foundation.

Owner:HOHAI UNIV

Spirit level

ActiveUS20090139102A1Solve lack of contrastIncrease contrastIncline measurementEngineeringContrast enhancement

The invention concerns a spirit level (10) including a base body (11), e.g., in the form of a hollow profile, as well as a bubble level vial (12), formed of a vial body (14) with enclosed cavity (16), preferably of barrel shape, the vial being secured in the base body by means of a holder (28). The cavity contains a liquid (18) with gas bubble (20) floating therein and the vial body has end face regions (32, 36) running transversely to the lengthwise axis of the cavity. In order to achieve a high contrast between the end of the bubble and the liquid, it is proposed that the vial body (14) be joined to the holder (28) by an intimate material connection in the at least one end face region (32, 36) and that the holder and / or the intimate material connection be contrast intensifying in the region of the at least one end face region.

Owner:STABILA MESSGERATE GUSTAV ULLRICH GMBH & CO KG

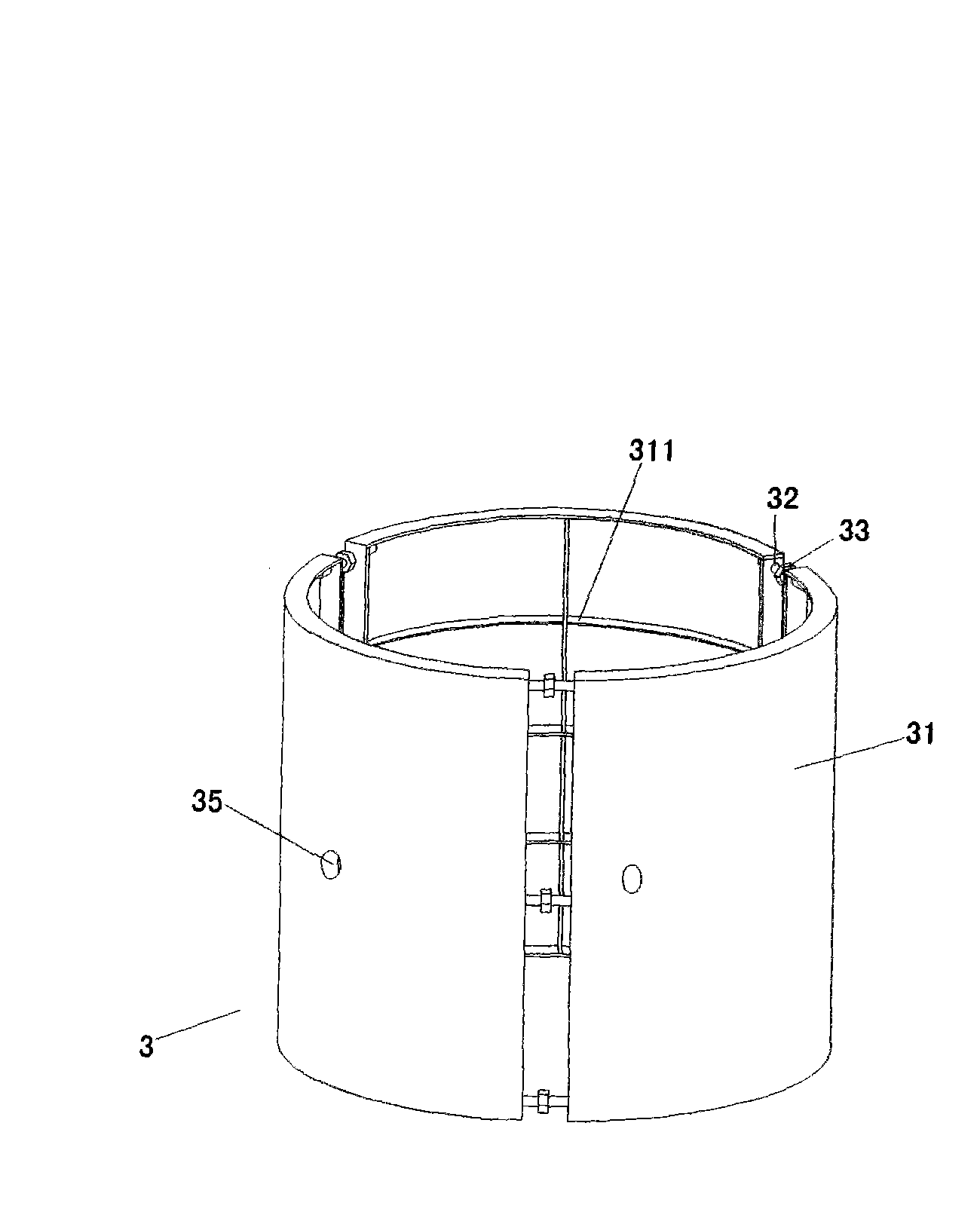

Manually digging hole full-steel cylinder-wall protecting construction device for building pile foundation and construction method thereof

The invention discloses a manually digging hole full-steel cylinder-wall protecting construction device for a building pile foundation and a construction method thereof. The device comprises a working chamber, an orifice protection joint, a full-steel cylinder protecting dilation joint and a lifting bracket, wherein the working chamber has an inverse barrel shape, the orifice protection joint is a T-shaped sleeve, and the full-steel cylinder protecting dilation joint is a cylinder which is formed by mutually screwing three steel templates. The construction method comprises the following steps: firstly, manually digging a hole, putting the working chamber into the hole, and then putting the orifice protection joint into the hole; secondly, putting the full-steel cylinder protecting dilation joint into the hole, screwing off a bolt to increase the diameter, making the full-steel cylinder protecting dilation joint support the wall of the hole, filling gaps by filling steel sheets, and downwards digging the hole and circularly putting the full-steel cylinder protecting dilation joint into the hole till digging to a designed depth; and screwing down the bolt for the down-most full-steel cylinder protecting dilation joint after finishing, lifting the full-steel cylinder protecting dilation joint out of the hole through the lifting of a winch, by inference, lifting all the full-steel cylinder protecting dilation joints out of the hole, finally withdrawing the working chamber, then putting the orifice protection joint into the hole, and pulling out the orifice protection joint when the pile foundation concrete is poured. The construction device and the construction method are safe to use and high in working efficiency.

