Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Pure tone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White glaze, boundary-free ceramic tile containing white glaze and production method of boundary-free ceramic tile

The invention relates to a white glaze, a boundary-free ceramic tile containing the white glaze and a production method of the boundary-free ceramic tile. The white glaze comprises, by weight percentage, 60-75% of opacifier, 15-28% of opacifying frit and 4-15% of clay. The boundary-free ceramic tile comprises a green body decoration layer, a white glaze layer, a comprehensive decoration layer anda transparent glaze or protecting glaze layer. The production method includes: using a sponge material to polish the surface of a green body; drying, and using a rubber roller to print the surface ofthe green body with the white glaze, and subjecting the white glaze to sintering of 1100-1200 DEG C to obtain the white glaze layer of the boundary-free ceramic tile, wherein the white glaze is weighed according to the formula, 45wt% of printing oil is added, ball milling is performed until the fineness of glaze slurry is smaller than 40 micrometers, the viscosity of the glaze slurry is regulatedto Engler viscosity 18-23 seconds, and glaze slurry proportion is 1.53-1.62.

Owner:JIANGXI HEMEI CERAMICS +3

Lanthanum-cerium co-doping bismuth vanadate inorganic pigment and preparation method thereof

InactiveCN103420417AUniform chemical compositionSmall particle sizeVanadium compoundsBismuth vanadateCerium

The invention discloses lanthanum-cerium co-doping bismuth vanadate inorganic pigment and a preparation method thereof. The general formula of the bismuth vanadate inorganic pigment is Bil-x-yLaxCeyVO4, wherein x is larger than or equal to 0.02 and less than or equal to 0.1, and y is larger than or equal to 0.02 and less than or equal to 0.1. Chelating agents are utilized to assist and a microwave hydrothermal method is adopted to prepare the lanthanum-cerium co-doping bismuth vanadate pigment, the slow release of metal ions in the reaction process is facilitated through the addition of various chelating agents, so that the process of preparing the lanthanum-cerium co-doping bismuth vanadate pigment is carried out relatively lenitively; through the adoption of the microwave hydrothermal method to prepare, the preparation time is reduced. The lanthanum-cerium co-doping bismuth vanadate pigment prepared by the invention has the advantages that the improvement of the color generating performance of the bismuth vanadate pigment is facilitated through the doping of lanthanum and cerium.

