Magnesium titanate based composite ceramic sintered at low temperature and preparation method thereof

A technology of composite ceramics and magnesium orthotitanate, which is applied in the field of microwave dielectric materials, low-temperature sintered magnesium orthotitanate-based composite ceramics and its preparation, can solve the problems of inability to co-fire silver electrode materials and limit the application of materials, and achieve excellent microwave Dielectric properties, abundant sources, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

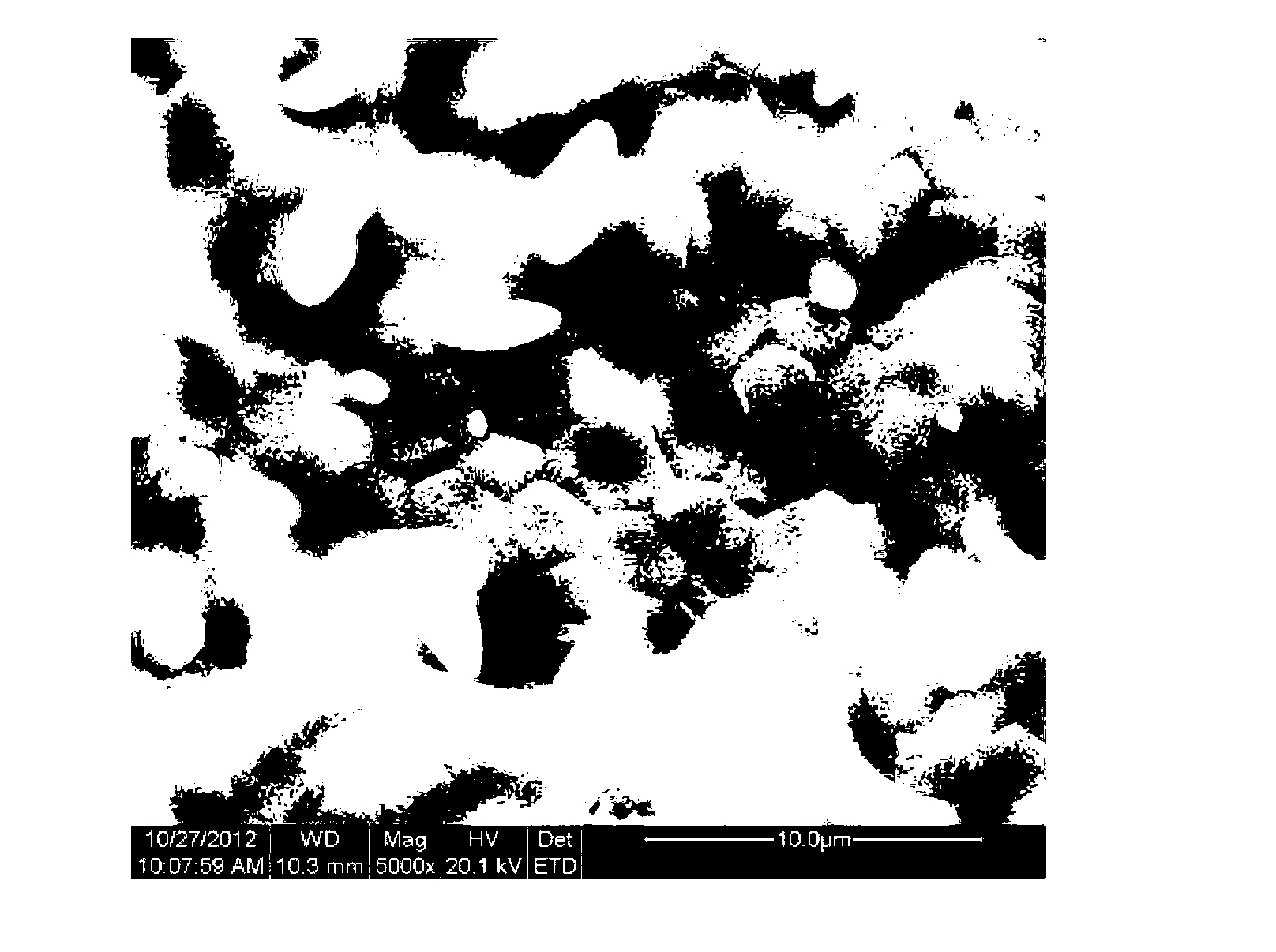

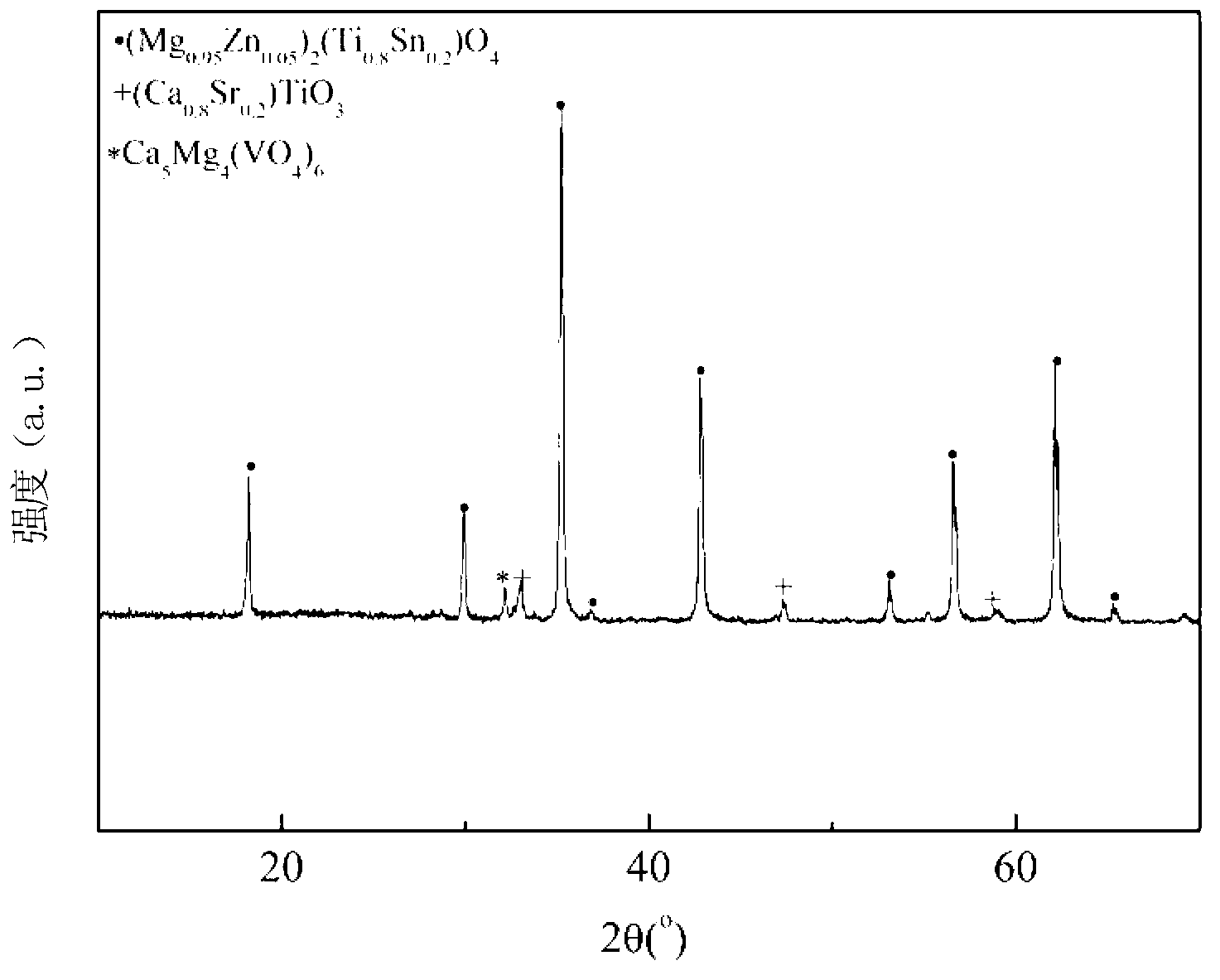

Image

Examples

Embodiment 1

[0021] To prepare 0.9(Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 -0.1 (Ca 0.8 Sr 0.2 )TiO 3 -3.0wt.%LiF-0.8wt.%Fe 2 o 3 -1.5wt.%V 2 o 5 Take the composite ceramic material shown as an example, the raw materials used and the preparation method are as follows:

[0022] 1. Preparation (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Burnt powder

[0023] Press (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 The stoichiometric ratio of raw materials MgO4.285g, ZnO0.455g, TiO 2 3.574g and SnO 2 1.686g, put into nylon ball mill jar, add 20g agate