Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Good quality factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

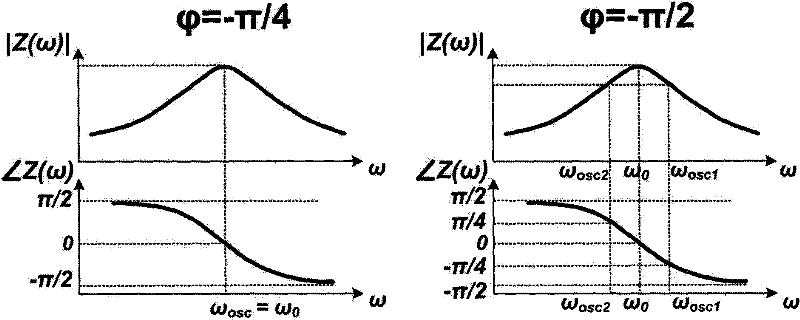

Method and circuit for tuning lc oscillator frequency based on phase tuning technology

ActiveCN102281061ALow peak frequencyHigh peak frequencyPulse automatic controlElectric pulse generatorPhase shiftedPhase shift module

A tunable multiphase ring oscillator includes a plurality of stages connected in series in a ring structure, where each stage generating a stage output from a stage input. Each stage of the tunable multiphase ring oscillator includes a plurality of trans-conductance cells, each generating an output from at least one portion of the stage input. Each stage further includes at least one phase shifting module for imparting at least one phase shift to the at least one portion of the stage input, an oscillator unit for generating the stage output from a combination of the plurality of outputs, and means for varying at least one of the plurality outputs so as to adjust a phase of the stage output.

Owner:THE HONG KONG UNIV OF SCI & TECH

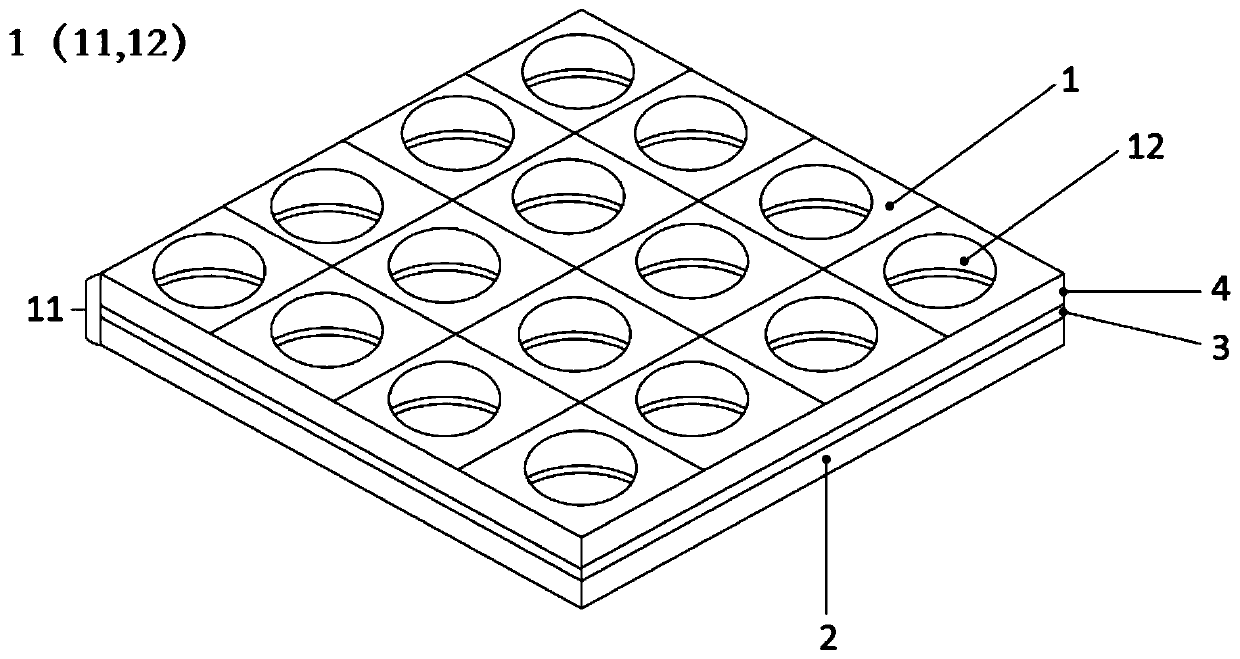

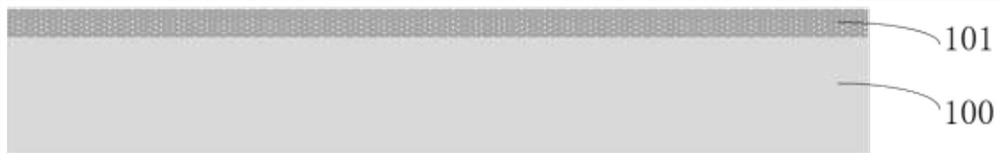

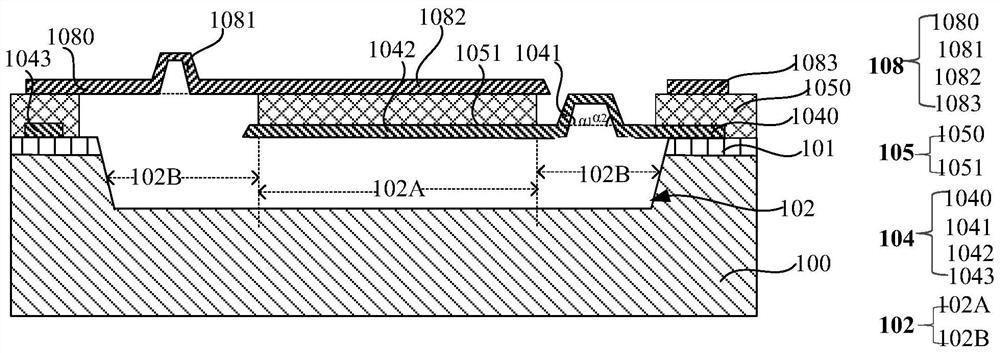

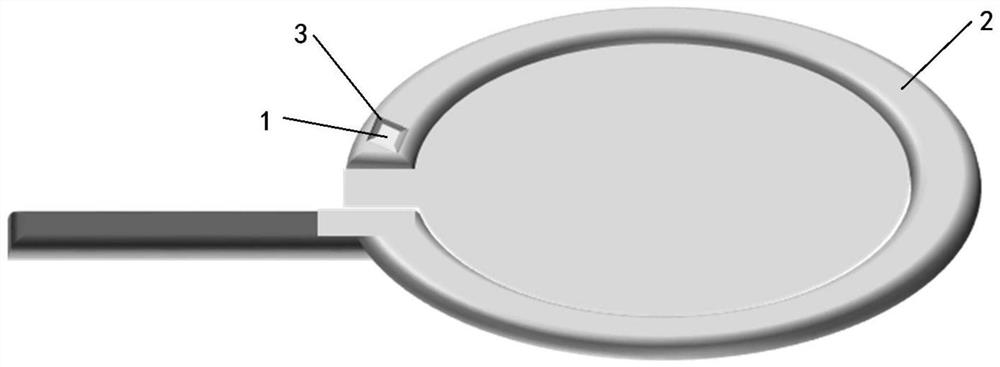

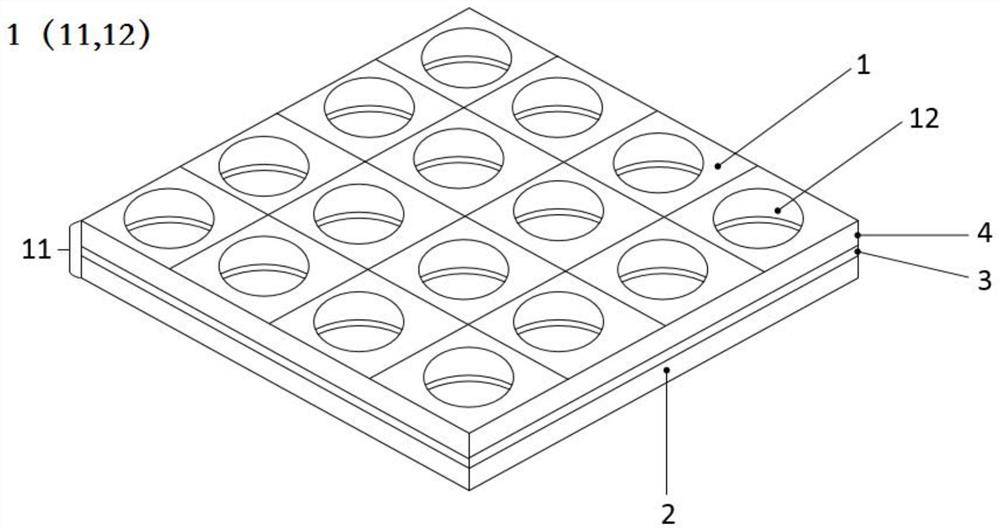

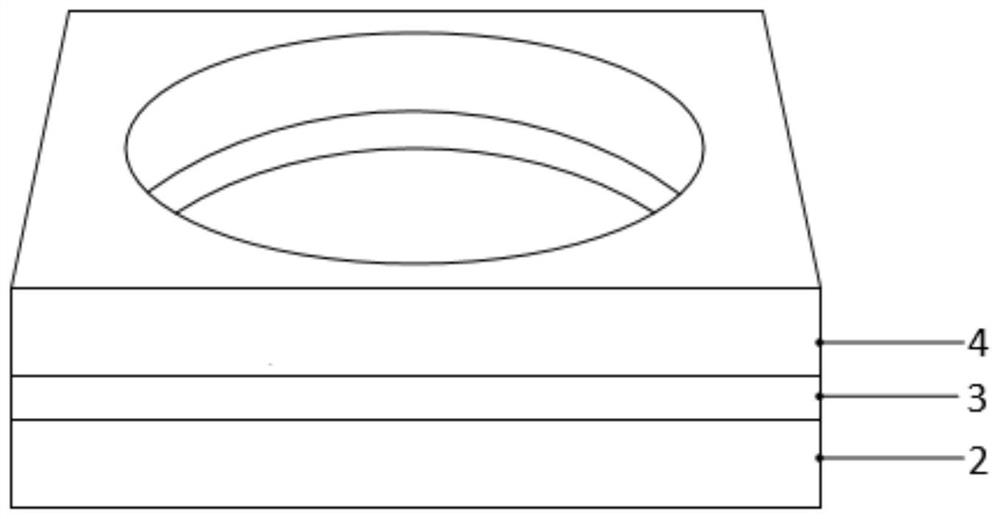

Photonic crystal and thin film piezoelectric sonic sensor

The invention discloses a thin film piezoelectric sonic sensor. The thin film piezoelectric sonic sensor comprises a substrate layer, a ground electrode layer and a piezoelectric layer which are arranged in a laminated mode, and one or more transducers are arranged on the side, away from the ground electrode layer, of the piezoelectric layer; and photonic crystals at least formed in the piezoelectric layer are correspondingly arranged on the two sides of the transducers, and the resonant frequency of the thin film piezoelectric sonic sensor is located in band gaps of the photonic crystals. According to the thin film piezoelectric sonic sensor, the photonic crystals are at least arranged on the piezoelectric layer, the mechanical vibration stability of the piezoelectric layer is improved, the sonic wave reflectivity is improved, the energy loss of sonic wave transmission is lowered, and the quality factor of the sensor is improved. The invention discloses a photonic crystal. The photonic crystal comprises a matrix and a scatterer formed on the matrix, the matrix is formed by at least two media layers in a laminated mode, and materials of any one of the media layers are different from those of other media layers. According to the photonic crystal, the sonic wave energy loss can be effectively reduced, and the quality factor of the sensor can be effectively improved when the photonic crystal is applied to the thin film piezoelectric sonic sensor.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