Owner:SHAANXI UNIV OF SCI & TECH

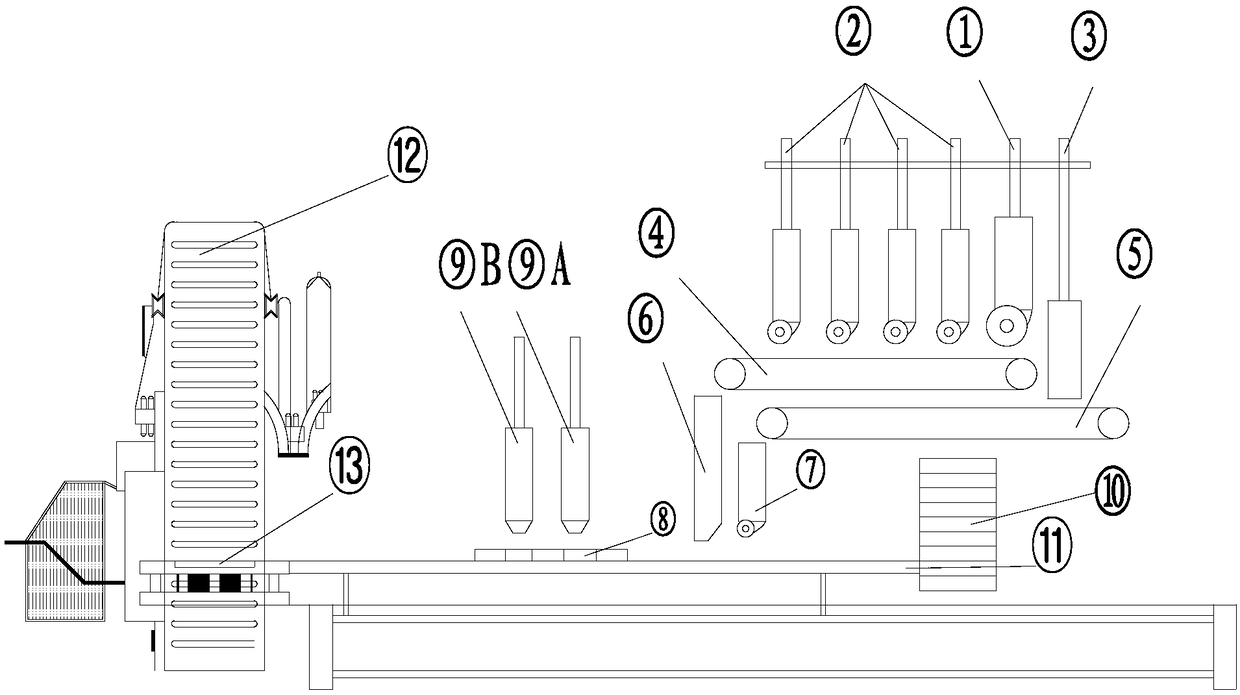

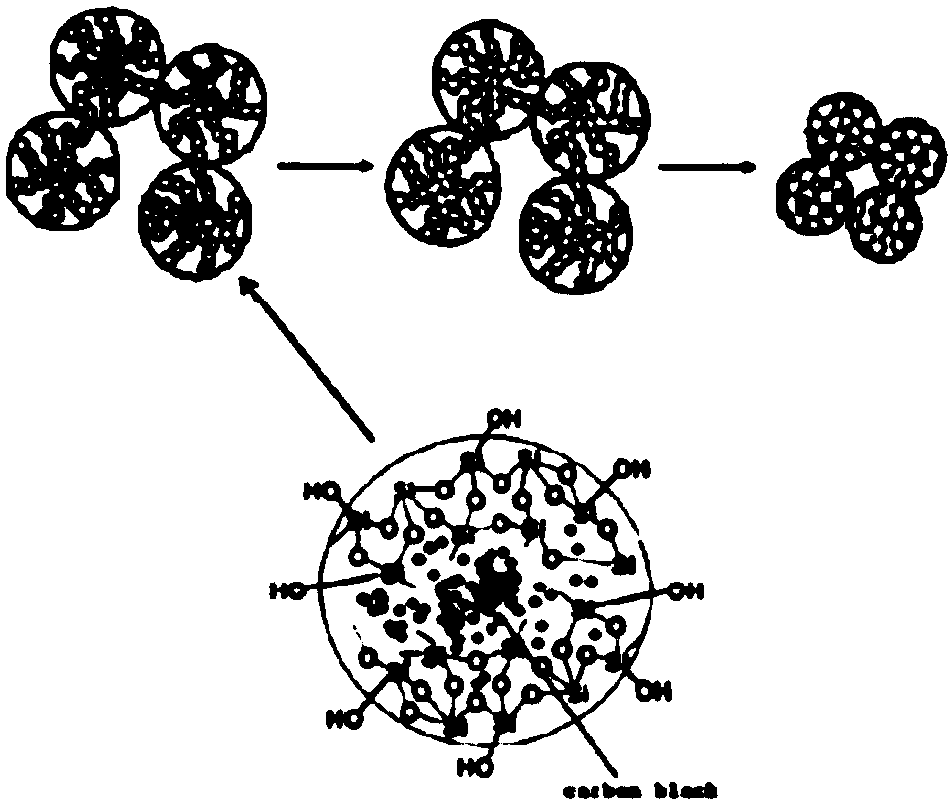

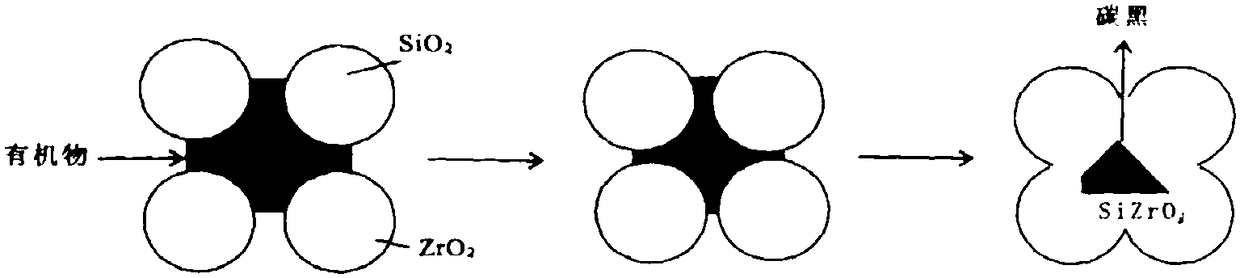

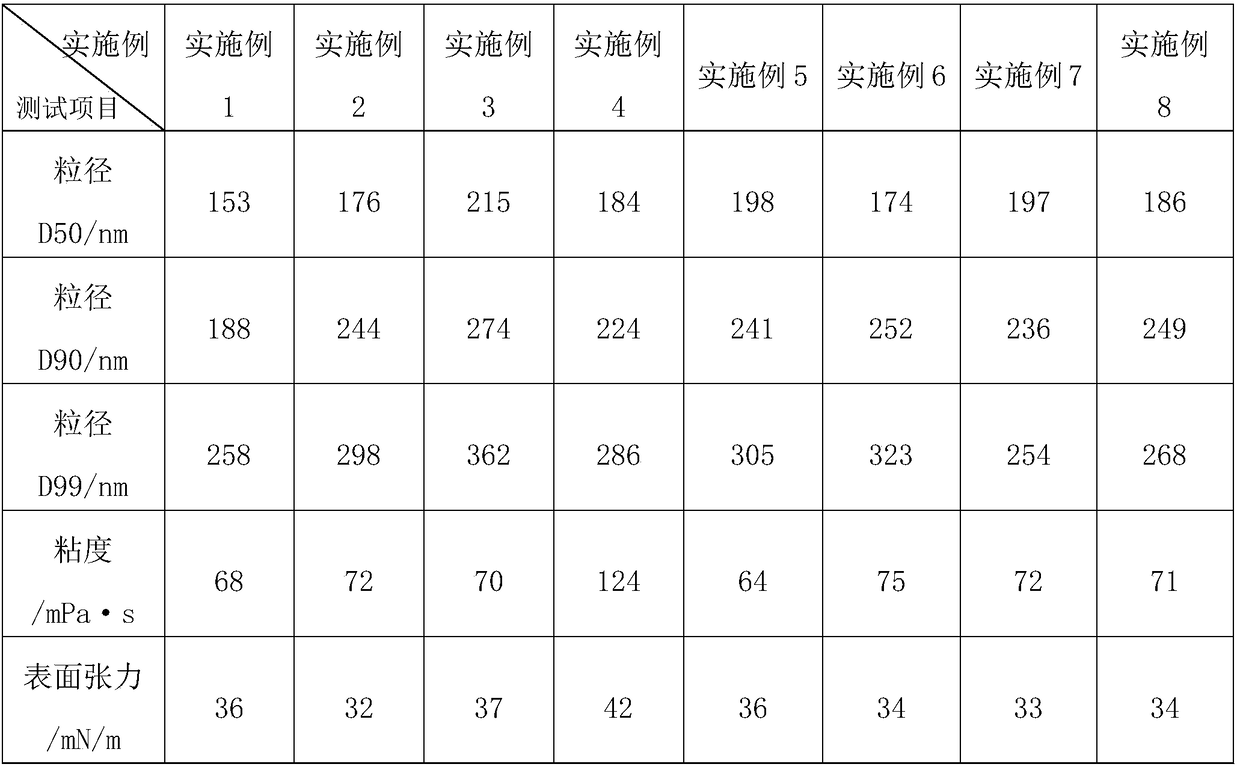

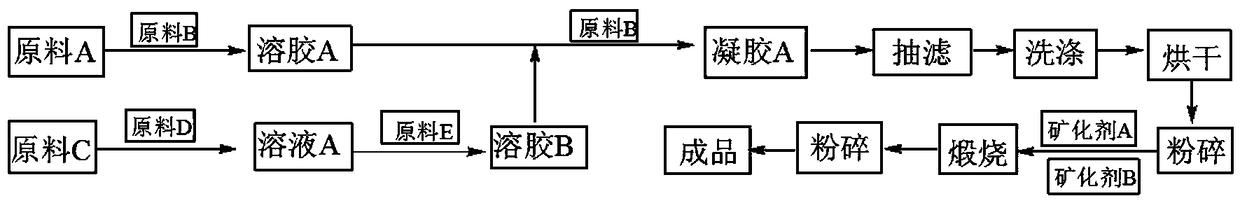

Preparation method of ceramic printing ink containing carbon black

The invention discloses a novel preparation method of ceramic printing ink containing carbon black. The preparation method comprises the steps of carbon black modification, preparation of modified carbon black sol, preparation of silica sol, preparation of zirconia sol, preparation of zirconium silicate containing carbon black precursor, preparation of zirconium silicate containing carbon black powder, and the preparation of zirconium silicate containing carbon black ceramic printing ink. The ceramic ink containing carbon black utilizes zirconium silicate containing carbon black nanoparticlesinstead of cobalt, chromium and other heavy metal elements in the prior art, being environmentally friendly without pollution. The cheap carbon black is used to replace the expensive cobaltous oxide in the existing black ceramic pigment material, greatly reducing the cost of black ceramic ink. The ceramic ink containing carbon black is in deep and pure color, and has good high temperature stability. The average particle size D50 of zirconium silicate containing carbon black nanoparticles in ceramic inkcontaining carbon black is less than 300nm, meeting the requirement of almost all ceramic nozzles for the fineness of ink particles in the market.

Owner:佛山市扬子颜料有限公司

Quasi graphene oxide, quasi graphene and pearlescent pigment based on quasi graphene oxide or quasi graphene

ActiveCN106893370AHigh hiding powerPure color saturationPigmenting treatmentCosmetic preparationsCvd graphenePotassium permanganate

The invention relates to quasi graphene oxide, quasi graphene and a quasi-graphene-based pearlescent pigment based on the quasi graphene oxide or quasi graphene. The quasi graphene oxide is obtained from the following steps: (A) oxidizing flake graphite powder with potassium permanganate; (B) intercalating concentrated sulfuric acid to oxidized graphite powder; and (C) peeling intercalated graphite powder, washing the obtained product till the product is neutral, and performing filtration and drying. Quasi graphene is prepared by reducing quasi graphene oxide. The quasi-graphene-based pearlescent pigment based on the quasi graphene oxide or quasi graphene is high in covering power and chroma and pure in tone, is controllable in technology, and can be widely applied to cosmetics, synthetic leather, plastics, textile and garment or paint.

Owner:FUJIAN KUNCAI MATERIAL TECH +1

Lanthanum, yttrium and cerium co-doped bismuth vanadate inorganic pigment and preparation method thereof

ActiveCN103449518AUniform chemical compositionSmall particle sizeVanadium compoundsGeneration processBismuth vanadate

The invention discloses a lanthanum, yttrium and cerium co-doped bismuth vanadate inorganic pigment and a preparation method thereof. The general formula of the inorganic pigment is Bi1-x-y-zLaxYyCezVO4, wherein x is not less than 0.02 and not more than 0.1, y is not less than 0.02 and not more than 0.1, and z is not less than 0.02 and not more than 0.1; chelating agents are utilized for assistance, and a microwave hydrothermal method is used for preparing the lanthanum, yttrium and cerium co-doped bismuth vanadate pigment; the different chelating agents are added so as to be favorable for slow release of metal ions in a reaction process, thereby enabling the generation process of the lanthanum, yttrium and cerium co-doped bismuth vanadate pigment to proceed more mildly; the microwave hydrothermal method is used to shorten the preparation time; and the doping of the prepared lanthanum element, yttrium element and cerium element is favorable for improving the color-forming performance of the bismuth vanadate pigment.

Owner:中山市正合色彩资源有限公司

Low-temperature bright red ceramic glaze and preparation method thereof

The invention relates to low-temperature bright red ceramic glaze and a preparation method thereof. The glaze comprises the main components of, by weight, 50-60 parts of PbO, 15-30 parts of SiO2, 10-20 parts of B2O3, 1-5 parts of Na2O, 1-5 parts of ZnO, 0.5-1.5 parts of CaO and 5-6 parts of inclusion red; the binder comprises red lead powder, quartz powder, sodium borate, boracic acid, calcium carbonate, zinc oxide and sodium silicate, the inclusion red is taken as a coloring agent, and the non-frit low-temperature bright red ceramic glaze is prepared. The glaze overcomes the defects that the preparation technology of frit glaze is complex, the melting temperature is high, the appearance and the performance of the glaze are unstable, and the glaze have to be fired in a reducing atmosphere. The low-temperature bright red ceramic glaze has the advantages that the color tone is pure, the glaze face is smooth and level, the glossiness is high, the glazing method is simple, and the sintering temperature range is wide. The glaze is ideal glaze for firing high-quality ceramic products.

Owner:LUOYANG NORMAL UNIV

Dysprosium and yttrium codoped pucherite inorganic pigment and preparation method thereof

InactiveCN103449519AUniform chemical compositionSmall particle sizeVanadium compoundsMicrowaveDysprosium

The invention discloses a dysprosium and yttrium codoped pucherite inorganic pigment and a preparation method thereof. A general formula of the pucherite inorganic pigment is Bi1-x-yDyxYyVO4, wherein x is smaller than or equal to 0.1 and greater than or equal to 0.02; y is smaller than or equal to 0.1 and greater than or equal to 0.02; the pucherite pigment codoped with a dysprosium element and a yttrium element is prepared by using assistance of chelating agents by a microwave hydrothermal method; different chelating agents are added; slow release of metal ions in a reaction process is facilitated, so that the process of generating the pucherite pigment codoped with the dysprosium element and the yttrium element is carried out in a mitigating manner; the preparation time is shortened in preparation employing the microwave hydrothermal method. According to the pucherite pigment codoped with the dysprosium element and the yttrium element prepared by the preparation method, doping of the dysprosium element and the yttrium element contributes to improvement of the coloring property of the pucherite pigment.

Owner:SHAANXI UNIV OF SCI & TECH

Dysprosium and praseodymium co-doped bismuth vanadate inorganic pigment and preparation method thereof

InactiveCN103421353AUniform chemical compositionSmall particle sizePigment treatment with non-polymer organic compoundsBismuth vanadateDysprosium

The invention discloses a dysprosium and praseodymium co-doped bismuth vanadate inorganic pigment and a preparation method thereof. The bismuth vanadate inorganic pigment has a general formula of Bil-x-yDyxPryVO4, wherein x is not less than 0.02 and not more than 0.1 and y is not less than 0.02 and not more than 0.1; the dysprosium and praseodymium co-doped bismuth vanadate pigment is prepared by chelating agents and a microwave hydrothermal method; the addition of different chelating agents is favorable for slow release of metal ions in a reaction process, so that the process of generating the dysprosium and praseodymium co-doped bismuth vanadate pigment is more slowly proceeded; the microwave hydrothermal method is used to prepare the pigment, so that the preparation time is shortened; the doping of dysprosium and praseodymium in the dysprosium and praseodymium co-doped bismuth vanadate pigment prepared by the method is favorable for improving the color generation performance of the bismuth vanadate pigment.

Owner:SHAANXI UNIV OF SCI & TECH

Method for controlling fertilizer appearance by double-caramel pigment

ActiveCN102786345AShorten the cycle timeEasy to adjust and control appearanceFertiliser formsFertilizer mixturesAgricultural engineeringSlurry

The invention relates to a method for controlling the fertilizer appearance by double-caramel pigment. In the fertilizer production process, the operation is carried out according to the following steps that (1) firstly, the double-caramel pigment and the water are taken according to a mass ratio being 1:0-0.5 and are mixed and stirred uniformly; (2) the double-caramel pigment uniformly mixed in the first step is conveyed into a slurry neutralizing tank by a plunger type mechanical metering pump, a plunger type diaphragm metering pump or a miniature single screw rod pump to be fully stirred with fertilizer slurry, in addition, the double-caramel pigment is completely dissolved and mixed uniformly, one ton of added double-caramel pigment fertilizer consumes 0.1 to 5.0 kg of double-caramel pigment, and a variable frequency flow meter is used for metering; and (3) the fertilizer slurry mixed with the double-caramel pigment is pelletized, and the fertilizer in the required color is prepared. The method has the advantages that the fertilizer appearance can be conveniently regulated and controlled through the double-caramel pigment, the fertilizer color is uniform and stable, the color mixing of fertilizers cannot occur, in addition, the consumption is low, the cost is low, the biodegradable effect is realized, the environment is favorably protected, the operation is convenient, no pollution, no poison and no public hazard exist, and the like.