balls, 20g dehydrated ethanol, the mass ratio of raw material and agate balls, dehydrated ethanol is 1: 2: 2, with planetary ball mill ball mill 6 hours, rotating speed is 360 revs / minutes, put it in an oven and dry it at 80-100°C for 4 hours, put it into a corundum crucible and pre-fire it at 1150°C for 3 hours, and prepare (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Burnt powder.

[0024] 2. Preparation (Ca 0.8 Sr 0.2 )TiO ...

Embodiment 2

[0030] To prepare 0.9(Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 -0.1 (Ca 0.8 Sr 0.2 )TiO 3 -3.0wt.%LiF-0.8wt.%Fe 2 o 3 -0.5wt.%V 2 o 5 Take the composite ceramic material shown as an example, the raw materials used and the preparation method are as follows:

[0031] In step 3 of the preparation of low-temperature sintered magnesium orthotitanate-based composite ceramics in embodiment 1, press 0.9 (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 -0.1 (Ca 0.8 Sr 0.2 )TiO 3 -3.0wt.%LiF-0.8wt.%Fe 2 o 3 -0.5wt.%V 2 o 5 The stoichiometric ratio of raw materials (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Calcined powder 9.123g, (Ca 0.8 Sr 0.2 )TiO 3 Calcined powder 0.877g, LiF0.03g, Fe 2 o 3 0.008g and V 2 o 5 0.005g, packed into a nylon ball mill