Air bag with high intensity and its manufacturing technique

A production process and high-strength technology, which is applied to other household appliances, ships, hollow objects, etc., can solve the problems of uneven force on the skeleton, low internal pressure of blasting, uneven vulcanization, etc., and achieve self-strength improvement and air tightness. Good, the effect of increasing the strength and the number of impact fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

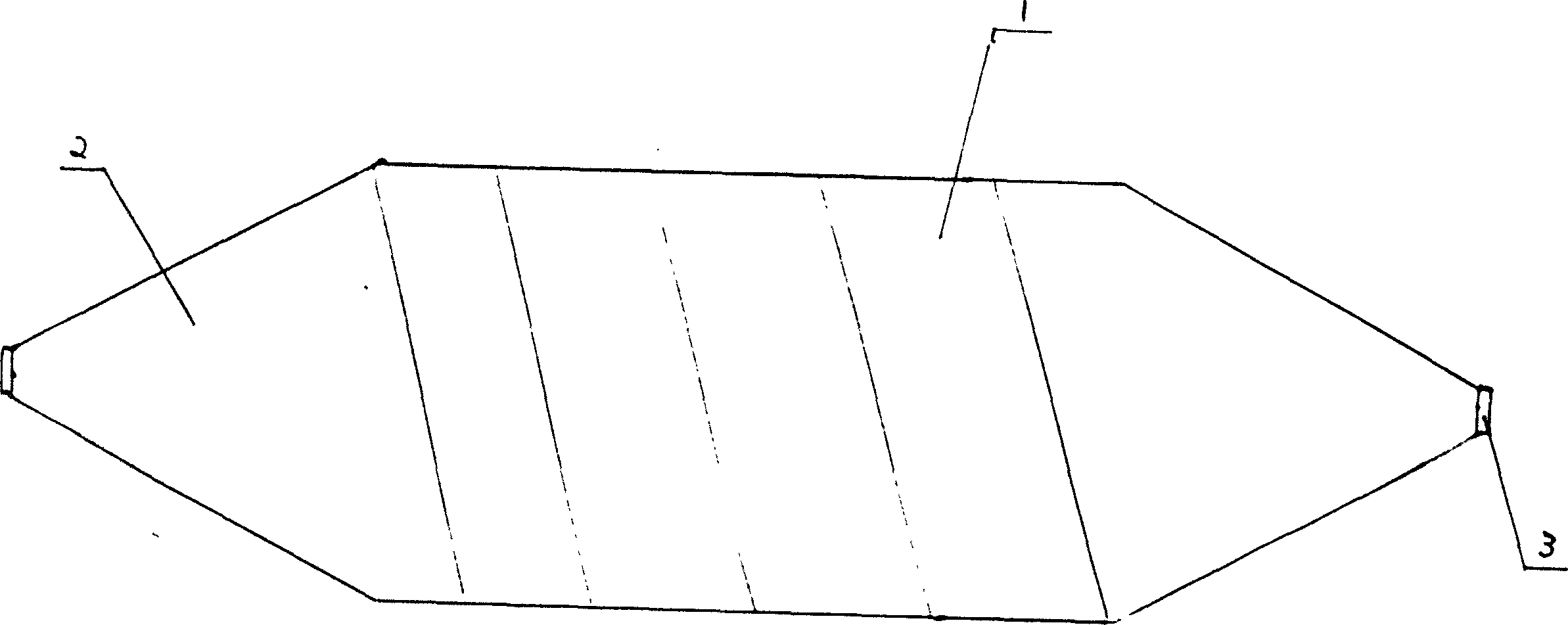

[0017] Embodiment 1 The high-strength airbag described in the present invention is composed of an airbag body 1, an airbag head 2, and an airbag valve 3. The airbag body 1 is composed of an inner sleeve layer and several layers of hanging glue that are cross-applied from the inside to the outside. The cord fabric is formed, and the airbag head 2 is connected together with the airbag body 1 into a conical shape, and the airbag valve 3 for inflation is fixedly installed on the airbag head.

[0018] The direction of the glued cord fabric of the airbag body 1 is arranged parallel to the longitudinal fabric bars from one end of the bag head to the other end, and the two sides are glued and rolled into a barrel shape as the inner sleeve, and then the inner sleeve is circled from the inside to the outside to apply two Layers of rubber cord fabric, the angle of application between the two layers of cord fabric intersects, and the direction of the cross application of the outer layer of...

Embodiment 2

[0022] Embodiment 2 The high-strength airbag of the present invention is composed of an airbag body 1, an airbag head 2, and an airbag valve 3. The airbag body 1 is composed of an inner jacket layer and several layers of hanging glue that are cross-applied from the inside to the outside. The cord fabric is formed, and the airbag head 2 is connected together with the airbag body 1 into a conical shape, and the airbag valve 3 for inflation is fixedly installed on the airbag head.

[0023] The direction of the glued cord fabric of the airbag body 1 is arranged parallel to the longitudinal fabric bars from one end of the bag head to the other end, and the two sides are glued and rolled into a barrel shape as the inner sleeve, and then the inner sleeve is circled from the inside to the outside to apply two Layers of rubber cord fabric, the angle of application between the two layers of cord fabric intersects, and the direction of the cross application of the outer layer of cord fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com