Owner:HUBEI FORBON TECH

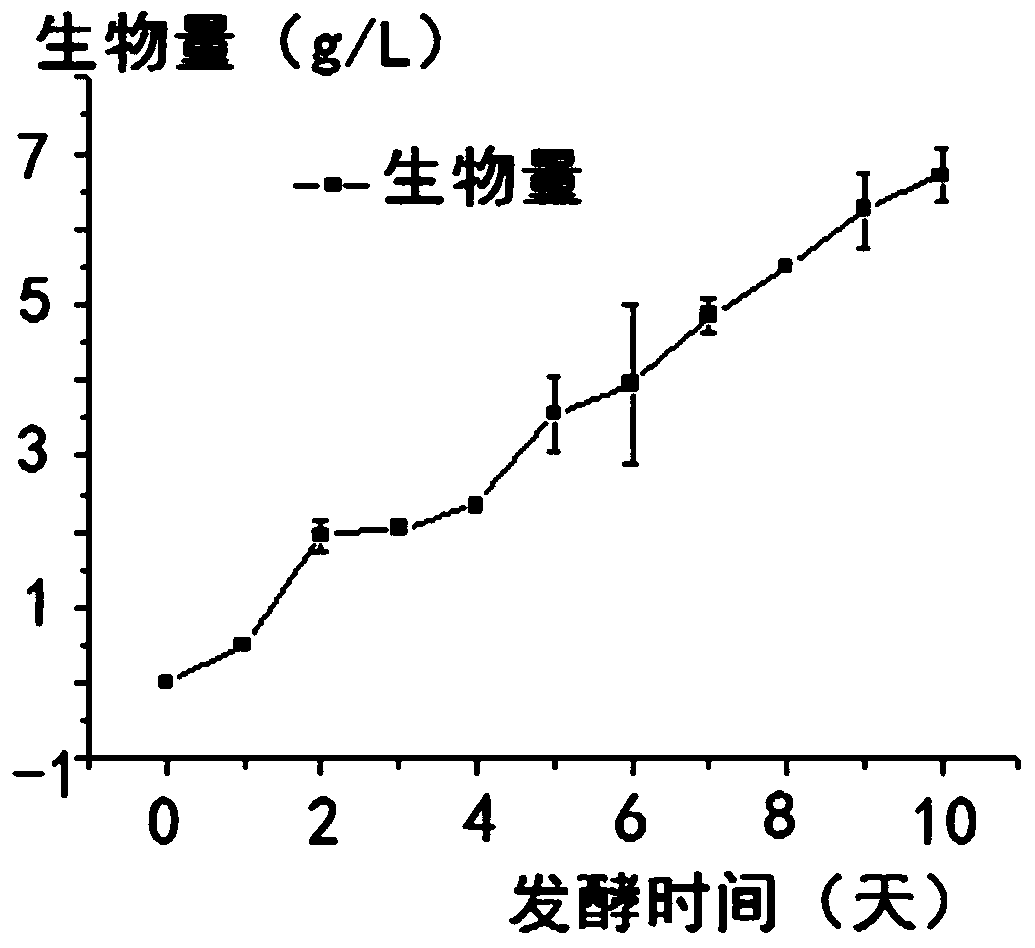

Original red beer and production process thereof

InactiveCN109628245AImprove securityBright colorMetabolism disorderBeer fermentationYeastCholesterol

The invention discloses original red beer and a production process thereof and relates to the field of beer. The original red beer is prepared from, by weight, the following raw materials: 20-30% of barley malt, 3-10% of red malt, 1-5% of red kojic rice, 0.2-0.4% of hop, 0.5-0.7% of yeast, 0.1-0.5% of medlar, 0.1-0.5% of red dates and 60-70% of drinking water, wherein the original red beer is produced through raw material preparation, saccharification, filtration, boiling, inoculation and fermentation and filling. The original red beer has the advantages that the red kojic rice, the red malt,the medlar and the red dates are added in the original red beer, so that the original red beer has bright eye-catching red color, rich taste and nutrition, has the nutritional and health-care effectsof resisting fatigue and aging, regulating cholesterol in the body and expanding blood vessel and the like and can meet the nutritional health needs of consumers.

Owner:青岛威沃啤酒饮料生物科技有限公司

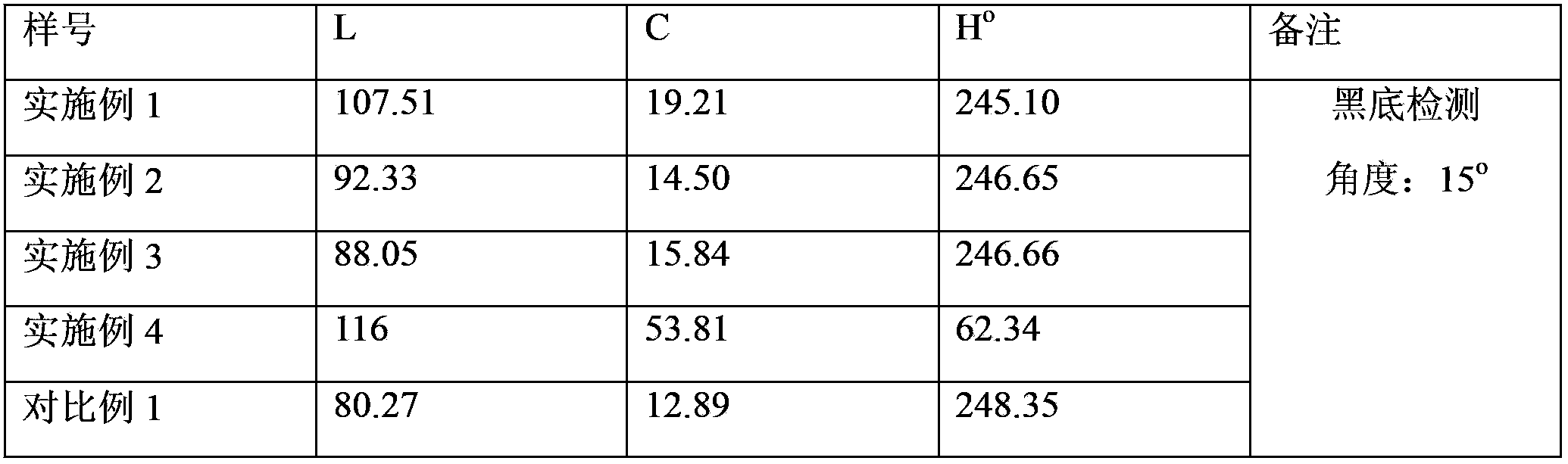

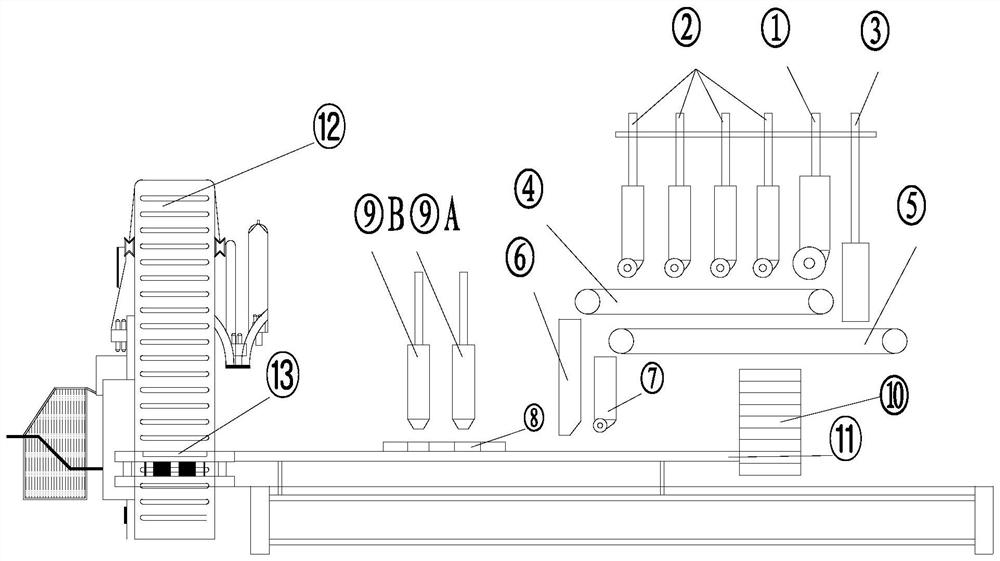

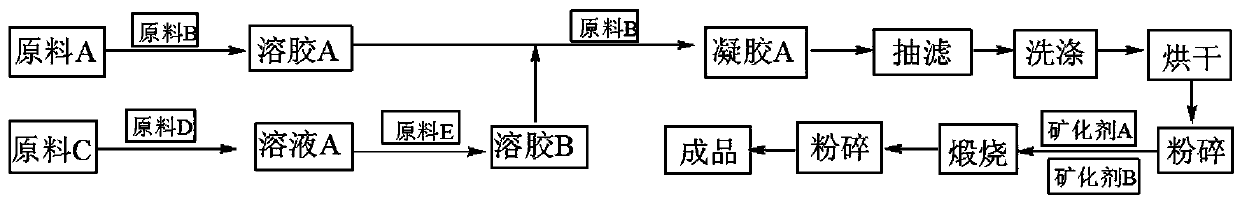

Nano vanadium-zirconium blue ceramic coloring material and preparation method thereof

The invention relates to a nano vanadium-zirconium blue ceramic coloring material and a preparation method thereof. The nano vanadium-zirconium blue ceramic coloring material is prepared from the following raw materials in parts by weight: 8 to 15 parts of vanadium pentoxide, 30 to 50 parts of zirconium oxychloride, 30 to 45 parts of sodium silicate, 25 to 40 parts of acid or strong acid and weakalkali salt, 1 to 2.5 parts of sodium chloride and 1 to 2.5 parts of sodium fluoride. The nano vanadium-zirconium blue ceramic coloring material provided by the invention takes the sodium silicate, the zirconium oxychloride, sodium hydroxide, the vanadium pentoxide and the acid or strong acid and weak alkali salt are used as starting raw materials and water is used as a solvent; then a vanadium-zirconium blue gel precursor is synthesized through a sol-gel method; the sodium chloride and the sodium fluoride are used as a compound mineralizing agent and low-temperature sintering is carried out to prepare the nano vanadium-zirconium blue ceramic coloring material; the coloring material has the advantages of pure tone, low firing temperature, less energy consumption, cheap raw material price and easiness for obtaining the raw materials, simple and easy-to-control production technology, environment-friendly solvents, loose and easy-to-pulverize product, good coloring effect, convenience forindustrial production and the like and is an ideal coloring material for producing and firing a high-quality ceramic product.

Owner:LUOYANG NORMAL UNIV

A kind of cobalt black material for ceramic ink and preparation method thereof

The invention discloses cobalt black pigment for ceramic ink. The cobalt black pigment is prepared from the following raw materials in percentage by weight: 35%-45% of Co3O4, 15%-20% of NiO, 8%-15% ofFe2O3, and 20%-30% of Cr2O3. Through massive test, an ideal pigment component formula scope and a pigment preparation method are obtained, and the obtained cobalt black pigment is plump in color, pure in color shaft and low in magnetic property.

Owner:广东丰霖新材料科技有限公司

Cobalt black pigment for ceramic ink and preparation method of cobalt black pigment

The invention discloses cobalt black pigment for ceramic ink. The cobalt black pigment is prepared from the following raw materials in percentage by weight: 35%-45% of Co3O4, 15%-20% of NiO, 8%-15% ofFe2O3, and 20%-30% of Cr2O3. Through massive test, an ideal pigment component formula scope and a pigment preparation method are obtained, and the obtained cobalt black pigment is plump in color, pure in color shaft and low in magnetic property.

Owner:广东丰霖新材料科技有限公司

Large-sized synthesized mica pearlescent pigment and preparation method thereof

ActiveCN102660157BChange electronegativityAccelerated settlementCosmetic preparationsInorganic pigment treatmentMicrometerRefractive index

The invention relates to a large-sized synthesized mica pearlescent pigment, which is characterized in that large-sized synthesized mica powder with d50 being equal to 50 to 600 micrometers is adopted as a substrate, wherein a high-refraction oxide membrane is arranged on the surface of the substrate, the high-refraction oxide membrane is formed by implementing the hydrolysis enveloping adopting soluble salt which can be hydrolyzed into high-refraction oxide as a hydrolysis precursor under the existence of soluble trivalent aluminum salt which is used as a depositing agent. The invention also relates to a preparation method of the large-sized synthesized mica pearlescent pigment. The large-sized synthesized mica pearlescent pigment has strong star-like twinkling property and good decoration effect and can be widely applied to the industries such as cosmetics, synthesized leather, plastics, texture costumes, paint and the like.