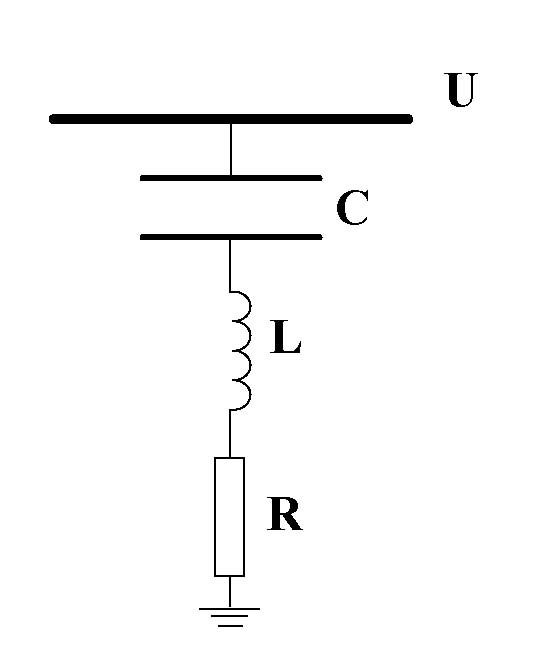

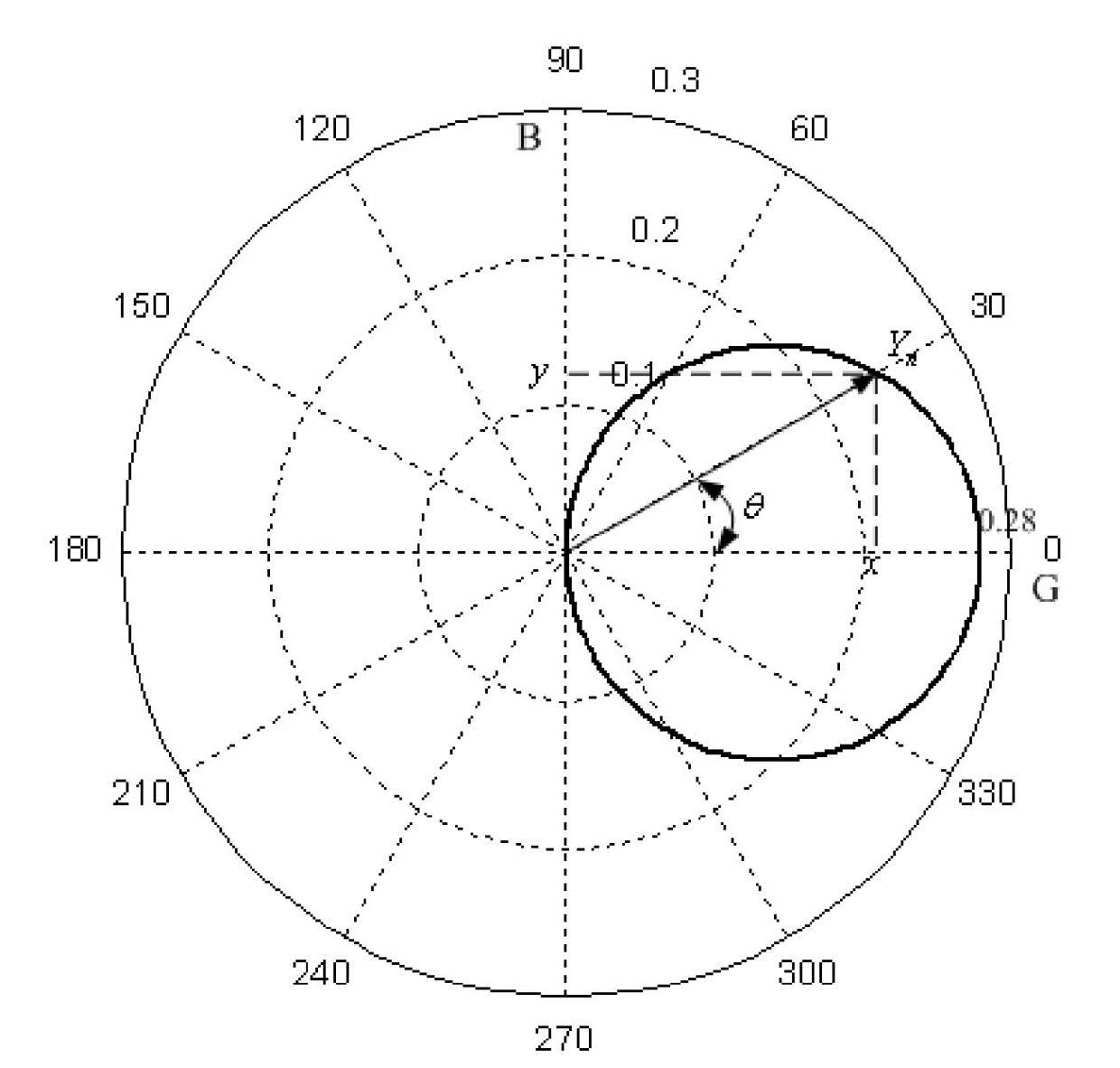

Single-tuned filter and optimal quality factor calculation method thereof

InactiveCN102386621AGood quality factorEnsure filtering effectReactive power adjustment/elimination/compensationReactive power compensationTerminal voltageAlternating current

The invention discloses a single-tuned filter and an optimal quality factor calculation method thereof. The single-tuned filter mainly comprises a capacitor C, an inductor L and a resistor R which are sequentially connected in series, wherein the other end of the capacitor C is connected with an alternating current voltage line; and the other end of the resistor R is grounded. The method comprises the following steps of: A, calculating the maximum equivalent frequency offset of a system; B, determining a maximum impedance angle of the system; and C, calculating an optimal quality factor of the filter. By the single-tuned filter and the method, the terminal voltage of the filter can be ensured to have a minimum value at characteristic frequency when the system has the maximum impedance angle, so filtering effects and system stability are ensured.