Owner:邢利奥 +1

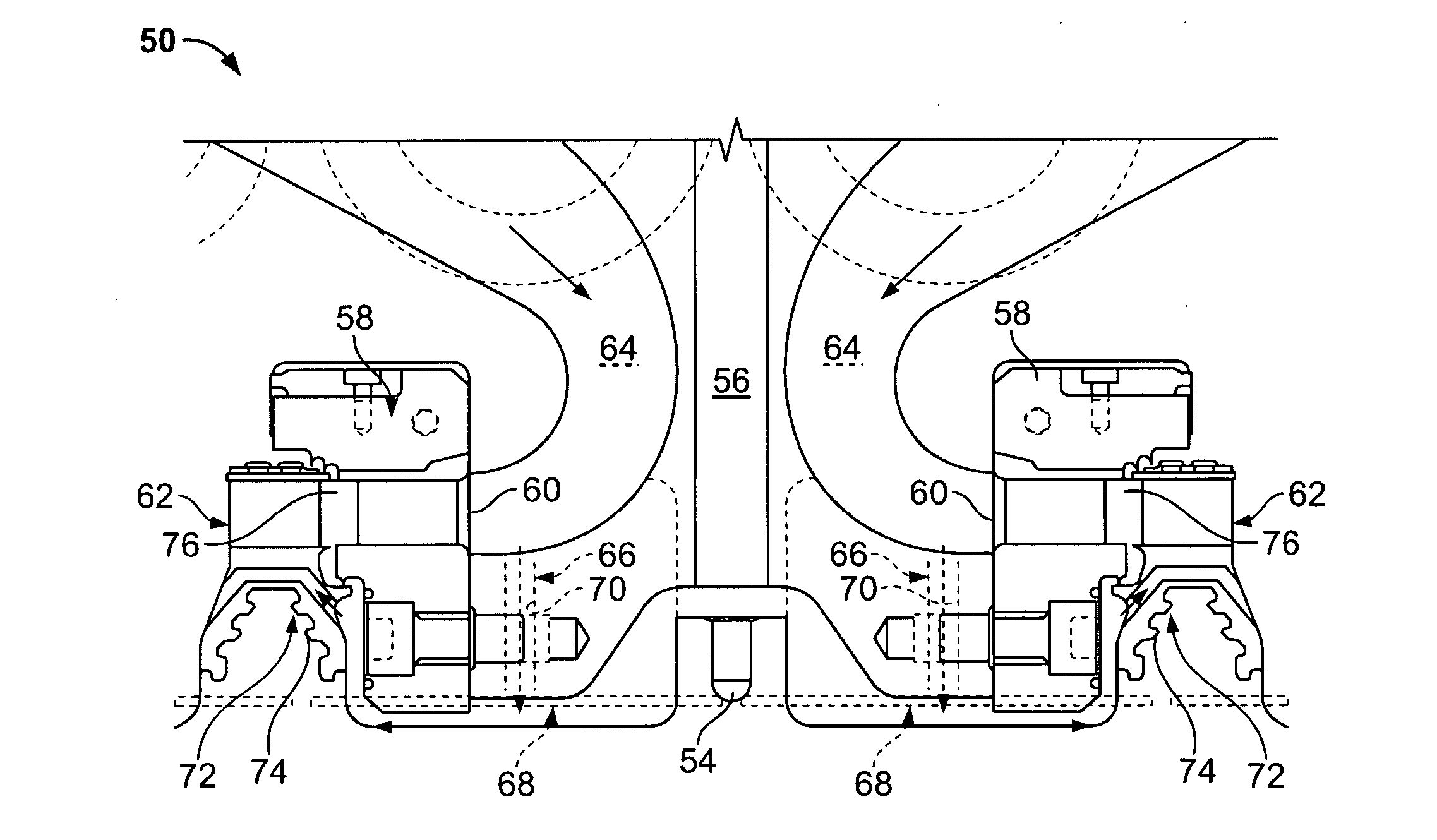

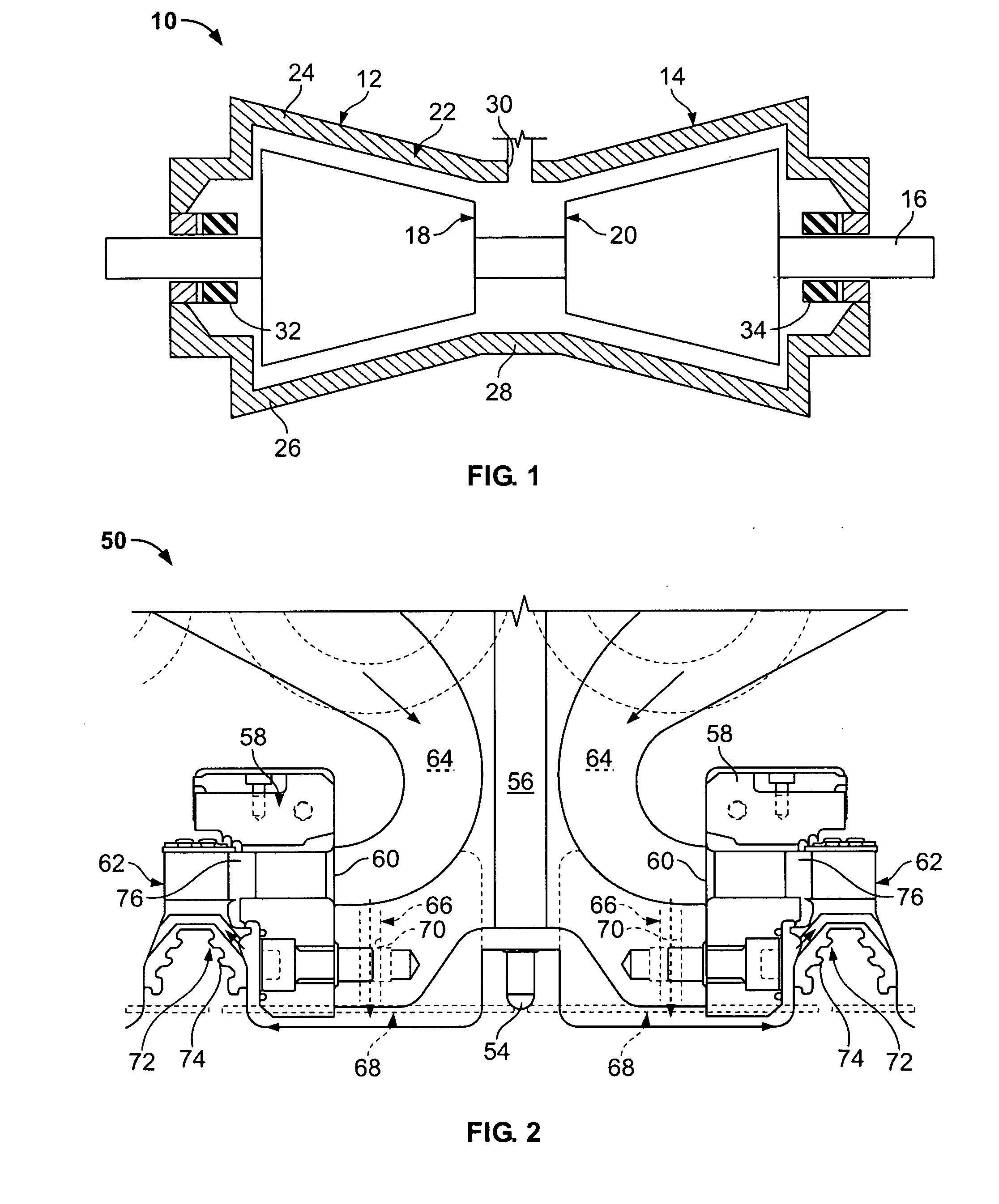

Methods and apparatus for double flow turbine first stage cooling

Method and apparatus for cooling a double flow steam turbine are provided. In one embodiment, the method includes supplying steam to the turbine to form a main inlet steam flow, allowing steam to bleed from the main inlet flow to an annulus bounded by an inner shell, nozzle plate and rotor body of the turbine, and directing the bleed steam to bucket dovetail steam balance holes.