Owner:FUJIAN KUNCAI MATERIAL TECH

White glaze, whole body borderless ceramic tile containing white glaze and preparation method thereof

Owner:JIANGXI HEMEI CERAMICS +3

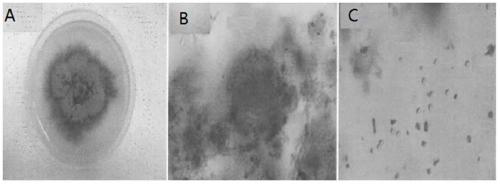

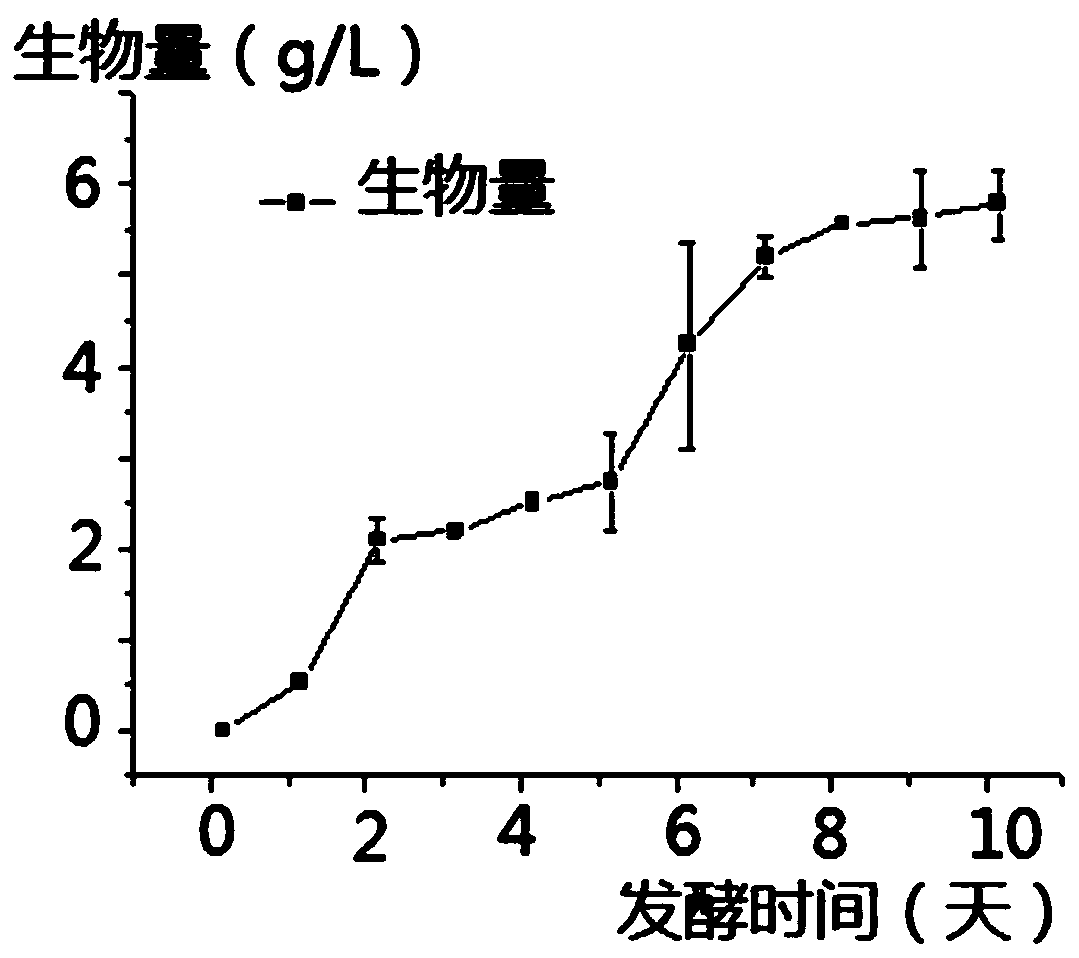

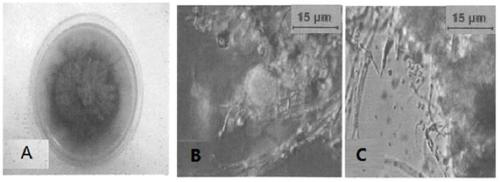

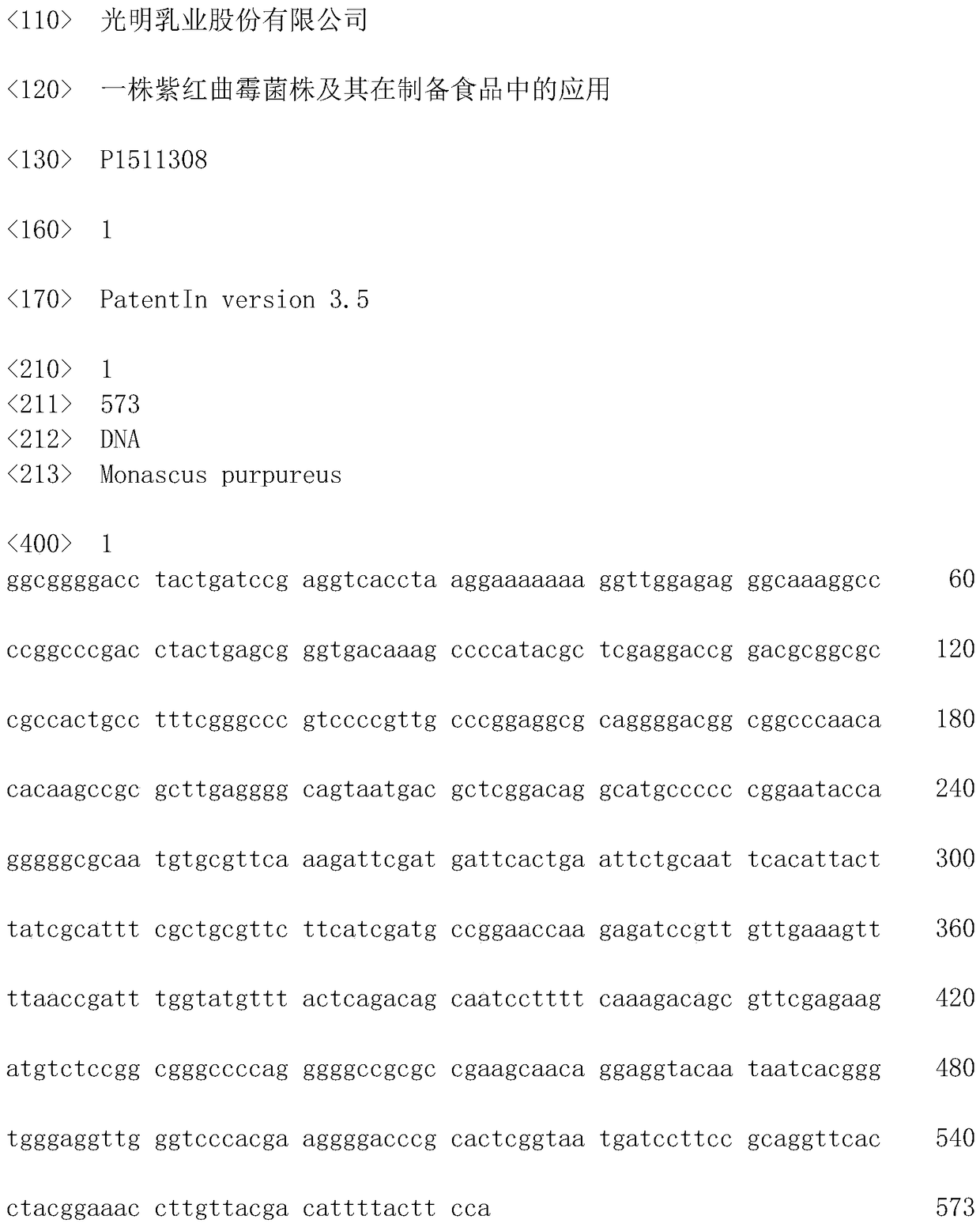

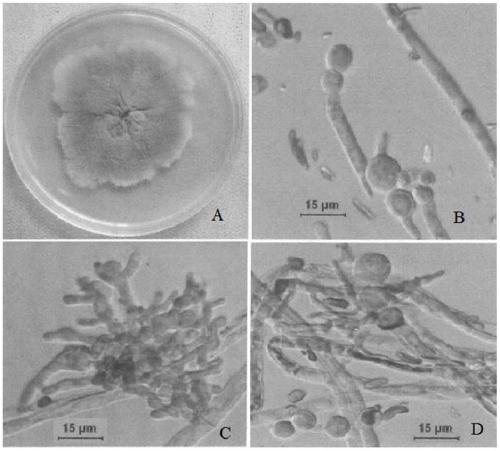

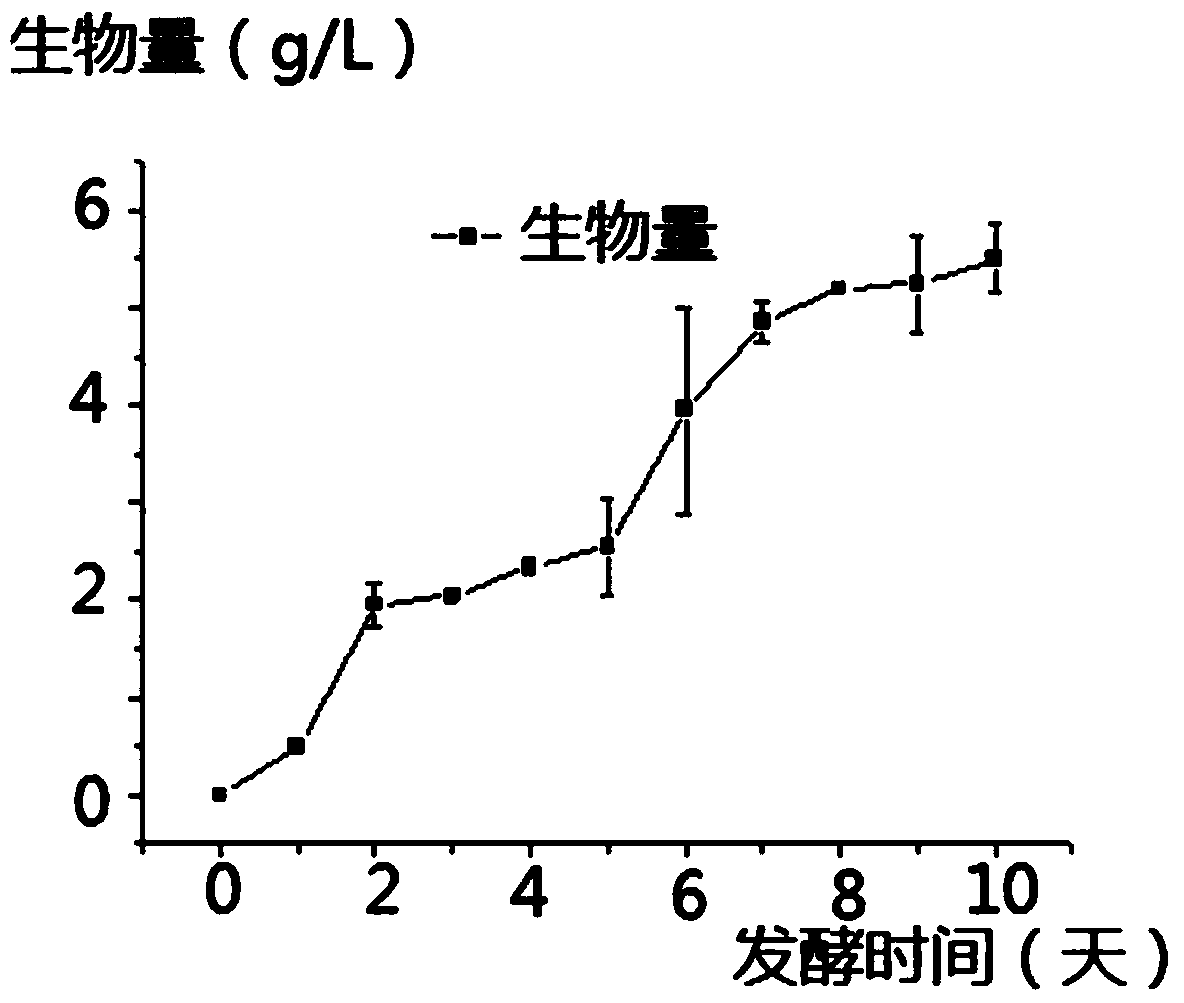

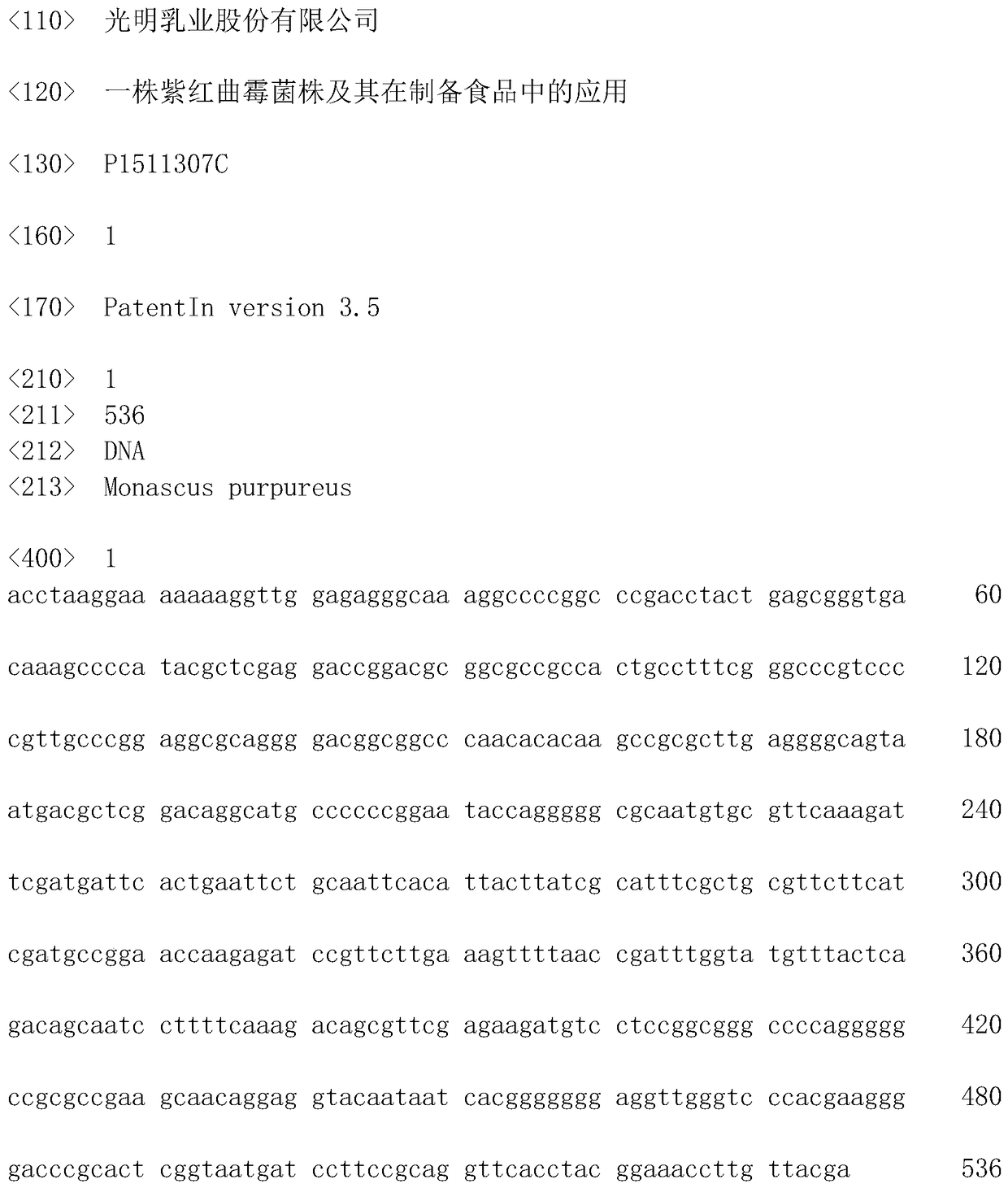

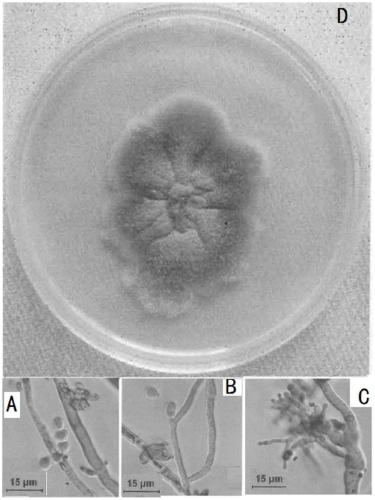

A strain of Monascus purpura and its application in food preparation

ActiveCN105505791BReduce contentMonascus pigment is expensiveFungiMicroorganism based processesMicroorganismBiotechnology

The invention discloses a Monascus purpureus and its application in food production. The Monascus purpura is preserved in the General Microorganism Center of China Microorganism Culture Collection Management Committee, and the preservation number is: CGMCC No.11319. It does not produce citrinin at all, and it can produce natural monascus pigment, which has a high color value and can be used in the preparation of dairy products or other food processing techniques.

Owner:BRIGHT DAIRY & FOOD CO LTD

Preparation method of green pigment for ceramic high-temperature glaze

Owner:PINGDING YINGYU PORCELAIN

Lanthanum-yttrium co-doping bismuth vanadate inorganic pigment and preparation method thereof

InactiveCN103420688BUniform chemical compositionSmall particle sizeInorganic pigment treatmentBismuth vanadateCerium

