A kind of bottom glaze for the production of fully polished glazed tiles, which is beneficial to the color development of ceramic inks

A technology of ceramic ink and full glaze, which is applied in the field of underglaze for color development of ceramic ink, which can solve problems such as unsatisfactory color development, pinholes on the brick surface, and wide firing range, and achieve the effect of widening the firing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment the present invention is described in further detail:

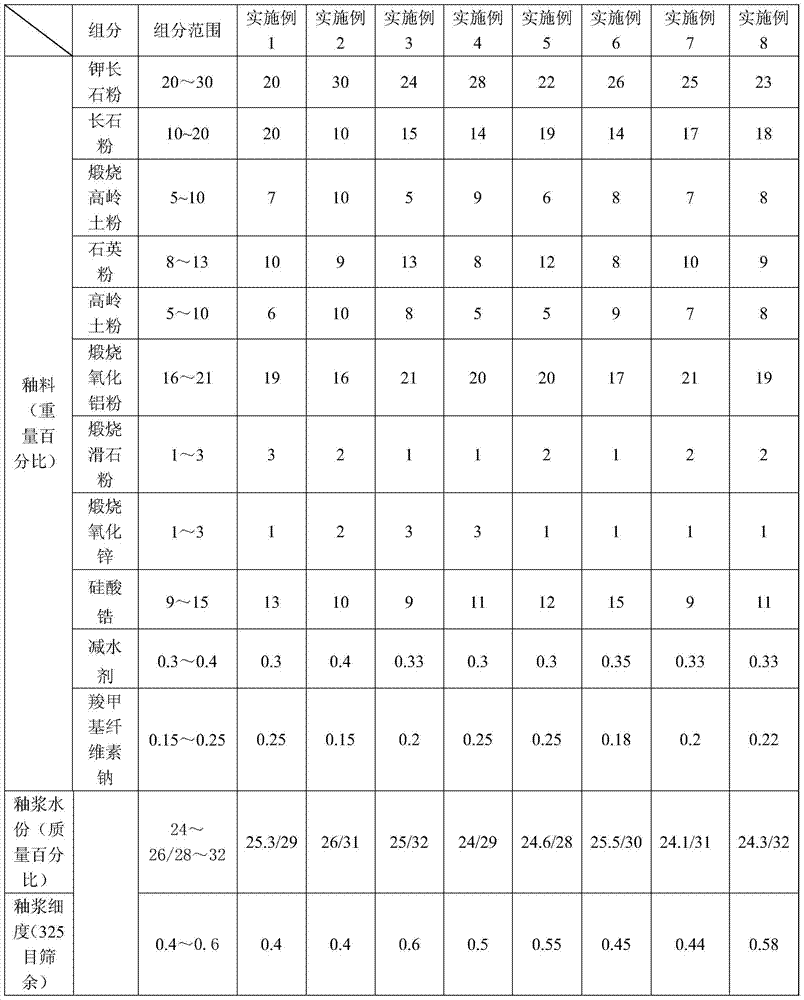

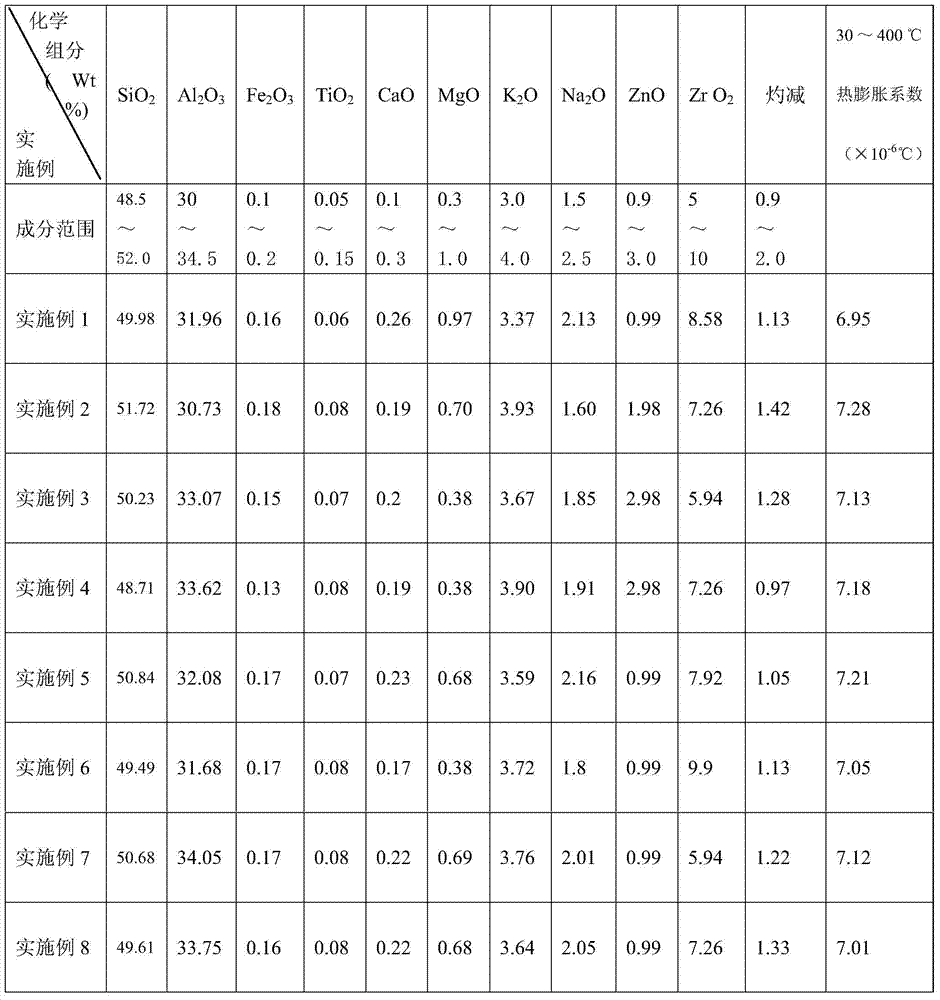

[0036] Table 1

[0037]

[0038]

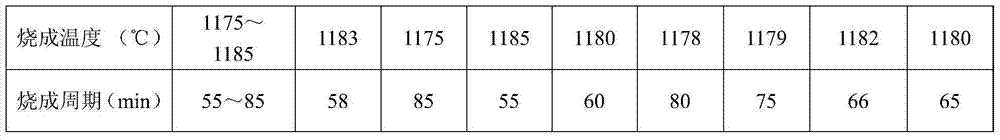

[0039] Table 2

[0040]

[0041] The process flow of the bottom glaze processing and use:

[0042] Batching → ball milling → sieving → iron removal → glaze slurry stale → sieving → iron removal → bell jar glaze (or linear glaze).

[0043] The processing technological process of the bottom glaze: batching → ball milling → sieving → iron removal → glaze slurry stale. Glaze slurry fineness: 0.4-0.6% remaining on 325 mesh sieve; glaze slurry moisture content: 41-42%; glaze slurry specific gravity: 1.88-1.90; glaze slurry flow rate: 30-40 seconds.

[0044] The using method of the bottom glaze is as follows: glazing by a bell jar glazing process or a linear glazing process. Glazing slurry flow rate: 30-40 seconds by bell-jar glazing process; specific gravity of glazing slurry by bell-jar glazing process: 1.88-1.90; glazing by be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com