jar, (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Calcined powder and (Ca 0.8 Sr 0.2 )TiO 3 The molar ratio of calcined powder is 9:1, LiF, Fe 2 o 3 and V 2 o 5 The addition amount is (Mg 0.95 Zn 0.05 ) 2...

Embodiment 3

[0033] To prepare 0.9(Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 -0.1 (Ca 0.8 Sr 0.2 )TiO 3-3.0wt.%LiF-0.8wt.%Fe 2 o 3 -3.0wt.%V 2 o 5 Take the composite ceramic material shown as an example, the raw materials used and the preparation method are as follows:

[0034] In step 3 of the preparation of low-temperature sintered magnesium orthotitanate-based composite ceramics in embodiment 1, press 0.9 (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 -0.1 (Ca 0.8 Sr 0.2 )TiO 3 -3.0wt.%LiF-0.8wt.%Fe 2 o 3 -3.0wt.%V 2 o 5 The stoichiometric ratio of raw materials (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Calcined powder 9.123g, (Ca 0.8 Sr 0.2 )TiO 3 Calcined powder 0.877g, LiF0.03g, Fe 2 o 3 0.008g and V 2 o 5 0.03g, packed into a nylon ball mill jar, (Mg 0.95 Zn 0.05 ) 2 (Ti 0.8 sn 0.2 )O 4 Calcined powder and (Ca 0.8 Sr 0.2 )TiO 3 The molar ratio of calcined powder is 9:1, LiF, Fe 2 o 3 and V 2 o 5 The addition amount is (Mg 0.95 Zn 0.05 ) 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com