Owner:GENERAL ELECTRIC CO

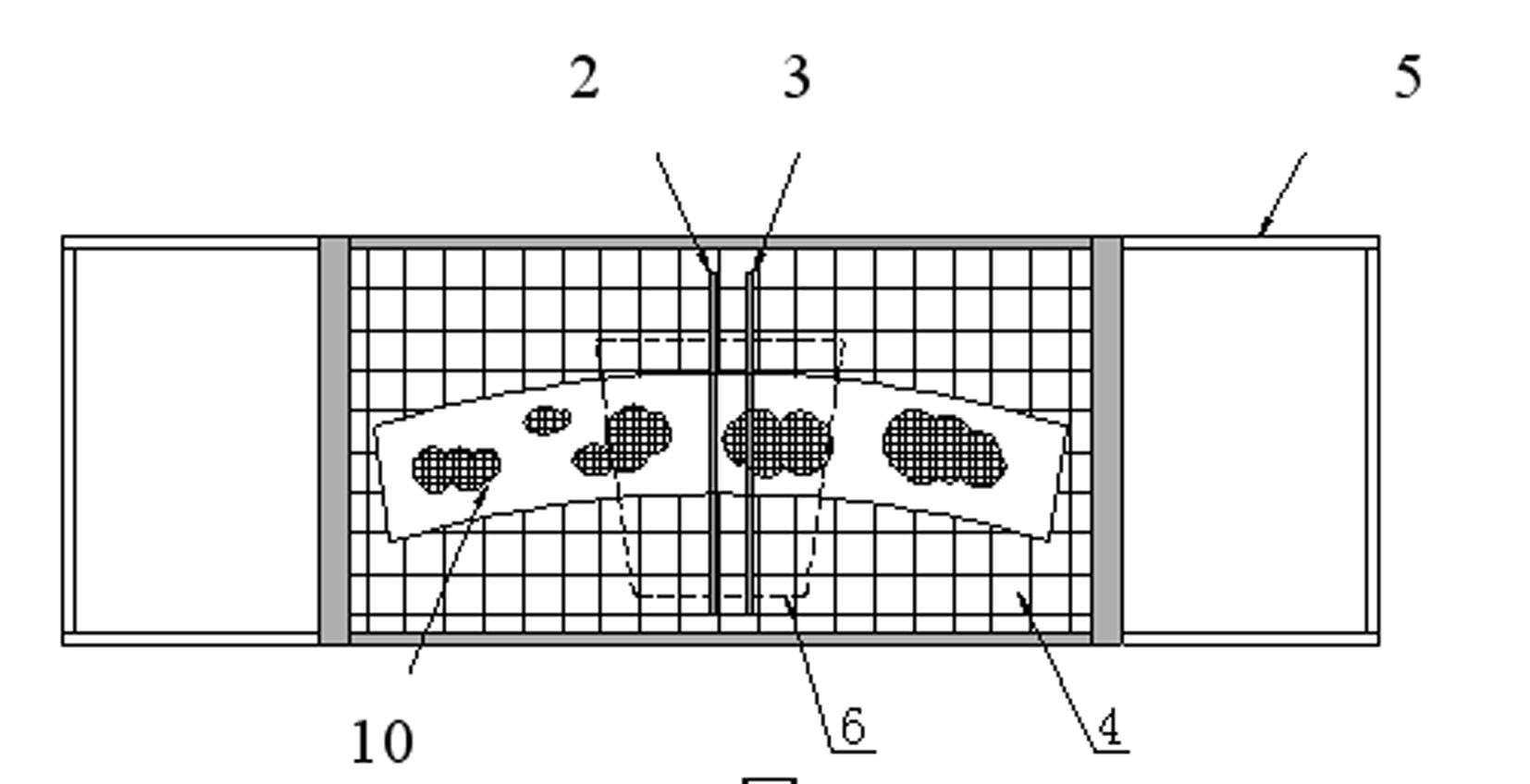

Multi-stage fracturing sliding sleeve device and using method thereof

ActiveCN102704904AEasy to openTurn on the implementationFluid removalWell/borehole valve arrangementsPetroleum engineeringBarrel Shape

The invention relates to a multi-stage fracturing sliding sleeve device and a using method thereof. The multi-stage fracturing sliding sleeve device is characterized by comprising an upper pipe column joint, a sleeve body, a lower pipe column joint, a switch sleeve and a reducing tee, wherein the lower part of the upper pipe column joint is connected with the upper part of the sleeve body; the lower part of the sleeve body is connected with the upper part of the lower pipe column joint; the sleeve body is in a circular barrel shape; a plurality of side holes are formed at the circumference near the upper position of the sleeve body at intervals; a circle of steps are formed at the inner side near to the lower position of the sleeve body; the switch sleeve which is also in a circular barrel shape is arranged in the sleeve body and below the upper pipe column joint and is fixed with the sleeve body through a plurality of pins; the inner diameter of the lower part of the switch sleeve is larger than that of the upper part of the switch sleeve; the reducing tee is arranged at the inner lower part of the switch sleeve; the circumference of the upper part of the reducing tee is fixedly connected with the switch sleeve through the plurality of pins; a plurality of cutting slits are formed at the lower part of the reducing tee; sealing mediums are filled in each cutting slit; the top of the lower pipe column joint is in a taper shape; a circle of steps bulging inwards are arranged at the bottom of the reducing tee, and the outer diameter of the top of the lower pipe column joint is smaller than that of the bottom of the reducing tee.

