Middle-dielectric-constant microwave dielectric ceramic with adjustable temperature coefficient of resonance frequency

A technology of microwave dielectric ceramics and temperature coefficient, applied in the field of ceramic compositions, can solve problems such as limited application value of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

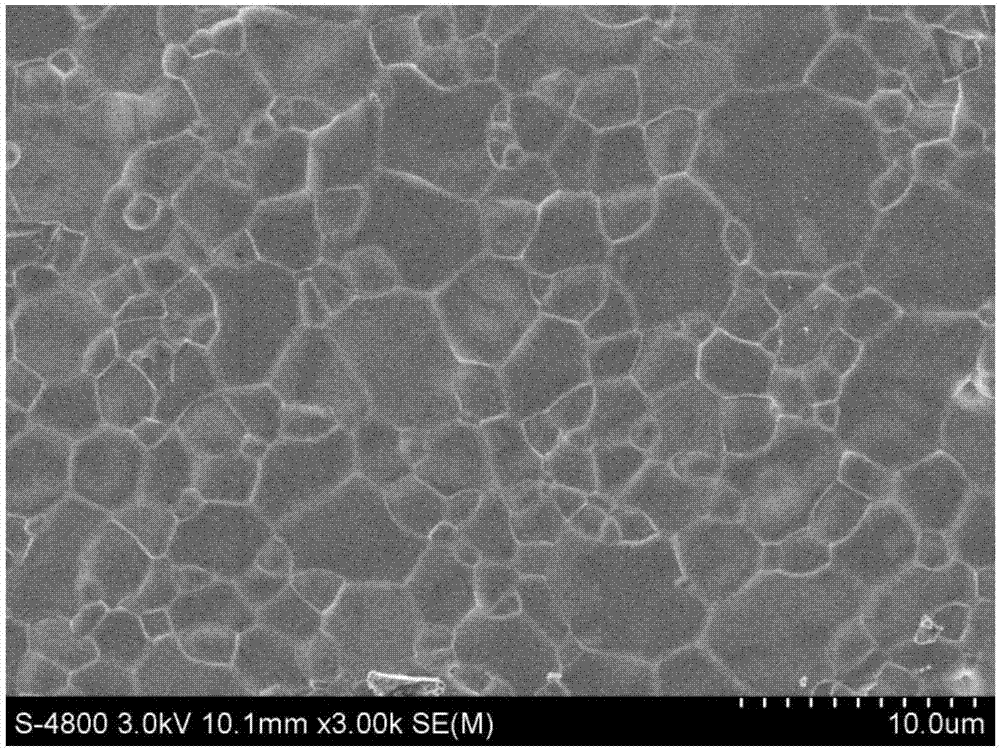

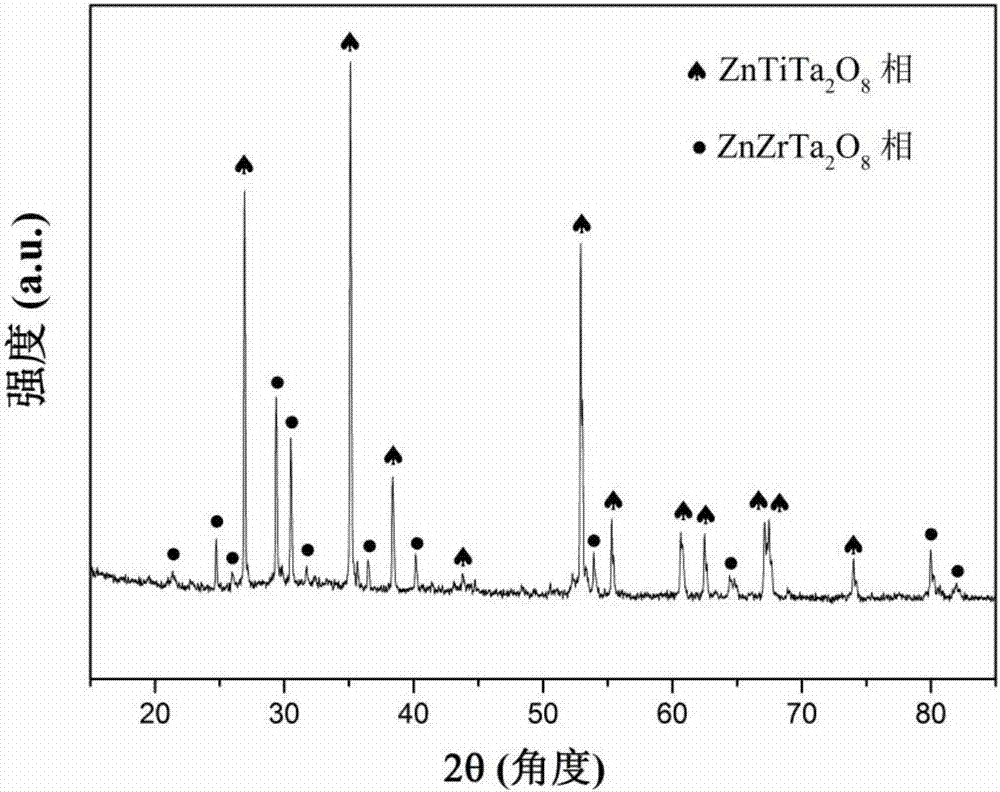

Image

Examples

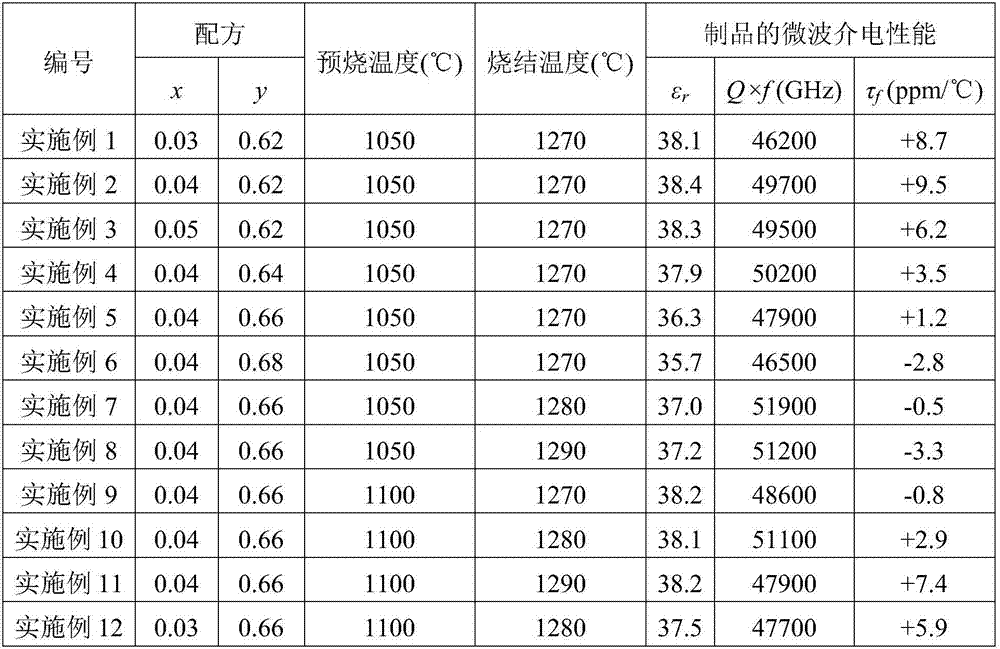

Embodiment 1

[0029] Raw materials ZnO, MgO, TiO with analytical purity 2 , ZrO 2 、 Ta 2 o 5 According to the formula (Zn 0.97 Mg 0.03 )(Ti 0.38 Zr 0.62 ) Ta 2 o 8 After the molar ratio is configured, fully mix and ball mill for 6 hours, then dry at 100°C, pass through a 40-mesh sieve, pre-fire at 1050°C in an air atmosphere, and keep warm for 3 hours to synthesize a frit; then pass the frit through a 40-mesh sieve After the mesh sieve is crushed, add polyvinyl alcohol powder with a mass fraction of 0.75%, ball mill for another 12 hours, dry at 100°C and pass through 40-mesh and 80-mesh sieves respectively to obtain the required microwave dielectric ceramic raw material; The raw materials are pressed and formed into a cylindrical body of Φ10mm×5mm as required, and then sintered into porcelain at 1270°C in air and kept for 4 hours to obtain a microwave dielectric ceramic with a medium dielectric constant.

[0030] Finally, the microwave dielectric properties of the product were meas...

Embodiment 2