The invention discloses lanthanum-yttrium co-doping bismuth vanadate inorganic pigment and a preparation method thereof. The general formula of the inorganic pigment is Bil-x-yLaxYyVO4, wherein x is larger than or equal to 0.02 and less than or equal to 0.1, and y is larger than or equal to 0.02 and less than or equal to 0.1. Chelating agents are utilized to assist and a microwave hydrothermal method is adopted to prepare the lanthanum-yttrium co-doping bismuth vanadate pigment, the slow release of metal ions in the reaction process is facilitated through the addition of various chelating agents, so that the process of preparing the lanthanum-yttrium co-doping bismuth vanadate pigment is carried out relatively lenitively; through the adoption of the microwave hydrothermal method to prepare, the preparation time is reduced. The lanthanum-yttrium co-doping bismuth vanadate pigment prepared by the invention has the advantages that the improvement of the color generating performance of the bismuth vanadate pigment is facilitated through the doping of lanthanum and cerium.

Owner:SHAANXI UNIV OF SCI & TECH

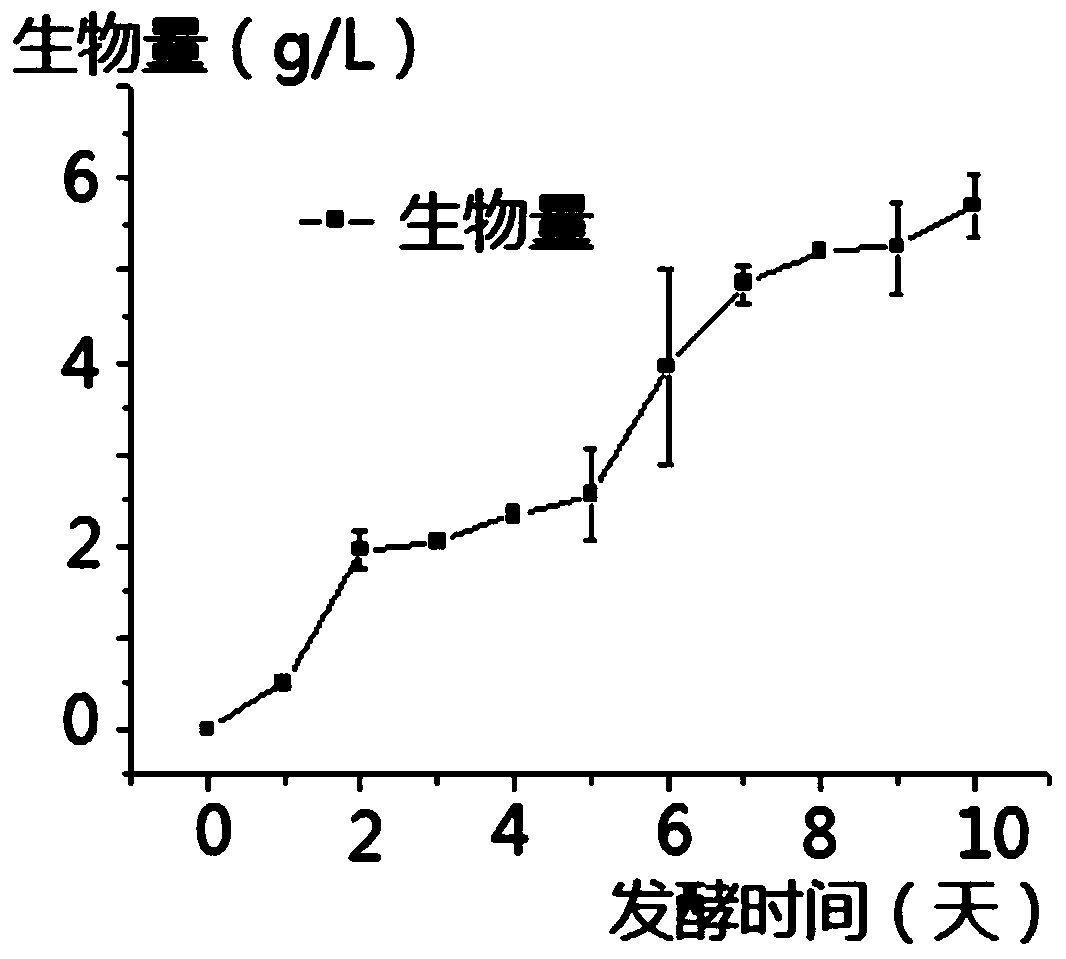

A strain of Monascus purpura and its application in food preparation

ActiveCN105505789BReduce contentMonascus pigment is expensiveFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a Monascus purpureus and its application in food production. The Monascus purpura is preserved in the General Microorganism Center of China Microbiological Culture Collection Management Committee, and the preservation number is: CGMCC No.11317. It does not produce citrinin at all, and it can produce natural monascus pigment, which has a high color value and can be used in the preparation of dairy products or other food processing techniques.