Owner:CHINA NAT OFFSHORE OIL CORP +1

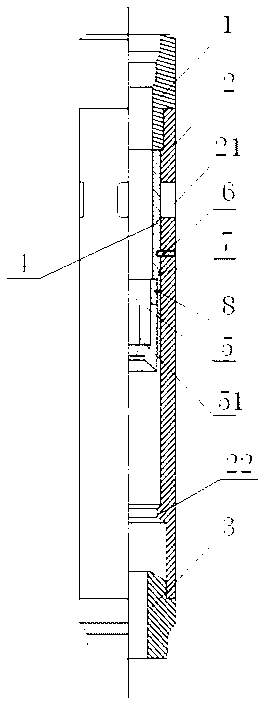

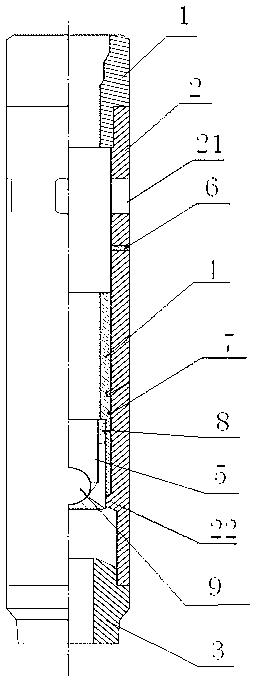

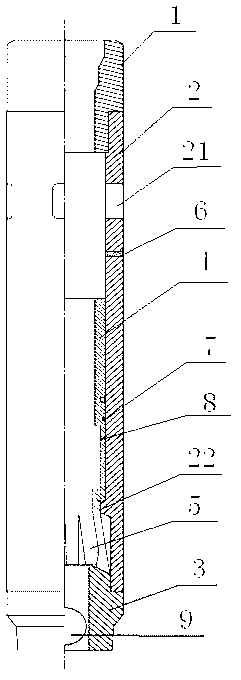

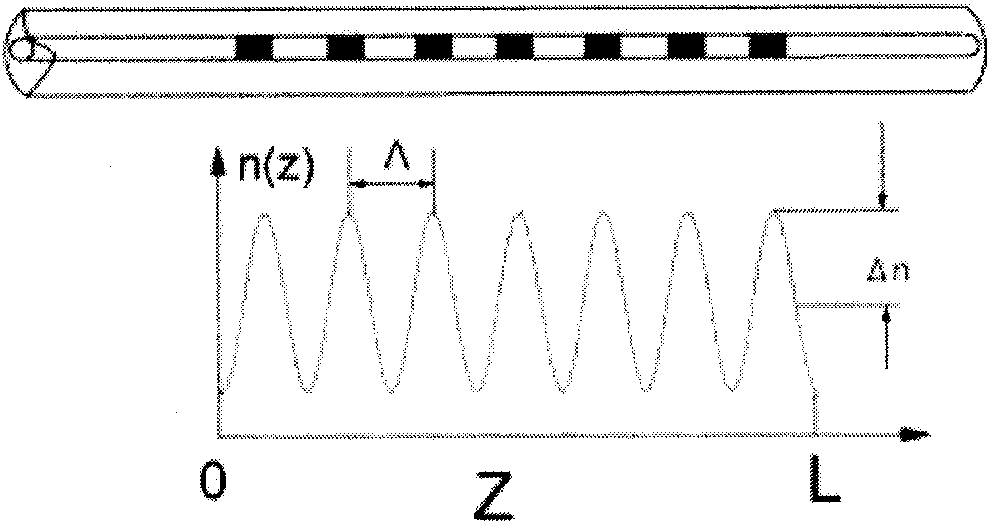

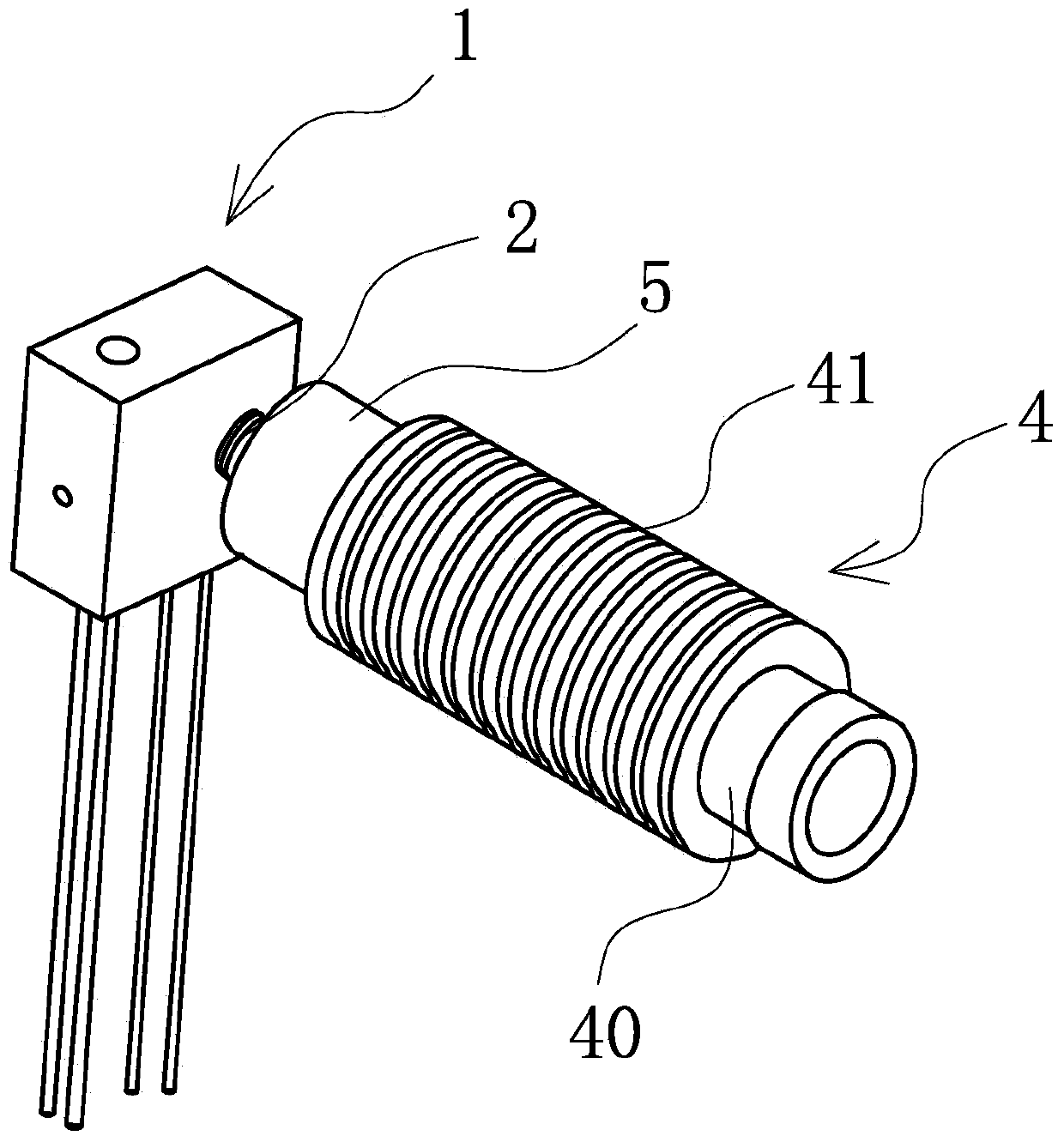

Ultra-precise fiber grating displacement sensor

The invention discloses an ultra-precise fiber grating displacement sensor which is characterized by being provided with a fixed measuring head shell, wherein the measuring head shell is a barrel-shaped body, an open mouth is arranged at the bottom of the barrel-shaped body, and a crossbeam is arranged on the end surface of the open mouth along the radial direction; a measuring rod is fixed on the inner side wall of the measuring head shell through an upper leaf spring and a lower leaf spring which are mutually parallel, and the measuring rod and the measuring head shell are kept coaxial to form parallel leaf spring guide rails; a pressure spring is arranged at the top end of the measuring rod; and the bottom end of the measuring rod extends from the measuring head shell, and a hard measuring head is fixedly connected with the bottom end of the measuring rod extended from the measuring head shell. The invention has very high sensitivity, simple structure and lower cost and can realize nano-scale micrometer precision within a small range.