Owner:STATE GRID CORP OF CHINA +1

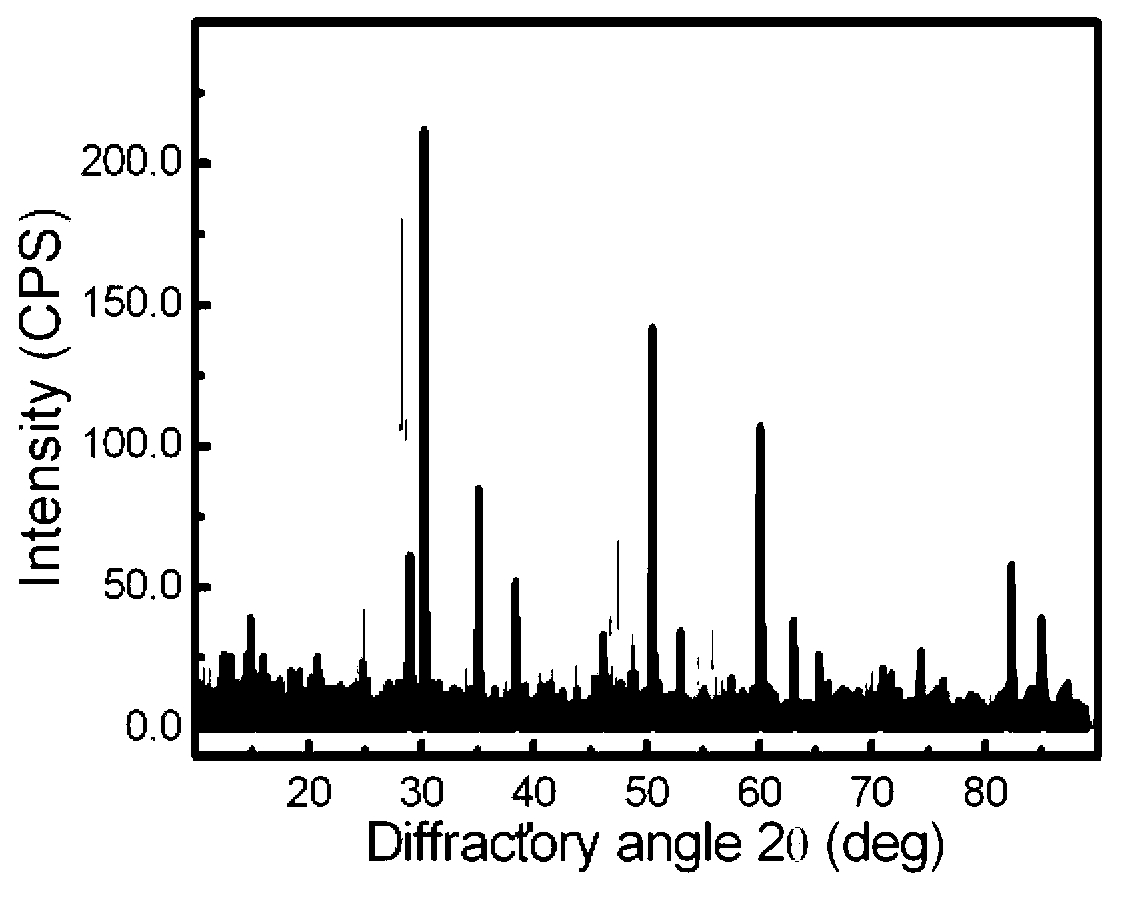

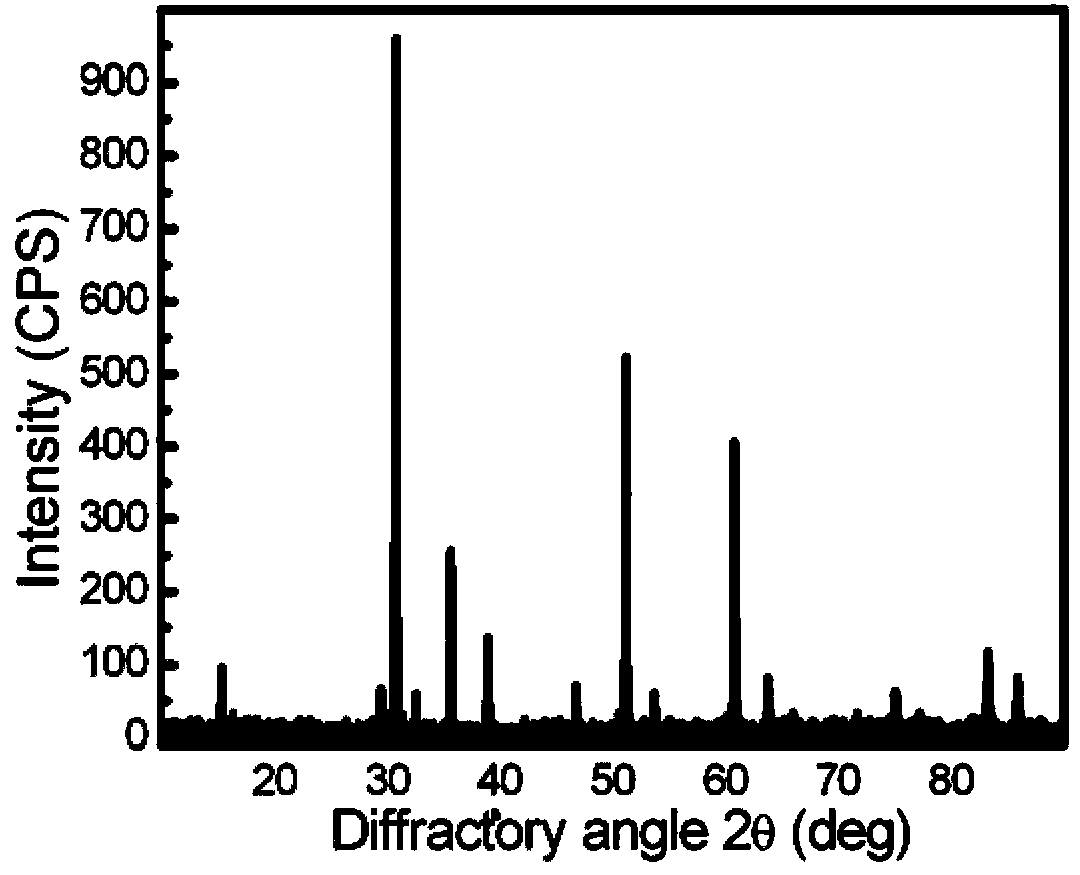

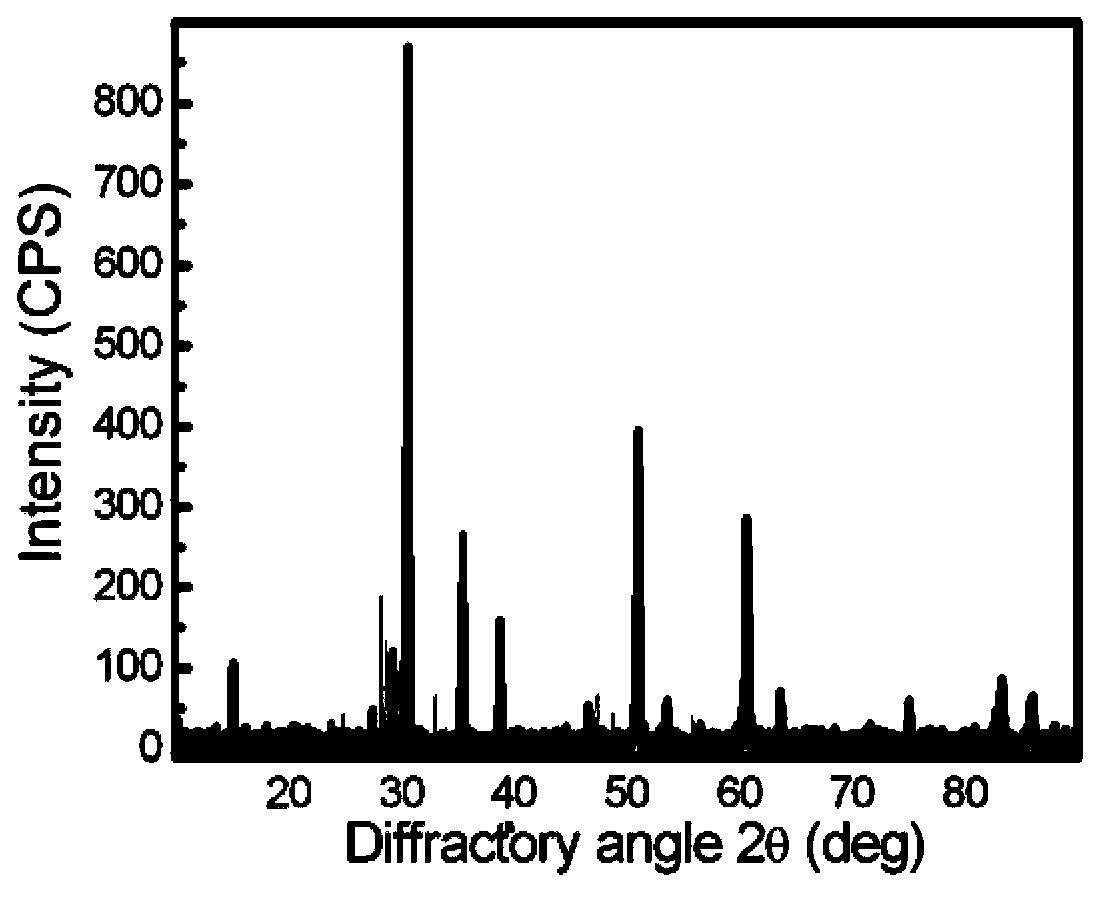

Silicon-based low-dielectric microwave dielectric ceramic and preparation method thereof

ActiveCN113004028ALow dielectric constantGood quality factorDielectric ceramicsDielectric permittivity

The invention belongs to the technical field of microwave dielectric ceramics, and particularly relates to a silicon-based low-dielectric microwave dielectric ceramic and a preparation method thereof. The preparation method comprises the following steps: a compound with a chemical general formula of xBaO-yMO-zSiO2 (M = Ca, Sr; 0 <x<=1.0; 1.0 <= y <=2.0; 1.0 <= z <= 3.0) is used for preparing a microwave dielectric ceramic material. The ceramic has a low dielectric constant (epsilon r = 7.3-11.0), an excellent quality factor (Q * f = 5370-40500 GHz) and a wide sintering temperature range (1150-1250 DEG C), meanwhile, the microwave dielectric ceramic has a negative temperature coefficient of resonance frequency (-76.6 ppm / DEG C<=tau f <=-36.3 ppm / DEG C). Due to the low sintering temperature and the excellent quality factor of the microwave dielectric ceramic, the silicon-based low dielectric microwave dielectric material can be applied to the field of BME-MLCC.

Owner:WENZHOU ADVANCED MFG TECH INST OF HUAZHONG UNIV OF SCI & TECH

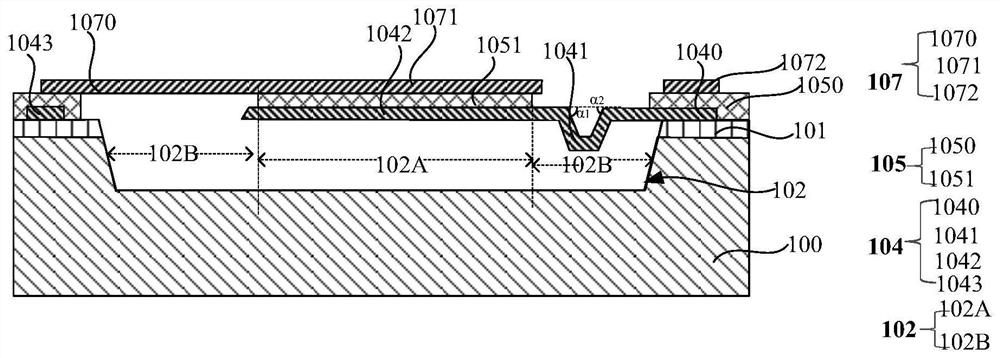

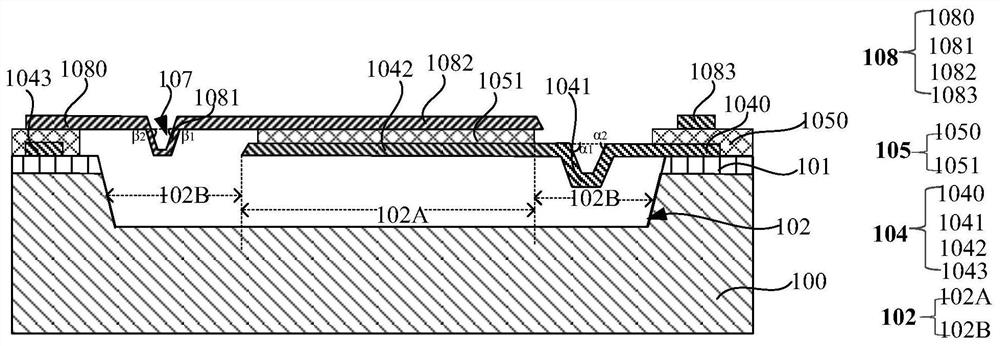

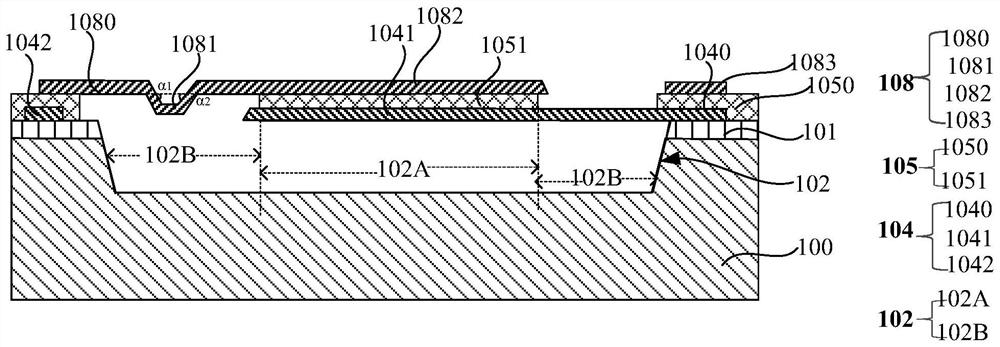

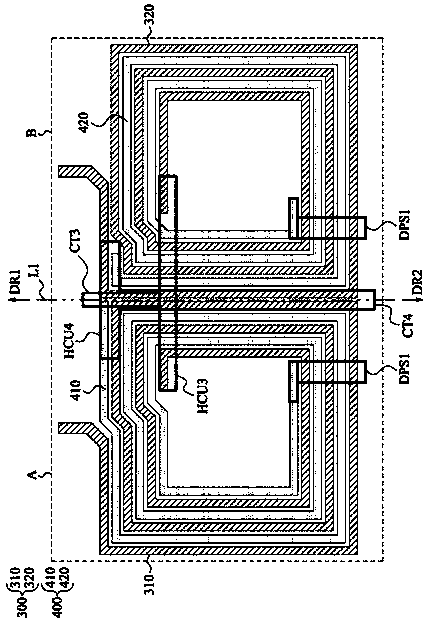

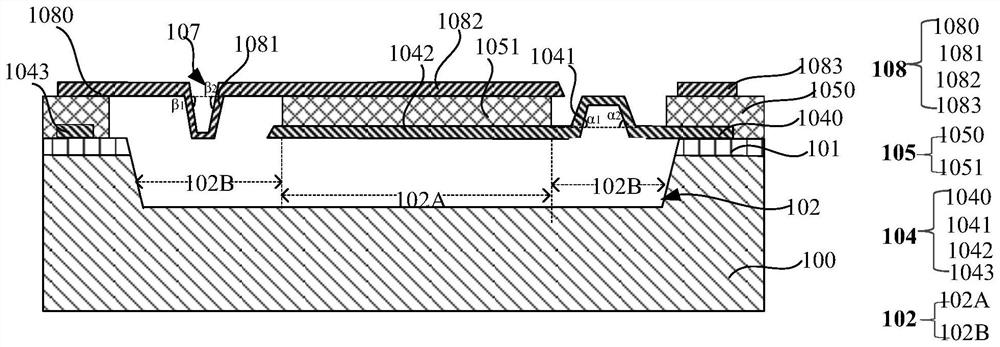

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786651AHigh quality factorImprove performanceImpedence networksCommunications systemPiezoelectric resonance

