Al-Mg-Si aluminum alloy and extrusion method for sectional bar of Al-Mg-Si aluminum alloy

An al-mg-si, extrusion method technology, applied in the field of aluminum alloy, can solve the problems of poor stability, poor elongation, difficult on-line quenching control, etc., to ensure consistency, ensure comprehensive performance, and improve aging production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

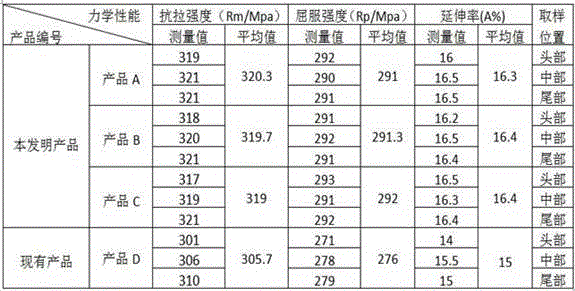

Examples

Embodiment 1

[0038] An Al-Mg-Si aluminum alloy, its composition and weight percentage are: Mg: 0.9%, Si: 0.5%, Cu: 0.2%, Fe: 0.1%, Cr: 0.07%, Mn: 0.15%, Zn: 0.22%, Ti: 0.15%, V: 0.05%, Hf: 0.5%, Sc: 0.25%, Ag: 1.0%, and the rest is Al.

Embodiment 2

[0040] An Al-Mg-Si aluminum alloy, its composition and weight percentage are: Mg: 0.9%, Si: 0.5%, Cu: 0.2%, Fe: 0.1%, Cr: 0.07%, Mn: 0.15%, and the rest is Al.

Embodiment 3

[0042] An Al-Mg-Si aluminum alloy, its composition and weight percentage are: Mg: 0.9%, Si: 0.5%, Cu: 0.2%, Fe: 0.1%, Cr: 0.07%, Mn: 0.15%, V: 0.05%, the rest is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com