Owner:HEFEI UNIV OF TECH

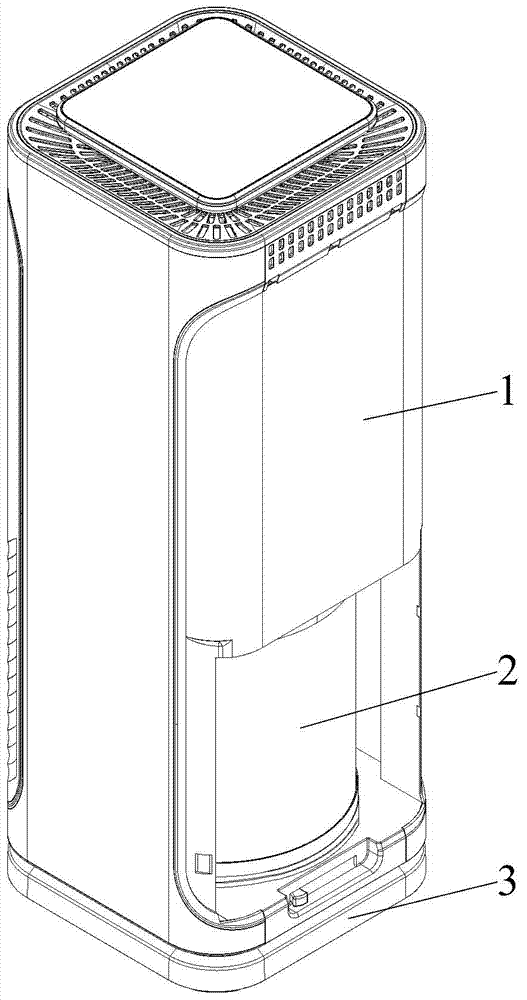

Air purifier

ActiveCN103933800AEasy to disassembleEasy to operateDispersed particle filtrationBiochemical engineeringAir purifiers

The invention discloses an air purifier which comprises a purifier body and a barrel-shaped filter element, wherein the purifier body is provided with an air purification cavity for containing the filter element; furthermore, the air purifier further comprises a filter element mounting and fixing device which is arranged in the air purification cavity and is used for mounting and fixing the filter element; the filter element mounting and fixing device consists of a lifting disk fixing frame, a lifting disk, a knob and a base which are connected in sequence from top to bottom; a hole from which the lifting disk extends out is formed in the lifting disk fixing frame; the knob is arranged on the base in a rotatable manner; the upper end of the knob supports the lifting disk and drives the lifting disk to do reciprocating movement in the direction perpendicular to the base; and therefore, the filter element is easy to dismount and mount; meanwhile, damage to the filter element filter element dismounting and mounting processes can be avoided; the filter purification effect is guaranteed.

Owner:MIDEA GRP CO LTD

Printing head sprayer structure of 3D (3-dimensional) printer

The invention belongs to the technical field of printing equipment, relates to a printing head sprayer structure of a 3D (3-dimensional) printer, and solves the technical problems of high energy consumption, low silk discharging efficiency of a sprayer, high possibility of blocking the sprayer, difficulty for consumable material extrusion and the like in the prior art. The printing head sprayer structure comprises a heating mechanism in which a nozzle assembly and a heating assembly are arranged, wherein the heating mechanism is connected with a barrel-shaped heat dissipating mechanism; a heat insulation mechanism is arranged between the heating mechanism and the heat dissipating mechanism and is communicated with the nozzle assembly and the heat dissipating mechanism. The printing head sprayer structure has the advantages of low energy consumption, high silk discharging efficiency, low possibility of blocking a nozzle, simplicity for consumable material extrusion and the like.

Owner:德清中科金融信息技术研究所

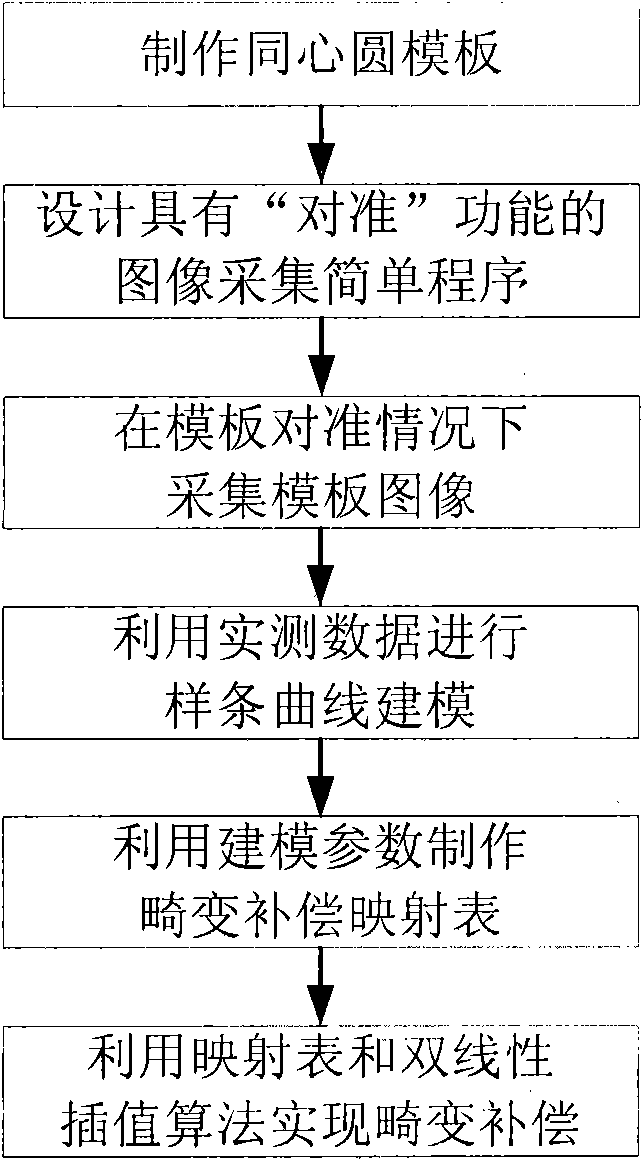

Distortion compensation method based on wide-angle lens

InactiveCN101661162AImprove calculation accuracyEffective Distortion CompensationOptical elementsEngineeringDistortion