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode concave part formed on the periphery of apiezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that the sound wave loss is reduced, the quality factor of the resonator is improved, and finally, the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottomelectrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and thelike can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

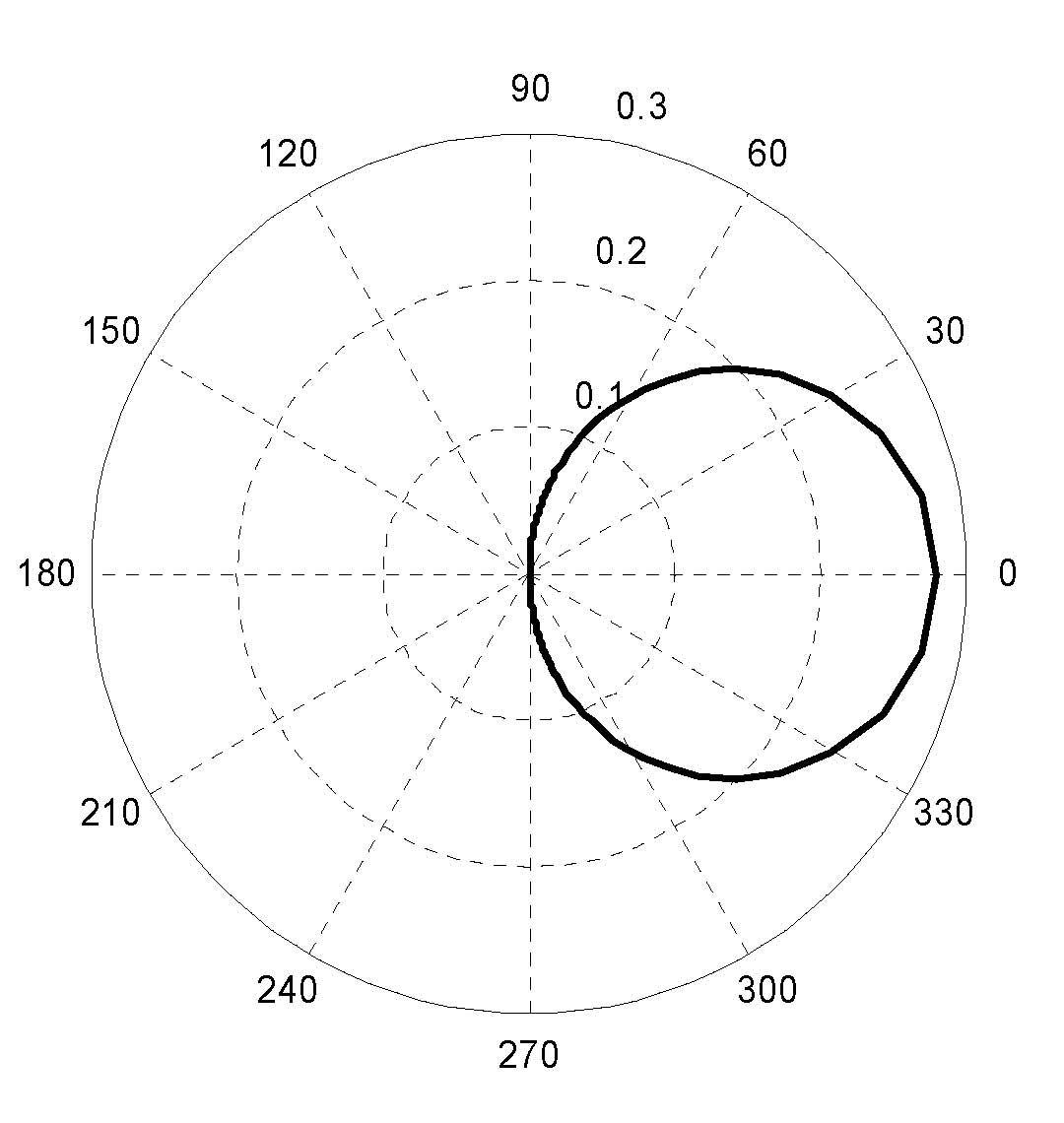

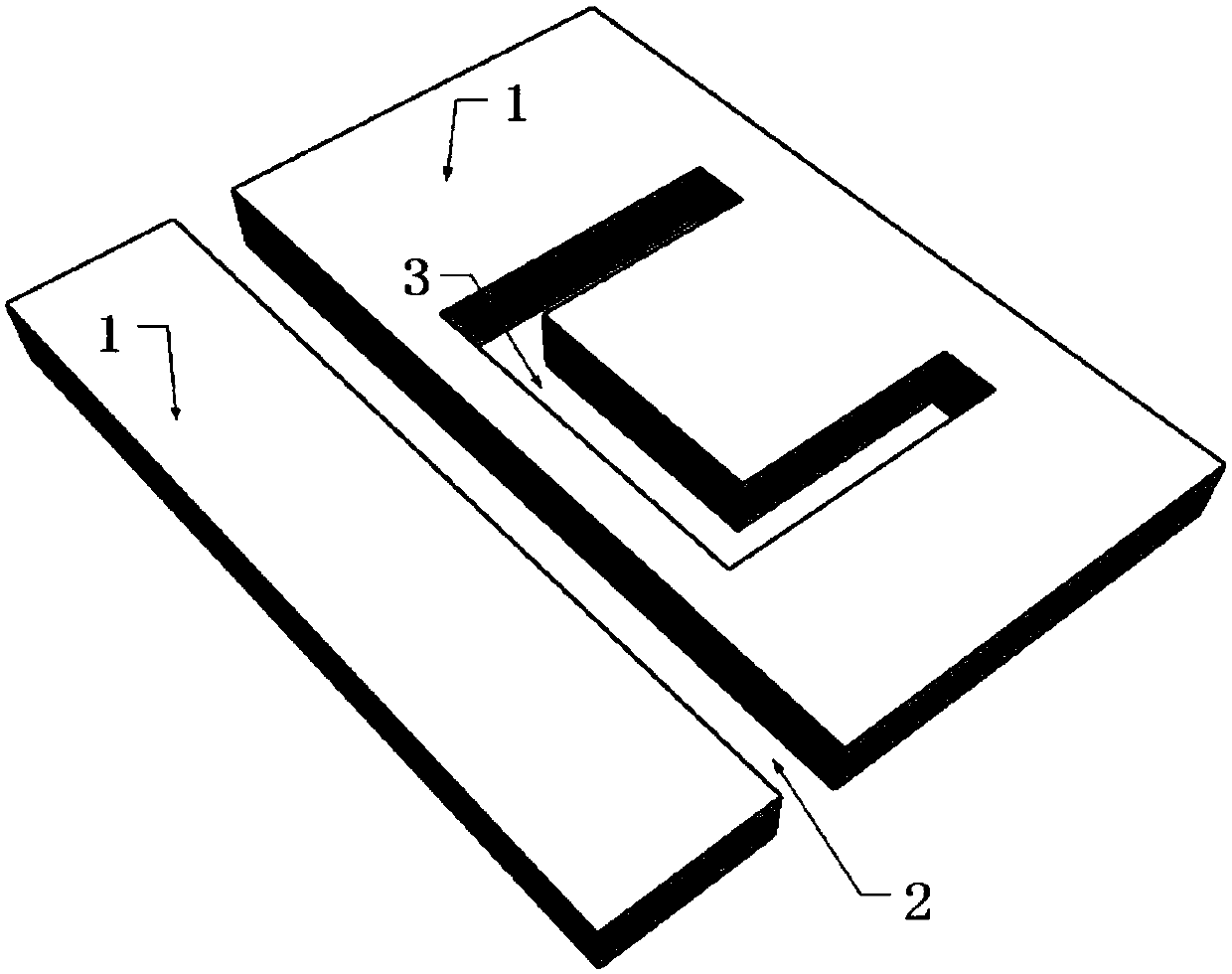

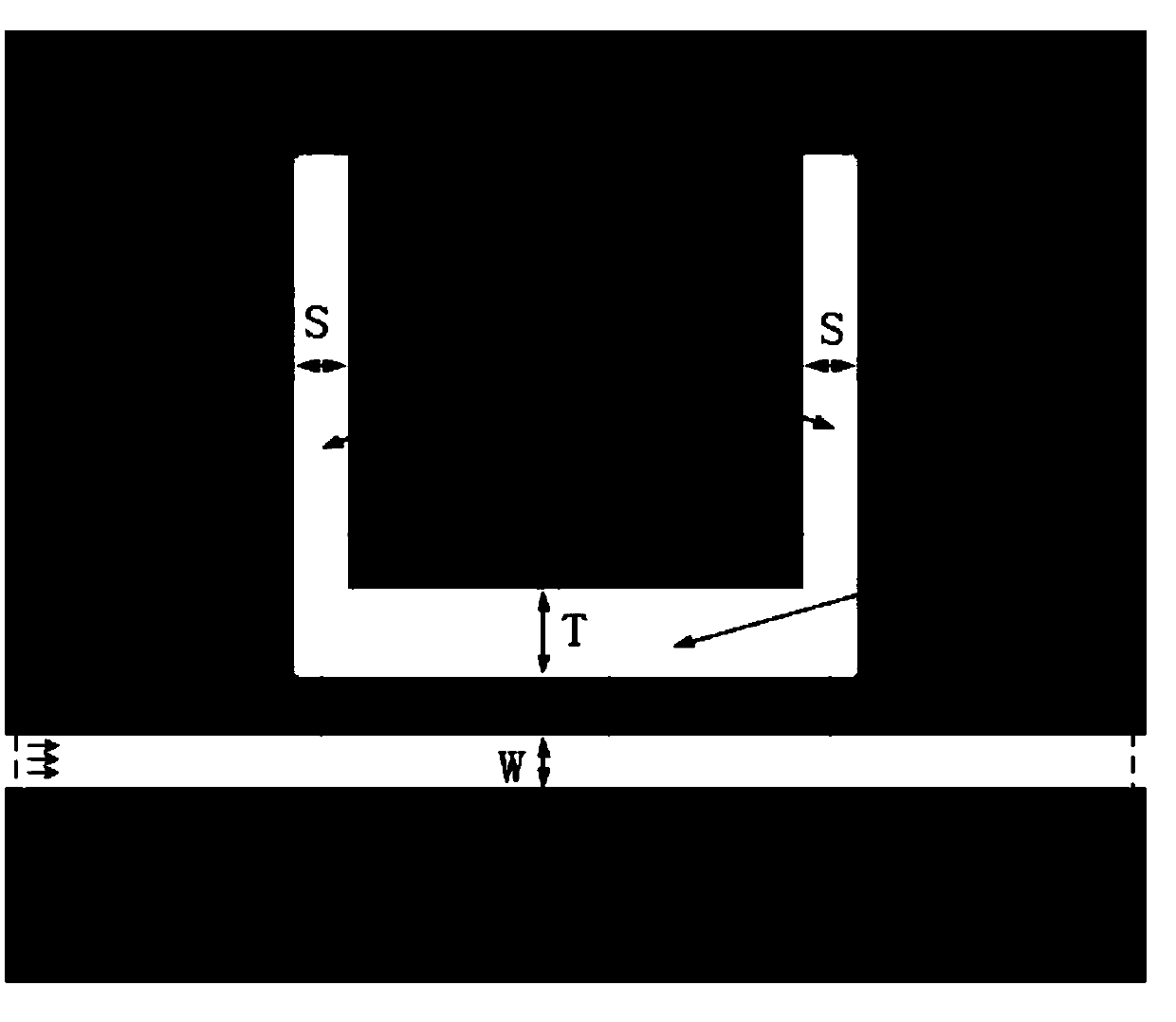

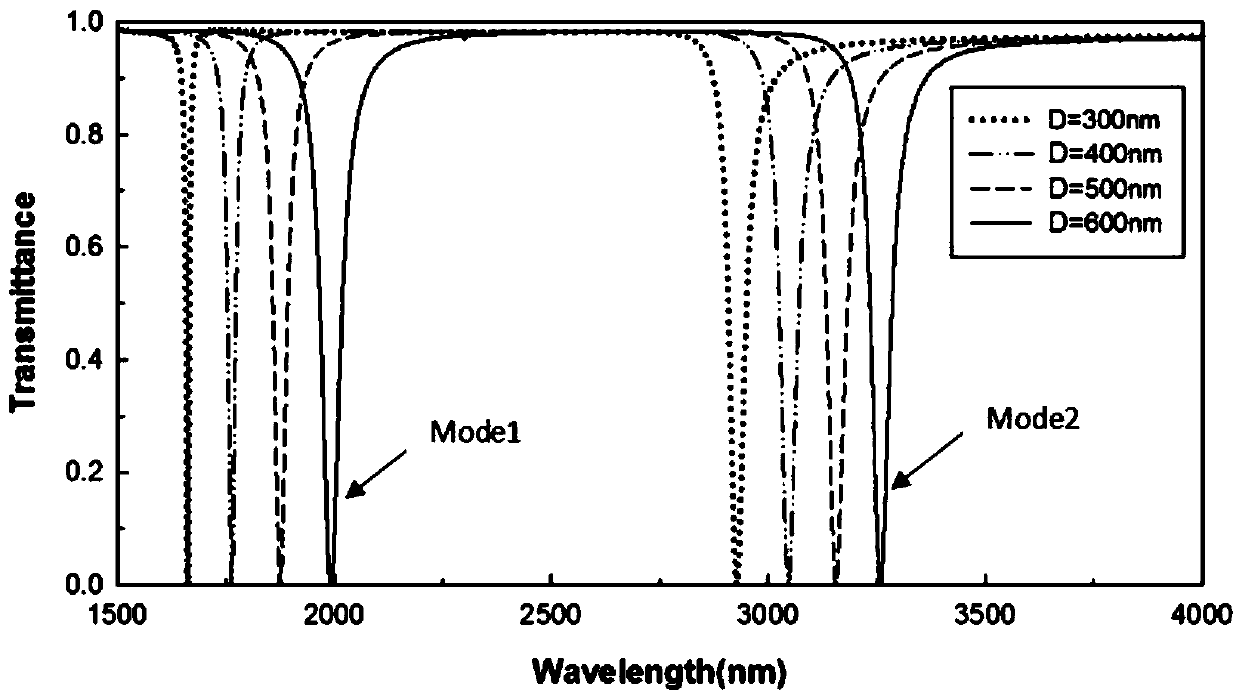

Surface plasmon based waveguide band-stop filter

InactiveCN110361798AHigh quality factorPassband smoothingOptical light guidesSurface plasmon wavePhysics

The invention relates to a surface plasmon based waveguide band-stop filter which is composed of a metal film, waveguide tube and a resonant cavity. The waveguide tube is shaped as a long-strip rectangular hole, the resonant cavity is of a square U shape composed of one horizontal extension hole and two vertical extension holes connected to the horizontal extension hole, the shape and size of theone vertical extension hole are completely the same with those of the other, and each of the horizontal and vertical extension holes is shaped as a long-strip rectangular hole of a regular rectangularshape. The filter is simple in structure, small in packaging size, multi-mode, high in transmissivity, smooth in passband, narrower in stop band, high in quality factor and adjustable. The stop bandwidth can be adjusted by changing a structural parameter. It is proved that the stop band transmittance can be lower than 0.01 and the maximal passband transmittance can reach 0.98 with smooth distribution in the top. The filter can be widely applied in micro nano optical integrated devices.

