Ultra-precise fiber grating displacement sensor

A technology of displacement sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of high price, harsh use conditions, and low precision, and achieve high resolution, high sensitivity, and high displacement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

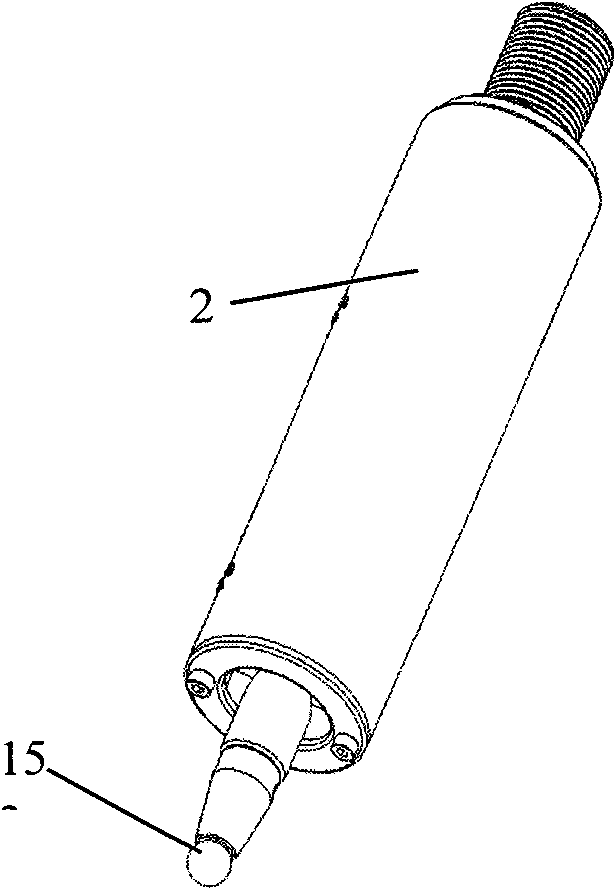

[0038] see Figure 3a , Figure 3b , Figure 3c and Figure 4 , in the present embodiment, the probe housing 2 fixed by the sensor clamping 1 is set, the probe housing 2 is a cylindrical body, the top of the cylindrical body has a central screw hole; the bottom of the cylindrical body is open, On the open end face, a beam 12 is arranged radially;

[0039] A measuring rod 9 is arranged axially inside the probe housing 2, and the measuring rod 9 is fixed on the inner side wall of the probe housing 2 by the upper leaf spring 3 and the lower leaf spring 4 parallel to each other, and holds the measuring rod 9 is coaxial with the probe housing 2 to form a parallel leaf spring guide rail; a compression spring 6 is arranged on the top of the measuring rod 9, and the compression spring 6 is set on the force measurement adjustment nut 5, and the force measurement adjustment nut 5 is connected by its external thread It is threadedly connected with the top central screw hole of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com