The invention discloses a technology which realizes distortion compensation by using triple smoothing spline curve to perform modeling and compensating on barrel distortion caused by a wide-angle lens, comprising the following steps: 1) manufacturing a concentric-circle template, and making a cross at the center of the concentric circle; 2) aligning and shooting the concentric-circle template image to obtain the ideal radius value and the actual-measurement radius value of the template; 3) according to two groups of radius values, using a natural spline curve to construct a forward spline curve and a backward spline curve; 4) using the forward spline curve to calculate and restore the size of the image, using the backward spline curve, and establishing a distortion compensation mapping table; and 5) according to the mapping table, using bilinear interpolation algorithm to calculate and realize distortion compensation. The invention has a plurality of criteria points to calculate the radius of the concentric circle, so that the invention has high radius calculation precision and strong anti-noise capability; the invention adopts the spline curve to model and compensate barrel distortion and has simple and reliable calculation; according to modeling results, the invention manufactures a distortion compensation mapping table to realize efficient and effective distortion compensation in real time.

Owner:GUANGZHOU KINGRAY INFORMATION TECH +2

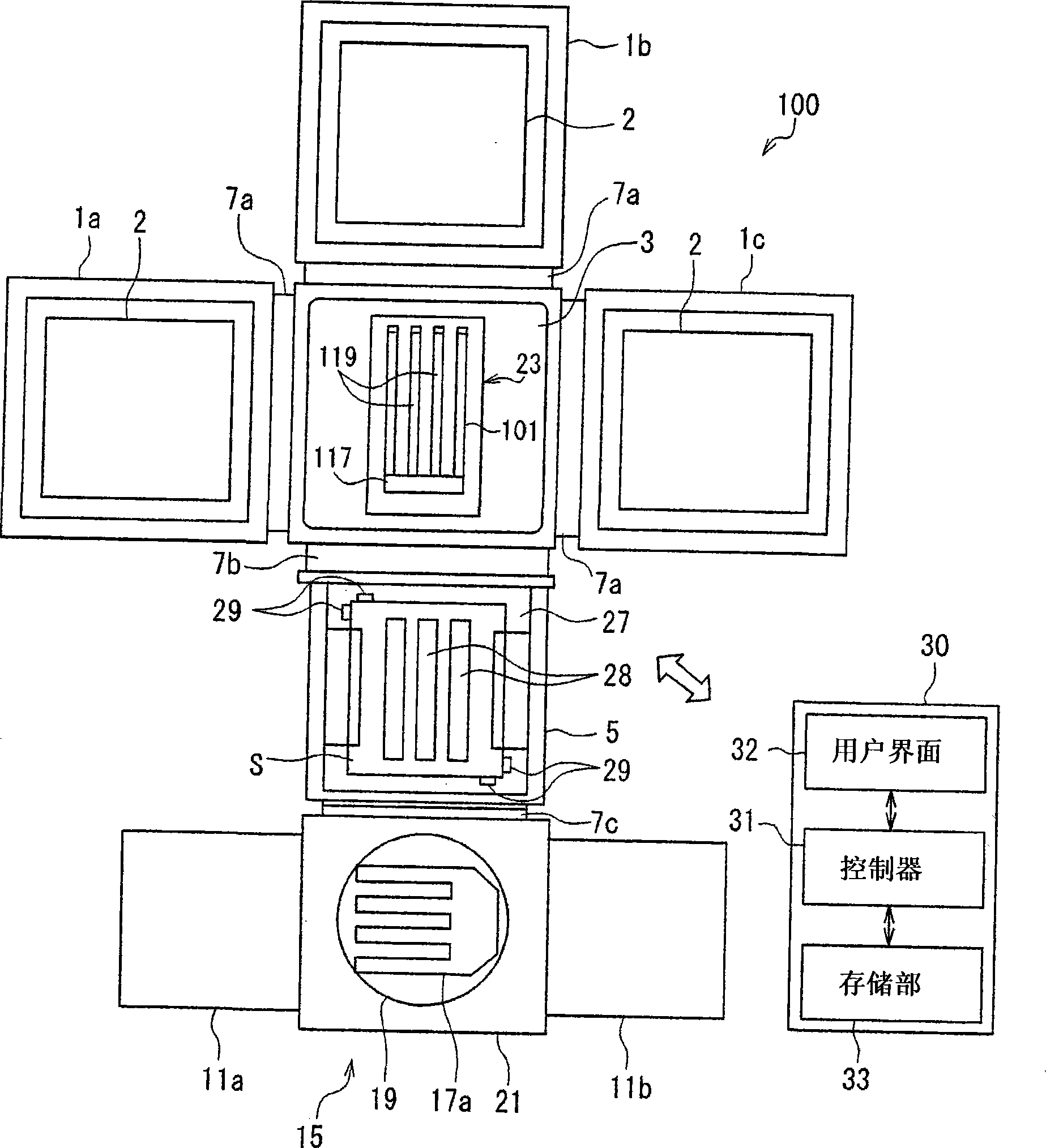

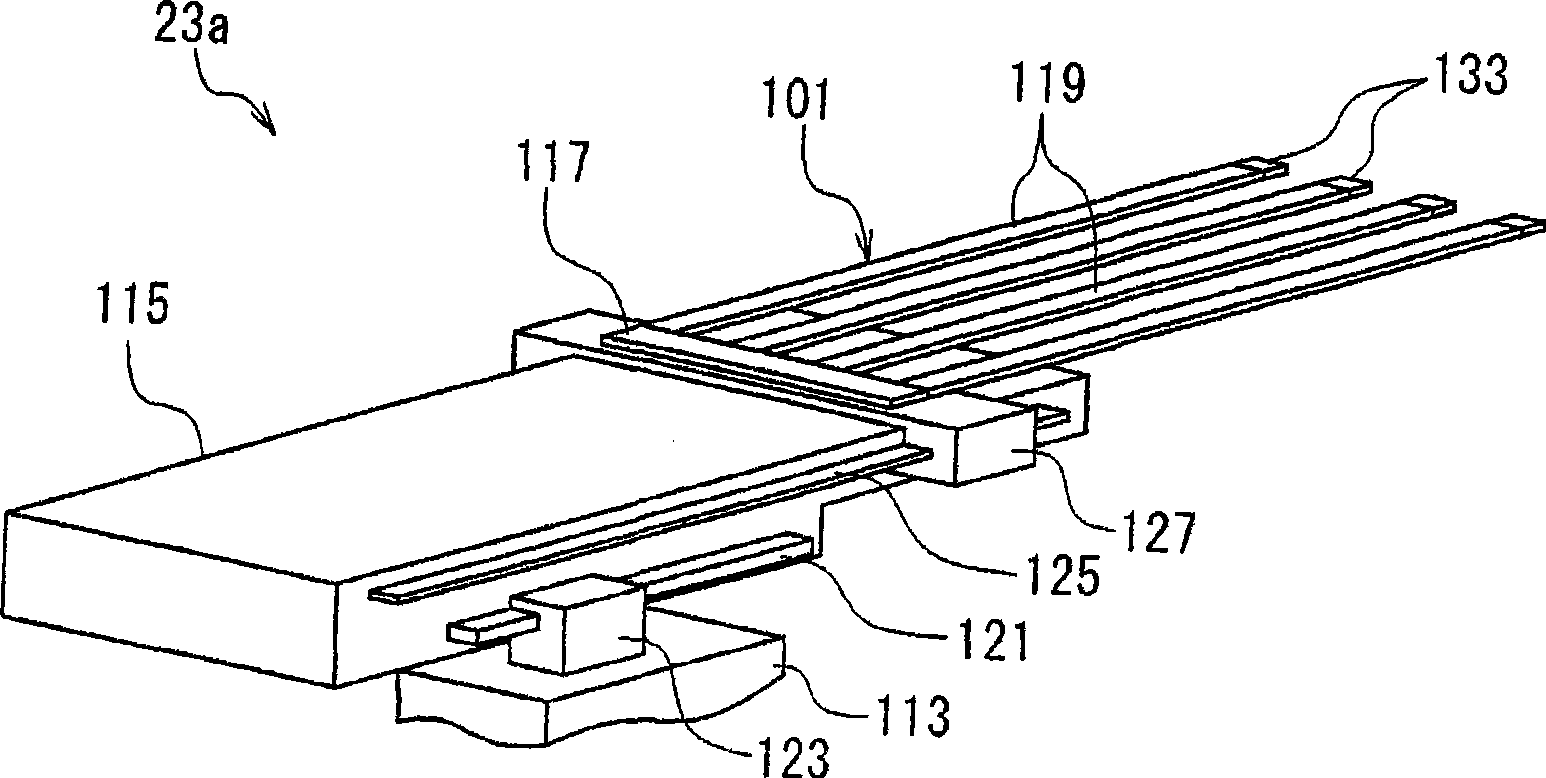

Substrate holder, substrate conveying device and substrate processing system

InactiveCN101450752AAvoid damageSolution to short lifeSemiconductor/solid-state device manufacturingCharge manipulationHandling systemBiomedical engineering