Owner:GUILIN UNIV OF ELECTRONIC TECH

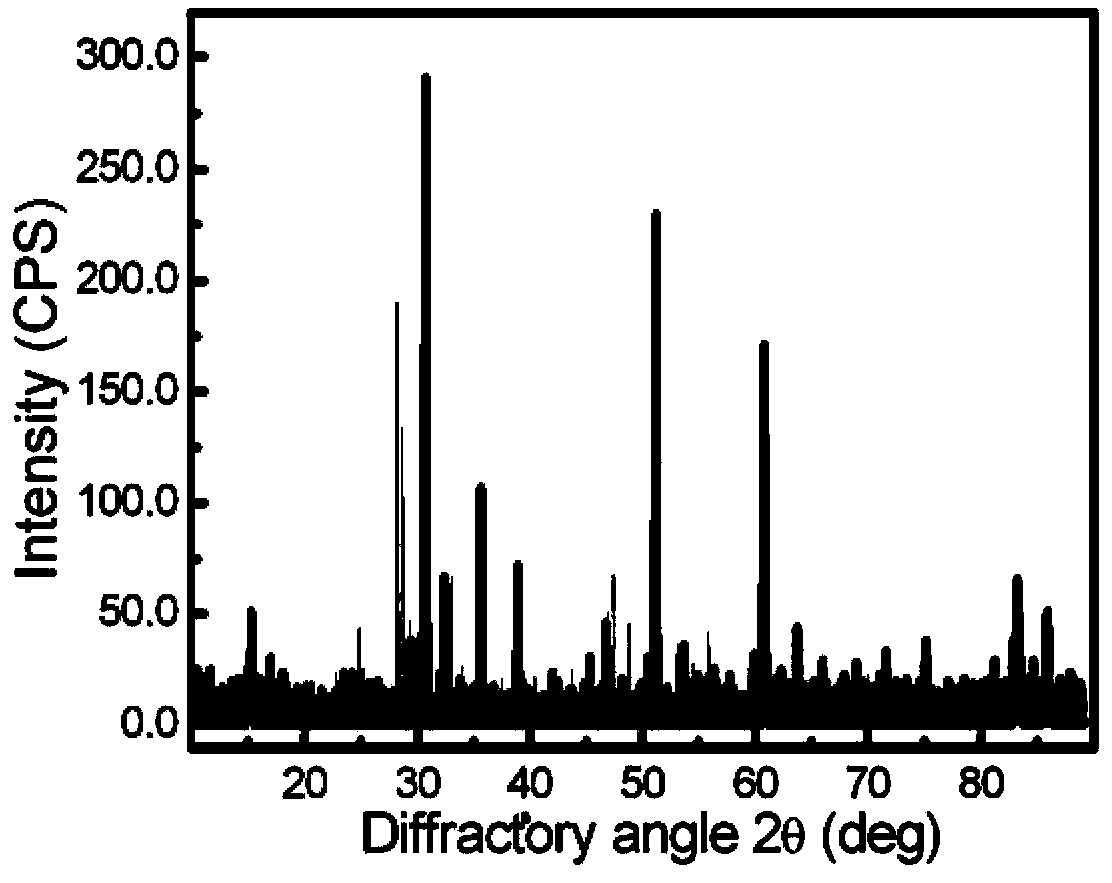

Low-dielectric microwave dielectric ceramic material and temperature-frequency characteristic regulation and control method thereof

The invention belongs to the technical field of microwave dielectric ceramics, and discloses a low-dielectric microwave dielectric ceramic material and a temperature-frequency characteristic regulation and control method thereof. The chemical general formula of a main crystalline phase of the low-dielectric microwave dielectric ceramic material is CaO-SnO2-xSiO2-yGeO2, x is larger than or equal to0 and smaller than or equal to 1.0, y is larger than or equal to 0 and smaller than or equal to 1.0, and the main crystalline phase is a maleite phase; the microwave dielectric ceramic material is alow-dielectric microwave dielectric ceramic material, and the relative dielectric constant epsilon r is 10.37-11.7. By regulating the molar ratio 1:1:x:y of Ca:Sn:Si:Ge, the microwave dielectric ceramic material can be obtained correspondingly, l with a relative dielectric constant as low as 10.37-11.7 and the self-adjustable resonant frequency temperature coefficient tau f is acquired under the condition of avoiding the use of Ti element, thereby effectively widening the selection range of the low-dielectric-constant microwave dielectric ceramic material. Moreover, the resonance frequency temperature coefficient tau f of the microwave dielectric ceramic material can be regulated and controlled by regulating and controlling the ratio of SiO2 to GeO2 and utilizing ion substitution.

