Mineral bone powder, crystal bone china and production method of the crystal bone china

A production method and technology of bone china, applied in the field of ceramics, can solve the problems of easy cracking of bone china, achieve the effects of stable chemical composition, easy firing control, and reduced firing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment.

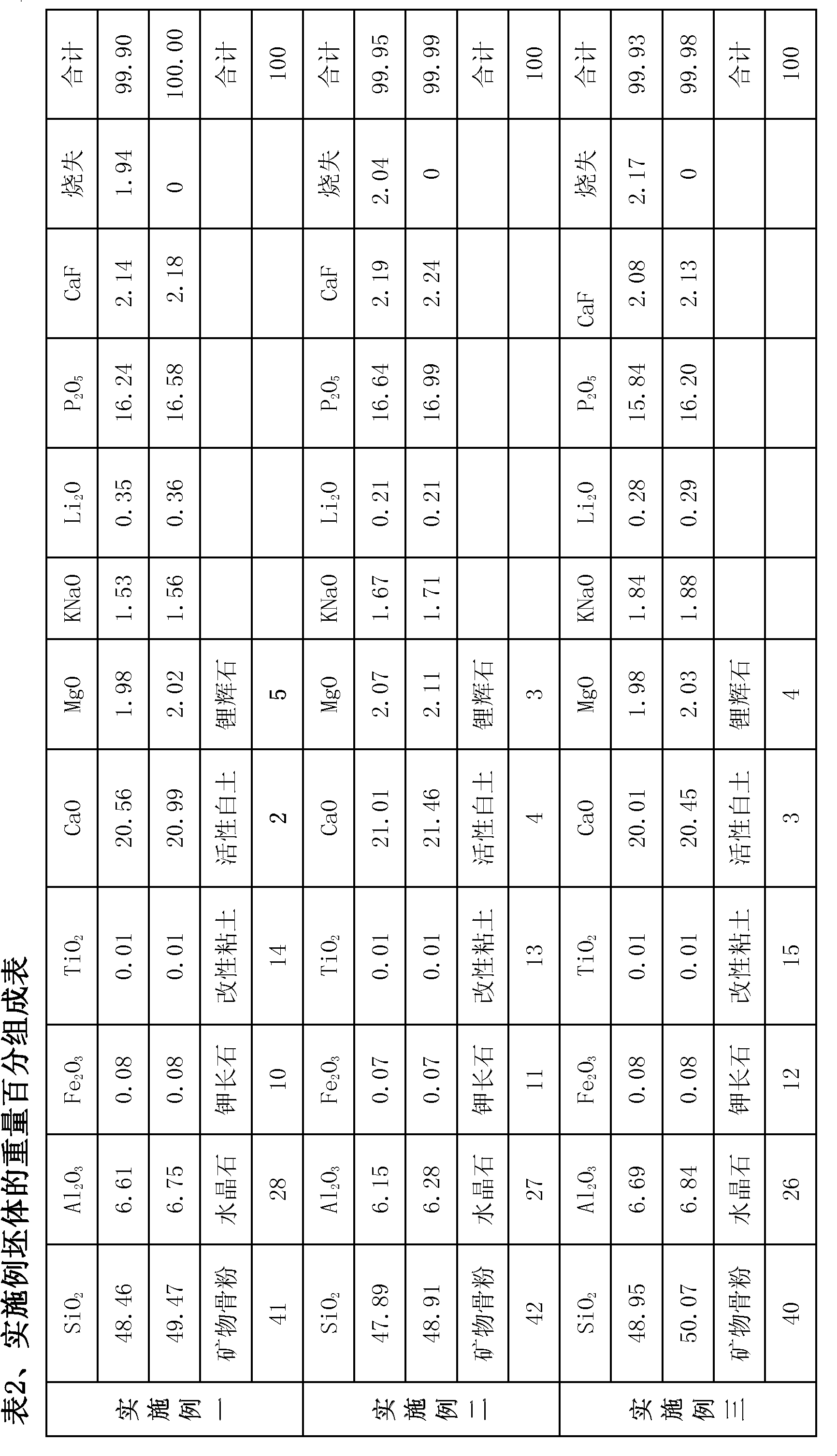

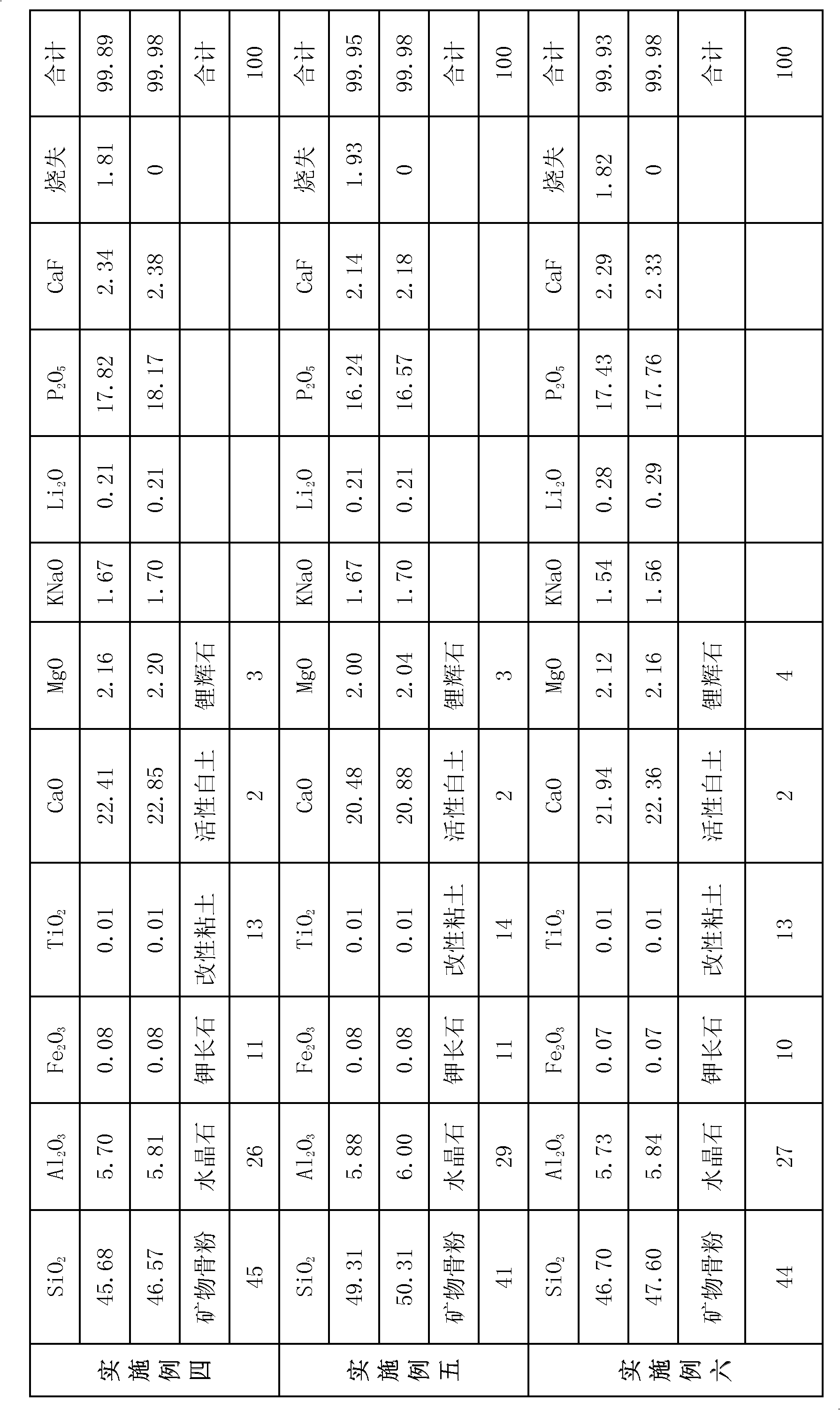

[0038] The mineral bone meal and the chemical composition of the raw materials used in the examples are shown in Table 1, and the body composition is shown in Table 2.

[0039] The same glaze is applied to the bodies of all the embodiments, and the weight percentages of the glaze ingredients are as follows: frit 95%, Suzhou soil 3%, Shulongyan soil 2%. The chemical weight percentage of the frit is composed of: SiO 2 54.44%, Al 2 o 3 11.56%, Fe 2 o 3 0.01%, TiO 2 0.01%, CaO 3.78%, MgO 1.49%, KNaO 12.27%, Li 2 O 0.35%, BaO 3.67%, B 2 o 3 5.51%, ZnO 3.87%, SrO 3.05%.

[0040] The chemical weight percentage of the glaze is composed of: SiO 2 54.27%, Al 2 o 3 12.86%, Fe 2 o 3 0.01%, TiO 2 0.01%, CaO 3.61%, MgO 1.43%, KNaO 11.73%, Li 2 O 0.33%, BaO 3.49%, B 2 o 3 5.23%, ZnO 3.68%, SrO 2.99%, and the balance is loss on ignition.

[0041] The main production methods are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com