Owner:BRIGHT DAIRY & FOOD CO LTD

Dysprosium and yttrium codoped pucherite inorganic pigment and preparation method thereof

InactiveCN103449519BUniform chemical compositionSmall particle sizePigmenting treatmentVanadium compoundsMicrowaveDysprosium

The invention discloses a dysprosium and yttrium codoped pucherite inorganic pigment and a preparation method thereof. A general formula of the pucherite inorganic pigment is Bi1-x-yDyxYyVO4, wherein x is smaller than or equal to 0.1 and greater than or equal to 0.02; y is smaller than or equal to 0.1 and greater than or equal to 0.02; the pucherite pigment codoped with a dysprosium element and a yttrium element is prepared by using assistance of chelating agents by a microwave hydrothermal method; different chelating agents are added; slow release of metal ions in a reaction process is facilitated, so that the process of generating the pucherite pigment codoped with the dysprosium element and the yttrium element is carried out in a mitigating manner; the preparation time is shortened in preparation employing the microwave hydrothermal method. According to the pucherite pigment codoped with the dysprosium element and the yttrium element prepared by the preparation method, doping of the dysprosium element and the yttrium element contributes to improvement of the coloring property of the pucherite pigment.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of nano-vanadium-zirconium blue ceramic pigment and preparation method thereof

InactiveCN108250804BPure toneLow firing temperaturePigmenting treatmentEngineeringZirconium oxychloride

The invention relates to a nano-vanadium-zirconium blue ceramic colorant and a preparation method thereof. The nano-vanadium-zirconium blue ceramic colorant is made of the following raw materials in parts by weight: 8-15 parts of vanadium pentoxide, 30-50 parts of zirconium oxychloride 30-45 parts of sodium silicate, 25-40 parts of acid or strong acid and weak base salt, 1-2.5 parts of sodium chloride and 1-2.5 parts of sodium fluoride; the present invention uses sodium silicate, zirconium oxychloride, hydrogen Sodium oxide, vanadium pentoxide and acid or strong acid and weak base salt were used as initial raw materials, and water was used as solvent to synthesize vanadium-zirconium blue gel precursor by sol-gel method, and sodium chloride and sodium fluoride were used as composite minerals A nano-vanadium-zirconium blue ceramic pigment was prepared by low-temperature sintering; the obtained pigment has pure color tone, low firing temperature, low energy consumption, low-cost and easy-to-obtain raw materials, simple and easy-to-control production process, and the solvent environment used Friendly, the product is loose and easy to powder, the color rendering effect is good, and it is convenient for industrial production. It is an ideal color material for the production and firing of high-quality ceramic products.

Owner:LUOYANG NORMAL UNIV

A kind of graphene oxide, graphene-like and pearlescent pigment based on it

ActiveCN106893370BHigh hiding powerHigh color saturationCosmetic preparationsPigmenting treatmentFiltrationPigment

The invention relates to quasi graphene oxide, quasi graphene and a quasi-graphene-based pearlescent pigment based on the quasi graphene oxide or quasi graphene. The quasi graphene oxide is obtained from the following steps: (A) oxidizing flake graphite powder with potassium permanganate; (B) intercalating concentrated sulfuric acid to oxidized graphite powder; and (C) peeling intercalated graphite powder, washing the obtained product till the product is neutral, and performing filtration and drying. Quasi graphene is prepared by reducing quasi graphene oxide. The quasi-graphene-based pearlescent pigment based on the quasi graphene oxide or quasi graphene is high in covering power and chroma and pure in tone, is controllable in technology, and can be widely applied to cosmetics, synthetic leather, plastics, textile and garment or paint.

Owner:FUJIAN KUNCAI MATERIAL TECH CO LTD +1

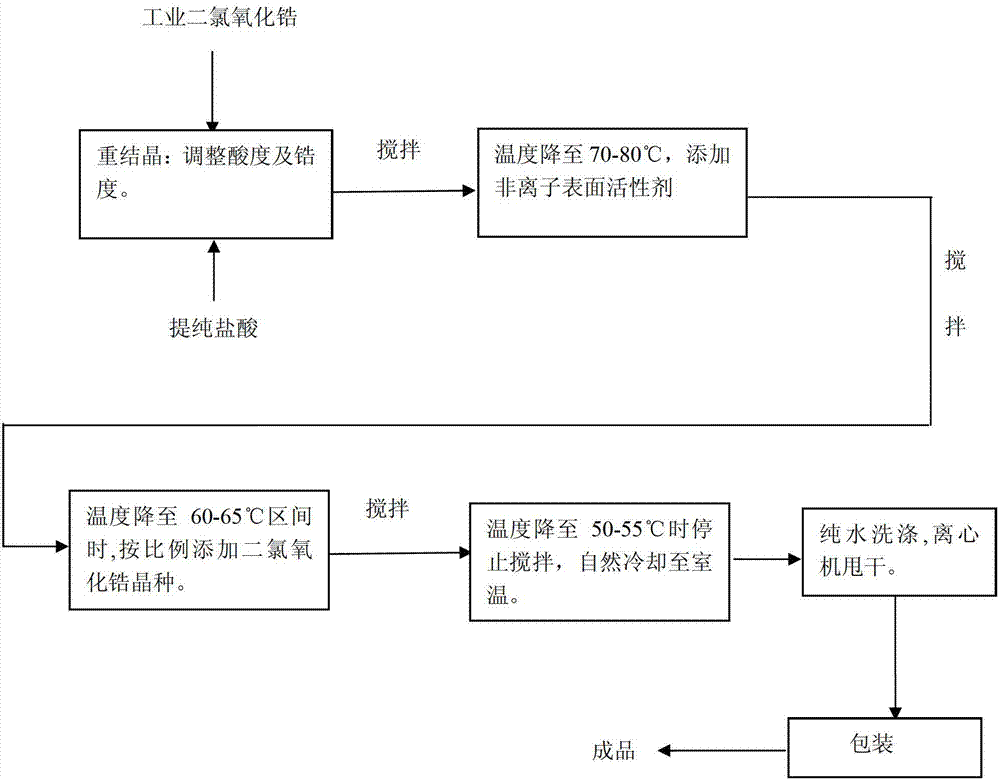

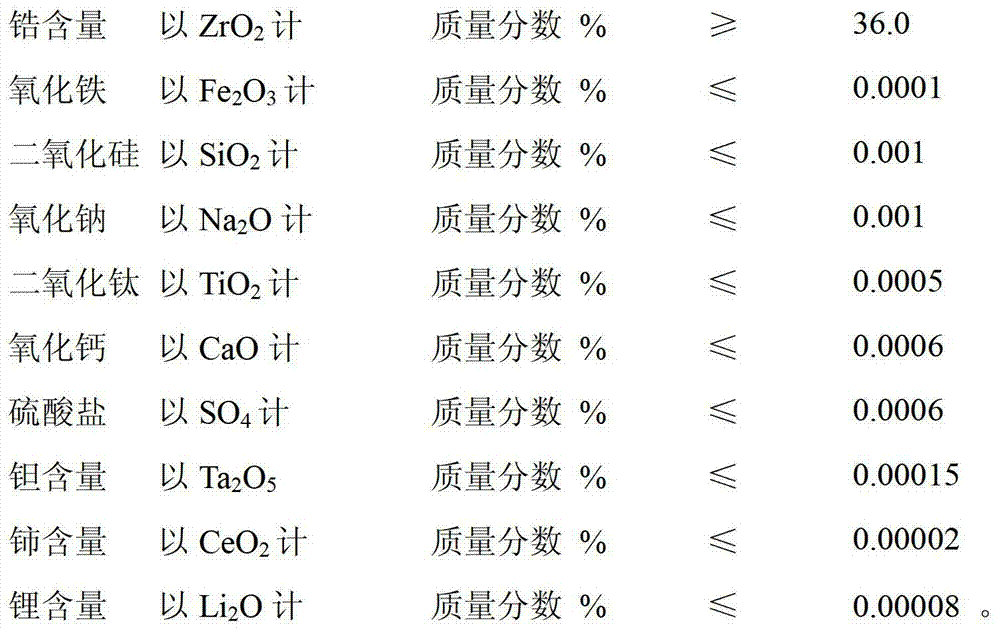

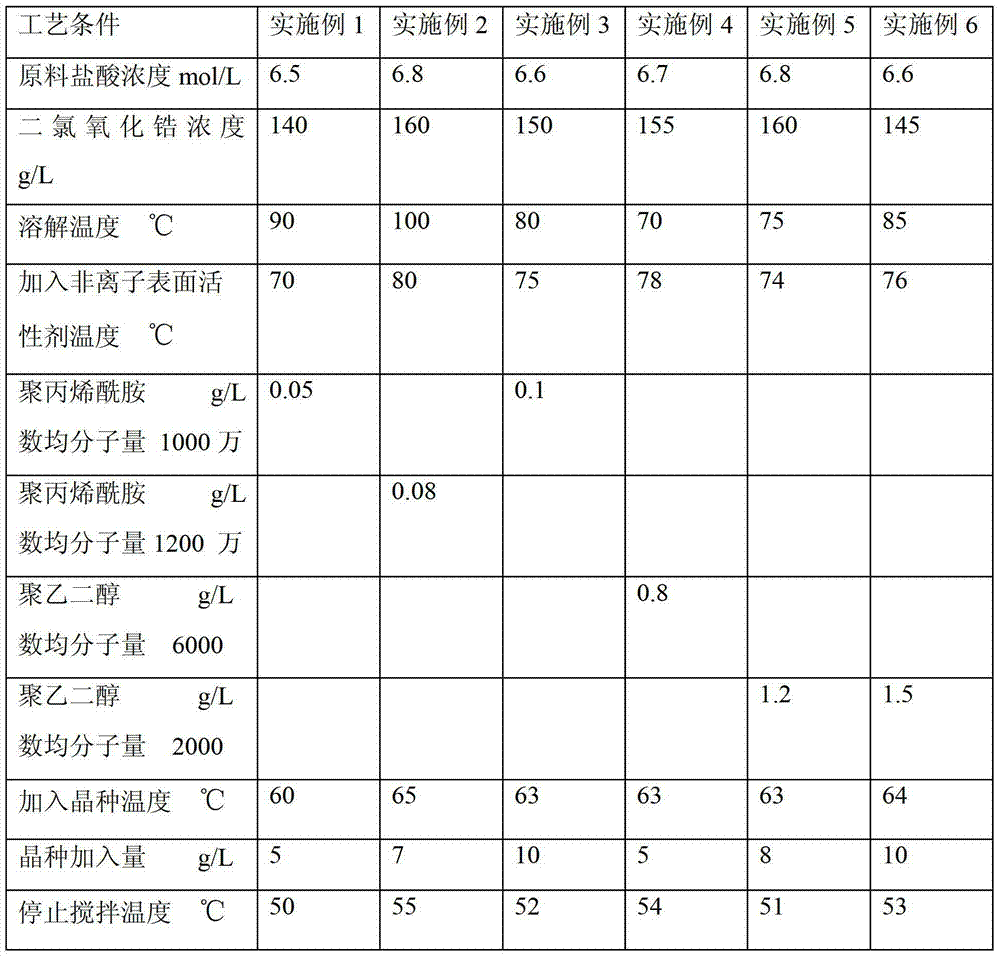

Special zirconium oxychloride for coated cadmium selenide red ceramic pigment and preparation method thereof