Owner:HUAZHONG UNIV OF SCI & TECH

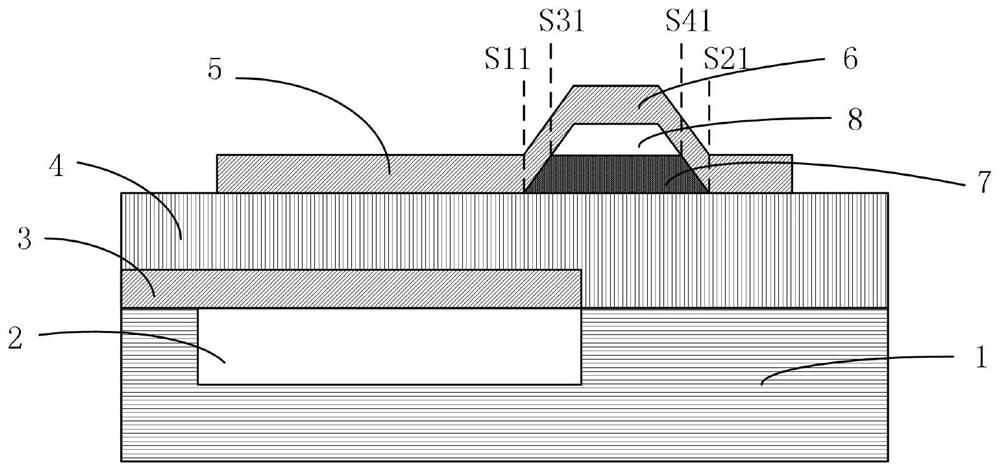

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786653AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode concave part and a top electrode concavepart formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

Polyimide/polyurethane aerogel film air filtering material as well as preparation and application thereof

ActiveCN114181423AGood quality factorImprove mechanical propertiesDispersed particle filtrationMembrane filtersAir filtrationImide

The invention belongs to the field of preparation of air filtering materials, relates to a polyimide / polyurethane aerogel film air filtering material as well as preparation and application thereof, and particularly discloses a PI / TPU aerogel film with mesopores and macropores in a certain proportion, which is obtained by introducing polyurethane (TPU) to adjust a pore structure during preparation of PI aerogel. The filter material has the advantages of high filter efficiency, low piezoresistance and high quality factor, is relatively simple to prepare, and has a good industrial prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

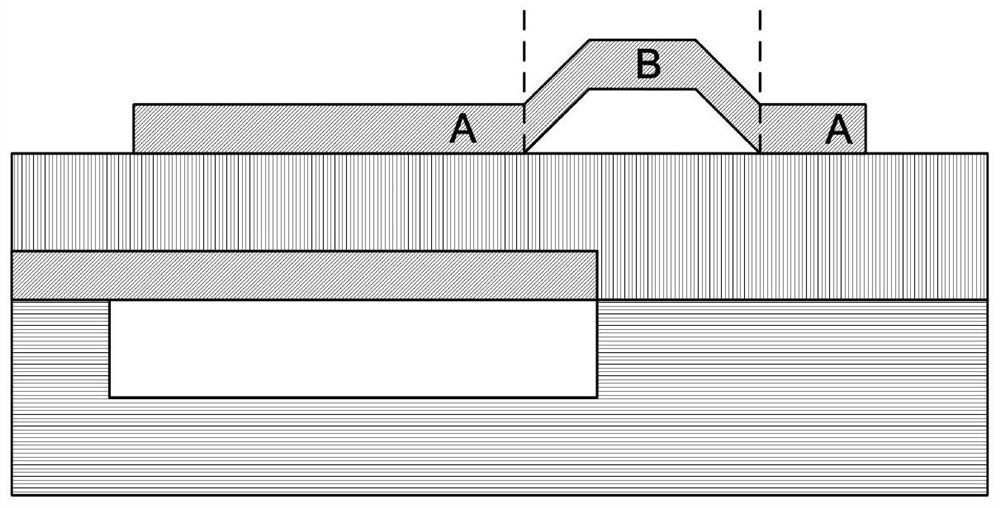

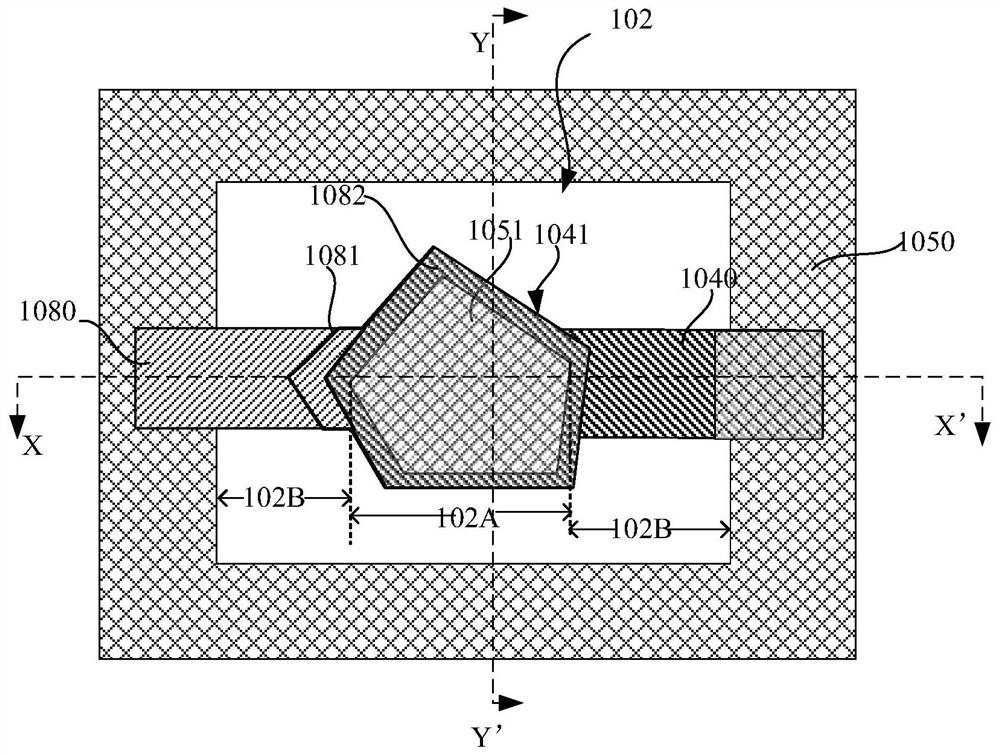

Preferred structure of film bulk acoustic resonator with high quality factor

ActiveCN111049495AHigh quality factorReduce transmissionImpedence networksThin-film bulk acoustic resonatorAir bridge

The invention relates to a preferred structure of a film bulk acoustic resonator with a high quality factor. The structure comprises a substrate with a groove in the upper surface, a bottom electrodelayer located above the substrate and a piezoelectric layer, and is characterized by further comprising a top electrode layer with a special-shaped air bridge structure, and an acoustic springback structure capable of playing a role in springback of transverse acoustic waves is arranged in the air bridge structure; the sound springback structure is a convex or trapezoidal polyhedron opposite to abridge cavity of the special-shaped air bridge structure and is horizontally arranged in an area above the bridge cavity of the special-shaped air bridge structure. The top end surface of the sound springback structure is embedded and clung to a bridge cavity upward top surface groove of the special-shaped air bridge structure; an air gap is reserved between the bottom end face of the sound springback structure and the suspended structure in the area below the bridge cavity of the special-shaped air bridge structure, and the left side face and the right side face of the sound springback structure are embedded into and tightly attached to the grooves in the adjacent inner side faces of the bridge cavity supporting structure of the special-shaped air bridge structure respectively. The quality factor of the film bulk acoustic resonator can be remarkably improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

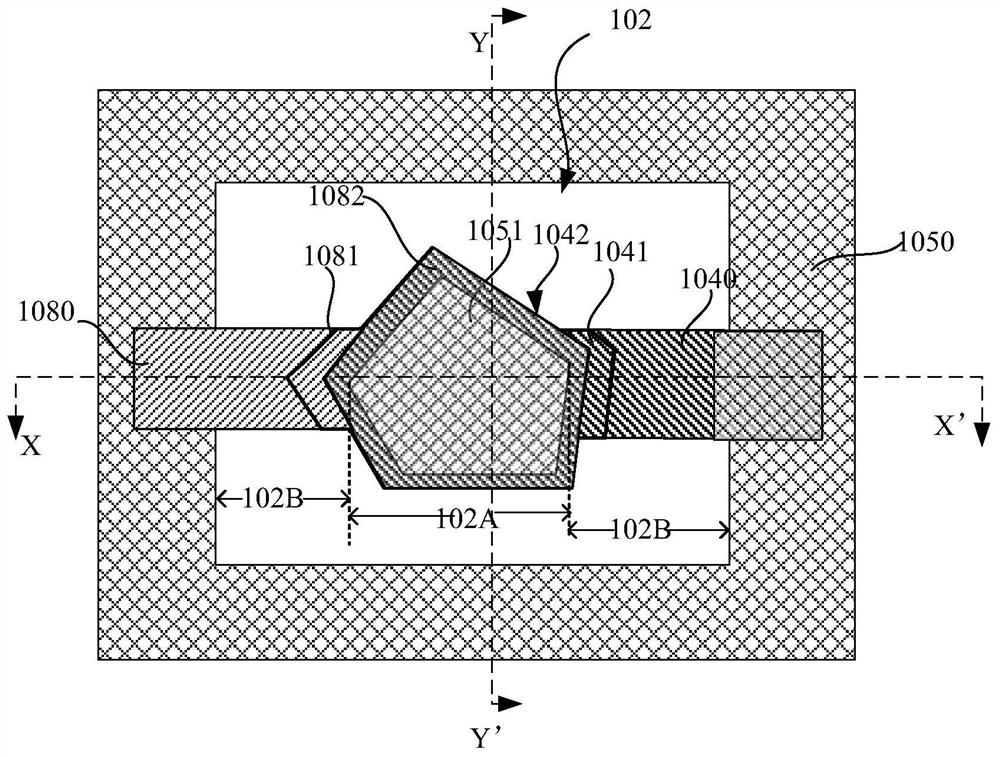

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786650AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A top electrode concave part formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that the sound wave loss is reduced, the quality factor of the resonator is improved, and finally, the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

