Microwave dielectric ceramic material, preparation method and application thereof, and filter ceramic material

A technology of microwave dielectric ceramics and ceramic materials, which is applied in the field of filter ceramic materials, can solve the problems of low dielectric constant, high insertion loss, and the dielectric constant needs to be improved, and achieves the effect of high dielectric constant and low loss value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the present invention, the preparation method of the E component preferably includes the following steps:

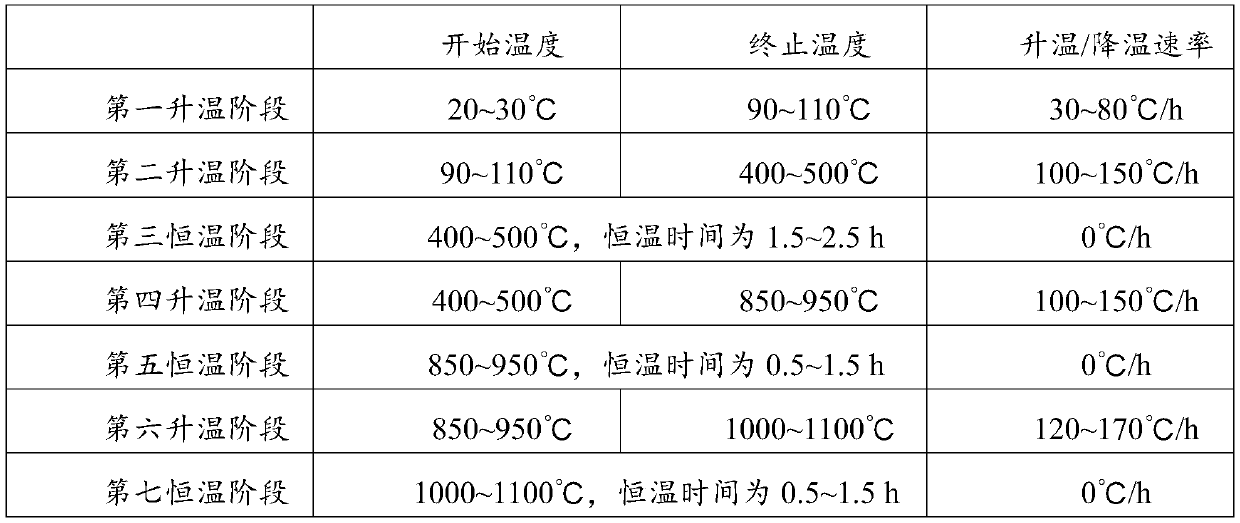

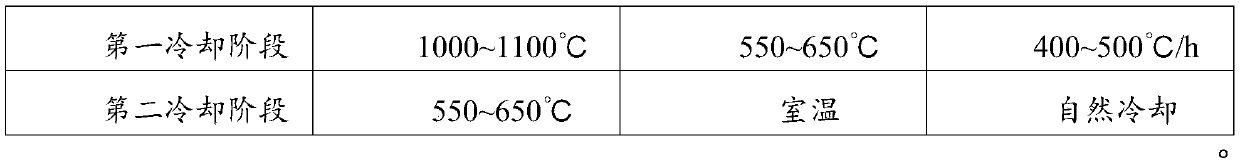

[0048] Mix silicon oxide, calcium oxide and magnesium oxide, perform sintering treatment, and then cool to obtain flux; the sintering treatment includes 7 stages in sequence, specifically the first heating stage, the second heating stage, and the third constant temperature stage , the fourth heating stage, the fifth constant temperature stage, the sixth heating stage, the seventh constant temperature stage; the cooling treatment includes two stages carried out in sequence, including the first cooling stage and the second cooling stage; the sintering treatment and cooling The specific parameters of the processing are shown in Table 1:

[0049] Table 1 Sintering treatment and cooling treatment parameters when preparing component E

[0050]

[0051] In the present invention, the sintering treatment and cooling treatment parameters when preparing the E componen...