[0032] Raw materials ZnO, MgO, TiO with analytical purity 2 , ZrO 2 、 Ta 2 o 5 According to the formula (Zn 0.96 Mg 0.04 )(Ti 0.38 Zr0.62 ) Ta 2 o 8 After the molar ratio is configured, fully mix and ball mill for 6 hours, then dry at 100°C, pass through a 40-mesh sieve, pre-fire at 1050°C in an air atmosphere, and keep warm for 3 hours to synthesize a frit; then pass the frit through a 40-mesh sieve After the mesh sieve is crushed, add polyvinyl alcohol powder with a mass fraction of 0.75%, ball mill for another 12 hours, dry at 100°C and pass through 40-mesh and 80-mesh sieves respectively to obtain the required microwave dielectric ceramic raw material; The raw materials are pressed and formed into a cylindrical green body of Φ10mm×5mm as required, and then sintered in the air at 1270°C and kept warm for 4 hours to form a porcelain, that is, a microwave dielectric ceramic with a medium dielectric constant.

[0033] Finally, the microwave dielectric properties of the...

Embodiment 3

[0035] Raw materials ZnO, MgO, TiO with analytical purity 2 , ZrO 2 、 Ta 2 o 5 According to the formula (Zn 0.95 Mg 0.05 )(Ti 0.38 Zr 0.62 ) Ta 2 o 8 After the molar ratio is configured, fully mix and ball mill for 6 hours, then dry at 100°C, pass through a 40-mesh sieve, pre-fire at 1050°C in an air atmosphere, and keep warm for 3 hours to synthesize a frit; then pass the frit through a 40-mesh sieve After the mesh sieve is crushed, add polyvinyl alcohol powder with a mass fraction of 0.75%, ball mill for another 12 hours, dry at 100°C and pass through 40-mesh and 80-mesh sieves respectively to obtain the required microwave dielectric ceramic raw material The raw materials are pressed and formed into a cylindrical green body of Φ10mm×5mm as required, and then sintered in air at 1270°C, and kept warm for 4 hours to form porcelain, that is, microwave dielectric ceramics with medium dielectric constant.

[0036] Finally, the microwave dielectric properties of the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com