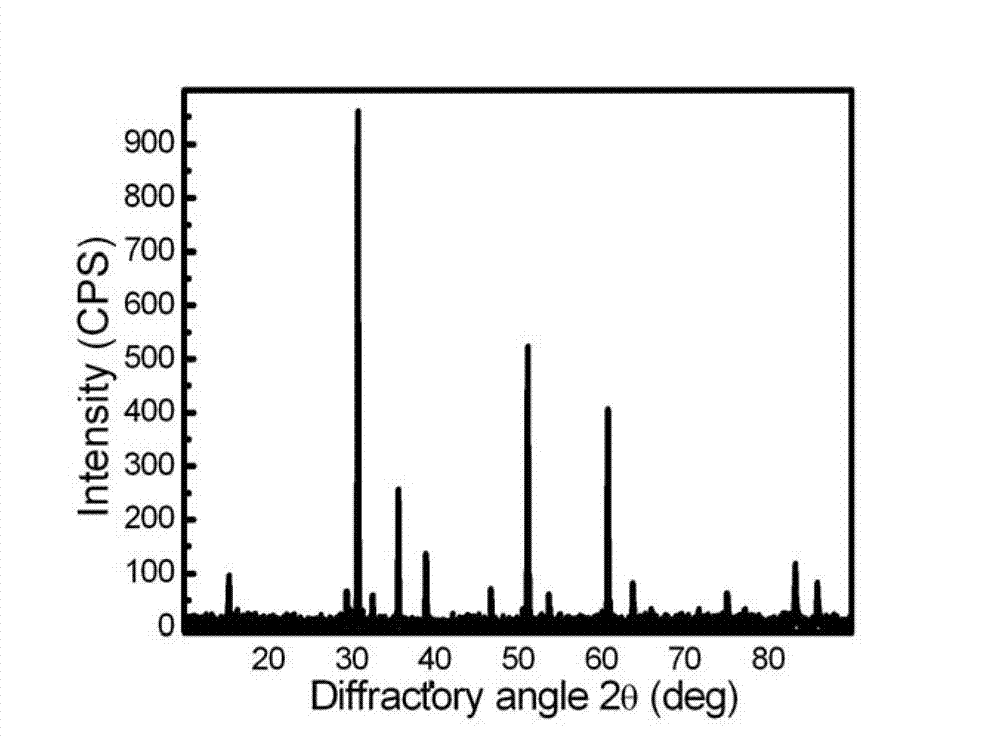

Microwave dielectric ceramics and preparation process thereof

The invention discloses microwave dielectric ceramics and a preparation process thereof, belonging to the technical field of microwave dielectric materials and manufacture thereof. The microwave dielectric ceramics comprises carbonate, oxide and Na, Gd, Dy, Er, Lu and Ti organic matters, and has a chemical formula of Na0.5Re4.5Ti4O15, wherein Re=Gd, Dy, Er and Lu. The invention provides a novel rare-earth-containing microwave dielectric material, and the selection range of a microwave dielectric application material is enlarged; and aiming at the microwave dielectric ceramics, the invention provides a novel matched process, namely, the microwave dielectric ceramics with better ceramic formation is obtained by combination of a process of preparing a powder material by adopting a sol-gel process and a process of preparing the ceramics by adopting a solid-phase reaction process.

Owner:CHINA JILIANG UNIV

Monocrystal FBAR piezoelectric film and preparation method thereof

PendingCN114362704AHalf height widthGood quality factorImpedence networksThin-film bulk acoustic resonatorSurface roughness

The invention discloses a cavity film bulk acoustic resonator which comprises a first substrate, a bonding layer, an opaque dielectric layer, a piezoelectric oscillation pile and a metal pad layer. Wherein a bonding layer is formed on the first substrate, an opaque dielectric layer is formed on the bonding layer, a piezoelectric oscillation pile is formed on the opaque dielectric layer, a cavity is formed between the opaque dielectric layer and the piezoelectric oscillation pile, and the metal pad layer is connected with the piezoelectric oscillation pile. The surface roughness of the resonator is low, and the thickness of each area of the film can be measured conveniently and accurately. The invention also discloses a preparation method of the cavity film bulk acoustic wave resonator, and the preparation method saves preparation processes, and is simple and efficient.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

Novel microwave dielectric ceramic and preparation method thereof

A novel microwave dielectric ceramic and a preparation method of the novel microwave dielectric ceramic belong to a microwave dielectric material and the technical field of microwave dielectric material manufacture. The microwave dielectric ceramic is composed of K, Dy, Ho, Er, Yb, Lu and Ti in modes of carbonate and oxide, a chemical formula of the microwave dielectric ceramic is K0.5Re4.5Ti4O15, and the Re is equal to the Dy, Ho, Er, Yb, Lu in the formula. The novel microwave dielectric ceramic provides a new material containing a rare earth microwave dielectric and expands selecting ranges of microwave dielectric application materials. A matched process is provided for the microwave dielectric ceramic, and the microwave dielectric ceramic with a good ceramic forming ratio is obtained.

Owner:CHINA JILIANG UNIV

Microwave dielectric ceramic and preparation method thereof

A novel microwave dielectric ceramic and a preparation method of the novel microwave dielectric ceramic belong to a microwave dielectric material and the technical field of microwave dielectric material manufacture. The microwave dielectric ceramic is composed of K, Dy, Ho, Er, Yb, Lu and Ti in modes of carbonate and oxide, a chemical formula of the microwave dielectric ceramic is K0.5Re4.5Ti4O15, and the Re is equal to the Dy, Ho, Er, Yb, Lu in the formula. The novel microwave dielectric ceramic provides a new material containing a rare earth microwave dielectric and expands selecting ranges of microwave dielectric application materials. A matched process is provided for the microwave dielectric ceramic, and the microwave dielectric ceramic with a good ceramic forming ratio is obtained.

Owner:CHINA JILIANG UNIV

Preferred structure of film bulk acoustic resonator with high quality factor

ActiveCN113131894AHigh quality factorReduce transmissionImpedence networksThin-film bulk acoustic resonatorAir bridge

The invention relates to a preferable structure of a film bulk acoustic resonator with a high quality factor, and the structure comprises a substrate with a groove on the upper surface, a bottom electrode layer positioned above the substrate and a piezoelectric layer, and is characterized in that the structure also comprises a top electrode layer with a special-shaped air bridge structure; the special-shaped air bridge structure is internally provided with a sound springback structure which can play a role in springback of transverse sound waves and improve the quality factor of the film bulk acoustic wave resonator. The acoustic springback structure is made of a SiC and perovskite combined thin film medium or a SiN and perovskite combined thin film medium; the acoustic springback structure is a polyhedron opposite to a bridge cavity of the special-shaped air bridge structure and clings to the upper portion of the piezoelectric layer in a horizontal mode, and an air gap is reserved between the upper portion of the acoustic springback structure and a bridge cavity suspension structure of the special-shaped air bridge structure; the left side face and the right side face of the sound rebound structure are tightly attached to the grooves in the adjacent inner side faces of the bridge cavity supporting structure of the special-shaped air bridge structure respectively. The quality factor of the film bulk acoustic resonator can be remarkably improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Single-tuned filter and optimal quality factor calculation method thereof

InactiveCN102386621BGood quality factorReactive power adjustment/elimination/compensationReactive power compensationTerminal voltageAlternating current

The invention discloses a single-tuned filter and an optimal quality factor calculation method thereof. The single-tuned filter mainly comprises a capacitor C, an inductor L and a resistor R which are sequentially connected in series, wherein the other end of the capacitor C is connected with an alternating current voltage line; and the other end of the resistor R is grounded. The method comprises the following steps of: A, calculating the maximum equivalent frequency offset of a system; B, determining a maximum impedance angle of the system; and C, calculating an optimal quality factor of the filter. By the single-tuned filter and the method, the terminal voltage of the filter can be ensured to have a minimum value at characteristic frequency when the system has the maximum impedance angle, so filtering effects and system stability are ensured.

Owner:STATE GRID CORP OF CHINA +1

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

ActiveCN111786652AReduce lossesImprove sound wave lossImpedence networksEngineeringPiezoelectric resonance

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode convex part and the top electrode convexpart formed on the periphery of a piezoelectric resonance layer and suspended above a cavity and prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

An Optimum Structure of a High Quality Factor Thin Film Bulk Acoustic Resonator

ActiveCN111049495BHigh quality factorReduce transmissionImpedence networksThin-film bulk acoustic resonatorAir bridge

The invention relates to a preferred structure of a high quality factor thin film bulk acoustic resonator, comprising a substrate with a groove on the upper surface, a bottom electrode layer above the substrate, and a piezoelectric layer, and is characterized in that it also includes a The top electrode layer of the special-shaped air bridge structure, which is equipped with an acoustic rebound structure that can rebound the transverse sound wave; the acoustic rebound structure is a convex or opposite bridge cavity of the special-shaped air bridge structure. The trapezoidal polyhedron is arranged horizontally in the area above the bridge cavity of the special-shaped air bridge structure. The top surface of the acoustic rebound structure is embedded and closely attached to the groove on the top surface of the bridge cavity of the special-shaped air bridge structure. The acoustic rebound structure There is an air gap between the bottom end surface and the suspension structure in the area below the bridge cavity of the special-shaped air bridge structure. The left and right sides of the acoustic rebound structure are respectively embedded and adjacent to the bridge cavity support structure of the special-shaped air bridge structure. The grooves on the inner side fit snugly. The invention can significantly improve the quality factor of the film bulk acoustic wave resonator.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

A kind of manufacturing method of laminated inductor and the manufactured device

ActiveCN110459535BReduce occupancyReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesLithography processEngineering

The invention discloses a method for manufacturing a stacked inductor and a device obtained therefrom, wherein the method comprises the steps of: coating a first photoresist, performing a photolithography process on the bottom of an enhanced gate and the bottom of a first metal layer of the inductor; coating a first photoresist Two photoresist, perform photolithography process on the top of the enhanced gate and the top of the first metal layer of the inductor; deposit metal to form the enhanced gate and the first metal layer of the inductor; passivate the enhanced gate and the first metal layer of the inductor process, forming a first passivation layer; etching the depletion gate and the first passivation layer of nitride connected to the second metal layer of the inductor; coating a third photoresist to perform depletion gate and photolithography process of the second metal layer of the inductor; depositing metal to form the depletion gate and the second metal layer of the inductor. The inductance of the spiral stack shape prepared by this scheme has a better quality factor under high frequency conditions and also has a larger inductance value. And the process is carried out simultaneously with the existing transistor process without increasing the process cost.

