A kind of preparation method of dye-sensitized solar photovoltaic panel

A solar photoelectric panel, dye sensitization technology, applied in photovoltaic power generation, photosensitive equipment, circuits, etc., can solve the problems of poor wettability of electrolyte and electrode interface, low boiling point of liquid electrolyte, low light conversion efficiency, etc., to promote ion migration , high photoelectric conversion efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

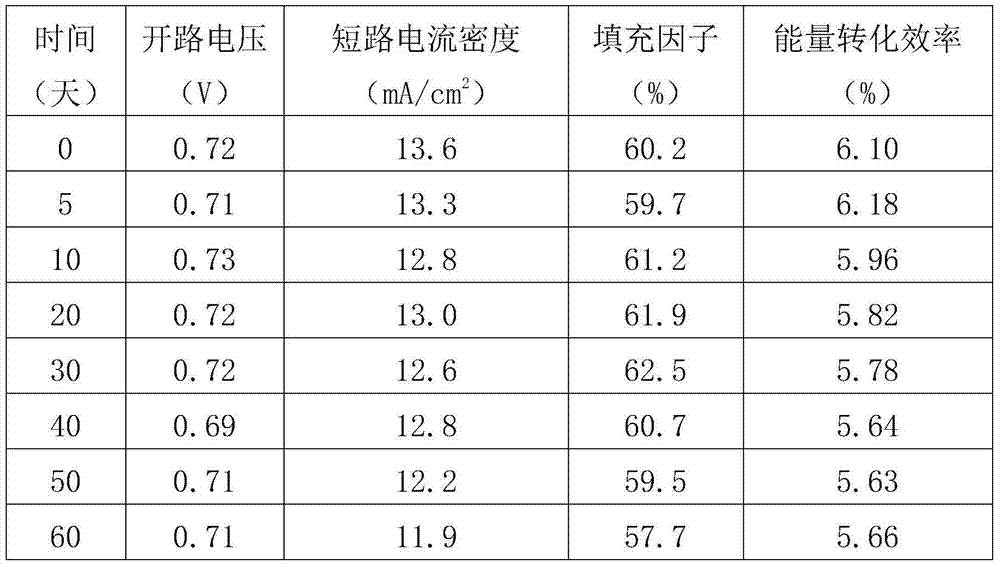

Examples

Embodiment 1

[0024] A method for preparing a dye-sensitized solar photovoltaic panel, comprising the steps of:

[0025] ①Mix ethylene carbonate, propylene carbonate and N-methylpyrrolidone with a mass ratio of 2:6:2, stir evenly and use it as a solvent, add 0.45mol / L sodium iodide and 0.02mol / L iodine , continue stirring;

[0026] ② Add a gelling agent with a mass fraction of 9%, and stir at 80°C for 2 hours until a uniform solution is formed to obtain a gel polymer electrolyte;

[0027] ③ Coat the gel polymer electrolyte on the titanium dioxide photoanode film sensitized in 0.2mmol / L N719 dye solution, and then cover the platinum counter electrode on the surface of the gel polymer electrolyte to obtain the dye Sensitized solar photovoltaic panels.

[0028] Wherein, the gelling agent is composed of 65% polyethylene oxide, 20% polyvinylidene fluoride and 15% polyethylene glycol 800 in mass fractions.

[0029] Polystyrene particles with a mass fraction of 6% are also dispersed in the tita...

Embodiment 2

[0032] A method for preparing a dye-sensitized solar photovoltaic panel, comprising the steps of:

[0033] ①Mix ethylene carbonate, propylene carbonate and N-methylpyrrolidone with a mass ratio of 4:4:2, stir evenly and use it as a solvent, add 1.6mol / L sodium iodide and 0.08mol / L iodine , continue stirring;

[0034] ②Add a gelling agent with a mass fraction of 15%, and stir at 80°C for 5 hours until a uniform solution is formed to obtain a gel polymer electrolyte;

[0035] ③ Coat the gel polymer electrolyte on the titanium dioxide photoanode film sensitized in 0.9 mmol / L N719 dye solution, and then cover the platinum counter electrode on the surface of the gel polymer electrolyte to obtain the dye Sensitized solar photovoltaic panels.

[0036] Wherein, the gelling agent is composed of 70% polyethylene oxide, 15% polyvinylidene fluoride and 15% polyethylene glycol 1500 with mass fractions respectively.

[0037] Polystyrene particles with a mass fraction of 13% are also disp...

Embodiment 3

[0040] A preparation method of a dye-sensitized solar photovoltaic panel, comprising the steps of:

[0041] ①Mix ethylene carbonate, propylene carbonate, and N-methylpyrrolidone with a mass ratio of 4:3:3, stir well and use it as a solvent, add 1.5mol / L sodium iodide and 0.05mol / L iodine , continue stirring;

[0042] ② Add a gelling agent with a mass fraction of 12%, and stir at 80°C for 3 hours until a uniform solution is formed to obtain a gel polymer electrolyte;

[0043] ③ Coat the gel polymer electrolyte on the titanium dioxide photoanode film sensitized in 0.5 mmol / L N719 dye solution, and then cover the platinum counter electrode on the surface of the gel polymer electrolyte to obtain the dye Sensitized solar photovoltaic panels.

[0044] Wherein, the gel is composed of 70% polyethylene oxide, 15% polyvinylidene fluoride and 15% polyethylene glycol 1000 in mass fractions.

[0045] Polystyrene particles with a mass fraction of 13% are also dispersed in the titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com