Large-sized synthesized mica pearlescent pigment and preparation method thereof

A technology for synthesizing mica and pearlescent pigments, which is applied in the fields of inorganic pigment treatment, chemical instruments and methods, and pharmaceutical formulations. It can solve the problems of large particle size, small specific surface area, and poor surface activity, and achieve pure color saturation and high refraction. The effect of high efficiency and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

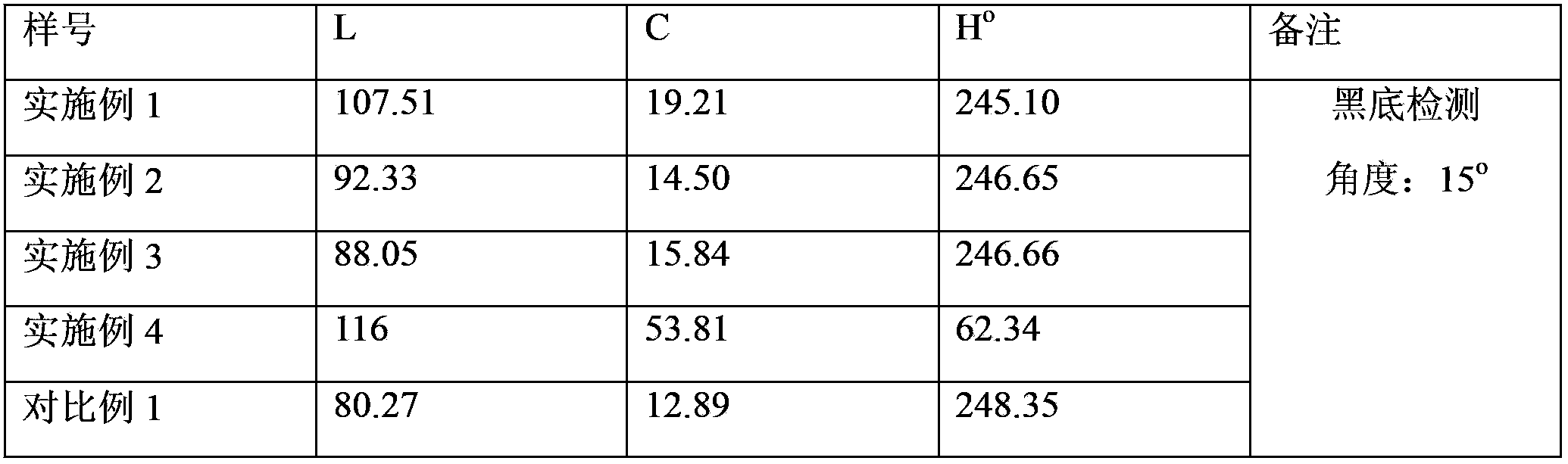

Examples

Embodiment 1

[0029] (1) Weigh d 50 =50μm synthetic mica powder 100g, add 1150ml of reverse osmosis water with a conductivity of 20μs / cm according to the solid-liquid ratio of 1:11.5, and stir until the temperature is 70°C while heating up;

[0030] (2) In the suspension obtained in step (1), add 2 grams of Al per kilogram of synthetic mica powder 3+ meter, that is, adding 20wt% crystalline aluminum chloride (AlCl 3 ·H 2 O) 9 grams of solution, stirred at a constant temperature of 70°C for 10 minutes;

[0031](3) At a temperature of 70°C, adjust the pH value to 1.6 with dilute hydrochloric acid, and feed titanium tetrachloride with a concentration of 4mol / L at a rate of 0.8mol / kg synthetic mica·h (20ml / h) evenly and slowly Add it to the suspension in step (2), and at the same time add dropwise a sodium hydroxide solution with a concentration of 20wt%, so as to keep the pH value constant at about 1.6. When the material is added to the hue of the silver-white pearlescent pigment standard ...

Embodiment 2

[0035] (1) Weigh d 50 =325μm synthetic mica powder 100g, add 825ml of deionized water with a conductivity less than 50μs / cm according to the solid-liquid ratio of 8.25, and stir until the temperature is 80°C while raising the temperature;

[0036] (2) In the suspension obtained in step (1), add 4 grams of Al per kilogram of synthetic mica powder 3+ meter, that is, adding 10wt% crystalline aluminum chloride (AlCl 3 ·H 2 O) 36 grams of solution, stirred at 80°C for 20 minutes;

[0037] (3) At a temperature of 80°C, adjust the pH value to 1.9 with dilute hydrochloric acid, and feed titanium tetrachloride with a concentration of 2.25mol / L at a rate of 0.45mol / kg to synthesize mica·h (20ml / h) evenly and slowly Add it to the suspension in step (2) while adding dropwise a 20% sodium hydroxide solution to keep the pH constant at about 1.9. When the material is added to the hue of the silver-white pearlescent pigment standard sample (for 100g of synthetic mica powder, 0.1mol solubl...

Embodiment 3

[0041] (1) Weigh d 50 =600μm synthetic mica powder 100g, add 500ml of reverse osmosis water with a conductivity of 20μs / cm according to the solid-liquid ratio of 1:5, stir while heating up to a temperature of 90°C;

[0042] (2) In the suspension obtained in step (1), add 6 grams of Al per kilogram of synthetic mica powder 3+ meter, that is, adding a concentration of 30wt% crystalline aluminum chloride (AlCl 3 ·H 2 O) 18 grams of solution, stirred at 90°C for 30 minutes;

[0043] (3) At a temperature of 90°C, adjust the pH value to 2.2 with dilute hydrochloric acid, and feed titanium tetrachloride with a concentration of 0.5mol / L at a rate of 0.1mol / kg to synthesize mica·h (20ml / h) evenly and slowly Add it to the suspension in step (2) while adding dropwise a 20% sodium hydroxide solution to keep the pH constant at about 2.2. When feeding to the standard sample hue of silver-white pearlescent pigment (for 100g of synthetic mica powder, 0.0625mol soluble salt is added at thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com