Preparation method of high strength high aluminum ceramic thin plate

A technology of high-alumina ceramics and thin plates, which is applied in the field of architectural ceramics, can solve the problems of increasing costs, and achieve the effects of reducing firing temperature, saving raw material costs, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

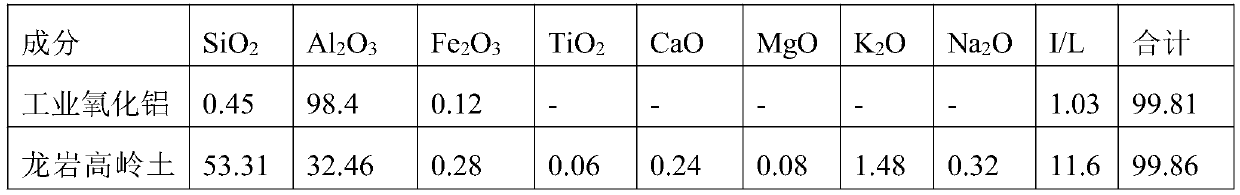

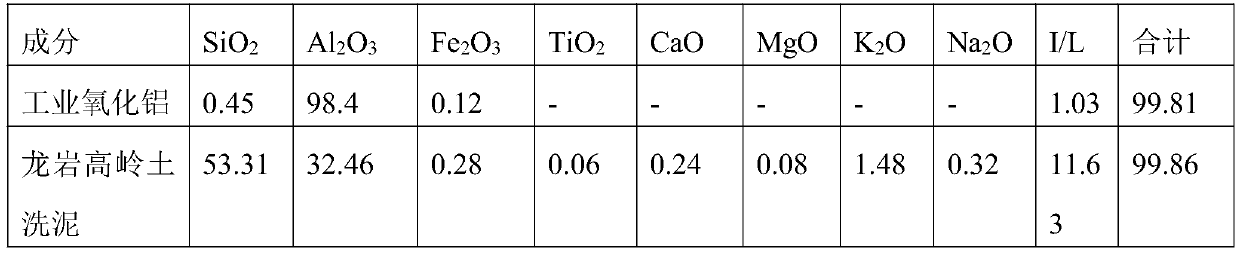

[0021] Raw material processing: Coal-series kaolin, calcined bauxite, ordinary Henan kaolin, potassium feldspar, albite and talc are ball-milled for 16 hours respectively, and passed through a 250-mesh sieve to obtain ordinary kaolin powder, coal-series kaolin powder, and calcined bauxite powder, potassium feldspar powder, albite feldspar powder and talcum powder, set aside. The specification of the calcined bauxite used is 300 mesh sieve, and the calcining temperature is 1500°C. The chemical composition on the calcined bauxite and the coal measures kaolin is shown in the following table:

[0022] Element SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO MgO K 2 o

Na 2 o

I / L total Calcined bauxite 7.68 85.11 0.85 4.22 0.32 0.24 0.69 0.07 0.38 99.5 Coal series kaolin 48.9 35.46 0.12 0.4 0.038 0 0.03 0 14.7 99.75

[0023] 2) Raw material ratio and mixing: according to the mass percentage of each raw mate...

Embodiment 2

[0031] Raw material processing: Coal-series kaolin, calcined bauxite, ordinary Henan kaolin, potassium feldspar, albite and talc are ball-milled for 20 hours respectively, and passed through a 250-mesh sieve to obtain ordinary kaolin powder, coal-series kaolin powder, and calcined bauxite powder, potassium feldspar powder, albite feldspar powder and talcum powder, set aside. The specification of the calcined bauxite used is 325 mesh sieve, and the calcining temperature is 1500°C. The chemical composition on the calcined bauxite and the coal measures kaolin is shown in the following table:

[0032] Element SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO MgO K 2 o

Na 2 o

I / L total Calcined bauxite 7.68 85.11 0.85 4.22 0.32 0.24 0.69 0.07 0.38 99.5 Coal series kaolin 48.9 35.46 0.12 0.4 0.038 0 0.03 0 14.7 99.75

[0033] 2) Raw material ratio and mixing: according to the mass percentage of each raw mate...

Embodiment 3

[0041] Raw material processing: Coal-series kaolin, calcined bauxite, ordinary Henan kaolin, potassium feldspar, albite and talc were ball-milled for 18 hours respectively, and passed through a 250-mesh sieve to obtain ordinary kaolin powder, coal-series kaolin powder, and calcined bauxite powder, potassium feldspar powder, albite feldspar powder and talcum powder, set aside. The specification of the calcined bauxite used is 310 mesh sieve, and the calcining temperature is 1500°C. The chemical composition on the described calcined bauxite and on the coal measures kaolin is shown in the table below:

[0042] Element SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO MgO K 2 o

Na 2 o

I / L total Calcined bauxite 7.68 85.11 0.85 4.22 0.32 0.24 0.69 0.07 0.38 99.5 Coal series kaolin 48.9 35.46 0.12 0.4 0.038 0 0.03 0 14.7 99.75

[0043]2) Raw material ratio and mixing: according to the mass percentage of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com