Integrated air-cooled axial flux motor

A technology of axial magnetic flux and integrated wind, applied in the direction of magnetic circuits, electric components, electromechanical devices, etc., can solve the problems of reduced winding heat flow channels, difficult heat dissipation of motor windings, and difficult cooling of axial flux motors, achieving enhanced Cooling effect, cooling effect improvement, strength strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

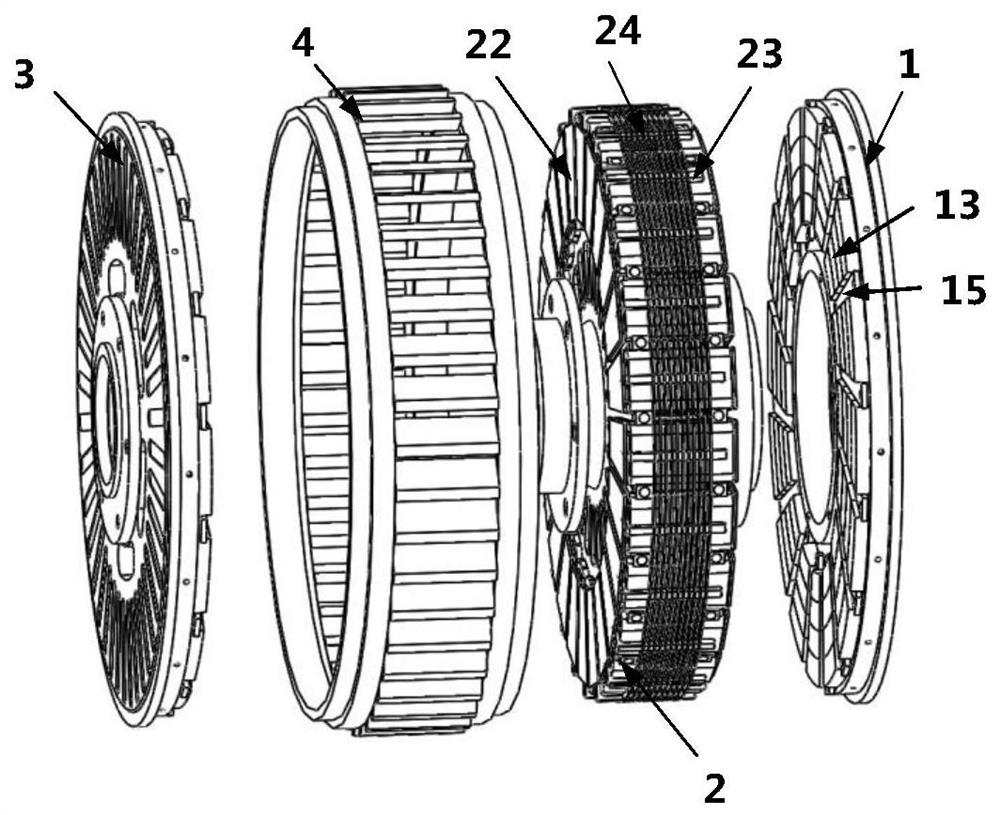

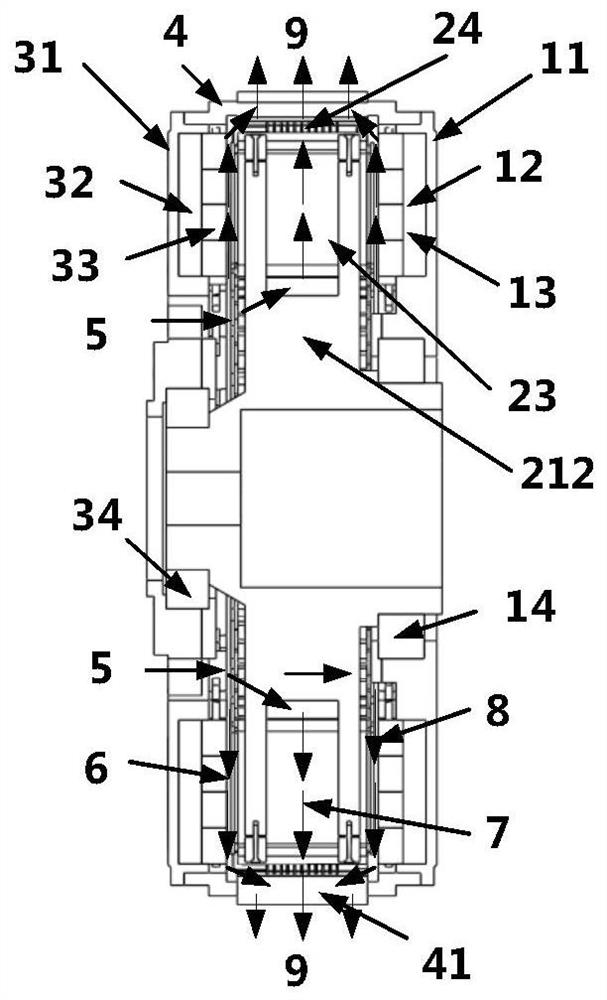

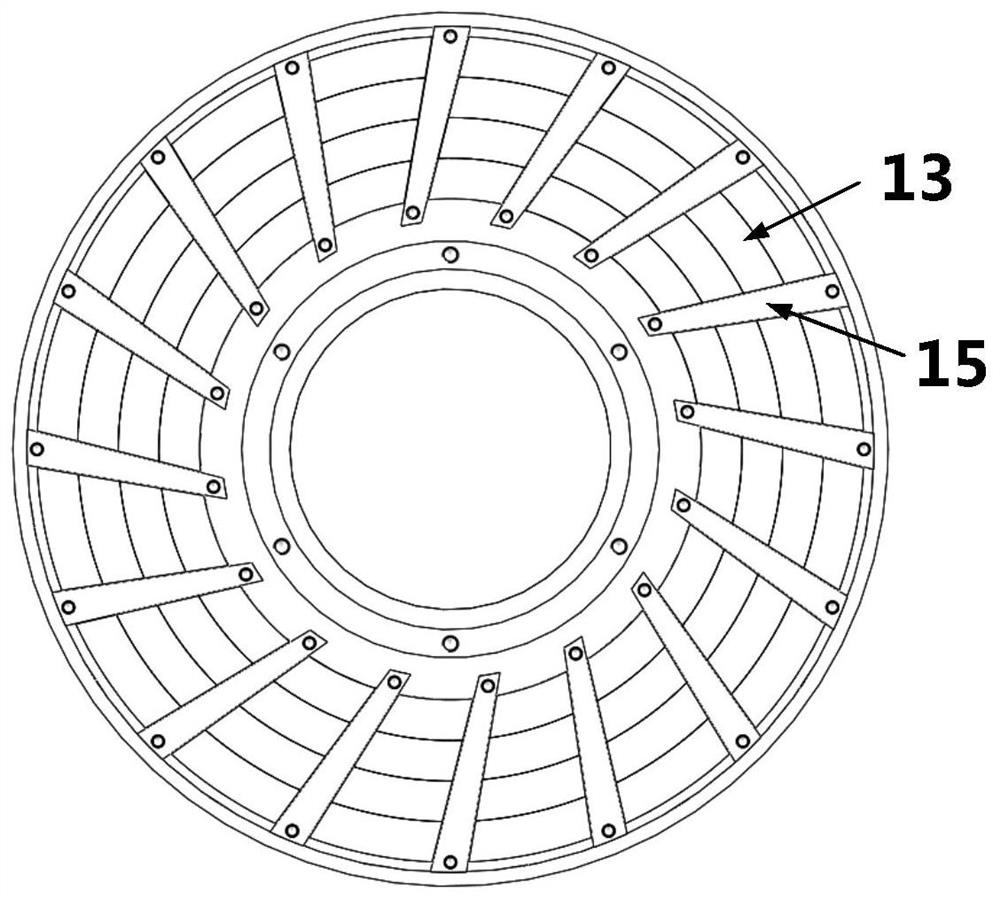

[0048] An integrated air-cooled axial flux motor such as figure 1 and figure 2 As shown, it includes: a front rotor 1, a stator 2 and a rear rotor 3 arranged coaxially in sequence, and an air gap is formed between the stator 2 and the two rotors; as image 3 As shown, the front rotor 1 includes a rotor disk 11, a rotor core 12, and a magnetic steel 13. The rotor core 12 is installed and attached to the rotor disk 11, and the magnetic steel 13 is installed and attached to the rotor iron core 12, and is fixed by a magnetic steel pressure plate 15. The structure of the rear rotor 3 is similar to that of the front rotor 1. Correspondingly, the rear rotor 3 includes a rotor disk 31, a rotor core 32 and a magnetic steel 33. The rotor core 32 is installed and attached to the rotor disk 31, and the magnetic steel 33 is installed and attached to the rotor disk 31. It is combined on the rotor core 32 and fixed by a magnetic steel pressure plate; the front rotor 1, the rear rotor 3 and...

Embodiment 2

[0064] An integrated air-cooled axial flux motor, this embodiment is similar to the above-mentioned embodiment 1, the difference is that in this embodiment, the air inlet is arranged on the front rotor;

[0065] For the rest of the structure and working principle of the motor, reference may be made to the description in Embodiment 1 above, which will not be repeated here.

Embodiment 3

[0067] An integrated air-cooled axial flux motor, this embodiment is similar to the above-mentioned embodiment 1, the difference is that, in this embodiment, both the front rotor and the rear rotor are provided with air inlets;

[0068] For the rest of the structure and working principle of the motor, reference may be made to the description in Embodiment 1 above, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com