Owner:福建省福联集成电路有限公司

A kind of phononic crystal and thin-film piezoelectric acoustic wave sensor

ActiveCN110277082BHigh quality factorAchieve total reflectionSound producing devicesThin membraneTransducer

A thin film piezoelectric sonic sensor, comprising: a substrate layer (2), a ground electrode layer (3), and a piezoelectric layer (4) which are stacked. At least one transducer (5) is provided on the side of the piezoelectric layer (4) distant from the ground electrode layer (3); phononic crystals (1) at least formed in the piezoelectric layer (4) are correspondingly provided on the two sides of the transducer (5), and the resonant frequency of the thin film piezoelectric sonic sensor is located in a band gap of the phononic crystals (1). According to the thin film piezoelectric sonic sensor, the phononic crystals (1) are at least provided on the piezoelectric layer (4), the mechanical vibration stability of the piezoelectric layer (4) is improved, the sonic wave reflectivity is improved, the energy loss of sonic wave transmission is lowered, and the quality factor of the sensor is improved. A phononic crystal (1) comprises a matrix and a scatterer formed on the matrix; the matrix is formed by at least two stacked dielectric layers; materials of any one of the dielectric layers are different from those of other dielectric layers. The phononic crystal (1) can effectively reduce the sonic wave energy loss, and effectively improve the quality factor of the sensor when the phononic crystal is applied to the thin film piezoelectric sonic sensor.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

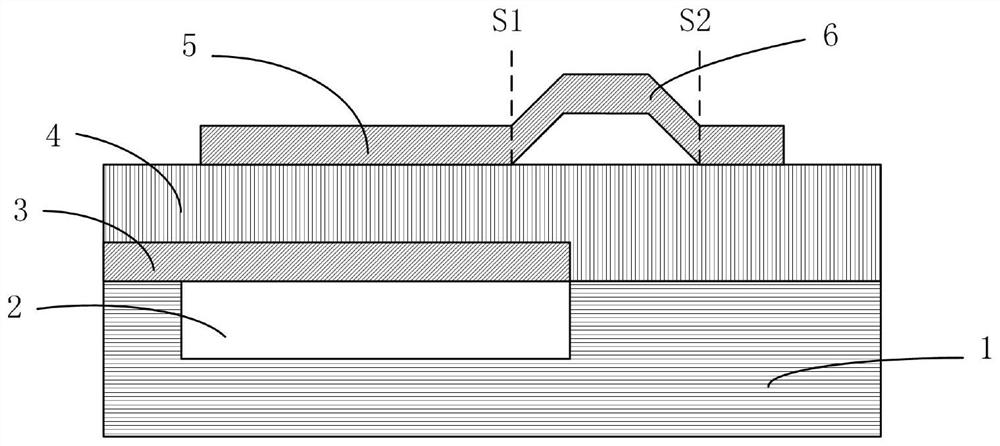

Inductor and manufacturing method thereof

InactiveCN111146185AGood quality factorIncrease the inductance valueSemiconductor/solid-state device detailsSolid-state devicesAir bridgeEngineering

The invention discloses an inductor and a manufacturing method thereof. The method comprises the following steps: depositing an inductance first metal layer, wherein the inductance first metal layer comprises a plurality of discrete metal sections; depositing a first nitride layer on the inductance first metal layer; depositing an inductance second metal layer on the first nitride layer, wherein the inductance second metal layer stretches across the middle position of the metal section; depositing a second nitride layer on the inductance second metal layer; forming openings on first nitrides at the two ends of the metal section; and manufacturing an air bridge by taking the openings as piers, so that different metal sections are connected end to end, wherein the second inductance metal layer is wound by an inductance coil formed by the metal sections and the air bridge. According to the technical scheme, the three-dimensional inductor can be manufactured, the quality factor is good under the high-frequency condition, and the inductor has large inductance.

Owner:福建省福联集成电路有限公司

A kind of low dielectric constant dielectric material for single-cavity filter and preparation method thereof

ActiveCN113563061BImprove stabilitySmall particle sizeCeramicsQuartz/glass/vitreous enamelsSpray GranulationPhysical chemistry

The invention discloses a low-permittivity dielectric material for a single-cavity filter and a preparation method thereof. The structure of the low-permittivity dielectric material of the single-cavity filter is (1-z / 2)Mg 2 SiO 4 -(z / 2)M 2 SiO 4 -mCa (x / 2) ln (2 / 3‑x / 3) TiO 3 ‑ySnO 2 ‑(0.05~0.15)wt%AF. Preparation method of low dielectric constant dielectric material for single cavity filter, including Ca (x / 2) ln (2 / 3‑x / 3) TiO 3 Pre-preparation of crystalline phases, batching, primary grinding, spray drying, sintering, secondary grinding and spray granulation. According to the above content, the present invention proposes a low-permittivity dielectric material for a single-cavity filter and a preparation method thereof, one of the purposes of which is to provide a low-permittivity dielectric material with high quality factor and high flexural strength; The second is to provide a preparation method with simple preparation, easy-to-obtain raw materials, large-scale production and cost disclosure.

Owner:GUANGDONG KANGRONG HIGH TECH NEW MATERIAL CO LTD

A kind of low dielectric microwave dielectric ceramic material and its ltcc material

ActiveCN110563463BLow relative permittivityGood quality factorDielectric ceramicsDielectric permittivity

The invention belongs to the technical field of microwave dielectric ceramics, and particularly relates to a low-dielectric microwave dielectric ceramic material and an LTCC material thereof. A compound with a chemical general formula of Ca2RE8Si6O26 (wherein RE is selected from the group consisting of Nd, Sm and Er) is used for preparing the microwave dielectric ceramic material, and the LTCC material is further prepared. The ceramic material has a low relative dielectric constant (wherein Epsilon r is in a range of 13.4-14.0), an excellent quality factor (wherein the value of Q*f is in a range of 16300-18600 GHz) and a relatively wide sintering temperature (1350-1400 DEG C); meanwhile, the microwave dielectric ceramic has a negative resonant frequency temperature coefficient (wherein Tauf is no less than -38.1 ppm / DEG C and no more than -17.8 ppm / DEG C). The sintering temperature of the microwave dielectric ceramic material can be reduced to 950 DEG C or below after a certain amountof a sintering aid, namely CaO-La2O3-B2O3-SiO2 glass is added, and the microwave dielectric ceramic can be used as an LTCC material.

Owner:HUAZHONG UNIV OF SCI & TECH

Bulk acoustic wave resonator, manufacturing method thereof, filter, radio frequency communication system

ActiveCN111786652BHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The present invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter, and a radio frequency communication system. The raised portion of the bottom electrode and the raised portion of the top electrode formed on the periphery of the piezoelectric resonant layer and suspended above the cavity can block The shear wave generated by the piezoelectric resonant layer is transmitted to the periphery of the cavity, and the shear wave is reflected back to the effective working area, thereby reducing and reducing the acoustic wave loss, improving the quality factor of the resonator, and finally improving the performance of the device. Furthermore, the overlapping parts of the bottom electrode lap and the top electrode lap and the cavity are all suspended, and the bottom electrode lap and the top electrode lap are staggered from each other, which can greatly reduce parasitic parameters and avoid leakage, Short circuit and other problems can improve device reliability.

Owner:NINGBO SEMICON INT CORP

Microwave dielectric ceramics and preparation process thereof

The invention discloses microwave dielectric ceramics and a preparation process thereof, belonging to the technical field of microwave dielectric materials and manufacture thereof. The microwave dielectric ceramics comprises carbonate, oxide and Na, Gd, Dy, Er, Lu and Ti organic matters, and has a chemical formula of Na0.5Re4.5Ti4O15, wherein Re=Gd, Dy, Er and Lu. The invention provides a novel rare-earth-containing microwave dielectric material, and the selection range of a microwave dielectric application material is enlarged; and aiming at the microwave dielectric ceramics, the invention provides a novel matched process, namely, the microwave dielectric ceramics with better ceramic formation is obtained by combination of a process of preparing a powder material by adopting a sol-gel process and a process of preparing the ceramics by adopting a solid-phase reaction process.

Owner:CHINA JILIANG UNIV

Transformer structure

InactiveCN110690034AReduce shockGood quality factorTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a transformer structure including a first inductor and a second inductor. The first inductor has a first turn and a second turn. The second inductor has a third turn and a fourth turn. The first turn of the first inductor and the third turn of the second inductor are disposed in a first region of a first metal layer. The second turn of the first inductor and the fourth turnof the second inductor are disposed in a second region of the first metal layer. The first region is adjacent to the second region.

Owner:徐州国力电力设备有限公司

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786648AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A top electrode protruding part formed on the periphery of apiezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that the sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottomelectrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and thelike can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

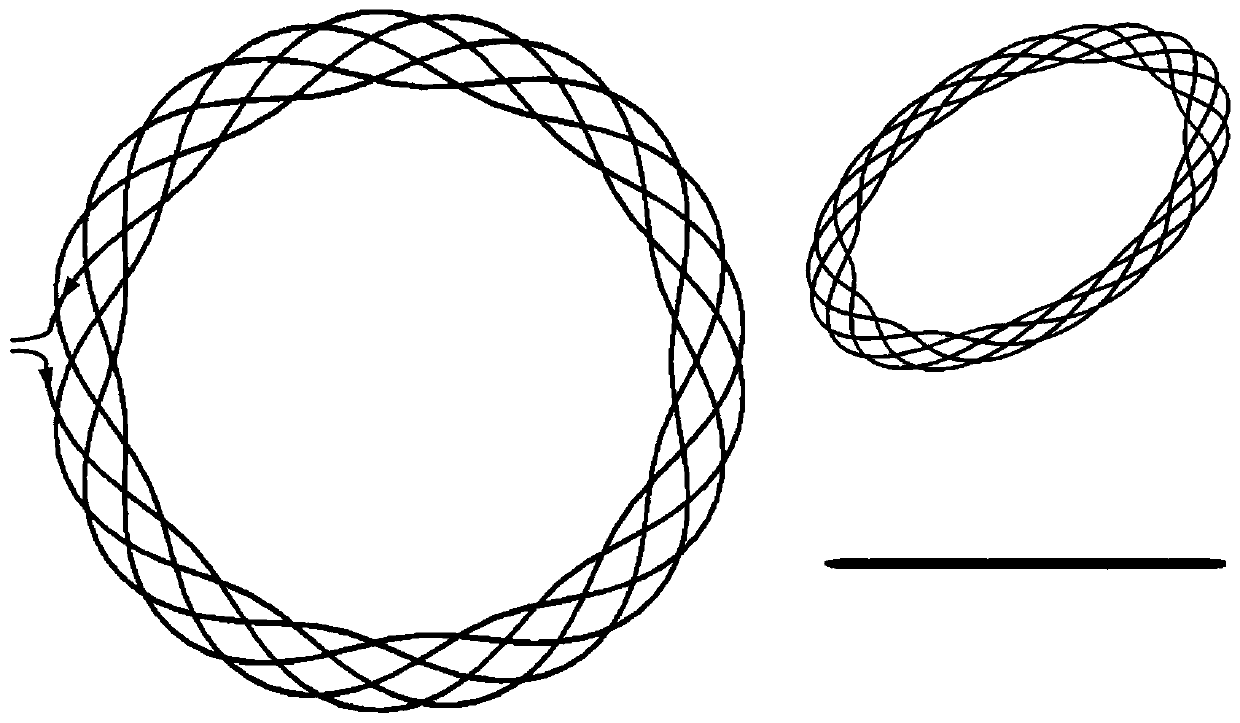

A kind of winding method of braided coil

The invention provides a winding method of a braided coil, belongs to the technical field of the magnetic field coupling type wireless electric energy transmission, and especially relates to a windingmethod of the braided coil. The problem that the quality factor is reduced when the eddy loop is formed between the coil turns, the inter-turn proximity effect is large, the coil AC internal resistance is large, and the working efficiency is high in the magnetic coupling type wireless electric energy transmission system is solved, and the Litz wire is used for winding. The winding method is mainly used for winding the braided coil of the magnetic field coupling type wireless electric energy transmission system.

Owner:HARBIN INST OF TECH

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

ActiveCN111786654AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode convex part and a top electrode concave part formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by a piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performanceof a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity aresuspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com