Embodiment 1-1

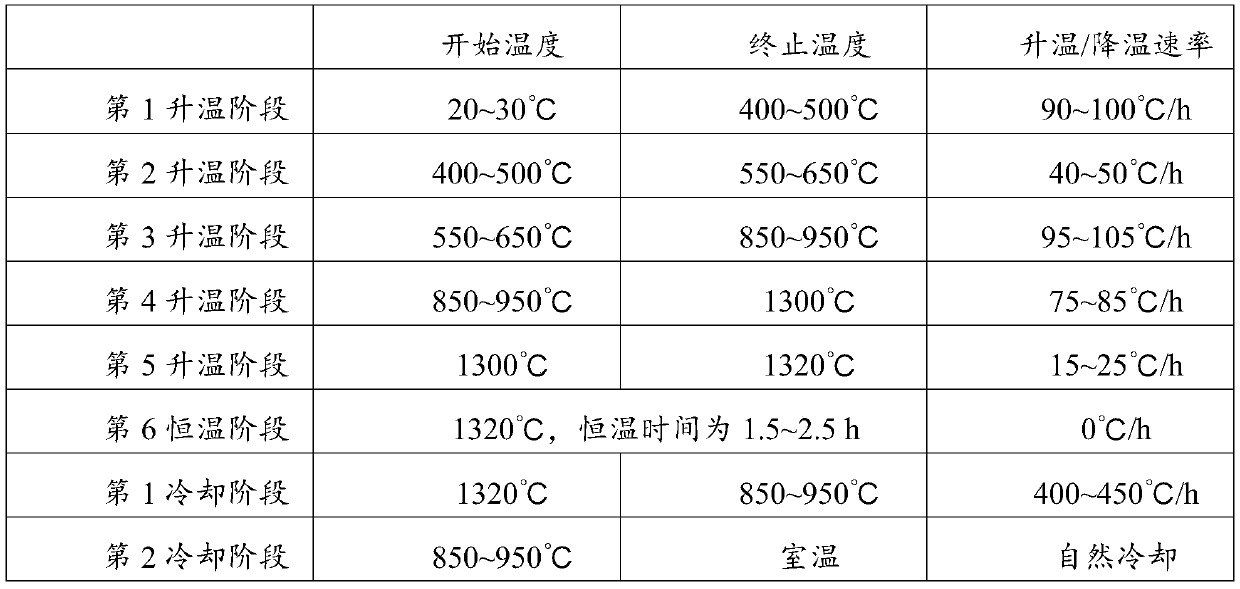

[0100] Mix A component, B component, C component, D component and E component, where A component is BaTi 4 o 9 , the mass fraction of A component is 65%; B component is Ba 2 Ti 9 o 20 , the mass fraction of component B is 24%, component C is BaWO 4 , the mass fraction of component C is 0.2%, and component D is ZnTiO 3 , SnTiO 3 、LaTiO 3 , NdTiO 3 、BaSm 2 Ti 4 o 12 and PrTiO 3 a mixture of ZnTiO in the D component 3 , SnTiO 3 、LaTiO 3 , NdTiO 3 、BaSm 2 Ti 4 o 12 and PrTiO 3 The mass ratio of the component is 26.3:24.7:16:16:8.2:8.8; the mass fraction of the D component is 0.8%, the E component is a flux, and the mass fraction of the E component is 10%, and the preparation method of the E component is : CaO, MgO and SiO 2 The mixture is sequentially sintered and cooled to obtain the E component, the SiO 2 The mass ratio of , CaO and MgO is 10:3:1. The sintering and cooling process is as follows: from room temperature to 100°C, the heating rate is 50°C / h; fro...

Embodiment 1-2

[0105] Mix A component, B component, C component, D component and E component, wherein the ingredients of A component, B component, C component, D component and E component are the same as in Example 1-1 Similarly, the mass fractions of component A, component B, component C, component D and component E are 66%, 23%, 2.3%, 0.7% and 8% in sequence.

[0106] Then, according to the method of Example 1-1, components A, B, C, D and E were mixed, ball milled, granulated, pressed, fired and cooled to obtain a microwave dielectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com