The invention relates to a special zirconium oxychloride for a coated cadmium selenide red ceramic pigment and a preparation method thereof, belonging to preparation of zirconium compounds. The special zirconium oxychloride is prepared from industrial zirconium oxychloride by purification by recrystallization. The preparation method is characterized by comprising the following steps: (1) dissolving industrial zirconium oxychloride in a 6.5-6.8 mol / L purified hydrochloric acid water solution, and supplementing industrial zirconium oxychloride until the zirconium oxychloride concentration is 140-160 g / L on the basis of ZrO2; and (2) adding a nonionic surfactant as a dispersing agent into the crystalline solution. The invention provides a high-coating-rate favorable-high-temperature-stability special zirconium oxychloride for a coated cadmium selenide red ceramic pigment capable of ensuring pure color tone of the pigment and a preparation method thereof. The coating rate of the coated cadmium selenide red ceramic pigment prepared from the special zirconium oxychloride is up to 7.2%; and the coated cadmium selenide red ceramic pigment has pure color tone and excellent high-temperature stability, and can resist high temperature of 1150 DEG C above.

Owner:山东广通新材料有限公司

A strain of Monascus purpura and its application in food preparation

ActiveCN105505788BReduce contentMonascus pigment is expensiveFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a Monascus purpureus and its application in food production. The Monascus purpura is preserved in the General Microorganism Center of China Microbiological Culture Collection Management Committee, and the preservation number is: CGMCC No.11316. It hardly produces citrinin, and it can produce natural monascus pigment, which has a high color value and can be used in the preparation of dairy products or other food processing techniques.

Owner:BRIGHT DAIRY & FOOD CO LTD

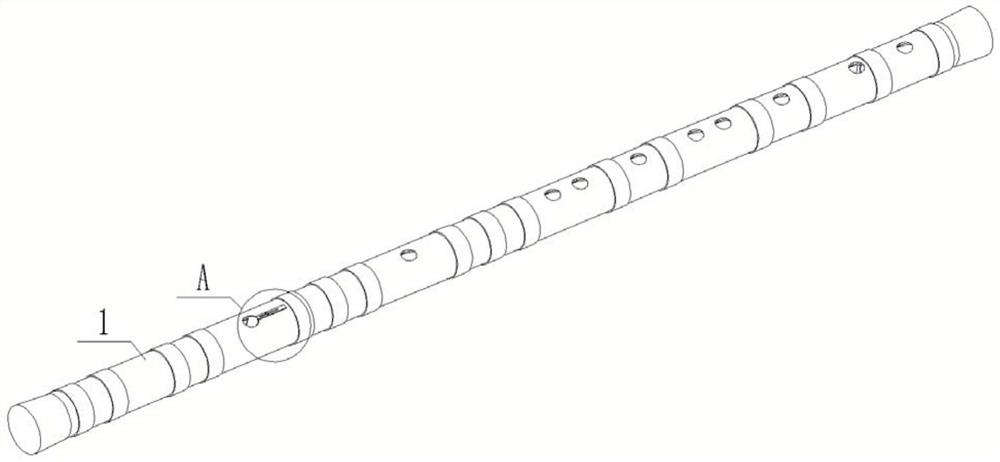

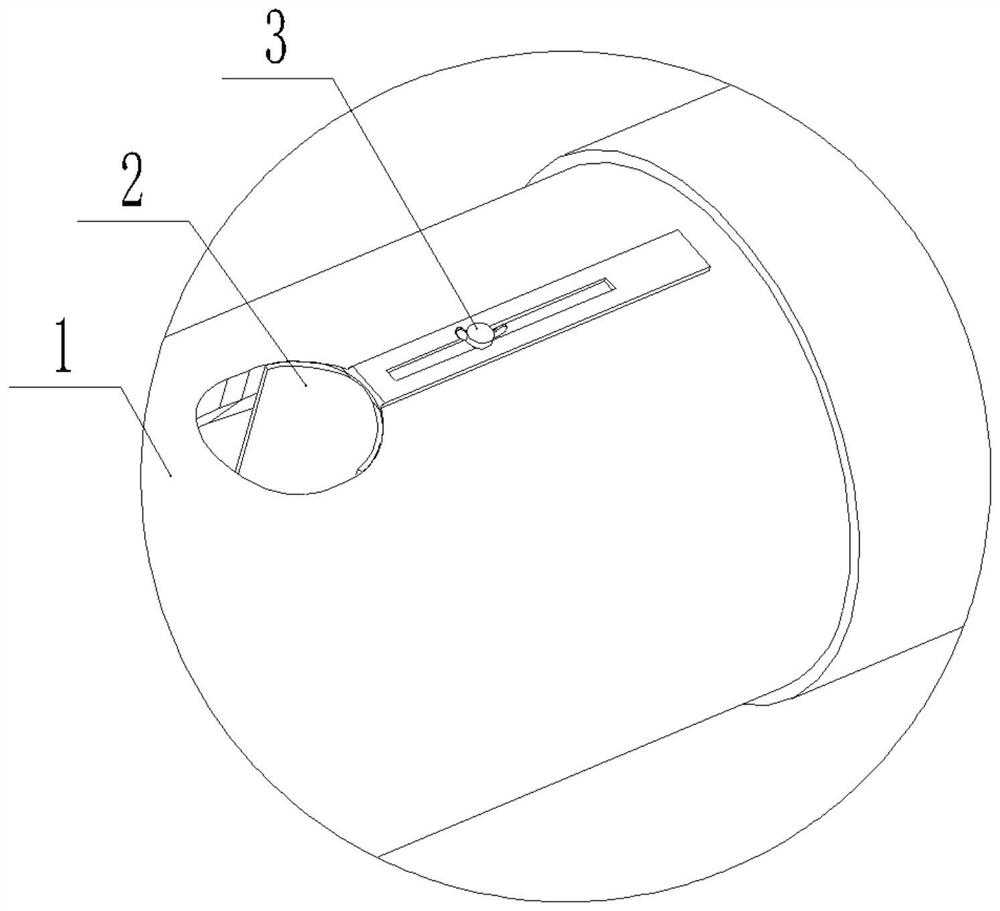

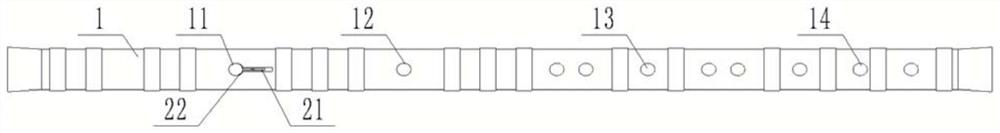

Whole-section tunable bamboo flute

The invention discloses a whole-section tunable bamboo flute which comprises a flute pipe, a tuning piece and a limiting fixing piece, the tuning piece is provided with a fixed plate and a baffle which are oppositely bent, the fixing plate is connected to the flute pipe, and the baffle matches the inner wall of one end of a blowing hole and extends downwards into a cavity of the flute pipe along the edge of the inner wall. The limiting fixing piece is arranged on the flute pipe to fix the fixed plate and the flute pipe. According to the bamboo flute, the bamboo flute is arranged to be of a whole-section type, the tone quality of bamboo can be brought into play to the maximum extent, and cracking is not likely to happen; secondly, a tone tuning piece composed of the fixed plate and a bafflewhich are oppositely bent is arranged at the blowing hole of the flute pipe, the baffle extending into the blowing hole can be used for guiding the direction of airflow entering the cavity of the flute pipe, and the incident angle of the airflow entering the cavity of the flute pipe is controlled by adjusting the bending angle between the baffle and the fixed plate; the purpose of adjusting the pitch of the bamboo flute is achieved, the playing effect is improved, the tone tuning piece is fixed to the surface of the flute pipe and cannot damage the bamboo flute body, and the authenticity of bamboo flute sound is guaranteed.

Owner:四川音乐学院 +2

A strain of Monascus purpura and its application in food preparation

ActiveCN105420123BReduce contentMonascus pigment is expensiveFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a Monascus purpureus and its application in food production. The Monascus purpura is preserved in the General Microorganism Center of China Microbiological Culture Collection Management Committee, and the preservation number is: CGMCC No.11315. It hardly produces citrinin, and it can produce natural monascus pigment, which has extremely high color value, and can be used in the preparation of dairy products or other food processing techniques.

Owner:BRIGHT DAIRY & FOOD CO LTD

Dysprosium and praseodymium co-doped bismuth vanadate inorganic pigment and preparation method thereof

InactiveCN103421353BUniform chemical compositionSmall particle sizePigment treatment with non-polymer organic compoundsBismuth vanadateDysprosium

The invention discloses a dysprosium and praseodymium co-doped bismuth vanadate inorganic pigment and a preparation method thereof. The bismuth vanadate inorganic pigment has a general formula of Bil-x-yDyxPryVO4, wherein x is not less than 0.02 and not more than 0.1 and y is not less than 0.02 and not more than 0.1; the dysprosium and praseodymium co-doped bismuth vanadate pigment is prepared by chelating agents and a microwave hydrothermal method; the addition of different chelating agents is favorable for slow release of metal ions in a reaction process, so that the process of generating the dysprosium and praseodymium co-doped bismuth vanadate pigment is more slowly proceeded; the microwave hydrothermal method is used to prepare the pigment, so that the preparation time is shortened; the doping of dysprosium and praseodymium in the dysprosium and praseodymium co-doped bismuth vanadate pigment prepared by the method is favorable for improving the color generation performance of the bismuth vanadate pigment.