The present invention provides a substrate holding member, a substrate conveying device and a substrate processing system, which may possibly prevent damage of a support member even the substrate holding member with a support member for supporting the substrate contacts with components of the system. A fork section (101) of the substrate holding member comprises a pick-up device base section (117) fixed on a slide member (127); and, such as a four support pick-up device (119) as support member connected with the pick-up device base section (117). The support pick-up device (119) comprises a body (131) with hollow corner barrel shape and a cap body (133) as a protect member freely assembled on the body (131).

Owner:TOKYO ELECTRON LTD

Pneumoperitoneum-free peritoneoscope suspending type abdominal wall puncture device

InactiveCN102846343AAvoid obstructionPain reliefCannulasSurgical needlesPERITONEOSCOPEAbdominal wall

The invention relates to a pneumoperitoneum-free peritoneoscope suspending type abdominal wall puncture device, and overcomes the defect that secondary trauma occurs easily to patients by using a kirschner pin to puncture into abdominal walls to suspend the abdominal walls. The puncture device comprises a sleeve and a plurality of supporting arms arranged on the sleeve in a central radial shape, wherein a deformation portion is connected to the end portion of the sleeve and connected with the supporting arms; and one ends of pull ropes are fixed on the end portion of the supporting arms, lugs with rope holes are arranged on the sleeve away from the deformation portion, and the other ends of the pull ropes penetrate through the rope holes in the lugs to be fixed on the outer portion of the abdominal wall. A supporting surface is arranged after the supporting arm is opened, and a barrel-shaped space is formed after the supporting arm is suspended, so that enough surgical fields are provided during the surgery; and the supporting arm of the puncture device is inserted from a cut of the abdominal wall and is opened gradually, so that the kirschner pin is not needed to perform puncture and suspension, the secondary trauma is prevented, and the puncture device is helpful for alleviating traumatic pains of patients.

Owner:王小军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com