Wear-resistant antifouling ceramic starlight glazed brick and preparation method thereof

A technology for polishing glazed tiles and starlight, which is applied in the field of wear-resistant and anti-fouling ceramic starlight polished glazed tiles and its preparation, can solve the problems of affecting the service life of ceramic tiles, poor wear resistance of glazed tiles, and complicated preparation processes, and achieves the firing temperature range. Wide, improve the grade and decoration, the effect of excellent color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

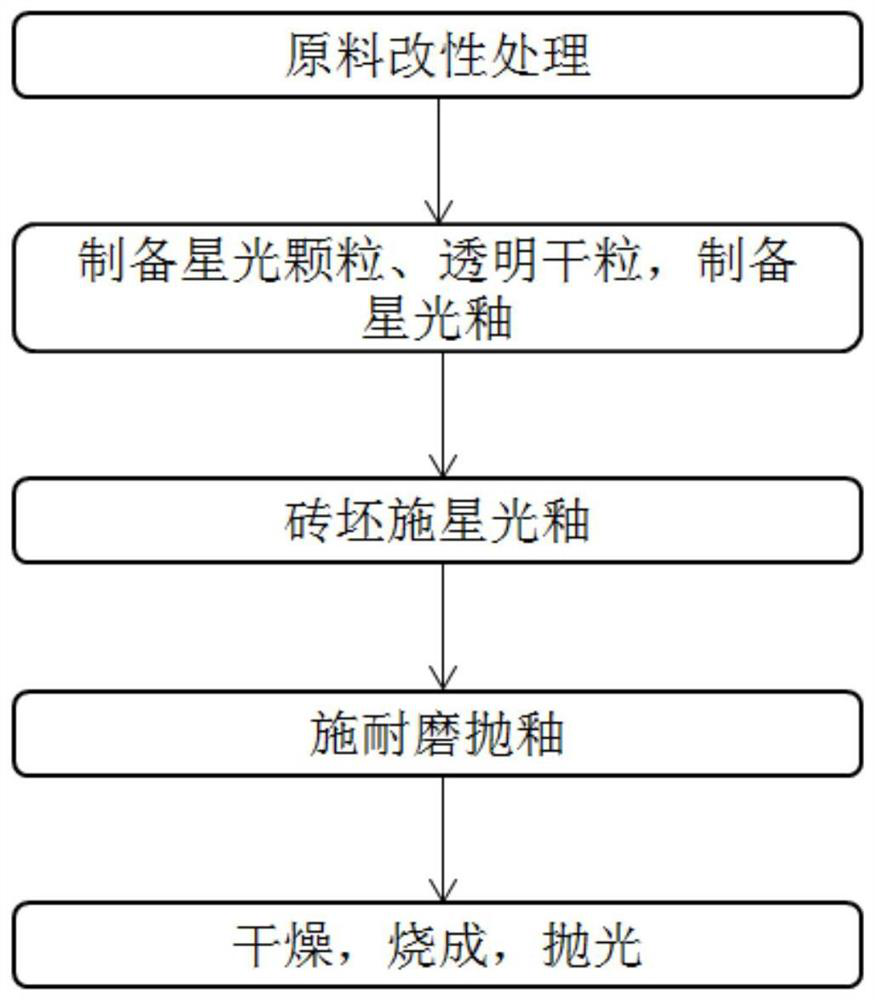

Method used

Image

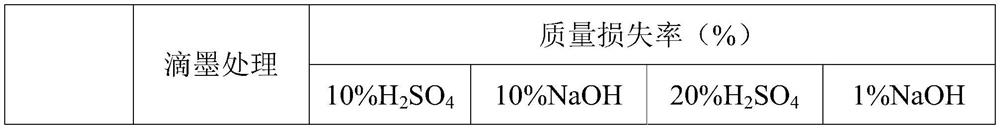

Examples

Embodiment 1

[0035] A wear-resistant and anti-fouling ceramic star-glazed glazed tile comprises a brick adobe, a star-light glaze layer and a wear-resistant glaze layer sequentially compounded from bottom to top, and the star-light glaze layer includes star-light granules and transparent dry granules. in:

[0036] The starlight particles include the following raw materials in parts by mass: 12 parts of magnesia-aluminum spinel, 20 parts of zircon sand, 15 parts of corundum, 12 parts of potassium albite feldspar, 10 parts of bauxite, 3 parts of barium carbonate, zinc oxide 3 parts, 3 parts of boric acid, 1 part of nano-titanium dioxide, and 1 part of barium titanate; the particle size distribution of the starlight particles and transparent dry particles is as follows: 0-80 mesh 5%, 80-150 mesh 70%, 150-200 mesh 25%.

[0037] The wear-resistant glazed layer includes the following raw materials in parts by mass: 20 parts of magnesium aluminum spinel, 15 parts of barium carbonate, 20 parts of...

Embodiment 2

[0045] A wear-resistant and anti-fouling ceramic star-glazed glazed tile comprises a brick adobe, a star-light glaze layer and a wear-resistant glaze layer sequentially compounded from bottom to top, and the star-light glaze layer includes star-light granules and transparent dry granules. in:

[0046] The starlight particles include the following raw materials in parts by mass: 25 parts of magnesia-aluminum spinel, 10 parts of zircon sand, 10 parts of corundum, 8 parts of potassium albite feldspar, 5 parts of bauxite, 8 parts of barium carbonate, zinc oxide 5 parts, 5 parts of boric acid, 5 parts of nano-titanium dioxide, and 3 parts of barium titanate; the particle size distribution of the starlight particles and transparent dry particles is as follows: 0-80 mesh 30%, 80-150 mesh 40%, 150-200 mesh 30%.

[0047] The wear-resistant glazed layer includes the following raw materials in parts by mass: 30 parts of magnesia-aluminum spinel, 25 parts of barium carbonate, 10 parts of...

Embodiment 3

[0055] A wear-resistant and anti-fouling ceramic star-glazed glazed tile, comprising brick adobes, an ink-jet layer, a star-light glaze layer and a wear-resistant glaze layer sequentially compounded from bottom to top, and the star-light glaze layer includes star-light granules and transparent dry granules. in:

[0056] The starlight particles include the following raw materials in parts by mass: 15 parts of magnesia-aluminum spinel, 13 parts of zircon sand, 12 parts of corundum, 10 parts of potassium albite feldspar, 6 parts of bauxite, 5 parts of barium carbonate, zinc oxide 3.5 parts, 3.5 parts of boric acid, 3.5 parts of nano-titanium dioxide, and 1.5 parts of barium titanate; the particle size distribution of the starlight particles and transparent dry particles is as follows: 0-80 mesh 15%, 80-150 mesh 65%, 150-200 mesh 20%.

[0057] The wear-resistant glazed layer includes the following raw materials in parts by mass: 22 parts of magnesium aluminum spinel, 18 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com