Owner:SHAANXI UNIV OF SCI & TECH

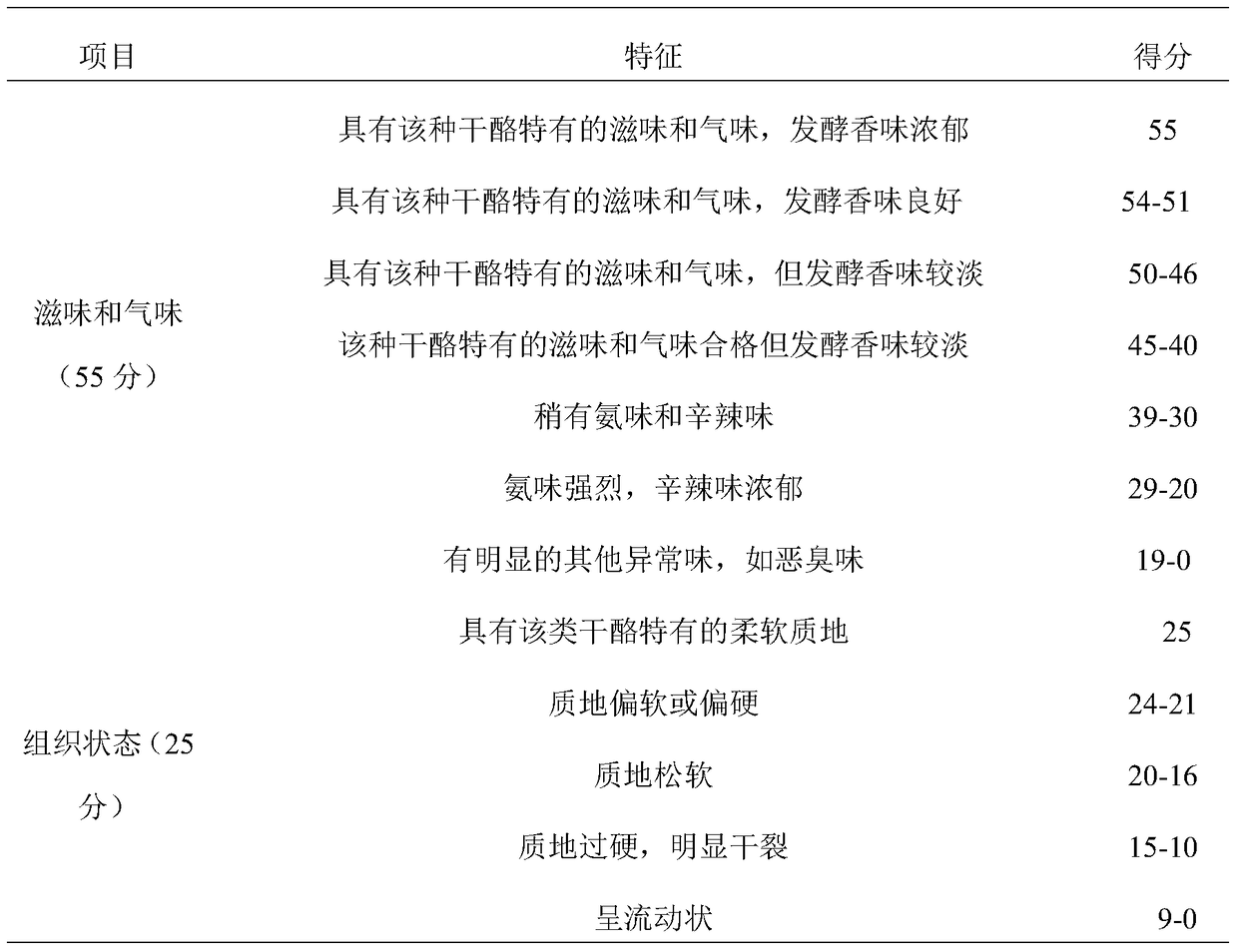

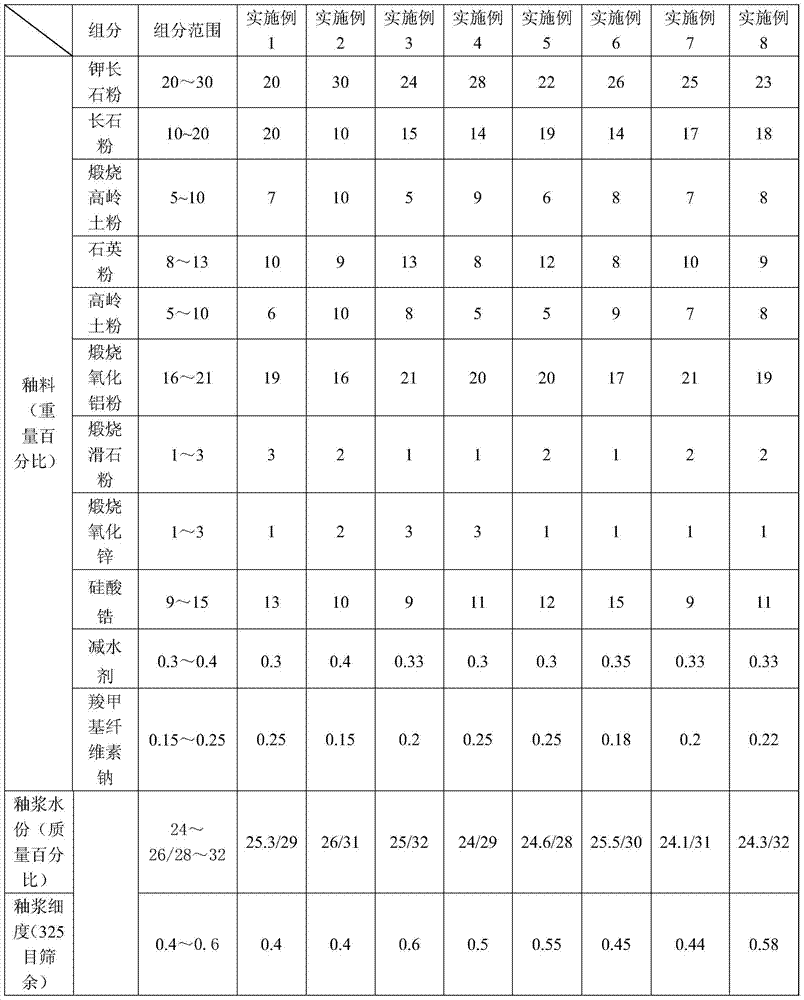

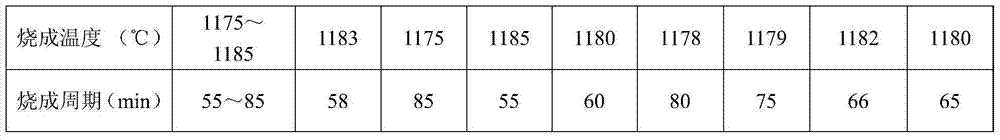

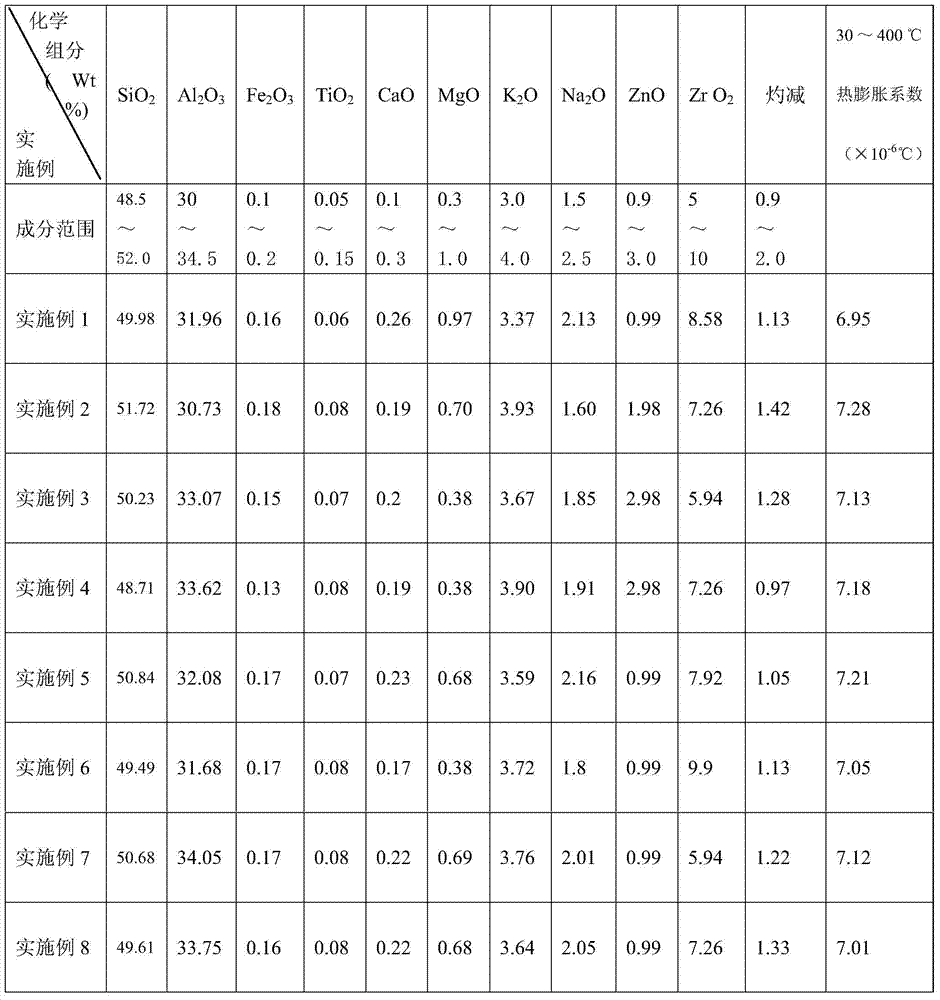

A kind of bottom glaze for the production of fully polished glazed tiles, which is beneficial to the color development of ceramic inks

An underglaze used in the production of fully polished glazed tiles, which is beneficial to the color development of ceramic inks. The main raw materials of the underglaze are: 20-30% of potassium feldspar powder, 10-20% of feldspar powder, 5-10% of calcined kaolin powder, quartz powder 8-13%, kaolin powder 5-10%, calcined alumina powder 16-21%, calcined talc powder 1-3%, calcined zinc oxide 1-3%, zirconium silicate 9-15%, water reducing agent 0.3 ~0.4%, methyl 0.15~0.25%; single raw material chemical composition CaO content<3%; bottom glaze raw material chemical composition: SiO248.5~52.0%, Al2O330~34.5%, Fe2O30.1~0.2%, TiO20. 05~0.15%, CaO 0.1~0.3%, MgO 0.3~1.0%, K2O 3.0~4.0%, Na2O 1.5~2.5%, ZnO 0.9~3.0%, ZrO25~10%, firing reduction 0.9~2.0%; Technological process: batching→ball milling→sieving→iron removal→glazing slurry stale; method of using bottom glaze: glazing by bell-jar glazing process or linear glazing process. The invention enriches the color of the product, is beneficial to the color development of the ceramic ink, each color has a deeper color and a purer tone, and the product yield is high.

Owner:GUANGDONG XINRUNCHENG CERAMICS

A kind of preparation method of nano-praseodymium yellow ceramic pigment

The invention relates to the technical field of a fine ceramic material, and particularly to a preparation method of a nanometer praseodymium yellow ceramic pigment. The preparation method comprises: taking sodium silicate, zirconium oxychloride, praseodymia, ammonium oxalate, ammonium chloride, hydrochloric acid, and the like as original raw materials; adopting a sol-gel method to prepare a praseodymium yellow gel precursor; taking sodium chloride and sodium fluoride as a mixed mineralizer; and preparing the nanometer praseodymium yellow ceramic pigment through low temperature sintering. The raw materials are low in price and are easily available; the production technology is simple and easy to control; the reagents are environment-friendly, so that the preparation method is convenient for industrial production. The prepared pigment has advantages of pure color, low sintering temperature, low energy consumption, loose and easy-powdered product, and the like, and is an ideal pigment for sintering a high-quality ceramic product.

Owner:LUOYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com